Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69 results about "Hook wire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

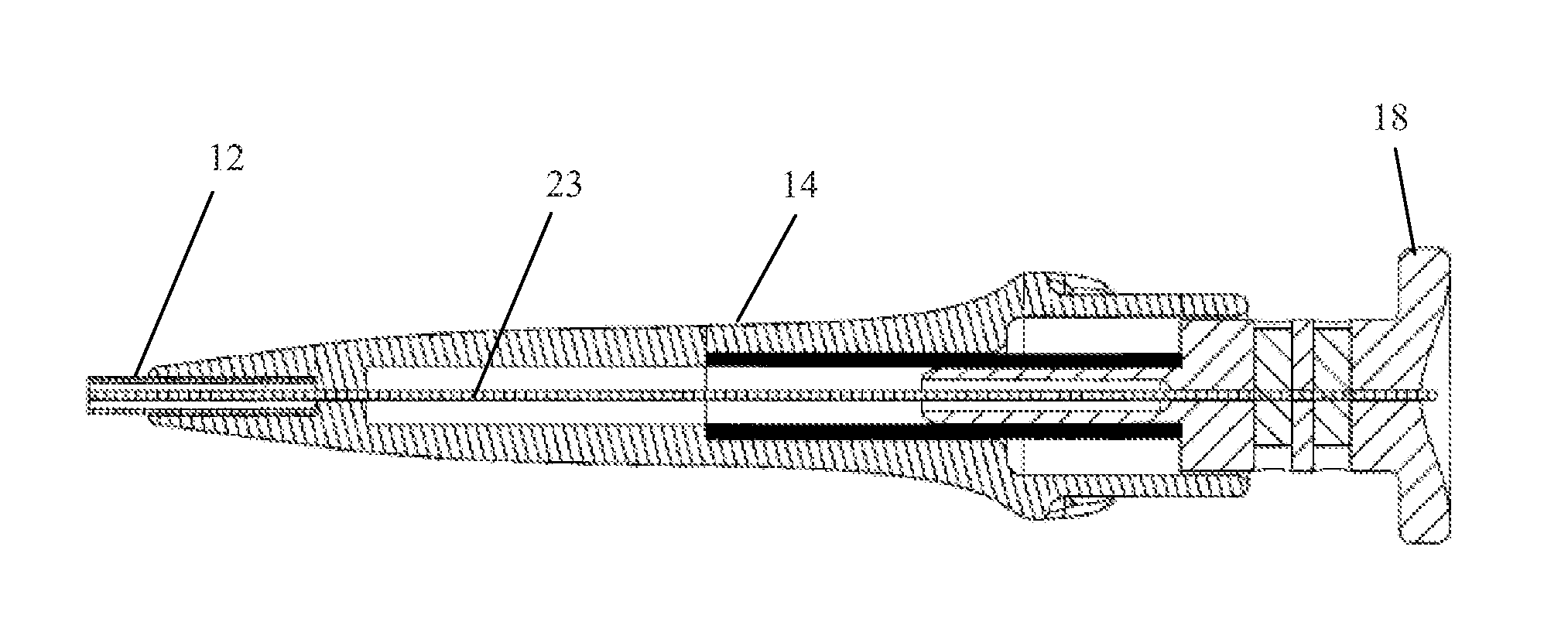

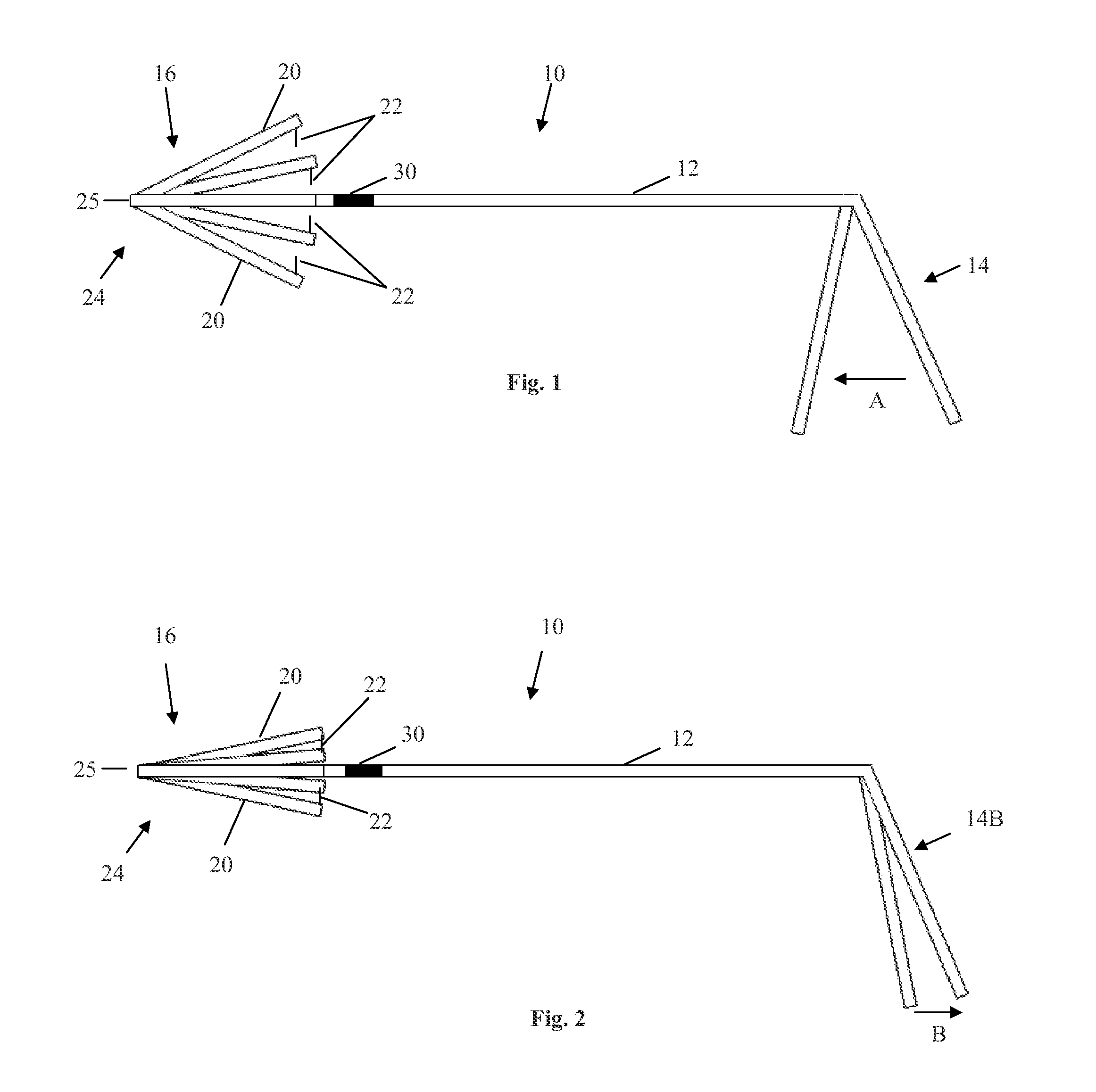

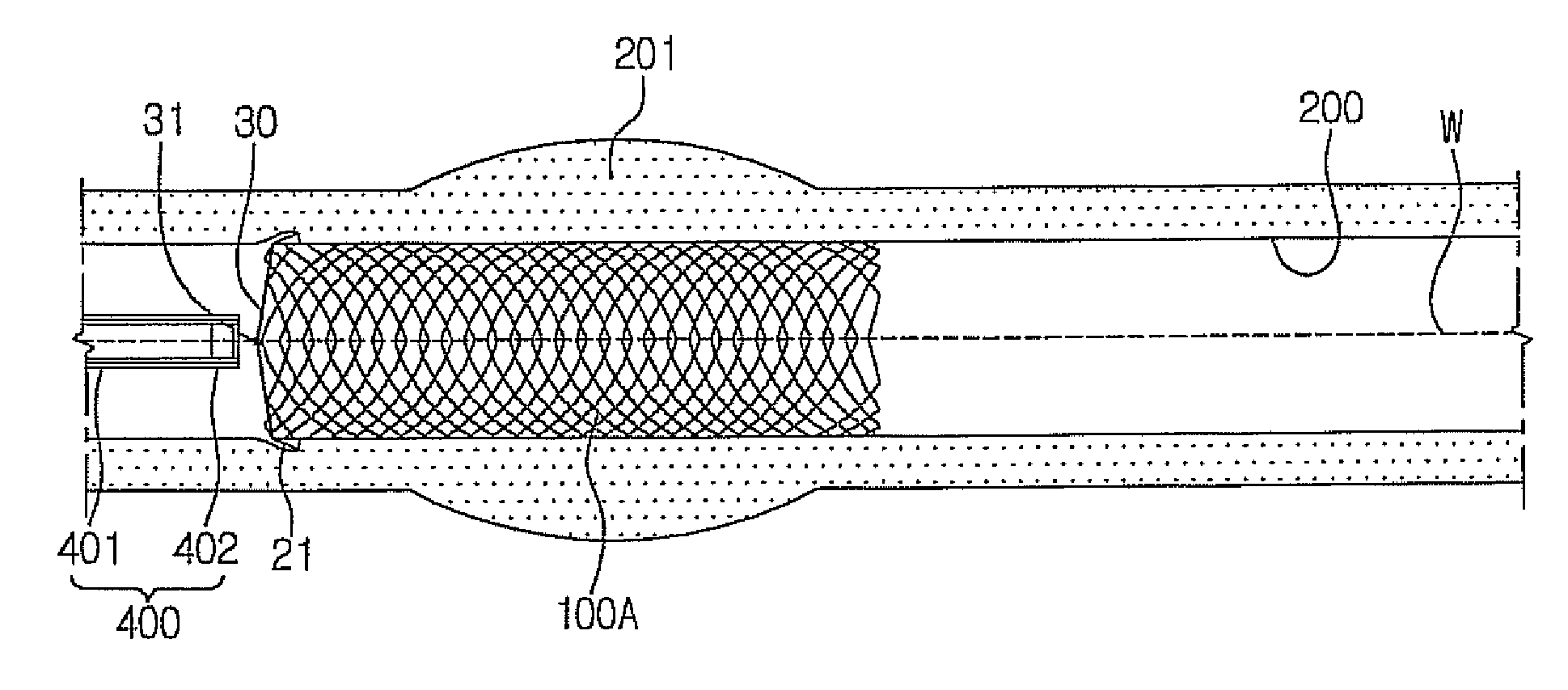

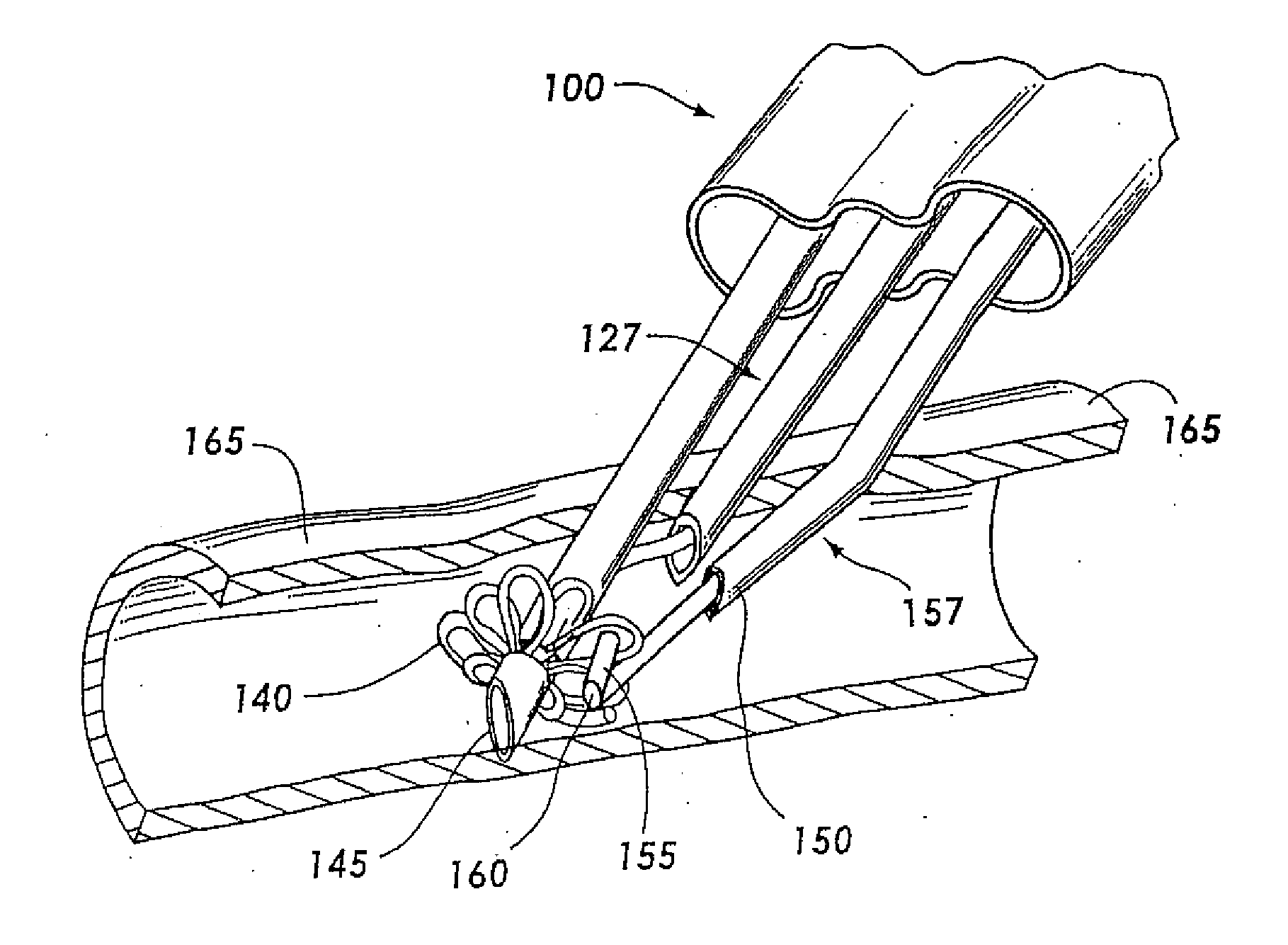

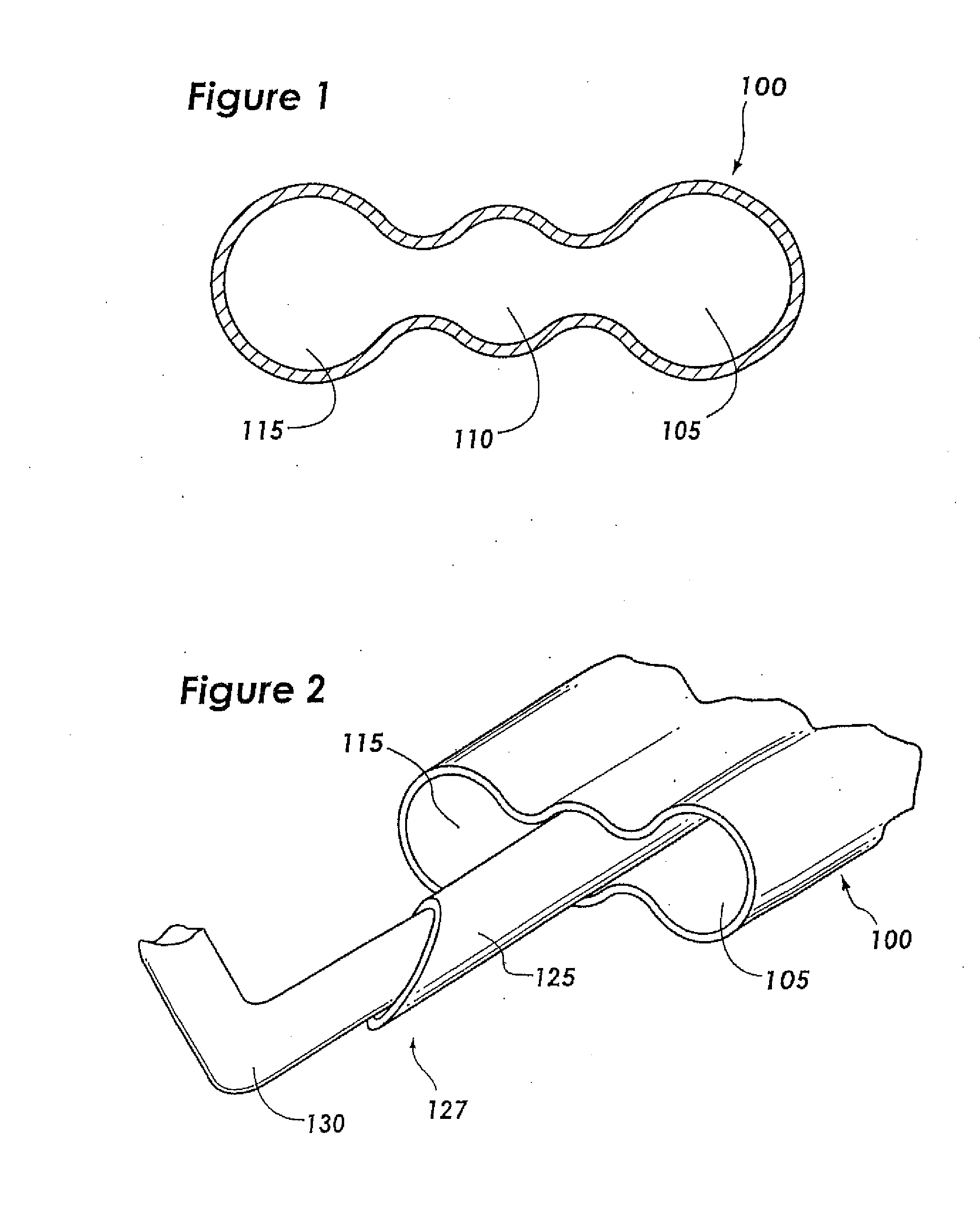

Three-needle closure device

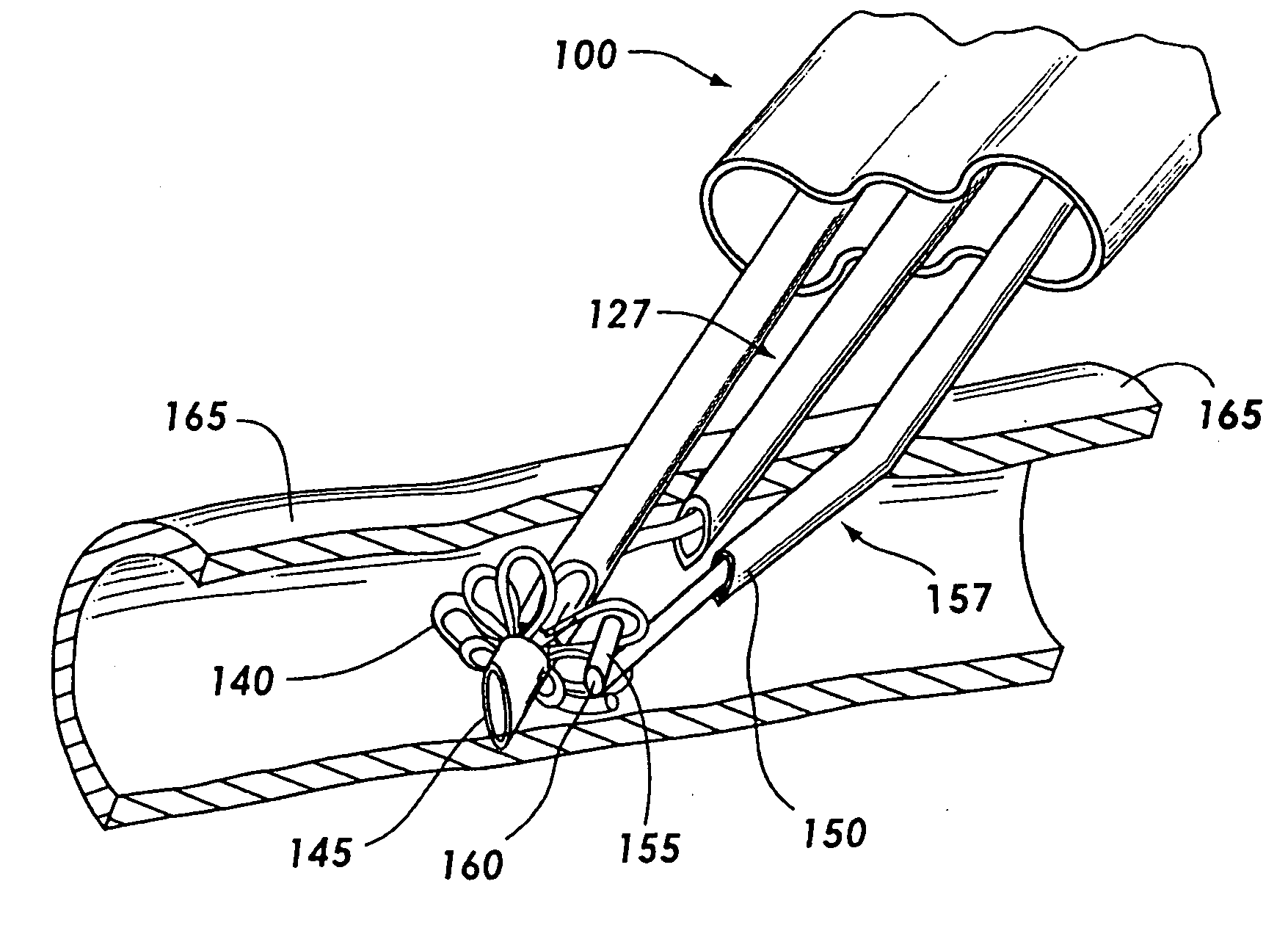

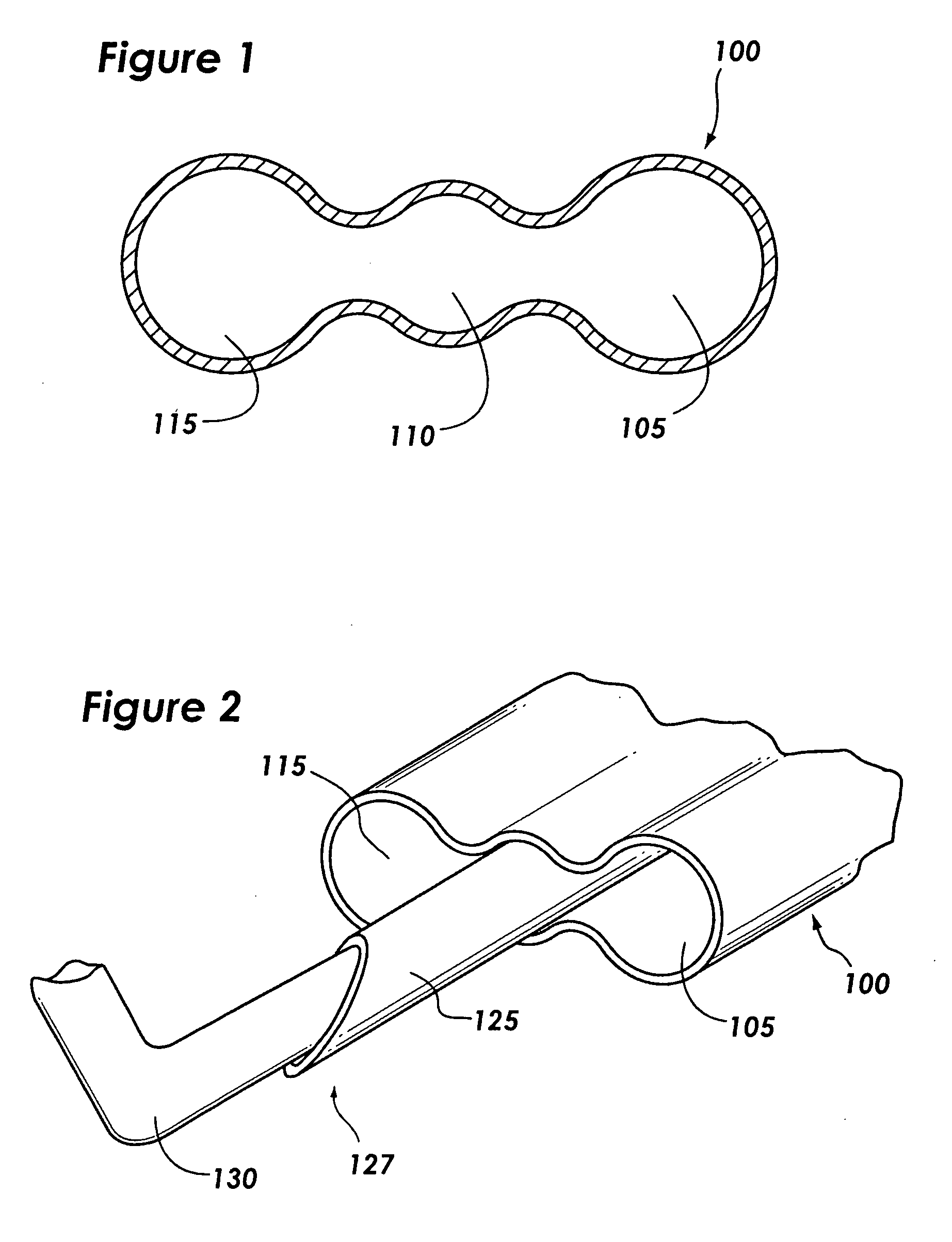

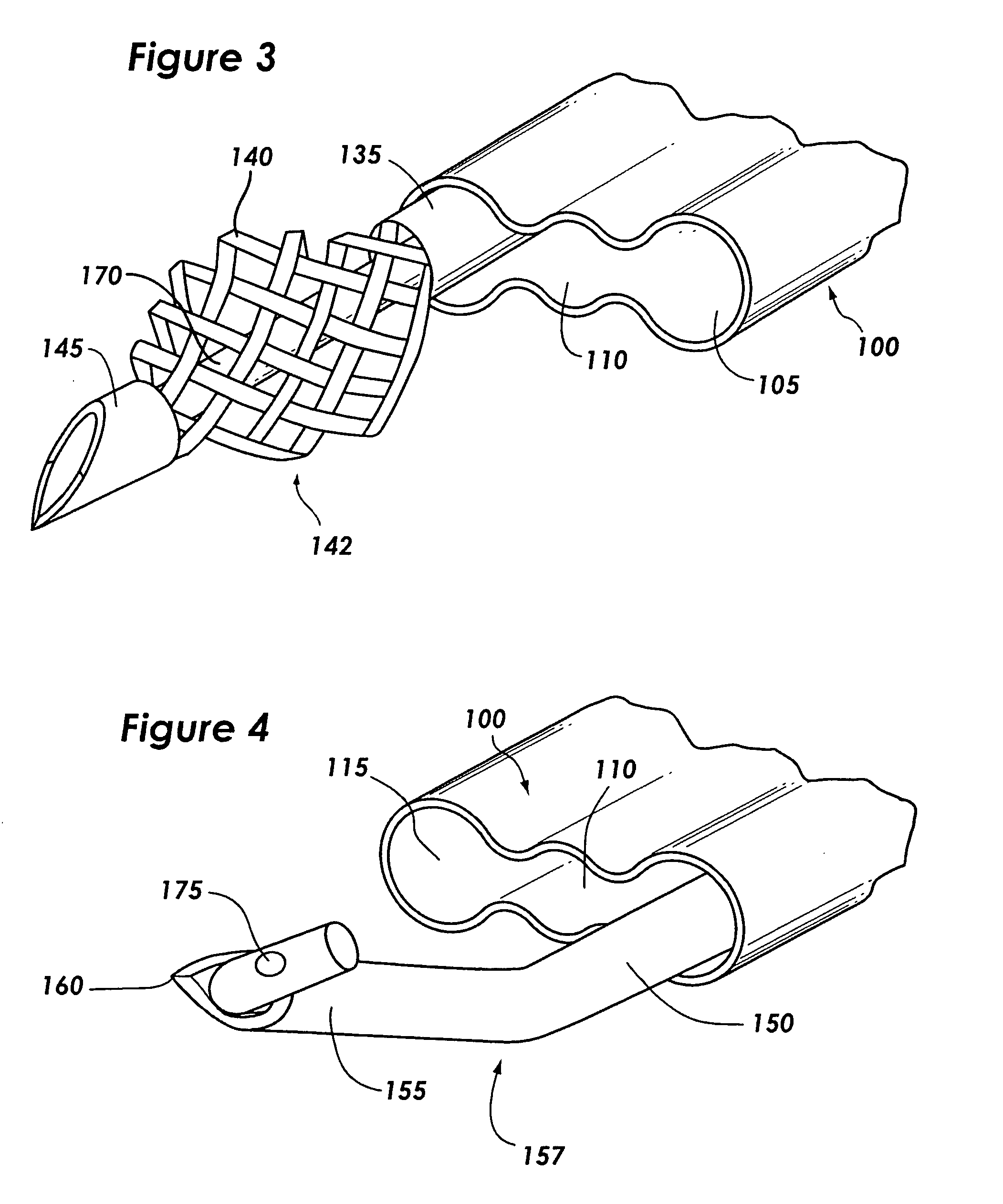

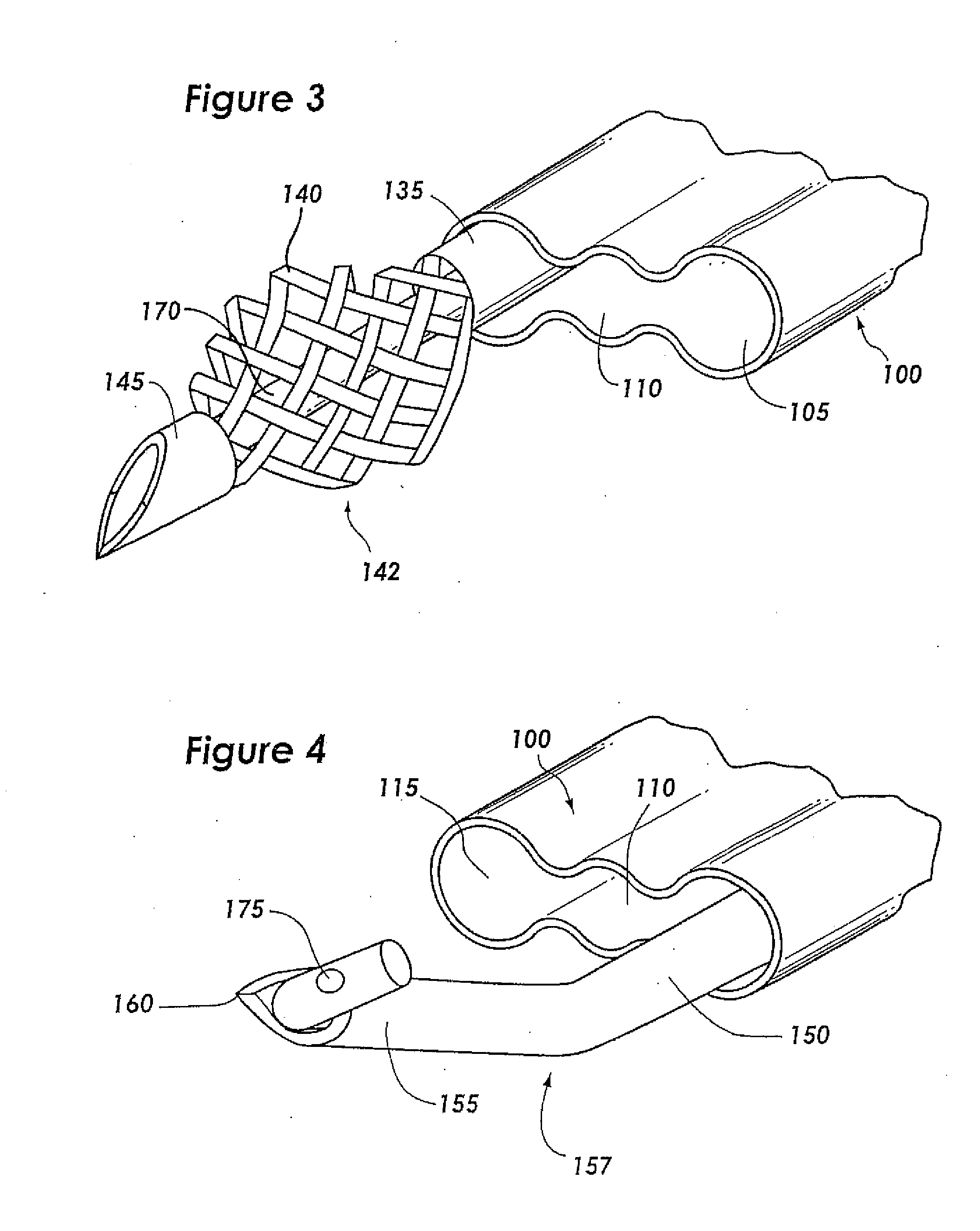

The present invention relates to a three-needle type vascular closure system. The closure system utilizes three needles in the form of a guiding device, an expandable needle, and a hooking device. The guiding device is used to make the initial opening in the vessel, where the opening provides access for a sheath through which a medical procedure is to be performed. The expandable needle is inserted into the vessel in which it expands radially from the needle to form a target. The hooking device is also inserted into the vessel and is used to hook the expandable needle so as to form an internal union between the hooking device and the expandable needle. The needles can then be retracted thereby extending a suture from the hooking device and forming an internal suture pass that can be used to approximate the tissue surrounding the initial opening in the vessel. In one embodiment, the suture is passed across the vessel opening prior to dilation of the vessel opening.

Owner:ST JUDE MEDICAL PUERTO RICO BV

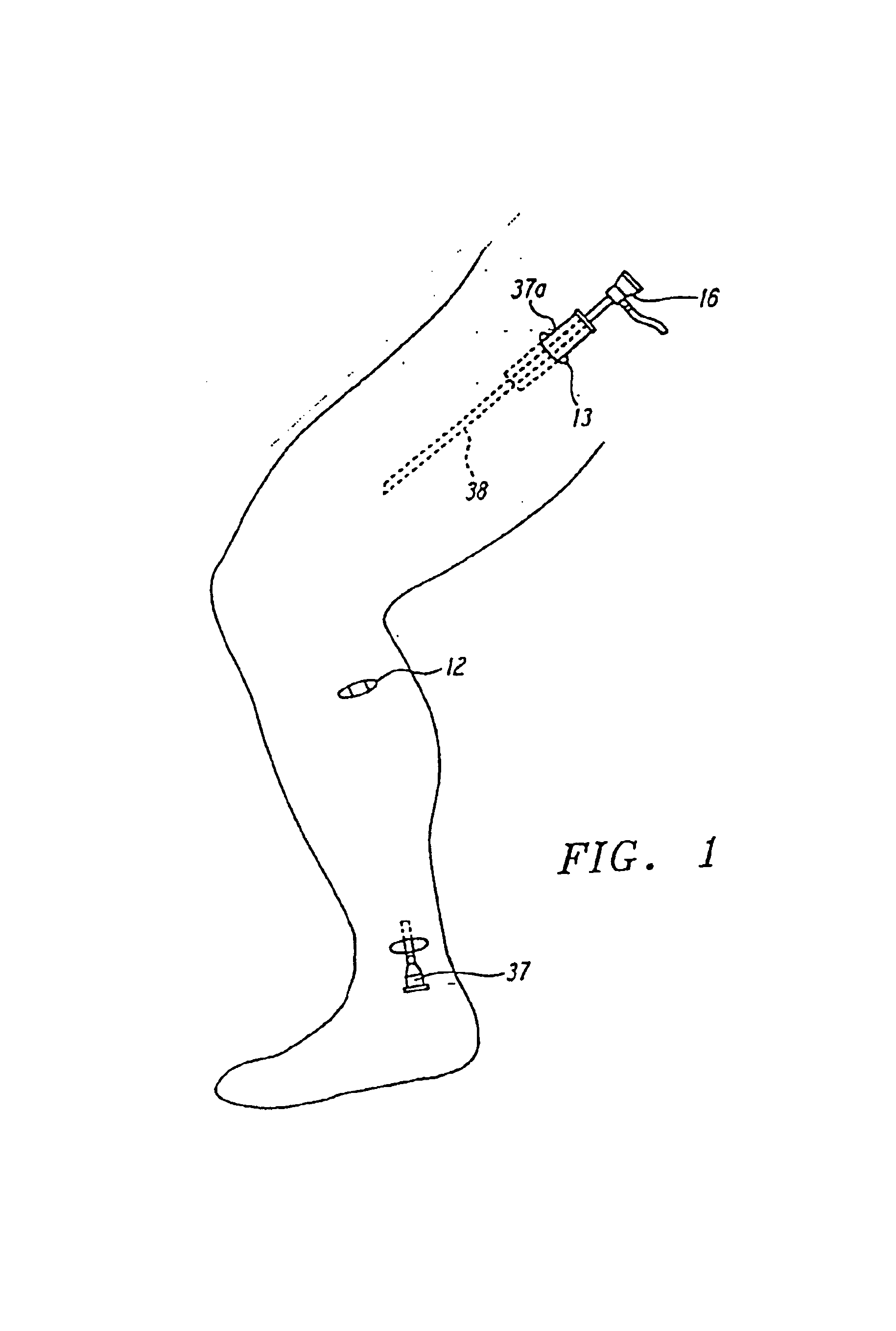

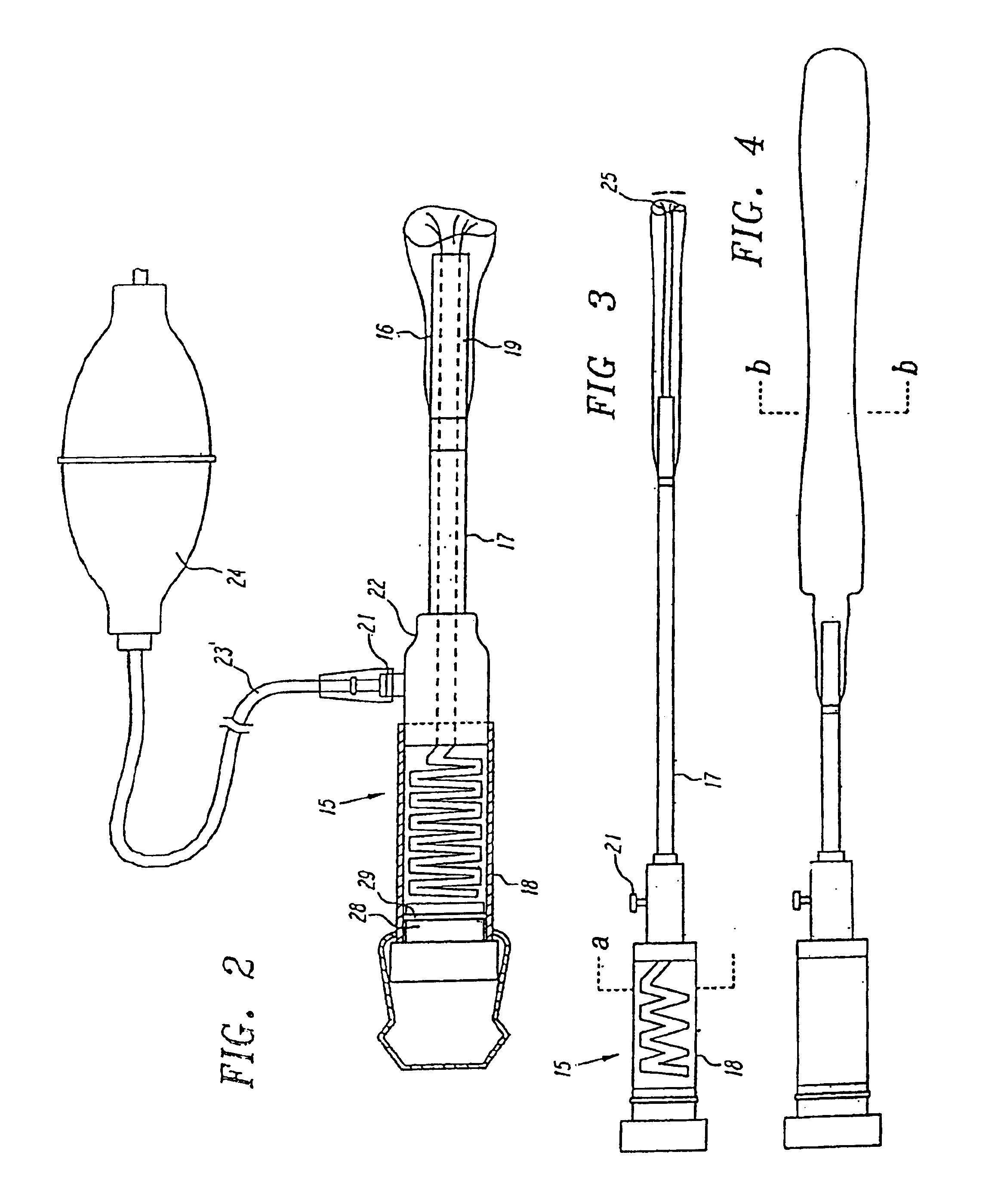

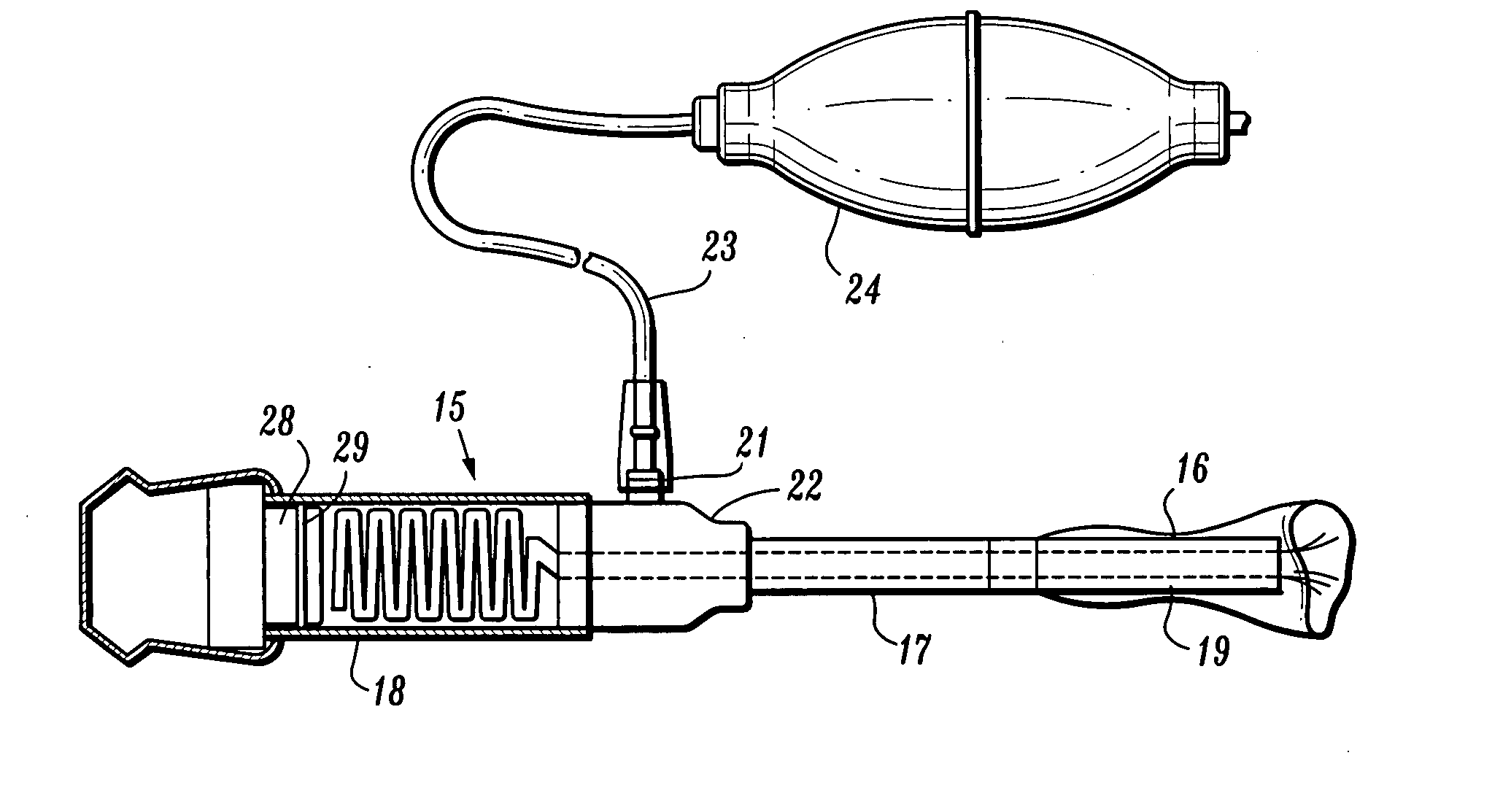

