Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

103results about How to "Small spot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

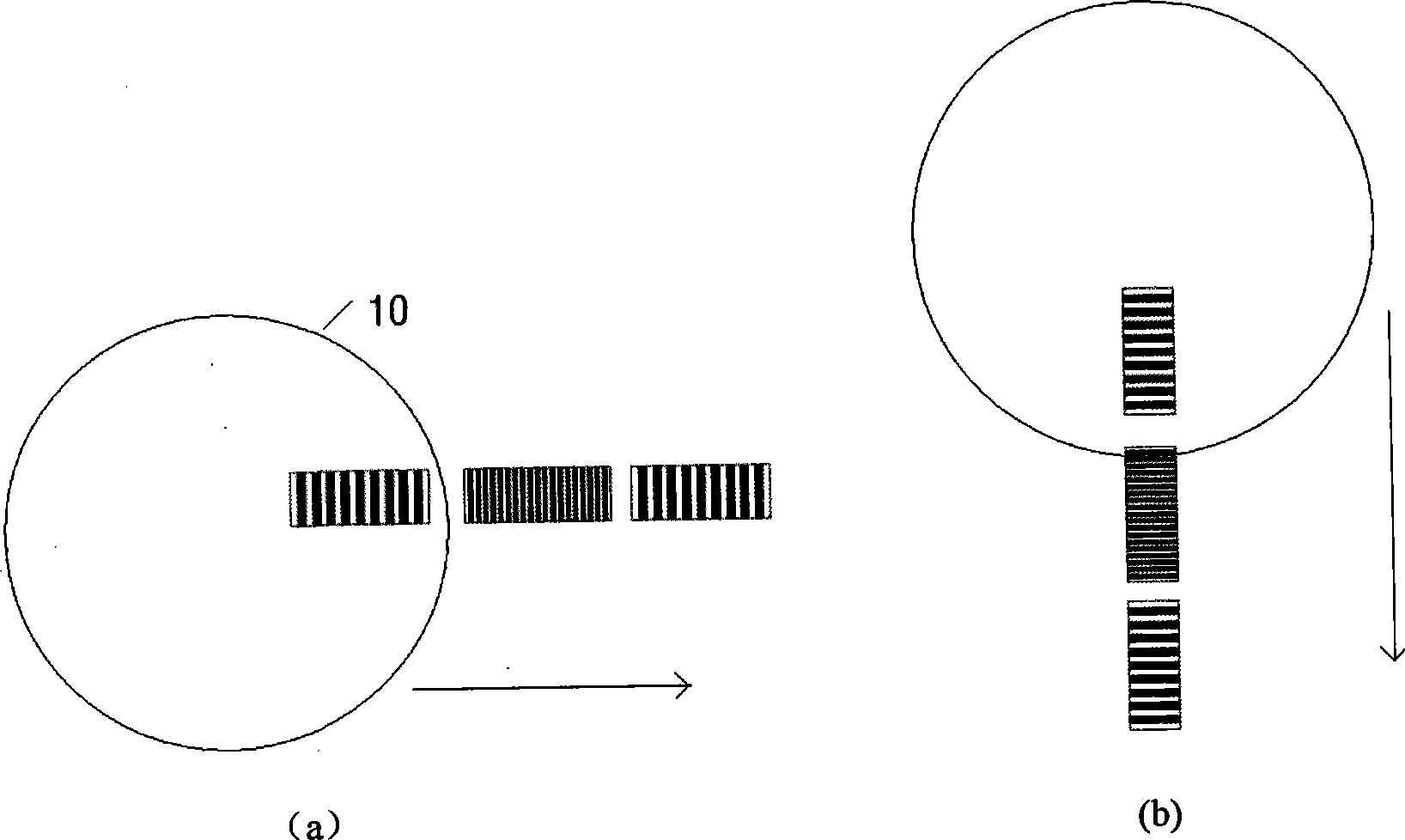

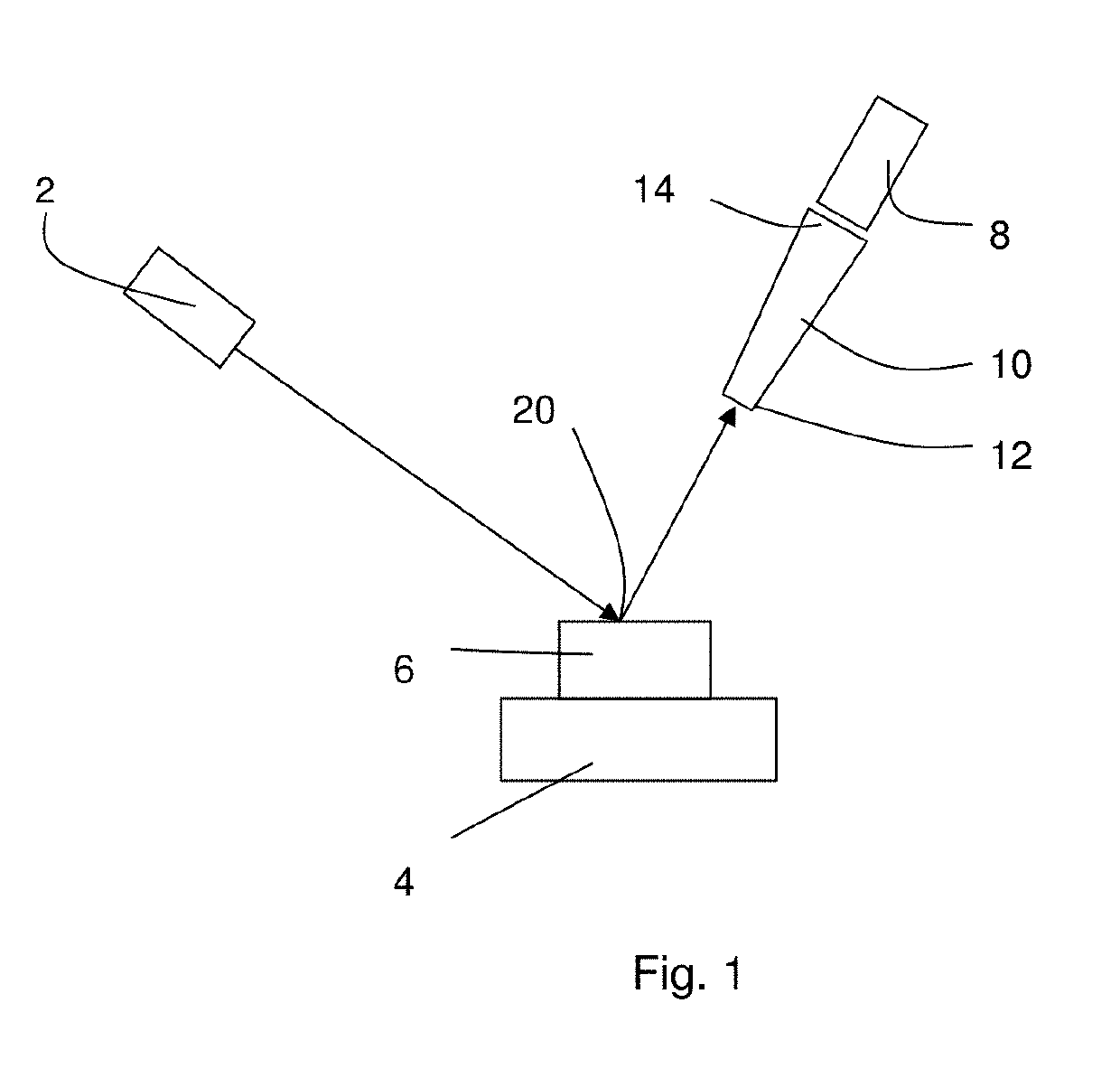

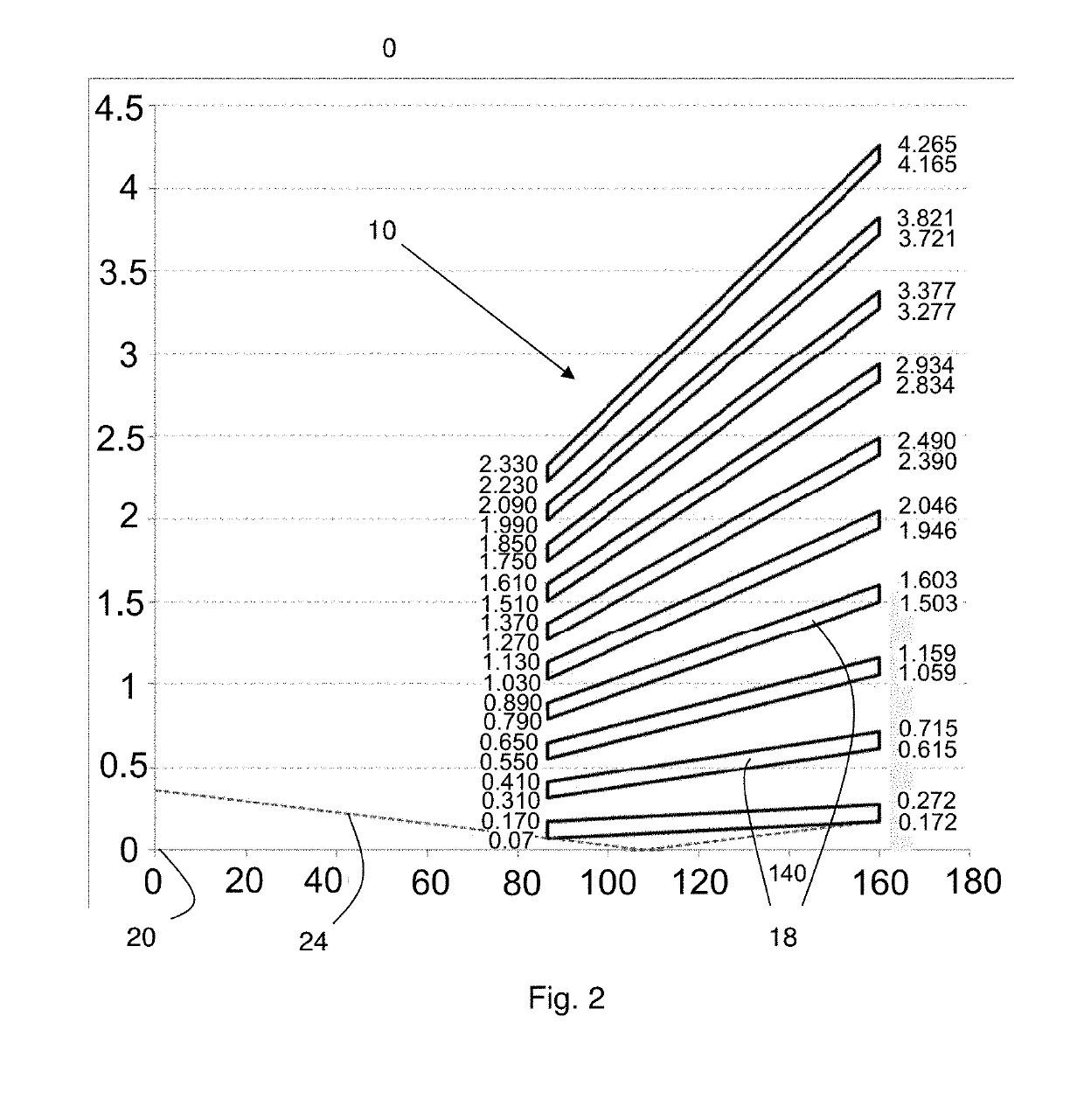

Ink ejector

InactiveUS6419336B1Large spot and areaReduce in quantityInking apparatusOther printing apparatusImage resolutionVoltage

