Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1507results about "Conduits/junctions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

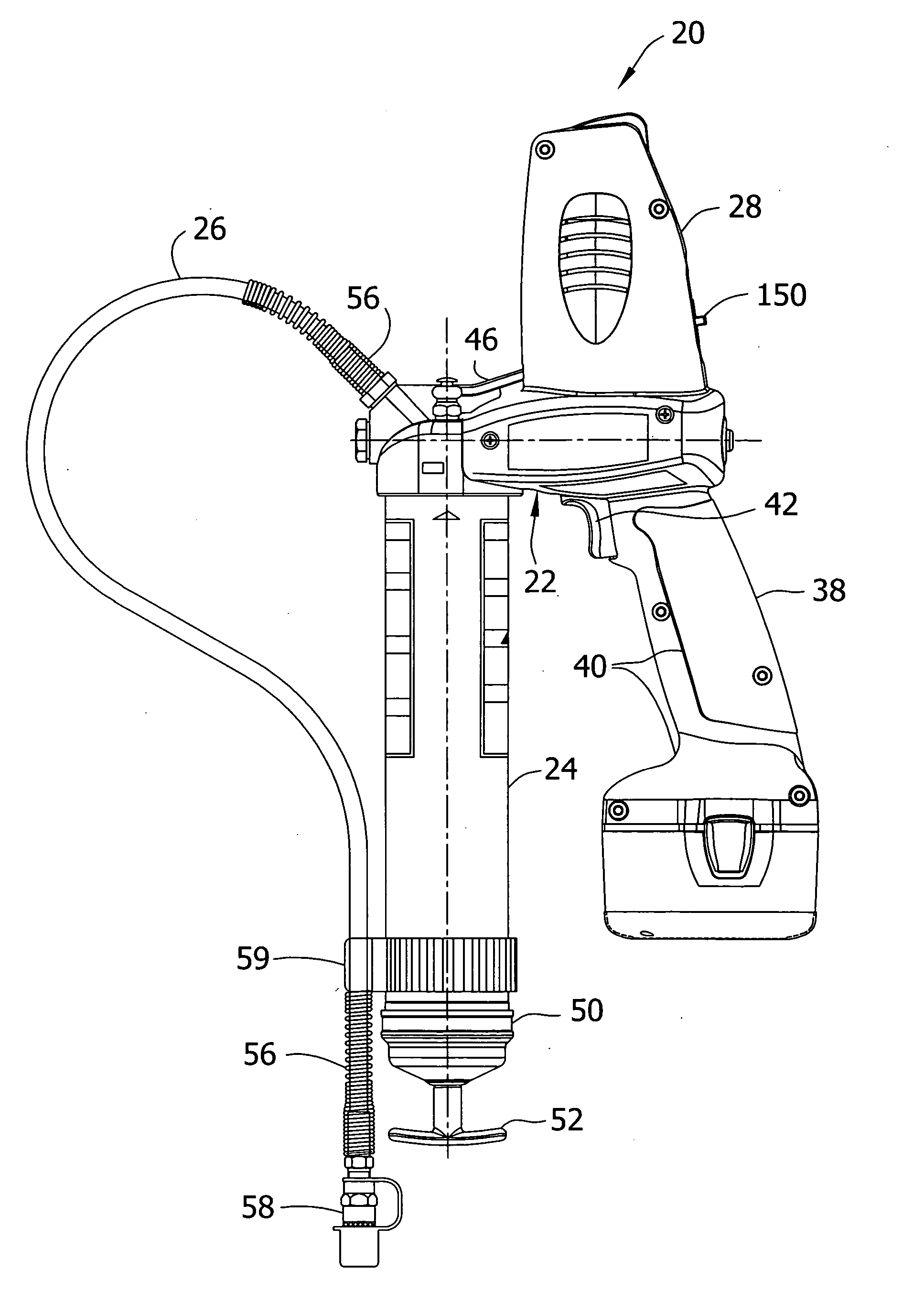

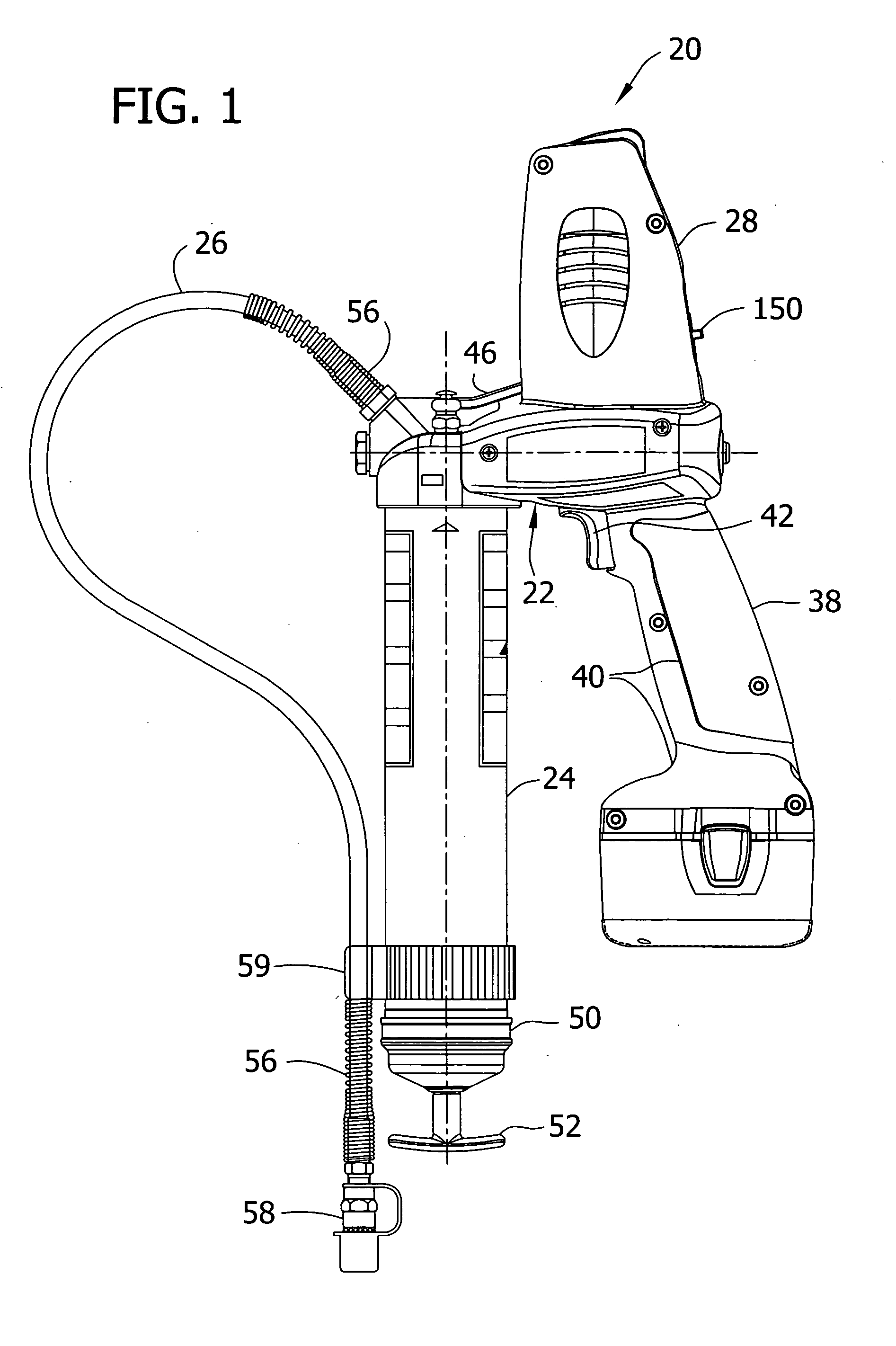

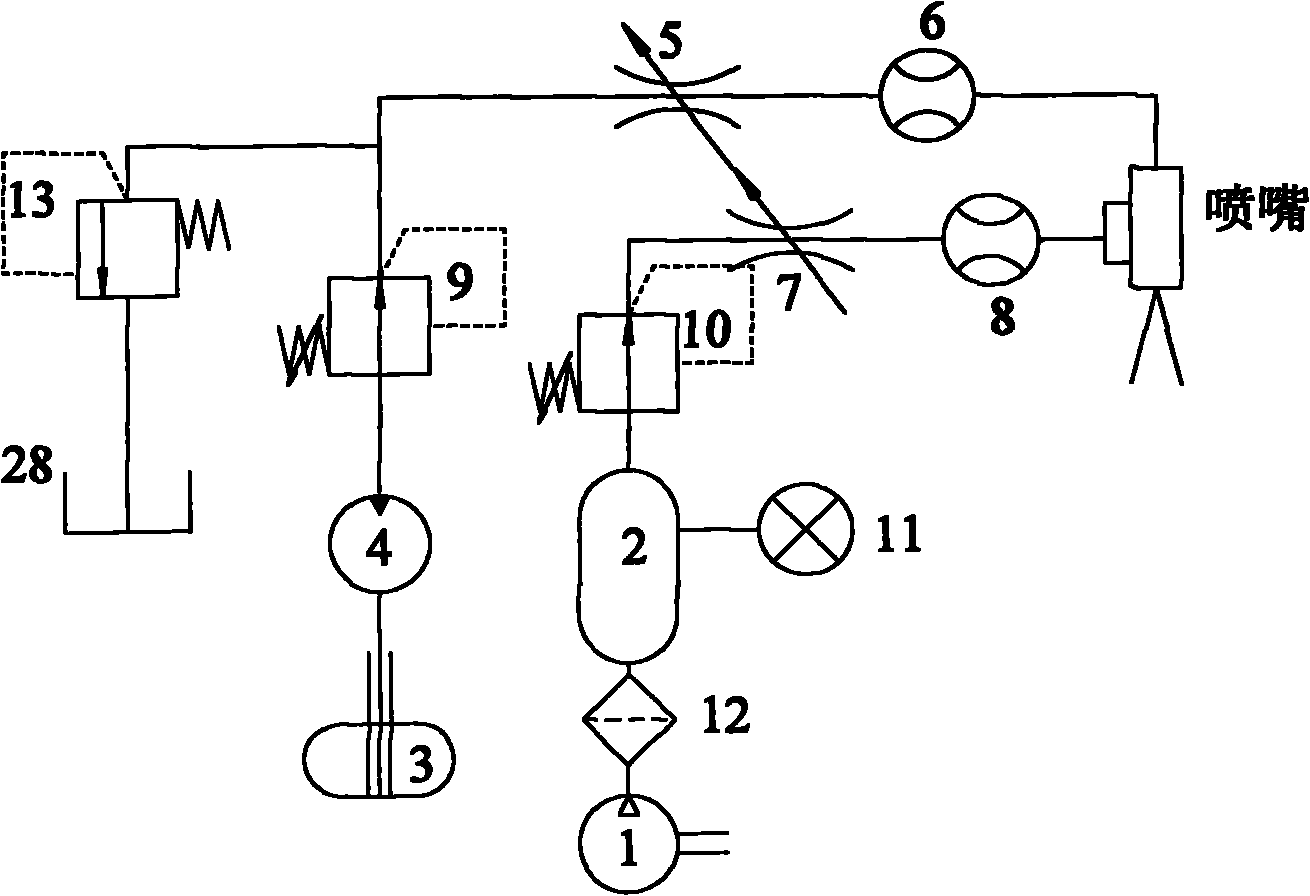

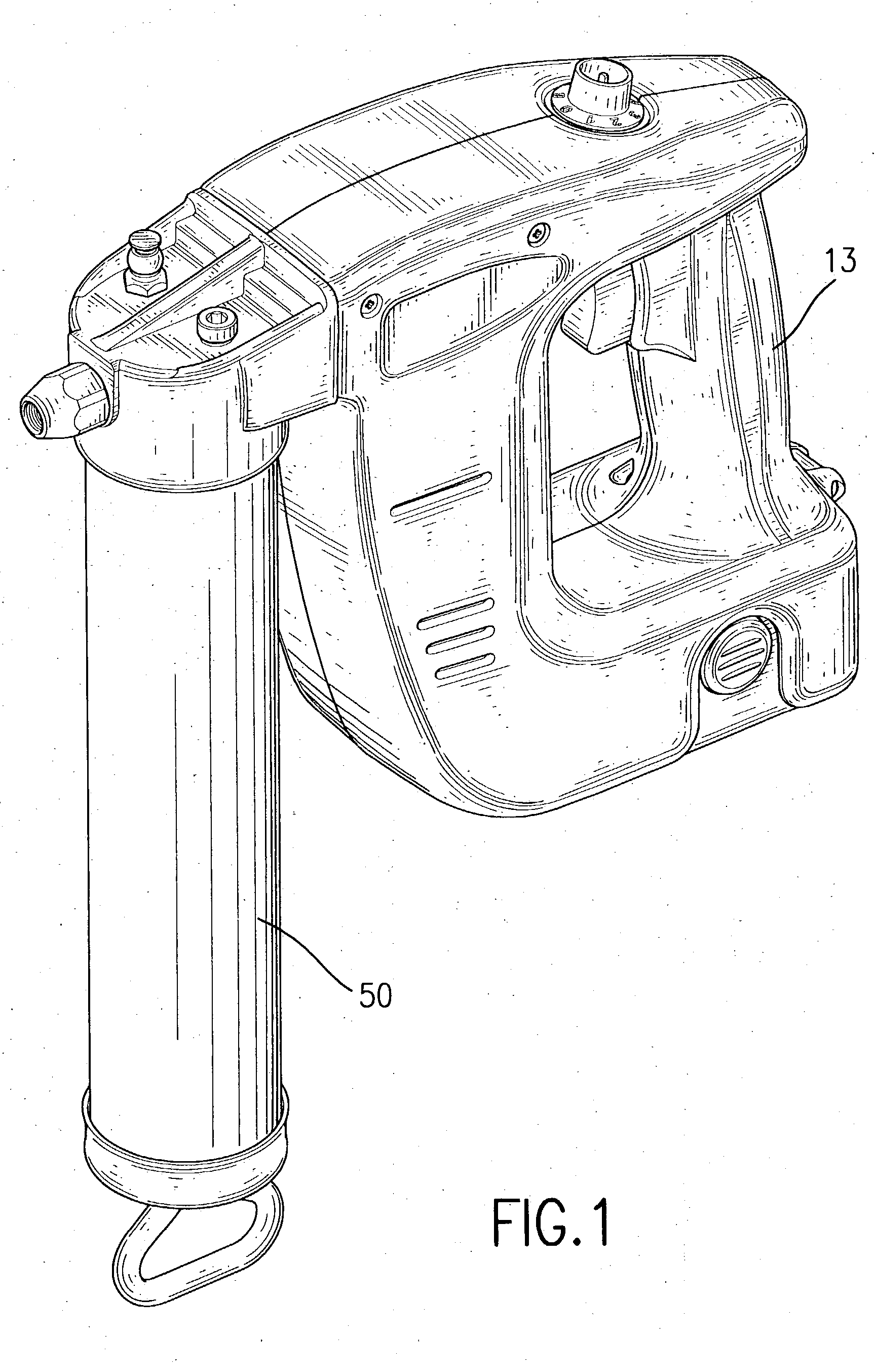

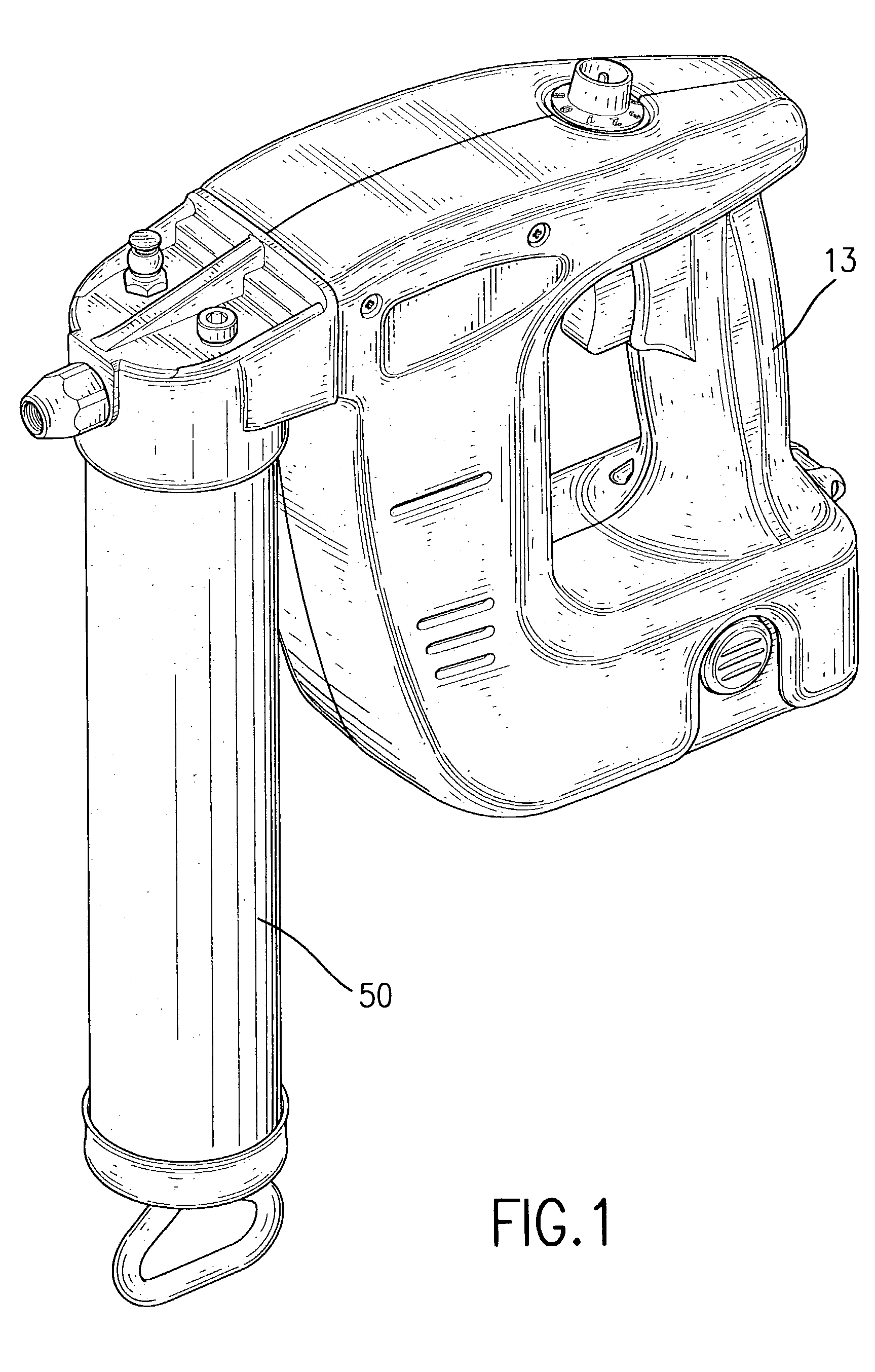

Grease gun

InactiveUS20060108180A1Avoid damageGuaranteed economic efficiencyManual lubricationMachines/enginesElectricityTransmitted power

A device for dispensing a viscous fluid, such as grease gun for dispensing lubricant. The grease gun delivers lubricant with a selectable variation in pressure and / or output. It includes a reservoir, a pump having a reciprocating plunger, an electric motor driving the pump, and a variable speed transmission for transmitting power from the motor to the pump. The transmission has at least two different output speed settings adapted to be selected for reciprocating the plunger at different cyclical frequencies. A cycle indicator provides an indication corresponding to a quantity of lubricant dispensed. Embodiments of the grease gun include a pressure relief valve which inhibits damage due to an over-pressure condition, and a circuit breaker which inhibits damage due to electrical overload.