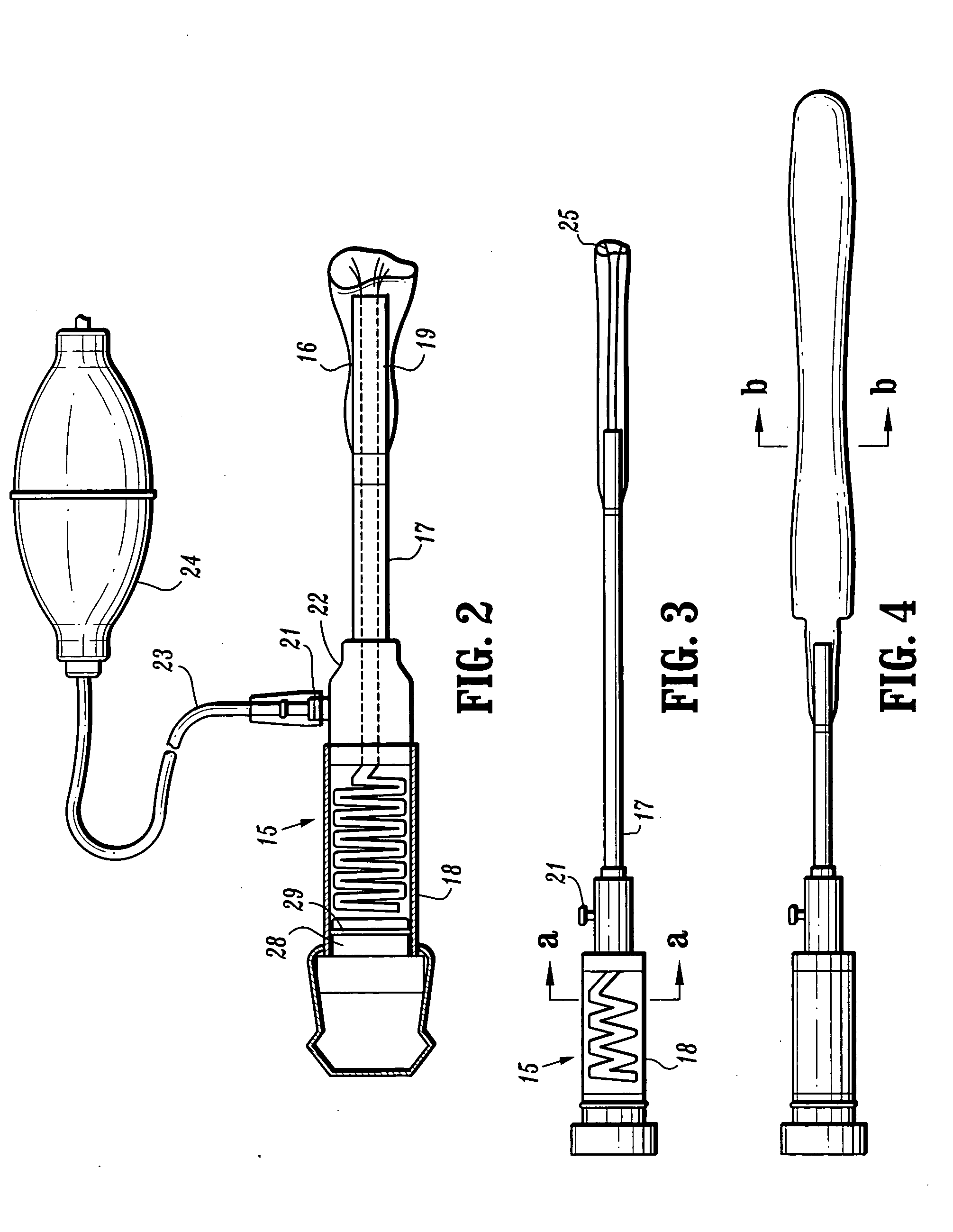

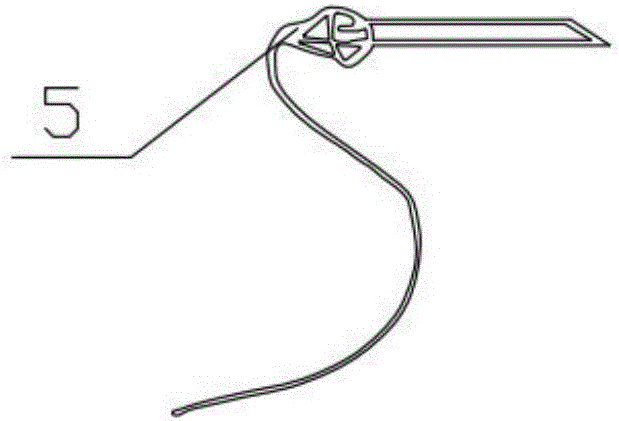

Methods and devices for blood vessel harvesting

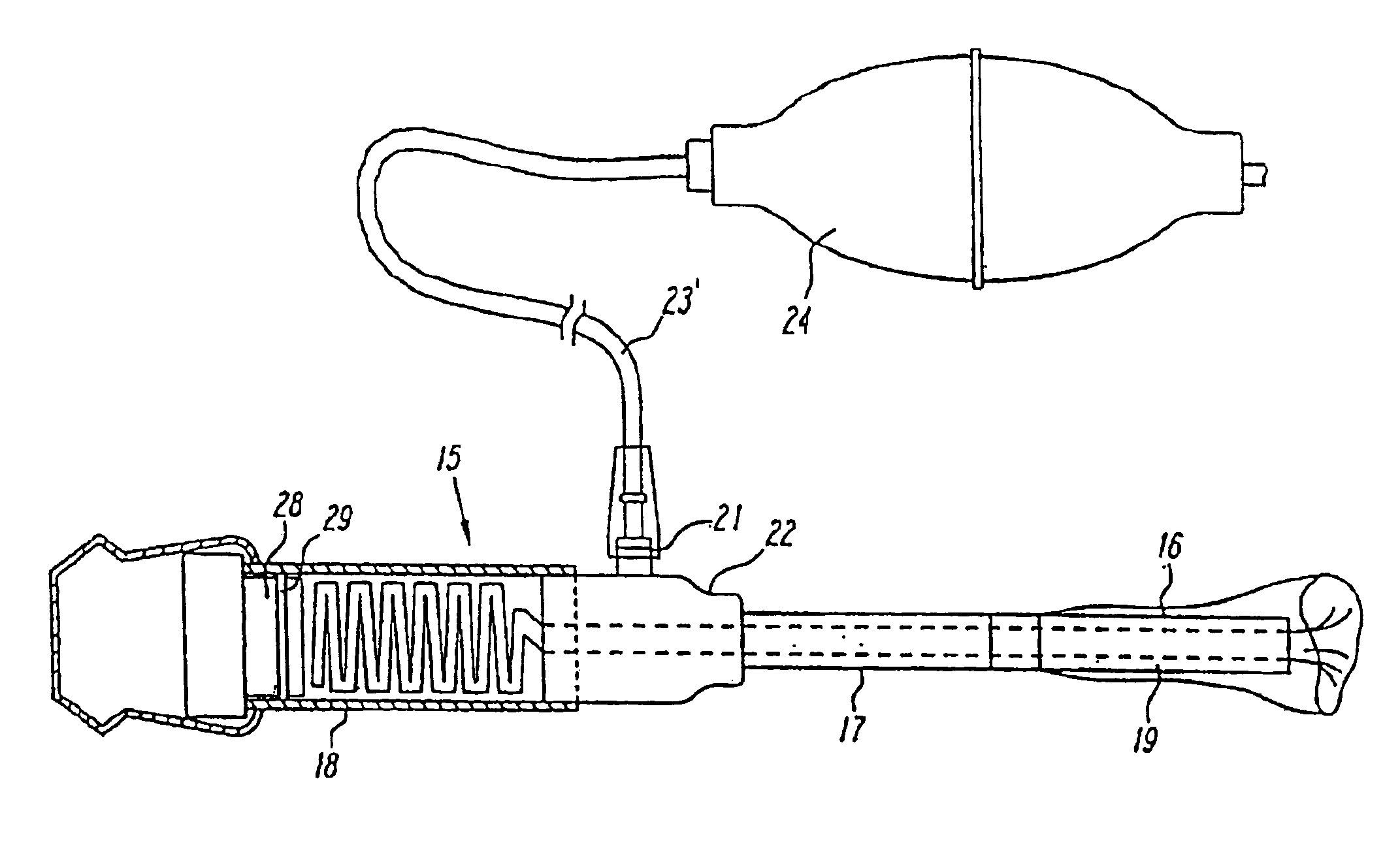

Methods and devices for harvesting veins from the body. The methods and devices allow vein harvesting using laparoscopic procedures. A working space is created over the vein using standard laparoscopic procedures and a side-hooked wire is inserted into the working space and twisted to insert the side-hook under the vein. The wire is then pulled or drawn along the vein to separate the vein from the surrounding tissue. In an alternative embodiment, vein separation is accomplished by threading a soft rubber tube under the vein, grasping the ends of the tube so as to surround the vein, and then pulling the tube along the vein. In other embodiments, the working space is created with everting balloons.

Owner:GEN SURGICAL INNOVATIONS

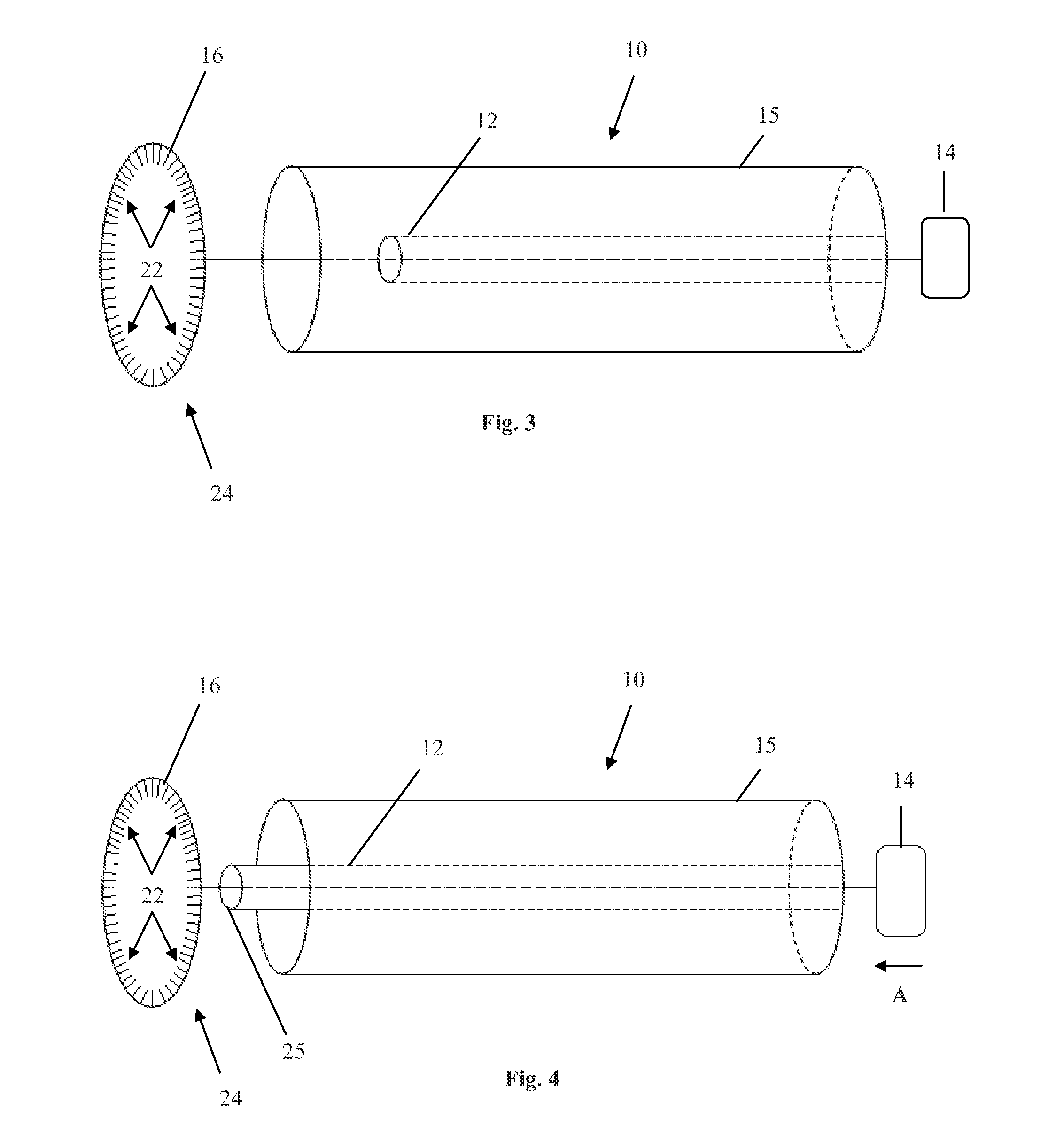

Device and method for extracting tubular structures

A device and method for extracting tubular structures are provided. An incision is made at a proximate and at a distal end of a tubular structure. An extracting device is inserted into and passed through a tubular structure until the operational head of the device extends past the distal incision. An actuator on the handle of the device is actuated, longitudinally extending the operational head of the device. The edge of a tubular structure is positioned axially in the mouth of a hook wire on the operational head. The actuator on the handle is released and the hook wire engages and captures the tubular structure. The user manually pulls the tubular structure, invaginating and removing it.