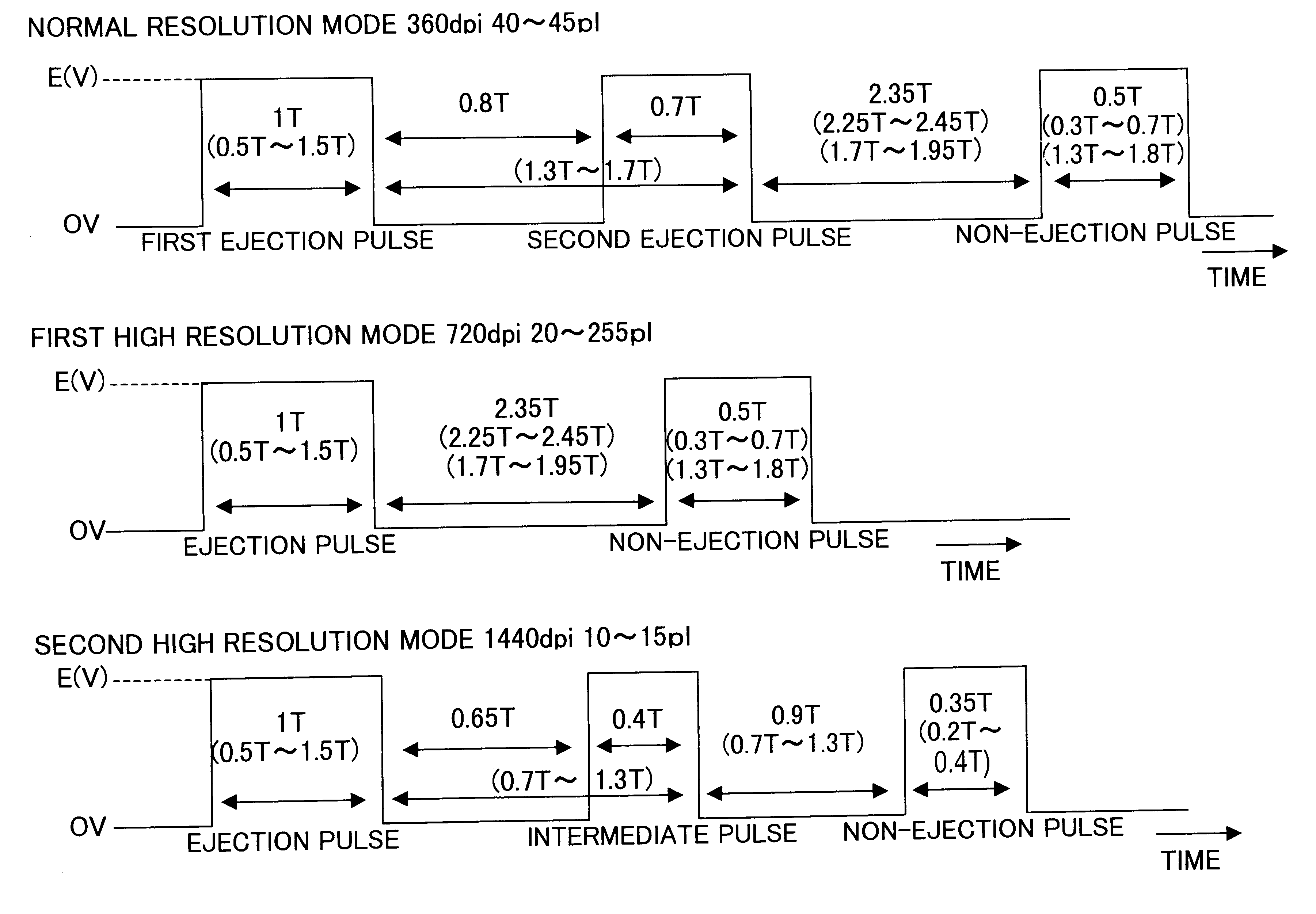

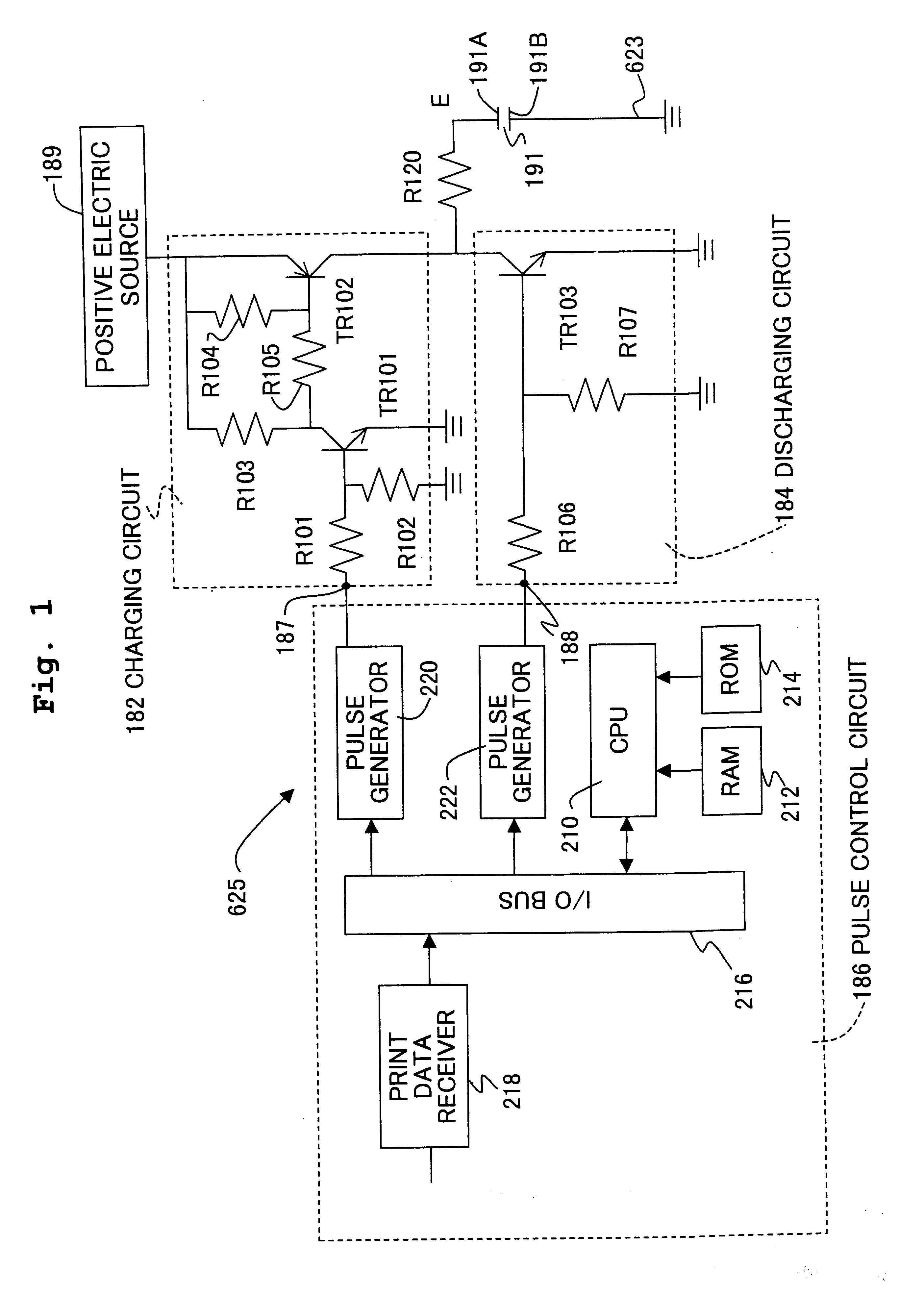

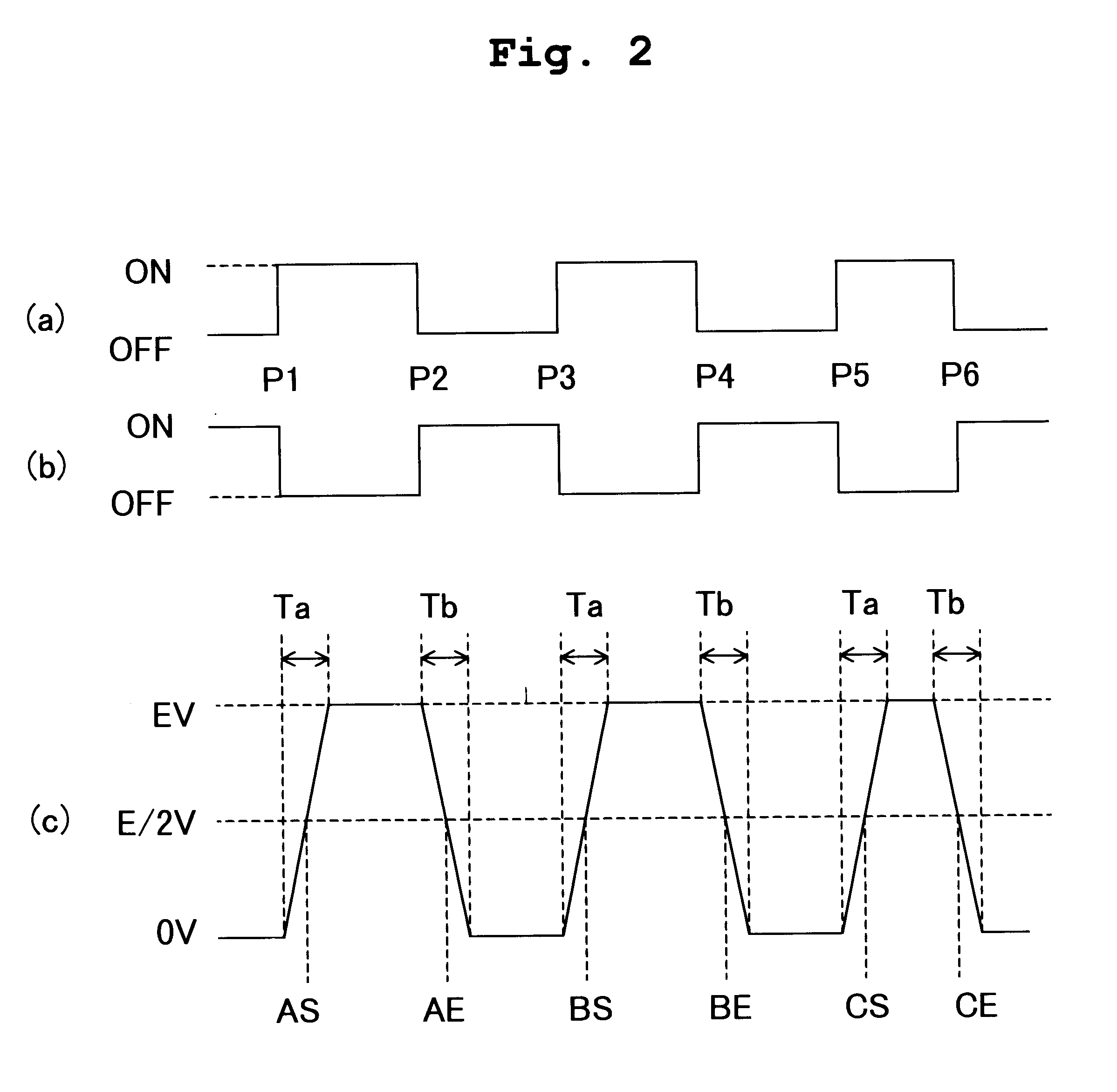

An ink ejector includes an ink jet head. The head has ink channels each defined between a pair of actuator walls. The head also has nozzles each communicating with one of the channels. In accordance with a print instruction, a controller applies to the appropriate actuator walls one or two ejection pulses of voltage depending on the resolution specified by the instruction. Each ejection pulse increases the volume of the associated channel once and decreases it subsequently to eject an ink droplet from the channel through the associated nozzle. In a normal resolution mode, two such ejection pulses are applied. In a first high resolution mode, one such ejection pulse is applied. In a second high resolution mode, one such ejection pulse is followed by an auxiliary pulse for making the droplet smaller. The ratio of the total volume of the two droplets in the normal resolution mode to the volume of the droplet in the first high resolution mode is approximately 2 / 1. The ratio of the droplet volume in the first high resolution mode to that in the second high resolution mode is approximately 2 / 1. This enables the difference in dot density between the resolution modes to be distinct for good printing.

