Automatic wire clamping guide device for magnetic ring winding machine

A technology of guiding device and winding wire, which is applied in coil manufacturing, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of increasing design space and structure complexity, and achieve simple structure, lower positioning accuracy, and wire clamping Accurate and fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings of the specification:

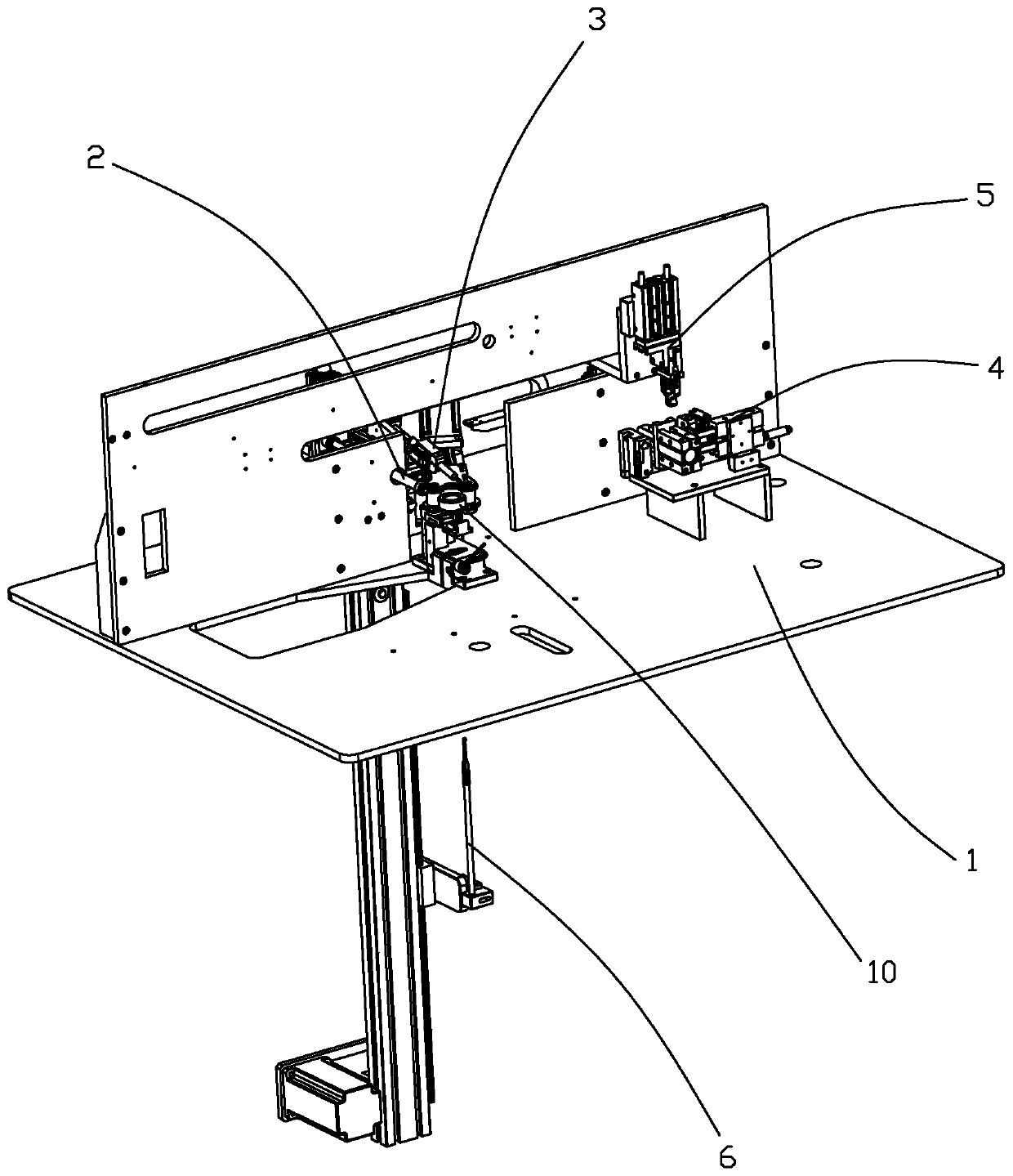

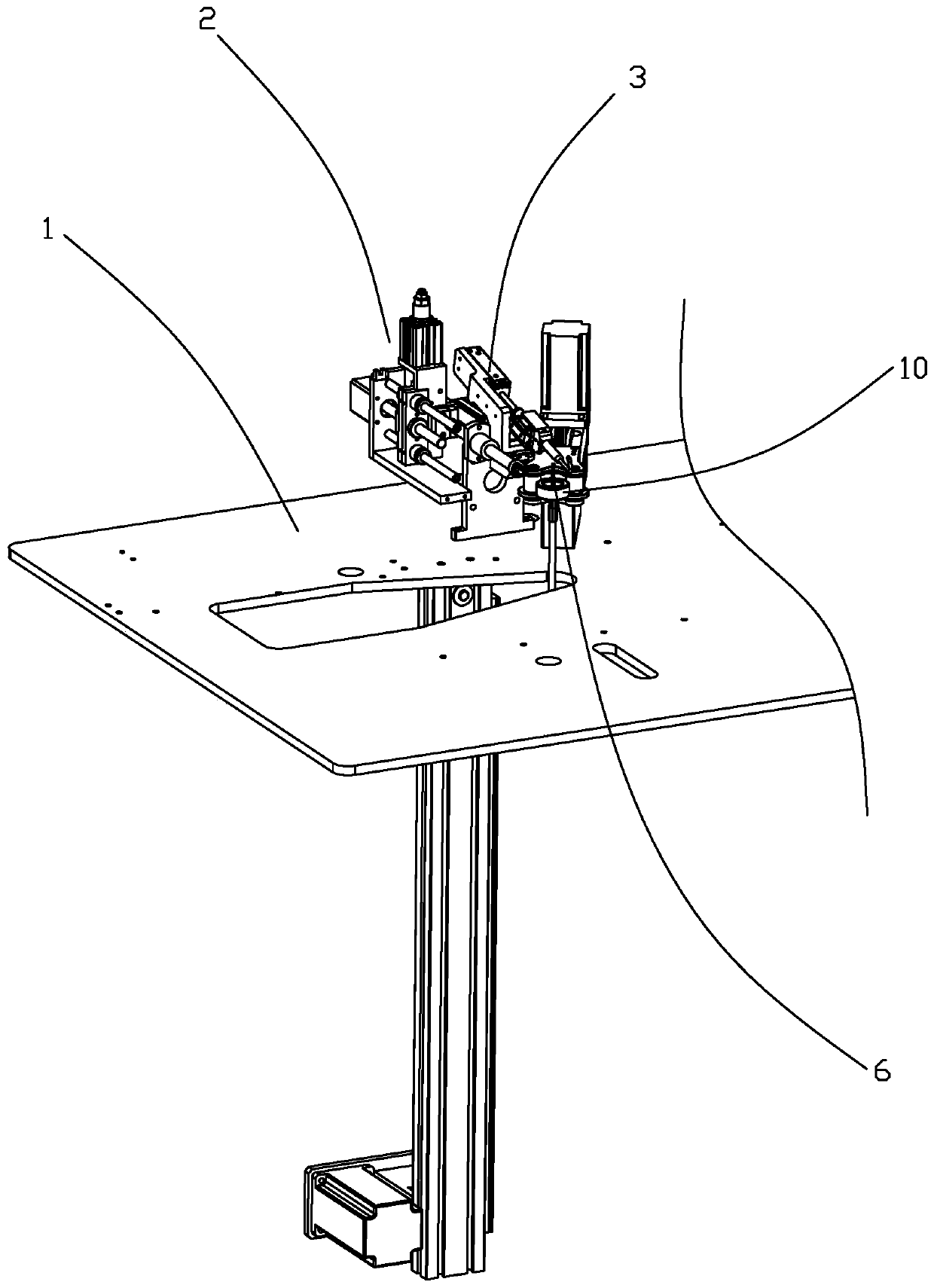

[0024] Such as Figure 1-6 As shown, an automatic thread-clamping guide device for a magnetic winding machine includes a thread-clamping mechanism 2 arranged on a frame 1 that can be retracted close to or away from the winding conveying direction. The frame 1 is also provided with a thread-clamping mechanism 2 On the wire-in side, a wire transfer mechanism 3 that can expand and contract to deviate the winding wire from its transmission line.

[0025] Specifically, the winding transmission direction passes through the torus of the magnetic ring 10, the wire clamping mechanism 2 clamps the winding from the wire exiting end of the winding through the torus of the magnetic ring 10, and the wire transfer mechanism 3 moves from the toroid of the magnetic ring 10 to make The winding deviates from its conveying route to facilitate winding and hooking....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com