Owner:NELSON MEDICAL ENTERPRISES

Methods and devices for blood vessel harvesting

Methods and devices for harvesting veins from the body. The methods and devices allow vein harvesting using laparoscopic procedures. A working space is created over the vein using standard laparoscopic procedures and a side-hooked wire is inserted into the working space and twisted to insert the side-hook under the vein. The wire is then pulled or drawn along the vein to separate the vein from the surrounding tissue. In an alternative embodiment, vein separation is accomplished by threading a soft rubber tube under the vein, grasping the ends of the tube so as to surround the vein, and then pulling the tube along the vein. In other embodiments, the working space is created with everting balloons.

Owner:GEN SURGICAL INNOVATIONS

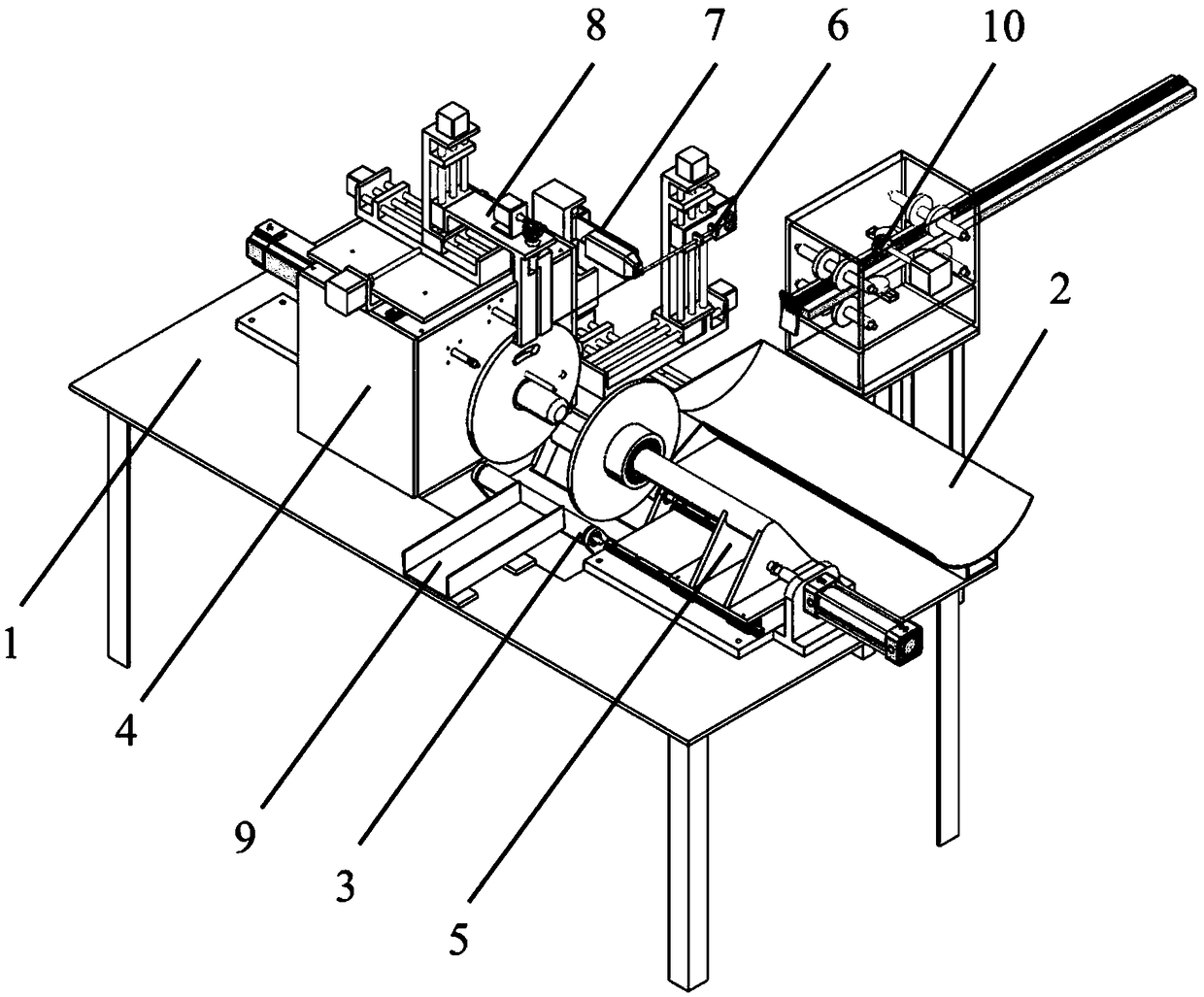

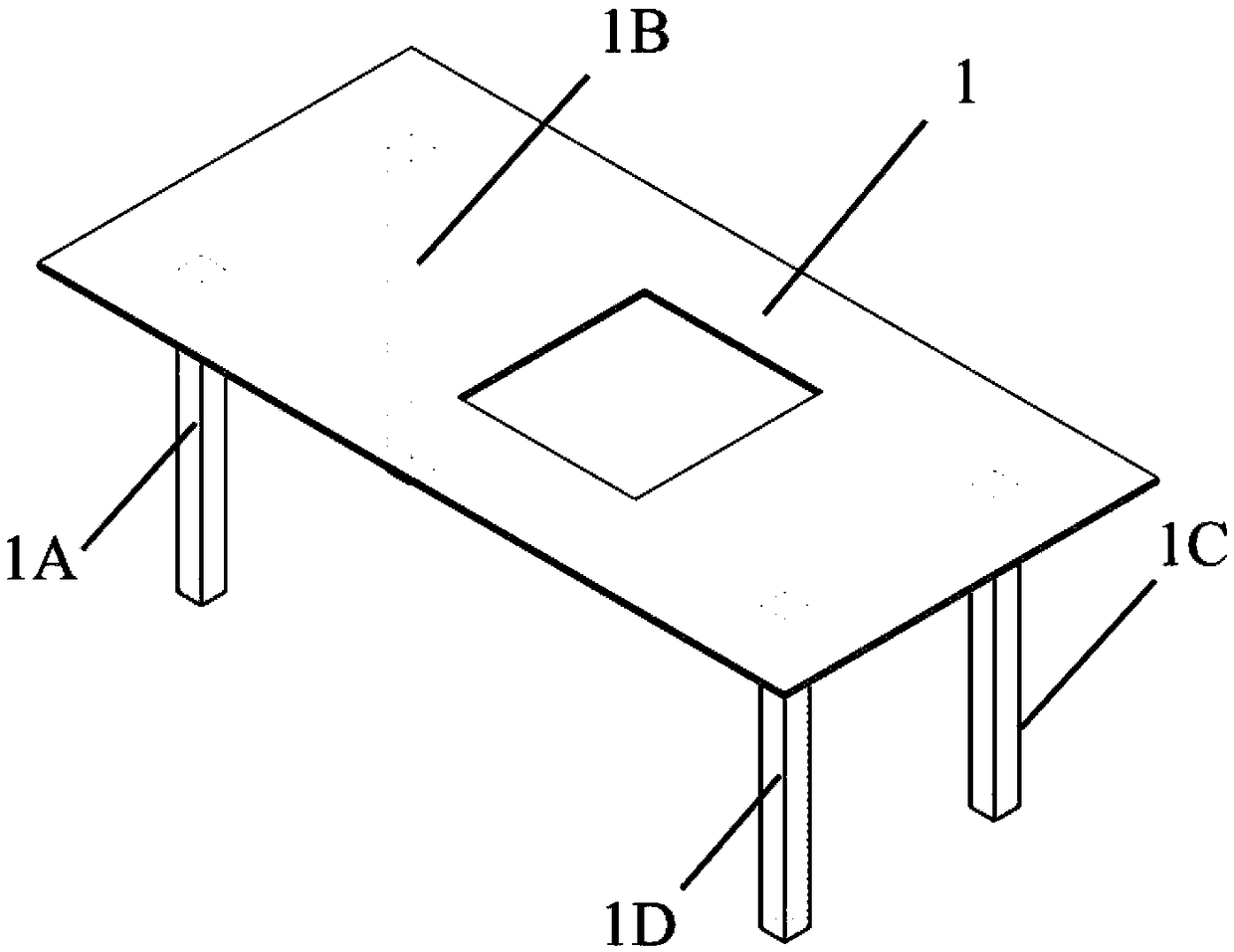

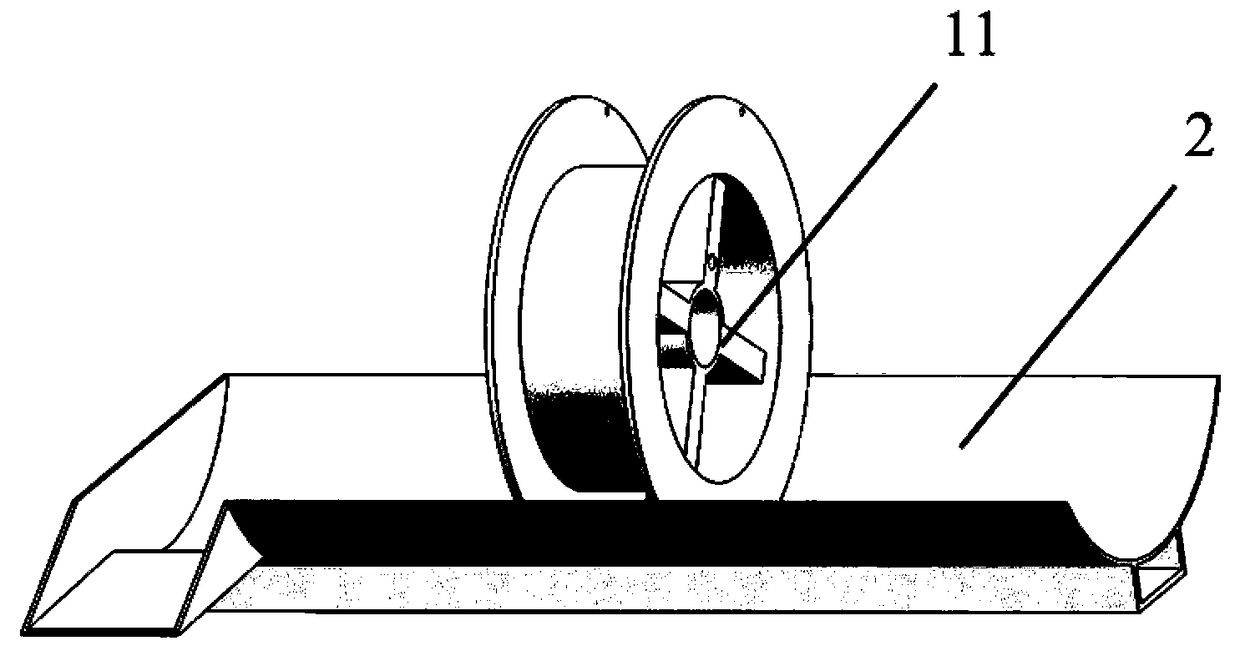

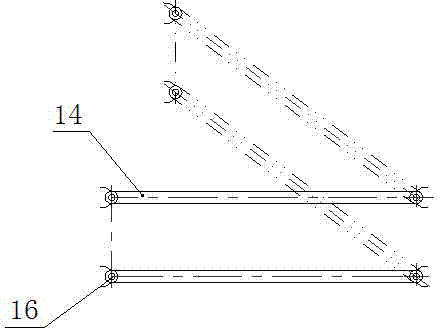

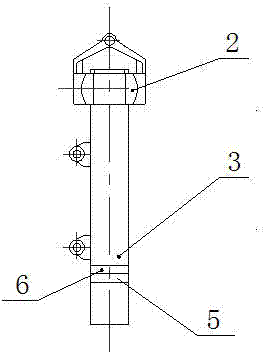

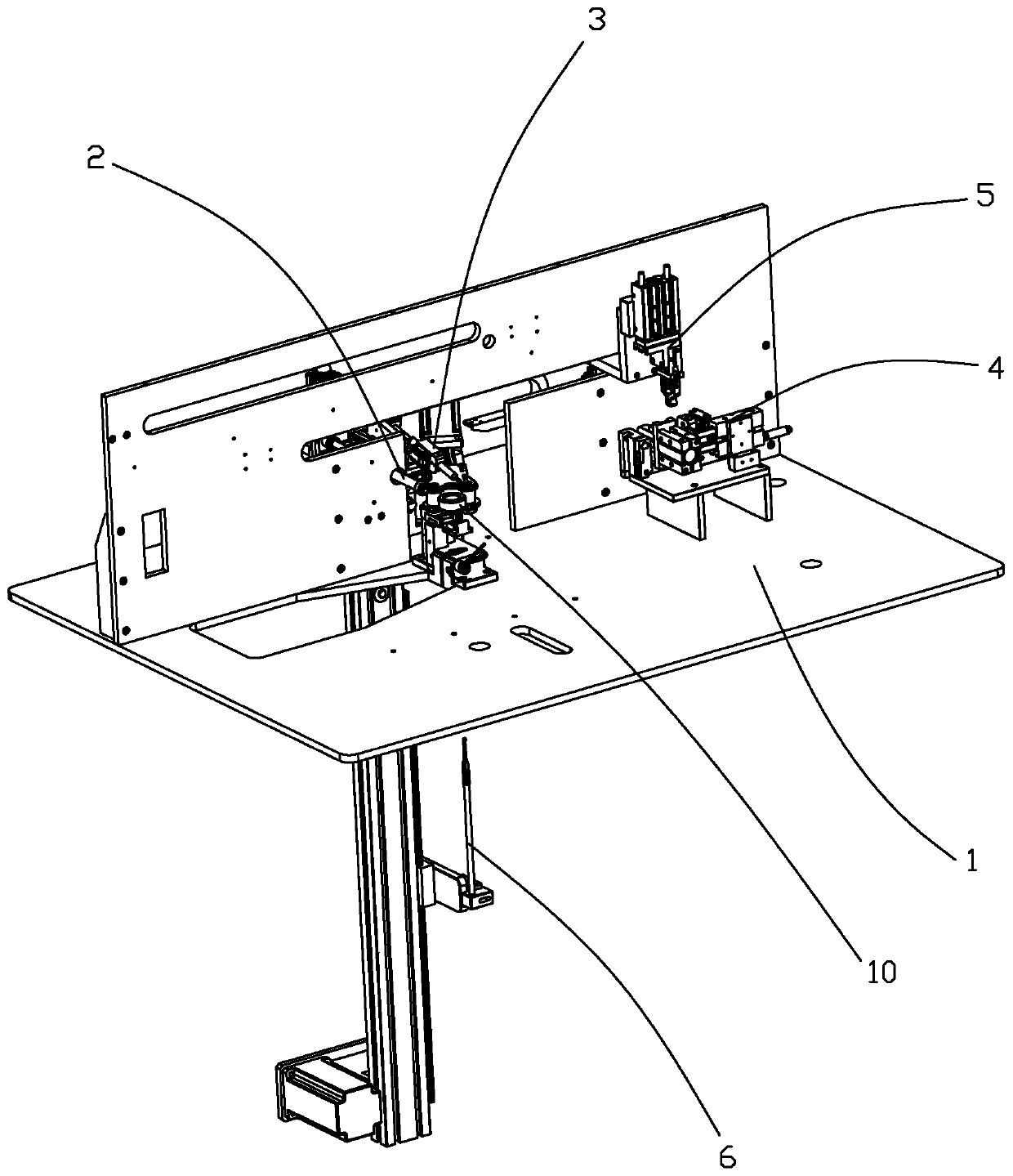

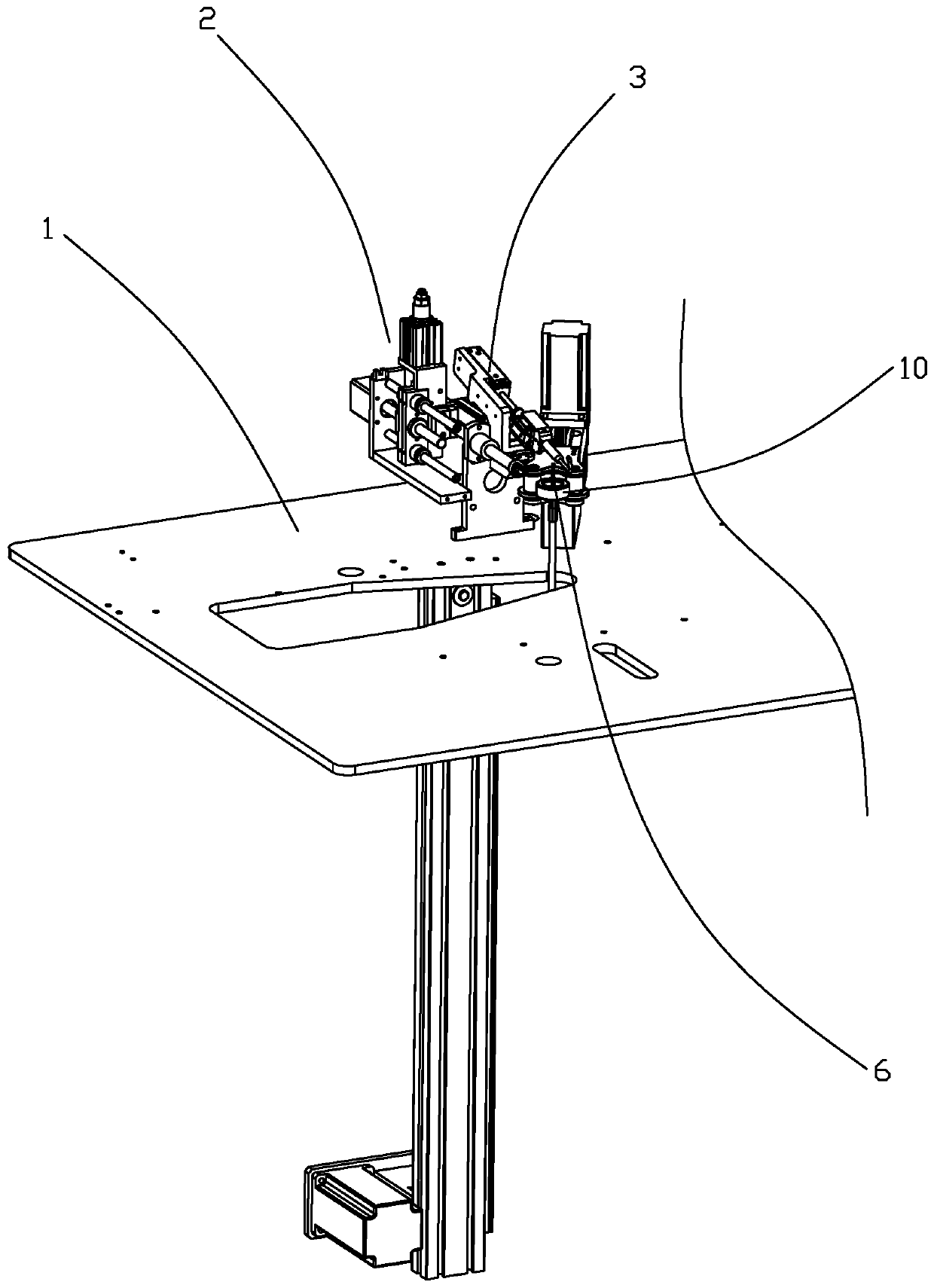

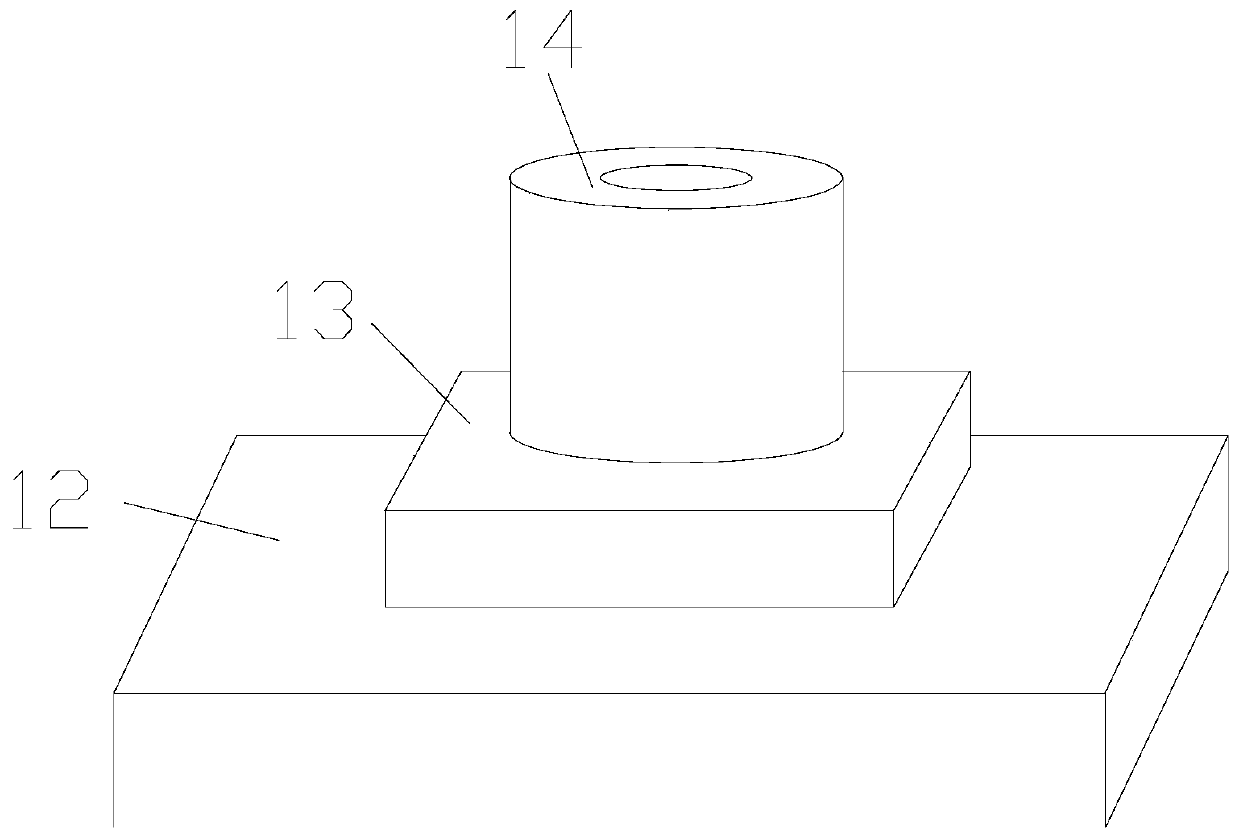

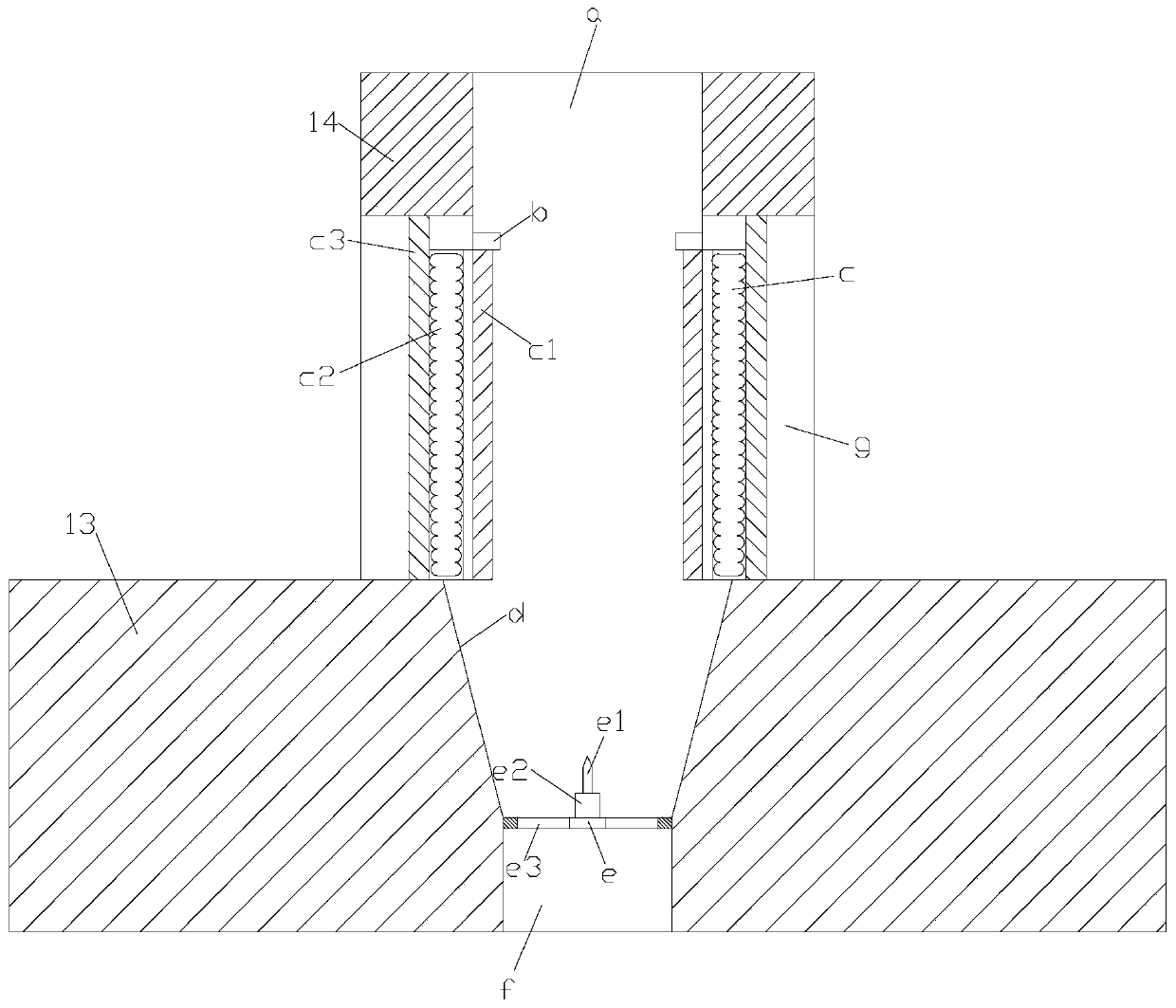

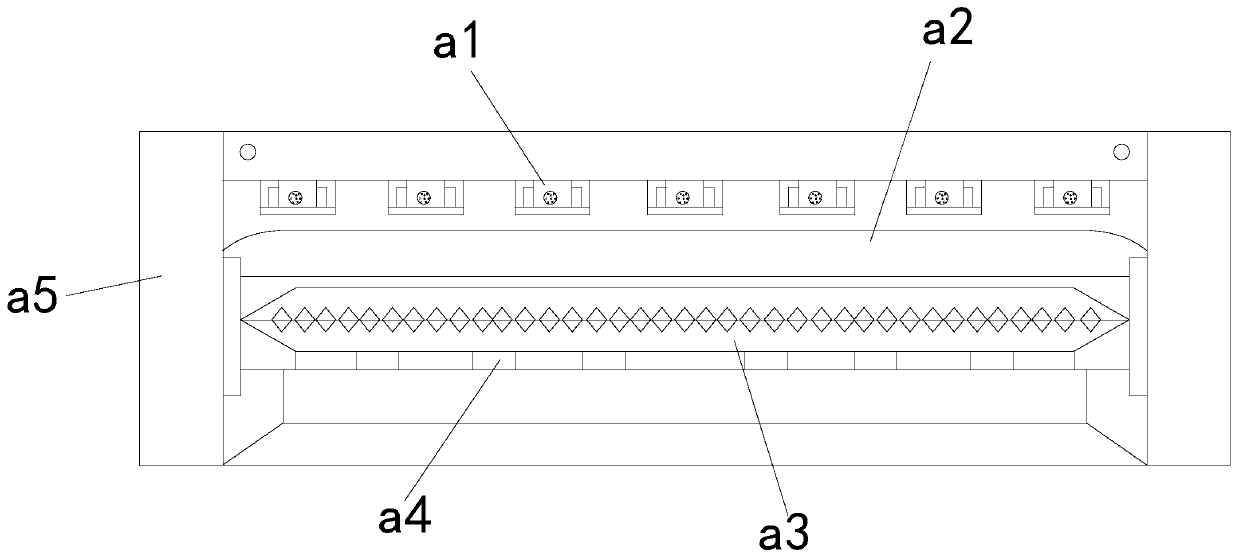

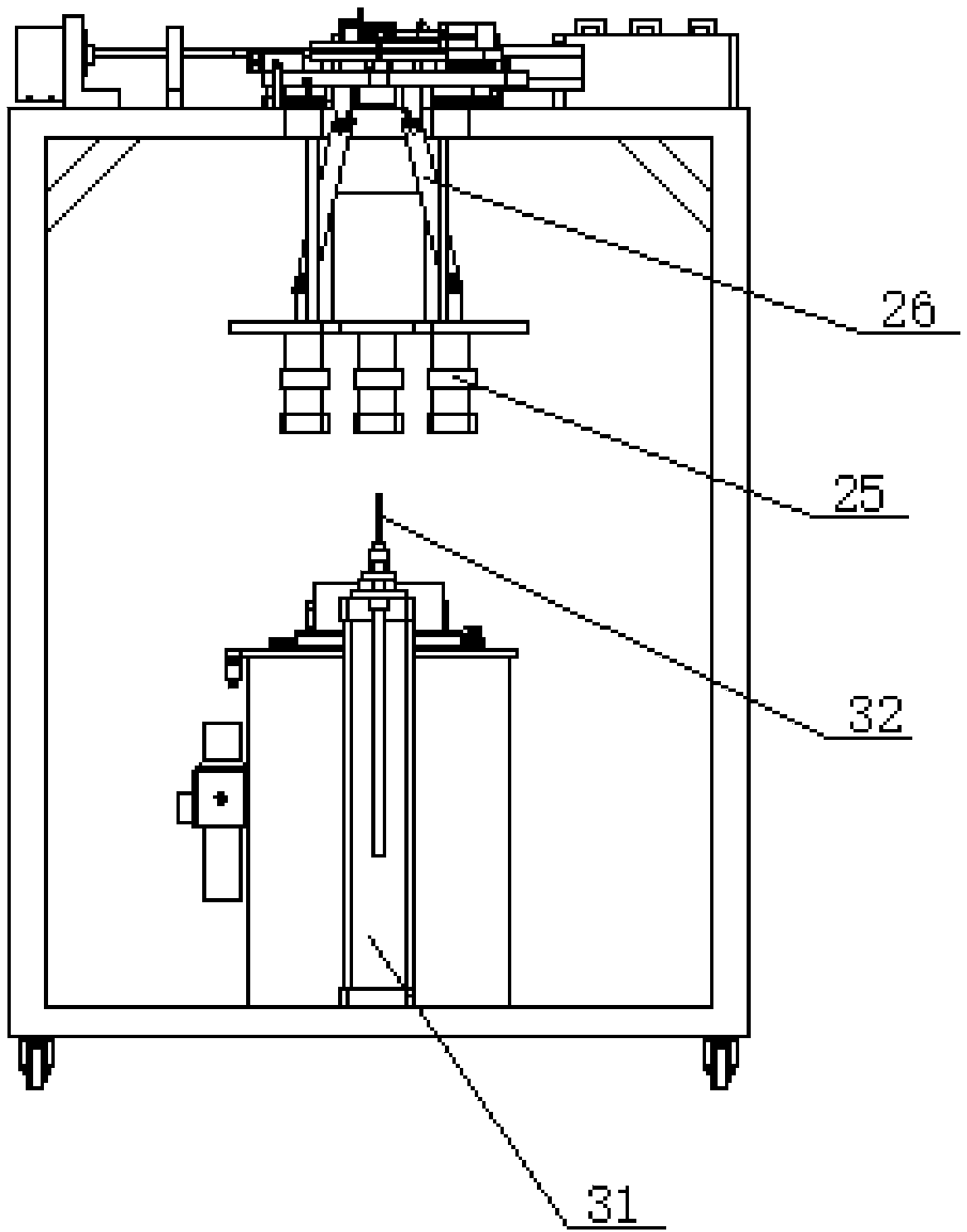

