Large-caliber steel-plastic reinforced composite pipe section and reinforced composite pipe forming process

A technology of reinforced composite and forming process, which is applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., which can solve the problems of bulky steel cylinder concrete pipes, troublesome transportation and construction, and high production costs of pipes, and achieve light weight and molding Efficient process and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

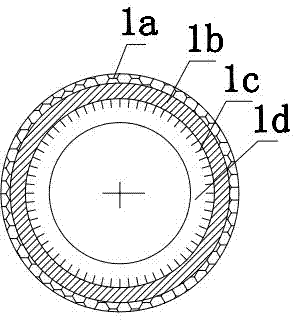

[0023] As shown in the figure, it is a large-diameter steel-plastic reinforced composite pipe joint, which is composed of a reinforced composite pipe 1 and flanges 2 connected at both ends. The central layer of the reinforced composite pipe 1 is a spiral welded steel pipe 1b, and the spiral welded steel pipe 1b is composed of The steel strip is formed by a spiral welding process. The outer layer of the spiral welded steel pipe 1b is compounded with a glass fiber reinforced plastic winding layer 1a to form the outer layer of the reinforced composite pipe 1. The inner surface of the spiral welded steel pipe 1b is connected with a wire mesh 1c with a hook, and a spin coating Layer 1d, spin plastic coating 1d and wire mesh with hook 1c cooperate to form the structural steel-plastic composite inner layer of reinforced composite pipe 1. This structural steel-plastic composite inner layer is simpler than the inner wall of the steel pipe. Good performance and the spin plastic layer can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com