Owner:BROTHER KOGYO KK

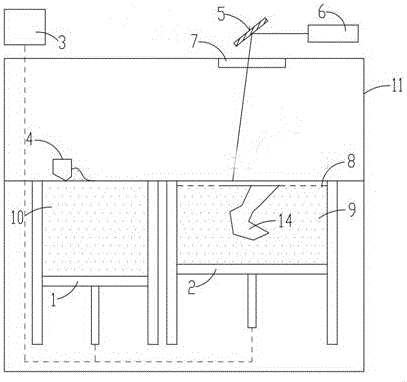

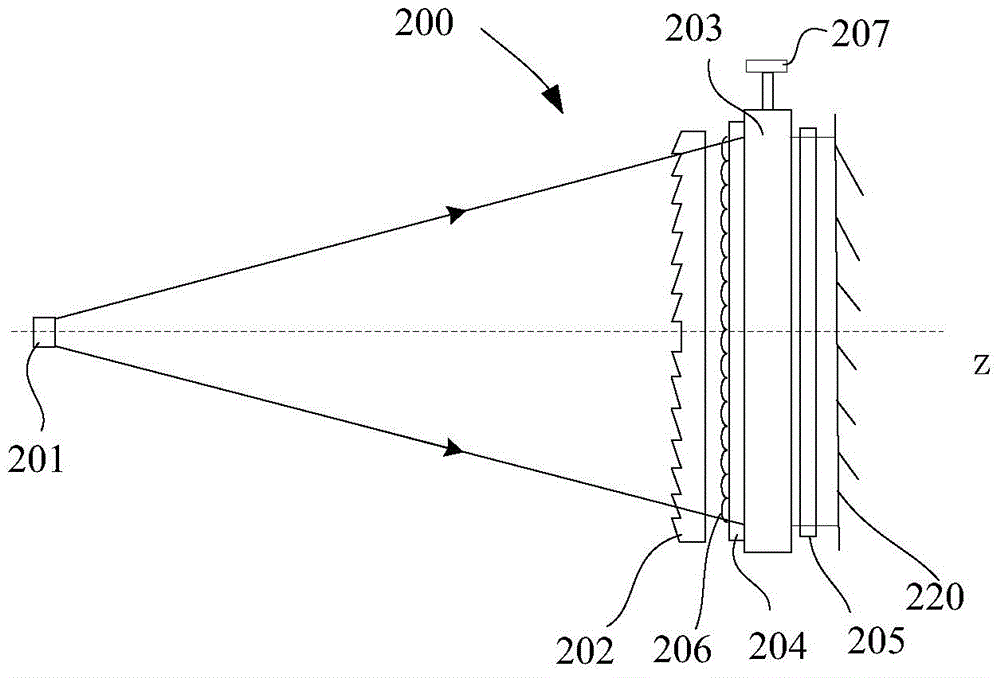

Projector

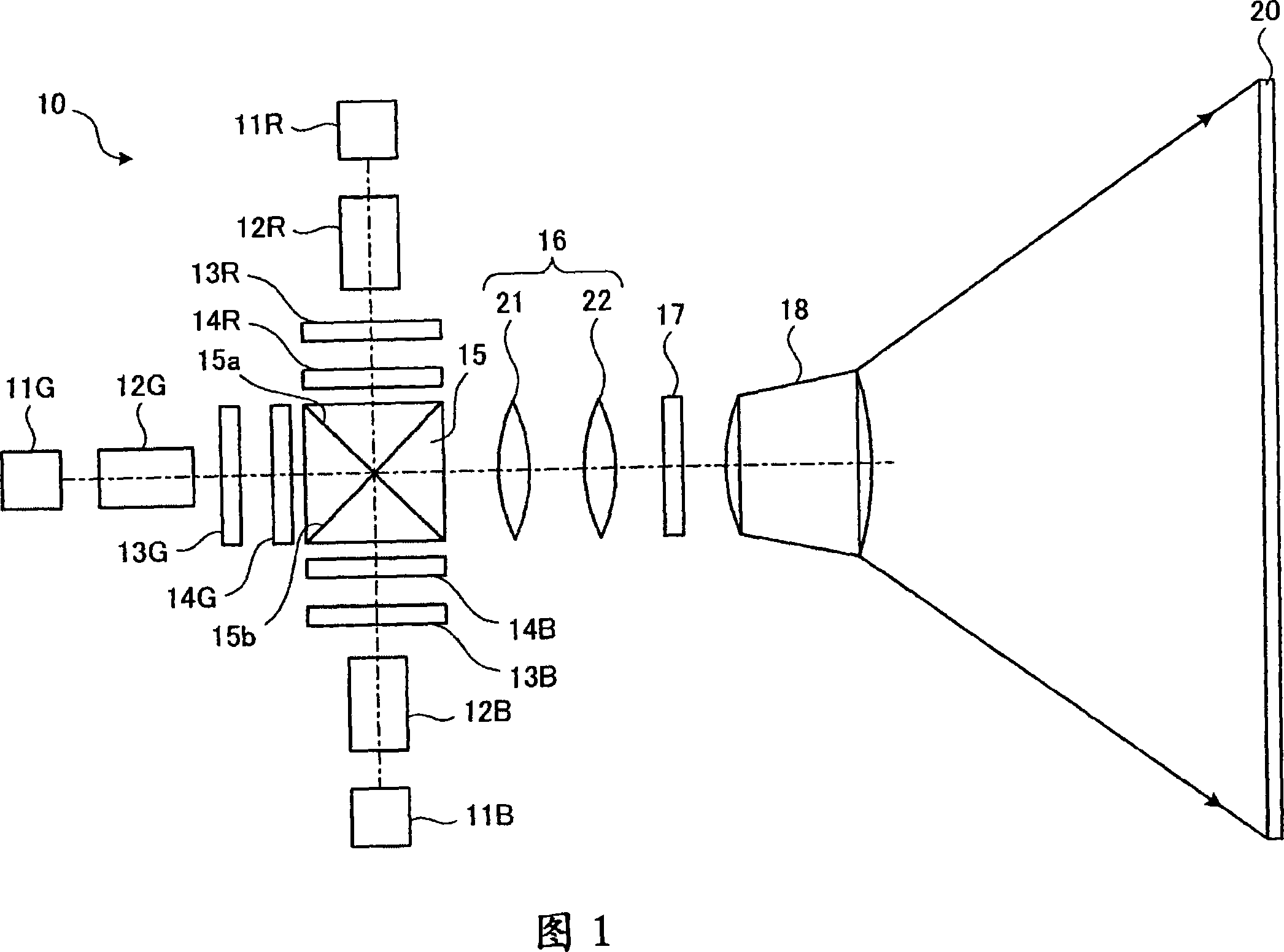

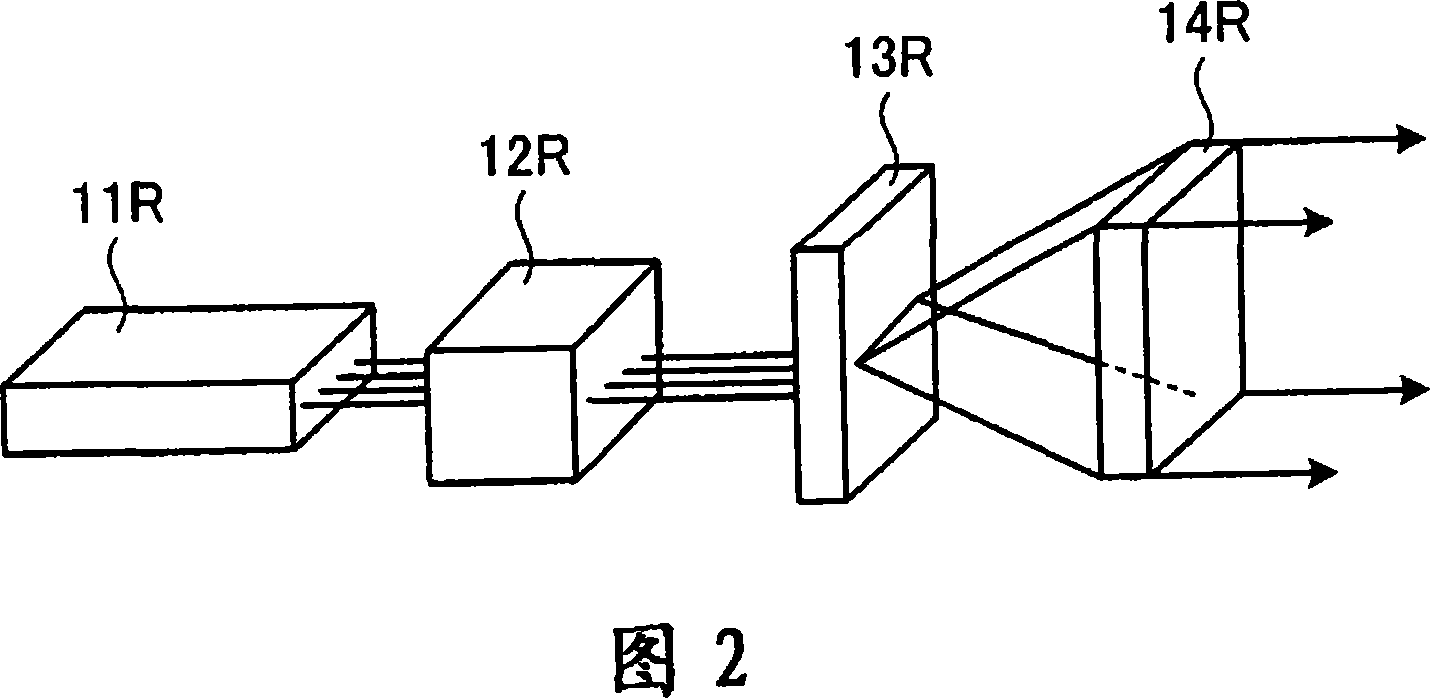

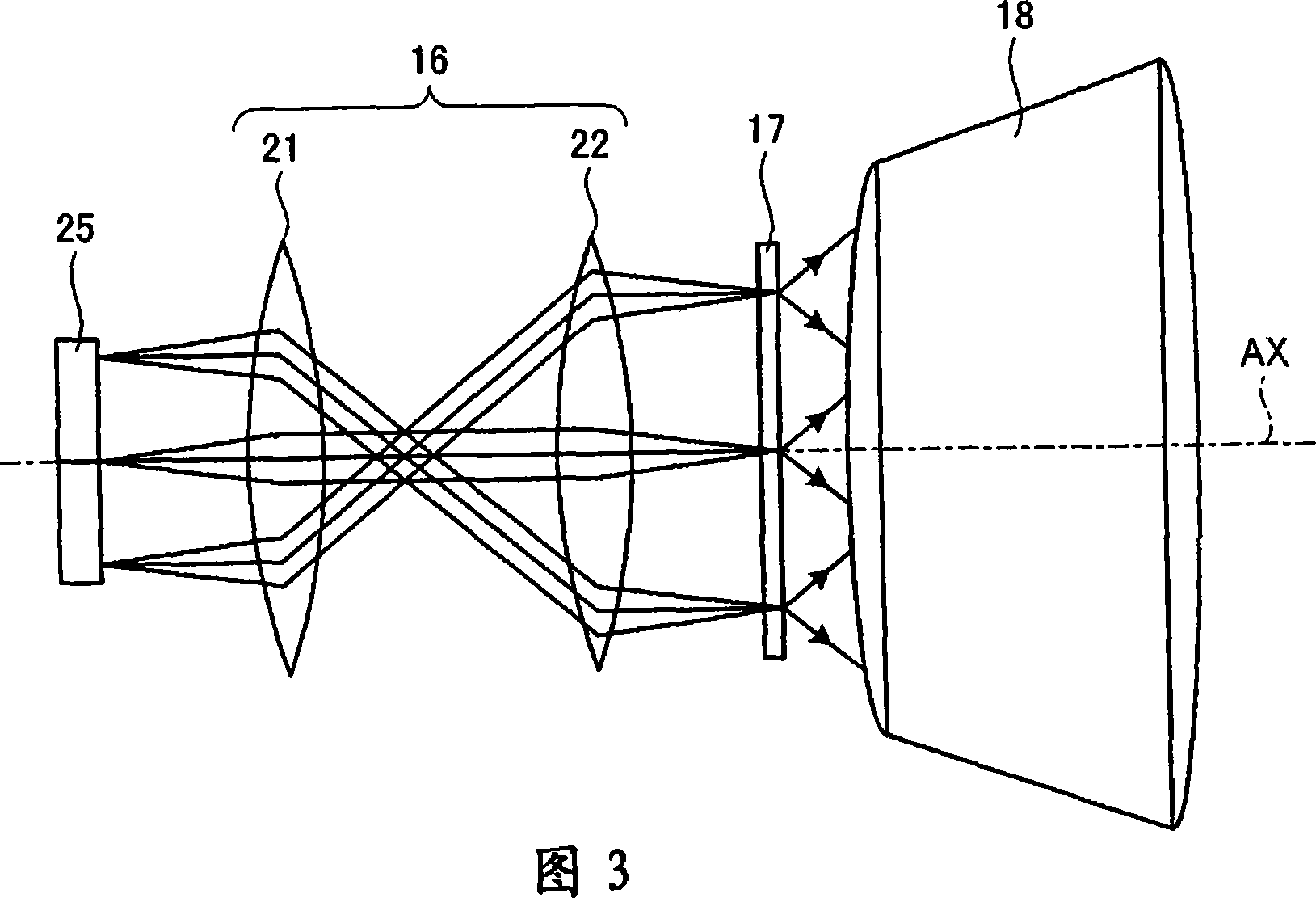

InactiveCN101051179AHigh color purityImprove coherenceTelevision system detailsProjectorsDiffusionLight spot

A projector reducing light spot by using simple structure includes: a liquid crystal type space light modulating devices (14R, 14G, 14B), which use light emitted from a light source section (11R, 11G, 11B) having solid-state light source form image forming section of image; a diffusion section (17) which is provided at focal positions of light components of the image formed by the image forming section and diffuses the light; a projection optical system (18) that projects the light emitted from the diffusion section (17), and the diffusion section (17) changed phase of light at each position of light incidence.

Owner:SEIKO EPSON CORP

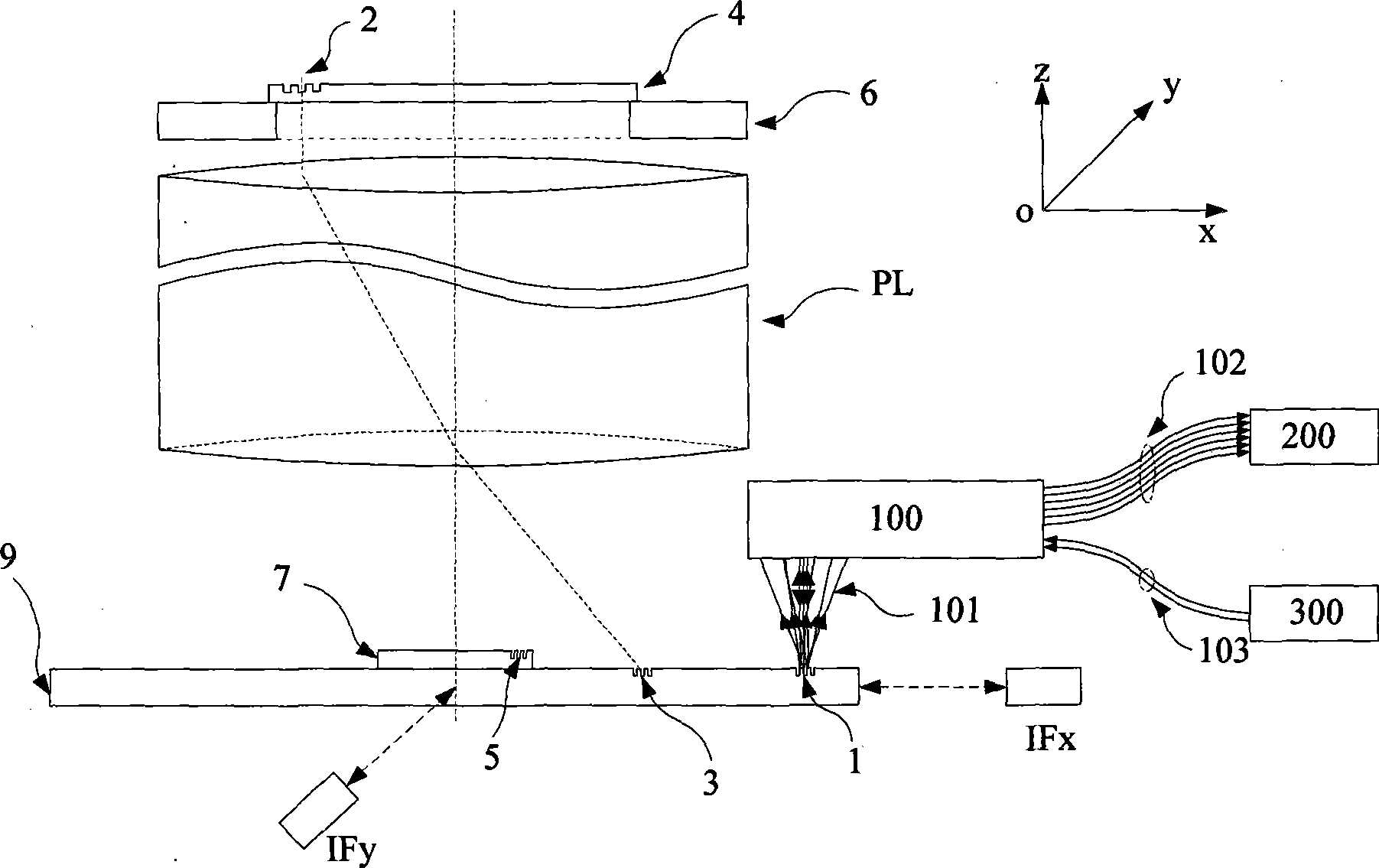

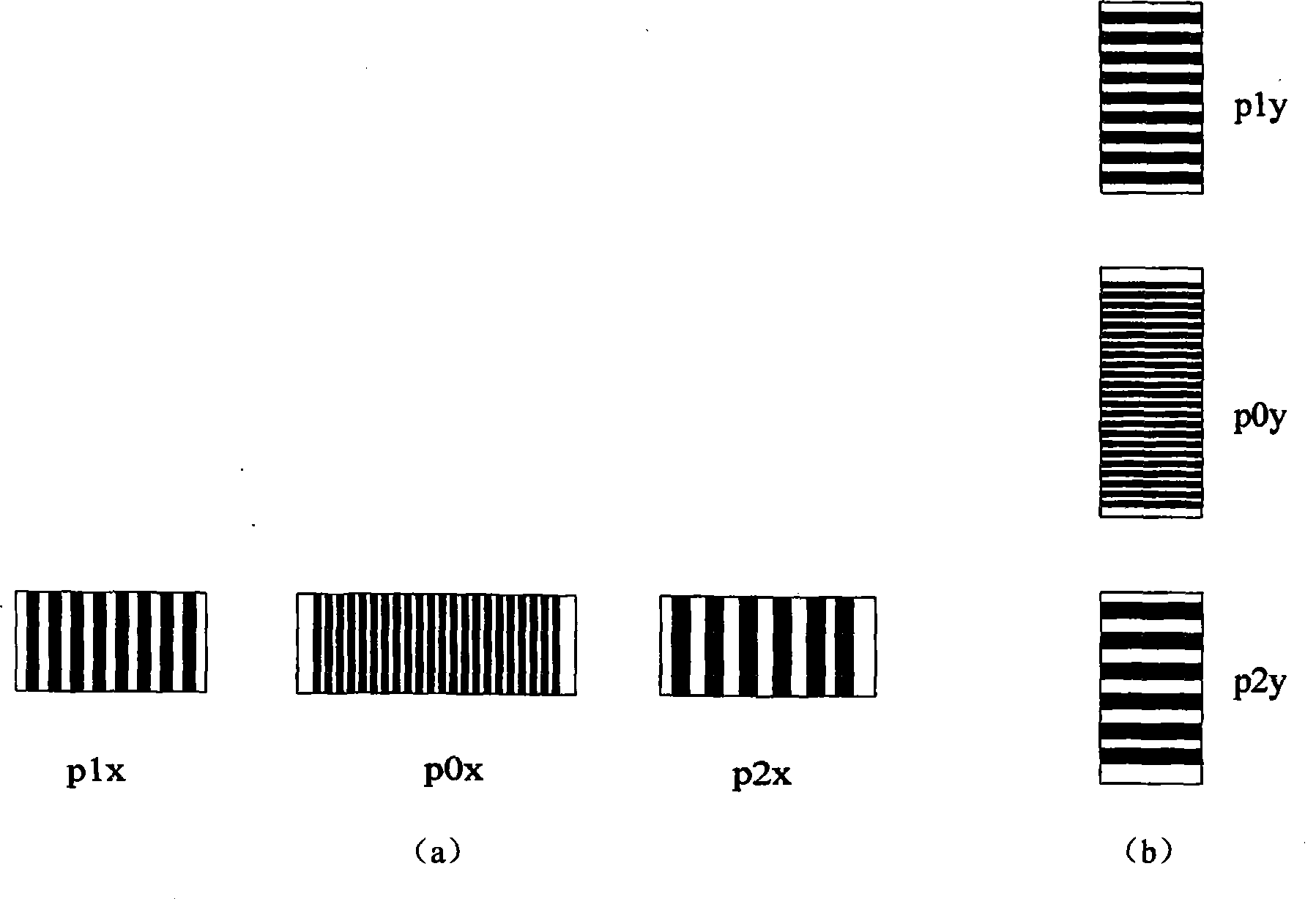

Alignment light source apparatus

ActiveCN101446775ASmall laser spotImprove the utilization rate of laser light energyPhotomechanical exposure apparatusMicrolithography exposure apparatusOptical pathPhase modulation

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Method and device for manufacturing polyamide three-dimensional object by laser

ActiveCN106626379AAchieve fusionSmall spotAdditive manufacturing apparatus3D object support structuresPolyamideLength wave

The invention discloses a method for manufacturing a polyamide three-dimensional object by laser. The method comprises the steps that a layer of manufacturing material is laid and conveyed onto a bottom plate or a selective fusion layer to form a novel material layer; a laser device emits laser; the laser is guided to selectively irradiate a fusion region on the novel material layer; the fusion region is a cross section position, corresponding the three-dimensional object to be manufactured, on the novel material layer, wherein the laser is generated by the laser device with the wavelength being 400 to 1080nm; the manufacturing material is a mixture of a polyamide powder material and a thermal medium material; the thermal medium material absorbs laser energy and conducts the laser energy to polyamide powder, so that the manufacturing material in the laser irradiation region realizes fusion. The polyamide three-dimensional object with high manufacturing precision can be manufactured according to the method.

Owner:HUNAN FARSOON HIGH TECH CO LTD

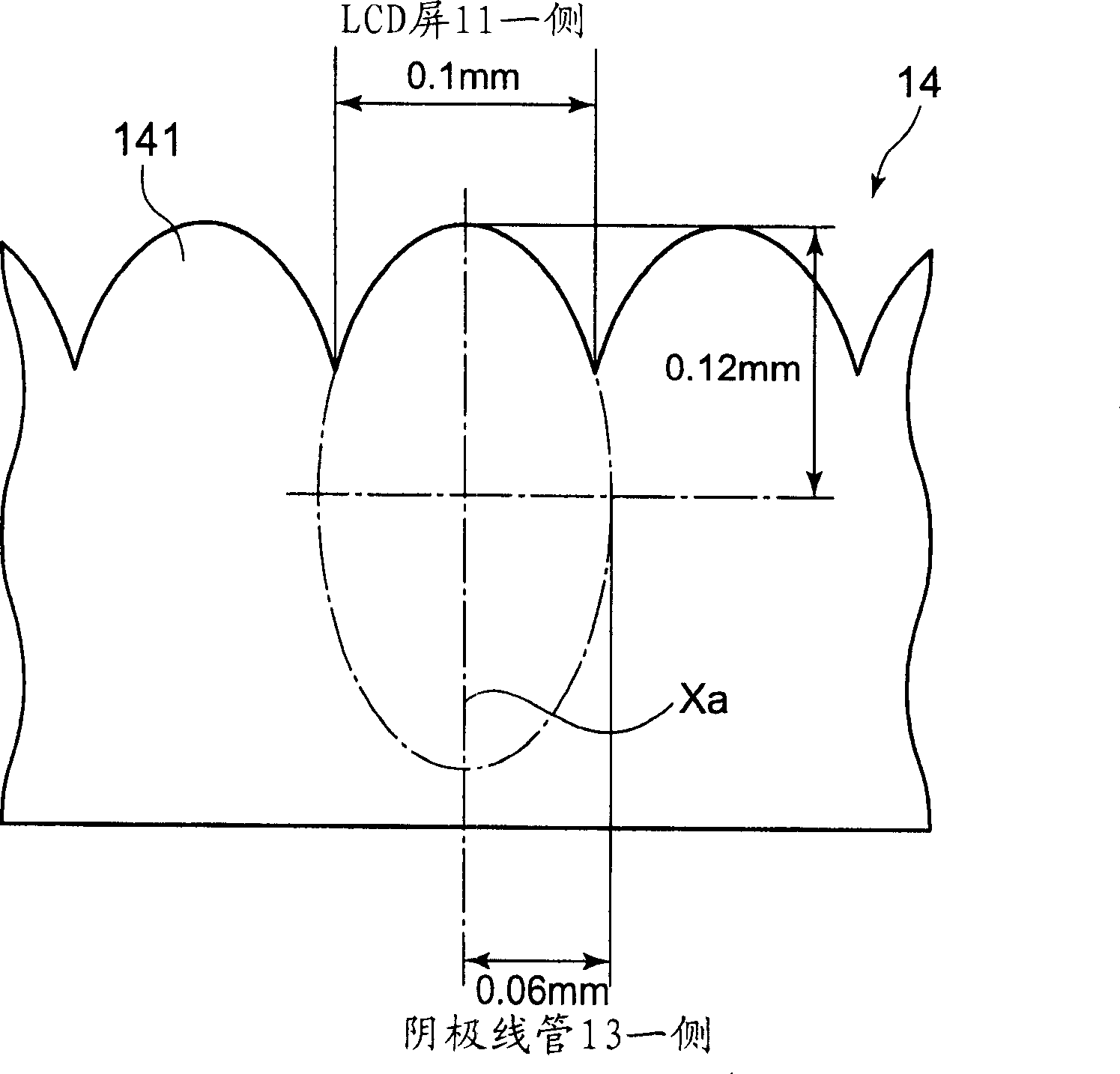

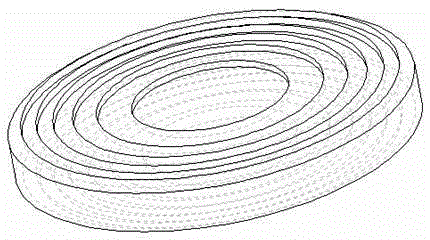

Diffusion plate, surface light source device and transmission type display device

InactiveCN1683974ANo reduction in utilization efficiencyUniform lightOther printing matterElongate light sourcesDiffusionEllipse

A diffusing sheet, a surface light source unit, and a transmission type display that can attain uniform illumination so that the brightness of light on the display screen appears uniform regardless of the position from which the display screen is observed. The diffusing sheet includes, on its light-emerging side surface, a diffusion lens array having a plurality of unit lenses, each unit lens being in a shape equivalent to a part of an elliptic cylinder having an elliptical cross section. The surface light source unit includes the diffusing sheet and a convergent sheet 12 that has a plurality of unit lenses 121 having almost trapezoidal cross sections, formed on one surface thereof. It is possible to attain uniform illumination by diffusing light from cathode ray tubes in the surface light source unit, and, at the same time, to converge the light serving as backlight to enhance optical efficiency.