Owner:LINCOLN INDUSTRIES CORP

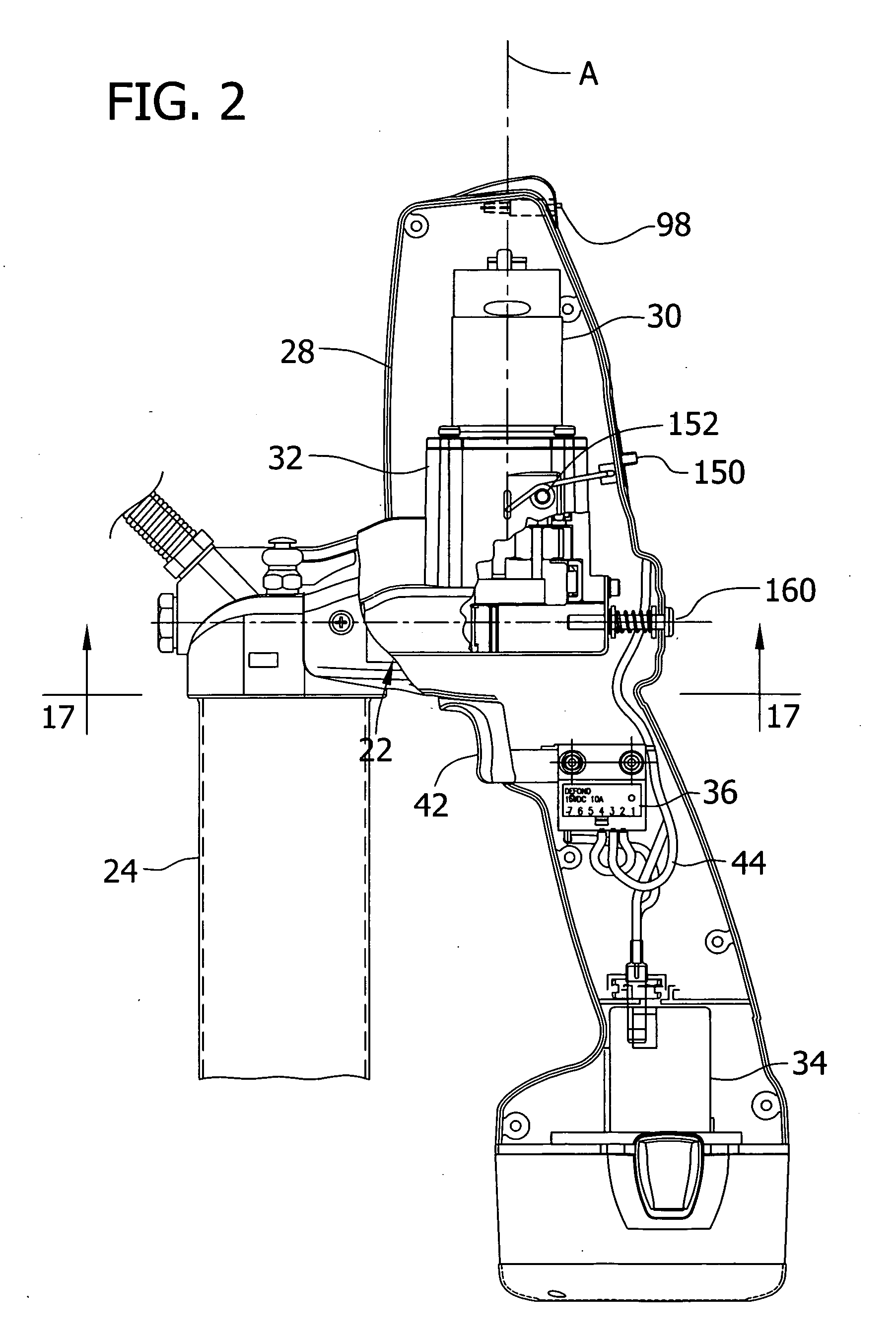

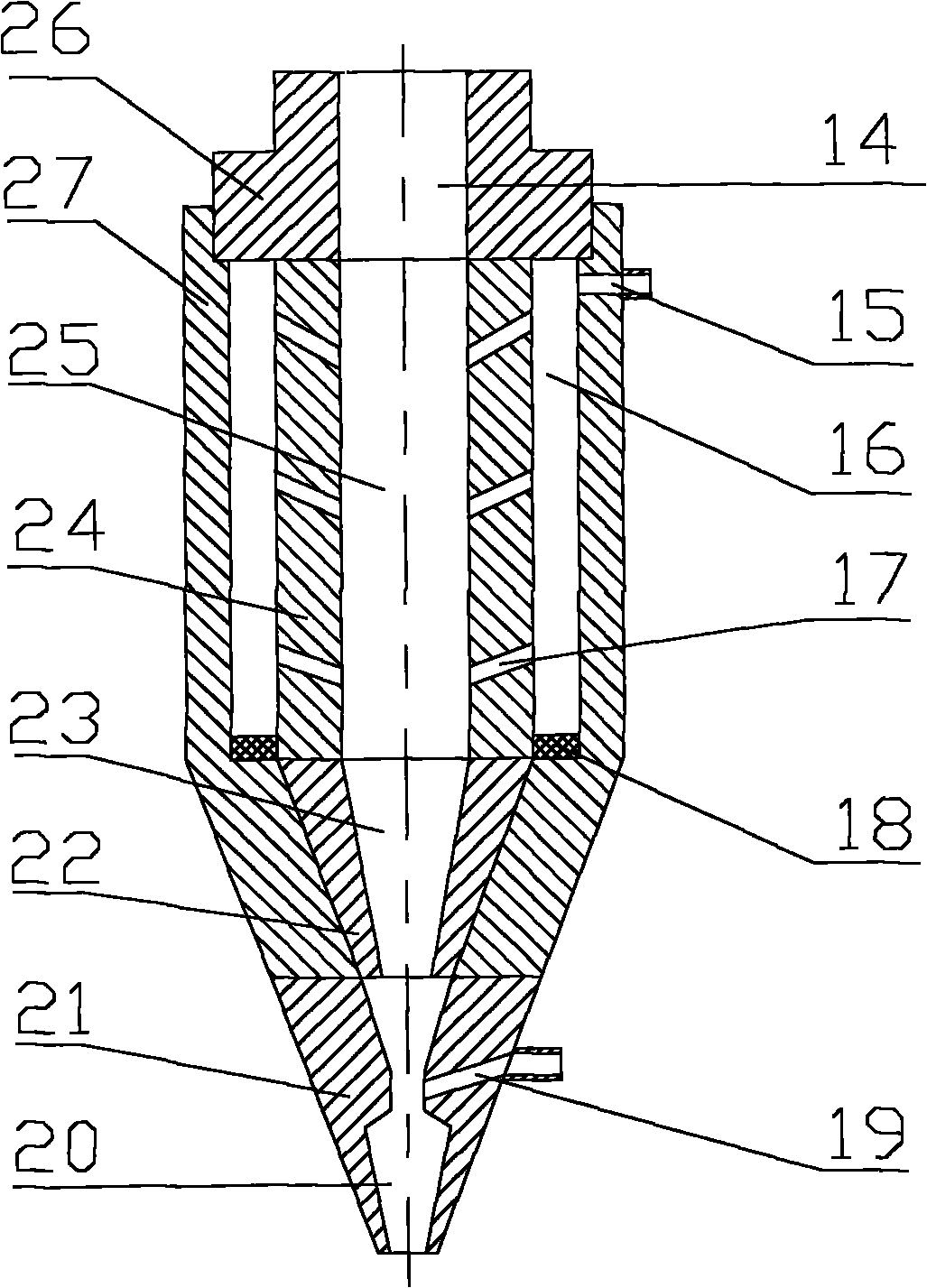

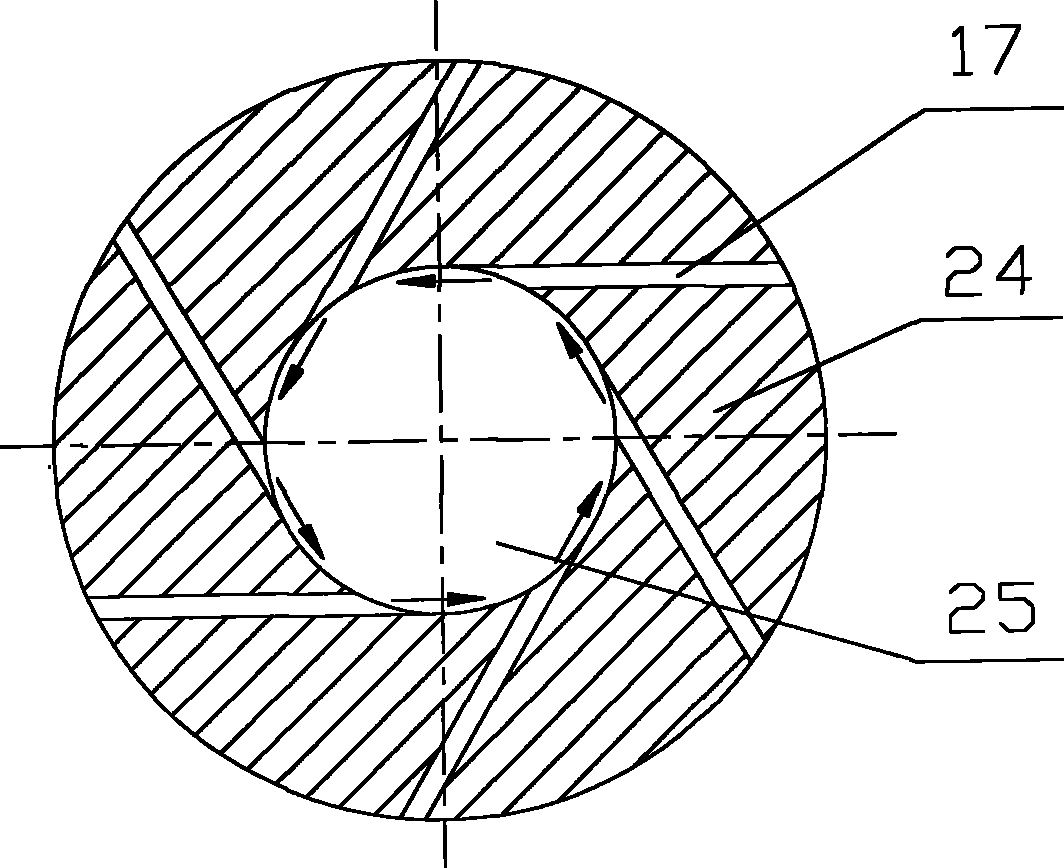

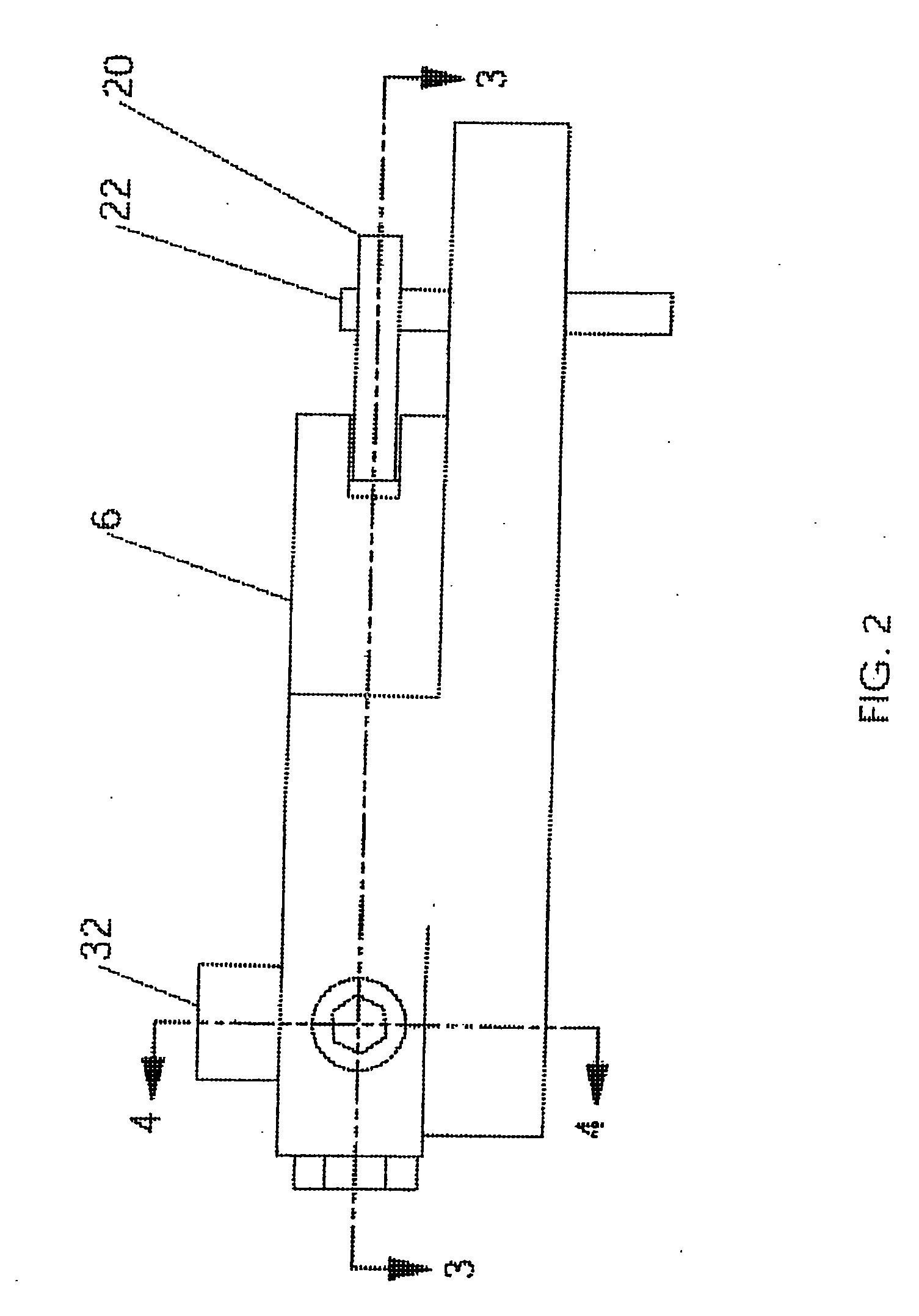

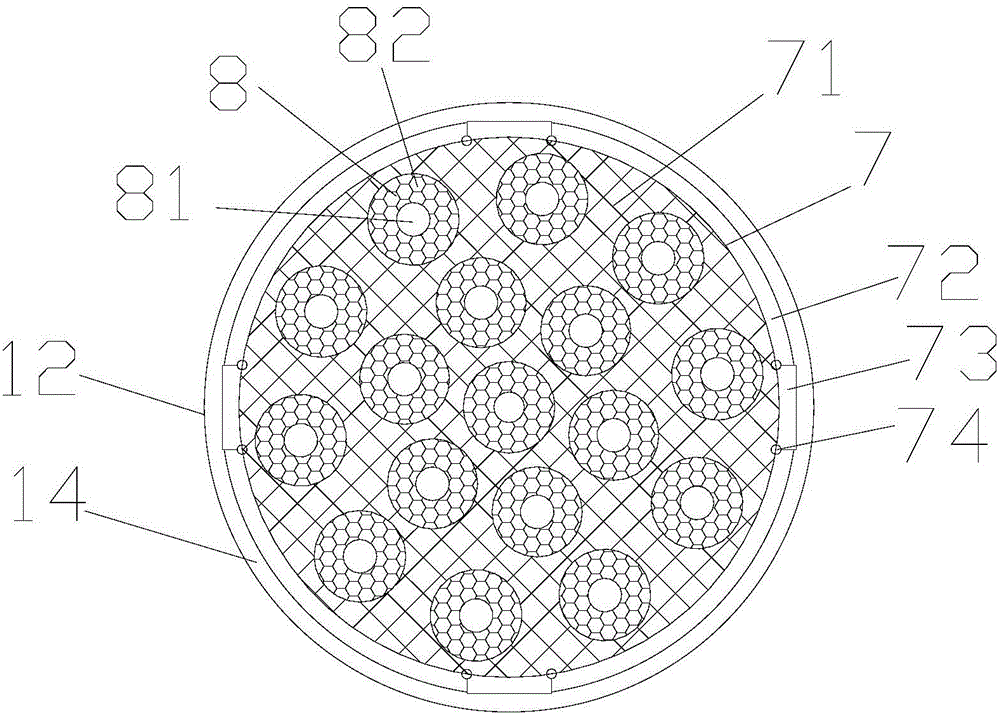

Three-phase flow supply system for nanoparticle jet micro-lubrication grinding

ActiveCN102287606AWell mixedIncrease the diameterConduits/junctionsLubrication check valvesEngineeringHigh pressure

The invention relates to the field of machining, in particular to a nano particle jet flow micro-scale lubricating and grinding three-phase flow supply system. The system is characterized in that: nano fluid is conveyed to a nozzle by a liquid path, high temperature gas enters the nozzle through a gas path at the same time, the high pressure gas and the nano fluid are fully mixed and atomized in the mixing room of the nozzle, the mixed high pressure gas and nano fluid are accelerated in an acceleration room and enter a vortex room, compressed gas enters from the vent hole of the vortex room, and a three-phase flow is further mixed and accelerated by rotating, and is jetted in the form of atomized liquid drops to a grinding area through the outlet of the nozzle. The system has the advantages that: the helical vent hole of the mixing room of the nozzle is tangent to the wall surface of the mixing room, and the nano fluid and the gas are uniformly mixed; pressure adjusting valves, throttles and flow meters are arranged in the gas path and the liquid path, and the pressure and the flow of the nano fluid and the high pressure gas can be adjusted as required so as to achieve an optimal micro-scale lubricating effect; and the problems of insufficient cooling capability in micro-scale lubricating, the large using quantity of a lubricant in pouring type grinding, high waste liquid processing cost and heavy environment pollution are solved.

Owner:青岛前瞻产业园区运营管理有限公司

Remote well servicing systems and methods

Embodiments of the present disclosure include a remote well servicing system including a control unit and a remote servicing manifold. The control unit further includes a service fluid source and a control system. The remote servicing manifold further includes a fluid input line coupled to the service fluid source, a fluid output line couplable to a well component, and a valve coupled to the fluid input line and the fluid output line, wherein the valve, when actuated, places the fluid input line in fluid communication with the fluid output line and permits delivery of a service fluid from the service fluid source to the well component. The remote servicing manifold also includes a control line coupling the valve and the control system wherein the control system controls actuation of the valve via the control line.

