Partition plate connection member and preparation method

A technology for connecting components and partition boards, which is applied to the special parts and preparation of partition walls, building materials and their preparation fields, which can solve the problems of low strength, easy oxidation, and poor water resistance of cast columns, and achieve resistance to distortion and deformation The effect of high performance, enhanced strength, and low expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

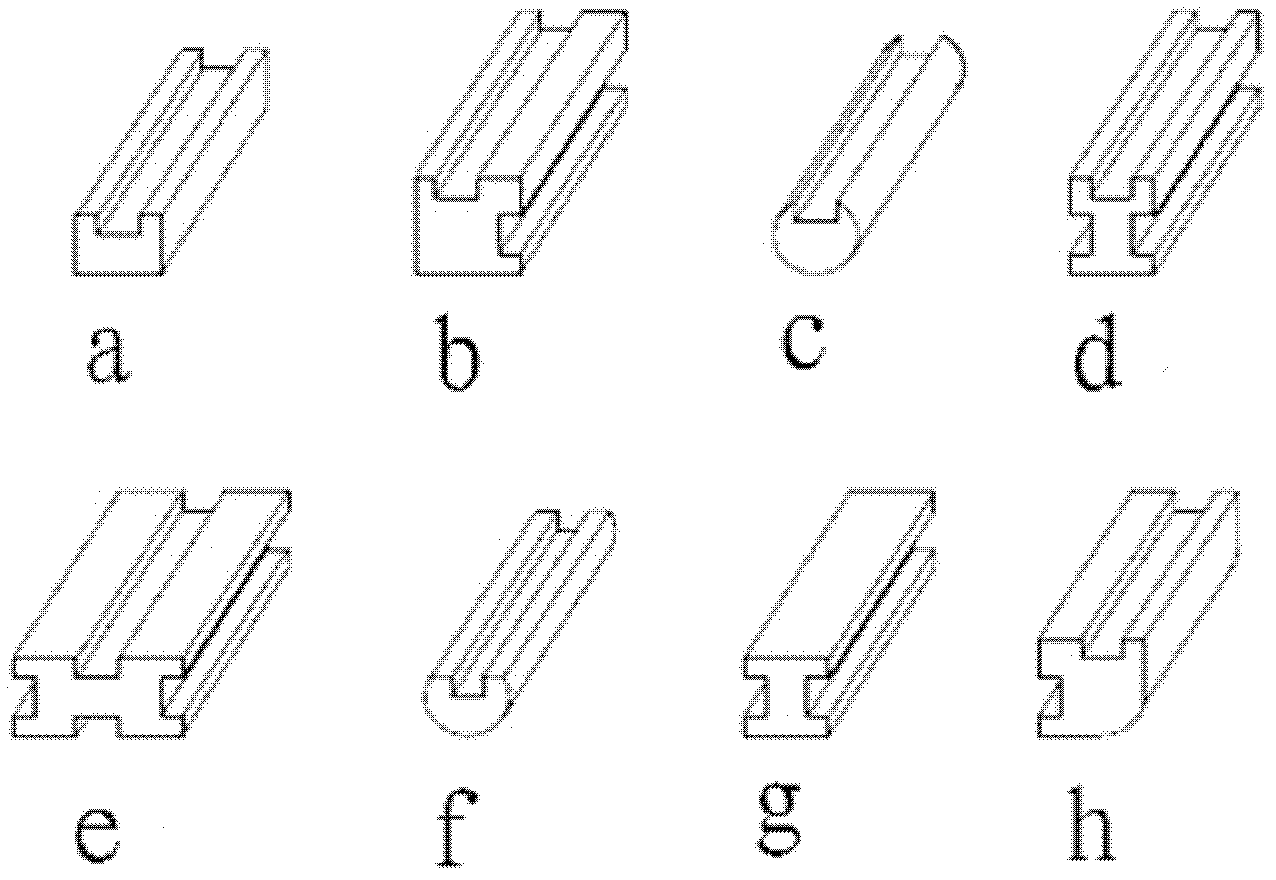

Image

Examples

Embodiment 1

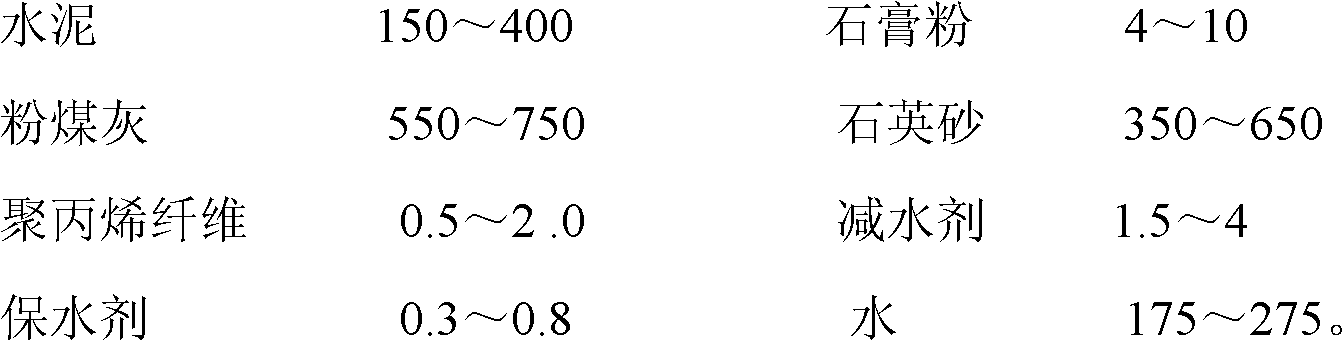

[0060] 1. Prepare raw materials according to the following dosage (kg)