Owner:DAI NIPPON PRINTING CO LTD

Conical Collimator for X-ray Measurements

ActiveUS20190204246A1Increase the solid angle of the sourceHigh strengthImaging devicesAdditive manufacturing apparatusSoft x rayX-ray

Owner:PANALYTICAL BV

Method for welding nuclear main pump shielding can

ActiveCN102091867AReduce the impactGuaranteed dimensional accuracyLaser beam welding apparatusHeat-affected zoneEngineering

The invention discloses a method for welding a nuclear main pump shielding can. A laser welding machine is utilized to perform pulse laser welding on the nuclear main pump shielding can. The method comprises the following steps of: bending and rolling a Hastelloy C-276 alloy sheet into a drum, arranging into a special welding fixture, protecting the front and back of a welding line by using inertgas, connecting a laser welding head with a Nd:YAG solid pulse laser through a transmission fiber, and welding a longitudinal seam of the nuclear main pump shielding can by controlling the accurate positioning and continuous movement of a laser welding head. By the method, on the one hand, a weld heat-affected zone of the nuclear main pump shielding can is small, a workpiece is not deformed, the diameter is high in precision, the correction treatment is not needed after welding, and the influence on the physical and mechanical properties of materials can be reduced to the minimum; on the other hand, a welding wire is not needed to be filled in the welding process, the size of the welding line is narrow, the complexity of controlling welding equipment and adjusting process parameters is simplified, and the production efficiency is improved.

