Pillow type automatic packaging machine

An automatic packaging machine, packaging film technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of crooked cutting of packaging bags, hooking and sticking knives, easy sliding of packaging films, etc., to ensure neat cutting and increase processing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

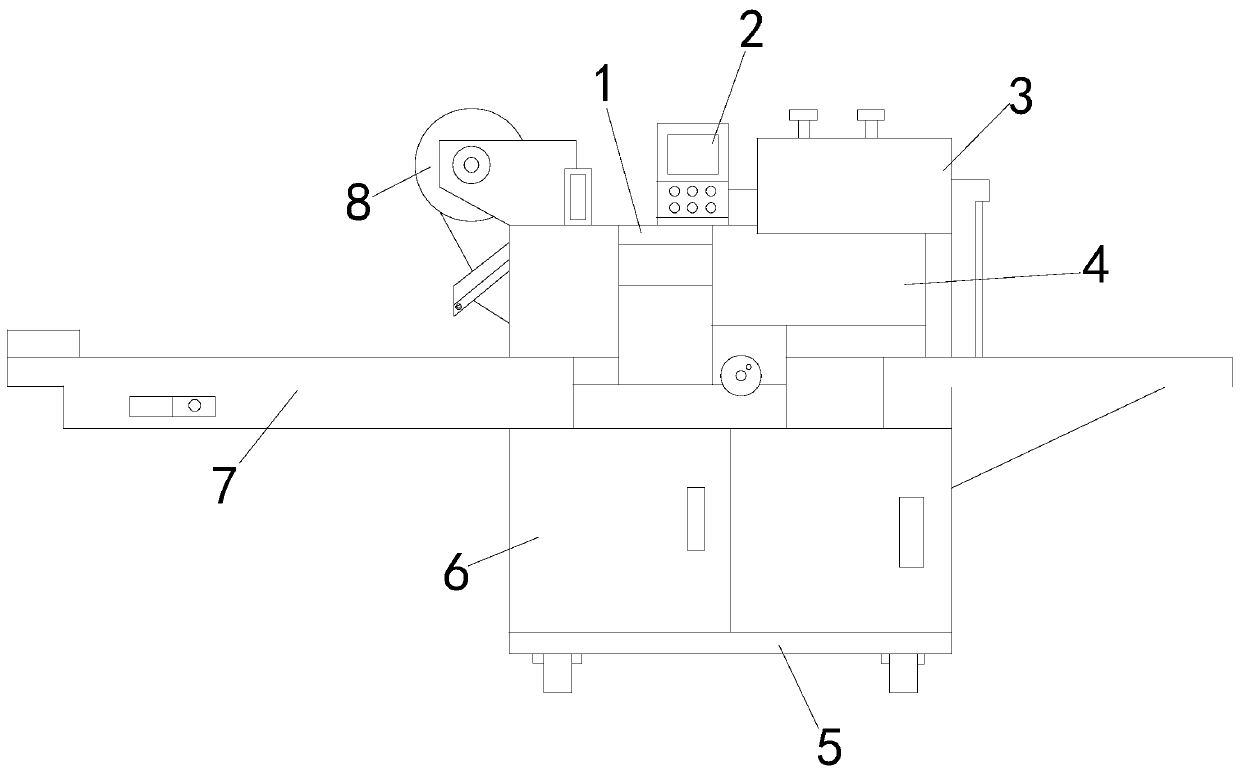

[0025] see Figure 1-Figure 2 , the present invention provides a technical proposal of a pillow-type automatic packaging machine: its structure includes: a pillow-type automatic packaging machine, its structure includes: a point-section body 1, a controller 2, a distribution box 3, a sealing groove device 4, a base 5. Assembly box 6, transfer table 7, packaging film roller 8, the base 5 is installed below the assembly box 6 and locked with the assembly box 6, a transfer table 7 is provided above the assembly box 6, and the transfer table 7 Fastened with the assembly box 6, the middle section of the transfer table 7 is provided with a packaging film roller 8 and is closely matched with the packaging film roller 8. The right side of the packaging film roller 8 is provided with a dot section body 1, and the dot section body 1 is connected with the packaging The film roller 8 is fastened, and the right side of the point section body 1 is provided with a sealing groove device 4, an...