[0061]

[0062] Wherein, the cement is Portland cement, whose label is 42.5R; the gypsum powder (calcium sulfate dihydrate). The particle size of the fly ash is the first-class fly ash of the thermal power plant, that is, the fly ash produced by the thermal power plant. 120 mesh; the water reducing agent is polycarboxylate superplasticizer (produced by Fuzhou Xingda Building Materials Co., Ltd., JSS type polycarboxylate high performance water reducer; solid content ≥ 40%; pH value is 6-8); The water-retaining agent is polyacrylamide (produced by Beijing Haichang Environmental Protection Kezhi Co., Ltd., PAM polyacrylamide, with a molecular weight of 18 million).

[0063] 2. Add cement, gypsum powder, fly ash, quartz sand, polypropylene fiber, water reducing agent and water retaining agent into the mixer in turn, stir, and mix the materials evenly. The stirring rate is 200 rpm, stirring for 15 minutes,...

Embodiment 2

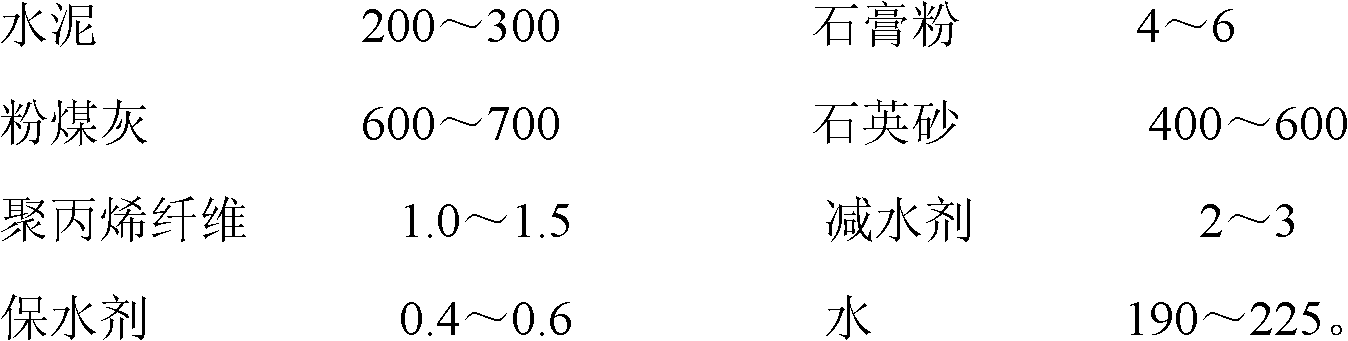

[0070] 1. Prepare raw materials according to the following dosage (kg)

[0071]

[0072] Among them, the particle size of the quartz sand is 120-200 mesh; the water reducer is a naphthalene-based high-efficiency water reducer (produced by Fuzhou Xingda Building Materials Co., Ltd., XD-1 type high-efficiency water reducer, which is a β-naphthalenesulfonic acid formaldehyde condensation product, solid Content ≥ 93%; pH value 7-9; fluidity of cement paste ≥ 230%);

[0073] 2. Add cement, gypsum powder, fly ash, quartz sand, polypropylene fiber, water reducing agent and water retaining agent into the forced mixer in turn, stir, and mix the materials evenly. The stirring speed is 300 rpm, stirring 10min, made into pre-mixed dry material;

[0074] 3. Add tap water to the pre-mixed dry material, stir and mix evenly, and the stirring rate is 300 rpm, stir for 8 minutes, and put the mixed material in the feeder for standby;

[0075] 4. Send the mixed material into the high-pressur...

Embodiment 3

[0080] 1. Prepare raw materials according to the following dosage (kg)

[0081]

[0082] Among them, the particle size of the quartz sand is 140-160 mesh; the water reducer is a polycarboxylate high-efficiency water reducer (produced by Fuzhou Xingda Building Materials Co., Ltd., JSS type polycarboxylate high-performance water reducer).

[0083] 2. Add cement, gypsum powder, fly ash, quartz sand, polypropylene fiber, water reducer and water retaining agent into the mixer in turn, stir, and mix the materials evenly. The stirring rate is 250 rpm, stirring for 12 minutes, Made into pre-mixed dry material;

[0084] 3. Add tap water to the pre-mixed dry material, stir and mix evenly, and the stirring rate is 250 rpm, stir for 9 minutes, and put the mixed material in the feeder for standby;

[0085] 4. Send the mixed material into a high-pressure vacuum extruder for extrusion molding. The extruded billet is embossed to form the required shape and then cut into the required lengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com