Owner:DALIAN UNIV OF TECH

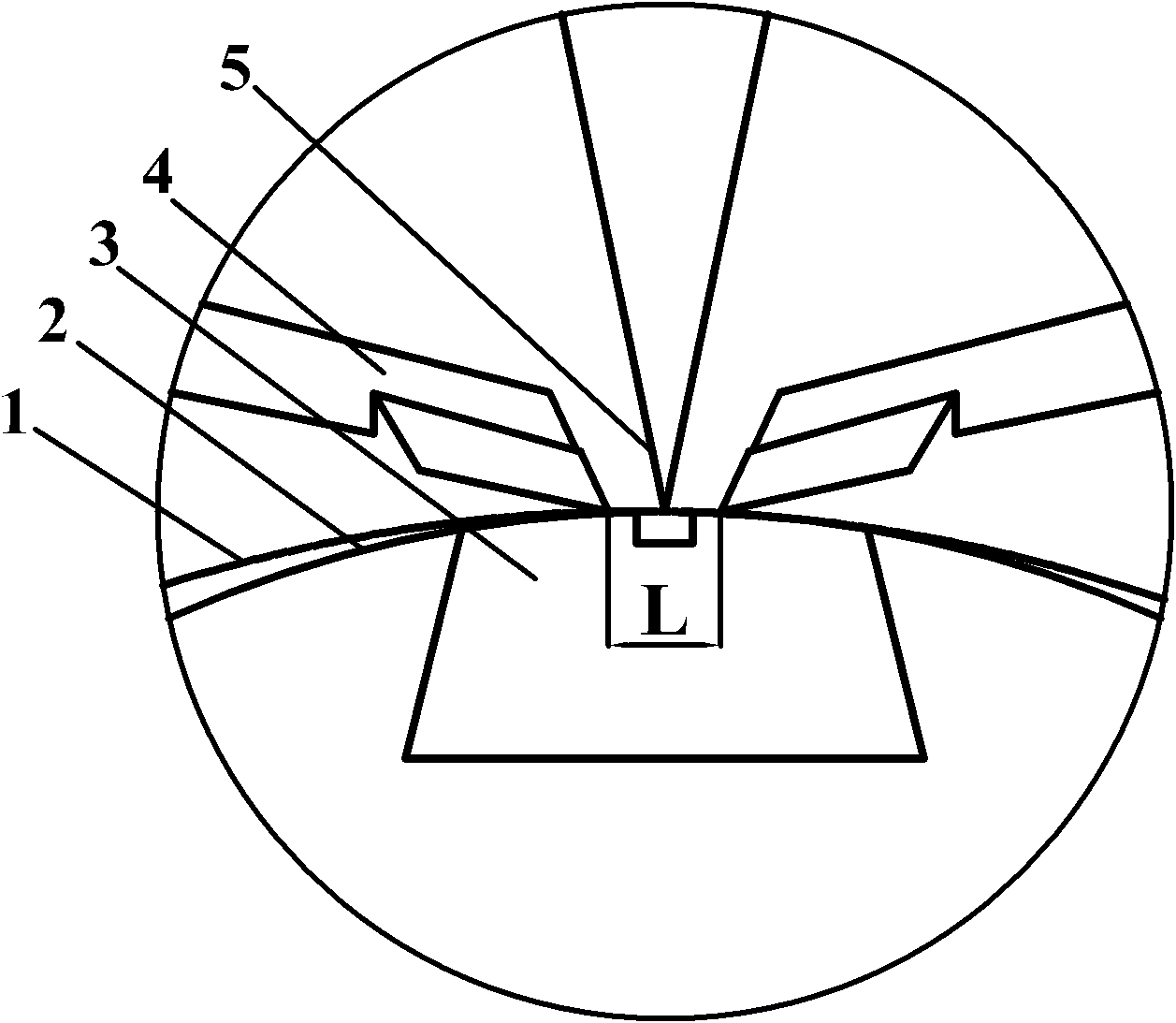

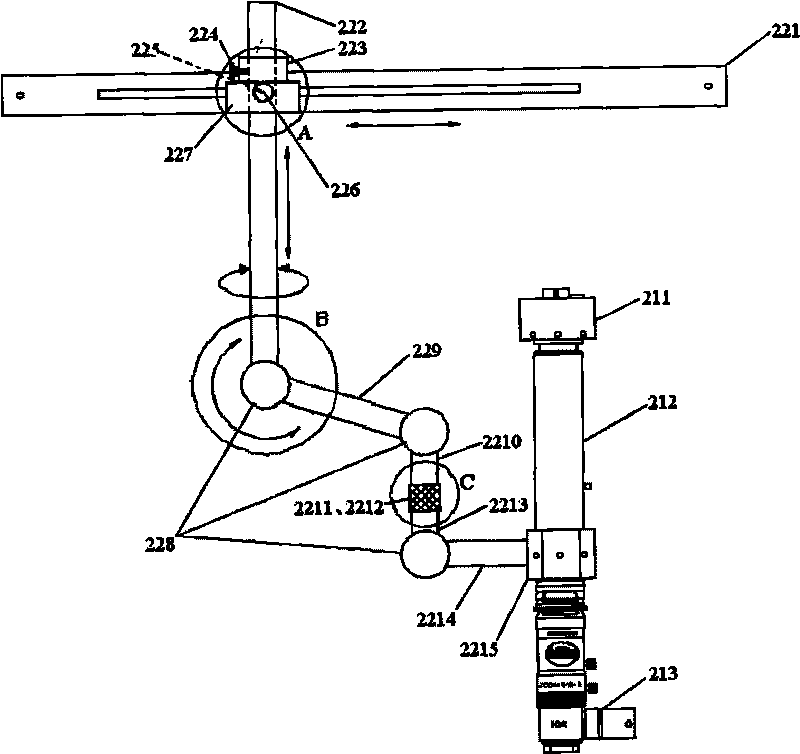

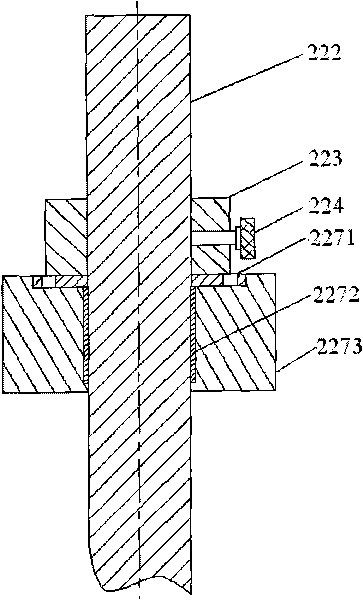

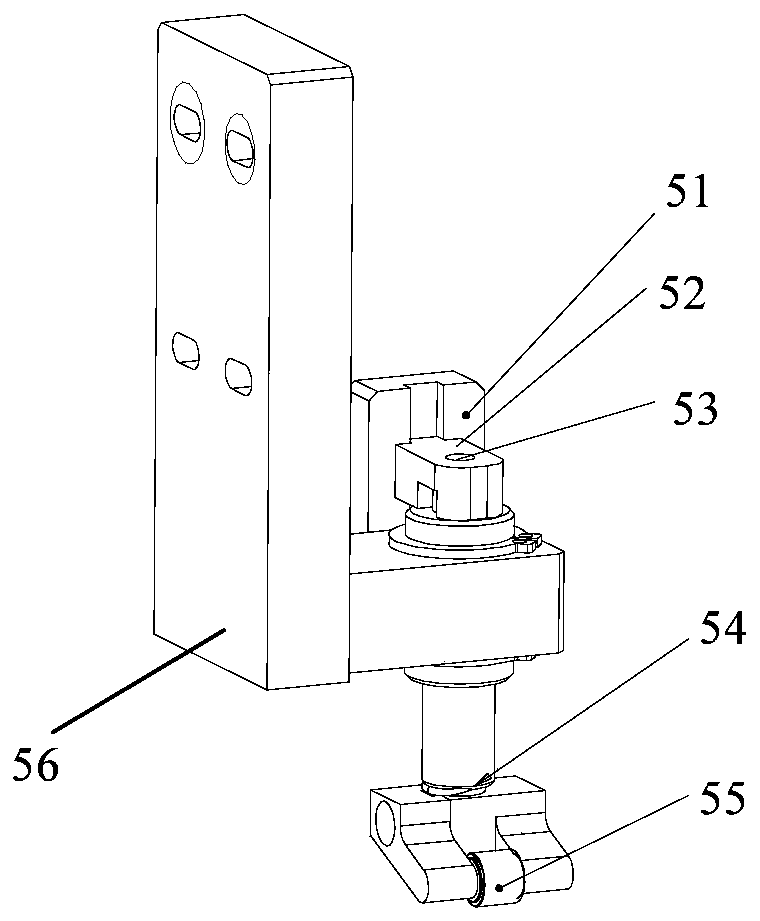

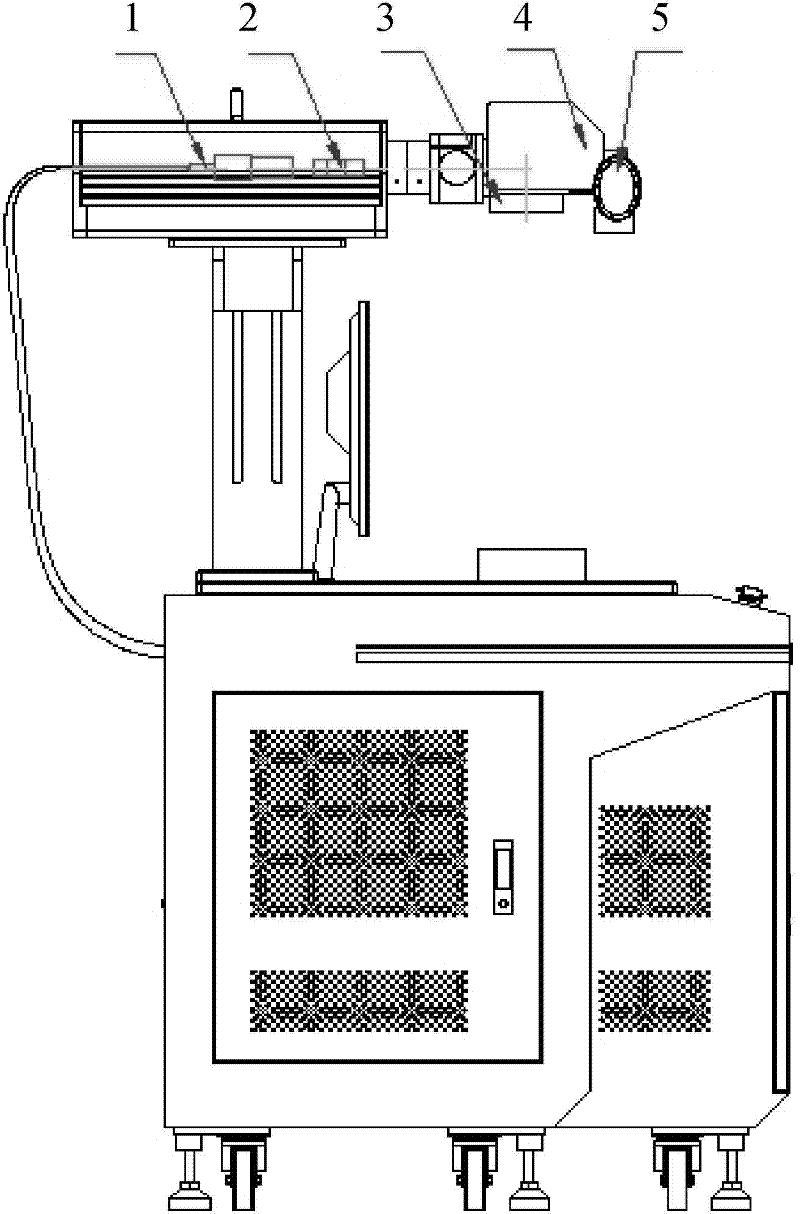

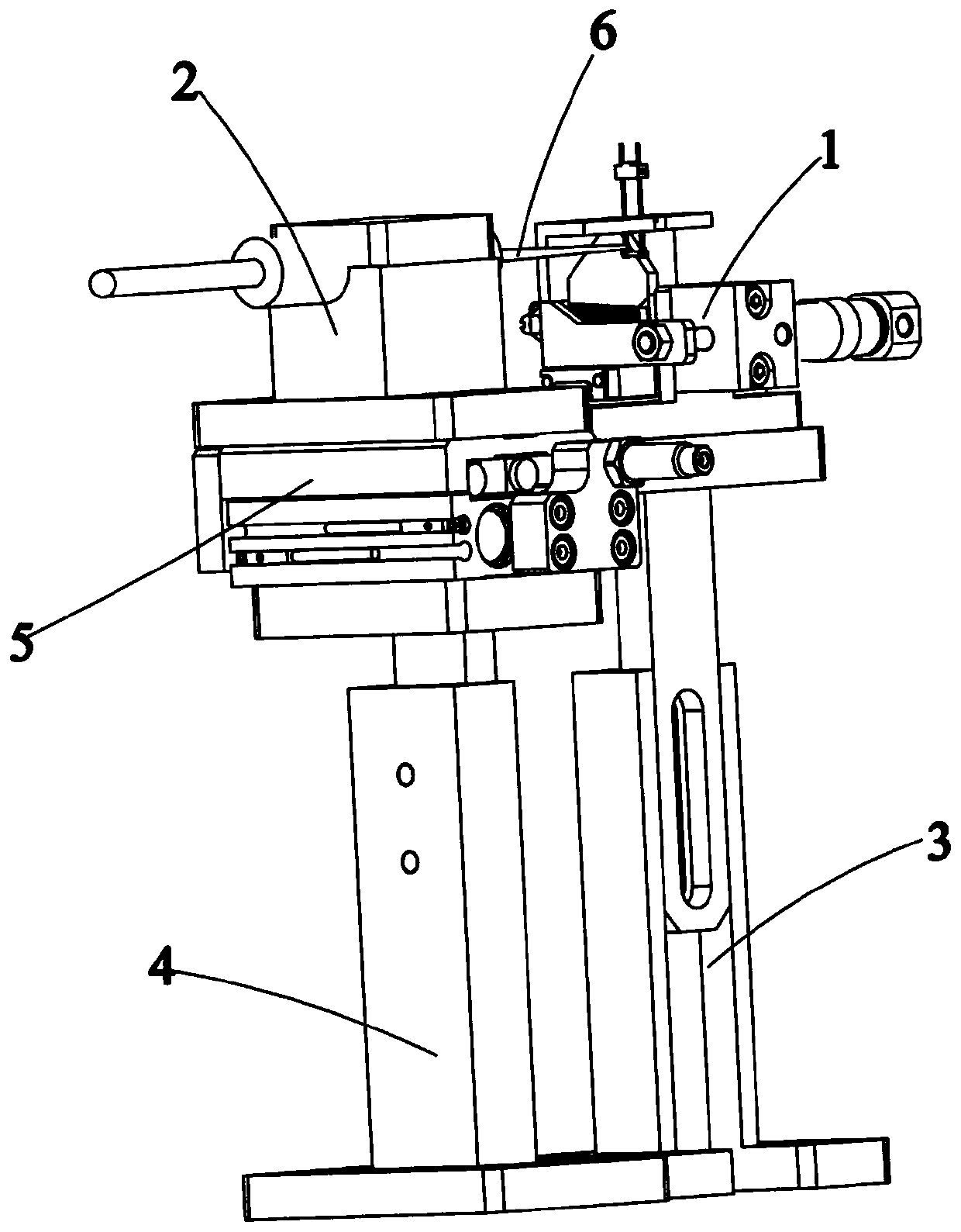

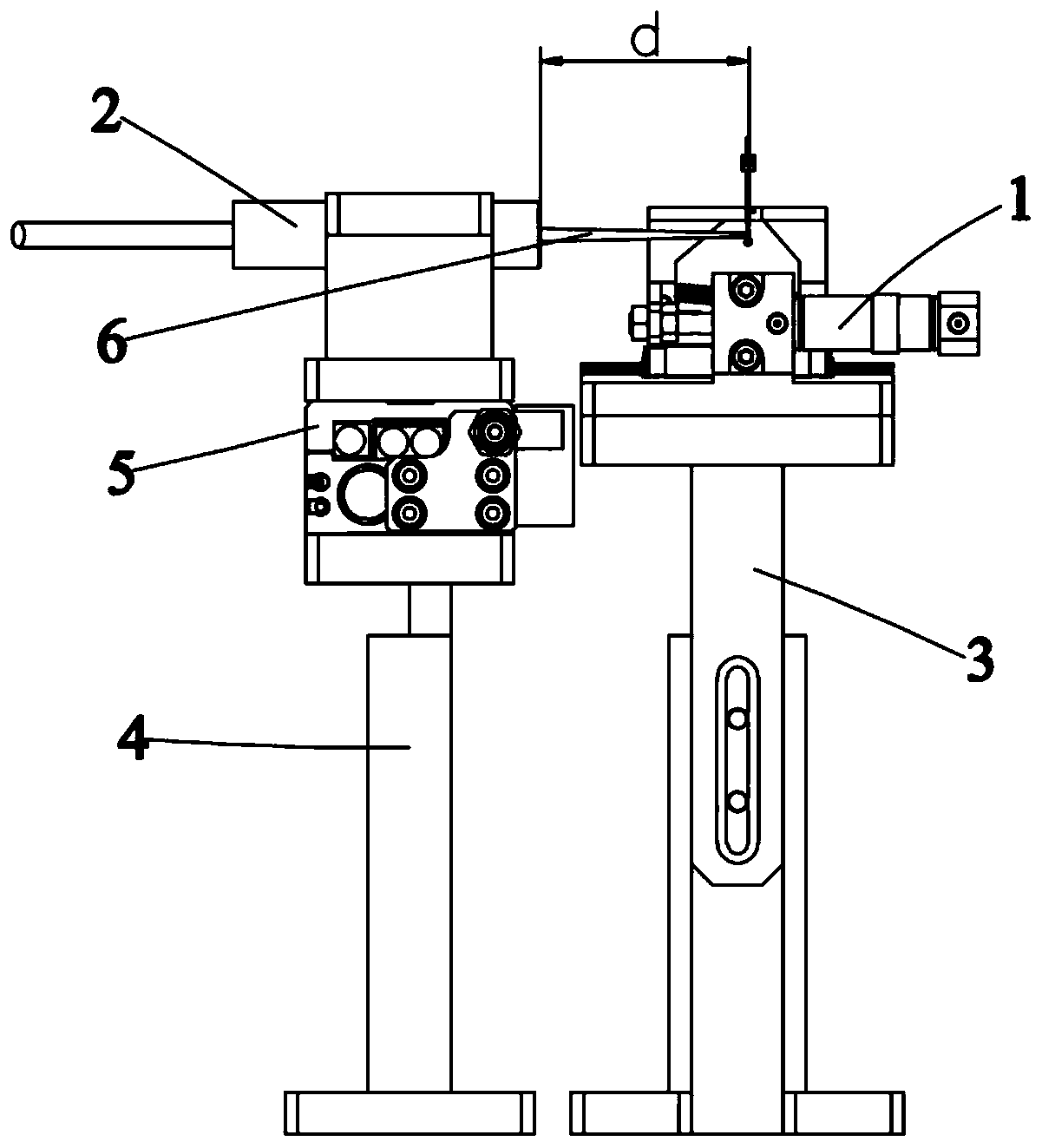

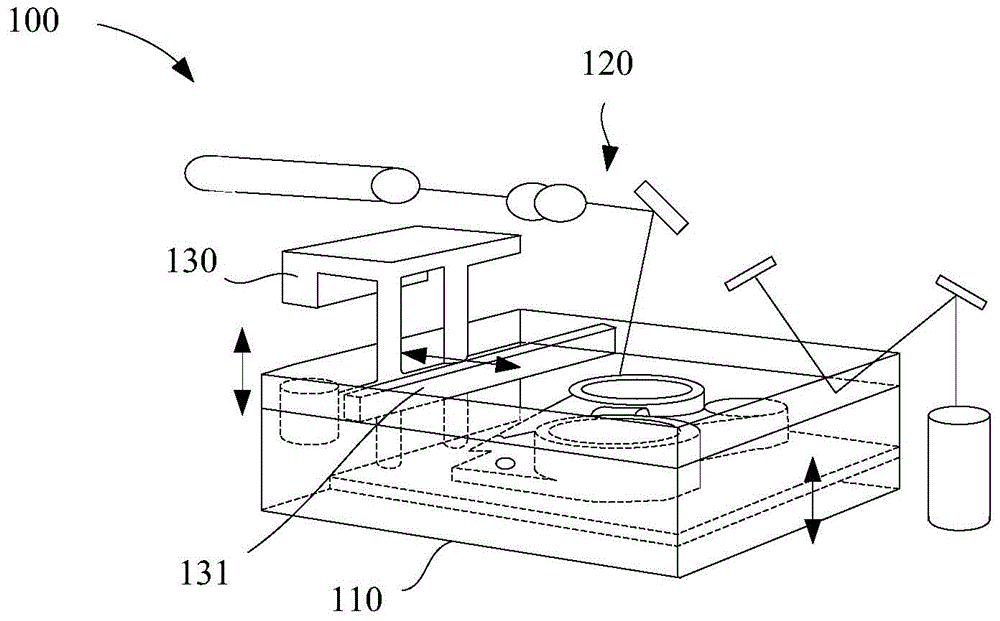

Single-lens multi-angle high-magnification photonic chip coupling and packaging device

The invention discloses a single-lens multi-angle high-magnification photonic chip coupling and packaging device which comprises a coupling adjusting device, a machine vision device and an optical-chip curing device, wherein the machine vision device comprises a lens camera assembly and a multi-angle fixing gyroscope, the lens camera assembly is arranged on the multi-angle fixing gyroscope and comprises a high-magnification lens with optical magnification of 3.5-22.5X and a high-sensitivity CMOS camera, and the high-magnification lens is arranged on the CMOS camera. By the total magnification of 175-1125X of imaging of a CMOS chip in a display, the single-lens multi-angle high-magnification photonic chip coupling and packaging device can realize 180-degree rotation under the self-designed fixing gyroscope and observation of submicron and nanometer wave guide light paths at any angle of nearly 90 degrees from vertical overlooking to horizontal side-looking, wherein an image can not shake.

Owner:SOUTHEAST UNIV

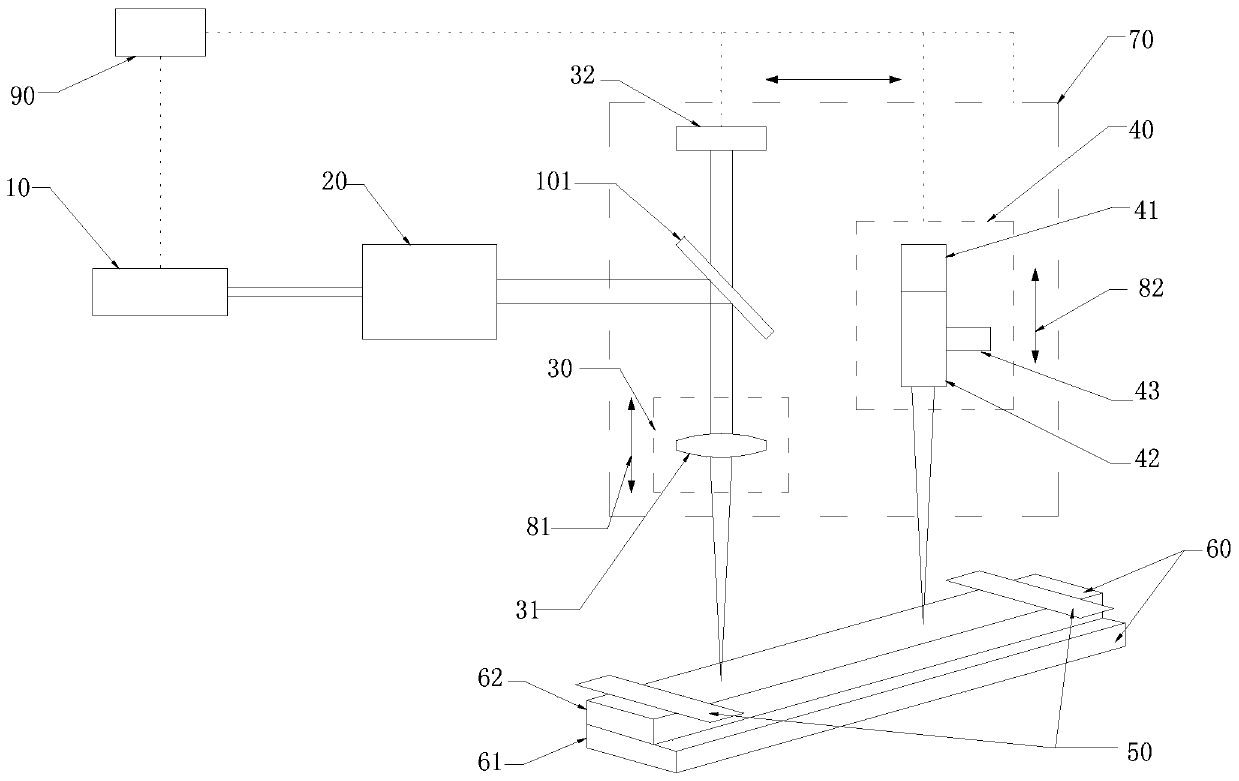

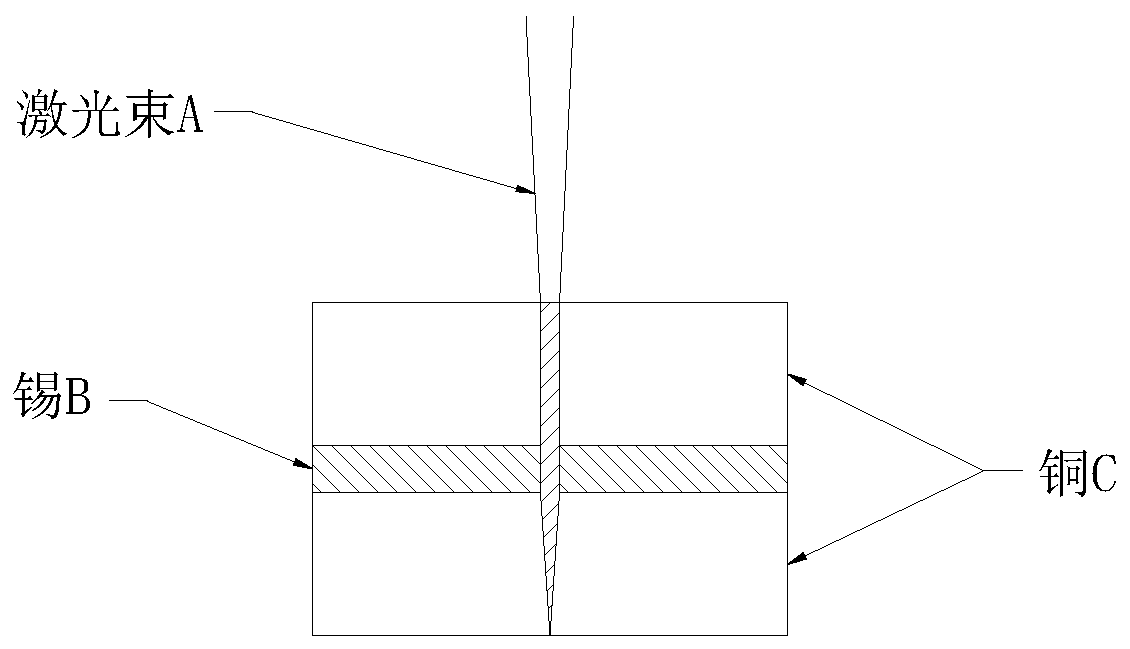

Penetrating type laser welding method of solar cell bus bars

PendingCN109986205AImprove heating efficiencySimplify the welding processLaser beam welding apparatusBeam expanderSurface layer

The invention relates to a penetrating type laser welding method of solar cell bus bars. The method comprises the following steps: outputting a laser beam through a pulse laser device, carrying out beam expansion control on diameter of the laser beam through a beam expander, focusing the laser beam subjected to beam expansion on a welding sample through a laser welding head, and enabling the laserwelding head to horizontally move up and down to adjust the size of a laser focal point and a laser welding spot; applying pre-pressure to a position near an area to be welded through a pre-pressingmechanism to enable two layers of welding strips to be in full contact with each other; receiving thermal radiation reflection laser in the welding process through a temperature feedback system, collecting a welding thermal radiation laser beam and converting the welding thermal radiation laser beam into temperature information, and calibrating the temperature of the welded area; enabling a visualimage system to move up and down to adjust a visual image focal point and identifying position information of the welding sample; focusing pulse laser on the welding strips, forming extremely high laser energy density in an action area, directly gasifying tin on the surface layers and copper on the inner sides of the welding strips, forming cavities in the materials and enabling the materials tobe tightly occluded with each other, and directly carrying out fusion welding of copper layers of the two layers of welding strips. The welding quality is high.