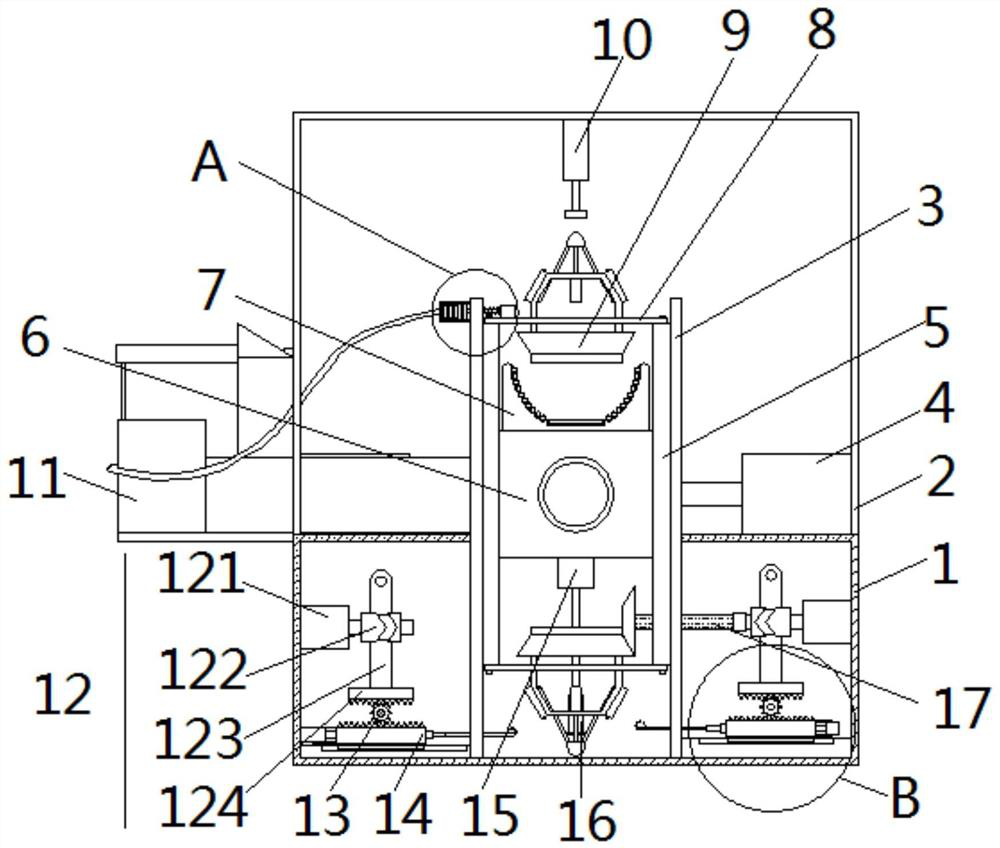

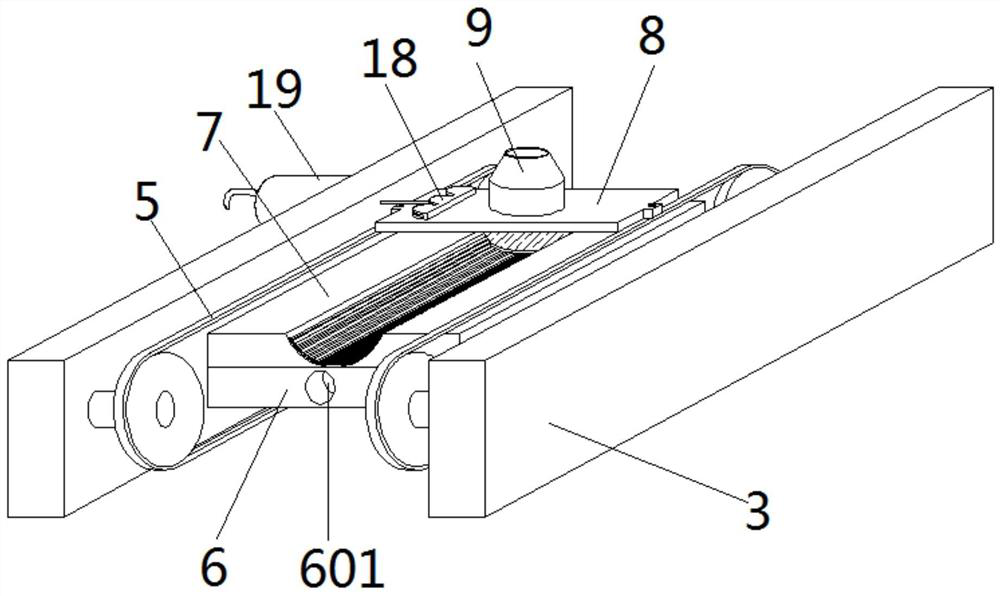

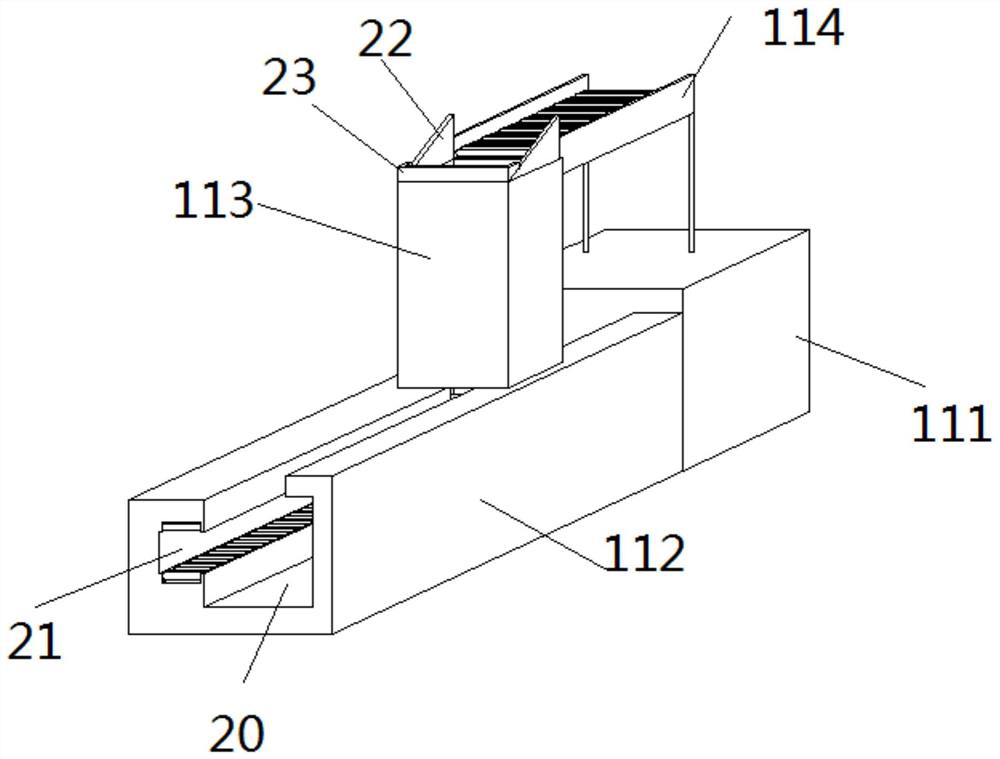

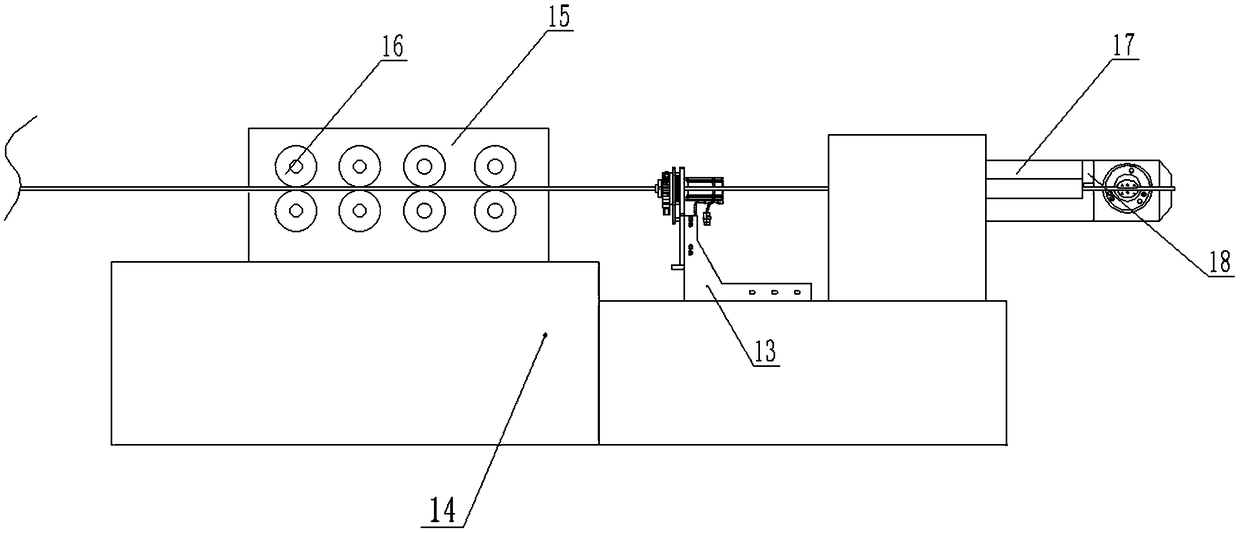

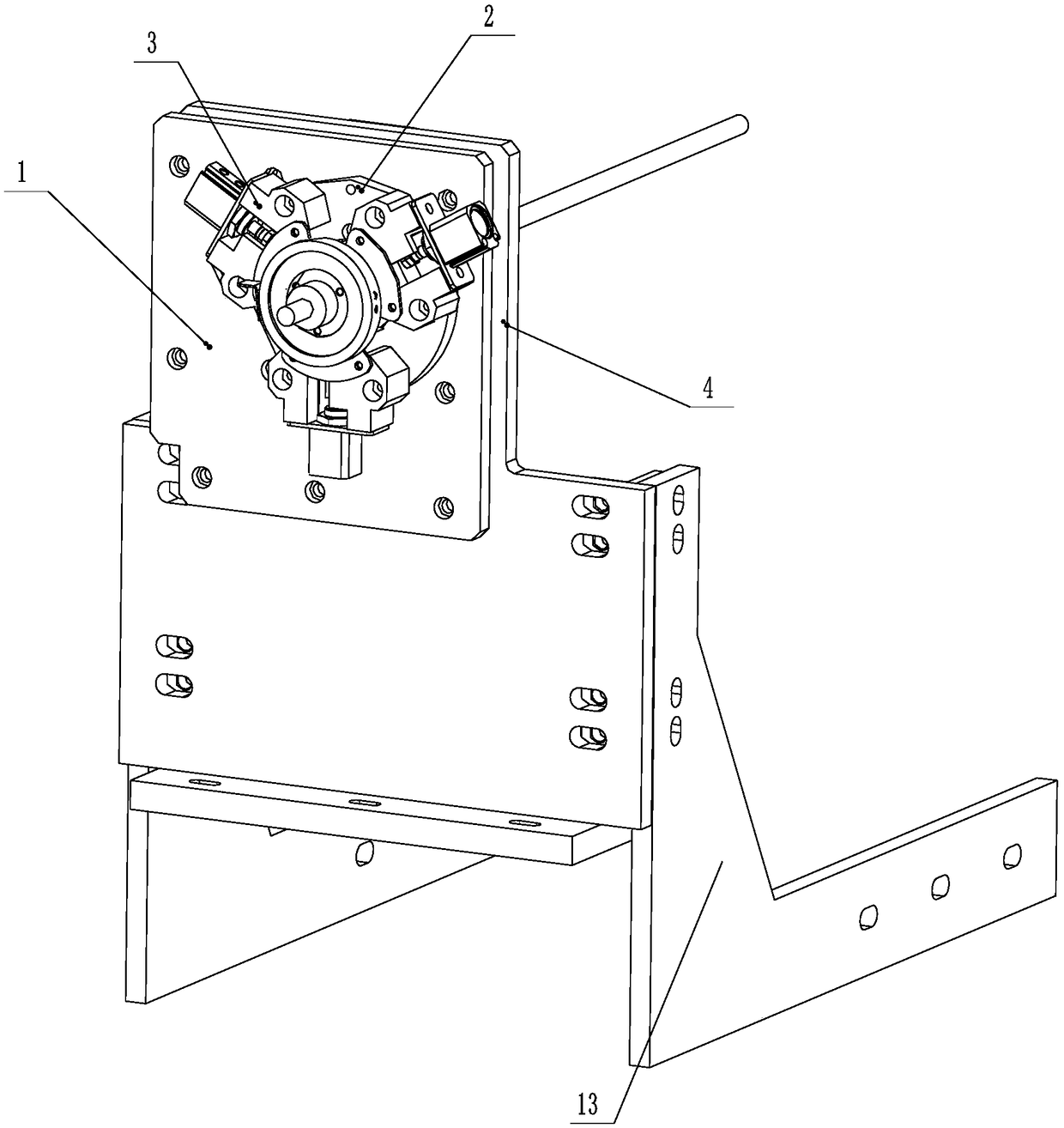

Full-automatic welding wire layer winding machine

The invention discloses a full-automatic welding wire layer winding machine. The full-automatic welding wire layer winding machine comprises a workbench and further comprises a welding wire disc feeding groove, a lifting part, a main shaft part, a tail base part, a wire feeding part and a welding wire disc discharging groove, all of which are formed in the workbench. The main shaft part is provided with a wire shearing part and a wire folding and inserting part. A moving part arranged on one side of the workbench is further included. The full-automatic welding wire layer winding machine can solve the three key technology problems about automatic hook wire rising, tight layer winding and hook wire terminating, accordingly the welding wire layer winding process is fully automatic, manual operation is not needed in the whole process, and the whole process is automatically finished through the machine. The work efficiency can be greatly improved, and the production cost is reduced.