Owner:VAULT PRESSURE CONTROL LLC

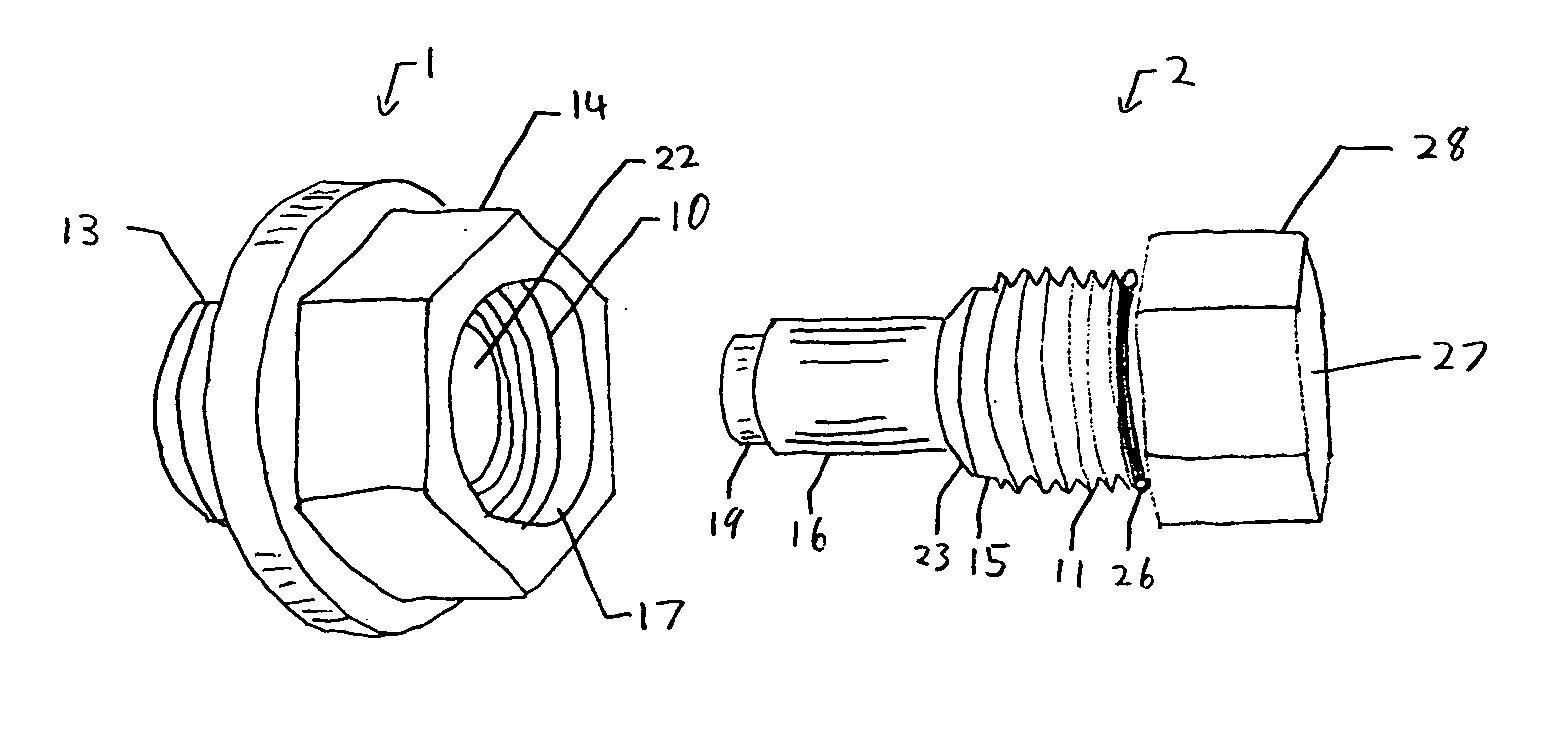

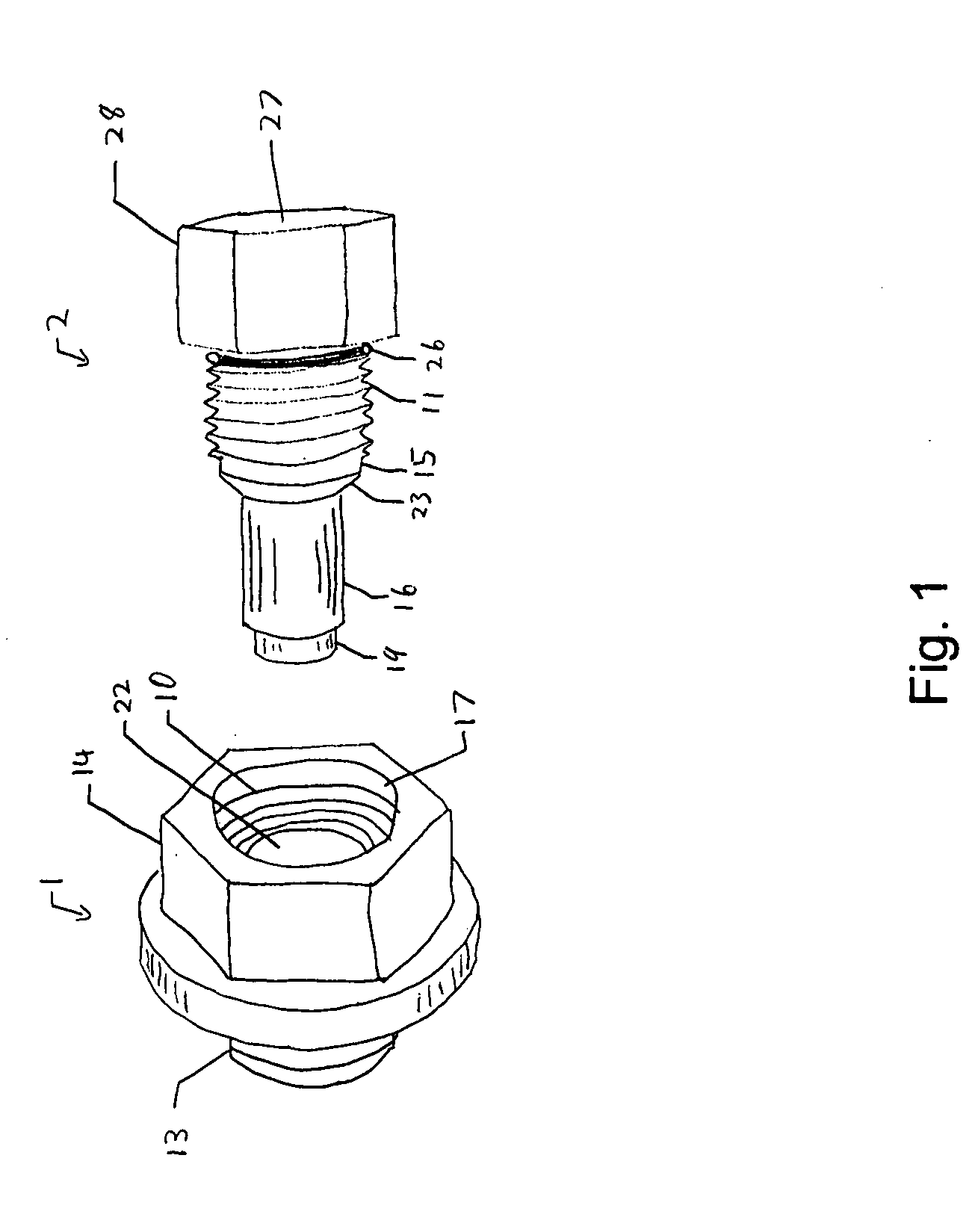

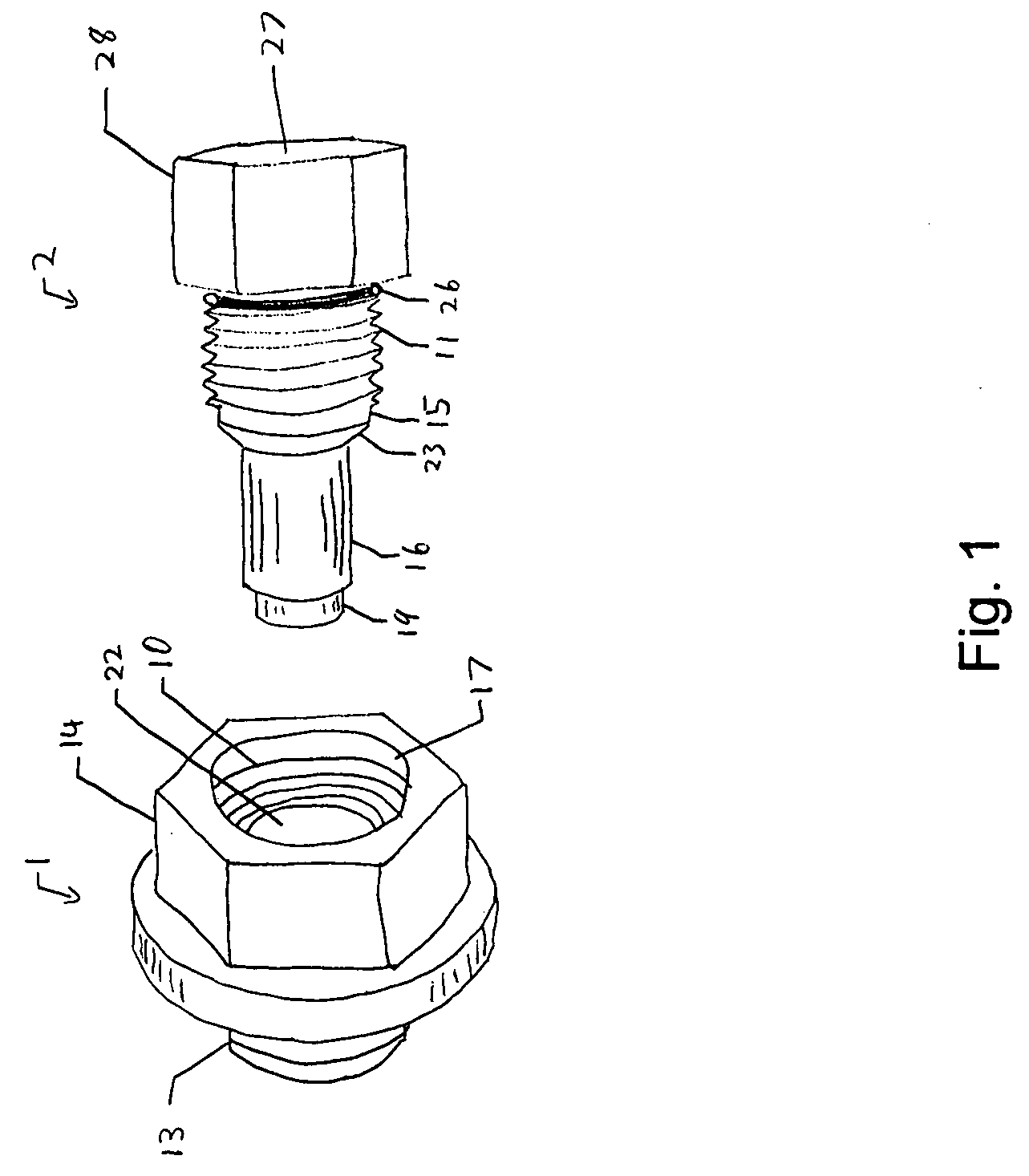

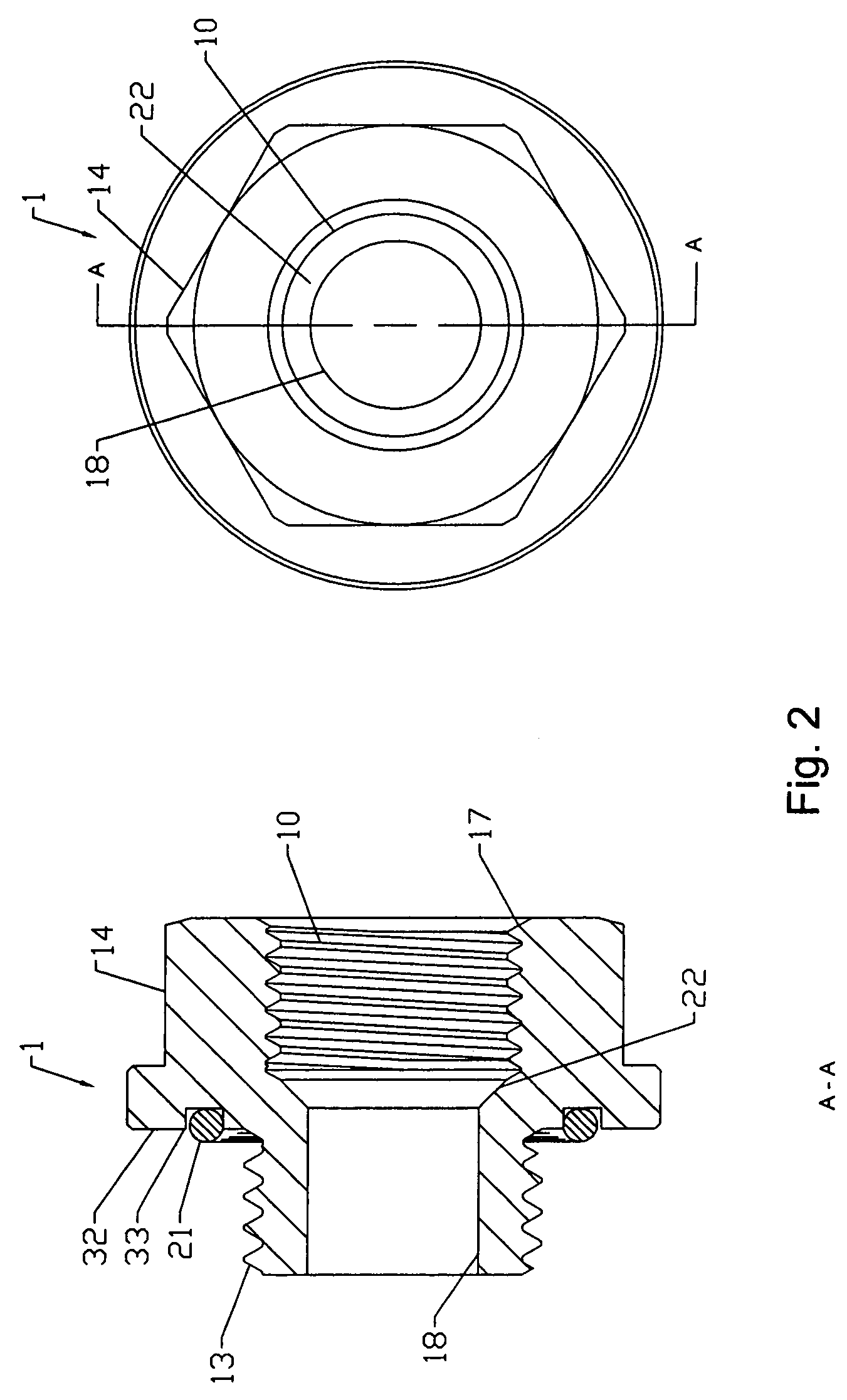

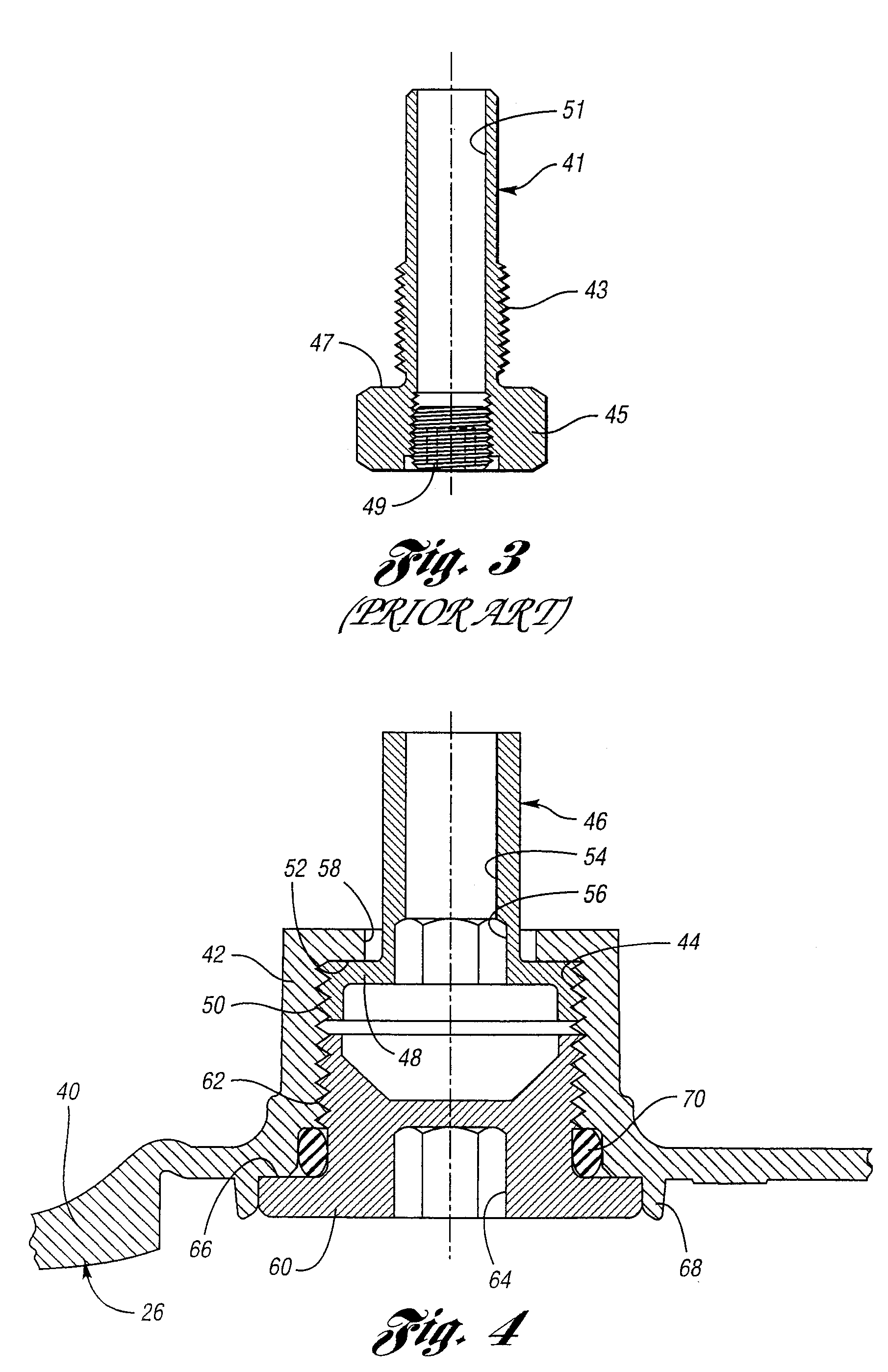

Two part oil or fluid drain plug with magnet

ActiveUS20060054402A1Precise positioningAvoid partialCrankshaftsElectrostatic separationEngineeringMagnet

This invention performs several functions. First; facilitating the draining of oil or fluid from a sump. Second; as a proactive and preventive method of preventing the threads of the sump (which receive the drain plug) from becoming striped or damaged. Third; adding in the determination of the physical condition (ware) of the engine, transmission, or the like, in which the sump is attached to.

Owner:DORIAN GEORGE P

Combined filter and fill tube

Owner:INT ENGINE INTPROP CO LLC

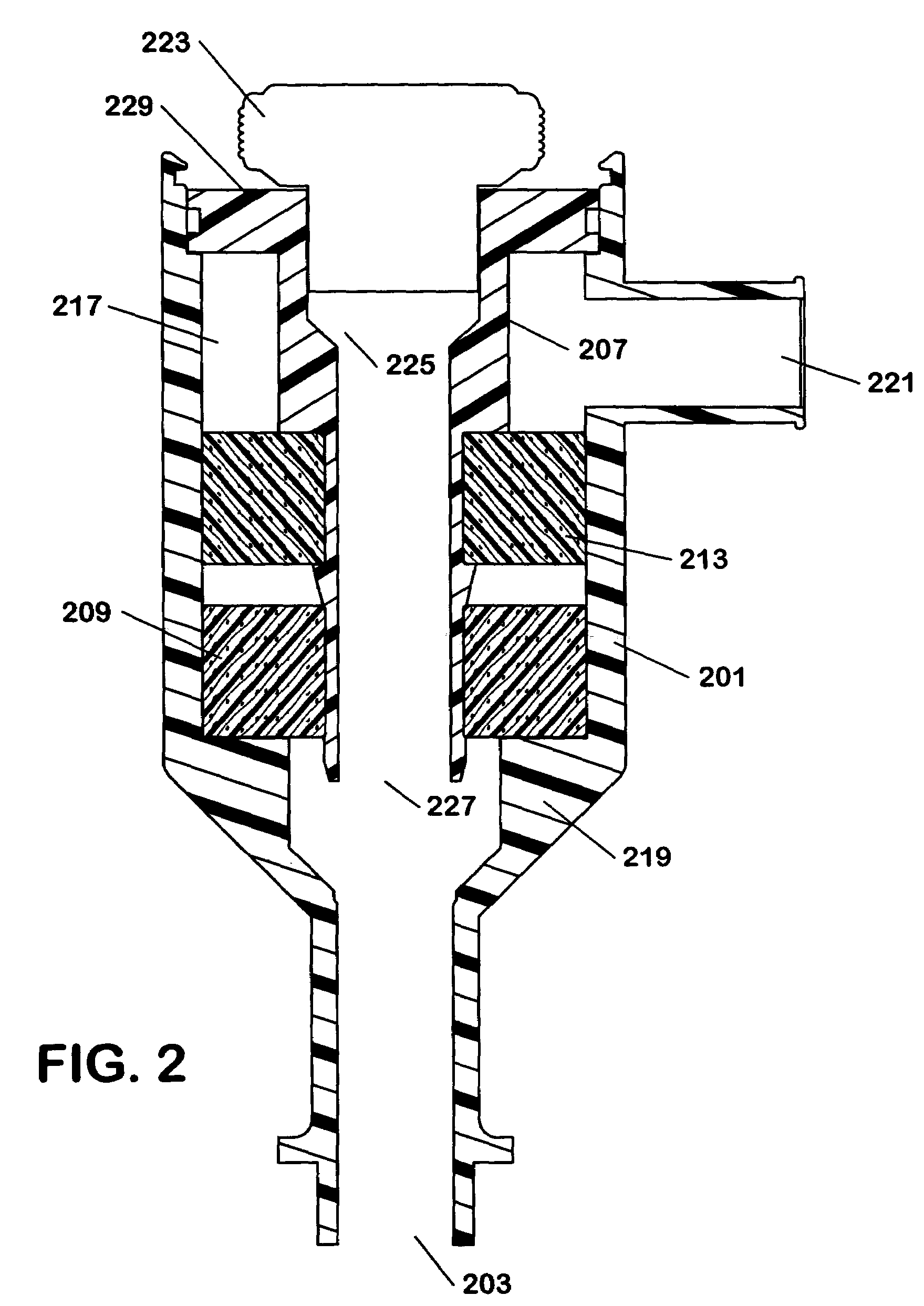

Ultrasonically controllable grease dispensing tool

ActiveUS20110253480A1Accurate fault diagnosisAccurate diagnosisDetection of fluid at leakage pointVibration measurement in fluidLubricationBiomedical engineering

A lubrication dispensing apparatus for lubricating a device with moving parts includes a lubricant reservoir, a lubricant dispenser for dispensing lubricant from the lubricant reservoir, an ultrasonic detection module which detects the amplitude of ultrasonic energy emitted by said device when its parts are moving and produces an signal related thereto, and a control module which analyzes the amplitude of the signal from the ultrasonic detection module and, in response to a lubricate signal, causes the lubricant dispenser to automatically dispense lubricant onto the moving parts of the device until the signal from the ultrasonic detector indicates that the ultrasonic energy produced by the device has decreased to a particular level. The control module includes a programmed processor and a storage memory. The memory stores as a base value the value of the detected amplitude of ultrasonic energy when the device is operating properly. After receiving a signal to lubricate the device, the processor causes the dispenser to start the flow of lubricant to the device, compares the signal from the ultrasonic detection module when the parts are moving to the base value, and causes the dispenser to cease the flow of lubricant when the signal substantially decreases.

Owner:U E SYST

Protection plug

A plug for protecting the interior of a recessed area of a component during storage is disclosed herein. The plug includes a lubrication fitting positioned thereon to flow a protective material, such as grease, into the cavity between the lower end of the plug and the recessed area and any remaining voids between the walls of the plug and the walls of the recessed area. The plug may also include an engagement surface to assist in the insertion and removal of the plug into and out of recessed areas of a component.

Owner:TUCKER ROBERT C

Protection plug

InactiveUS20010052438A1Avoid damageMachines/enginesLubricating pumpsMechanical engineeringLubrication

A plug for protecting the interior of a recessed area of a component during storage is disclosed herein. The plug includes a lubrication fitting positioned thereon to flow a protective material, such as grease, into the cavity between the lower end of the plug and the recessed area and any remaining voids between the walls of the plug and the walls of the recessed area. The plug may also include an engagement surface to assist in the insertion and removal of the plug into and out of recessed areas of a component.