Owner:江阴德龙能源设备有限公司

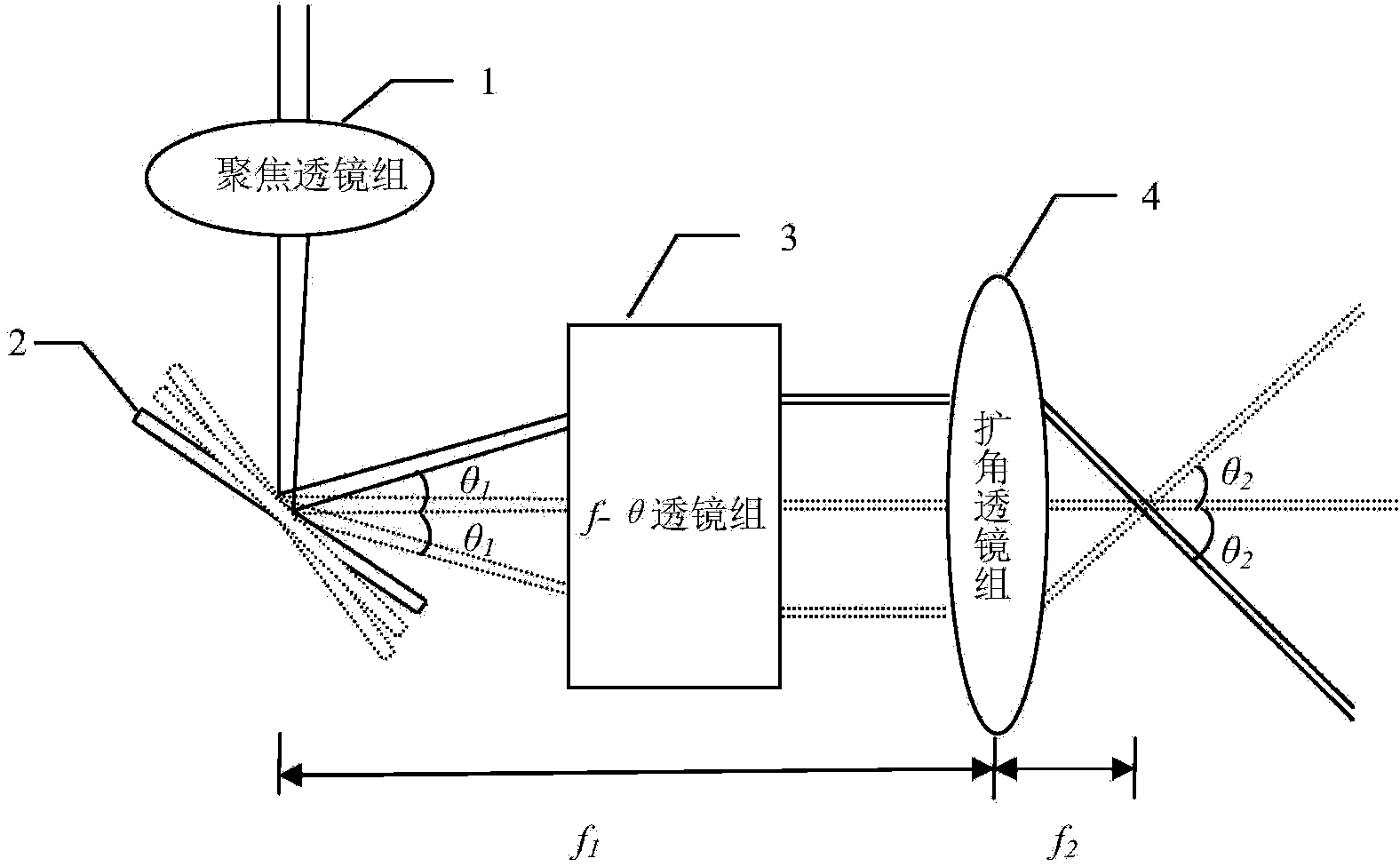

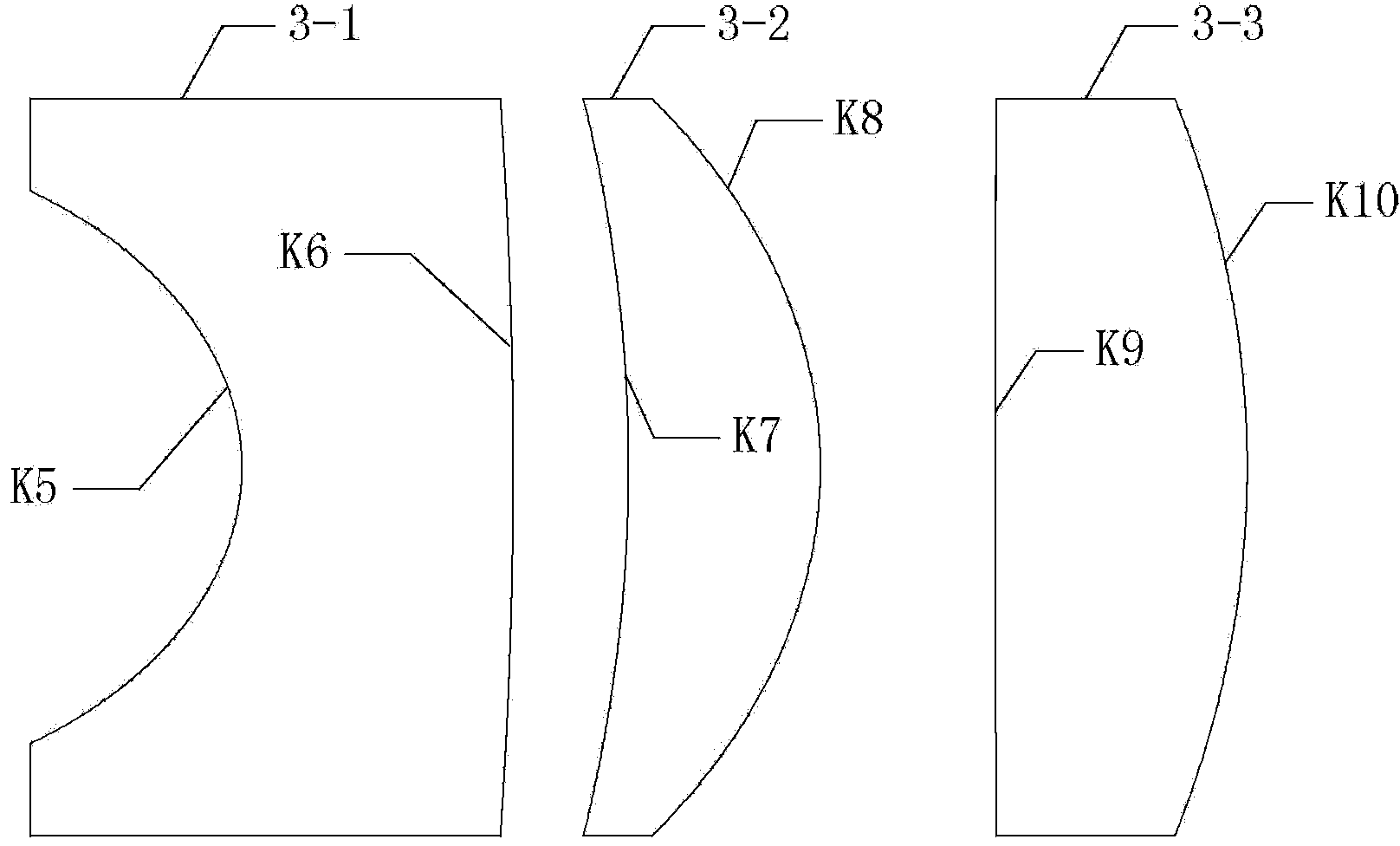

Folding type scanning optical system based on MEMS micro mirror

The invention provides a folding type scanning optical system based on an MEMS micro mirror, and belongs to the field of optics. The folding type scanning optical system solves the problem that an existing MEMS scanning system is small in the scan field angle. The folding type scanning optical system comprises a focusing lens group, the MEMS micro mirror, an f-theta lens group and an angle expanding lens group. After the incident light is transmitted by the focusing lens group and then is reflected by the MEMS micro mirror, the incident light is irradiated into the f-theta lens group, and is irradiated into the expanding angle lens group after being transmitted by the f-theta lens group, the inclined angle between the transmission light generated after angle expanding is conducted by the angle expanding lens group and a system optical axis is theta 2, and f2 is smaller than f1. Theta 1 serves as the inclined angle between the light reflected by the MEMS micro mirror and the system optical axis, the f2 represents the effective image space focal length of the angle expanding lens group, and the f1 represents the focal length of the f-theta lens group. The mechanical deflection angle of the MEMS micro mirror ranges from -4 degrees to 4 degrees, and the inclined angle theta 1 ranges from -8 degrees to 8 degrees. The folding type scanning optical system based on the MEMS micro mirror is mainly applied to the field of optical scanning.

Owner:HARBIN INST OF TECH

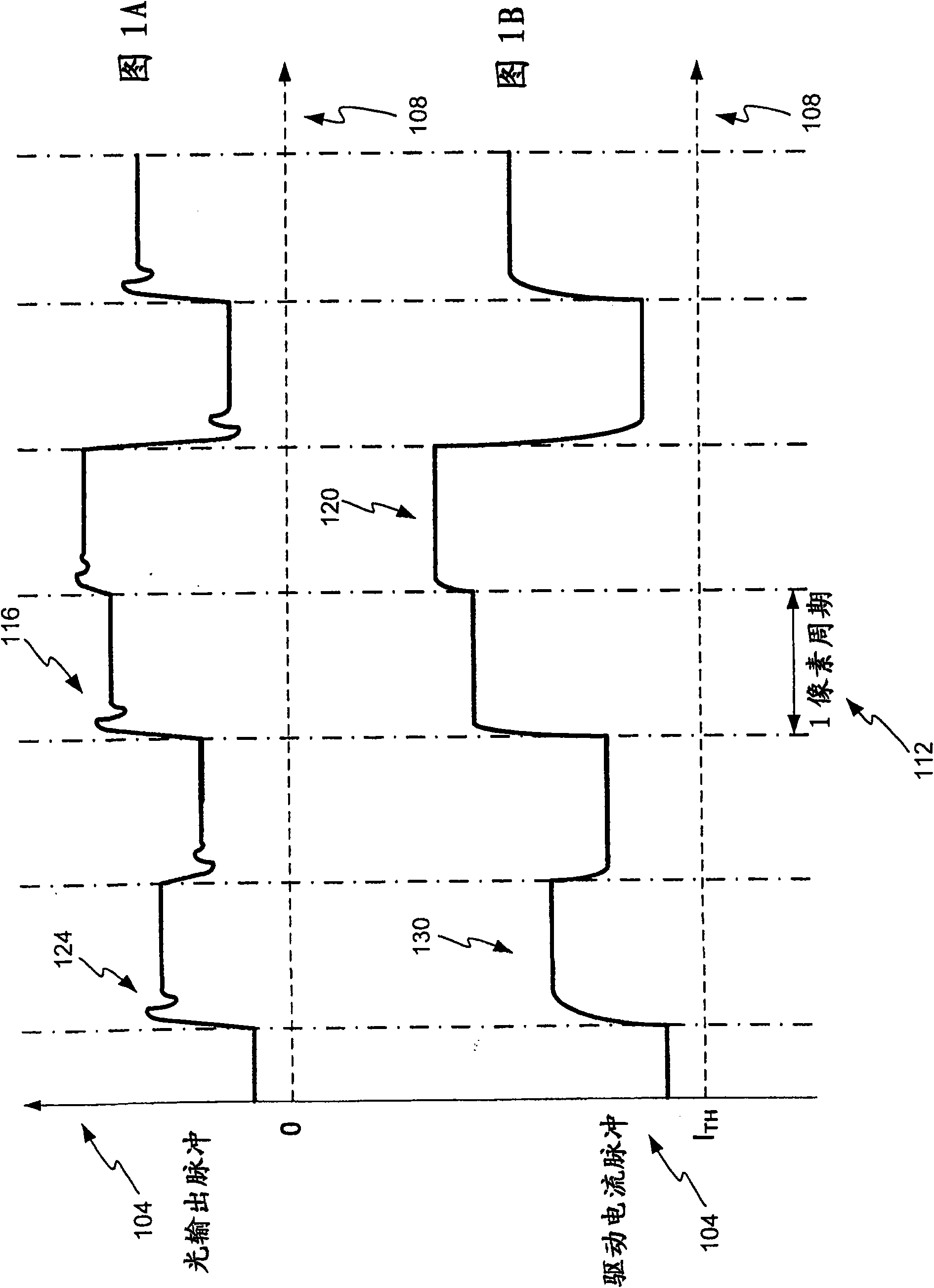

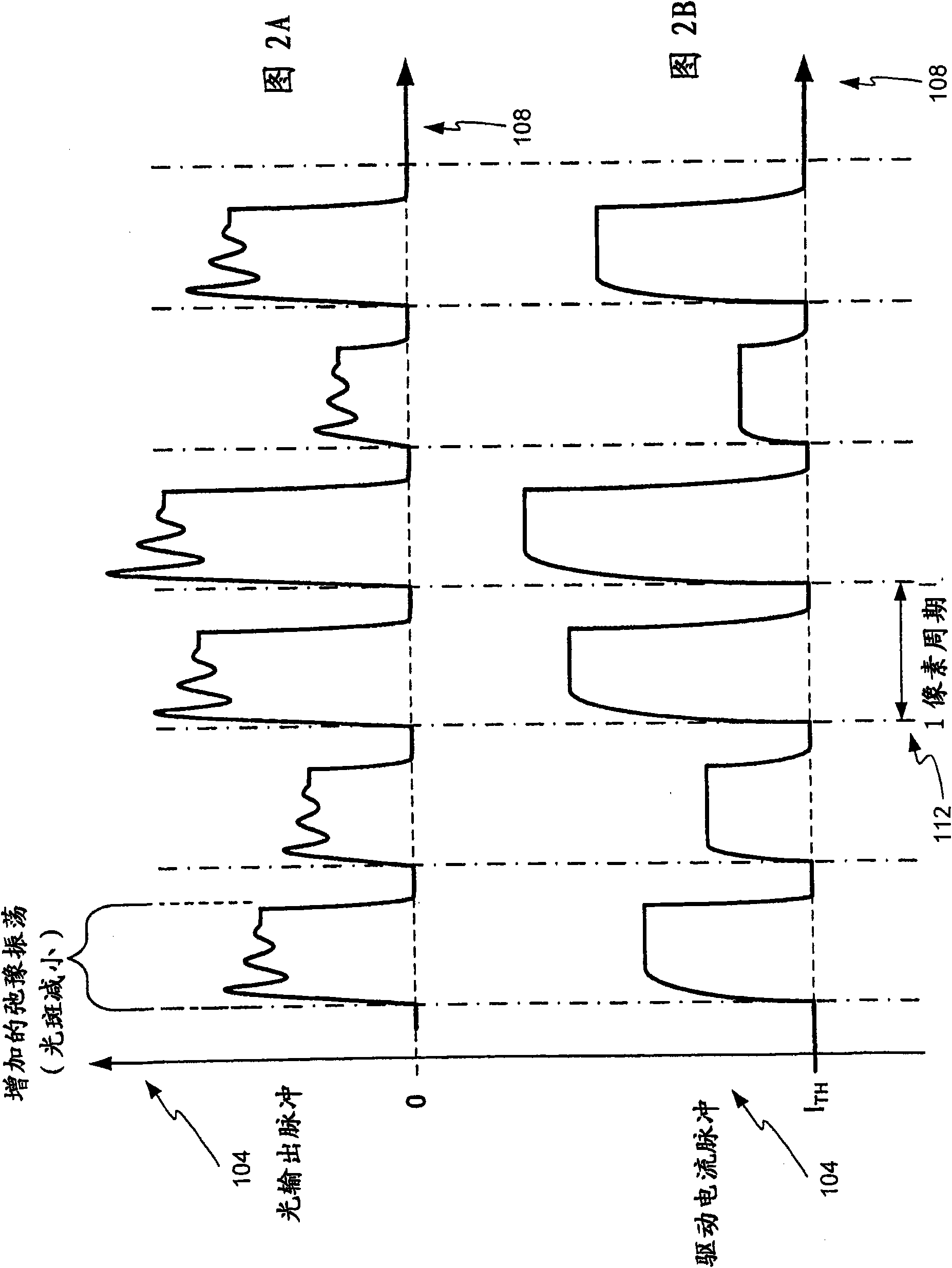

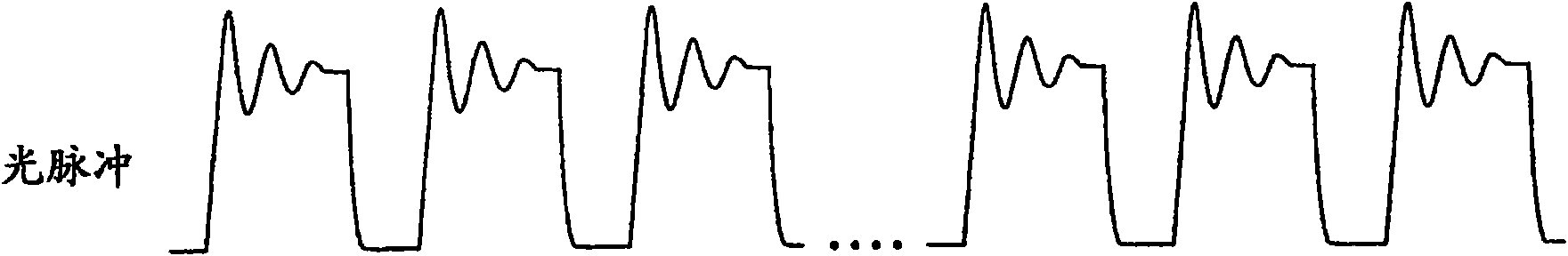

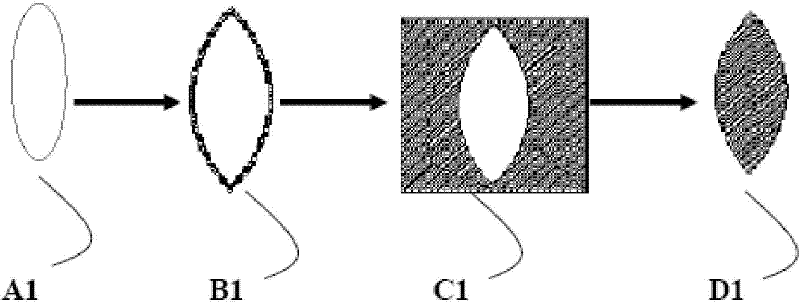

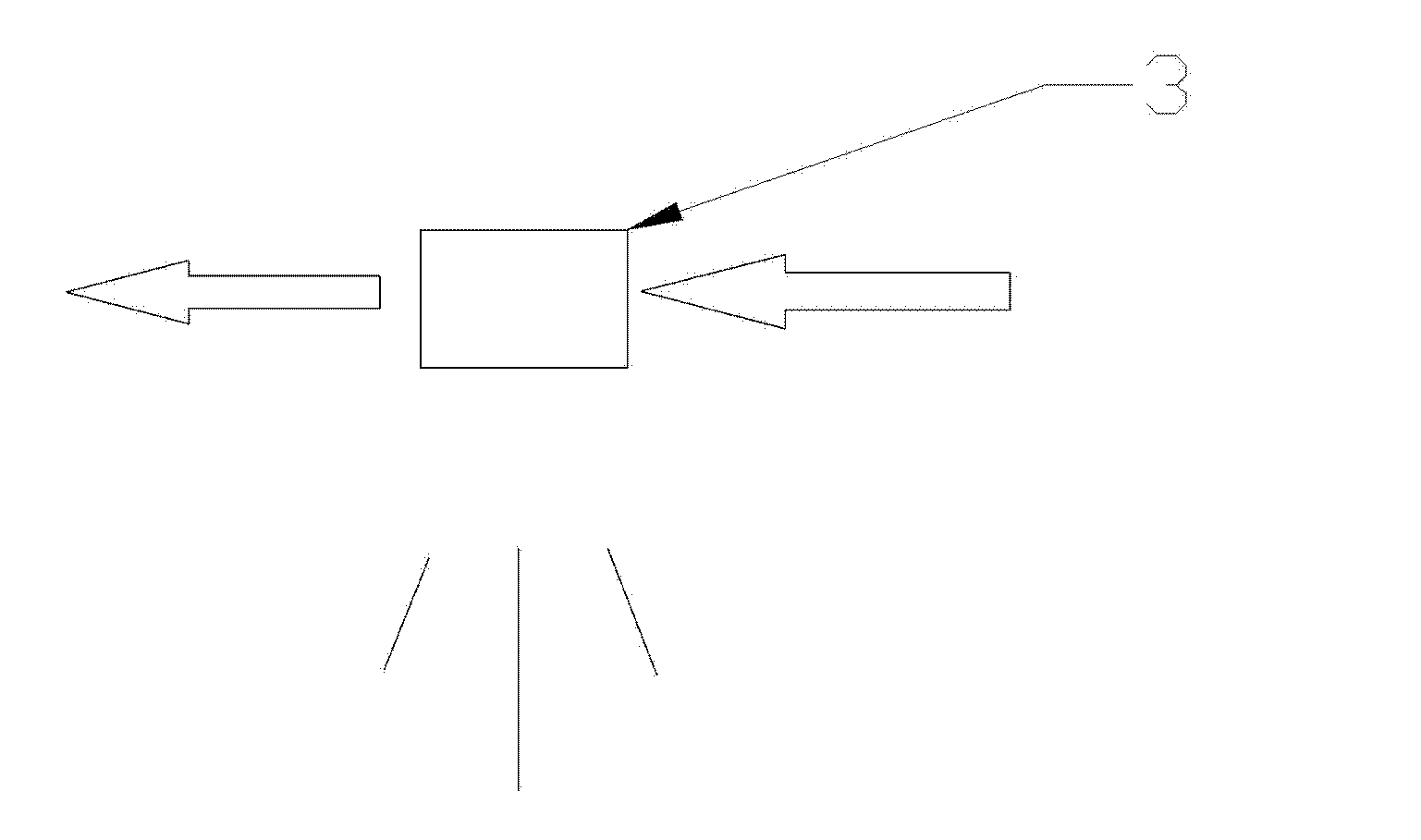

Method and apparatus for reducing optical signal speckle

InactiveCN101911401ASmall spotTelevision system detailsColor television detailsImpulse frequencyControl system