Owner:JIANGNAN UNIV

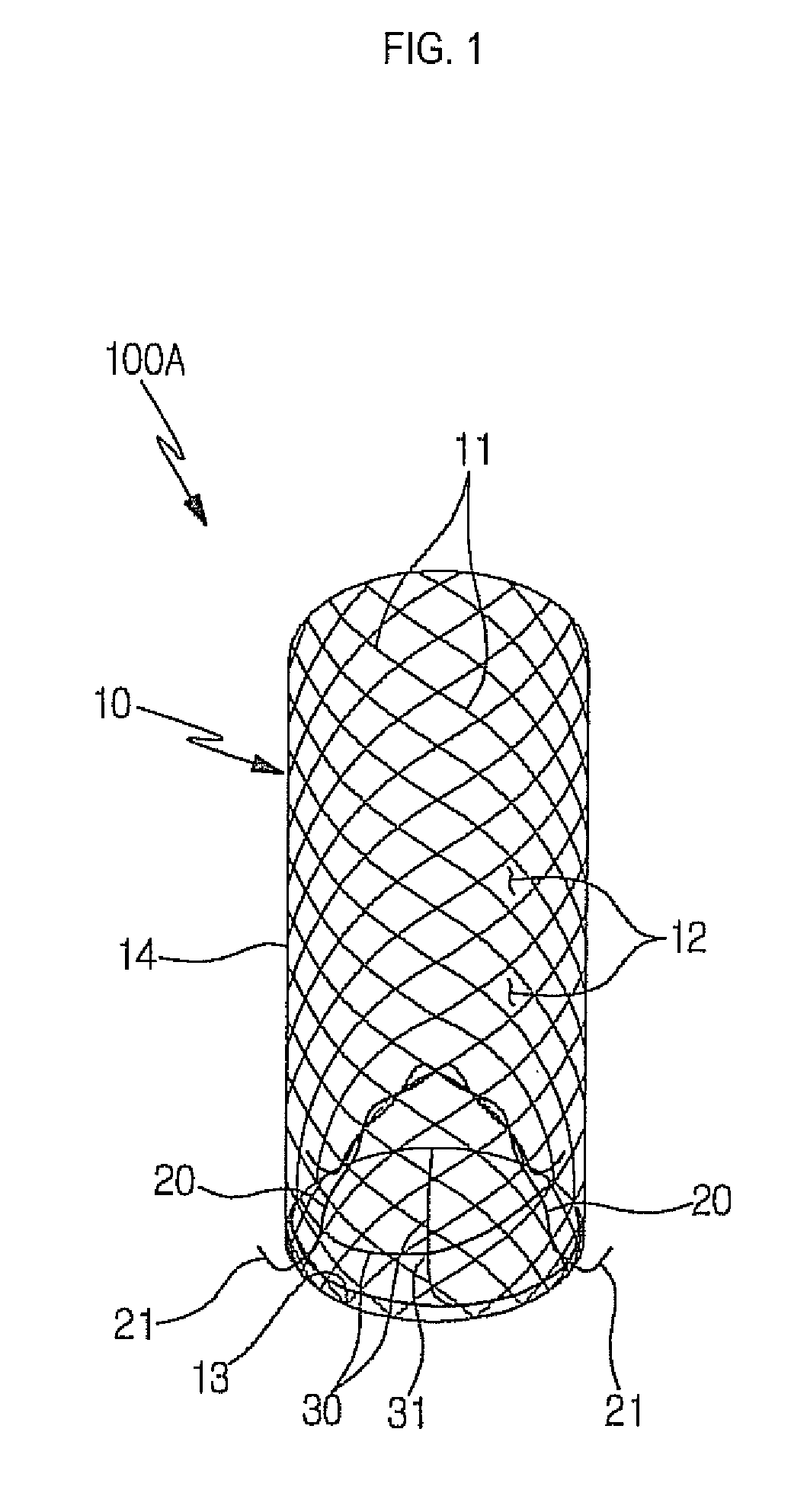

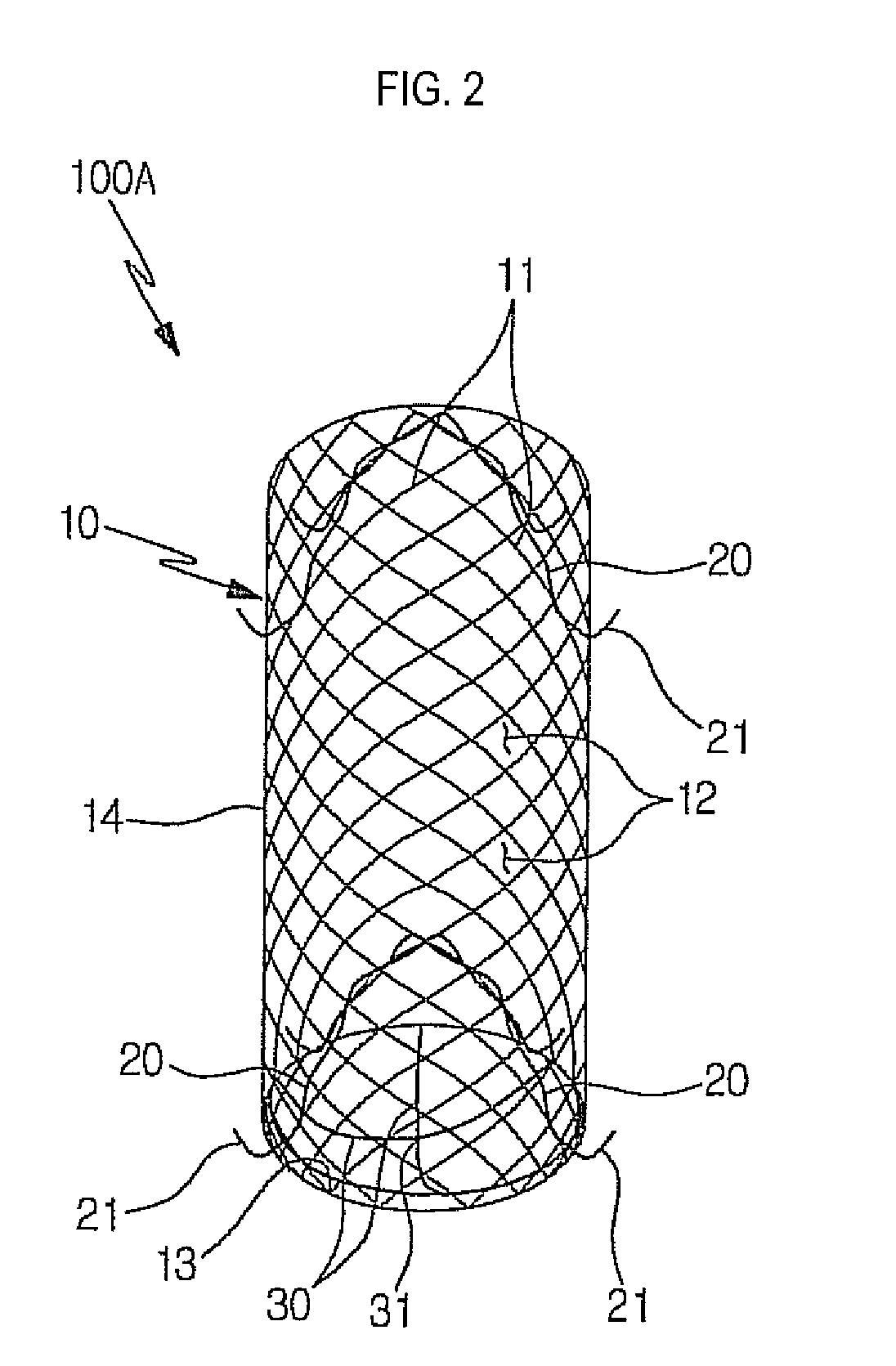

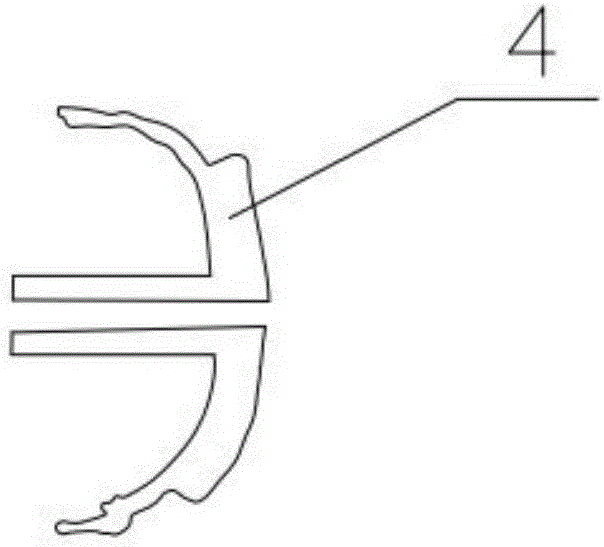

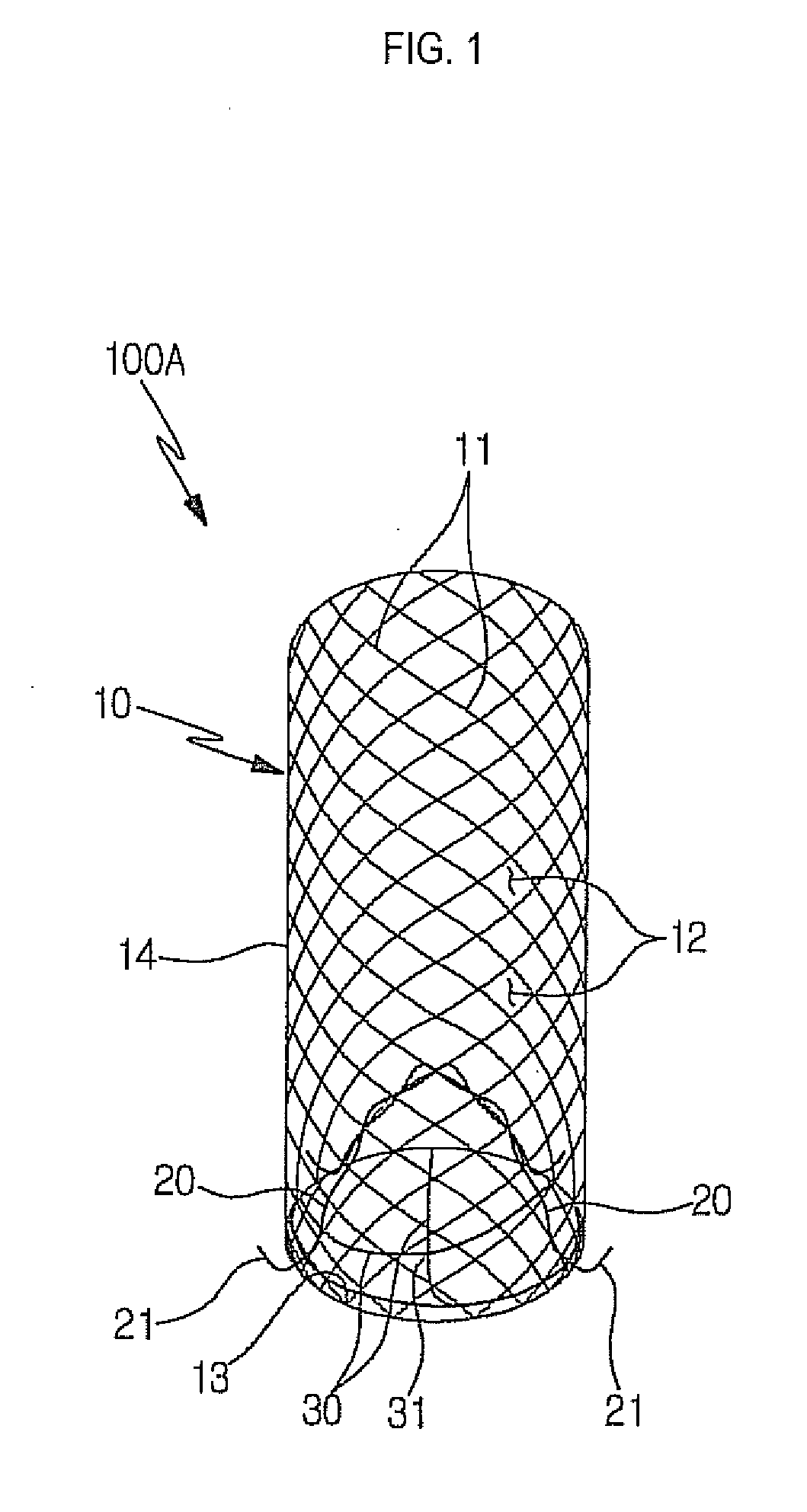

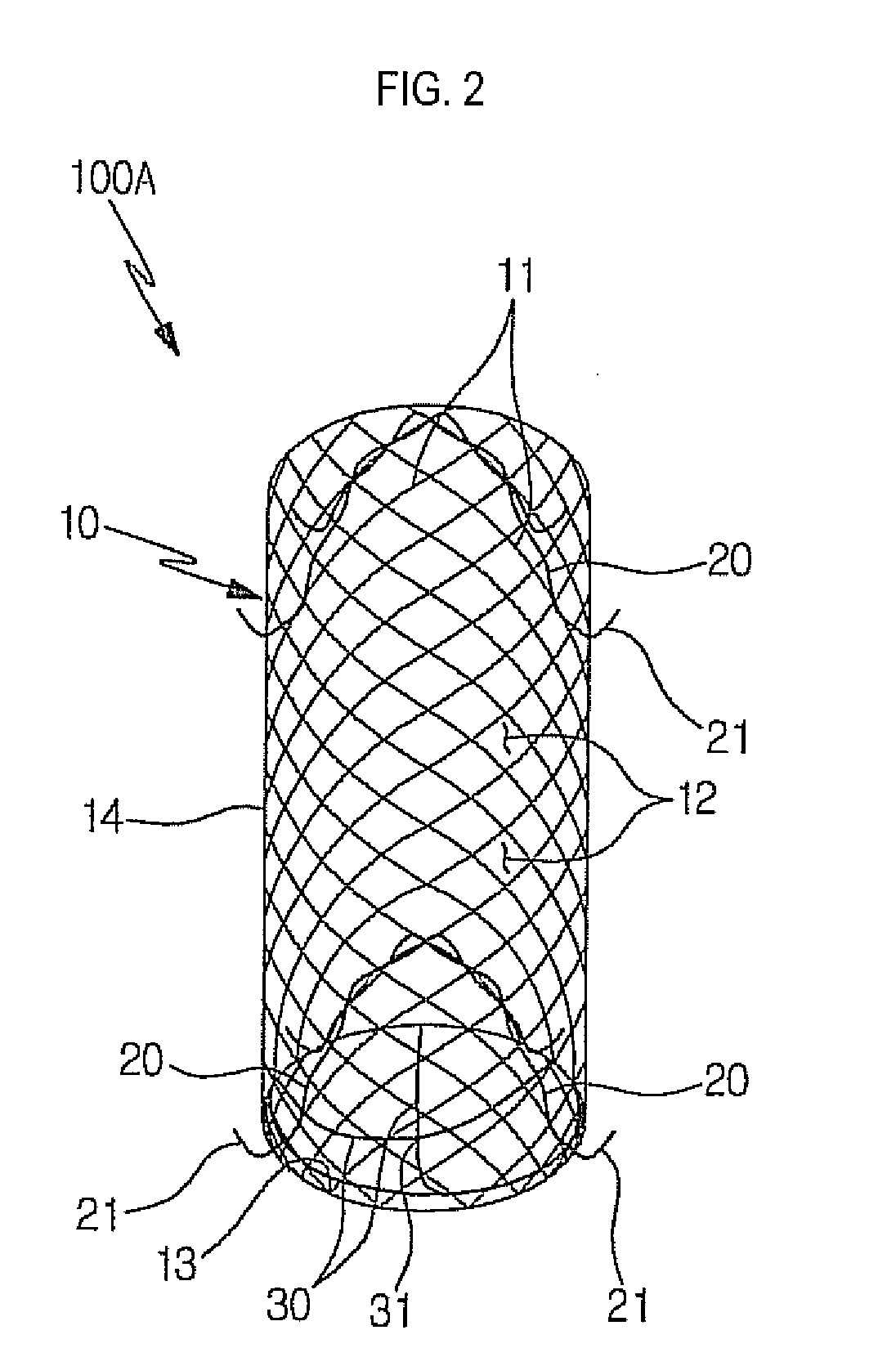

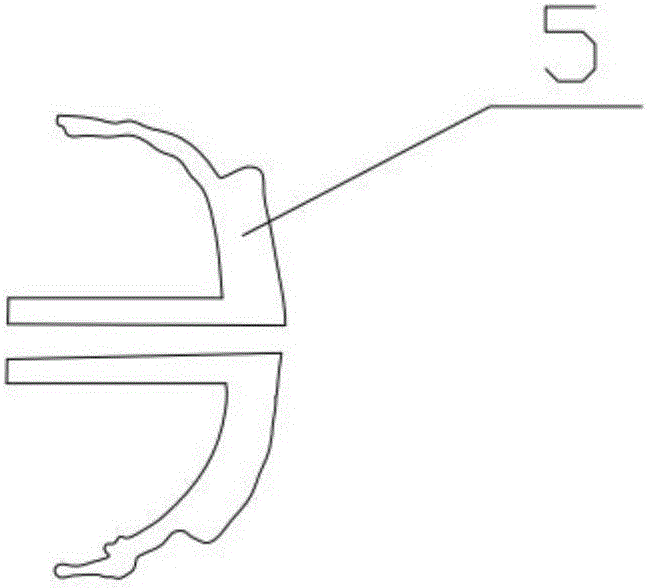

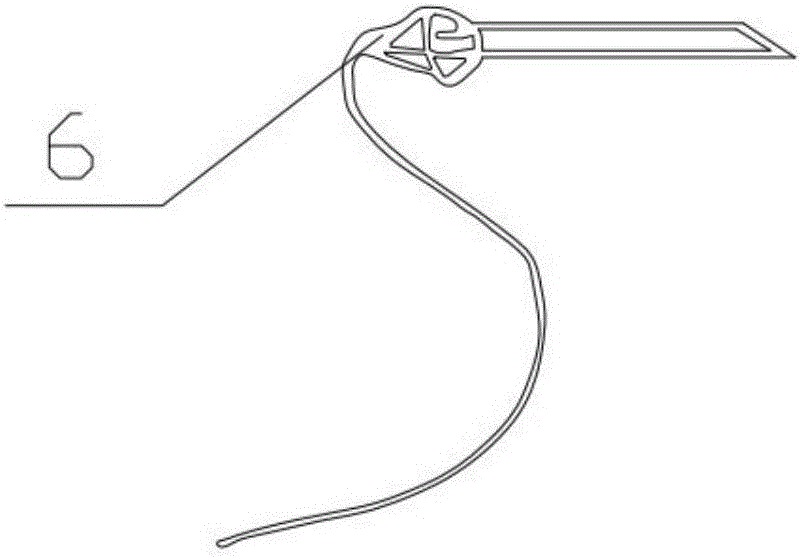

Stent for prostatic urethra expansion

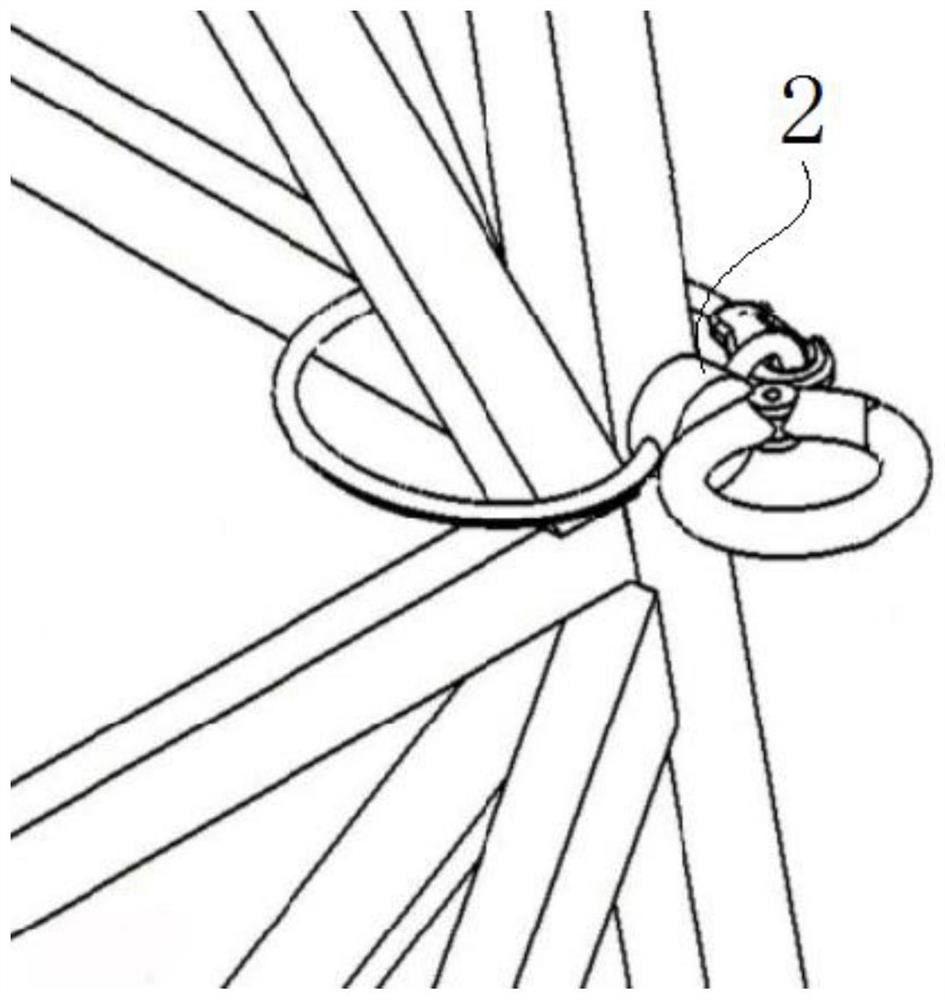

Disclosed herein is a stent for prostatic urethra expansion which does not generate bladder stones, is removable without causing injury on a urethra, and does not generate atrophy of a prostatic urethra even after removal. The stent for prostatic urethra expansion include a stent unit including a cylindrical body with space parts formed by knotting or crossing shape memory alloy wires and bending terminals formed at both ends of the cylindrical body, a pair of hook wires passing through the space parts and knotted to the shape memory alloy wires, both ends thereof being wound on the bending terminals and then being bent upwardly to produce hooks, and a pair of hanging strings arranged in opposite directions to form a hanging knot. The stent for prostatic urethra expansion does not move into the bladder, and expands and maintains a lumen of the stenosed prostatic urethra, thereby reducing post-operative recovery time.

Owner:TAEWOONG MEDICAL CO LTD +2

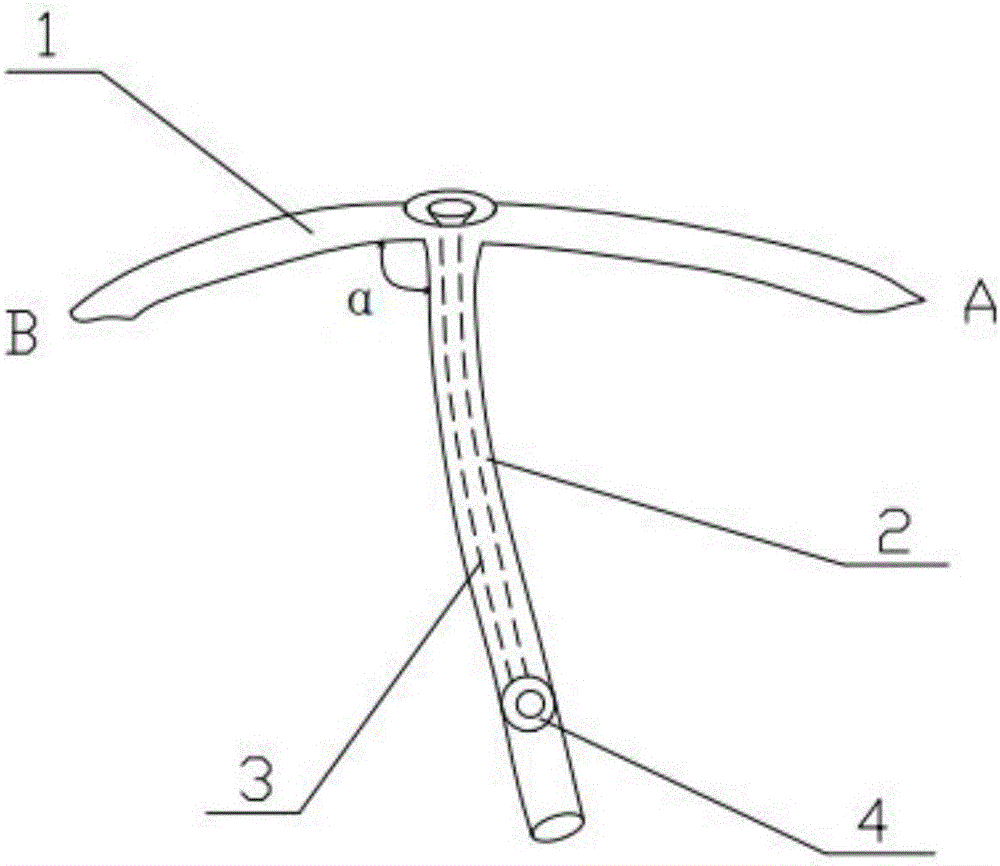

T-shaped positioning device adopting 3D printing in intrathoracic endoscopy and manufacturing method thereof

ActiveCN105796185APrevent decouplingReduce exposureDiagnosticsComputer-aided planning/modellingFlexible endoscopeEngineering

The invention discloses a T-shaped positioning device adopting 3D printing in an intrathoracic endoscopy and a manufacturing method thereof. The T-shaped positioning device is of a T-shaped structure adopting the 3D printing and comprising a vertical section and a horizontal section, wherein the upper end of the vertical section and the middle of the horizontal section are intersected at a certain angle, a hollow tube communicated with the surface of the horizontal section is arranged in the vertical section, the lower end of the vertical section is closed, and a nidus marking device connected with the hollow tube is arranged on the vertical section. When the T-shaped positioning device is used, the positioning device is arranged and fixed in the thorax of a patient in a conformal mode and marks the ground-glass node position of the lung through the nidus marking device. The T-shaped positioning device avoids the problem that a node and a hook-wire cannot be touched by adopting a method of touching by hand or a micro-coil is unhooked or falls into the thoracic cavity, the CV exposure to the patient and the working amount of a medical worker are decreased, and meanwhile the influence on the ribs or shoulder blades due to dissection is eliminated.

Owner:SHANGHAI PULMONARY HOSPITAL

Stent for prostatic urethra expansion

Disclosed herein is a stent for prostatic urethra expansion which does not generate bladder stones, is removable without causing injury on a urethra, and does not generate atrophy of a prostatic urethra even after removal. The stent for prostatic urethra expansion include a stent unit including a cylindrical body with space parts formed by knotting or crossing shape memory alloy wires and bending terminals formed at both ends of the cylindrical body, a pair of hook wires passing through the space parts and knotted to the shape memory alloy wires, both ends thereof being wound on the bending terminals and then being bent upwardly to produce hooks, and a pair of hanging strings arranged in opposite directions to form a hanging knot. The stent for prostatic urethra expansion does not move into the bladder, and expands and maintains a lumen of the stenosed prostatic urethra, thereby reducing post-operative recovery time.

Owner:TAEWOONG MEDICAL CO LTD +2

Intrathoracic L-shaped positioning device adopting 3D printing in endoscopy and manufacturing method thereof

ActiveCN105796186APrevent decouplingReduce exposureSuture equipmentsInternal osteosythesisFlexible endoscopeMicro coil

The invention discloses an intrathoracic L-shaped positioning device adopting 3D printing in an endoscopy and a manufacturing method thereof. The L-shaped positioning device is an L-shaped hollow tube adopting the 3D printing and comprises a vertical section, an elbow and a horizontal section, wherein a head end fit with the top face of the thorax of a patient is arranged at the top of the vertical section, the tail end of the horizontal section is closed, and a nidus marking device connected with the hollow tube is arranged on the horizontal section. When the intrathoracic L-shaped positioning device is used, the positioning device is arranged and fixed in the thorax of the patient in a conformal mode and marks the ground-glass node position of the lung through the nidus marking device. The L-shaped positioning device avoids the problem that a node and a hook-wire cannot be touched by adopting a method of touching by hand or a micro-coil is unhooked or falls into the thoracic cavity, the CV exposure to the patient and the working amount of a medical worker are decreased, and meanwhile the influence on the ribs or shoulder blades due to dissection is eliminated.

Owner:SHANGHAI PULMONARY HOSPITAL

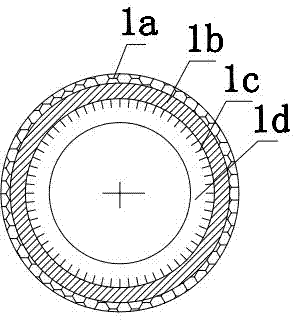

Large-caliber steel-plastic reinforced composite pipe section and reinforced composite pipe forming process

ActiveCN103615606AEffective moldingEnergy saving in molding processFlanged jointsRigid pipesEconomic benefitsHook wire

The invention provides a large-caliber steel-plastic reinforced composite pipe section and belongs to the technical field of reinforced composite pipelines. The large-caliber steel-plastic reinforced composite pipe section is composed of a reinforced composite pipe and flanges at two ends, a central layer of the reinforced composite pipe is a spiral welded steel pipe, the outer wall of the spiral welded steel pipe is provided with a glass reinforced plastic winding layer to form an outer layer of the reinforced composite pipe, and the inner wall of the spiral welded steel pipe is provided with a belt hook wire screen and a rotary-molding coating to form an inner layer of the reinforced composite pipe. A reinforced composite pipe forming process comprises the steps of adopting a spiral welding process to manufacture the spiral welded steel pipe, welding the belt hook wire screen on the inner wall of the steel pipe, adopting a rotary-molding forming device to manufacture the rotary-molding coating and arranging the formed glass reinforced plastic winding layer on the outer surface. The large-caliber steel-plastic reinforced composite pipe section has excellent corrosion resistance performance and light high-strength characteristic and is superior to various currently-used pipelines in the aspects of pressure resistance, corrosion resistance, service life, production cost and social and economic benefits, and high efficiency, energy saving and environmental protection are achieved in the forming process.