no. 2 example

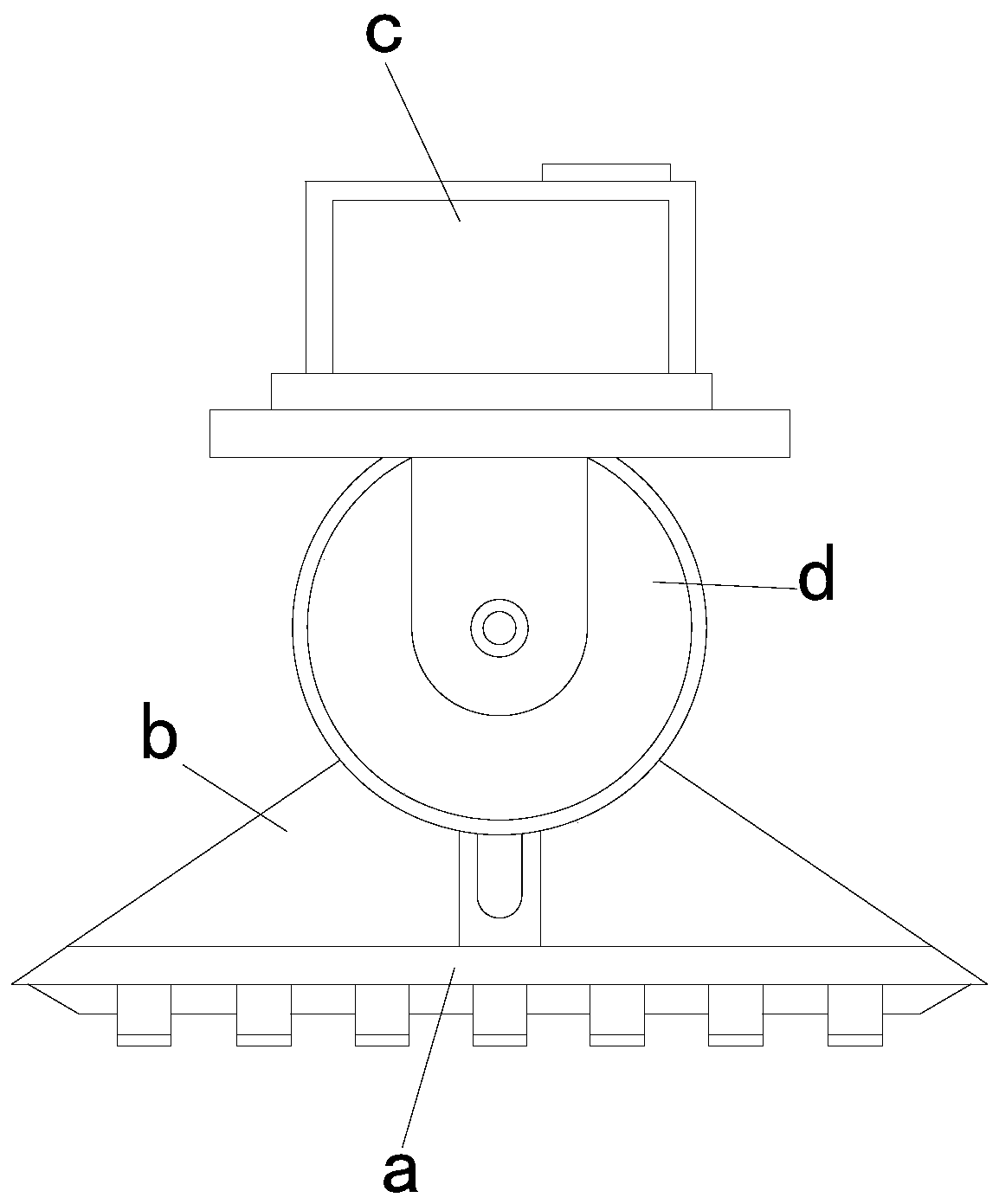

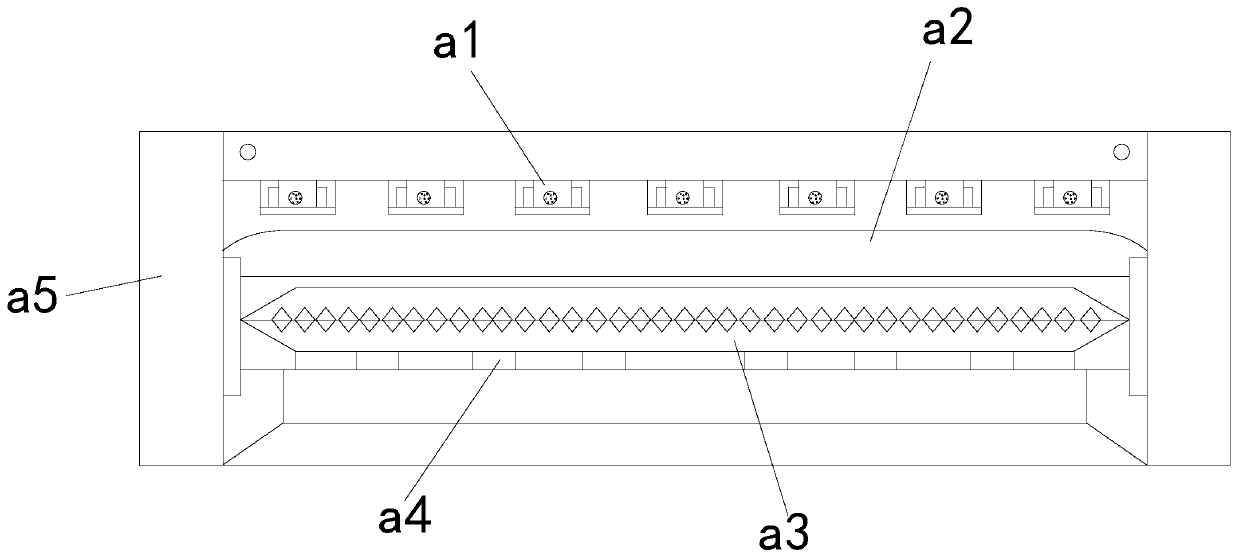

[0028] see Figure 3-Figure 5 , the present invention provides a pillow-type automatic packaging machine technical proposal: its structure includes: the point section knife set device a includes a fixed block a1, a progressive reaction device a2, a cutting knife set a3, a shaft-coupling brush device a4, and an outer casing a5, a cutting knife group a3 is provided on the middle side of the outer casing a5, and a coaxial brush device a4 is provided on the upper end of the side of the cutting knife group a3, and the coaxial brush device a4 cooperates with the cutting knife group a3 in a gap, and the cutting The knife set a3 is installed under the progressive reaction device a2 and fastened with the progressive reaction device a2, and a fixed block a1 is arranged under the outer end of the progressive reaction device a2, and the fixed block a1 is buckled with the progressive reaction device a2 .

[0029] The progressive reaction device a2 includes a reaction rod a21, a linkage fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com