An optical signal generator is configured with an associated control system and driver configured to reduce speckle. Speckle reduction occurs by pulsing the drive signal between a first current level and a second current level. These pulses force the optical signal generator to introduce oscillations into the optical signal. The coherence of the emitted light is reduced during the period of oscillations in the optical signal, which reduces speckle. In one embodiment, the pulsing of the drive signal brings the drive signal down to a level near or below threshold, which in turn intermittently turns off the optical signal output. Returning the optical signal to a desired optical output intensity introduces the speckle reducing oscillation. The pulse frequency, and duty cycle is controlled by a duty cycle control signal to modulate overall optical power and adjust amount of despeckle.

Owner:MANDERBÜHNE TECH GMBH

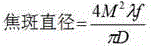

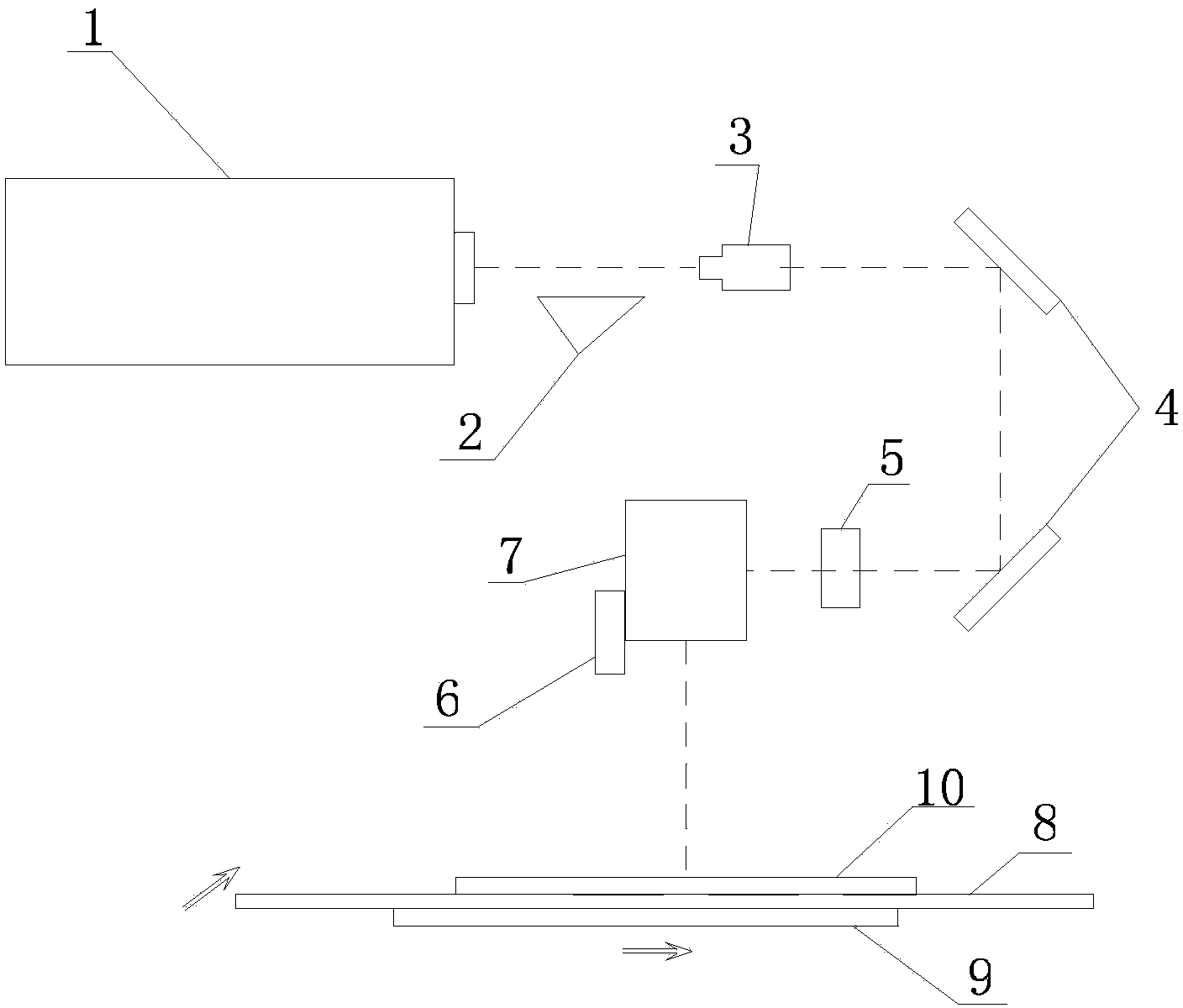

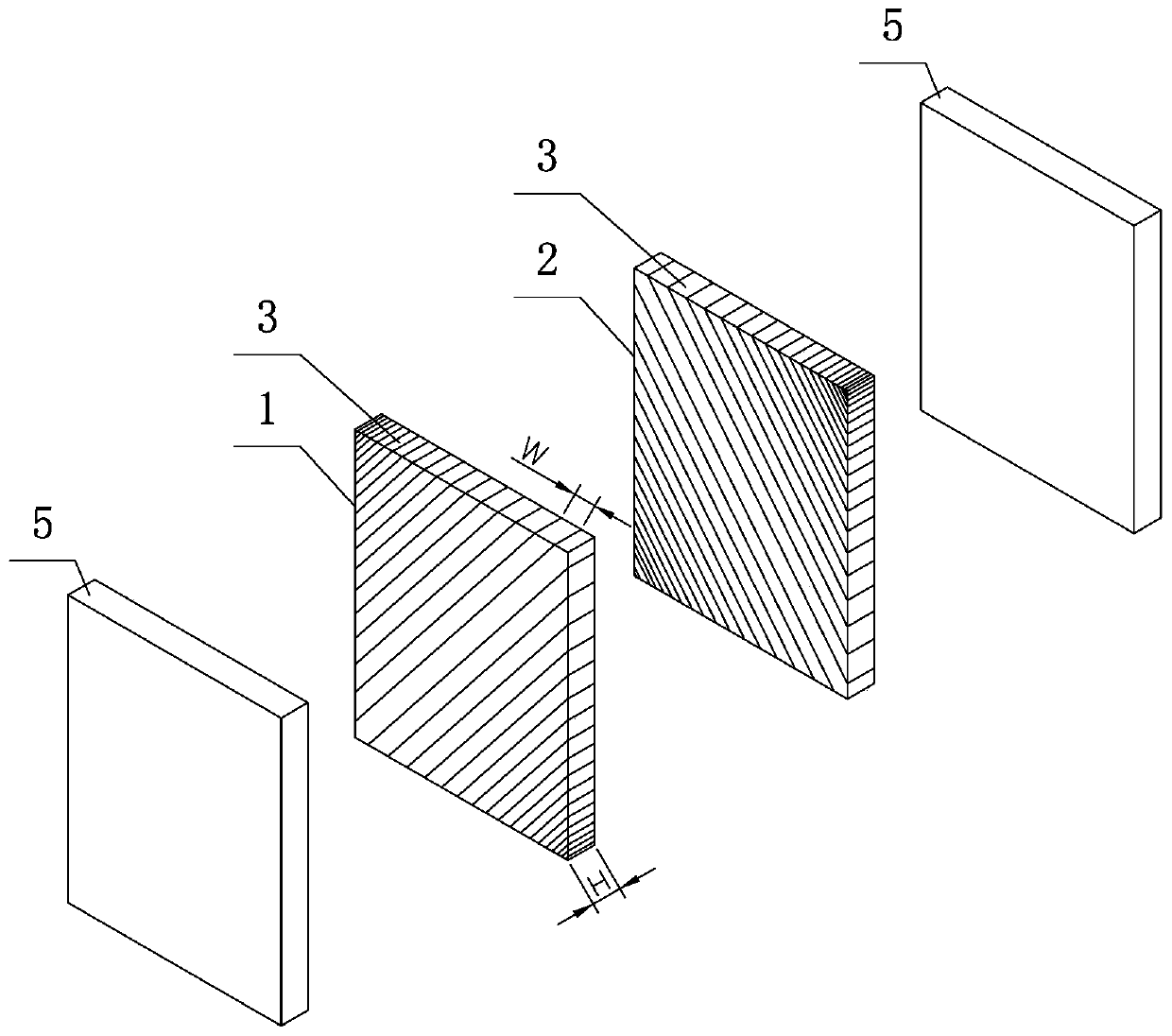

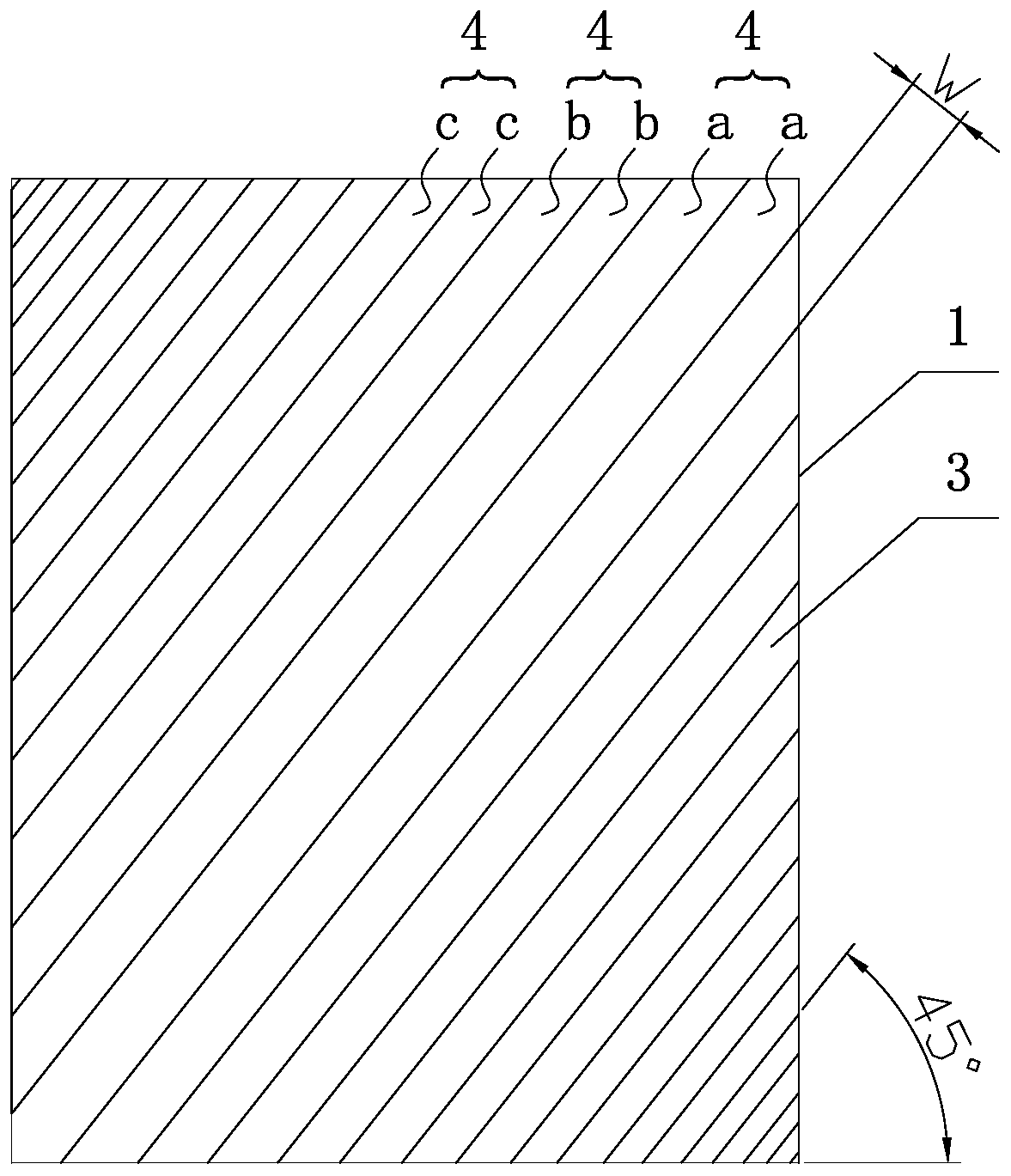

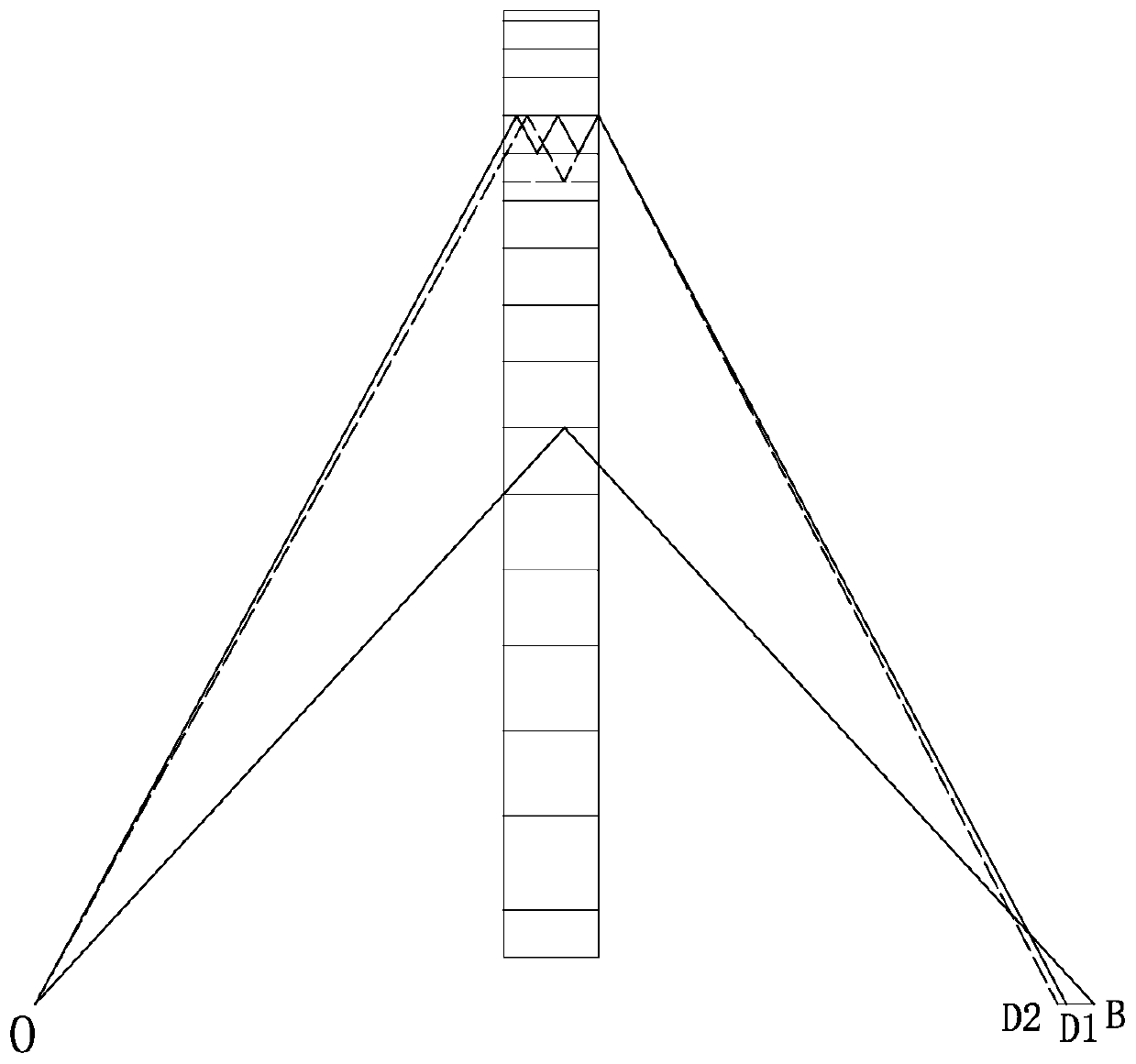

Device and method for carrying out laser machining on light guide board inside glass

InactiveCN104237997AImprove divergence angleSmall spotGlass shaping apparatusOptical light guidesCamera lensThree dimensional microstructure

The invention relates to a device and method for carrying out laser machining on a light guide board inside glass. A beam expander, a 45-degree total reflection mirror set, a beam shaping unit and a scanning galvanometer are arranged on a light path of the output end of a laser in sequence. The beam output end of the scanning galvanometer right faces a carrier platform. A CCD system is installed on the scanning galvanometer. A lens of the CCD system right faces the carrier platform. Laser beams emitted by the laser are coaxially expanded through the beam expander, the beam transmission divergence angle is improved, the light path is made to be aligned, and the light spot is smaller after focusing is carried out by coaxially expanding the laser beams; the expanded beams reach the 45-degree total reflection mirror set and enter the beam shaping unit, the shaped focusing light spot can be of a three-dimensional microstructure inside the glass, the shaped beams reach the scanning galvanometer, laser beams emitted by the scanning galvanometer are focused inside the glass serving as a workpiece to be machined, and marks are etched inside the glass. The device is high in light transmittance, wide in application range, long in service life, not prone to abrasion and accurate in machining position.