Owner:葛介昌

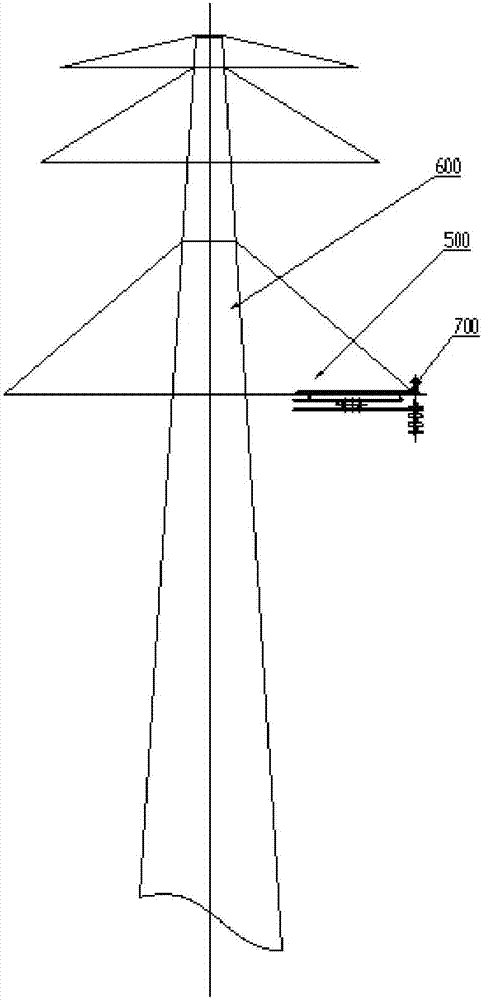

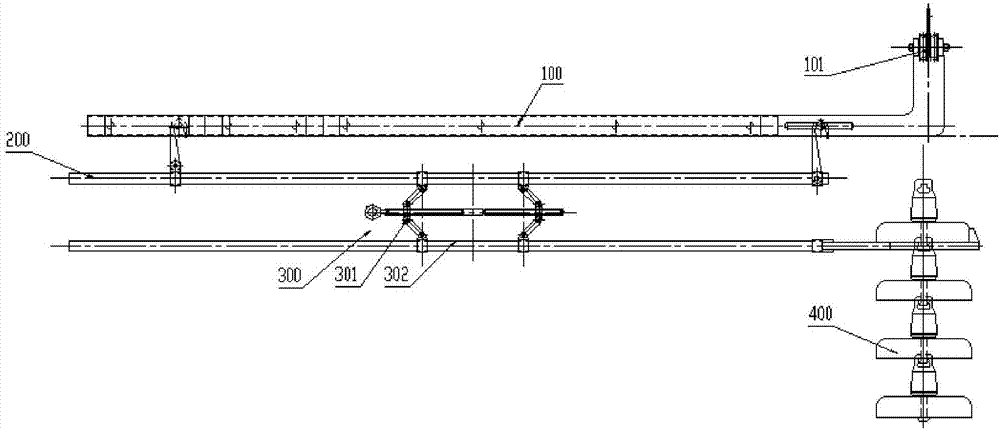

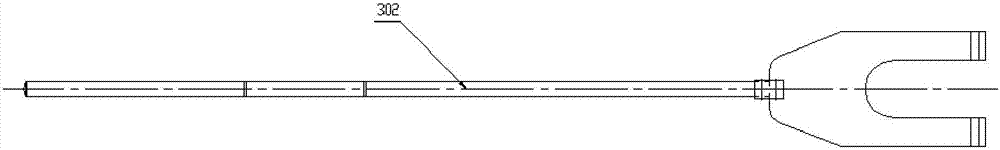

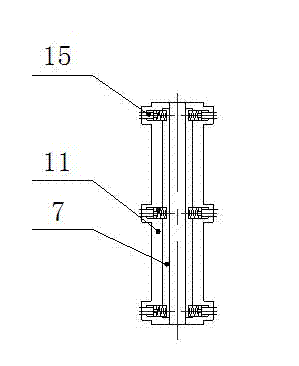

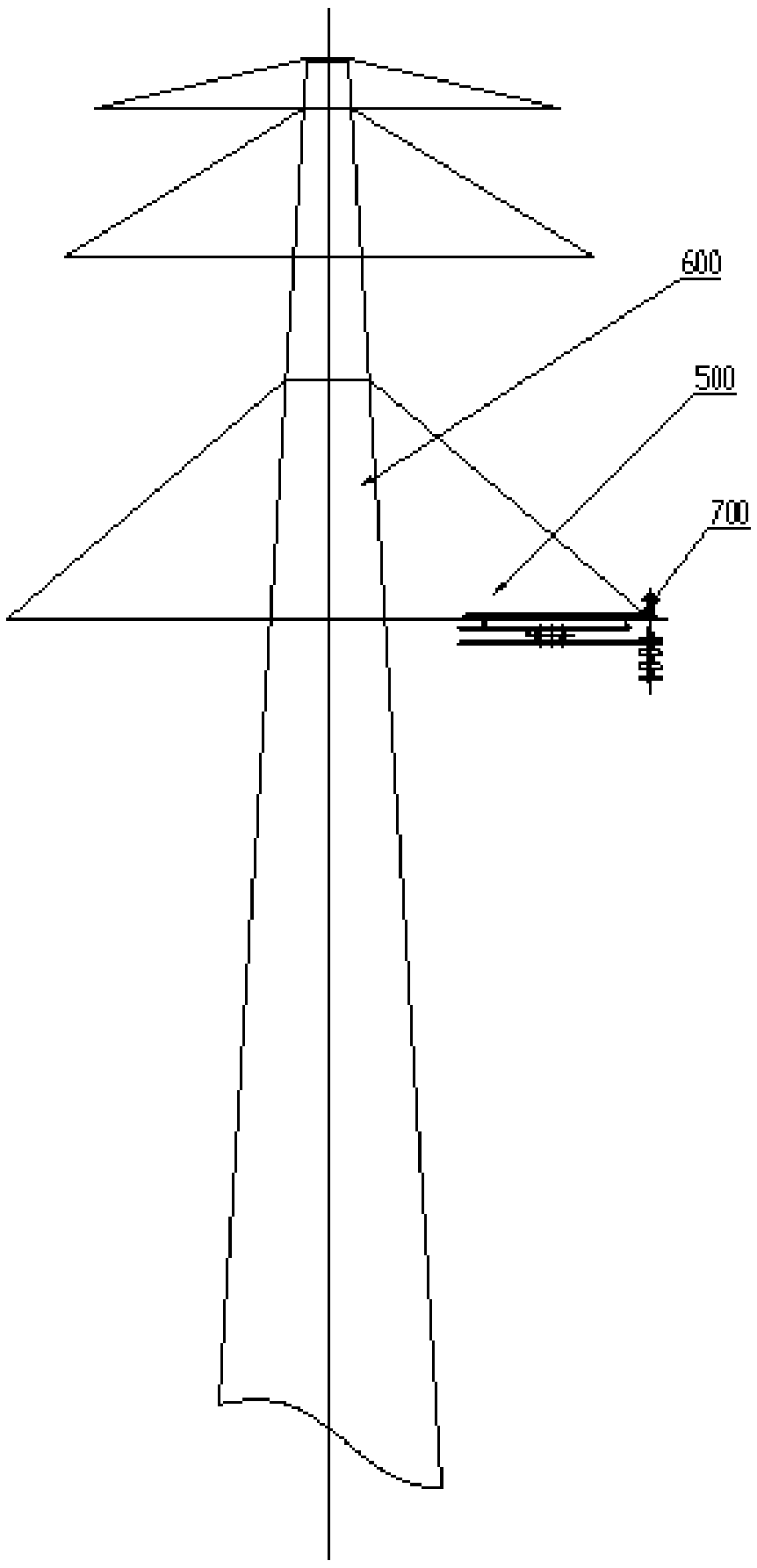

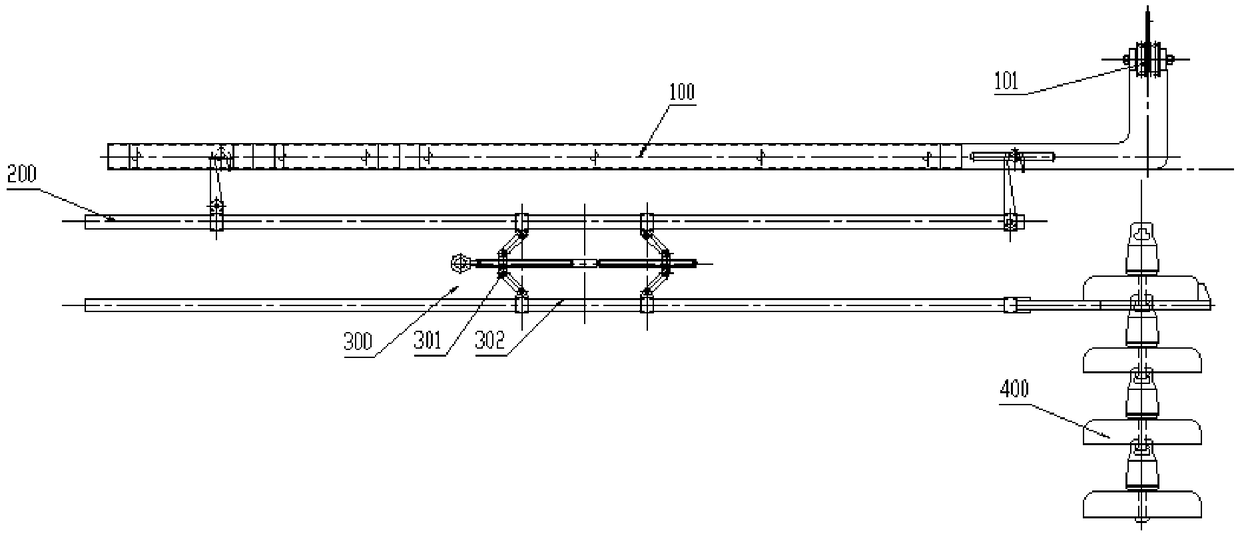

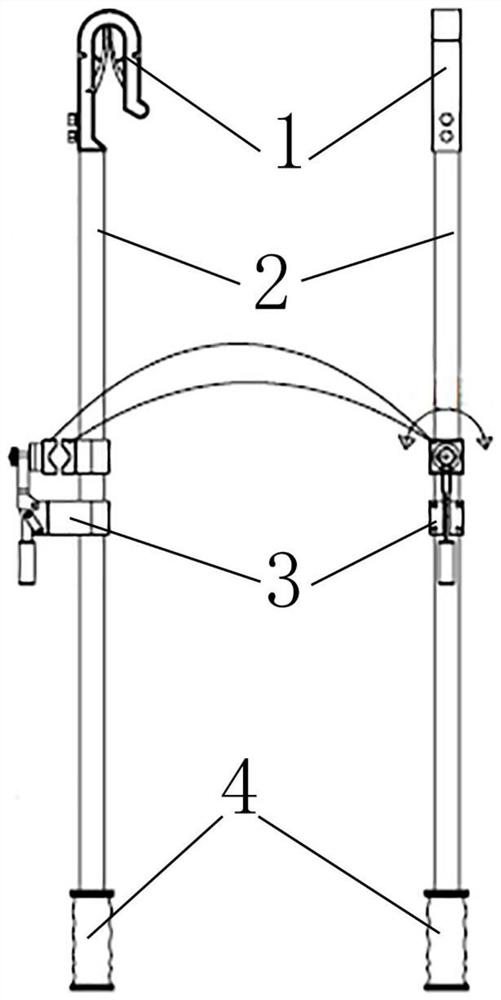

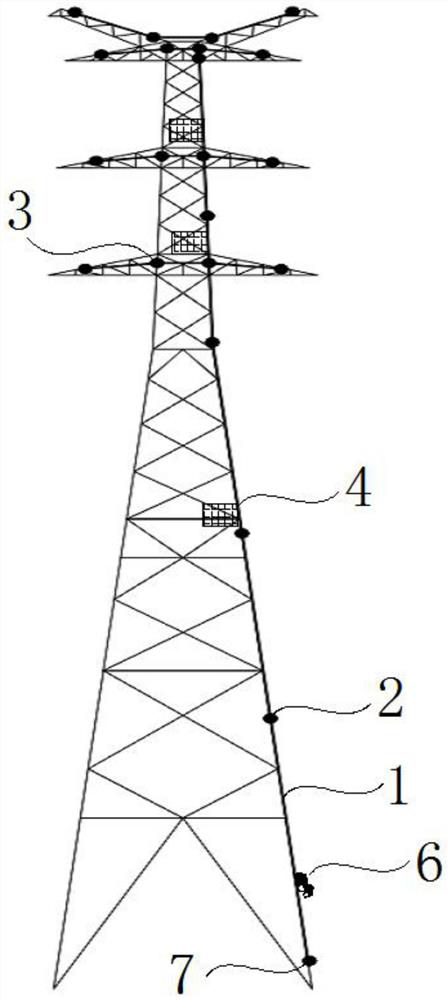

Live-line insulator replacement method and load transfer device

ActiveCN107069562AReduce workloadReduce contactApparatus for overhead lines/cablesHook wireEngineering

The invention relates to the technical field of electric power maintenance and relates to a live-line insulator replacement method and a load transfer device. The method comprises: a first operator on a cross arm of a tower body pushes an insulator stabilizing support to an insulator hanging point along the upper surface of the cross arm and adjusts the position of the device; a second operator installs two lifting pulleys connected with insulated ropes and wire hooks into a pulley groove of a pulley flip clamp by means of an operating lever, hooks wires with the wire hooks, and pulls the wires to transfer the tension force to a lifting device; an insulator lifting device is lifted, and a pin connecting an insulating string with a bulb hanging ring is taken out; the second operator moves the insulator string on the insulator lifting device to a side of the tower body along a clamp bearing support and then transfers old insulators to the ground. The operation safety is improved through the operation method. The load transfer device comprises an insulator stabilizing support, a clamp bearing support and a dismounting device. The load transfer device has the above advantages compared with the prior art.

Owner:QUJING POWER SUPPLY BUREAU YUNNAN POWER GRID CO LTD

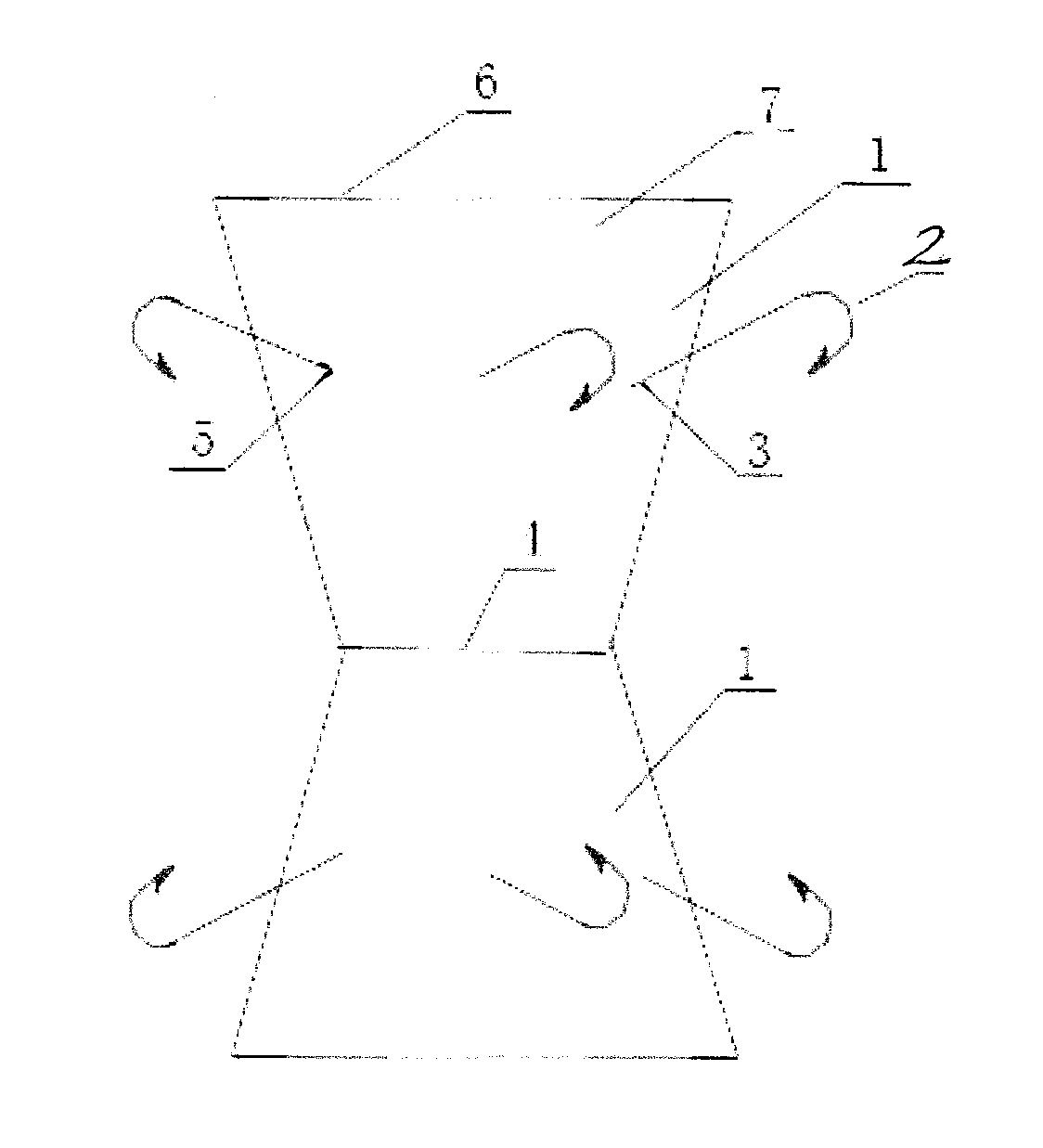

Tower-shaped combined hook

Disclosed is a tower-shaped combined hook. The tower-shaped combined hook is provided with a thin waist tower body which is formed by docking and fixing of two hoppers in a reversed mode. One set of fish hooks which are distributed in a circular ring shape is stood on the outer side of the middle portion of each hopper body. Hook back of each fish hook faces outwards, and hood tip of each fish hook faces inwards. The fish hooks are fixedly connected with the hopper bodies through hard brain wires. The tower-shaped combined hook is used when the bottom of a sea rod is hooked on a sea rod bottom hook, and therefore the fish bait can be prevented from sticking in sludge. A hook wire can not be hooked by free stones easily, the tower-shaped combined hook is free from troubles of small fishes, and the fish bait can not be washed away by water flow.

Owner:张有振

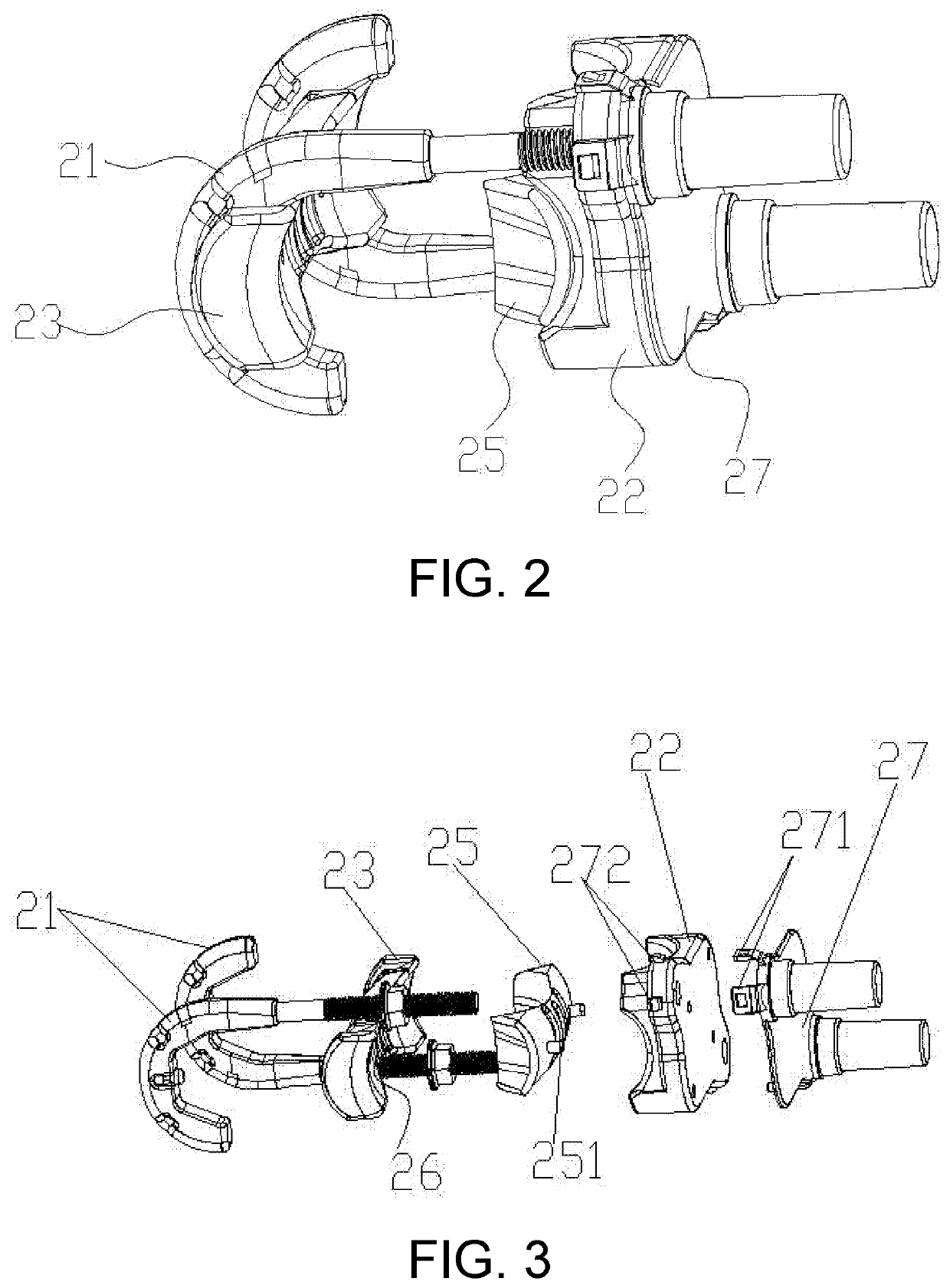

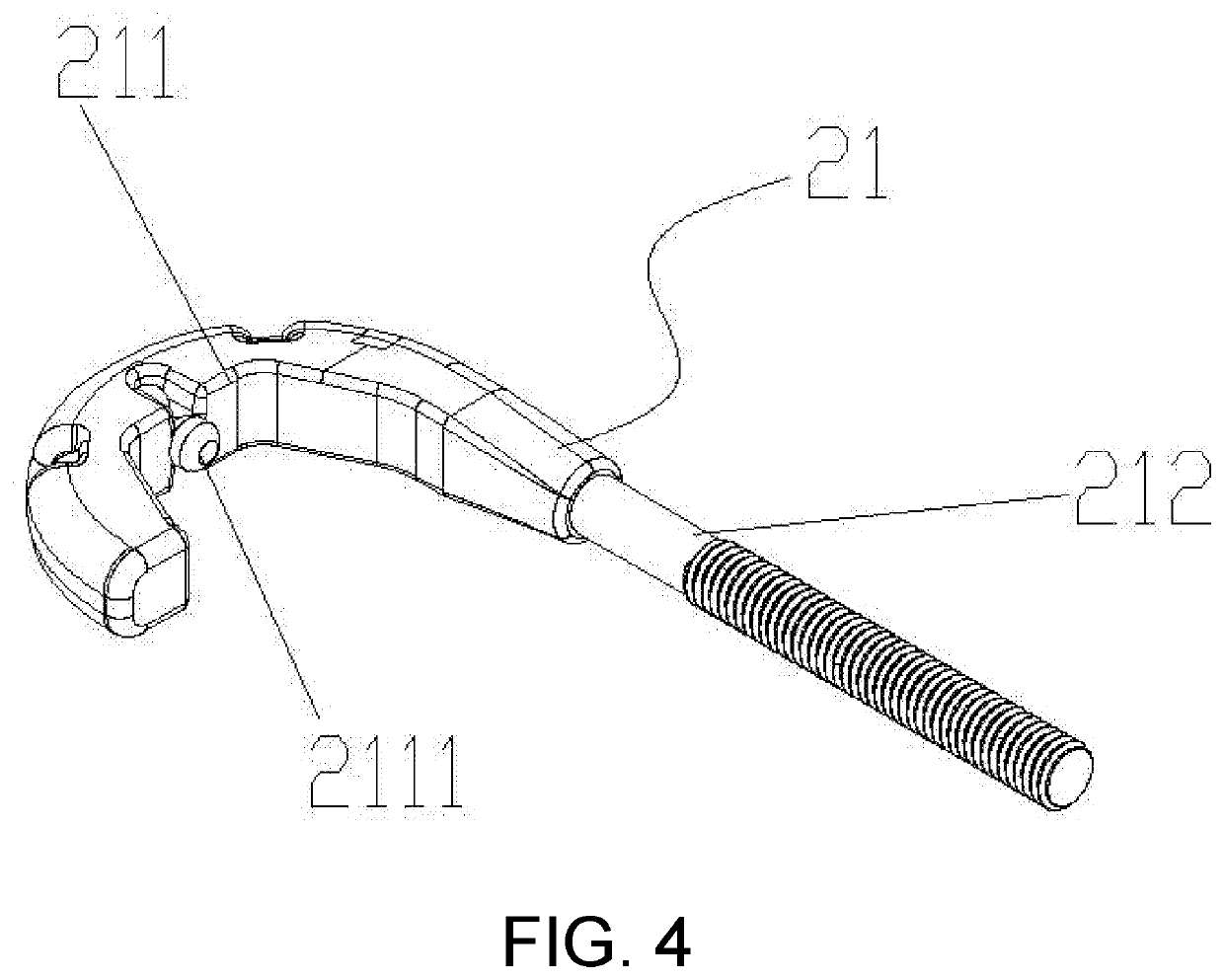

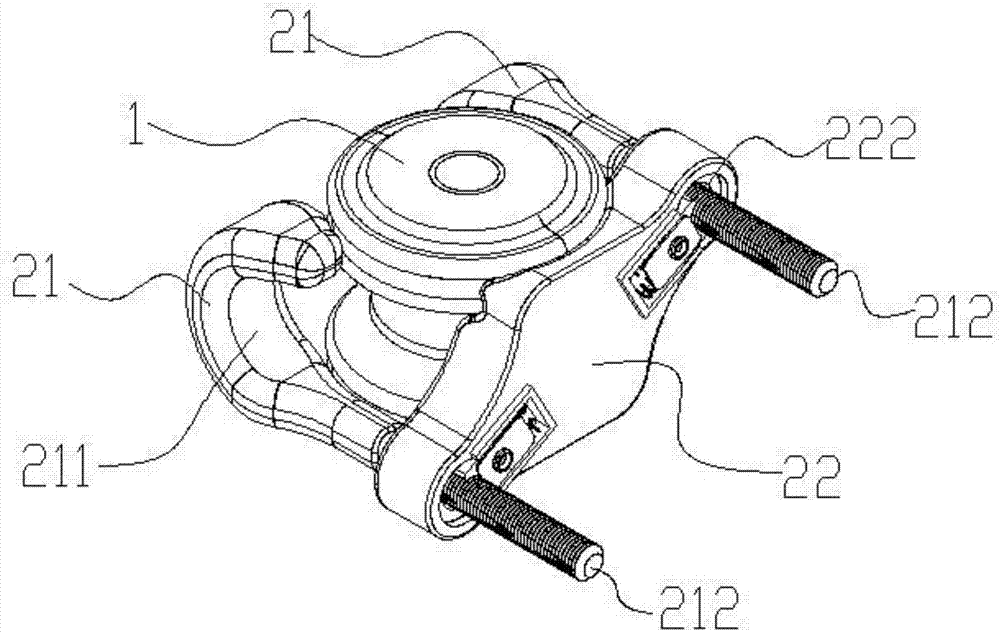

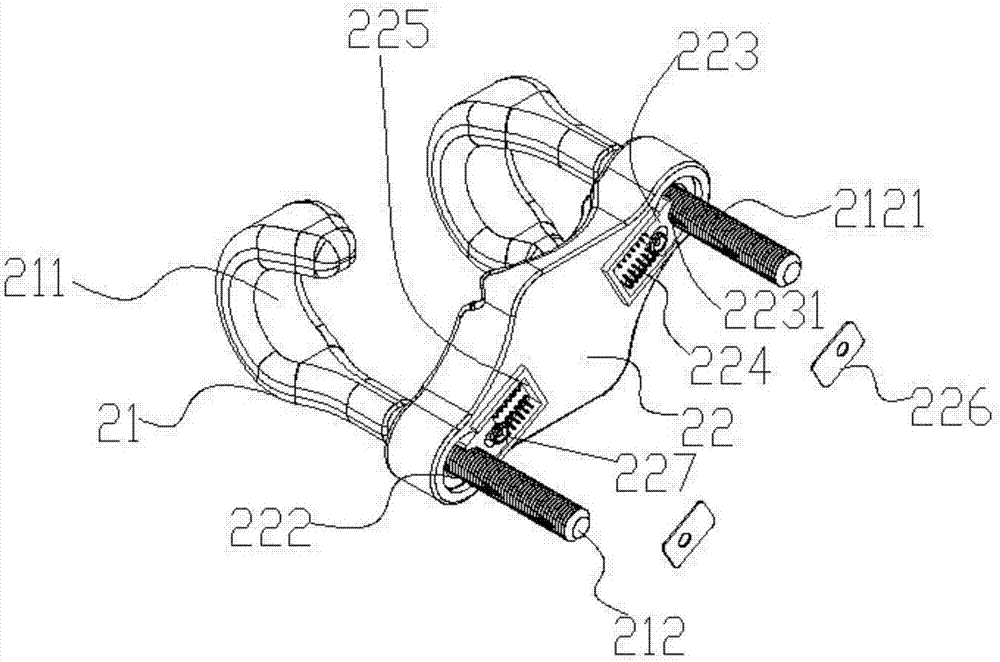

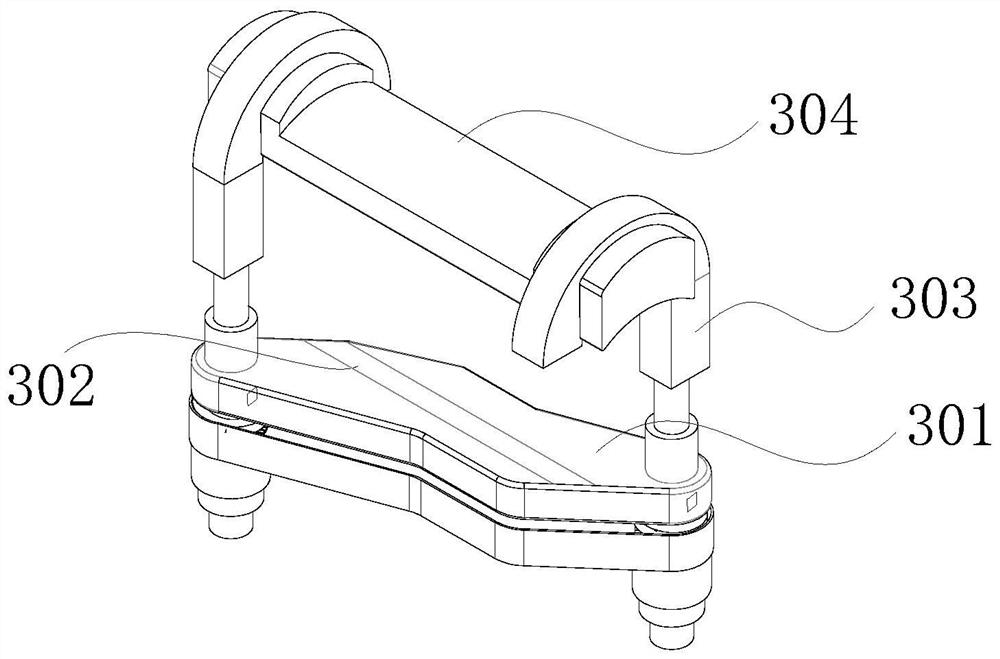

Integrated opposite hook wire clamp

ActiveUS20200044430A1Simple structureEasy to installSuspension arrangements for electric cablesApparatus for overhead lines/cablesHook wireEngineering

An integrated opposite hook cable clamp includes a clamping plate, a connecting plate, and at least two J-shaped clamps. Side bars of the J-shaped clamps are locking bars. Locking holes corresponding to the locking bars are provided on the clamping plate, and at least two of the locking holes are diagonally arranged on the clamping plate. The locking bars of the J-shaped clamps vertically pass through the locking holes on the clamping plate and are movably connected with the clamping plate by a locking mechanism. A back surface of the connecting plate is lap-jointed to the inner sides of hooks of each of the J-shaped clamps. A front surface of the connecting plate is opposite to a front surface of the clamping plate (22).

Owner:GUANGZHOU PANYU CABLE WORKS

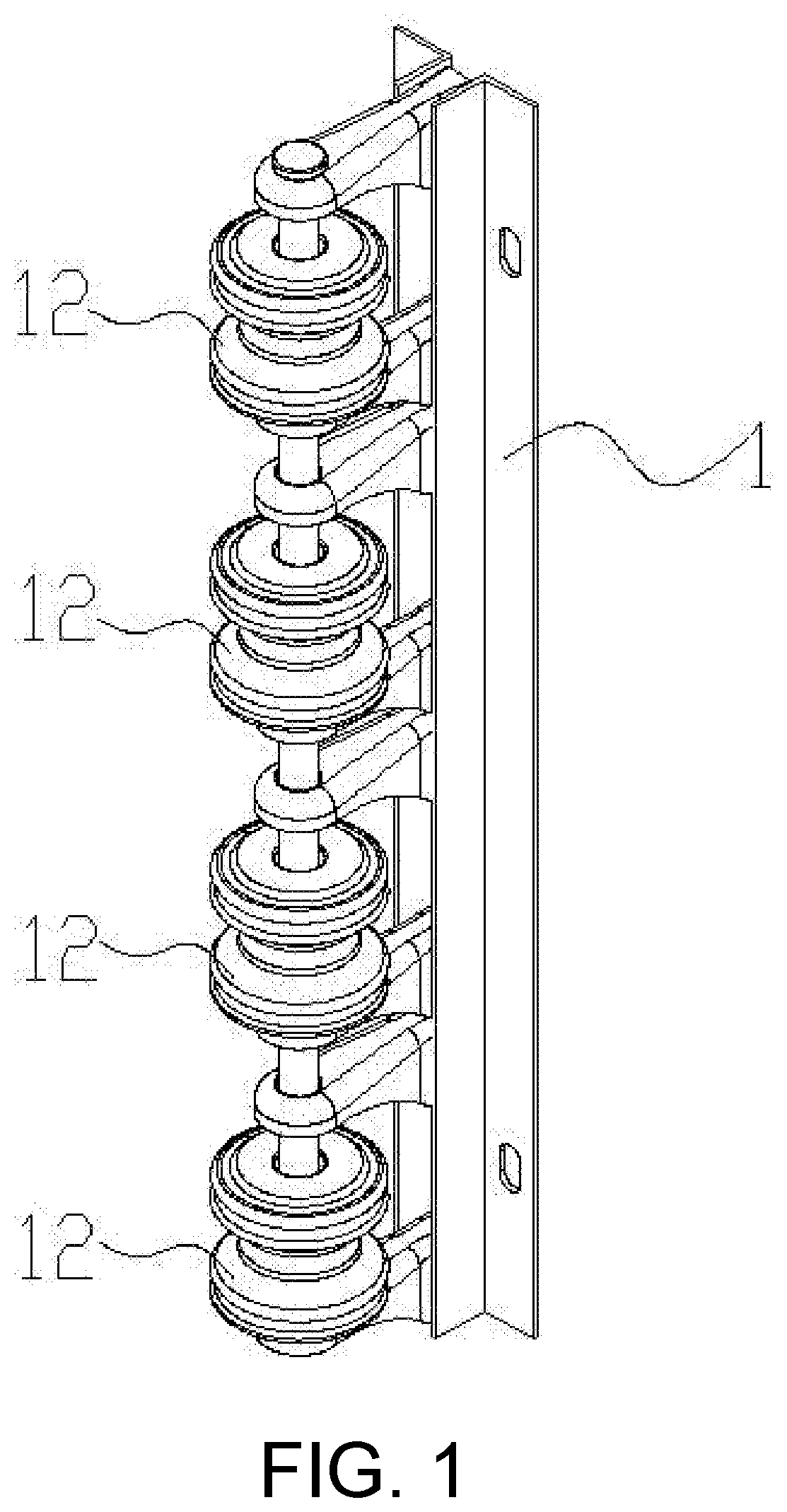

Self-locking hook wire clamp

ActiveCN107453309AEasy to fixSimple structureSuspension arrangements for electric cablesHook wireEngineering

The invention discloses a self-locking hook wire clamp. The self-locking hook wire clamp comprises a clamping plate and two J-shaped clamps, wherein the two J-shaped clamps are arranged on the clamping plate in opposite angles and hooks of the two J-shaped clamps are opposite, locking levers vertically pass through locking holes in the clamping plate respectively, a non-return valve is arranged on each locking lever, a movable locking block is arranged on the side edge of each locking hole, a locking block is provided with a locking tooth, the back of each locking block abuts against a locking spring, when the locking levers are inserted from inlets of the locking holes, the locking springs push the locking blocks so that the locking teeth abut against the non-return valves and the locking levers are limited to go forward only but not move backwards. During operation, the clamping plate is adhered to one side of an insulator, a cable is adhered to the other side of the insulator, and then the J-shaped clamps are automatically locked after being inserted into the clamping plate, so that the cable is locked on the insulator and is unlikely to get loose; when the cable needs to be opened, the locking springs need to be pressed so that the locking blocks are withdrawn, and the J-shaped clamps are taken out of the clamping plate freely, so that the cable is loosened, the operation is extremely convenient and fast and convenient to use, and the self-locking hook wire clamp is particularly applicable for high-altitude sectional construction.