Owner:TUCKER ROBERT C

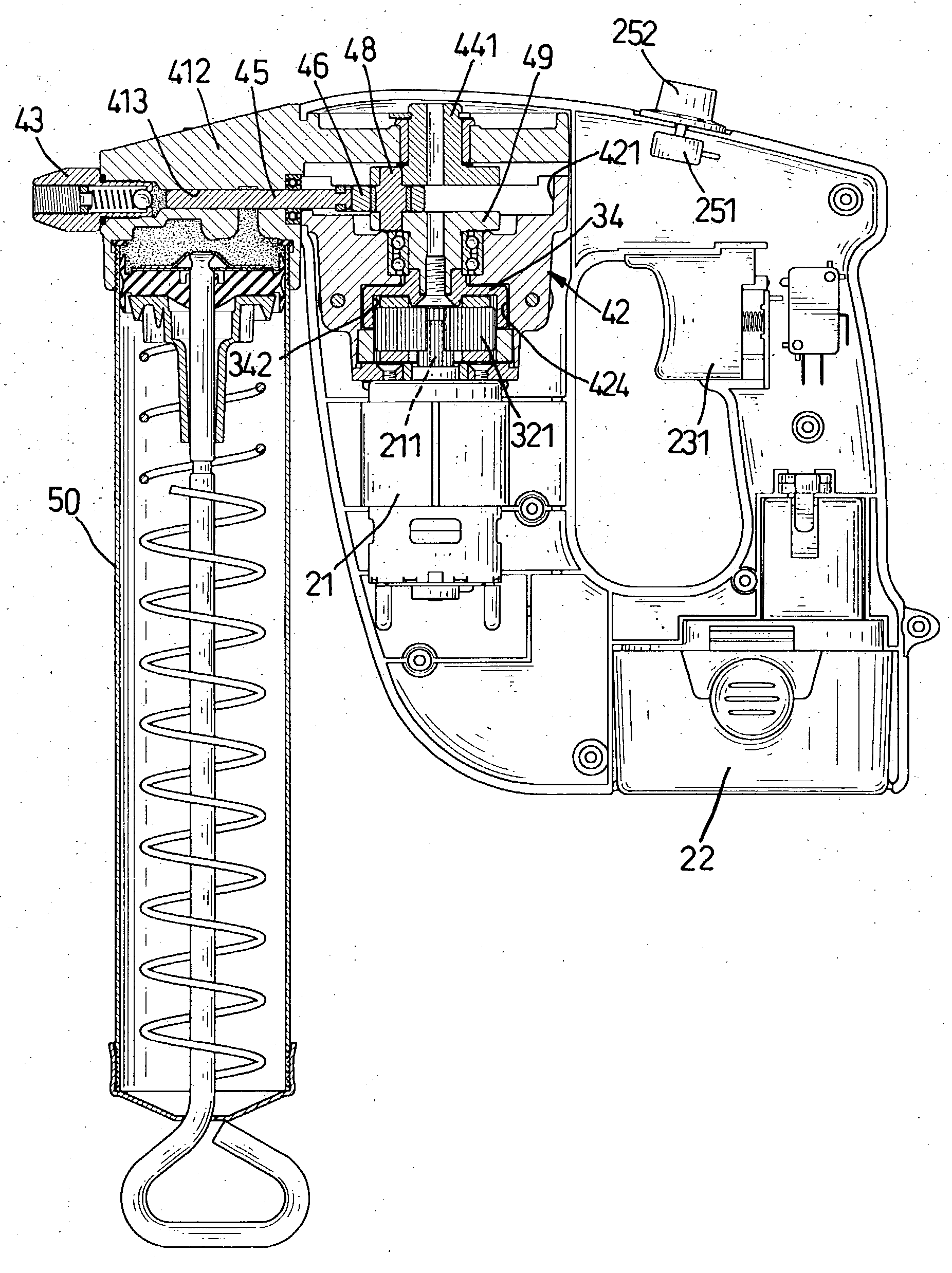

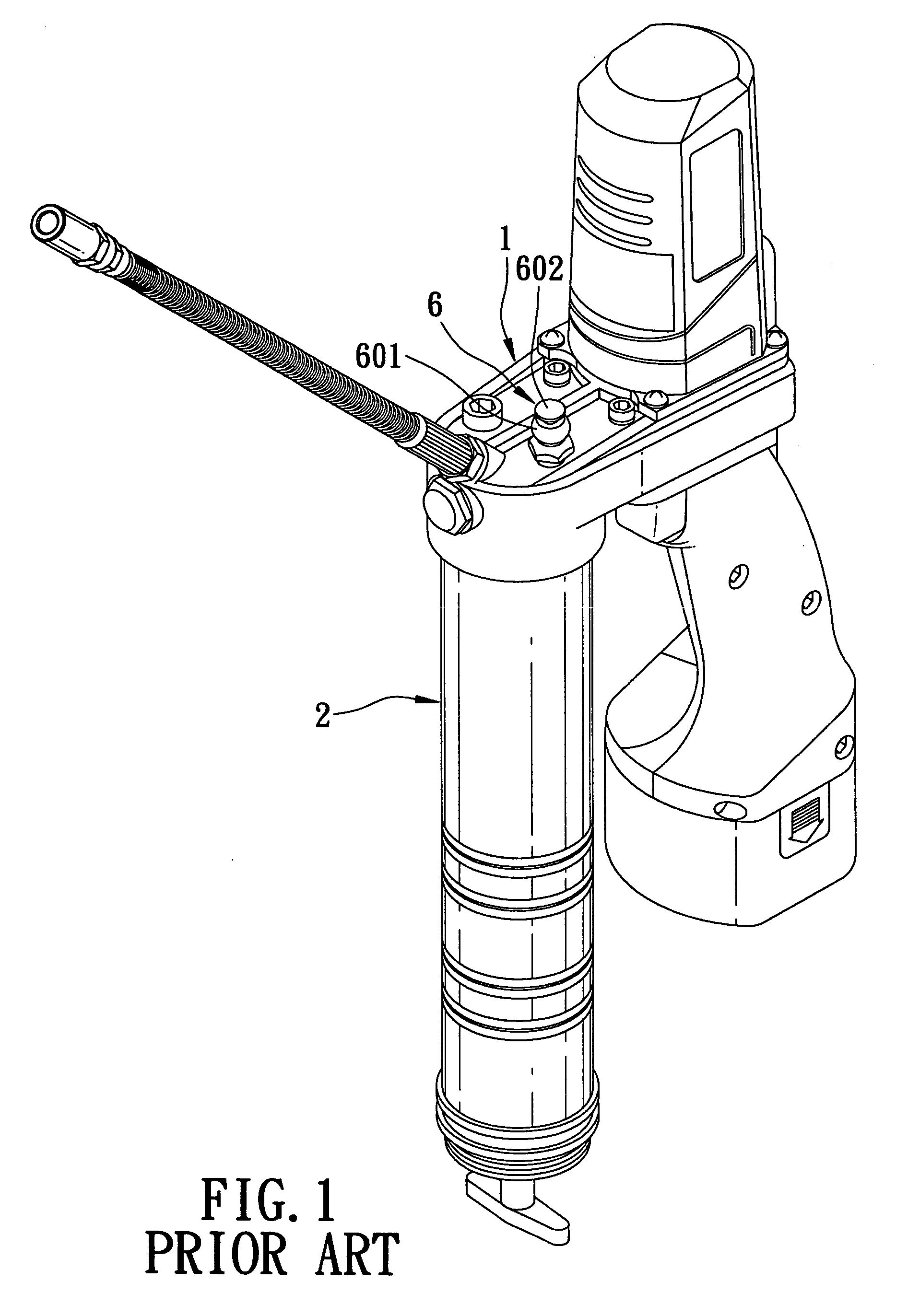

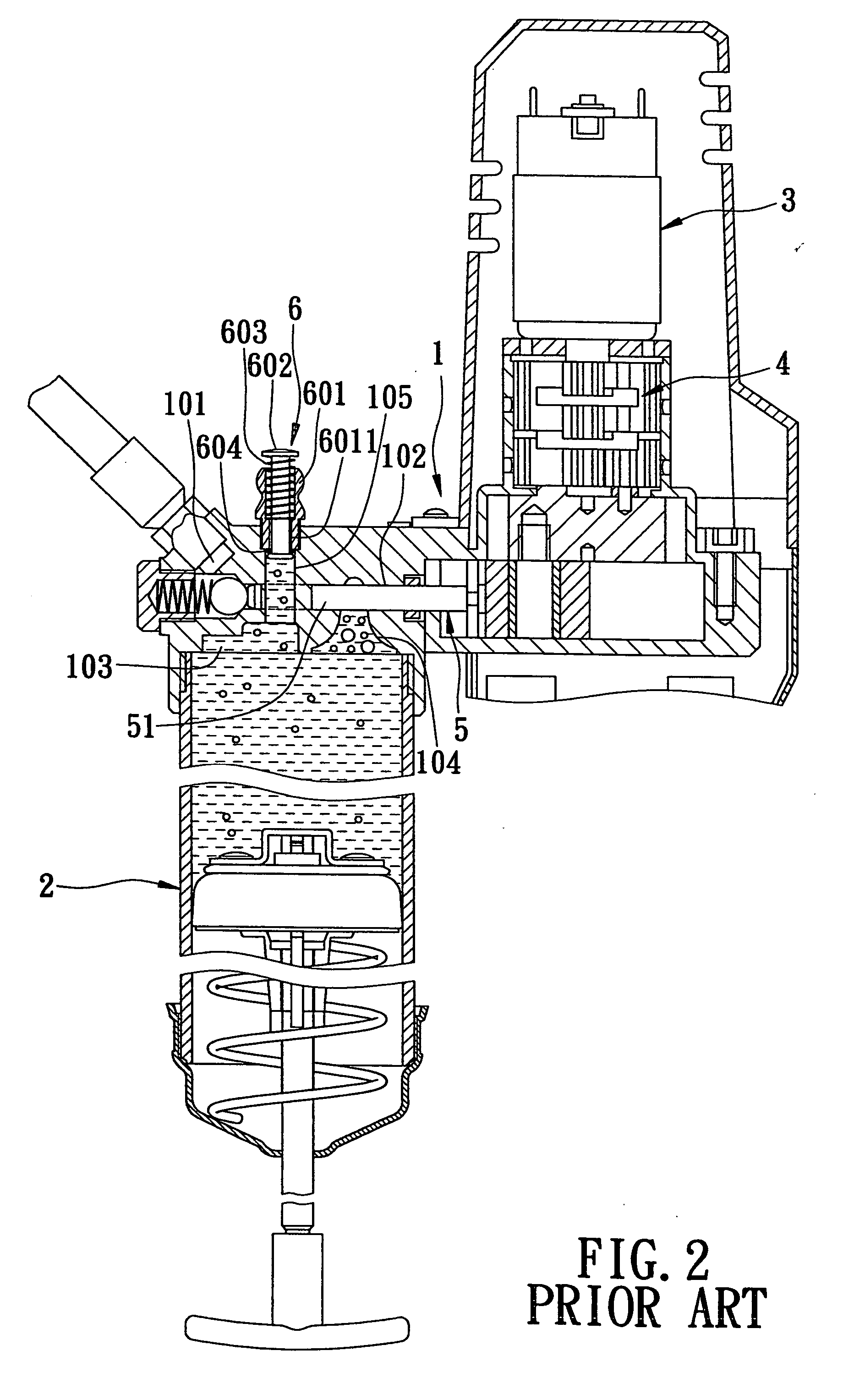

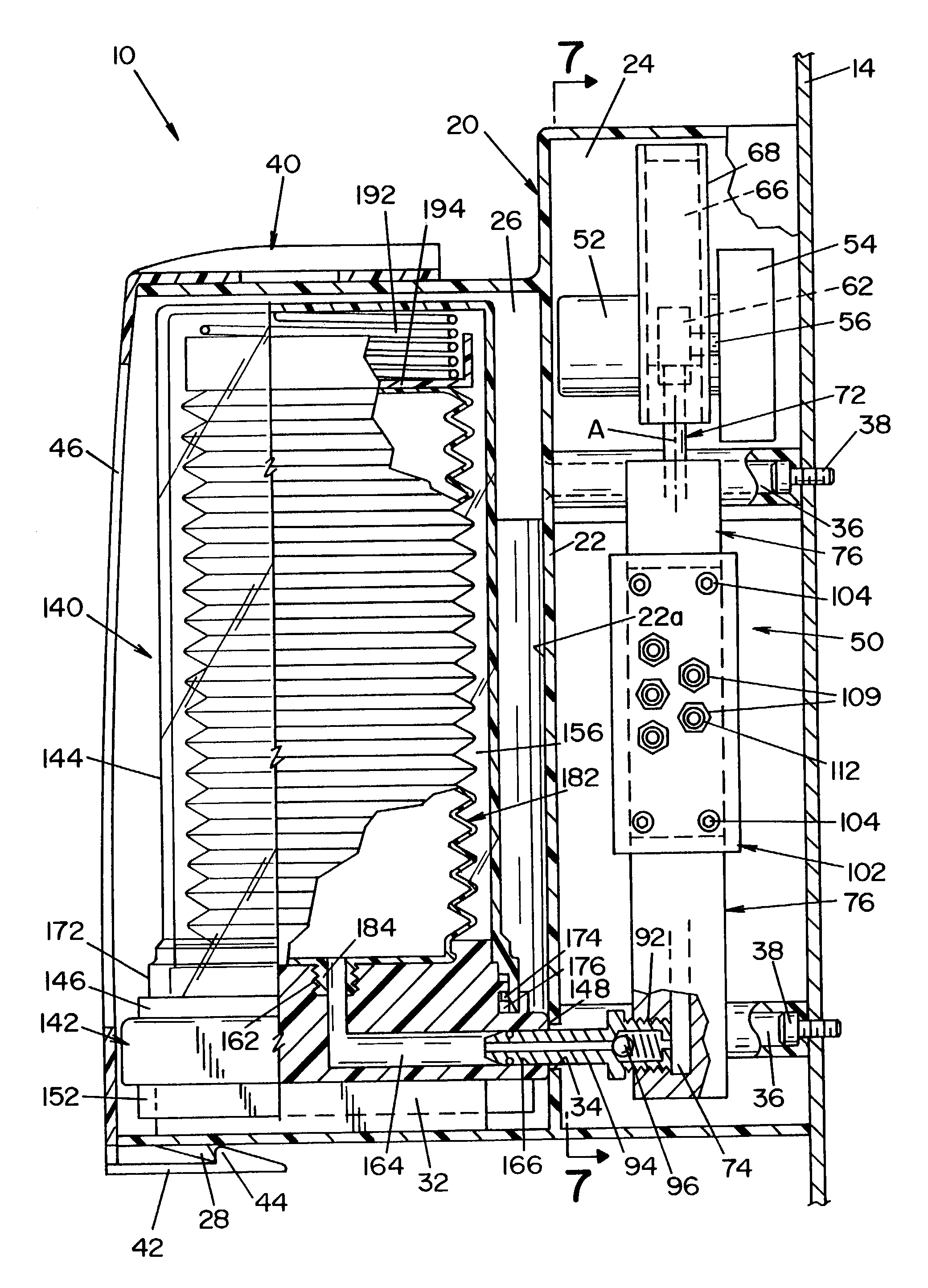

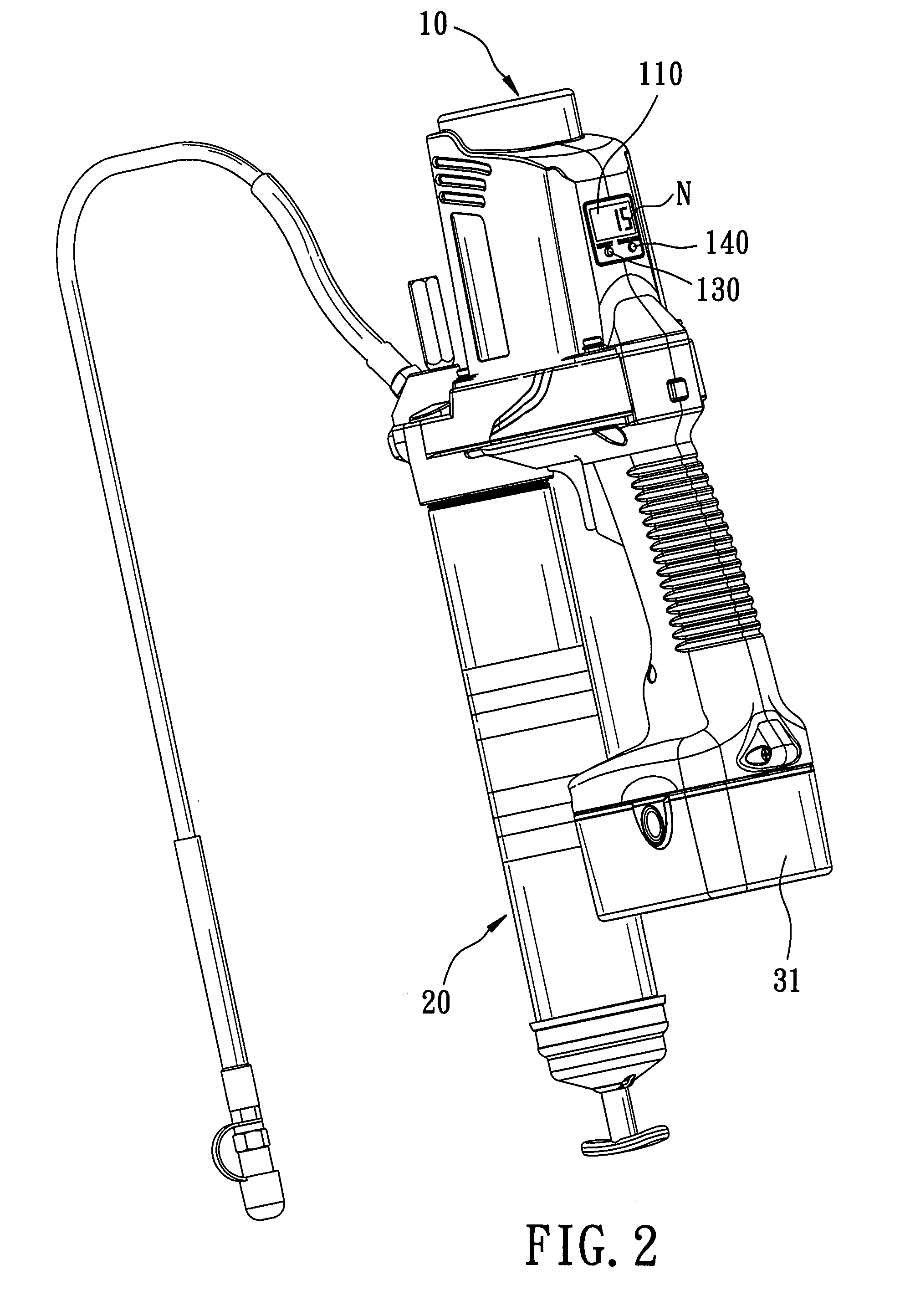

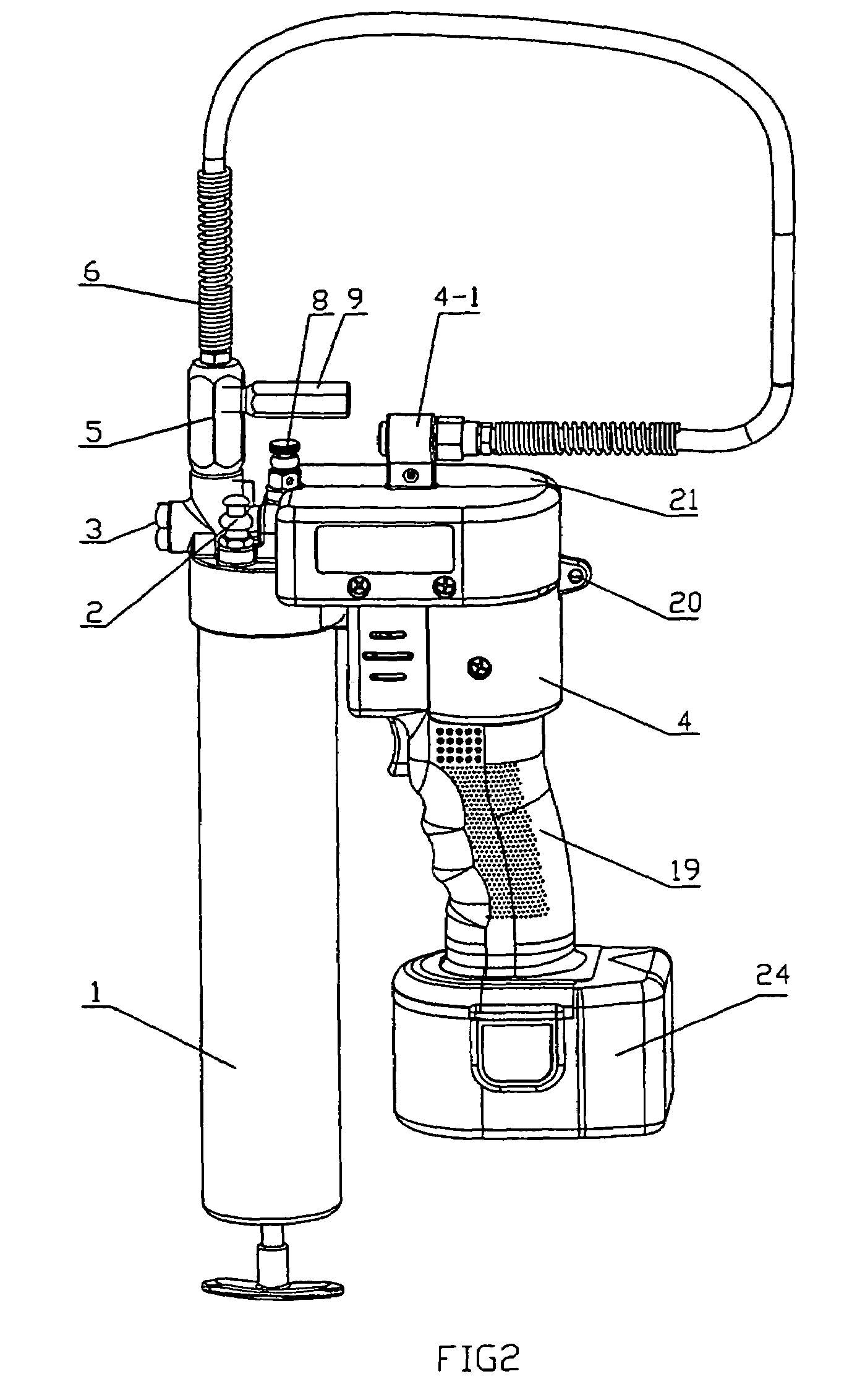

Battery-operated grease gun with an electronic pressure regulator for controlling pressure of the grease

InactiveUS20040231927A1Effective controlLarge containersMachines/enginesElectrical batteryGear wheel

A battery operated grease gun has a motor that drives a planetary gear assembly that is coupled to a pump assembly that drives a plunger reciprocally in an grease passage to discharge grease through a discharge spout. The pressure in the grease exerts a reaction force on the plunger that will change torque of the motor. The change of the torque of the motor will simultaneously effect voltage applied to the motor. When the voltage in the motor changes, an electronic pressure regulator measures the voltage in the motor to determine the pressure in the grease in the grease passage and stops the motor as the pressure in the grease reaches preset given valves in the pressure regulating device.

Owner:TECHWAY INDAL

Fluid reservoir assembly

A fluid reservoir assembly having a pan defining a drain opening and a plug disposed therein is disclosed. The pan includes a pair of ramps disposed on an inner surface thereof adjacent the drain opening. The plug includes a pair of wings in engagement with the ramps. The ramps increase in height relative to the inner surface of the pan along a first direction of rotation about the central axis. The plug is drawn into sealing engagement with an outer surface of the pan by rotating the plug in the first direction of rotation about the central axis thereby moving the wings up the ramps. The pan includes at least one stop to prevent over-rotation of the plug. The ramps define a recess to secure the wings in a closed position.

Owner:BASF AG

Two part oil or fluid drain plug with magnet

A two part oil drain plug assembly facilitates the draining of oil or fluid from a sump, and its use prevents the threads of the sump, which may be an automotive oil pan, from becoming stripped or damaged. Further, the device aids in the determination of the physical condition (wear) of the engine, transmission or the like to which the sump is attached, by attracting metal particles to an isolated magnet on the drain plug.

Owner:DORIAN GEORGE P

Lubricant reservoir refilling system with shut-off

InactiveUS20130256062A1Hinder lubricant from flowingAvoid flowOperating means/releasing devices for valvesLubricant transferLiquid tankEngineering

A lubricant reservoir system. The system includes a reservoir for containing lubricant. The reservoir has a top, a bottom, a peripheral wall, and an inlet for delivering lubricant to the reservoir from a supply. The system also includes a follower in the reservoir slidingly and sealingly engaging the peripheral wall of the reservoir, the follower moving up and down in the reservoir in response to a changing level of lubricant in the reservoir. The lubricant reservoir system has a shut-off valve in fluid communication with the inlet for selectively preventing lubricant flow through the inlet. The valve is operatively connected to the follower for closing the valve and preventing lubricant flow through the inlet when lubricant in the reservoir reaches a predetermined level.

Owner:LINCOLN INDUSTRIES CORP

Lubricant gun

A lubricant gun includes a housing, a lubricant reservoir, a plunger, and an exhaust valve. The housing includes a discharge spout, a slide channel fluidly communicated with the discharge spout, a lubricant supply passage having a lubricant supply hole fluidly connected to the slide channel, and a gas-discharging hole fluidly communicated with the slide channel. The lubricant reservoir is connected to the housing and is fluidly communicated with the slide channel through the lubricant supply passage and the lubricant supply hole. The plunger has a pushing portion received in the slide channel for sliding reciprocatingly therein. The exhaust valve is mounted on the housing and is fluidly communicated with the gas-discharging hole.

Owner:TECHWAY INDAL

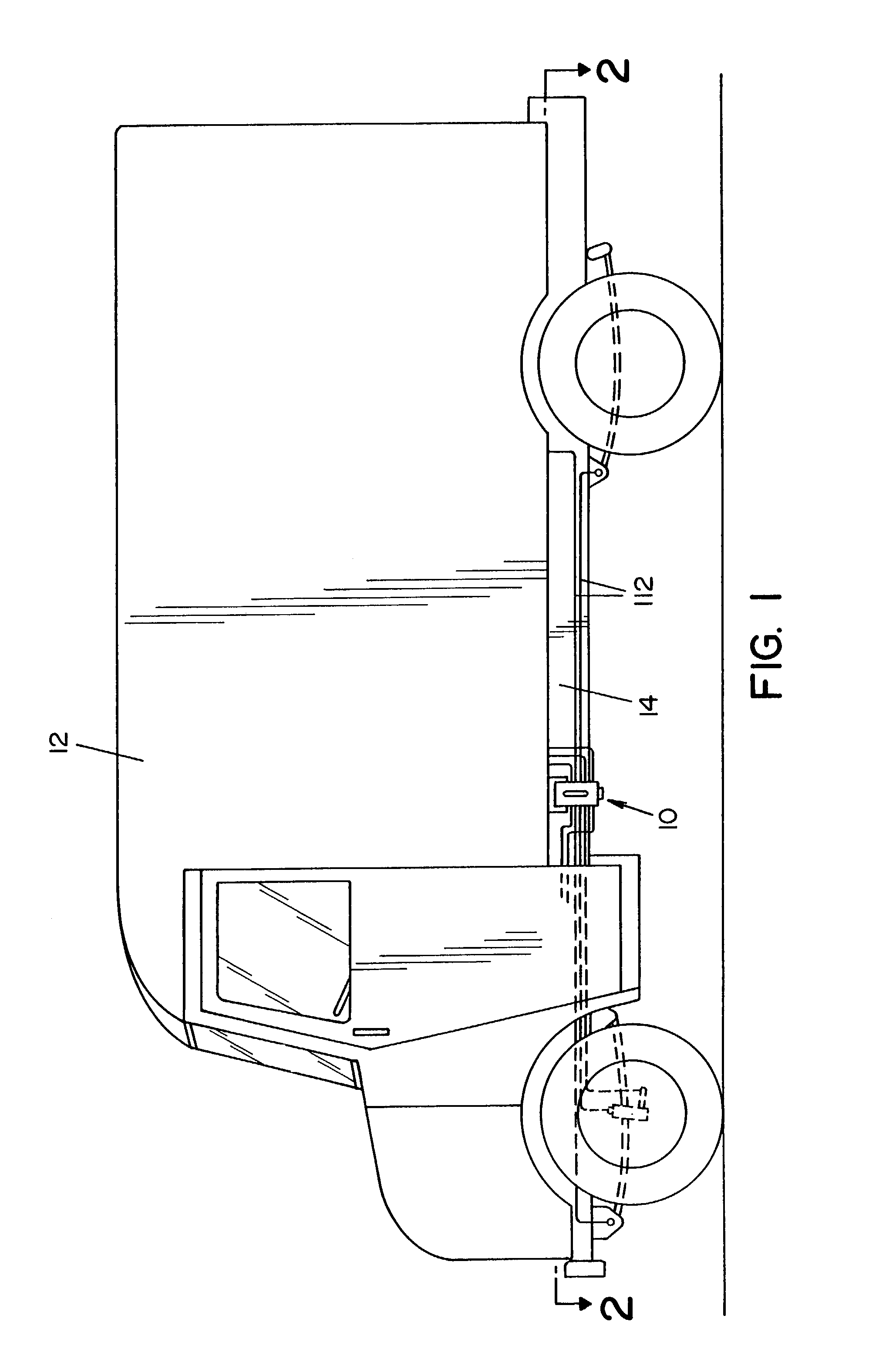

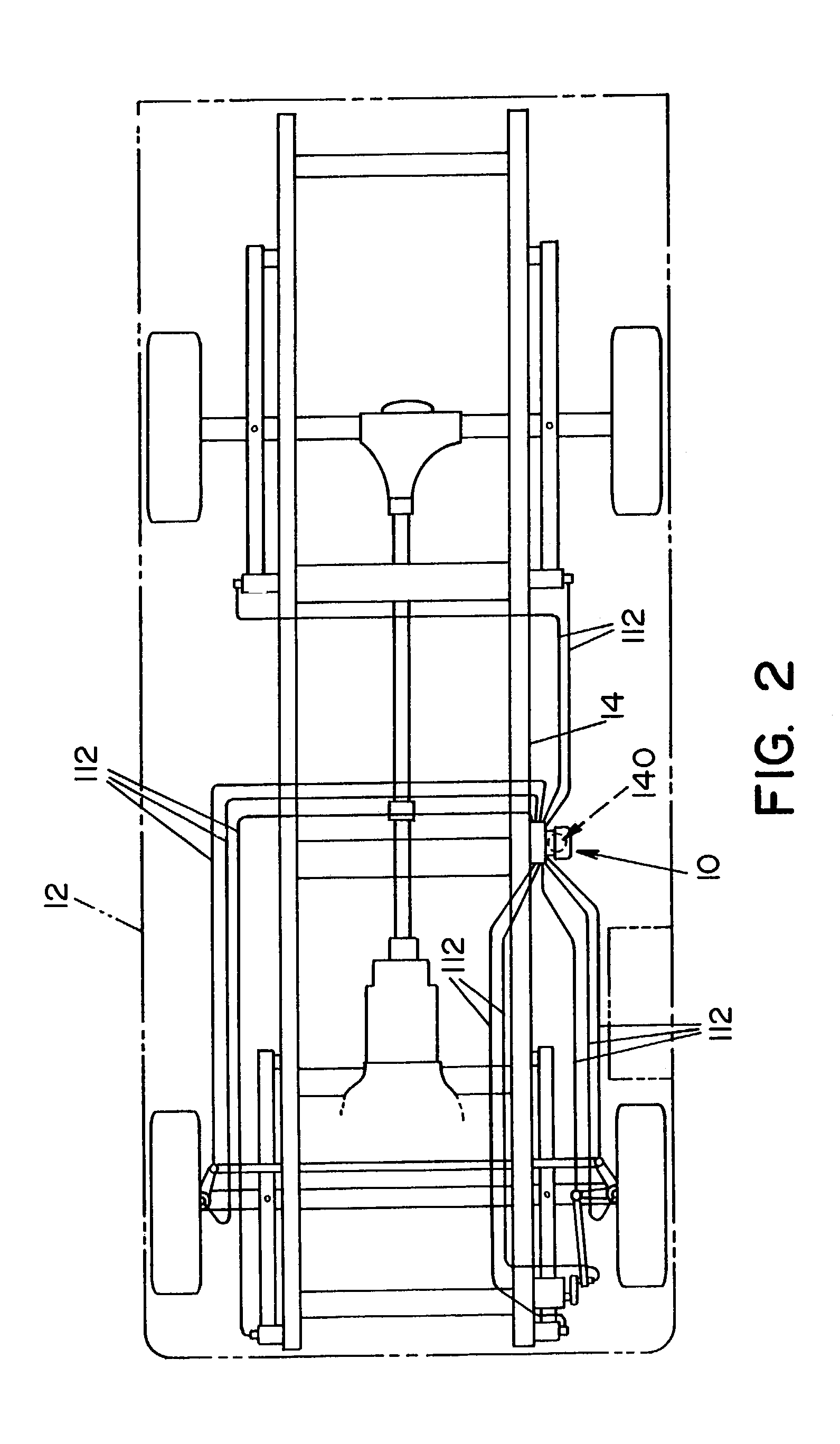

Automatic lubrication system

An automatic lubrication system for a vehicle, comprising a pump assembly having a plurality of outlet ports, a motor operable to drive the pump assembly, and a cartridge that is attachable to the pump assembly to provide a source of lubricant to the pump. The cartridge is removable from the pump assembly and has an interior space that is collapsible as lubricant is dispensed therefrom. A controller is provided to periodically initiate the motor to cause the pump to dispense lubricant to the outlet ports.

Owner:LIBRIQUIP INC

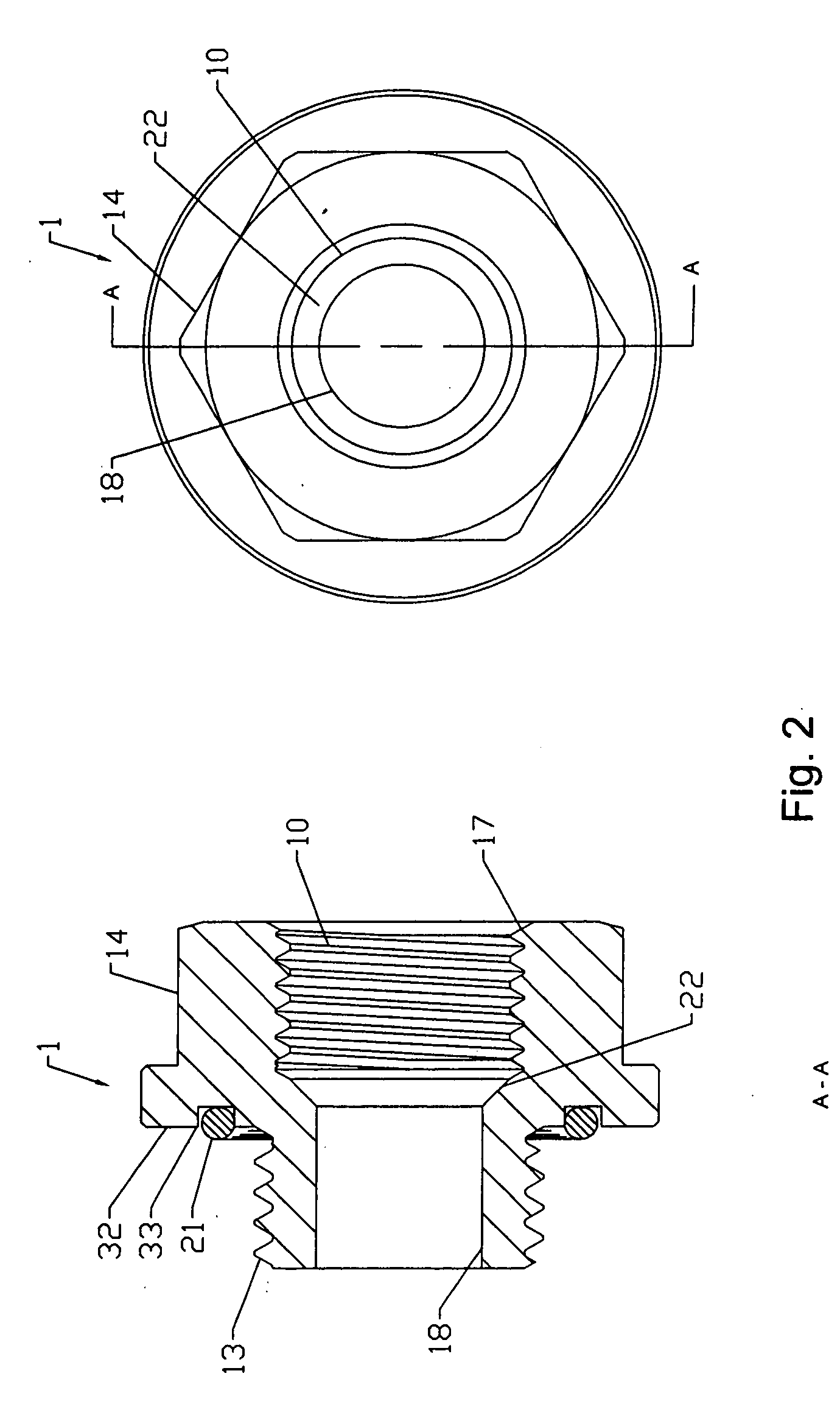

Gas intensifier with lubrication

InactiveUS20200040882A1Extended service lifeReduce decreasePositive displacement pump componentsFluid-pressure convertersLubricationPiston

A hydraulically driven intensifier for increasing pressure of gas comprising a piston-driven compression chamber for gas, operatively connected to an adjacent hydraulic chamber, with lubricant coupling in the compression chamber of the intensifier to circulate the lubricating fluid for cooling and lubricating the piston. A multistage compression system for gas, comprising the aforementioned intensifier, preferably several thereof operatively connected in series.

