Disposable woven double layer integrated fire hose and manufacture method thereof

A fire hose, one-piece technology, applied in the direction of fabrics, textiles, multi-strand fabrics, etc., can solve the problems of increasing fire hoses, friction, double-layer structure pressure resistance and wear resistance values are not up to expectations, etc. problems, to achieve the effect of small expansion rate and expansion rate, improved reliability, zero loss of wear resistance and pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

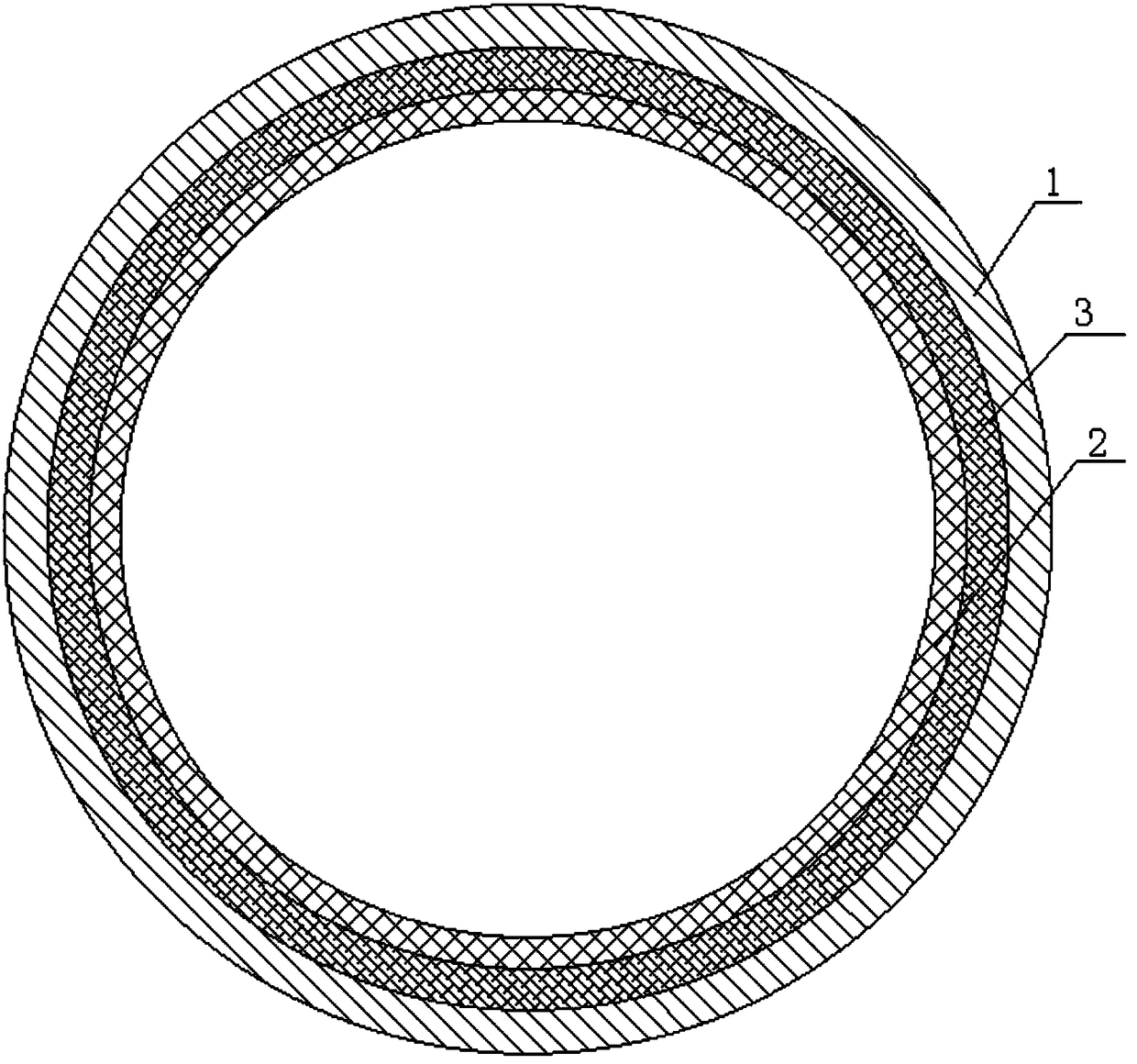

[0020] see figure 1 , a disposable braided double-layer conjoined fire hose, comprising an outer tube blank 1, an inner tube blank 2, and a braided wire layer 3; the outer tube blank 1 and the inner tube blank 2 are braided synchronously, and The braided wire layer 3 is tightly fixed into one body.

[0021] In this embodiment, the braided wire layer 3 is made of the same material as the outer tube blank 1 and the inner tube blank 2 .

[0022] In this embodiment, the outer tube blank 1 and the inner tube blank 2 are made of polyurethane.

[0023] In this embodiment, the sections of the outer tube blank 1 , the inner tube blank 2 , and the braided wire layer 3 are all circular.

[0024] During specific production, the outer tube blank 1 and the inner tube blank 2 are woven synchronously, and are woven synchronously through the braiding wire layer 3 therebetween, and are tightly fixed into one body.

Embodiment 2

[0026] The difference between this embodiment and the first embodiment is that the material of the braided wire layer 3 is different from that of the outer tube blank 1 and the inner tube blank 2 .

[0027] The hose tube blank in this embodiment has two inner and outer layers, and the tube blanks of the inner and outer layers are closely combined to form an inseparable double-layer structure, so that the inner and outer layers look like two layers, but they are actually the same structure, and the degree of fit is very good Well, the fire hose made in this way has the characteristics of small expansion rate and contraction rate, wear resistance and pressure resistance, and zero loss of blasting force value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com