Owner:广州勇艺邦电子科技有限公司

Universal cable-stayed detection device of lifting hook wire rope

InactiveCN102807157AReduce axial sliding frictionGuaranteed accuracyLoad-engaging elementsCable stayedHook wire

The invention discloses a universal cable-stayed detection device of a lifting hook wire rope. A locating sleeve of a wire rope deflection steering mechanism locks the wire rope; an adaptive guide sleeve is arranged between the wire rope and the locating sleeve; a plurality of adjusting members are arranged on the locating sleeve; a joint bearing is arranged at the upper end of an oscillating rod of an oscillating rod mechanism; a conductor and a potentiometer or an encoder are arranged at a lower end of the oscillating rod of the oscillating rod mechanism; hinge points are arranged at two ends of a connection rod in the connection member; one end of the connection rod is connected with the wire rope deflection steering mechanism, and the other end of the connection rod is connected with the oscillating rod mechanism: and an automatic rotary detection device is arranged at the bottom part of the oscillating rod. The conductor on the oscillating rod can ensure that a potentiometer signal is smoothly output when the automatic rotary detection device rotates or swings; and an automatic rotary balance locating mechanism of a plane can determine a deflection direction so as to ensure the accuracy of angle measurement. The maximal tilt angle of the wire rope detected by the detection device is 100 degrees.

Owner:DALIAN YILIY CONSTR MACHINERY +1

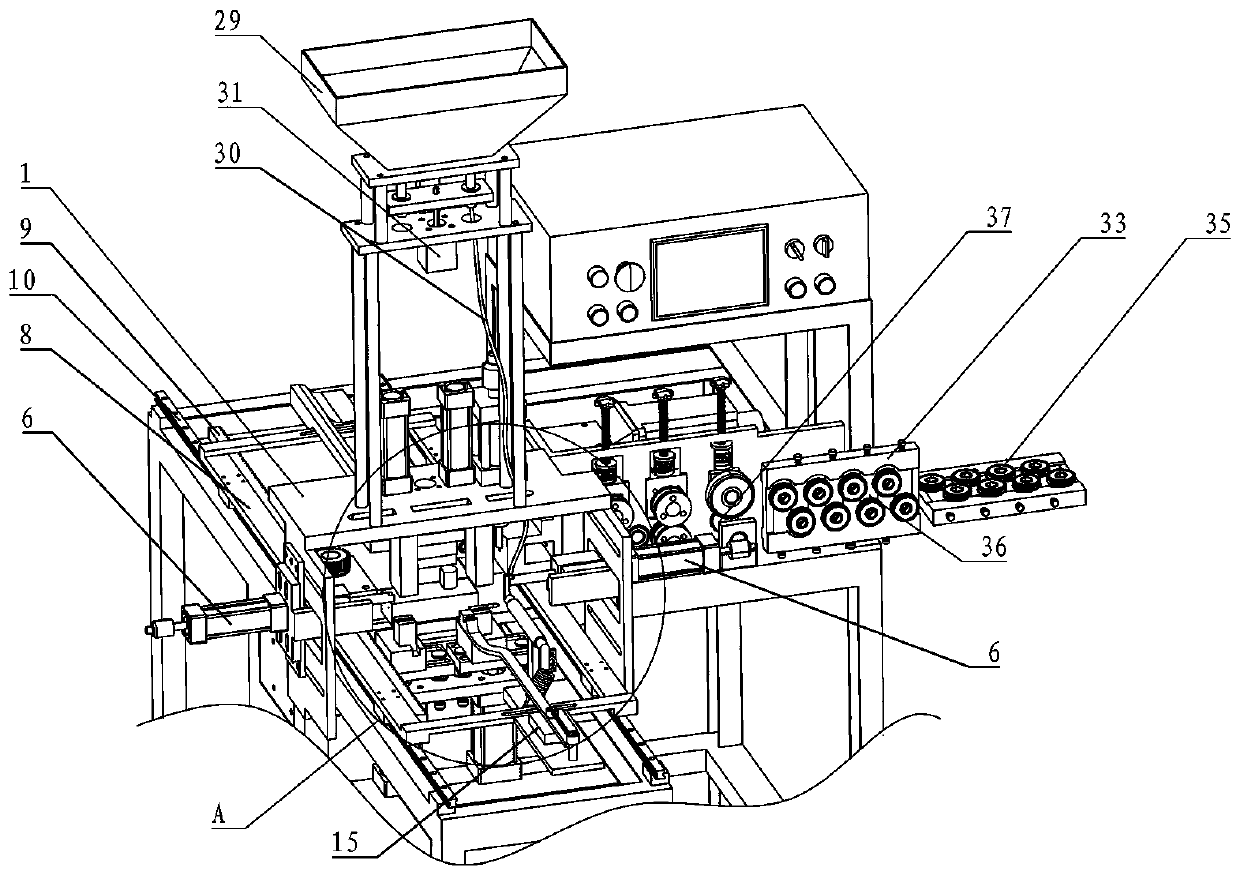

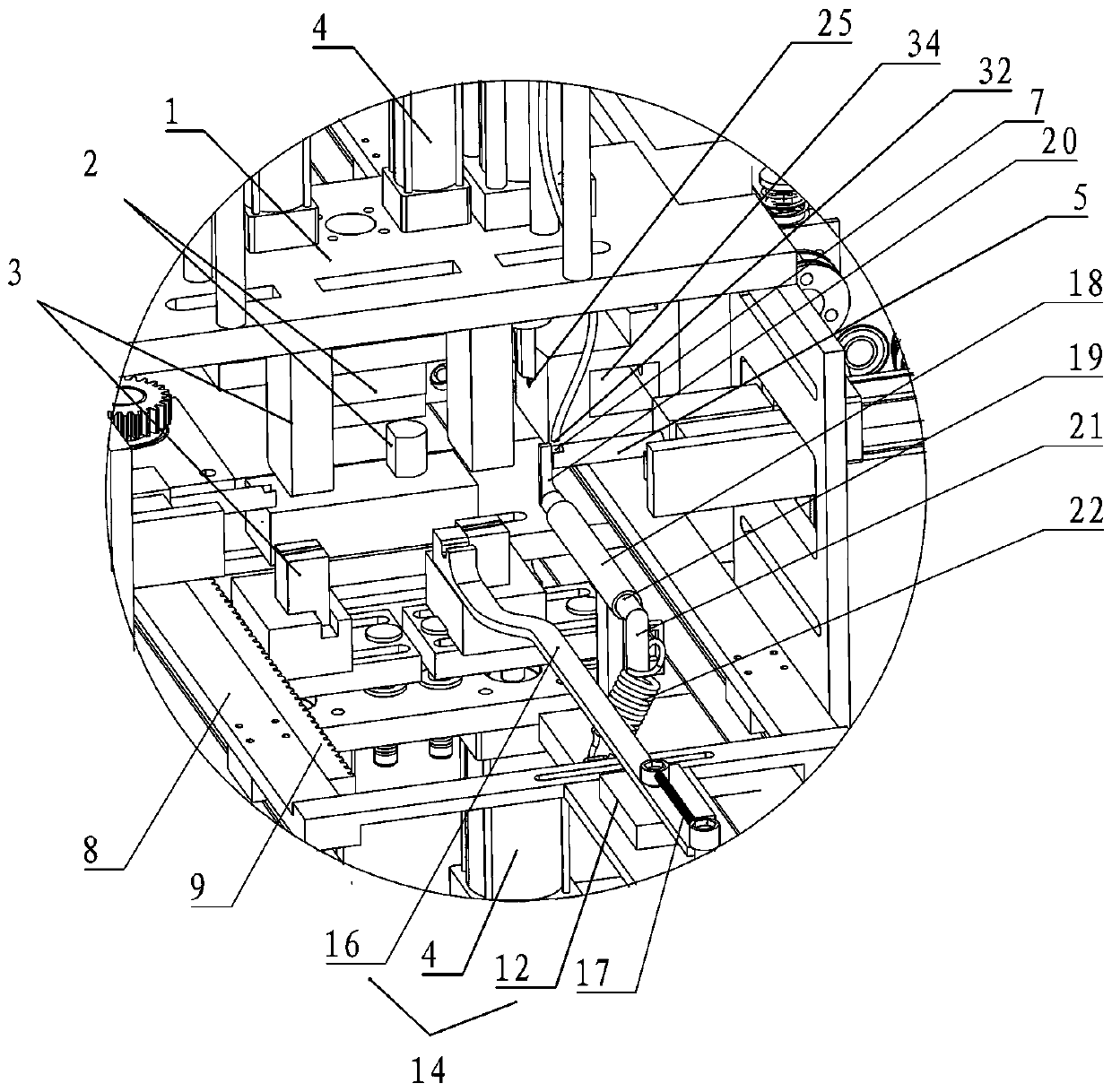

Automatic resistance welding machine

InactiveCN107649771AImprove automationIncrease productivityResistance welding apparatusButt weldingHook wire

The invention provides an automatic resistance welding machine. The automatic resistance welding machine comprises a horizontal moving mechanism provided with a framed bent, a welding device, a hook wire conveying device, a hook wire cutting device, a steel ball discharging device and a steel ball conveying electrode stem. The welding device is internally provided with a butt-welding set I and a butt-welding set II which are used for welding hook wires and steel balls correspondingly. The hook wire cutting device is installed on the side surface of the butt-welding set I. A wire outlet of thehook wire conveying device is connected with a feeding opening of the hook wire cutting device. The steel ball conveying electrode stem is installed on the side surface of the butt-welding set II andconnected with an electrode stem driving device. A discharging opening of the steel ball discharging device is located above the end part of the steel ball conveying electrode stem. The end part of the steel ball conveying electrode stem is provided with a receiving part. The horizontal moving mechanism is installed on the resistance welding machine and reciprocates at the welding position of thewelding device. The hook wires and the steel balls are welded to the framed bent automatically. The production efficiency is improved, and the labor cost is saved.

Owner:江门市新会区国正机电设备有限公司

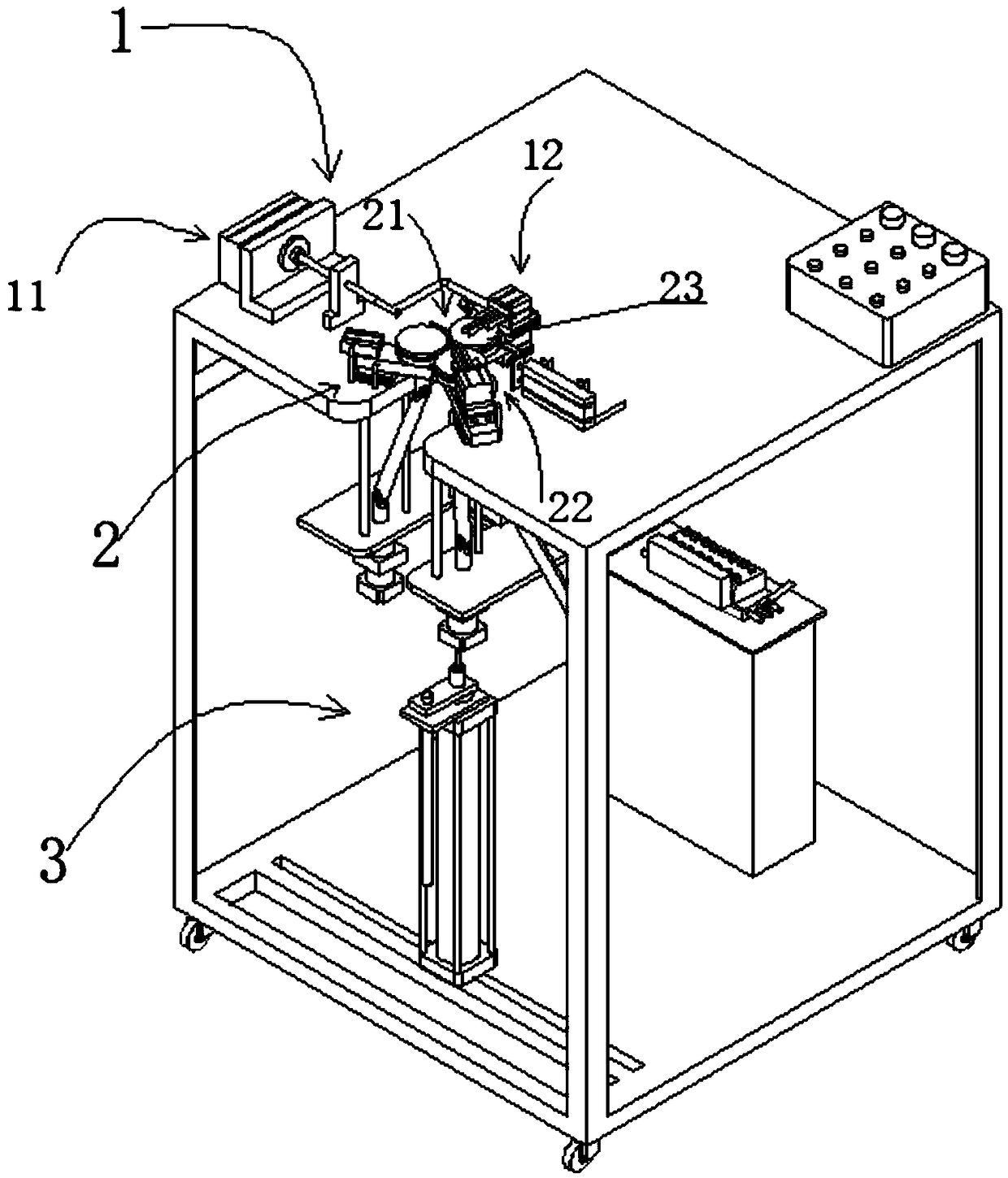

Automatic wire clamping guide device for magnetic ring winding machine

PendingCN110911161AReduce positioning accuracyAccurate and fast clampingCoils manufactureWinding machineHook wire

The invention discloses an automatic wire clamping guide device for a magnetic ring winding machine. The device comprises a wire clamping mechanism which is arranged on a rack and can be telescopically close to or far away from the winding conveying direction, and a wire moving mechanism which is positioned on the wire inlet side of the wire clamping mechanism and can be telescopically deviated from the conveying line of the wire clamping mechanism is also arranged on the rack. According to the invention, the wire clamping mechanism is matched with the wire moving mechanism and can be matchedwith the wire winding crochet hook to accurately and quickly hook wires, so that the positioning precision of the wire winding direction is reduced and the use is more flexible and stable. According to the telescopic wire clamping assembly of the wire clamping mechanism, the wire clamping shaft sleeve and the wire clamping shaft rotate relatively to open and close wire clamping, the structure is simple, and wire clamping is accurate and rapid.

Owner:ZHONGSHAN COMPETENT AUTOMATION EQUIP CO LTD

Three-needle closure device

The present invention relates to a three-needle type vascular closure system. The closure system utilizes three needles in the form of a guiding device, an expandable needle, and a hooking device. The guiding device is used to make the initial opening in the vessel, where the opening provides access for a sheath through which a medical procedure is to be performed. The expandable needle is inserted into the vessel in which it expands radially from the needle to form a target. The hooking device is also inserted into the vessel and is used to hook the expandable needle so as to form an internal union between the hooking device and the expandable needle. The needles can then be retracted thereby extending a suture from the hooking device and forming an internal suture pass that can be used to approximate the tissue surrounding the initial opening in the vessel. In one embodiment, the suture is passed across the vessel opening prior to dilation of the vessel opening.

Owner:ST JUDE MEDICAL PUERTO RICO BV

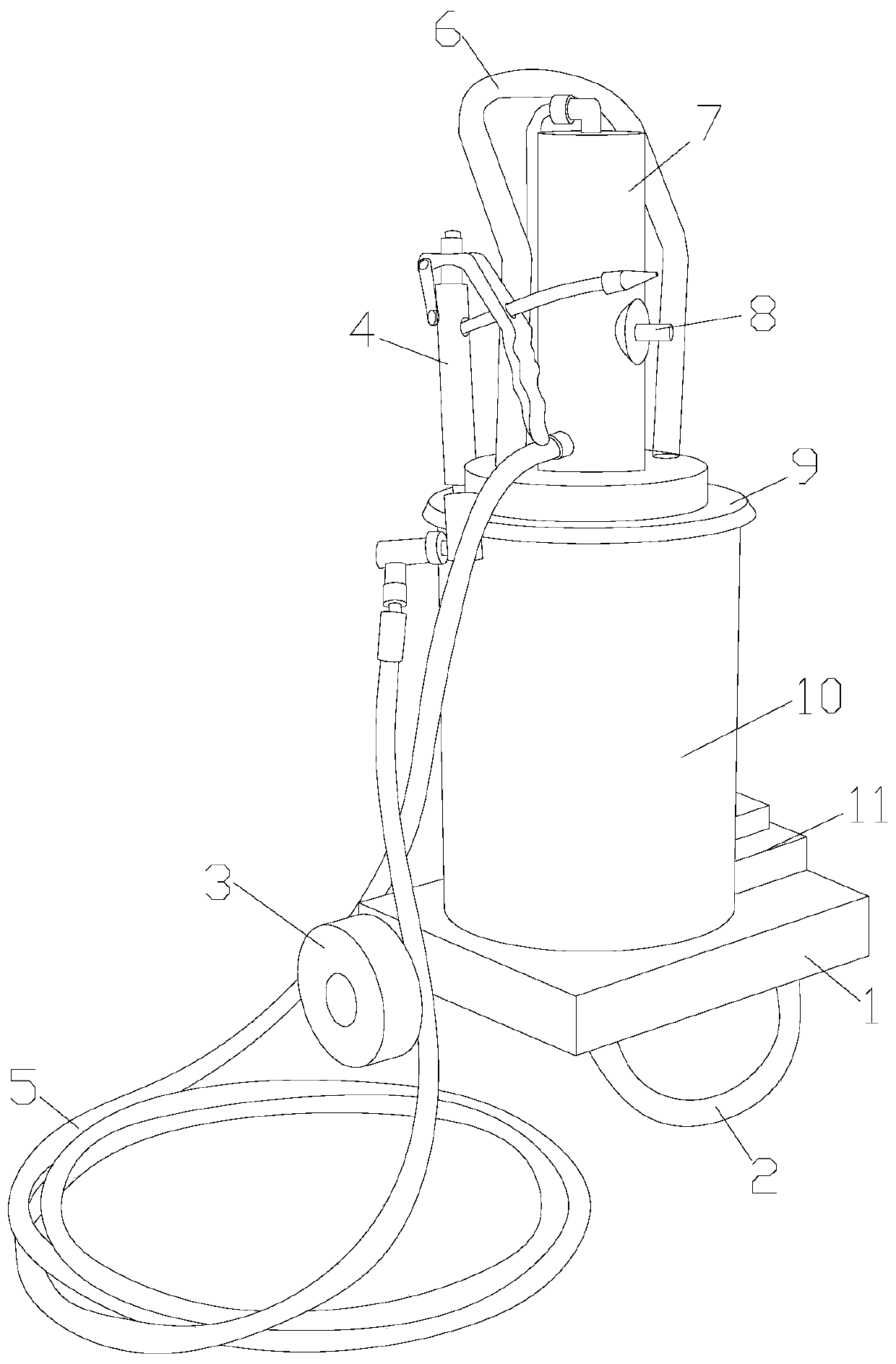

Lubricant filling machine for construction machinery

The invention discloses a lubricant filling machine for construction machinery. The lubricant filling machine for construction machinery structurally comprises a rack, a top frame, wheels, an oil injector, a rubber pipe, a push frame, a pneumatic pump, an air inlet, a cover, a charging barrel and a melting mechanism, wherein the top frame is welded at the bottom of the front end of the rack, the wheels are mounted at two sides of the rear end of the rack, the charging barrel is vertically mounted on the upper portion of the rack, the pneumatic pump is arranged at the top of the cover on the charging barrel, the pneumatic pump is provided with the air inlet, and a discharge port of the pneumatic pump is connected with the oil injector through the rubber pipe. The lubricant filling machine for construction machinery has the beneficial effects that heat conducting plates are arranged on two sides of the inner wall of an inner hole, and the heat generated by electric heating wires heats grease in the pipe through the heat conducting plates so that the solidified grease in the pipe can be in a molten state; a rotating conical head is arranged in a conical groove, a hook wire ring is wound on the rotating conical head, the rotating conical head smashes solidified grease on a nozzle, and the hook wire ring scrapes off hardened grease in the nozzle to prevent blockage.

Owner:安徽省瀚辰生态建设有限公司

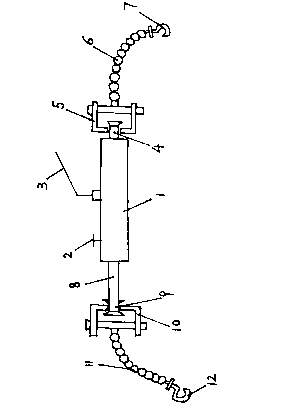

Hydraulic multifunctional wire fastener

The invention discloses a hydraulic multifunctional wire fastener. A pressure reducing valve (2) and a manual hydraulic rod (3) are arranged on a cylinder body of a hydraulic screw rod (1); a hydraulic screw lever (8) which is extended out from the left end of the cylinder body is arranged inside the cylinder body of the hydraulic screw rod (1); a connection pin (4) and a rotary square-shaped left support (5) are fixedly arranged on the lateral side of the right end of the cylinder body of the hydraulic screw rod (1); a right ring type chain (6) and a right wire fastening hook (7) are connected to a right sealing column of the rotary square-shaped left support (5); the head portion (9) of the hydraulic screw lever (8) is sleeved inside a rotary square-shaped right support (10); and a left ring type chain (11) and a left wire fastening hook (12) are connected onto a left sealing column of the rotary square-shaped right support (10). The hydraulic multifunctional wire fastener has the advantages of being light in weight, convenient to carry and simple to operate and solving the problems that the existing double-hook wire fastener is limited in extend and withdraw distance and large in labor intensity of operators.

Owner:STATE GRID CORP OF CHINA +1

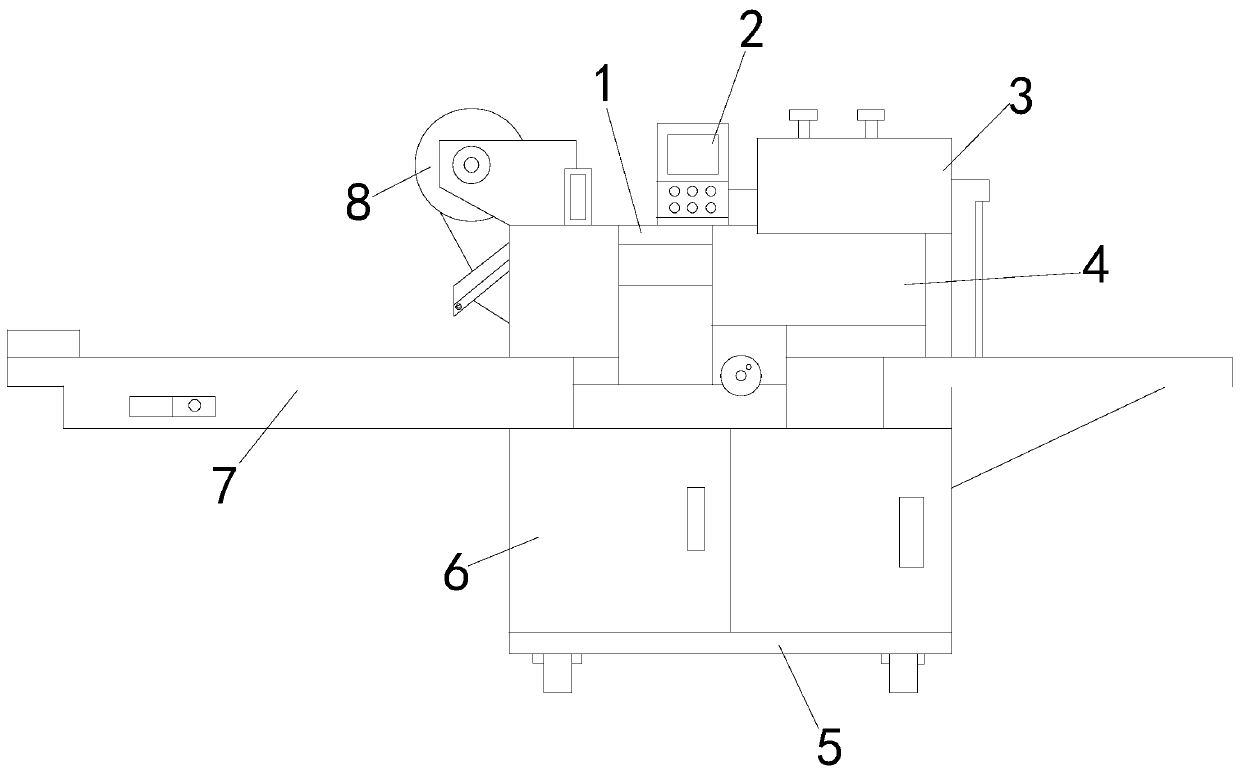

Pillow type automatic packaging machine

InactiveCN111453103AEnsure a clean cutImprove processing efficiencyWrapper twisting/gatheringHook wireStructural engineering

The invention discloses a pillow type automatic packaging machine. The pillow type automatic packaging machine structurally comprises a point section machine body, a controller, a distribution box, asealing groove device, a base, an assembling box, a transfer table and a packaging film roller. When the pillow type automatic packaging machine is used, through an arranged progressive cutter mechanism, the situations that a packaging film is prone to sliding, consequently, a packaging bag is cut obliquely, and the appearance is not attractive can be avoided; meanwhile, due to the fact that a cutting blade is of a tooth-shaped structure, the situation that a hook wire adheres to the cutter is prone to occurring, the cleanliness of next cutting is affected, and blockage is generated are avoided; in the packaging process of the pillow type automatic packaging machine, through cooperation of a progressive reaction device, a pressing groove plate and a fixing square block press the passing packaging film in advance, anti-skid auxiliary positioning is conducted, and then a cutter set cuts the packaging bag neatly; and meanwhile, through mutual cooperation of a fan-shaped hinge and a crossed brush, the cutter set can make contact with the fan-shaped hinge in the returning process, the hook wire of a tooth part is brushed down, and the machining efficiency of the pillow type automatic packaging machine is improved.