Owner:METENER OY

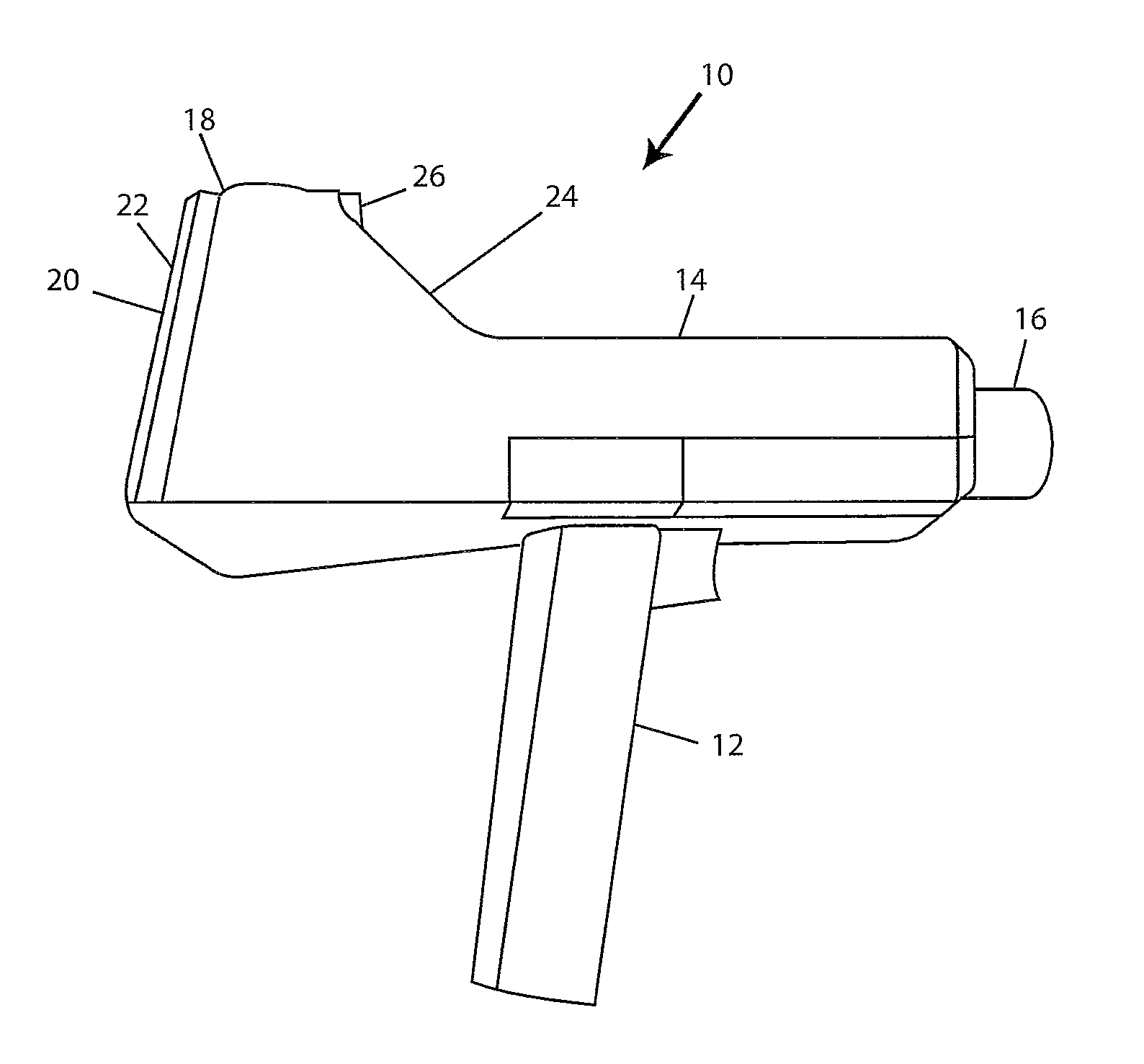

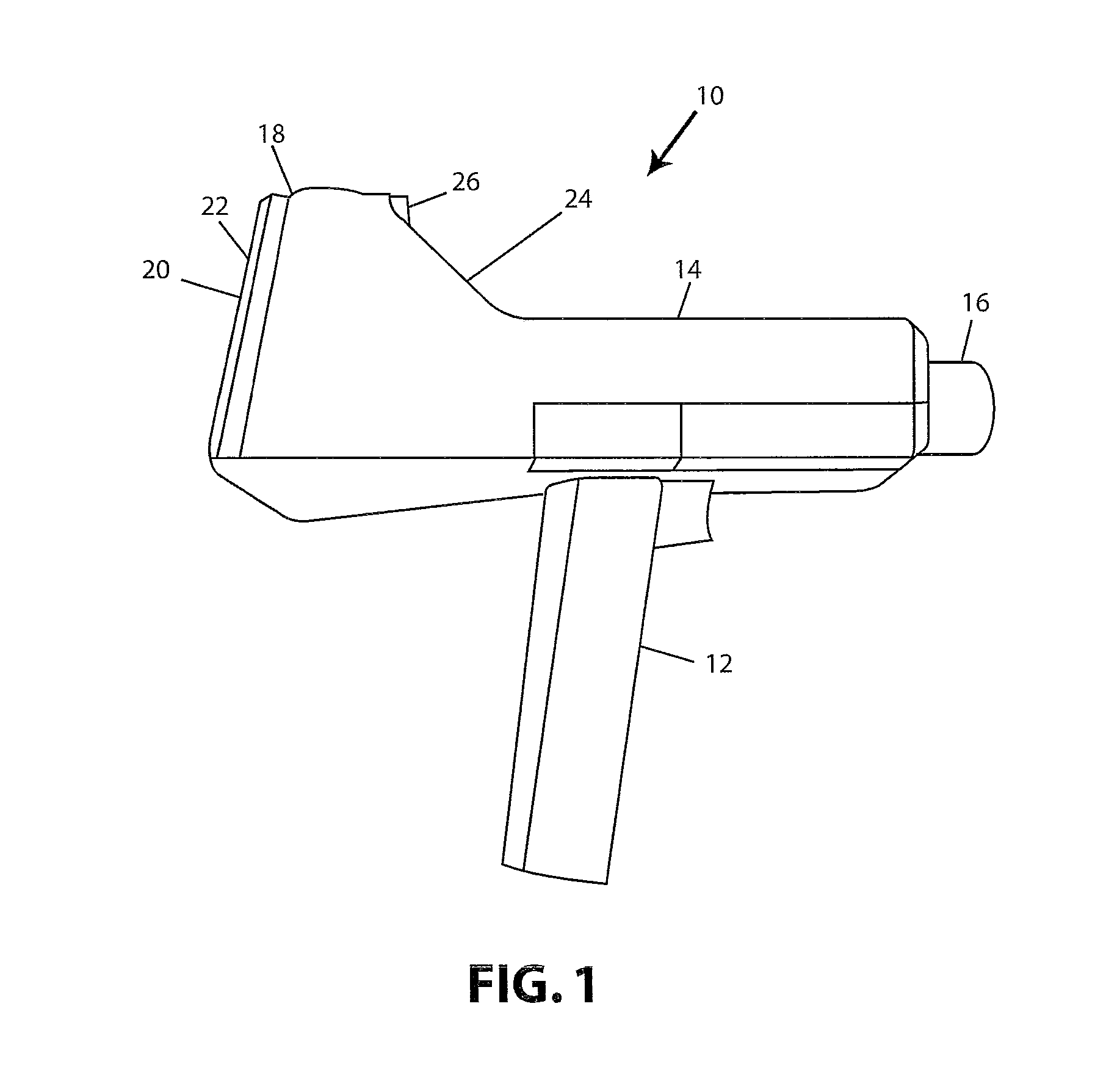

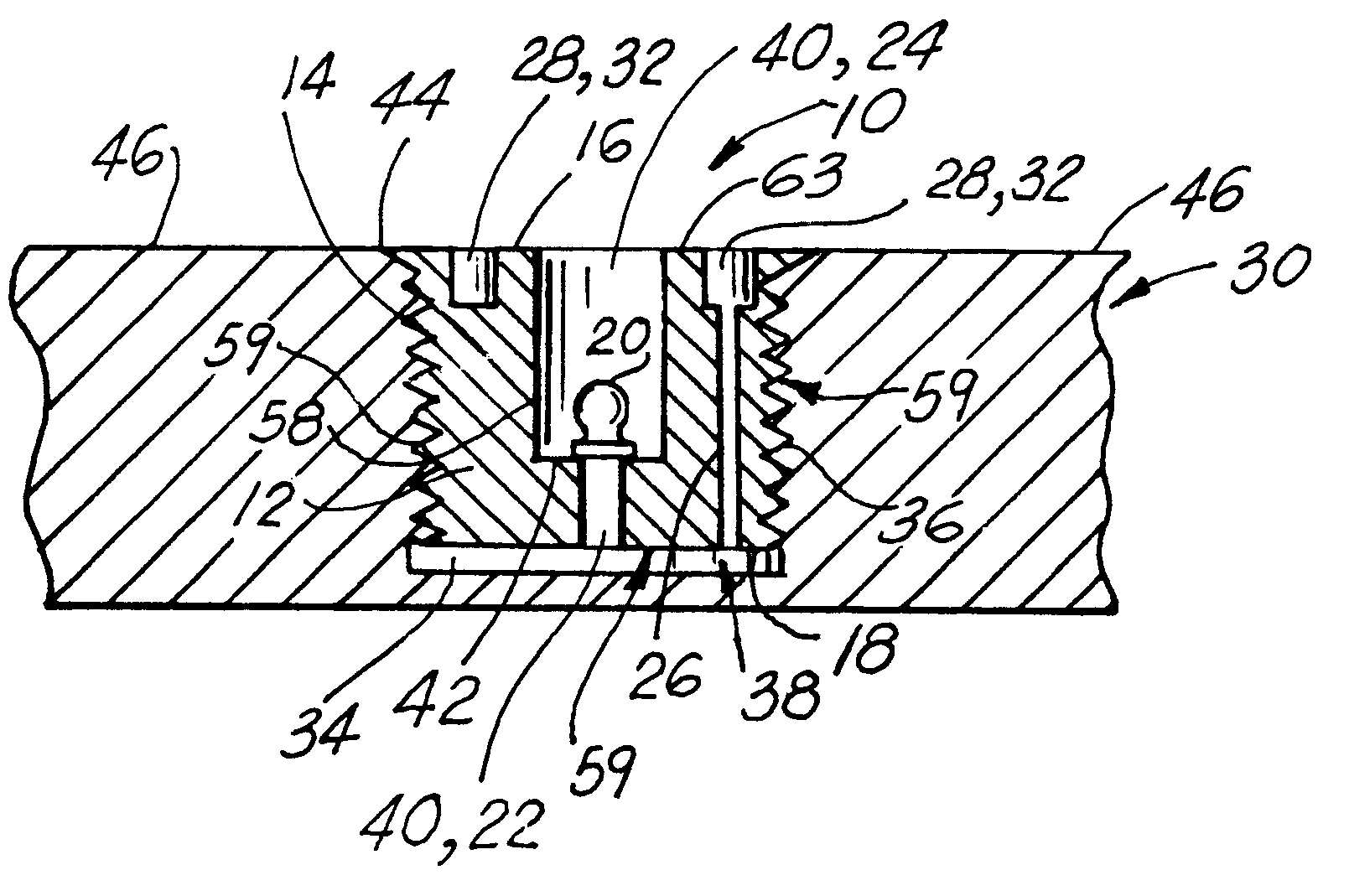

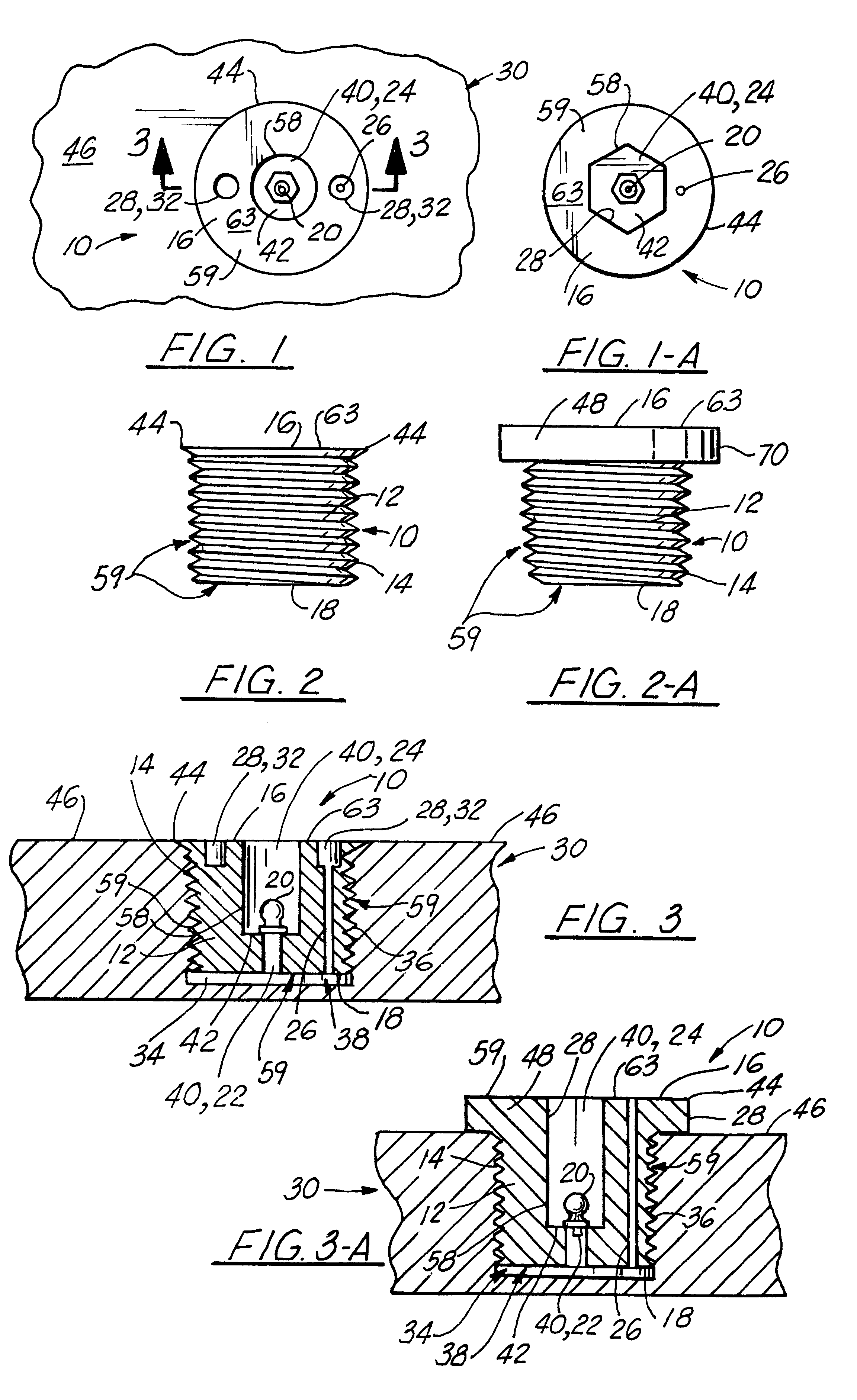

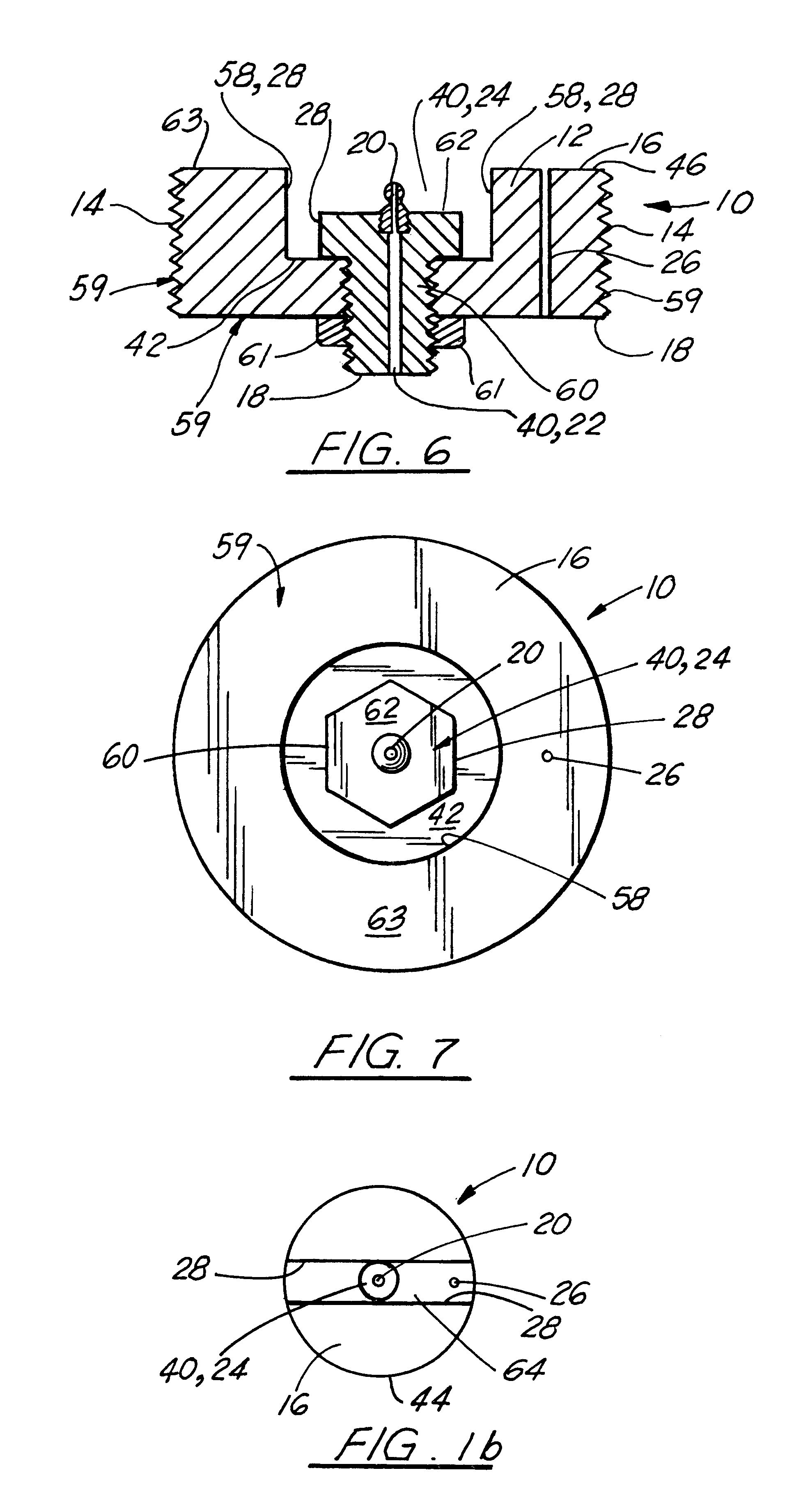

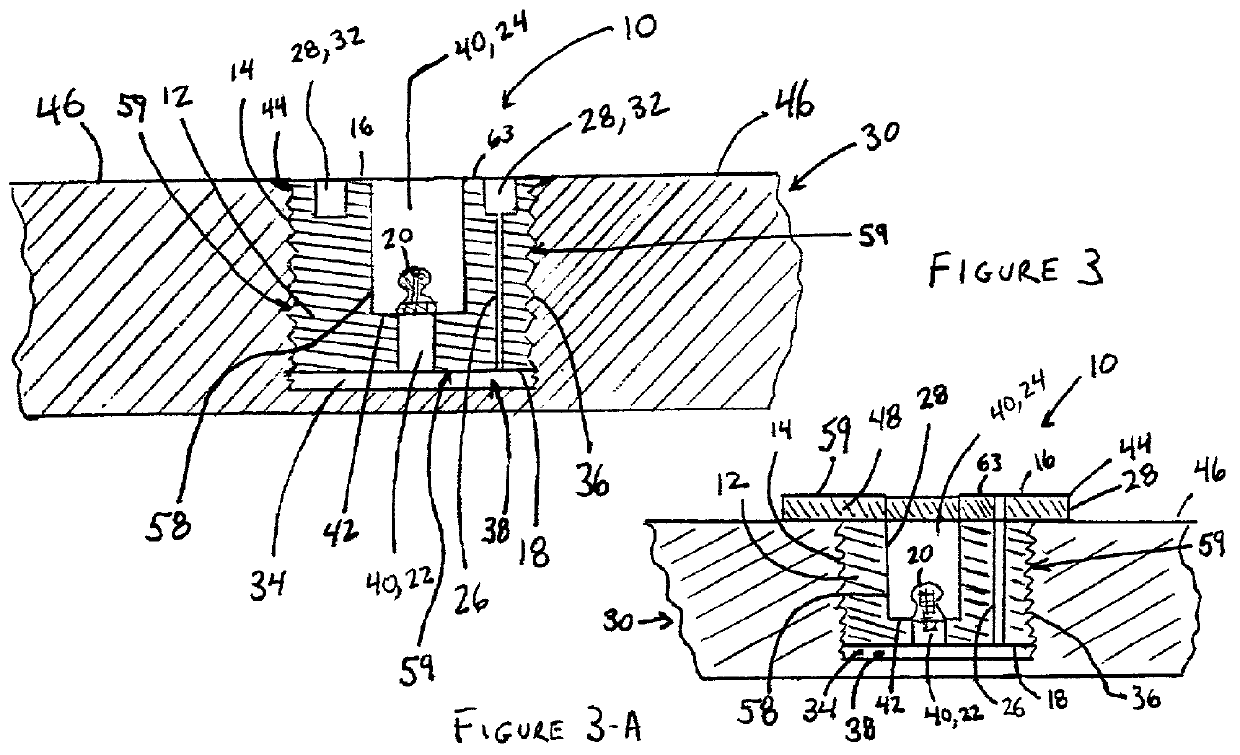

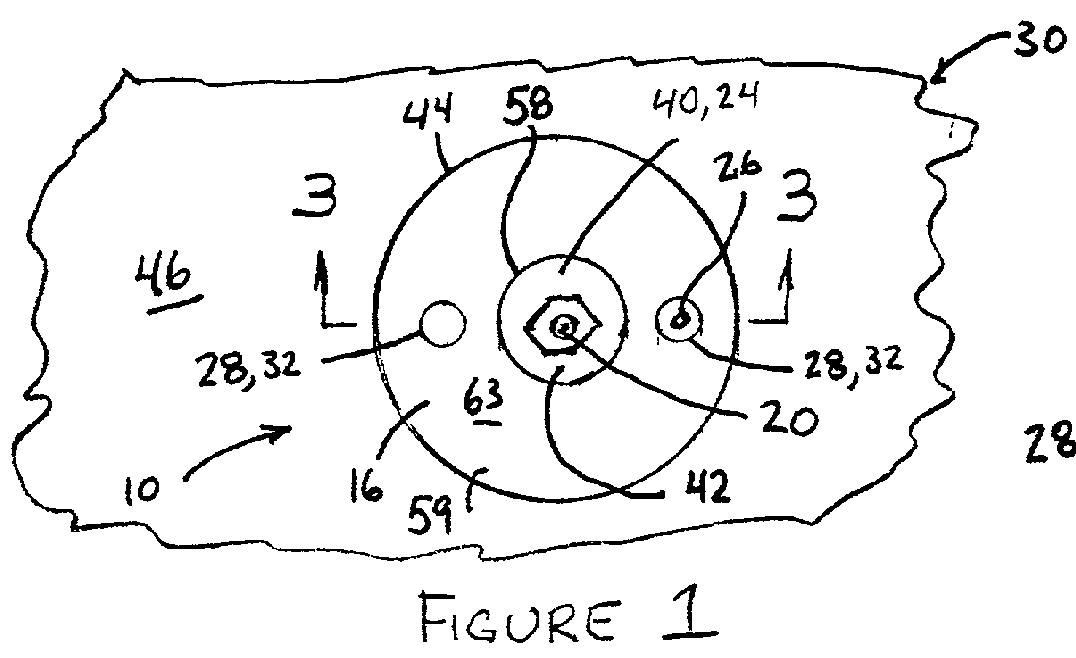

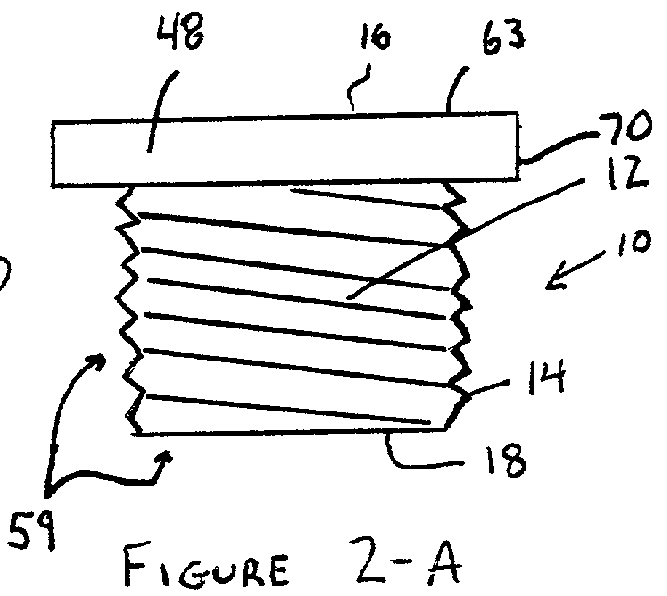

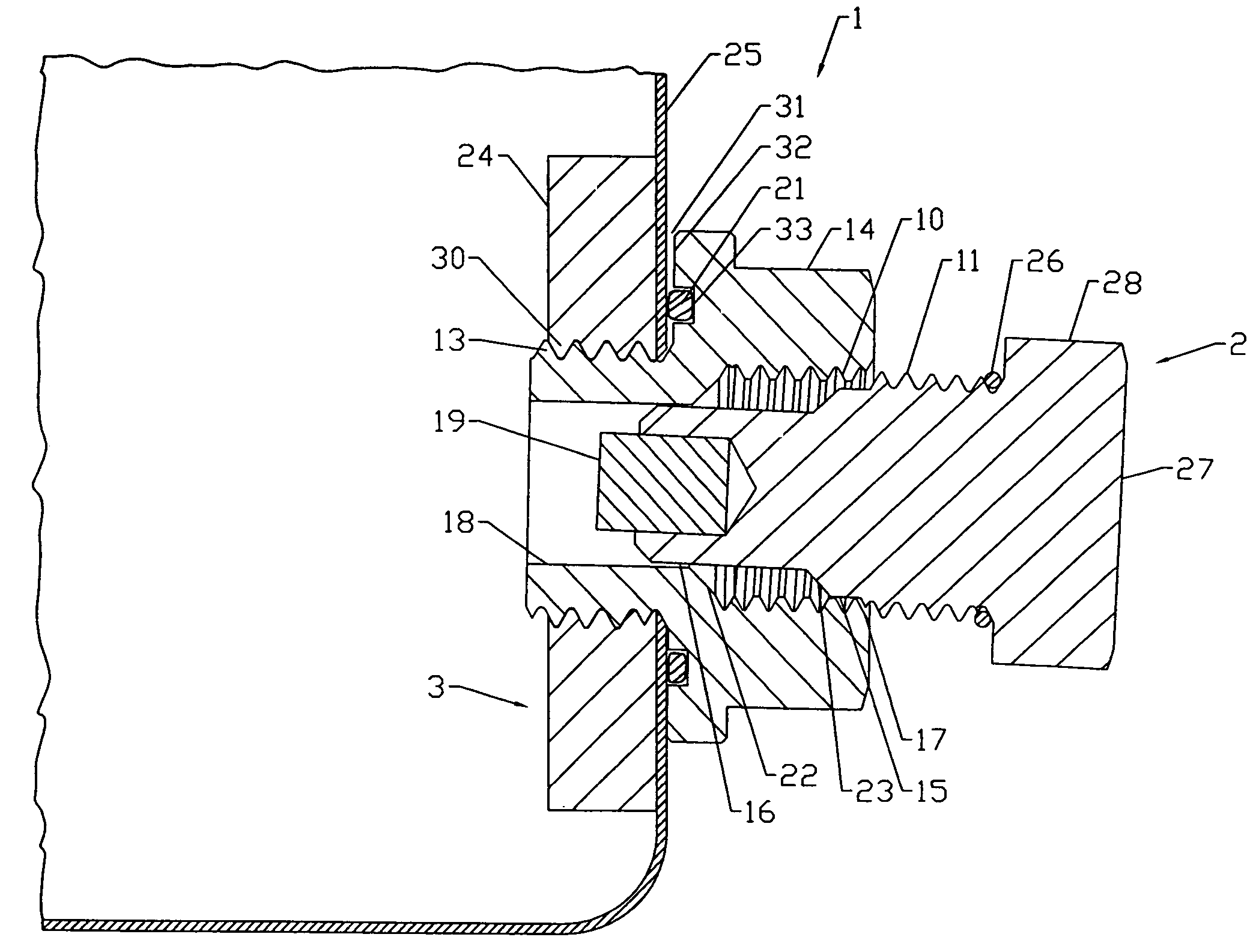

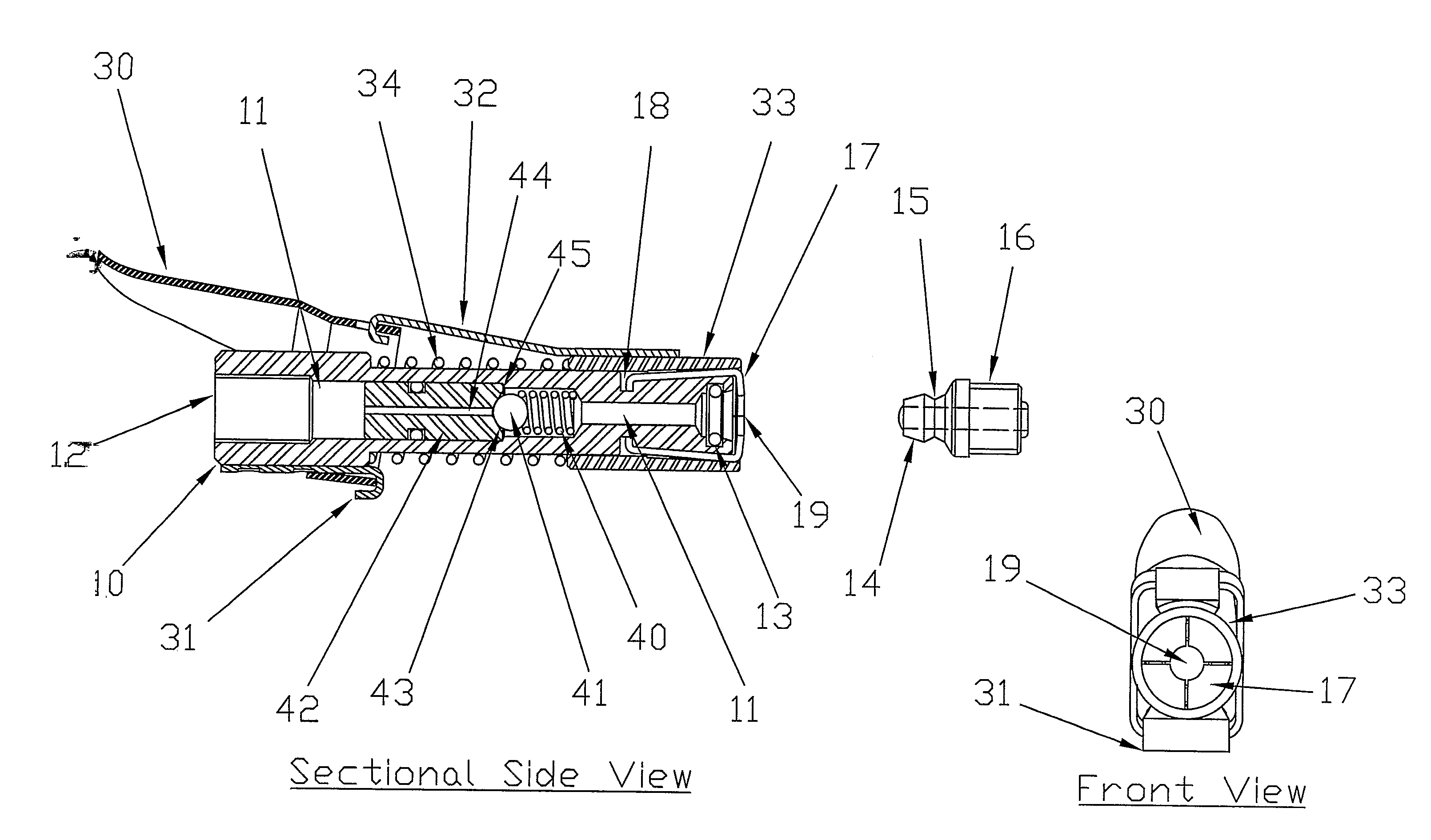

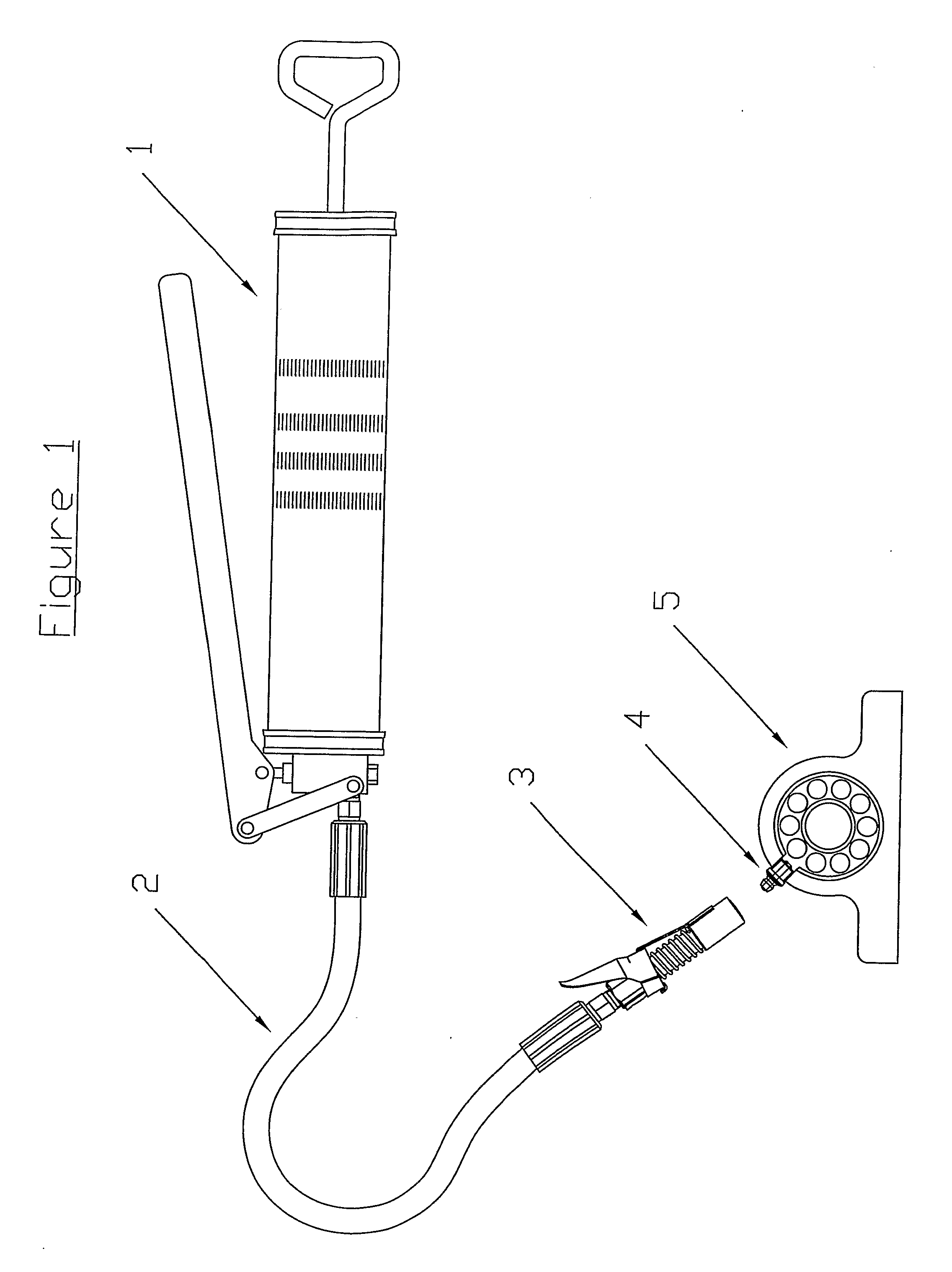

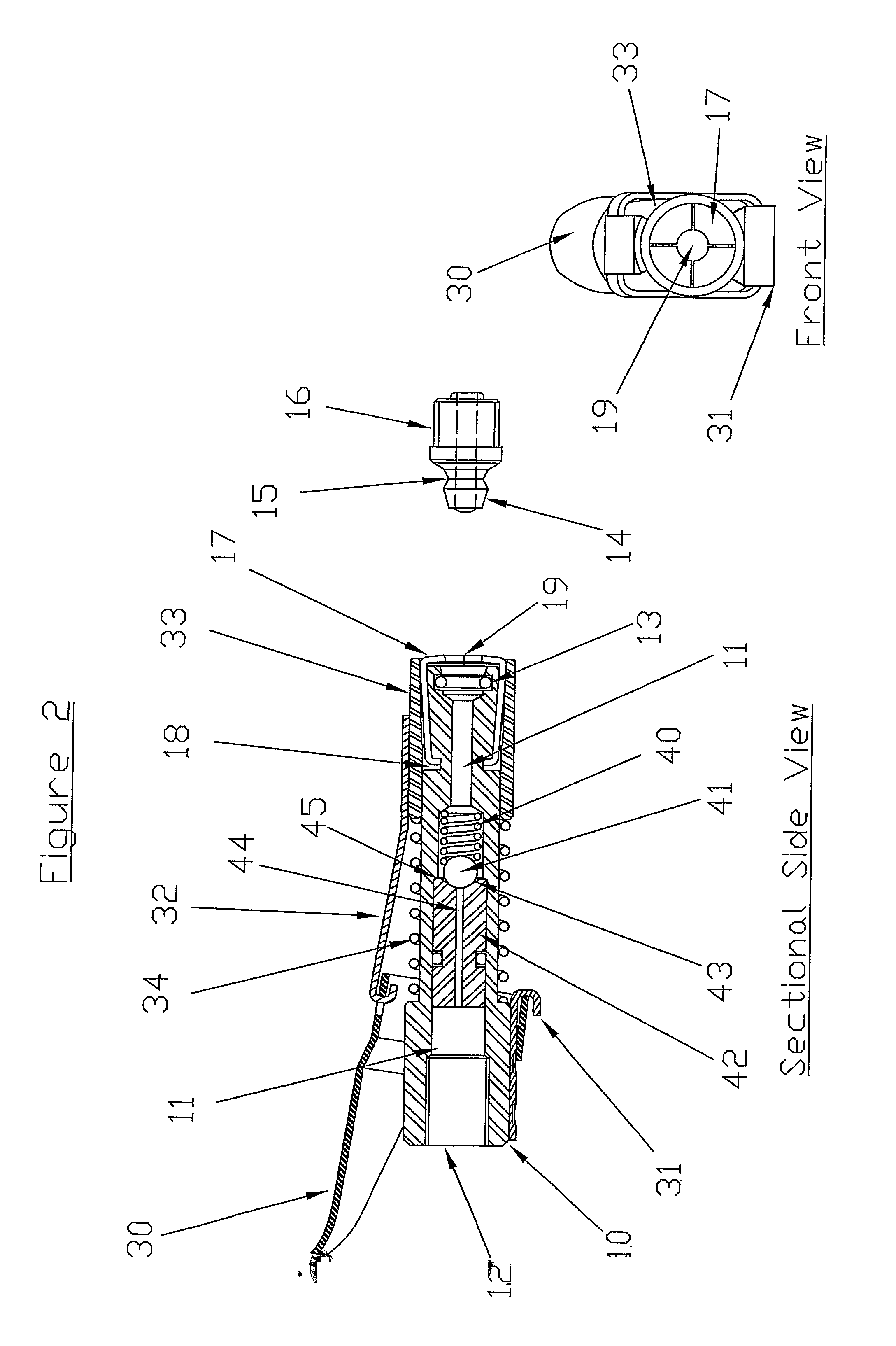

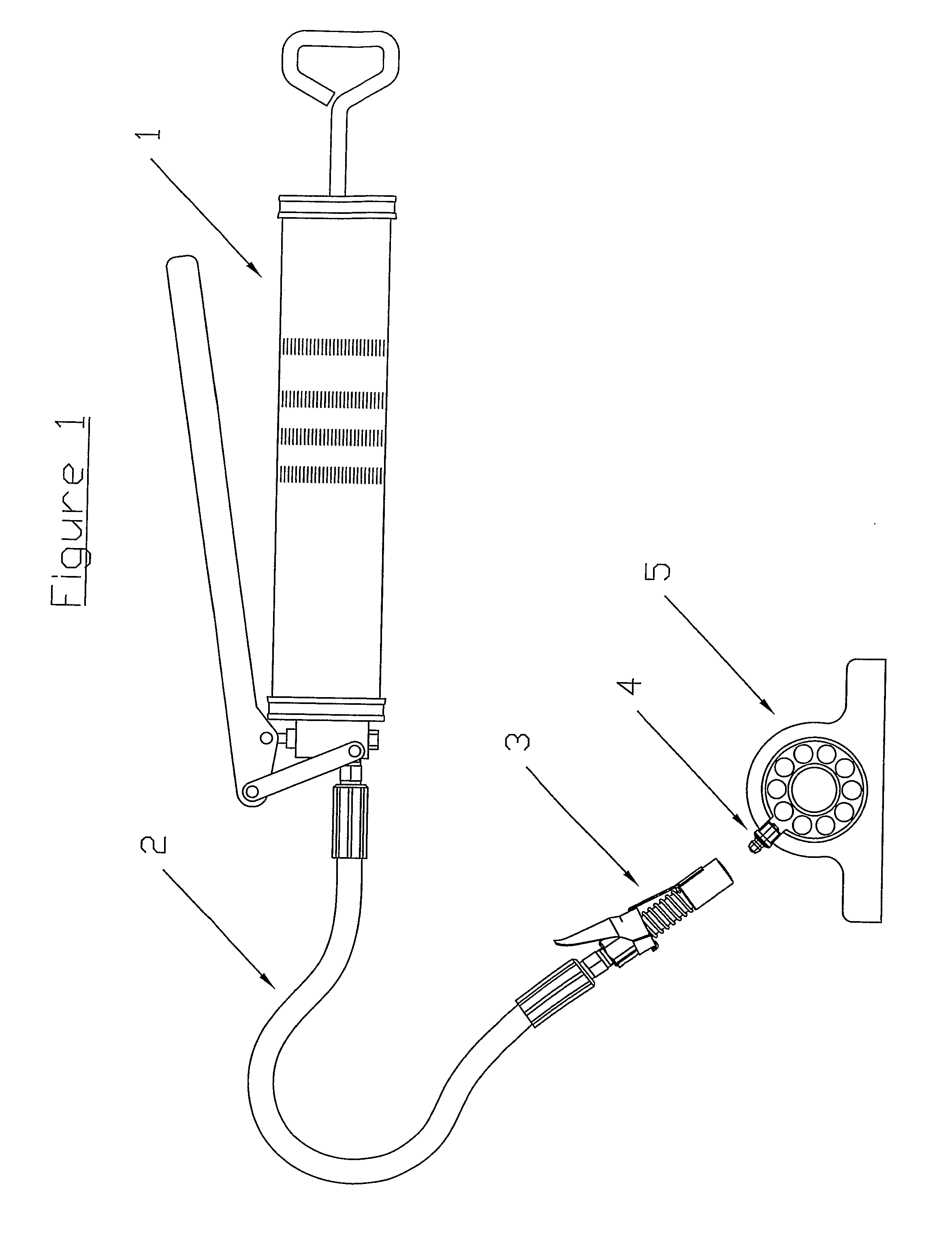

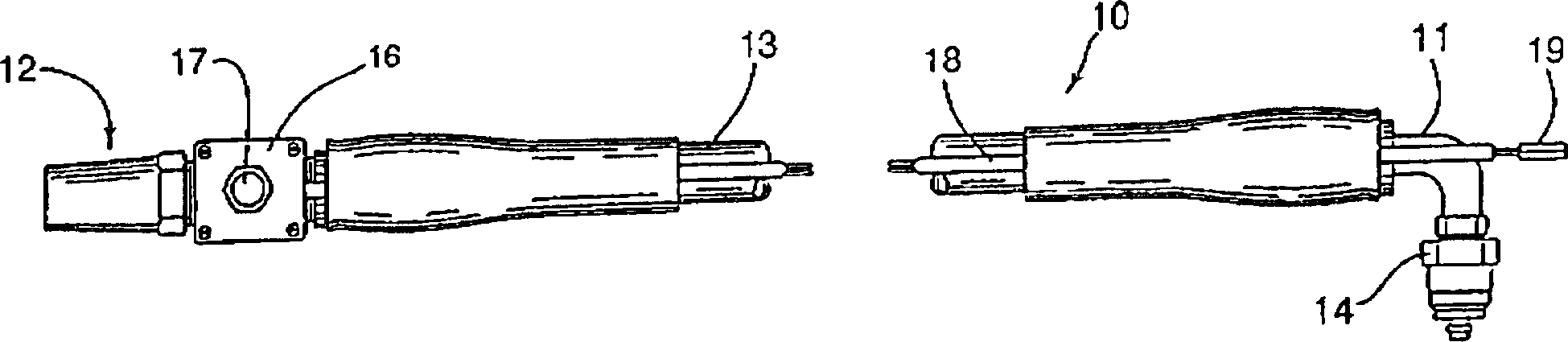

Grease coupler

ActiveUS20120267890A1Positively engageManual lubricationCheck valvesEngineeringMechanical engineering

An improved grease coupler 3 allows for positive, coupling and uncoupling from a grease nipple 4 via a manually operated trigger mechanism 30. The coupler includes a replaceable seal 13 and has an elongate body 10 with a grease passage 11 through the length of the body. A floating barrel plunger 42 acts as a check valve to prevent grease leaking from the discharge end of the elongate body 10 upon disconnection.

Owner:GURTECH

Grease coupler

