A hollow hook bending machine

A bending machine and hook technology, used in household appliances, other household appliances, applications, etc., can solve the problems of hollow hook deformation, hard points, low strength, etc., and achieve convenient installation and maintenance, easy cutting, and qualified high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

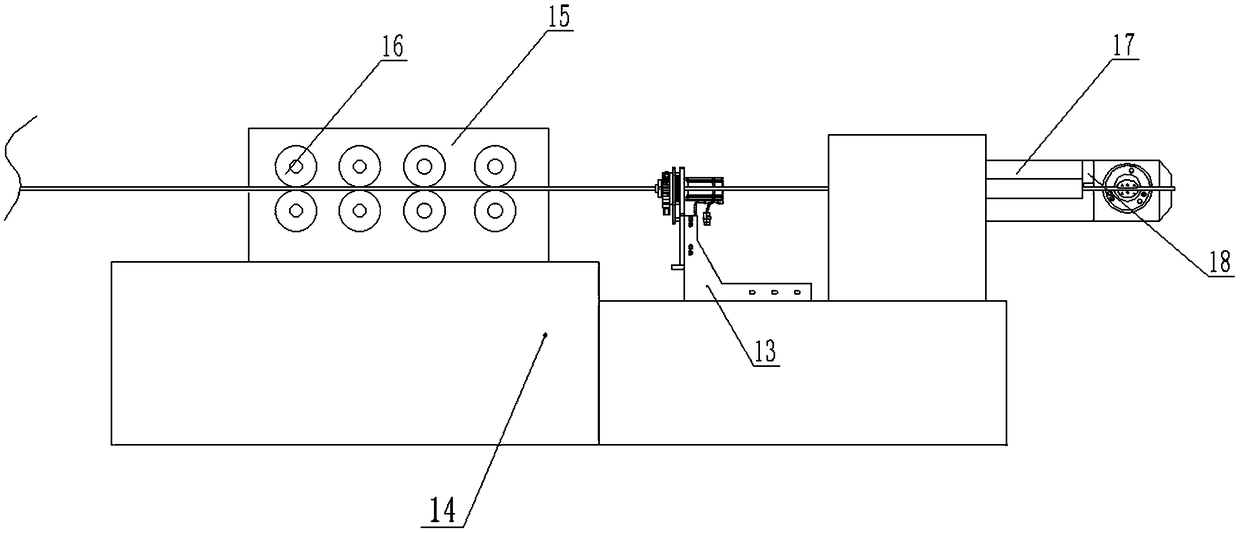

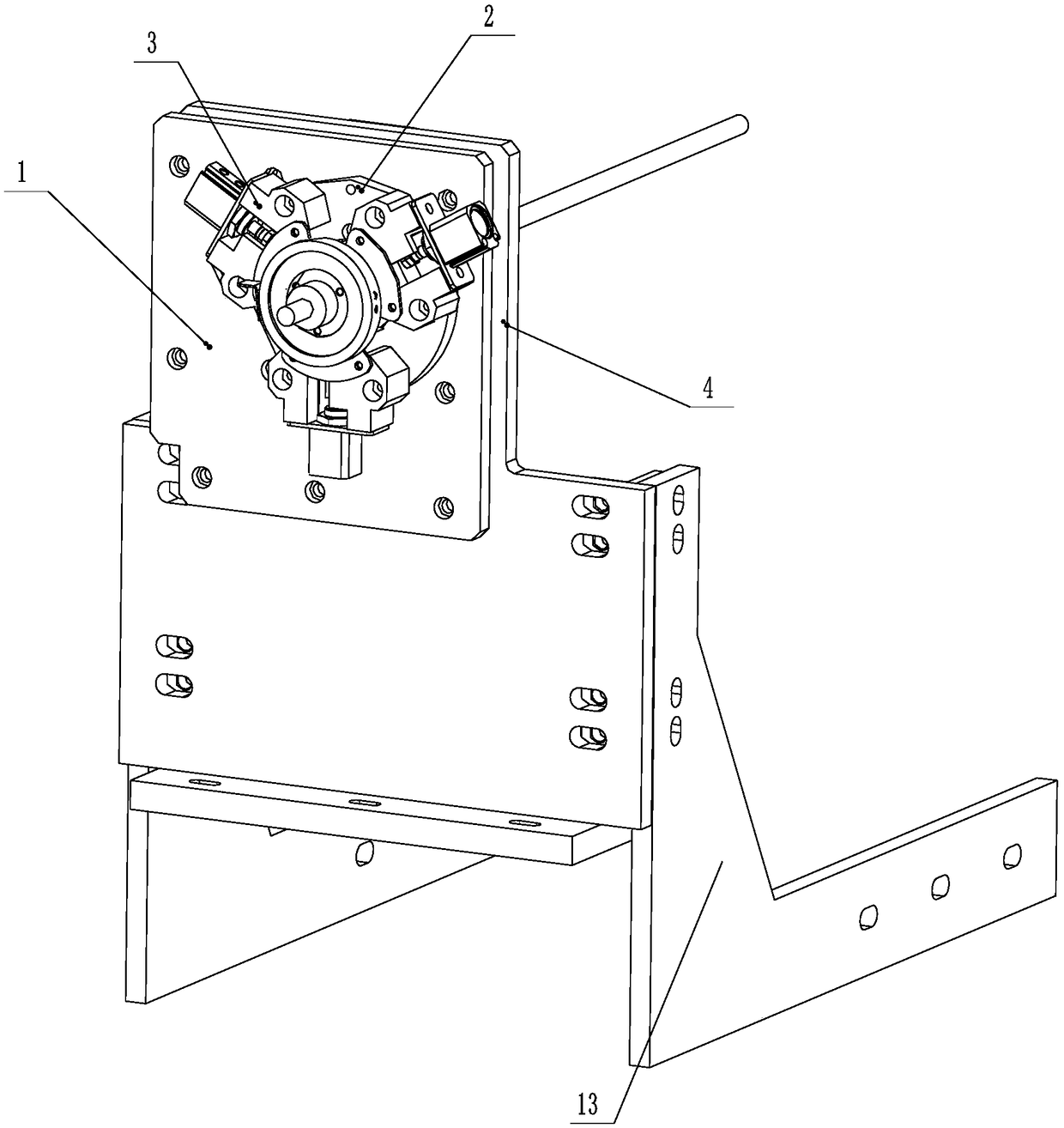

[0029] refer to Figure 1 to Figure 9 The shown hollow hook bending machine includes a frame 14 on which a hook wire feeding part 15 and a hook bending part are fixedly installed, and the hook bending part includes a bending machine Head 17, a mandrel head 27 and a rotating disk 19 are installed on the bending head 17, the mandrel head 27 is installed in the bending head 17, and the rotating disk 19 is connected to the bending head 17 On the telescopic rotary table 24, the mandrel head 27 is provided with a bending forming block 20, the rotating disk 19 is fixedly connected with a bending column, and the frame 14 is folded between the hook wire feeding part 15 and the hook. A hook pre-cutting device is also fixed between the bent parts. The hook pre-cutting device includes a first mounting plate 1, and a rotating disk 2 driven by a driving device is installed on the first mounting plate 1. The rotating disk 2 is fixedly connected with three cutting assemblies 3, the cutting a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com