Owner:施林全

Live insulator replacement method and load transfer device

ActiveCN107069562BReduce workloadReduce contactApparatus for overhead lines/cablesHook wireEngineering

The invention relates to the technical field of electric power maintenance and relates to a live-line insulator replacement method and a load transfer device. The method comprises: a first operator on a cross arm of a tower body pushes an insulator stabilizing support to an insulator hanging point along the upper surface of the cross arm and adjusts the position of the device; a second operator installs two lifting pulleys connected with insulated ropes and wire hooks into a pulley groove of a pulley flip clamp by means of an operating lever, hooks wires with the wire hooks, and pulls the wires to transfer the tension force to a lifting device; an insulator lifting device is lifted, and a pin connecting an insulating string with a bulb hanging ring is taken out; the second operator moves the insulator string on the insulator lifting device to a side of the tower body along a clamp bearing support and then transfers old insulators to the ground. The operation safety is improved through the operation method. The load transfer device comprises an insulator stabilizing support, a clamp bearing support and a dismounting device. The load transfer device has the above advantages compared with the prior art.

Owner:QUJING POWER SUPPLY BUREAU YUNNAN POWER GRID CO LTD

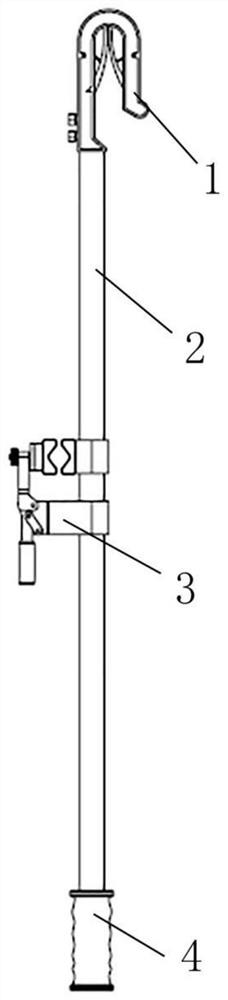

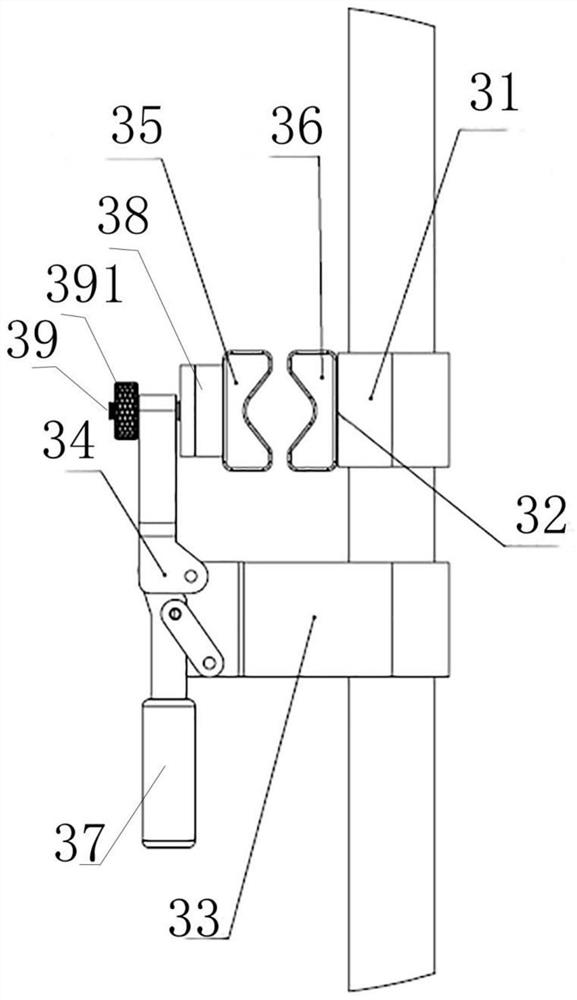

Insulating operating rod for temporarily fixing wire

ActiveCN113036656AOvercoming the problem that the cross-sectional area cannot be bentReliable Temporary FixationApparatus for overhead lines/cablesThrust bearingHook wire

The invention provides an insulating operating rod for temporarily fixing a wire. The insulating operating rod comprises an insulating tube, a hook wire clamp which is arranged at one end of the insulating tube, and a rapid clamp assembly which is arranged on the insulating tube in a sleeving manner. The rapid clamp assembly comprises a rotating seat fixing seat sleeving the insulating tube, a thrust bearing which is fixedly mounted on one side of the rotating seat fixing seat, a lower V-shaped rotating seat with the flat surface fixedly connected with the thrust bearing, a clamp fixing seat arranged on the insulating tube in a sleeving manner, a rapid clamp with the middle part rotatably connected with the clamp fixing seat to enable the rapid clamp to rotate by taking the rotating joint as a rotating point, a pressure head fixing block fixedly connected with one side, close to the insulating tube, of the rapid clamp, and an upper V-shaped rotating pressing block with the flat surface fixedly connected with one side, facing the insulating tube, of the pressing head fixing block. The upper V-shaped rotating pressing block is opposite to the V-shaped groove of the lower V-shaped rotating seat to form a clamping space. Thus, a lead with a large cross-sectional area can be effectively and temporarily fixed in a broken line fault.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

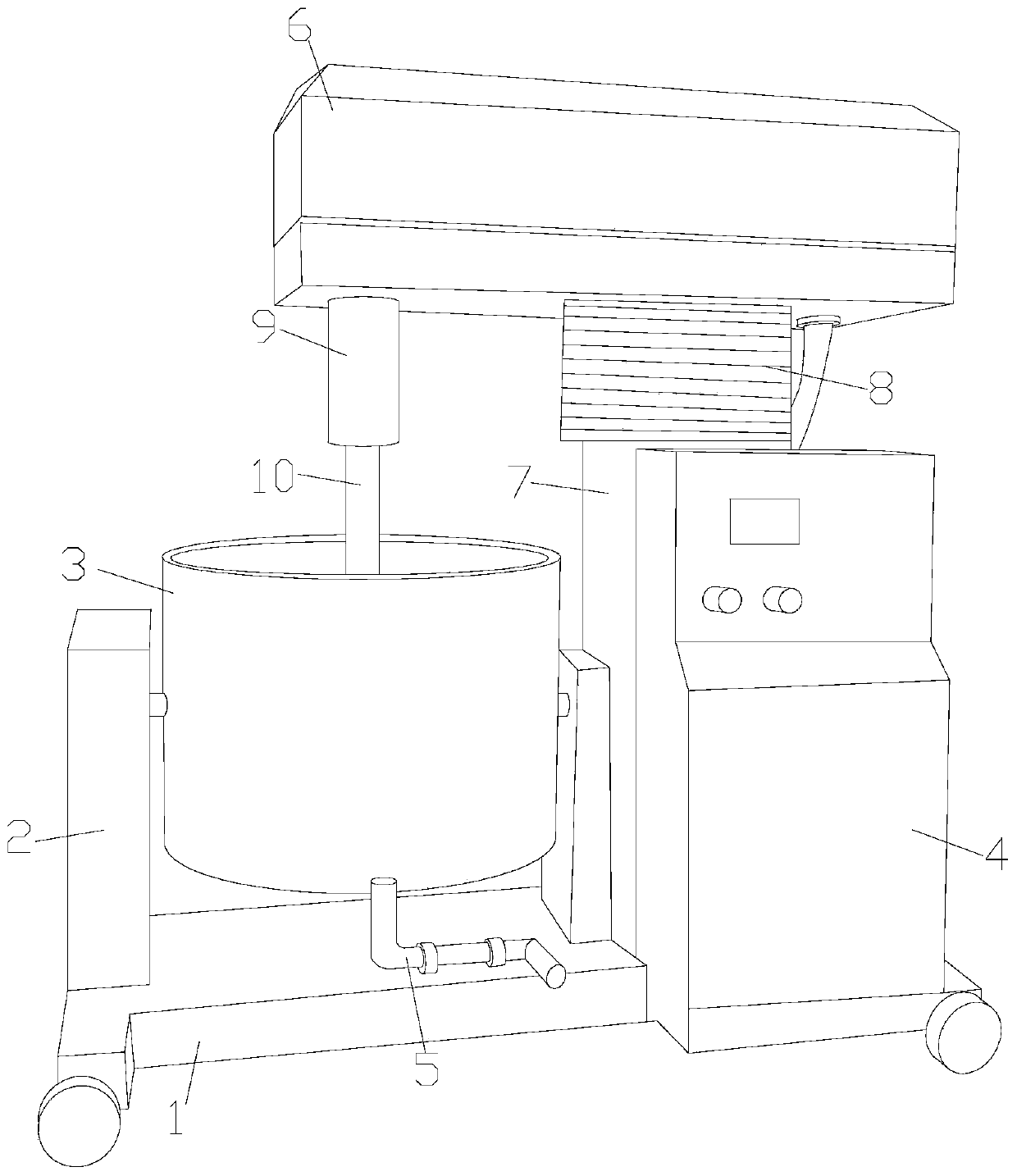

Pulper for papermaking machinery

InactiveCN111335060AEasy to install and disassembleEasy to replaceRaw material divisionCoil springHook wire

The invention discloses a pulper for papermaking machinery. The pulper structurally comprises a machine base, a vertical frame, a tank body, a control box, a balance fixator, a driver, a lifting column, a telescopic dustproof cover, a driving shaft and a stirring shaft. The vertical frame is arranged at the left end of the top of the machine base, the tank body is movably installed in the middle of the vertical frame, the lifting column and the control box are installed on the right side of the tank body, and the control box is located in front of the lifting column. The pulper provided by theinvention has the beneficial effects that: four groups of rotary hook sleeves are arranged on a pulp homogenizing rod, coil springs are arranged on the rotary hook sleeves, hook wires are fully distributed on the coil springs, when the stirring shaft rotates clockwise, the coil springs are in an unfolded state, sugarcane skin impurities in pulp are hooked by the hook wires, and the phenomenon that lumps exist on paper due to the fact that impurities remain in the pulp is prevented.

Owner:龙腾全

Manufacturing technology of polyvinyl-polyester hook wire

InactiveCN105155078AHigh breaking strengthSmall stretch rateJacquardsFibre typesPolyesterBreaking strength

The invention provides manufacturing technology of a polyvinyl-polyester hook wire. The manufacturing technology comprises the follow steps : 1) performing wire merging; 2) performing first twisting; 3) performing second twisting; 4) winding the twisted compound wire, the twist degree of which is 180-270, into a stranded wire with a yarn reeler; 5) performing slurry mixing in a slurry pool; 6) putting the stranded wire into the adjusted slurry; 7) removing 60-70% of slurry from the sized polyvinyl / polyester compound wire with a dehydrator; and 8) performing drawing setting of the sized compound wire through a wire waxing machine for 15-25 min, when the dryness of the obtained polyvinyl / polyester harness wire reaches 70-80%, performing manual waxing for 2-3 min, and performing air-drying after the wire passes through the wire waxing machine till the humidity is less than 3% to prepare the polyvinyl-polyester hook wire. The prepared polyvinyl-polyester hook wire is obviously enhanced in breaking strength, and reduced in expansion and contraction, and the friction coefficient is raised by 30-60%.

Owner:安徽创星实业有限公司

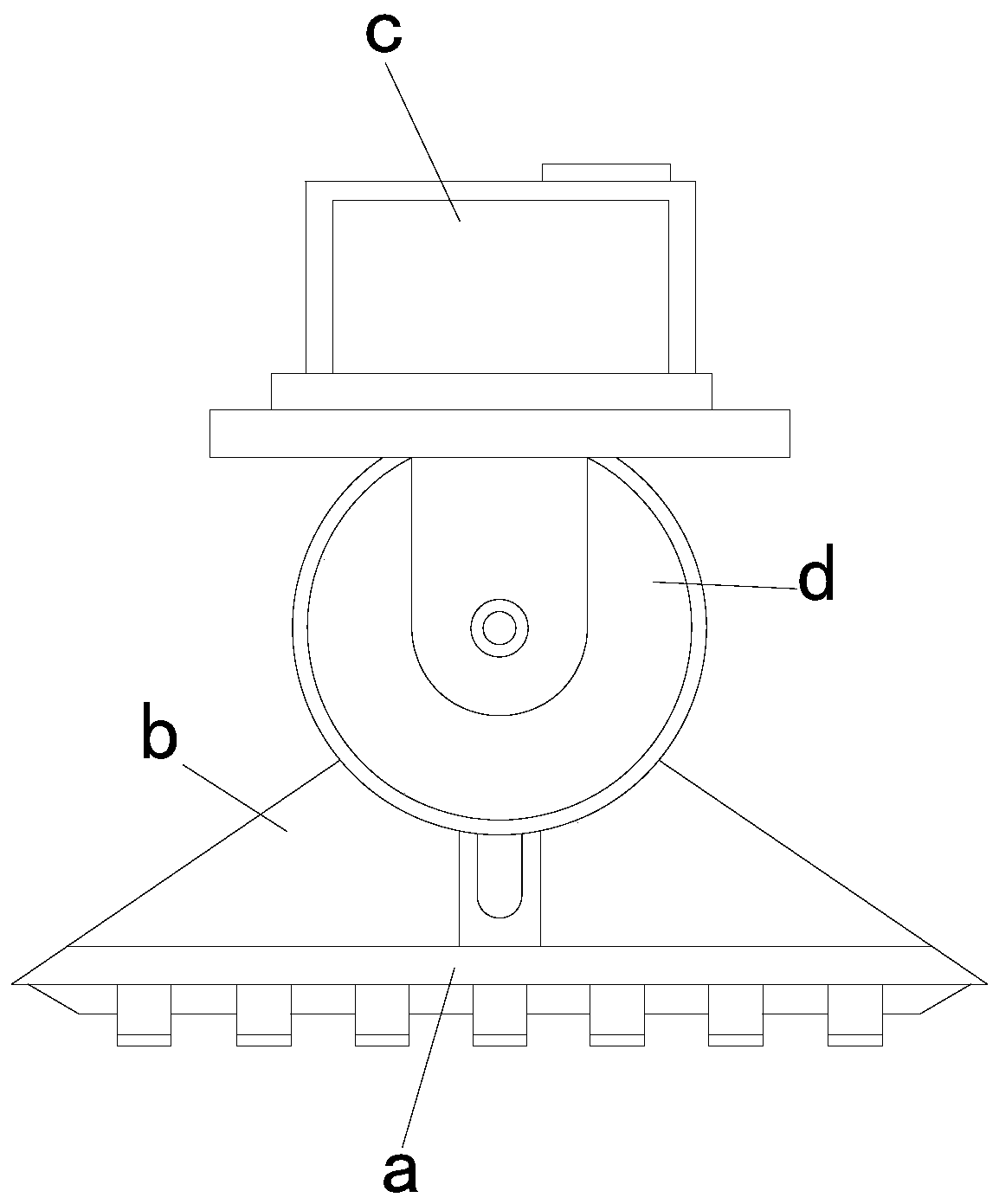

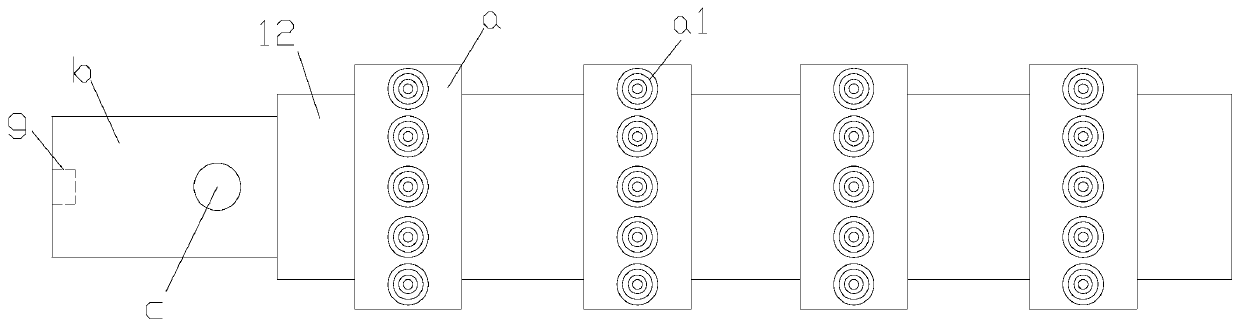

Loop inductance winding machine

A loop inductance winding machine comprises a rack and a thread turning mechanism arranged on the rack, a line arrangement mechanism and a hook mechanism, a line tur mechanism includes a first drive structure, a first clamping structure connected to the first drive structure, a line arrange mechanism includes a magnetic re frame and a second clamping structure, the magnetic ring frame comprises atleast three clamping rollers arranged in a circumferential direction, a second drive structure that drives each of the pinch rollers to rotate, a third driving structure for driving the clamping coilof the clamping roller, wherein each clamping roller is correspondingly connected with the second driving structure through a coupling, the second clamping structure is used for clamping the inductive wire, and the hook mechanism comprises a fourth driving structure, a winding hook, a push rod and a push rod driving structure connected with the fourth driving structure. The ring inductance winding machine realizes winding of the magnetic loop through the wire turning mechanism, the wire arranging mechanism and the hook wire mechanism, and reduces the winding strength and improves the windingefficiency.

Owner:陈荣亚

Climbing anti-falling device applied to power transmission line engineering

PendingCN114733103AHigh strengthImprove toughness and strengthSafety beltsRope making machinesHook wireEngineering

The invention discloses a climbing anti-falling device applied to power transmission line engineering. The climbing anti-falling device comprises a steel strand, and the steel strand is laid on a main rod or a crawling ladder of a tower and is fixedly connected with the tower through a plurality of anti-swing rings and a double-hook wire fixing device; the anti-swing rings are vertically distributed on the tower and are fixedly connected with the tower; the double-hook wire fixing device is horizontally distributed on a tower and is fixedly connected with the tower; the signboard is arranged on the steel strand and is fixedly connected with the tower; the self-locking type falling protector is arranged on the steel strand in a sliding mode and connected with a worker through a connector and a connecting rope, and a monitor is arranged on the self-locking type falling protector. Compared with the prior art, the self-locking type falling protector has the following advantage that potential safety hazards caused by repeated installation of the self-locking type falling protector are eliminated. And the steel strand is prevented from swinging excessively in the climbing process of a worker. The steel strand in the climbing anti-falling device is processed by adopting a new process and a new material, so that the strength, the toughness and the fatigue strength of the steel strand are improved.

Owner:广东景呈电力设备有限公司

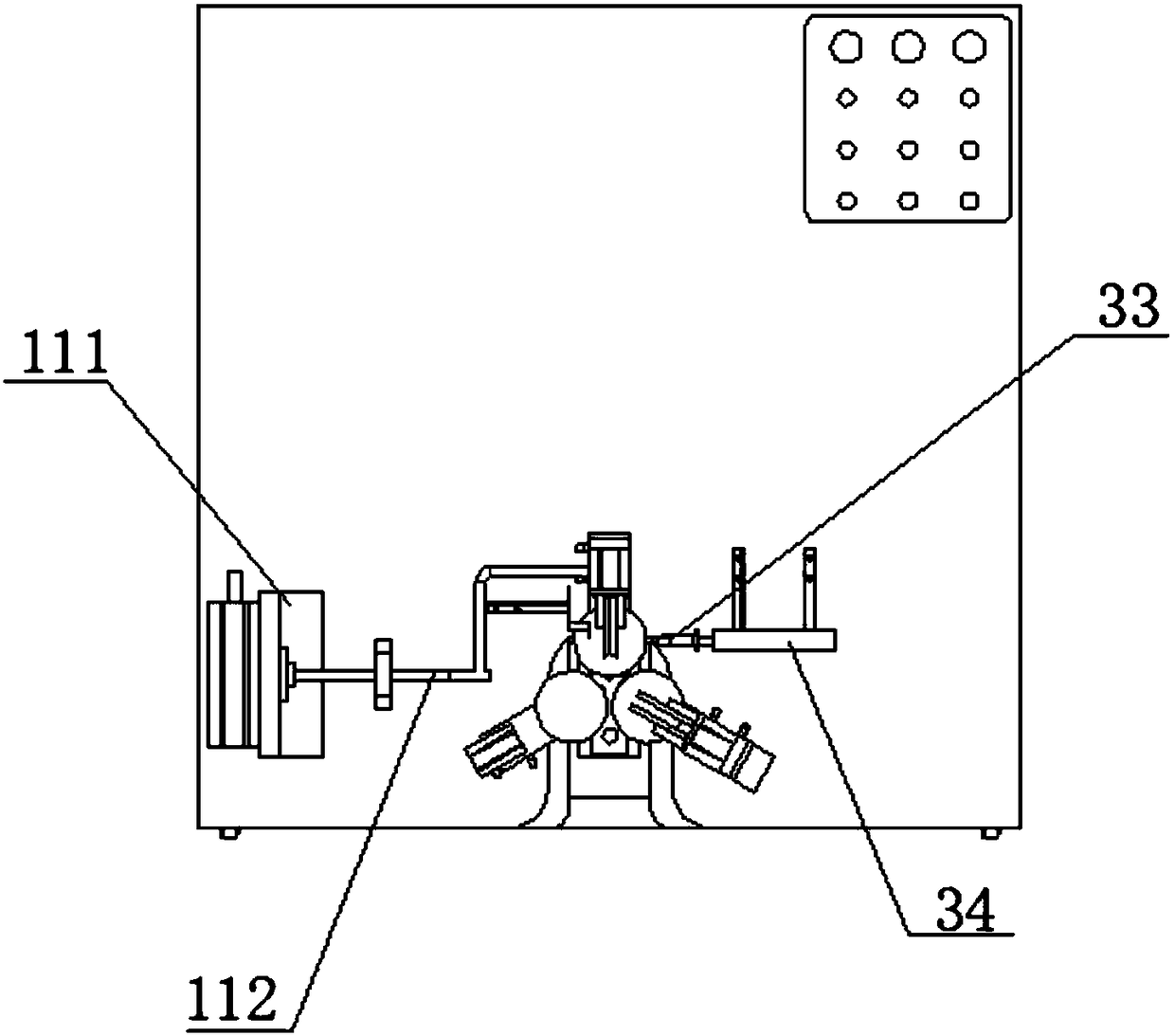

Hook thread knotting equipment for badminton production

InactiveCN112206488BImprove automationPrevent rolling outBall sportsRacket sportsHook wireStructural engineering

Owner:张宇

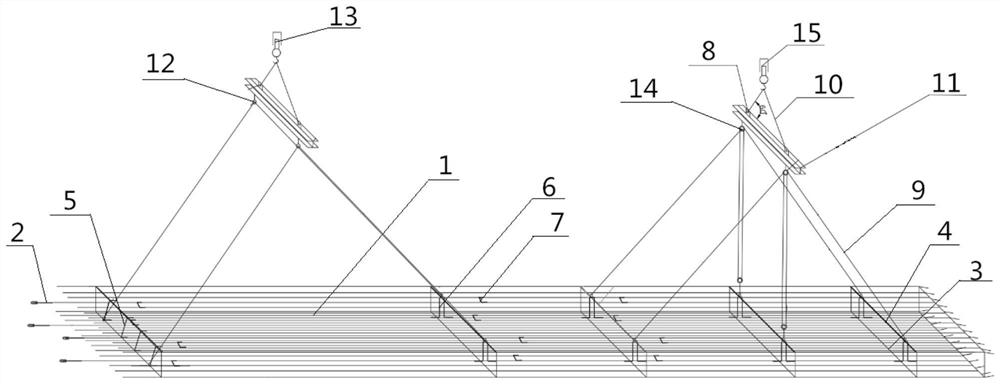

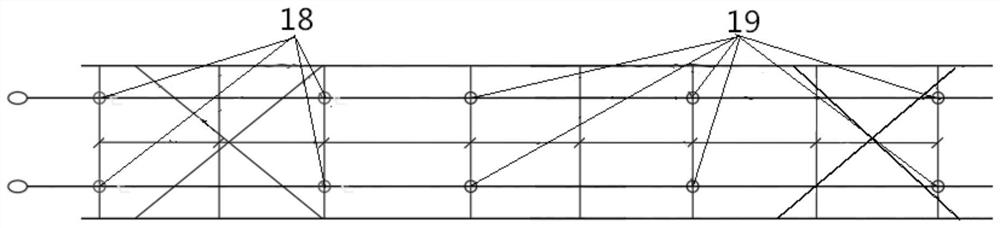

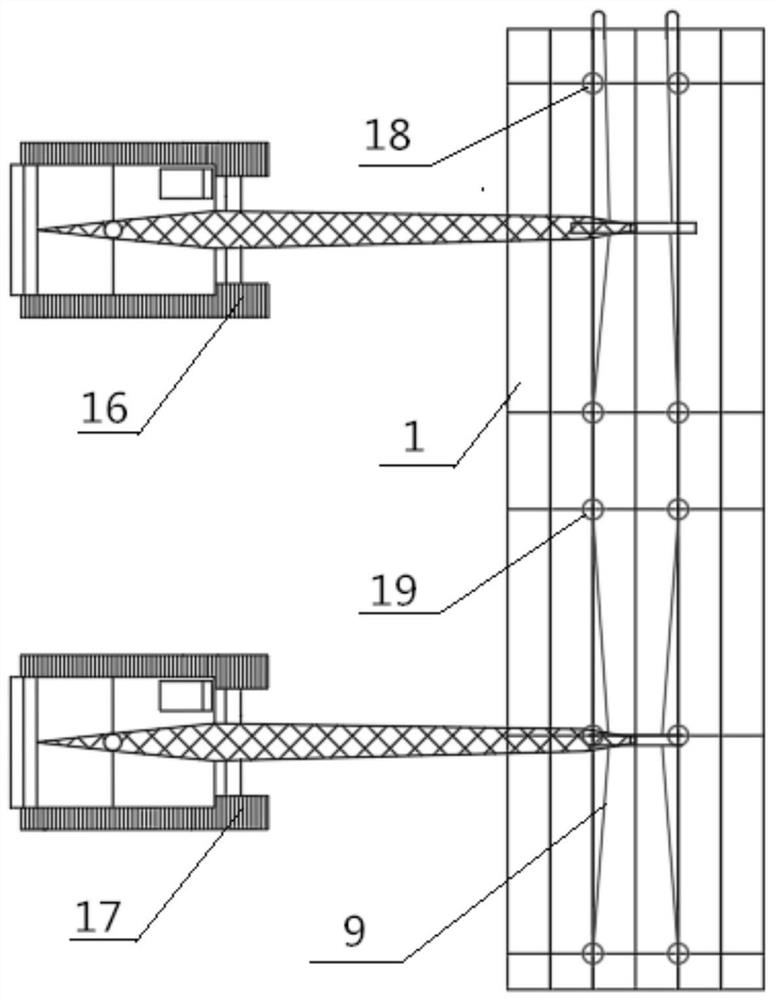

A method for safe hoisting and lowering of reinforcement cages connected to walls

ActiveCN113387267BGuaranteed stabilityIntegrity guaranteedCranesLoad-engaging elementsHook wireRebar

The invention provides a method for safely hoisting and lowering a ground-connecting wall steel cage, which belongs to the technical field of construction; the invention uses the main crane and the auxiliary crane to cooperate with hoisting, and adds two vertical lifting points to the auxiliary crane, which can effectively ensure that the steel cage is installed in During the lifting and hoisting process, there will be no large deflection and deformation, and there will be no problems of cracking of the weld seam and overall falling apart; the invention adopts an iron pole to connect the wire rope of the hook and the wire rope of the hanging cage, which can effectively ensure that the steel cage is hoisted during the hoisting process. In addition, the present invention is welded with lifting bars, lifting point pressure bars, support bars, and lifting point bars at the positions of the lifting points, and a plurality of groups of temporary laying bars are welded on the steel cage. During the hoisting process, it can avoid direct contact with the reinforcement cage, ensure the integrity of the reinforcement cage, and ensure the construction quality of the reinforcement cage.

Owner:THE THIRD CONSTR OF CHINA CONSTR EIGHTH ENG BUREAU

A hollow hook bending machine

The invention discloses a bending machine for a hollow lifting hook. The bending machine comprises a rack, wherein a lifting hook wire feeding part and a lifting hook bending part are fixedly mountedon the rack; the lifting hook bending part comprises a bending machine head; a lifting hook pre-cutting device is also fixed between the lifting hook wire feeding part and the lifting hook bending part on the rack; the lifting hook pre-cutting device comprises a first mounting plate; a rotary disc which is driven to rotate through a the driving device is mounted on the first mounting plate; the rotary disc is fixedly connected with at least one cutting assembly; each of the cutting assemblies comprises a telescopic mechanism; each of the telescopic mechanisms is connected with a correspondingcutter; the three cutting assemblies are uniformly and circularly arranged on the rotary disc; and the cutters on the cutting assemblies are positioned on the same circumference. According to the bending machine disclosed by the invention, before the hollow lifting hook is bent, a knife edge is pre-cut on the lifting hook, so that the phenomenon that the lifting hook cannot be deformed when the lifting hook is cut off is avoided.

Owner:重庆针尖内燃机部件制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com