An improved grease coupler 3 allows for positive, coupling and uncoupling from a grease nipple 4 via a manually operated trigger mechanism 30. The coupler includes a replaceable seal 13 and has an elongate body 10 with a grease passage 11 through the length of the body. A floating barrel plunger 42 acts as a check valve to prevent grease leaking from the discharge end of the elongate body 10 upon disconnection.

Owner:GURTECH

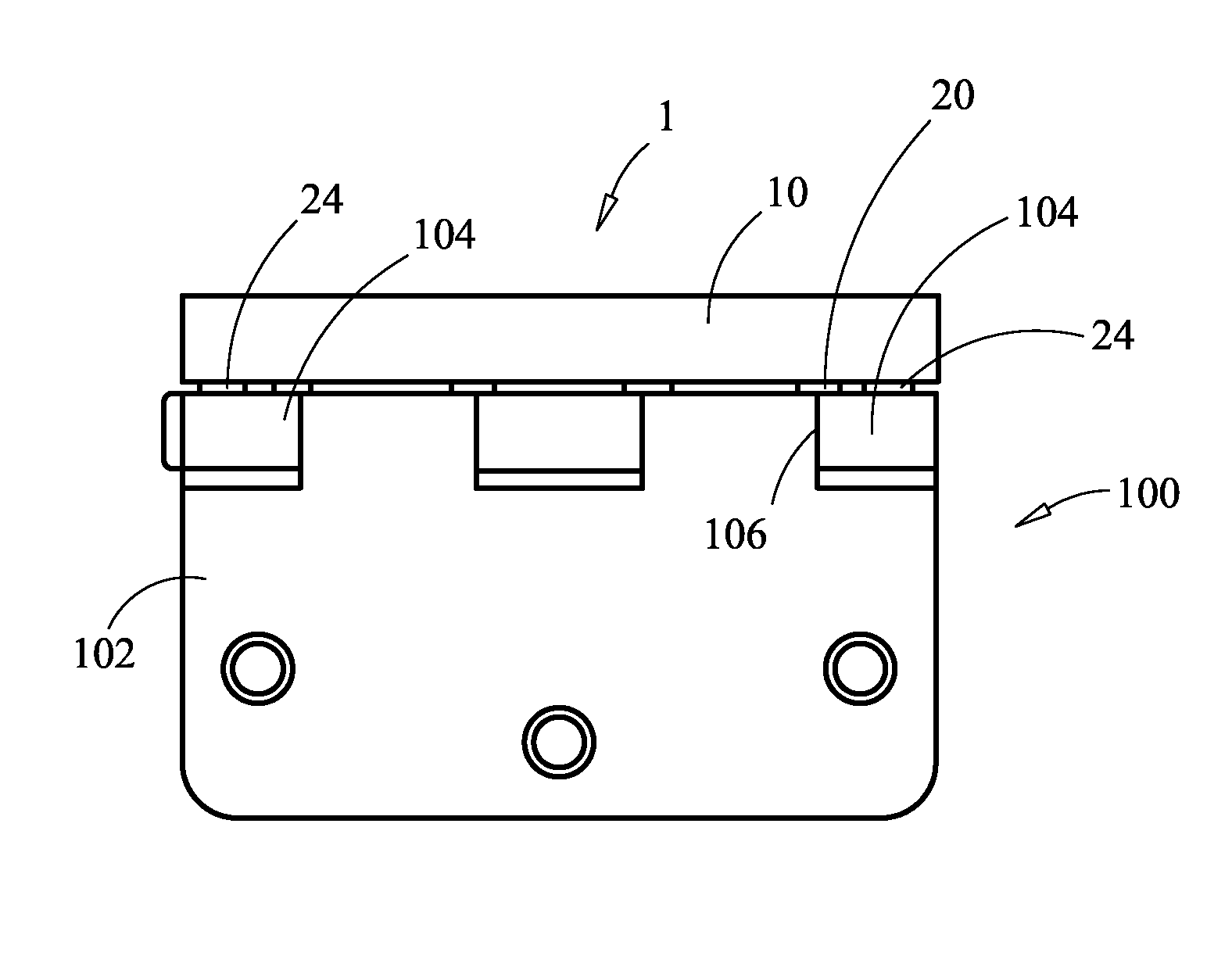

Door hinge lubricator

InactiveUS7703577B1Good adhesionEasy to disassembleWing accessoriesMachines/enginesLubricationLubricant

A door hinge lubricator includes a tube, a wicking material and at least one attachment device. At least one lubrication opening is formed through a wall of the tube. Each lubrication opening could be a hole or a slot. The wicking material is inserted into an inner perimeter of the tube. The wicking material is saturated with a lubricant, such as oil. Each end of the tube is sealed with an end plug or the like. The at least one attachment device is preferably attached substantially in-line with the at least one lubrication opening. It is preferable to place the single attachment device on each end of the tube. The door hinge lubricator is attached to one of the hinge plates, adjacent the hinge pin. Lubricant will be wicked into the joints between the opposing hinge plates. After a door hinge stops squeaking, the door hinge lubricator may be removed.

Owner:ZACH MARCO J +1

Battery powered grease gun with strain gauge based pressure transducer

InactiveUS20070137942A1Contracting/expanding measuring chambersLarge containersTransducerDisplay device

Owner:WEEMS IND INC

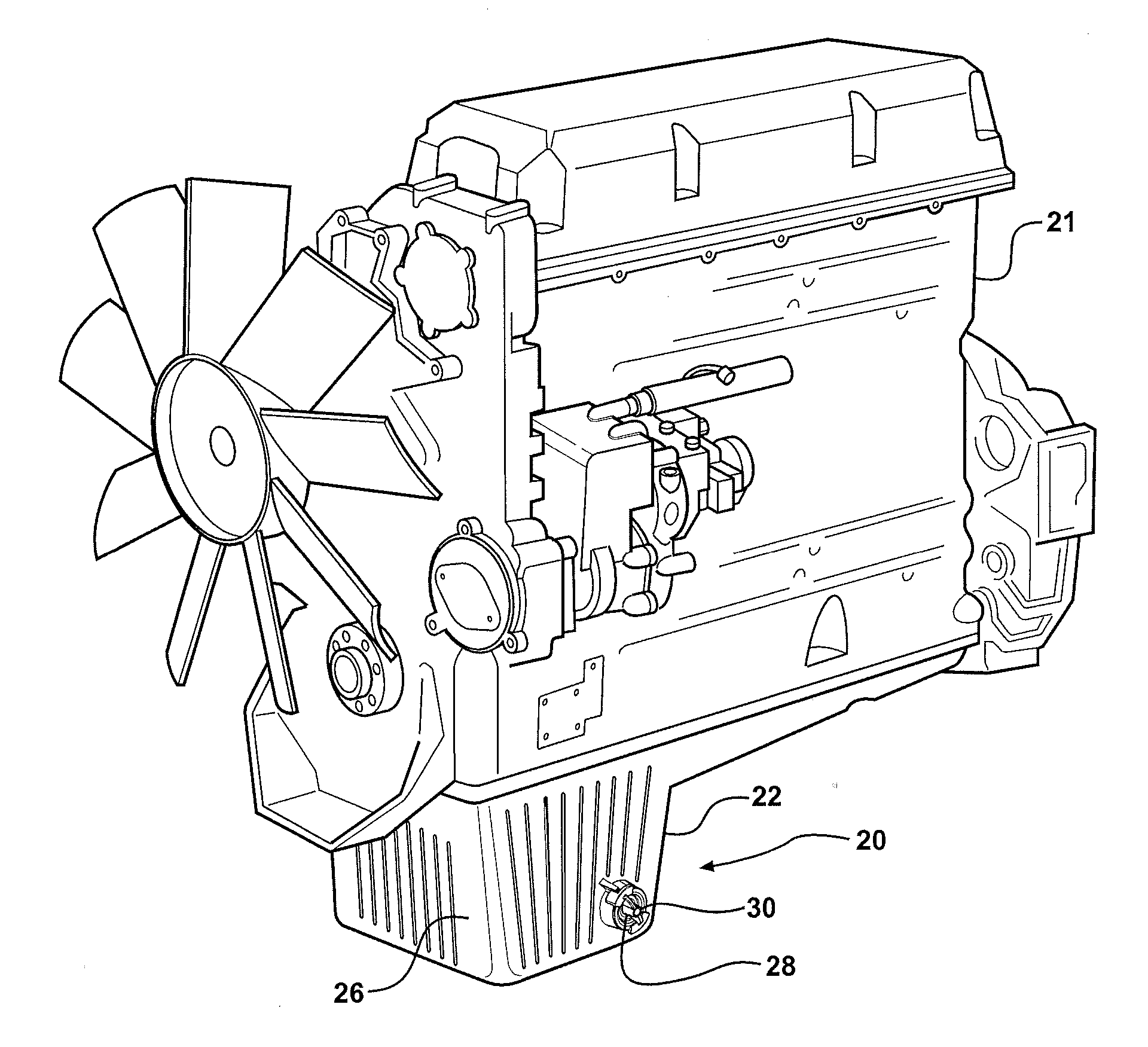

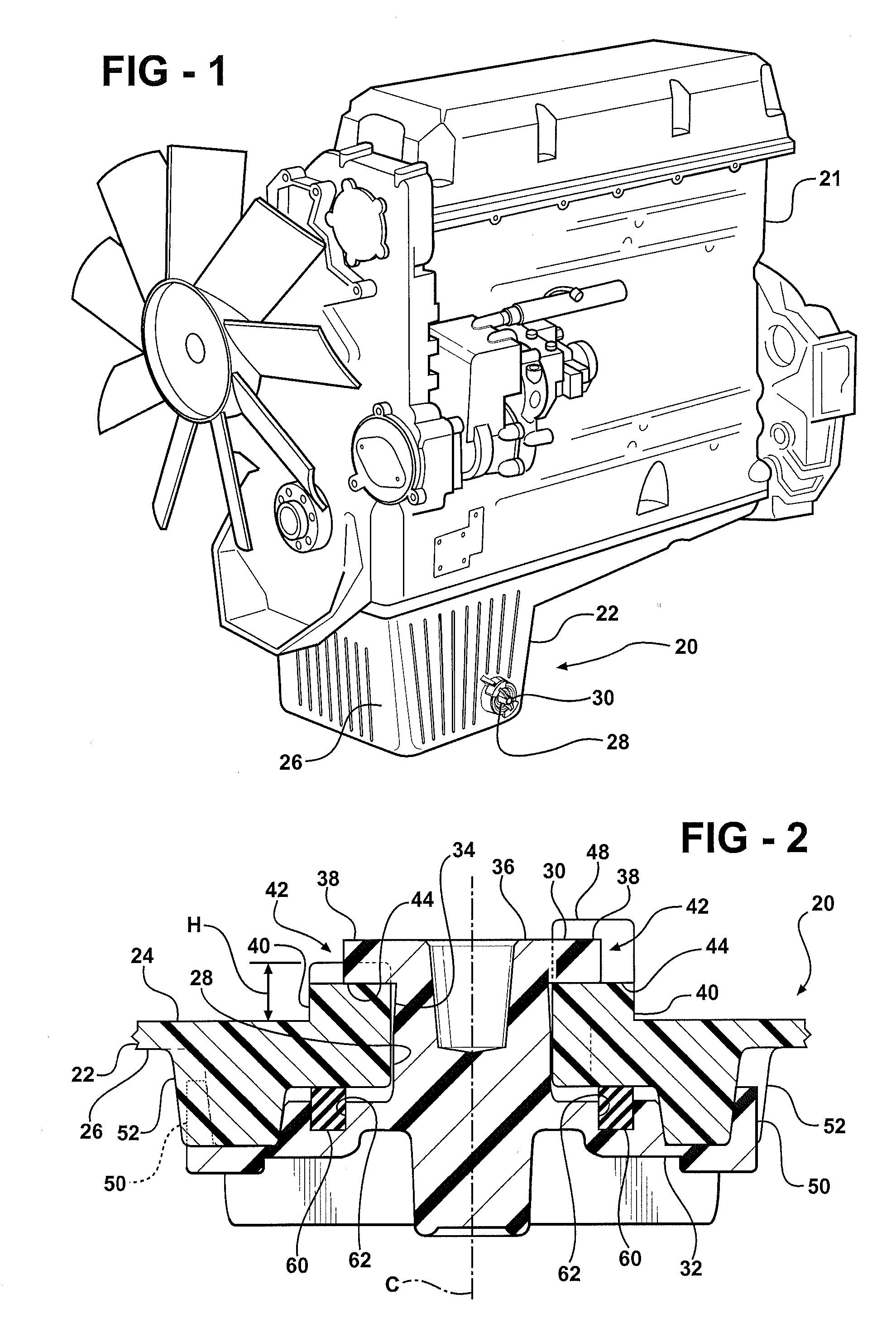

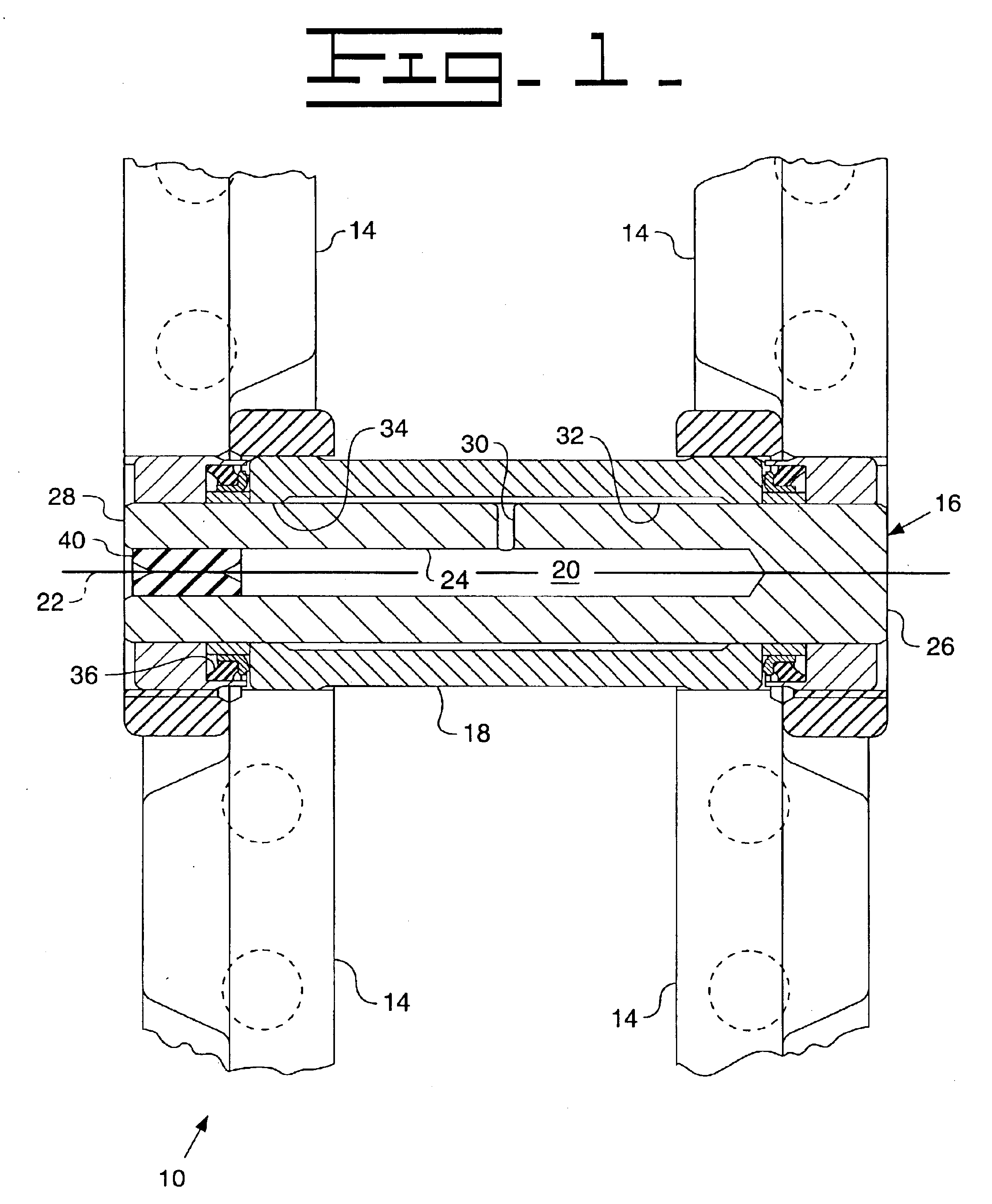

Externally serviceable transmission sump fill pipe and drain port assembly

ActiveUS20060037427A1Leakage problemImprove corrosion resistanceCrankshaftsGearboxesFuel tankAutomotive transmission

A transmission fluid sump for an automotive transmission comprising a reservoir portion, a threaded extension on the reservoir portion and a fill pipe threadably connected to the extension. A closure member seals a central opening in the extension independently of the fill pipe, thereby avoiding overlapping torque windows for the fill pipe and the closure member while providing a single leak flow path for the transmission fluid.

Owner:FORD GLOBAL TECH LLC

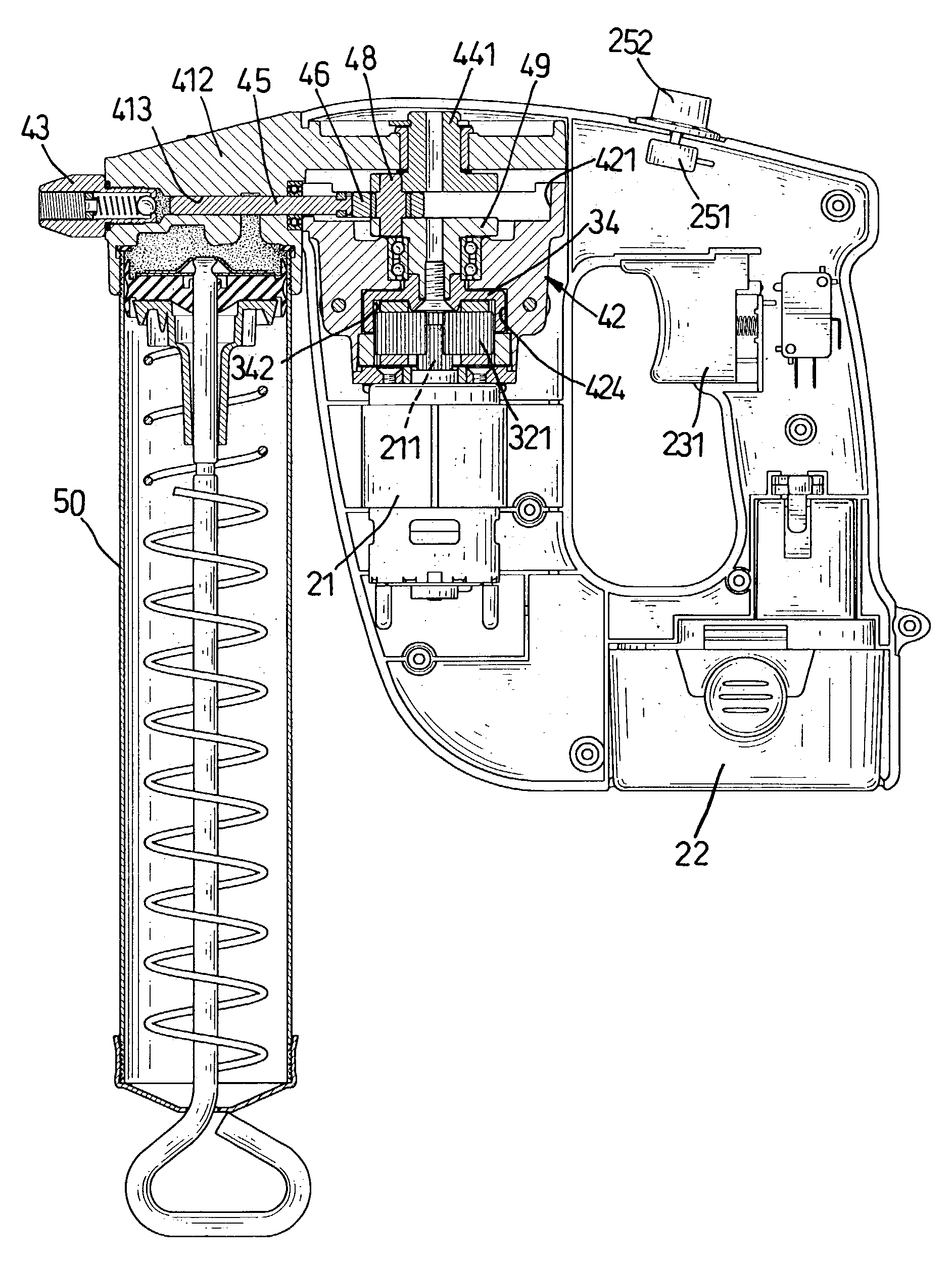

Battery-operated grease gun with an electronic pressure regulator for controlling pressure of the grease

InactiveUS7032713B2Effective controlLarge containersMachines/enginesControl theoryPressure regulator

A battery operated grease gun has a motor that drives a planetary gear assembly that is coupled to a pump assembly that drives a plunger reciprocally in an grease passage to discharge grease through a discharge spout. The pressure in the grease exerts a reaction force on the plunger that will change torque of the motor. The change of the torque of the motor will simultaneously effect voltage applied to the motor. When the voltage in the motor changes, an electronic pressure regulator measures the voltage in the motor to determine the pressure in the grease in the grease passage and stops the motor as the pressure in the grease reaches preset given valves in the pressure regulating device.

Owner:TECHWAY INDAL

Lubricant gun

A lubricant gun includes: a housing having a discharge spout and a longitudinal slide channel; a motor; a plunger disposed in the longitudinal slide channel to perform reciprocating movements; a power transmission unit driven by the motor to actuate the plunger, and including a crank connected to the plunger; a moving element movable along with the crank and the plunger to perform a cycle motion; a sensor mounted proximate to a moving path of the moving element to detect the moving element whenever the moving element moves past the sensor, and to generate a signal representative of a number of the cycle motions performed by the moving element; a processing unit connected to the sensor to produce information according to the signal generated by the sensor; and a display unit displaying the information produced by the processing unit.

Owner:TECHWAY INDAL

Replaceable lubricating oil applying device for bearing

The invention provides a replaceable lubricating oil applying device for a bearing. The replaceable lubricating oil applying device comprises a lubricating oil applying box, a sliding rod, a sliding sleeve, a negative-pressure fan and power source chamber, an oil storing box, a ventilating pipe and a bearing placing plate. The replaceable lubricating oil applying device disclosed by the invention can limit the movements of the bearing, and avoids the situation that the position of the bearing is changed in the lubricating oil applying process, so that the lubricating oil applying is non-uniform; an oil outlet pipe rotates applying the lubricating oil, so that the lubricating oil applying is uniform, environmental pollution caused by the outside splashing of the lubricating oil can be avoided, the redundant lubricating oil returns to an oil returning box through grid holes and oil leaking holes, the recovery of the redundant lubricating oil is realized, and the cost is greatly reduced; the replaceable lubricating oil applying device disclosed by the invention is simple in structure, a plurality of the bearings can be applied at the same time because a plurality of bearing placing blocks are arranged, so that the operating efficiency is improved in multiples, the economic cost is reduced, and the labor intensity of a worker is alleviated; the lubricating oil applying device is replaceable and can apply the bearings in different types and sizes, so that the economic benefits are good.

Owner:XINCHANG COUNTY SANHE BEARING

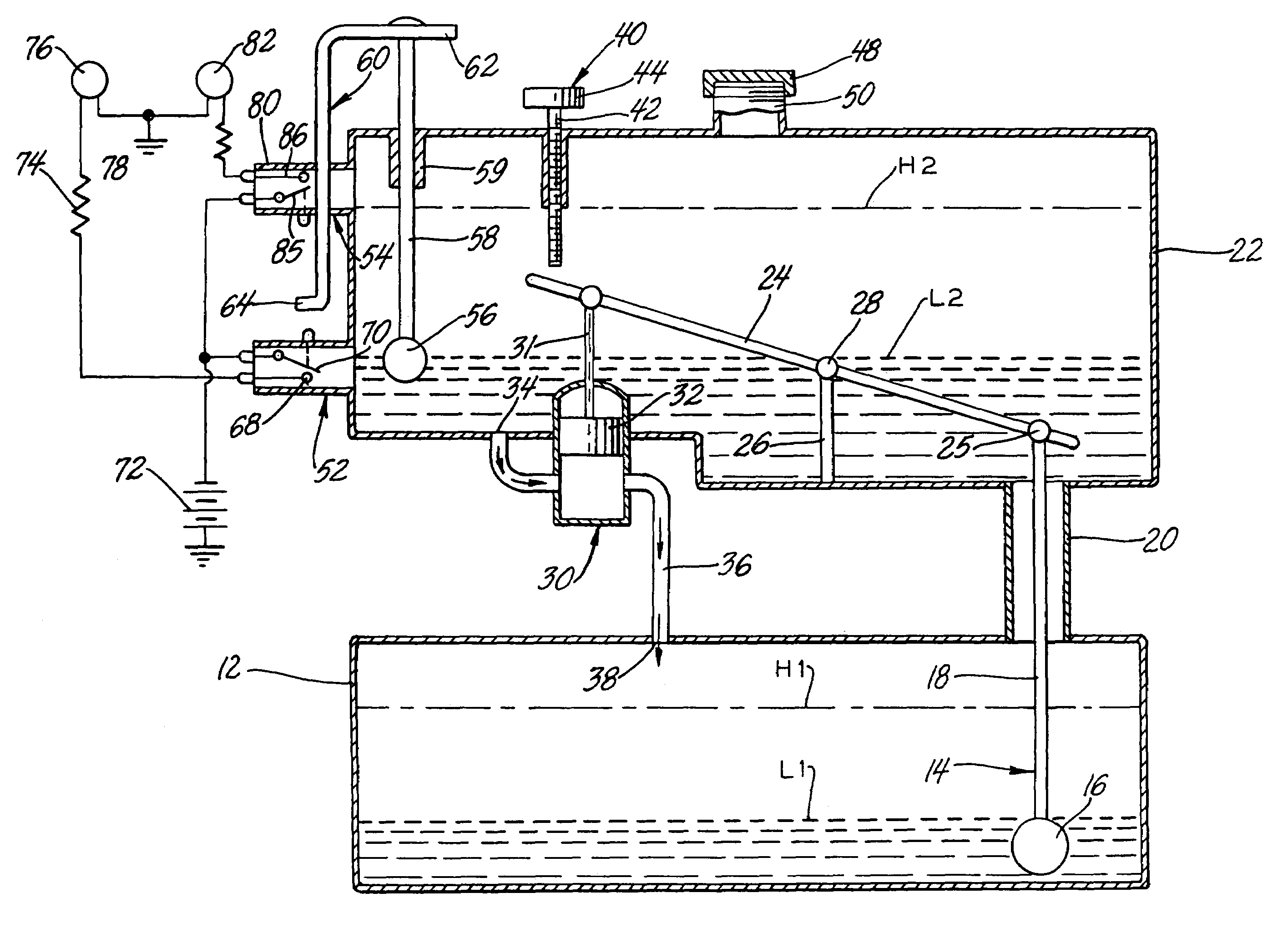

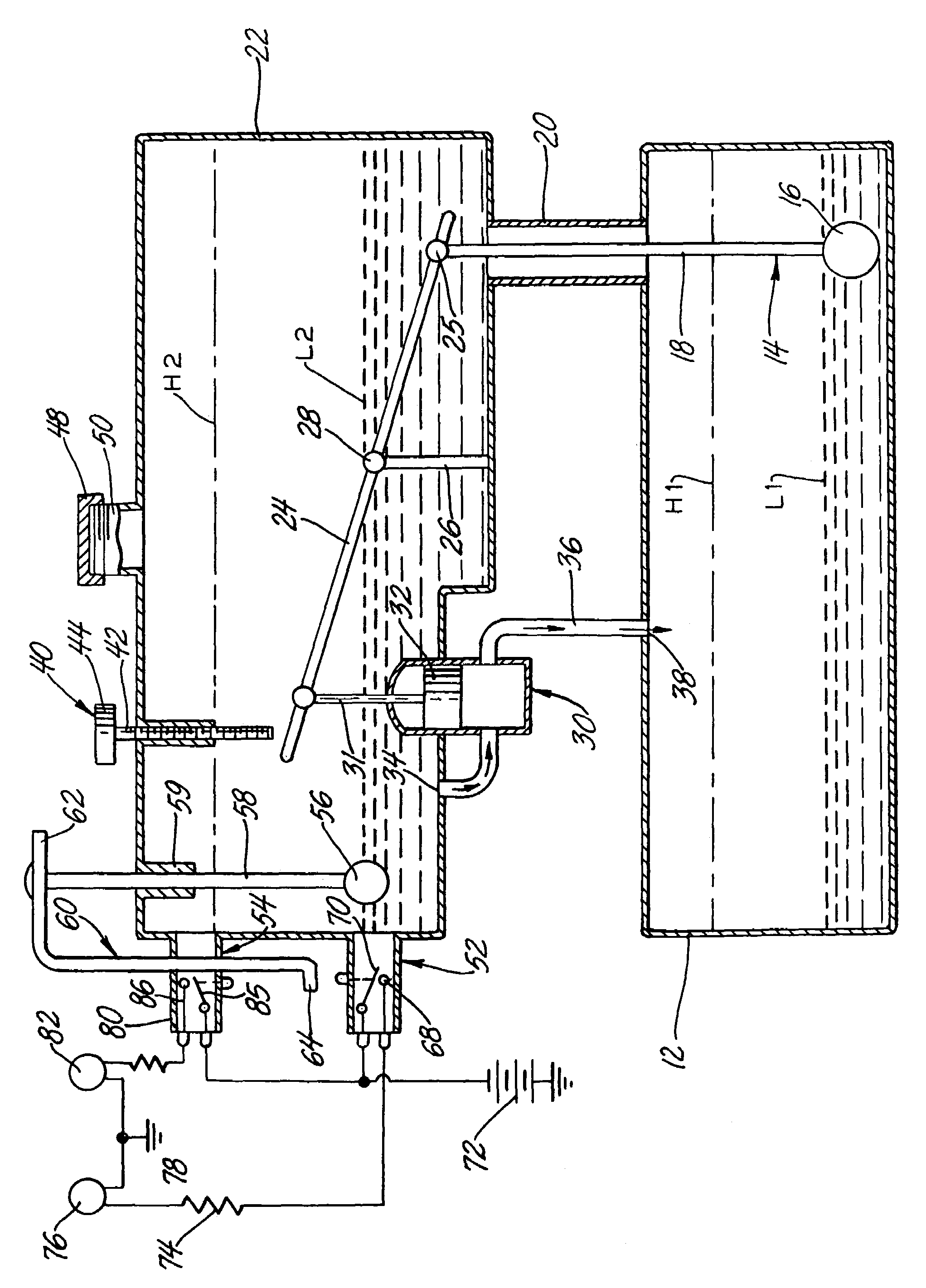

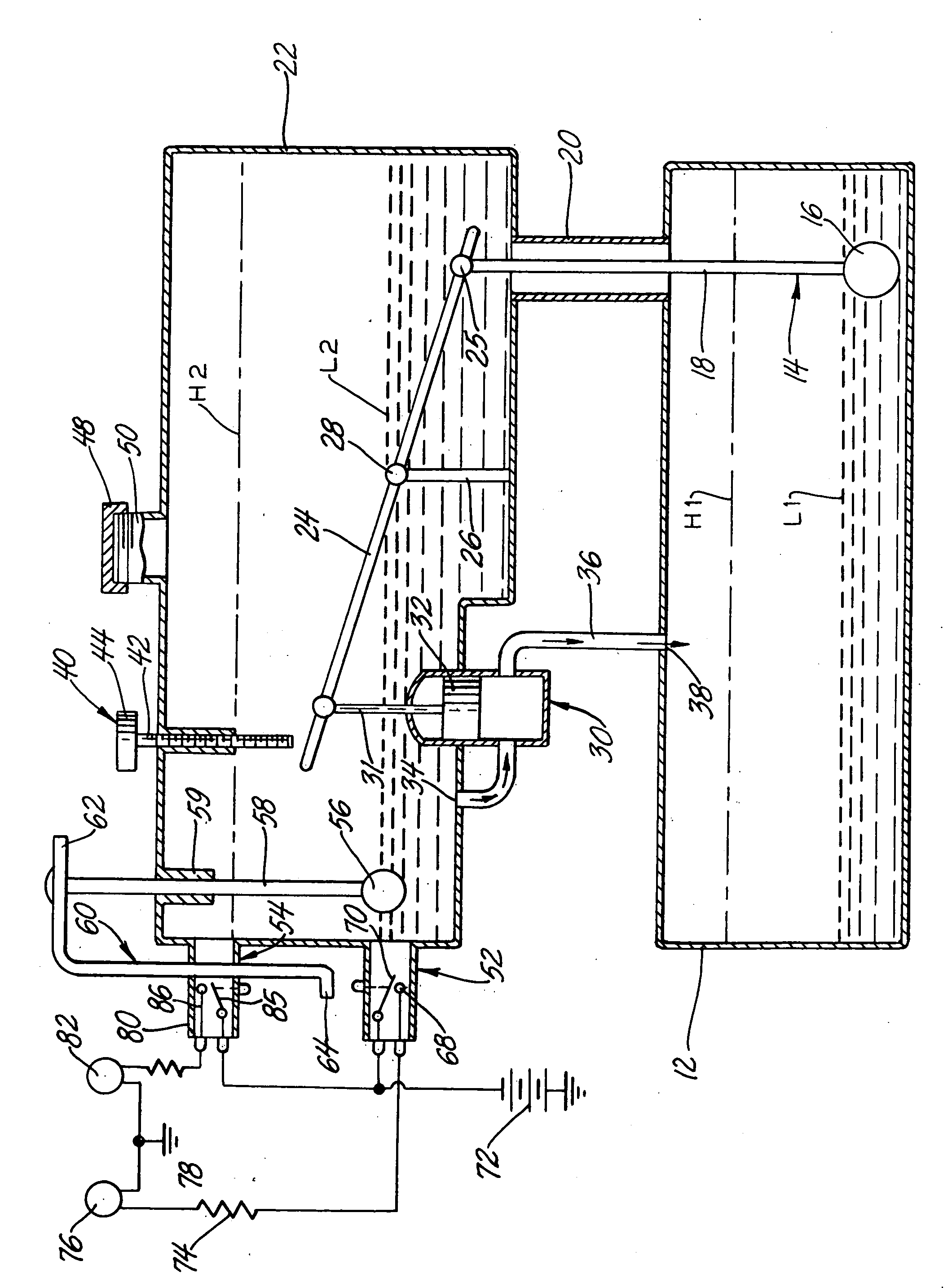

Electronic oil level detection and replacement system

An oil level monitoring and replenishment system for use with an internal combustion engine having an oil sump. The system as a sensor which continuously measures the sump level in the reservoir for holding a quantity of oil to be used in replenishment of the sump. A sensor monitors the oil level in the sump and causes replenishment from the reservoir when needed. The reservoir has warning circuit interactive with a reservoir sensor to signal from the reservoir has reached a lower level of oil and requires the filling. The sensor also provides means to signal when the reservoir has been filled to the desired level to prevent overfilling.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Oil-guiding shaft

Owner:ZF FRIEDRICHSHAFEN AG

Electronic oil level detection and replacement system

an oil level monitoring and replenishment system for use with an internal combustion engine having an oil sump. The system as a sensor which continuously measures the sump level in the reservoir for holding a quantity of oil to be used in replenishment of the sump. A sensor monitors the oil level in the sump and causes replenishment from the reservoir when needed. The reservoir has warning circuit interactive with a reservoir sensor to signal from the reservoir has reached a lower level of oil and requires the filling. The sensor also provides means to signal when the reservoir has been filled to the desired level to prevent overfilling.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

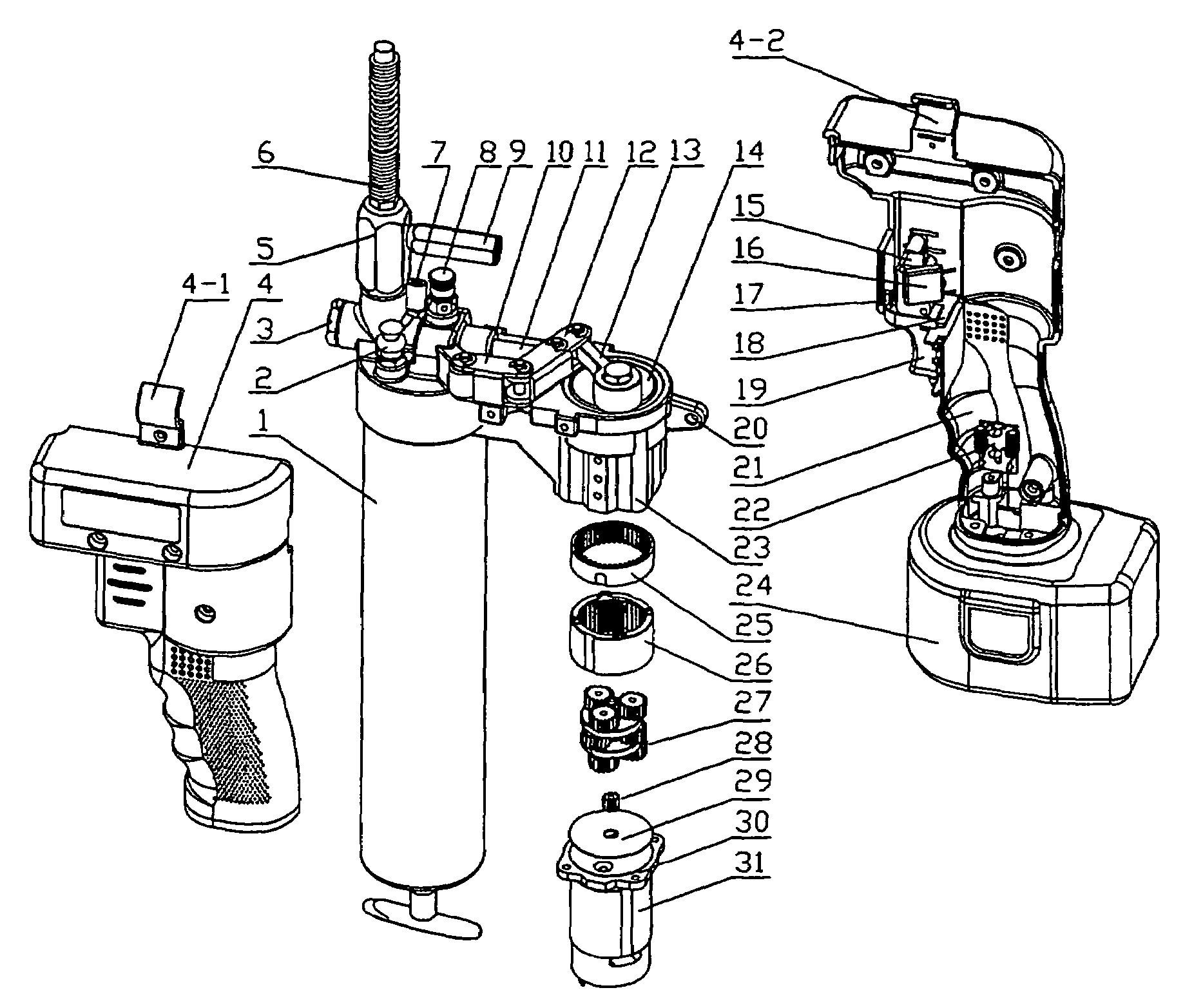

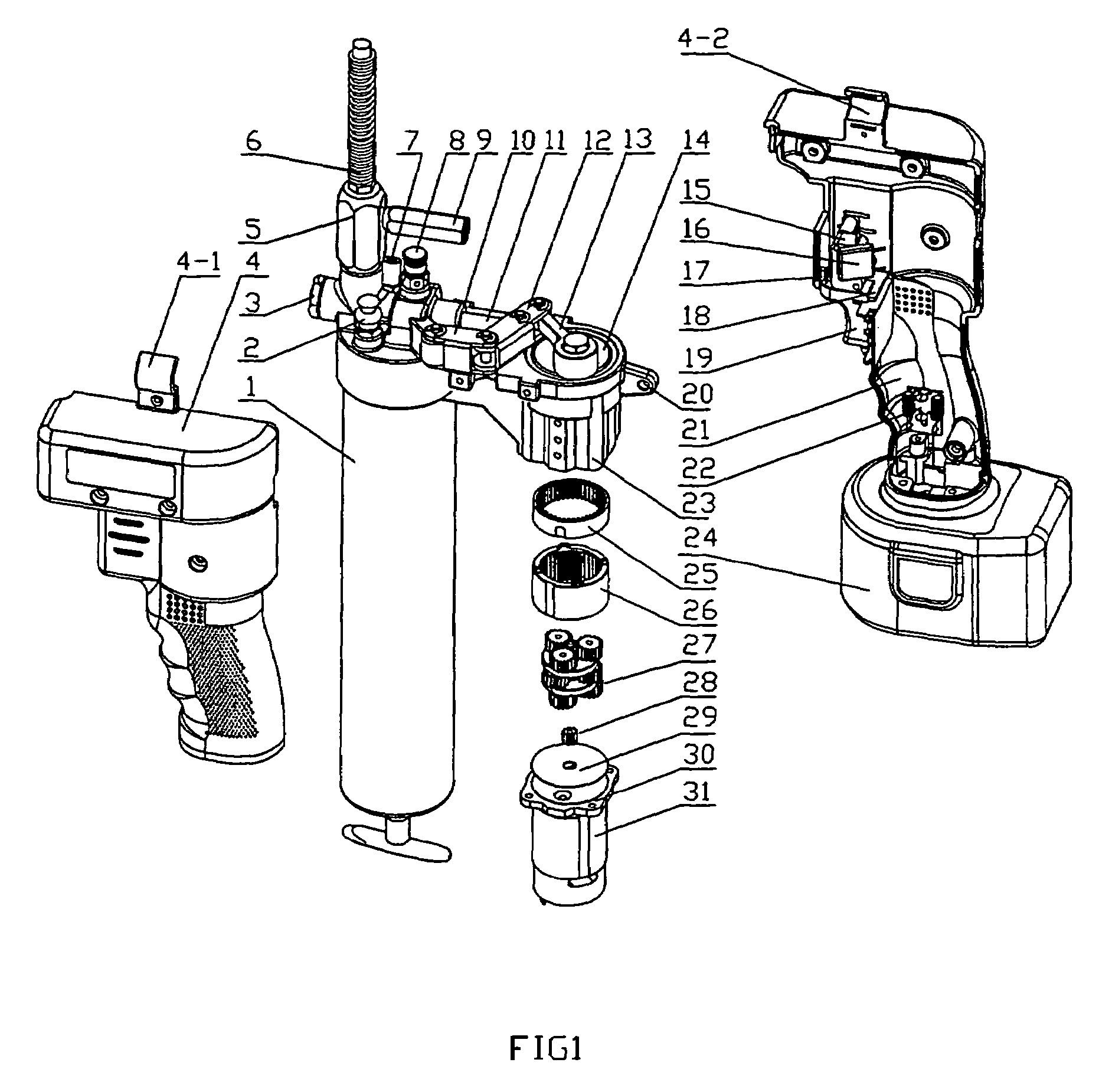

Portable electric grease gun

InactiveUS7267198B2Easy to transportSimple and compact structureManual lubricationLarge containersEngineeringMechanical engineering

This invention discloses a portable electrical grease gun which relates to electric tool field. The portable electrical grease gun according to the present invention, in which conventional slide block assembly driving structure is replaced by a crank link mechanism. As a result, the structure of the product is compact and simple. The crank link mechanism is constructed at low cost. The friction is low during operation. The operation is stable and reliable. It is easy for bulk production. In addition, the volume of the portable electrical grease gun according to the present invention is small so that it is easy to take and operate conveniently.

Owner:CEN JIANLI

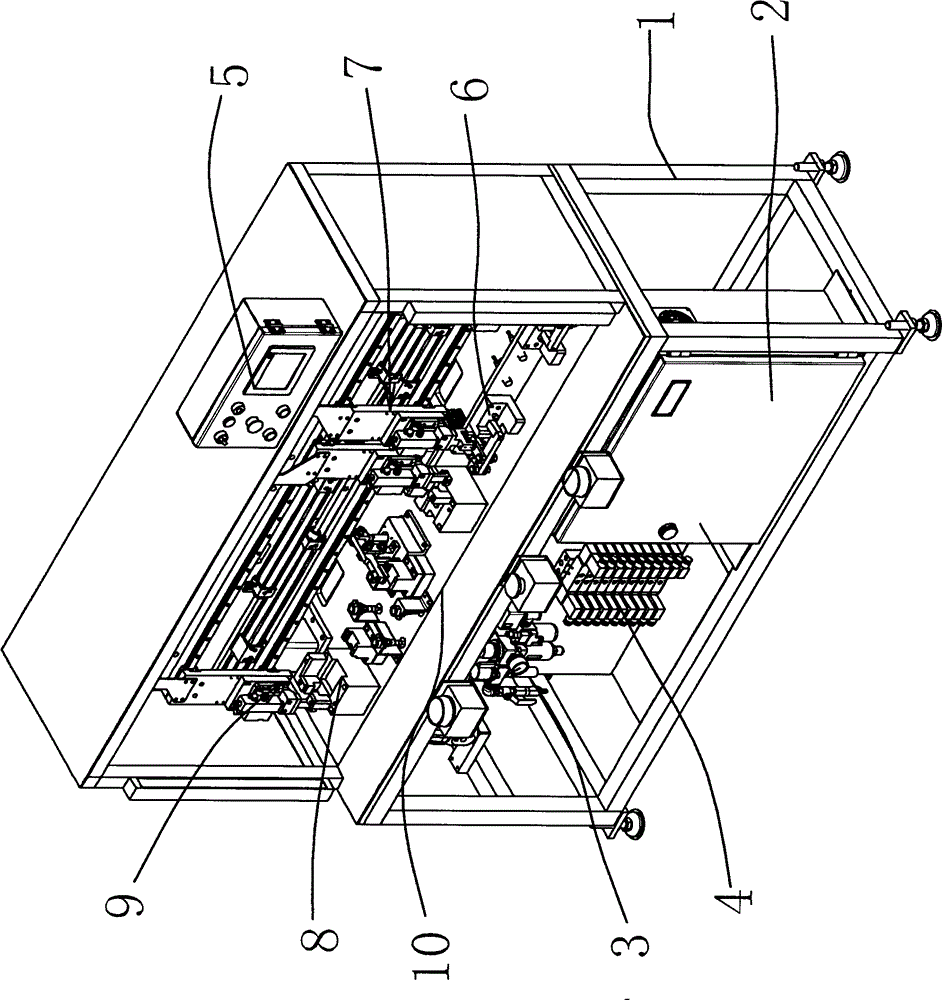

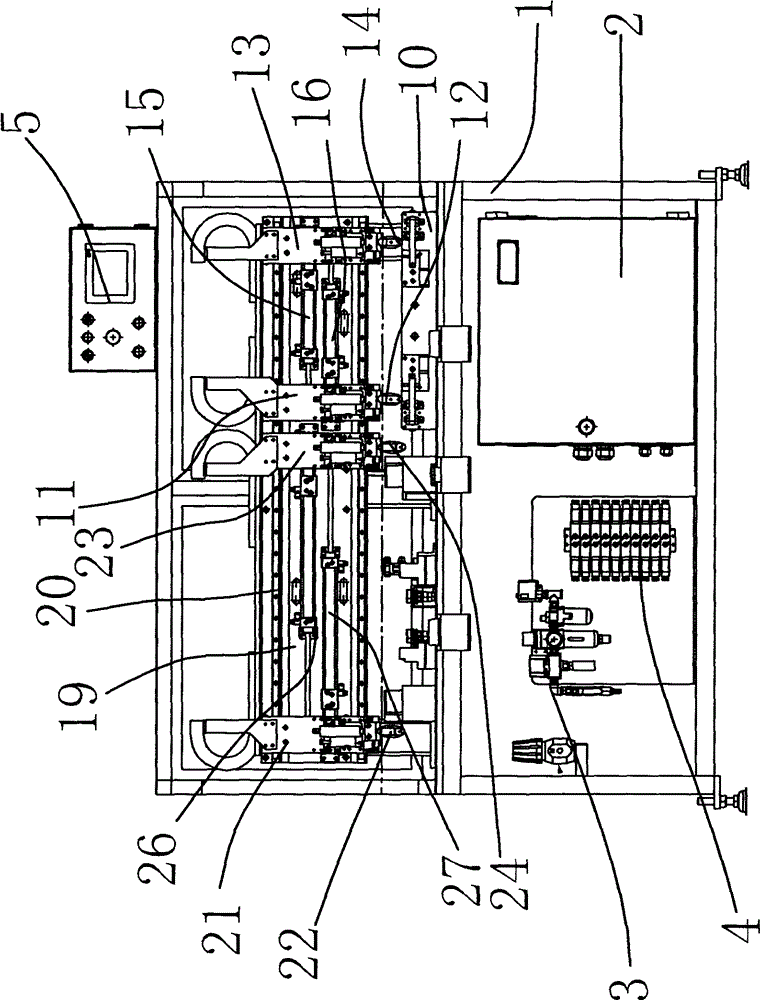

Special oiling machine used for producing sliding rails of automobile seats

ActiveCN103335200AReduce pollutionStable amount of coatingConduits/junctionsDistribution equipmentOil canCar seat

The invention belongs to the technical field of the processing of automobile spare parts, and provides a special oiling machine used for producing sliding rails of automobile seats. The special oiling machine comprises a machine frame, an electronic control system, an air source component, an oil circuit system, a central control system, an upper sliding rail fixing jig, an upper sliding rail oiling mechanism, a lower sliding rail fixing jig, a lower sliding rail oiling mechanism and a working table board, wherein an upper sliding rail and a lower sliding rail which are to be oiled are respectively placed on the upper sliding rail fixing jig and the lower sliding rail fixing jig, and then the electronic control system, the air source component, the oil circuit system, the upper sliding rail oiling mechanism and the lower sliding rail oiling mechanism are controlled by the central control system to oil the sliding rails. The special oiling machine has the advantages that the oiling amount of the special oiling machine can be adjusted, parts needing to be oiled of the sliding rails are oiled by using a copy out-spraying oil nozzle, the oiling amount is steady and accurate, the oiling face range is wide (areas which cannot be manually oiled can also be oiled by using the special oiling machine), oil pollution is reduced due to the closeness of an oil source in the production process, besides, the operation is simple, and the like.

Owner:JIAXING MINSHI MASCH CO LTD

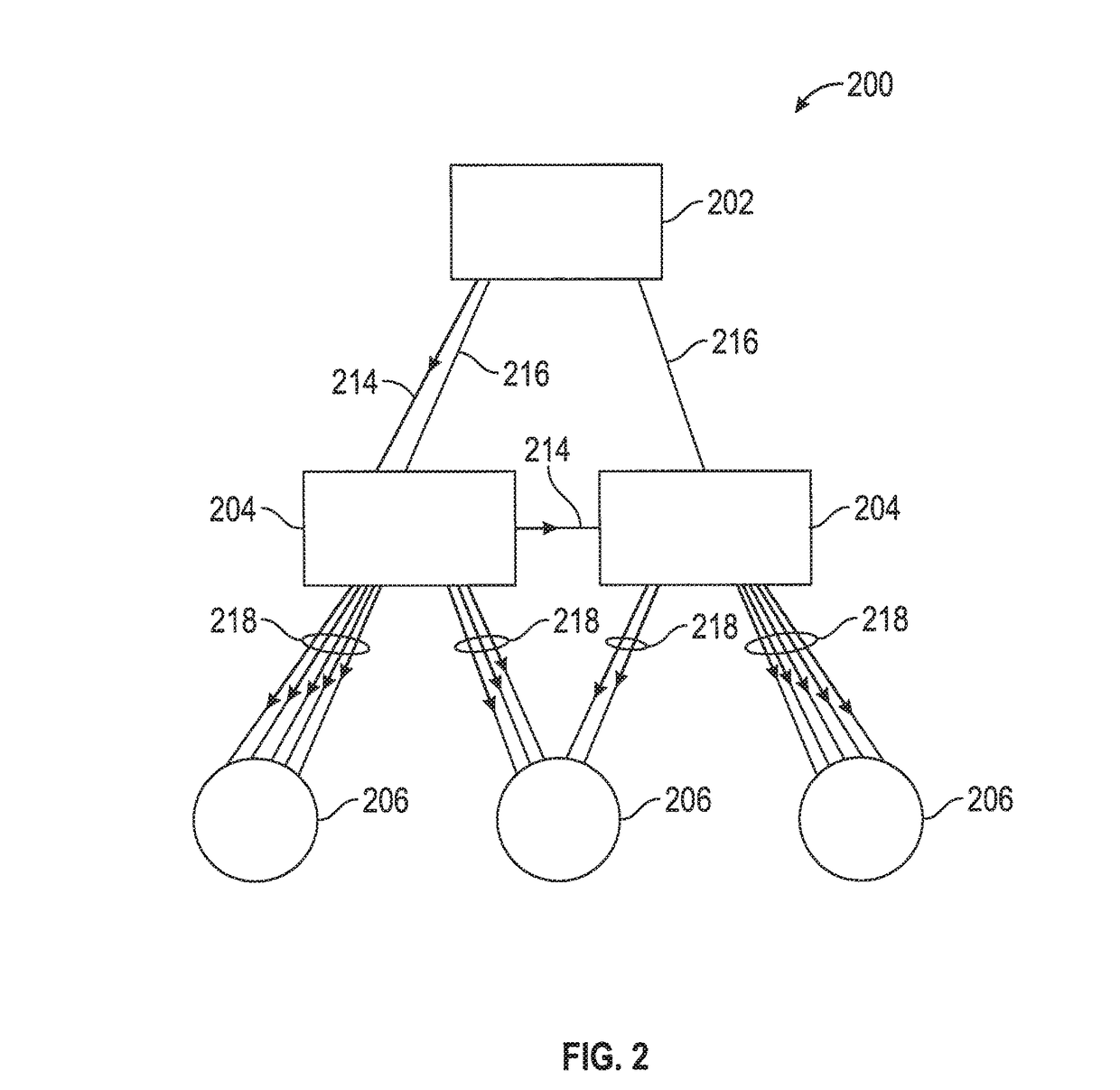

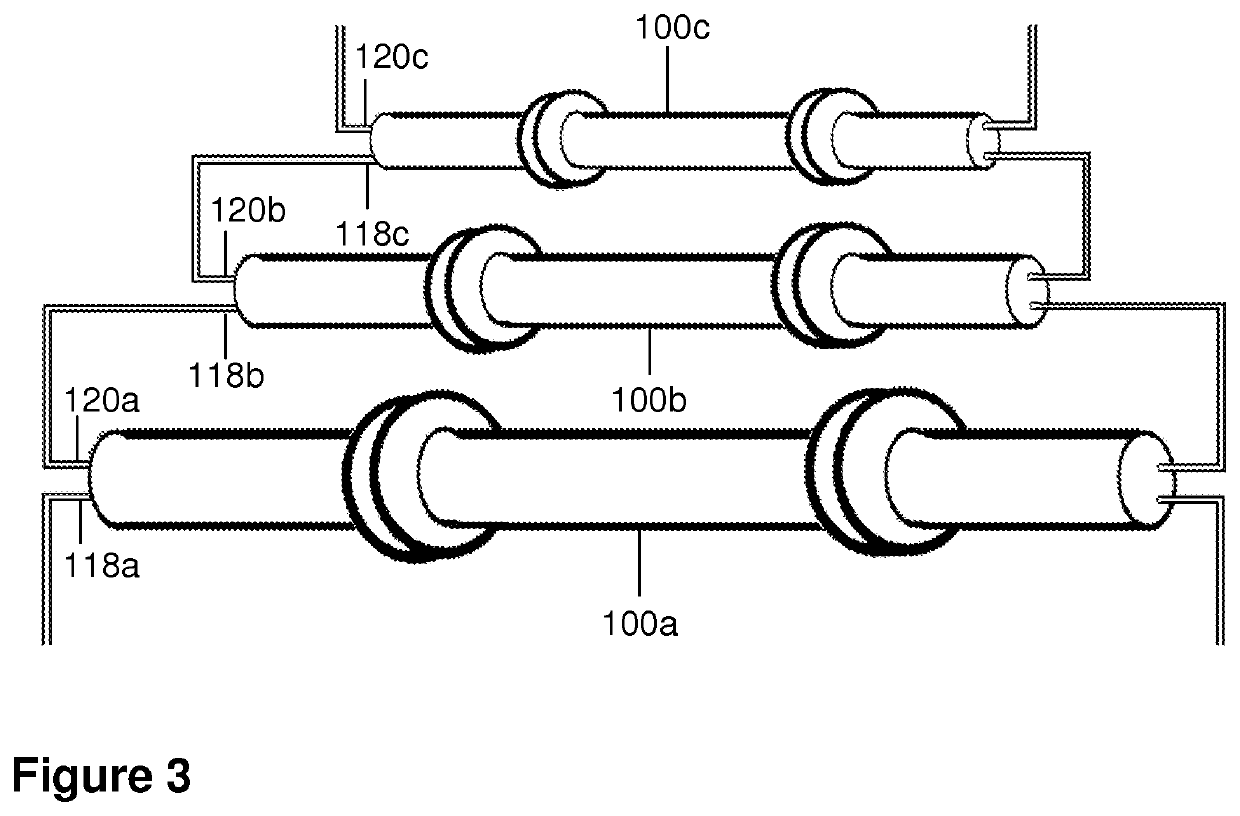

Methods and systems for performing, monitoring and analyzing multiple machine fluid processes

InactiveCN1836095AImprove performanceExtended service lifeLubricant transferMachines/enginesFluid systemBiomedical engineering

In one embodiment, a method is provided for performing a fluid process within a machine having a fluid system including at least two reservoirs of different types of fluids. The method includes the steps of identifying a first reservoir for use in performing a fluid process; (a) adjusting a configuration of a valve system operatively coupled to the fluid system to permit a fluid evacuation process to be performed for the reservoir, (b) subsequently performing the fluid evacuation process for the reservoir, (c) subsequently adjusting the configuration of the valve system to permit a fluid refill process to be performed for the reservoir, (d) subsequently performing the fluid refill process for the reservoir; and, subsequently identifying an additional reservoir and performing at least one of the steps (a), (b), (c) and (d) for the additional reservoir, wherein the first reservoir includes a fluid of a type which is different from a type of a fluid of the additional reservoir. Various system and computer-readable media embodiments are also provided.

Owner:RPM IND LLC

Articulated pin joint for a track chain

An improved articulated pin joint for a track chain used on track laying work machines is provided. The articulated pin joint includes a plug positioned in a central cavity of a track pin. The plug includes an axial passage in which a needle can be inserted to inject grease into the central cavity. The invention facilitates replenishing grease in the field without removing the track chain from the track laying work machine.

Owner:CATERPILLAR INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com