Owner:SUZHOU DELPHI LASER

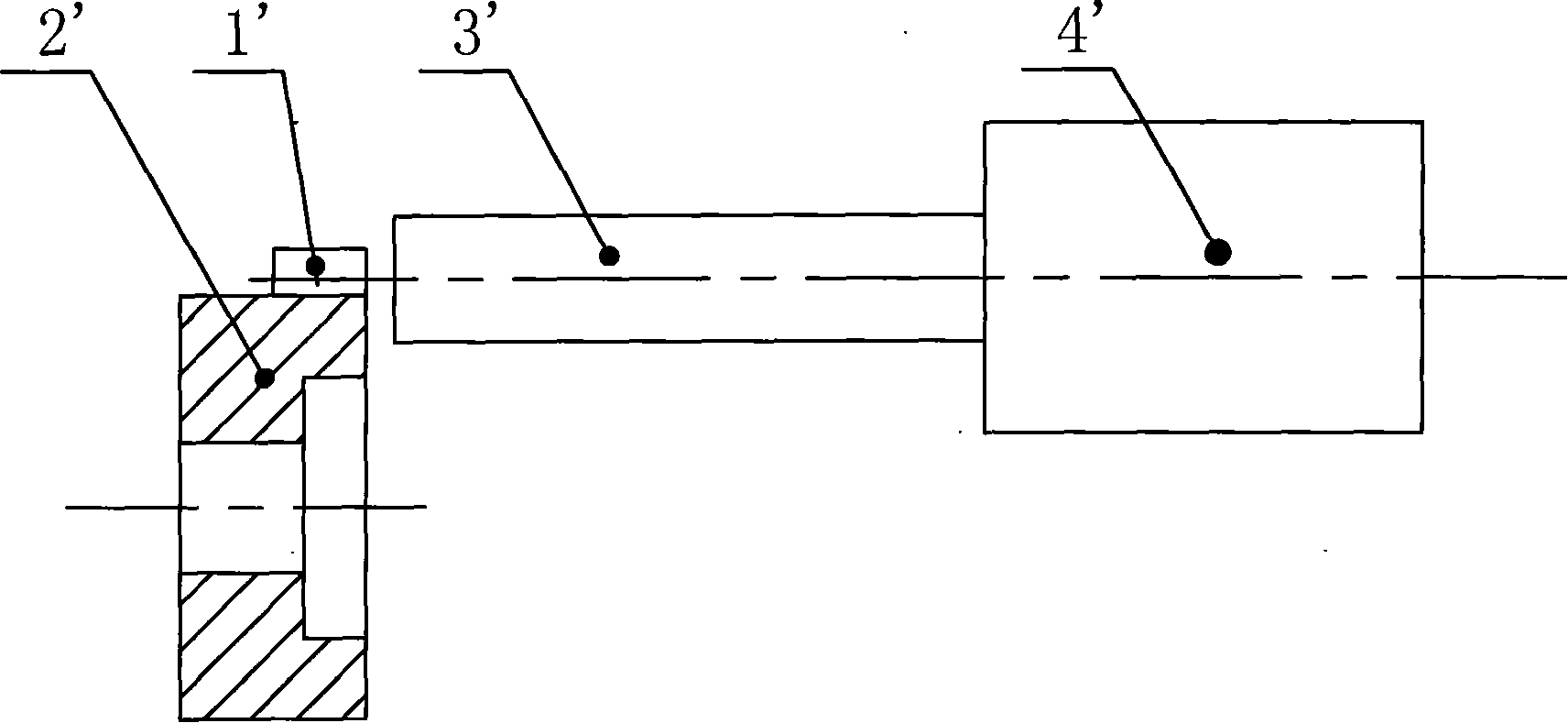

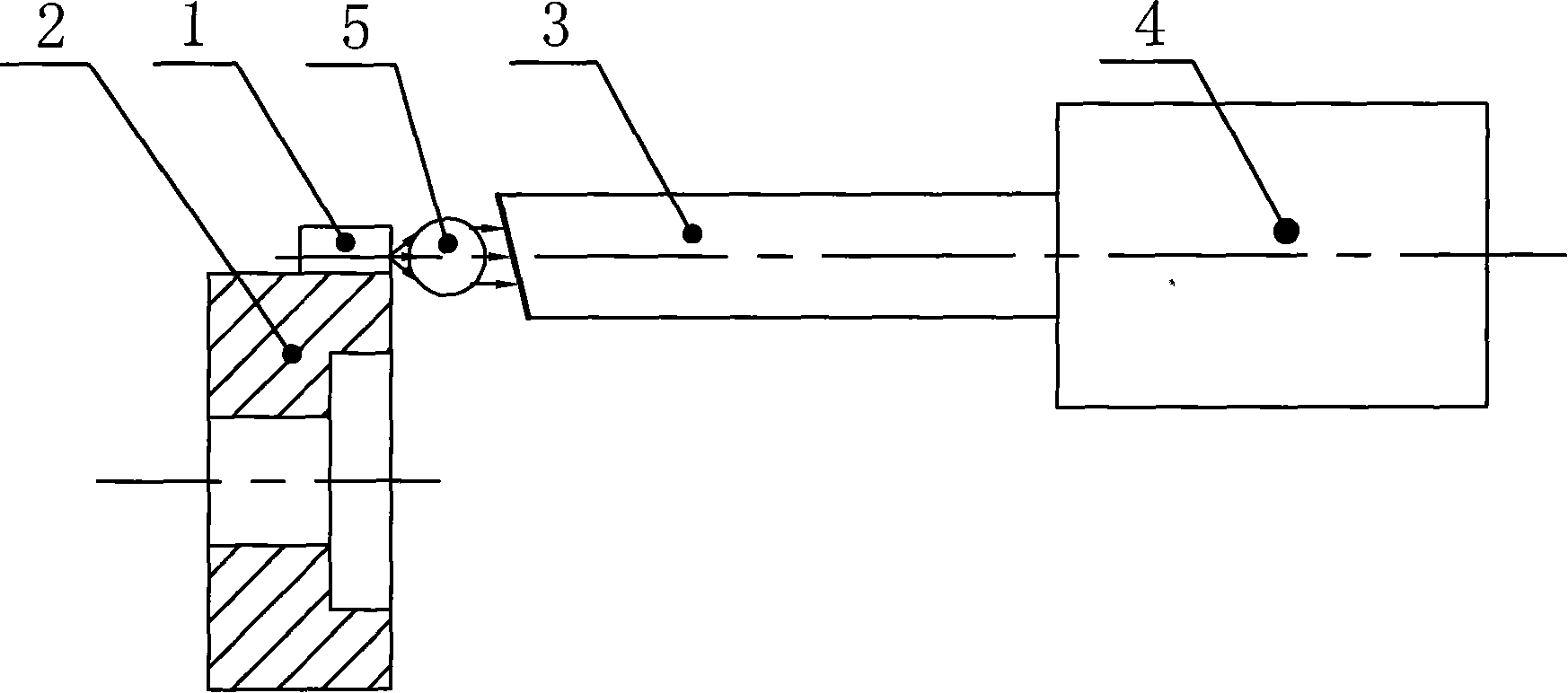

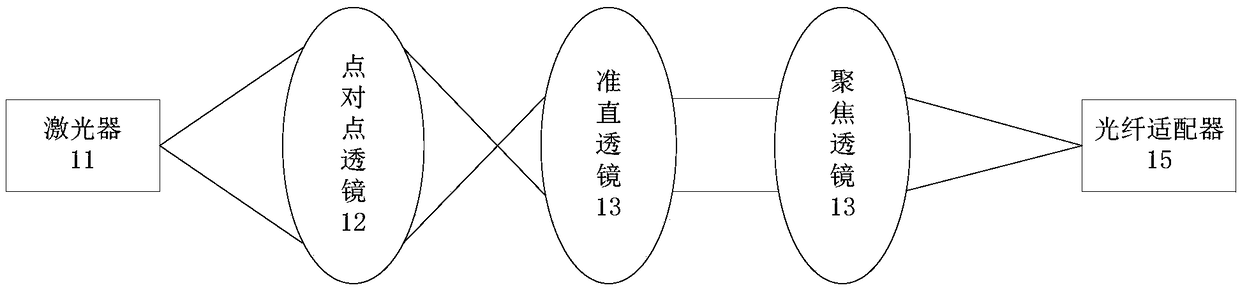

High power semiconductor laser device coupling packaging component

InactiveCN101162829AImprove power densityImprove coupling efficiencyLaser detailsSemiconductor laser structural detailsSemiconductorOptical fiber cable

The present invention discloses a large power semiconductor laser coupling encapsulation component, which comprises a C-Mount encapsulation laser for emitting laser, a transmitting optical fiber coupled with emitted laser, an optical fiber connecting head for outputting laser and connected with the transmitting optical fiber and a pillar lens which is arranged between the emitting end of the laser and the transmitting optical fiber for compressing laser. An inclined plane is formed on the coupled end of the transmitting optical fiber and the laser. An AR film is coated on the inclined plane. The coupling encapsulation form of the C-Mount encapsulation laser has the advantages of (1) high coupling efficiency of the optical fiber, (2) no influence on working stability of laser without reflection on the light emitting chip of the laser from the reflecting light on the end face of the transmitting optical fiber and (3) no damage on the light emitting chip of the laser during coupling of the optical fiber due to moderate distance between the end face of the transmitting optical fiber and the end face of the light emitting chip of the laser.

Owner:BUTTERFLY TECH SHENZHEN

Optical fiber sensing measurement method of laser plasma shock wave mechanical effect

ActiveCN103226205AShorten the timeReduce distortionX/gamma/cosmic radiation measurmentShock waveFiber

The invention relates to an optical fiber sensing measurement method of a laser plasma shock wave mechanical effect. According to the measurement method, a high-power density and short pulse femtosecond laser is used for irradiating a target to generate a high-pressure plasma stock wave, and an optical fiber sensing signal demodulation system for on-line monitoring of a femtosecond laser plasma is set up by using an optical fiber F-P (Fabry-Perot) acoustic emission sensing probe. A time history of the shock wave is obtained by measuring acoustic frequency and intensity information of the laser plasma shock wave in the same position at different times, the spatial distribution of the shock wave is obtained by measuring the intensity information of a microplasma shock wave at the same time in different positions, and the temperature compensation is conducted by using an FBG (Fiber Bragg Grating) sensing technology and a differential structure to study the macromechanical effect of the femtosecond laser plasma shock wave. The method for measuring the laser plasma shock wave mechanical effect is high in spatial resolution, response speed and sensitivity, and the measurement accuracy can be improved.

Owner:WUHAN UNIV OF TECH

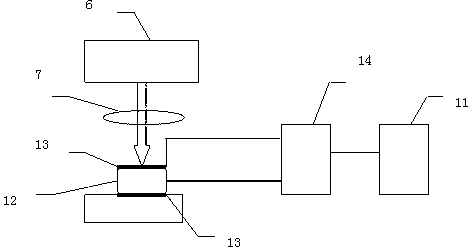

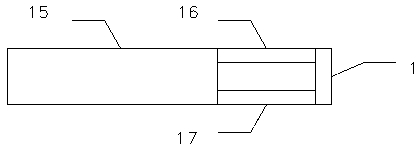

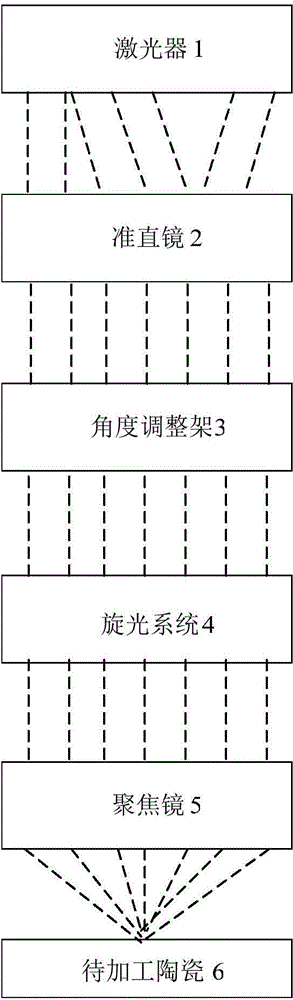

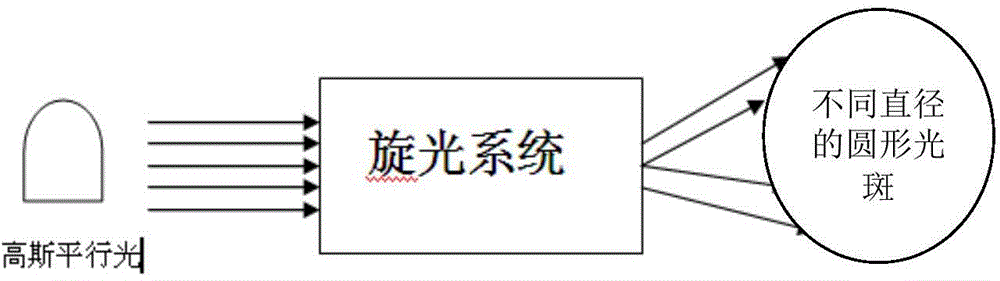

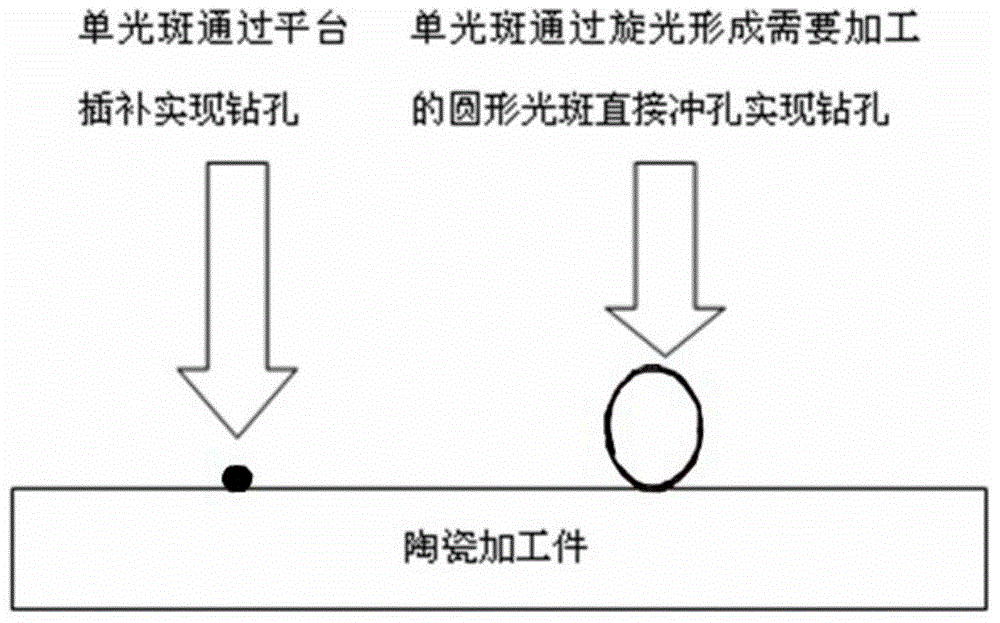

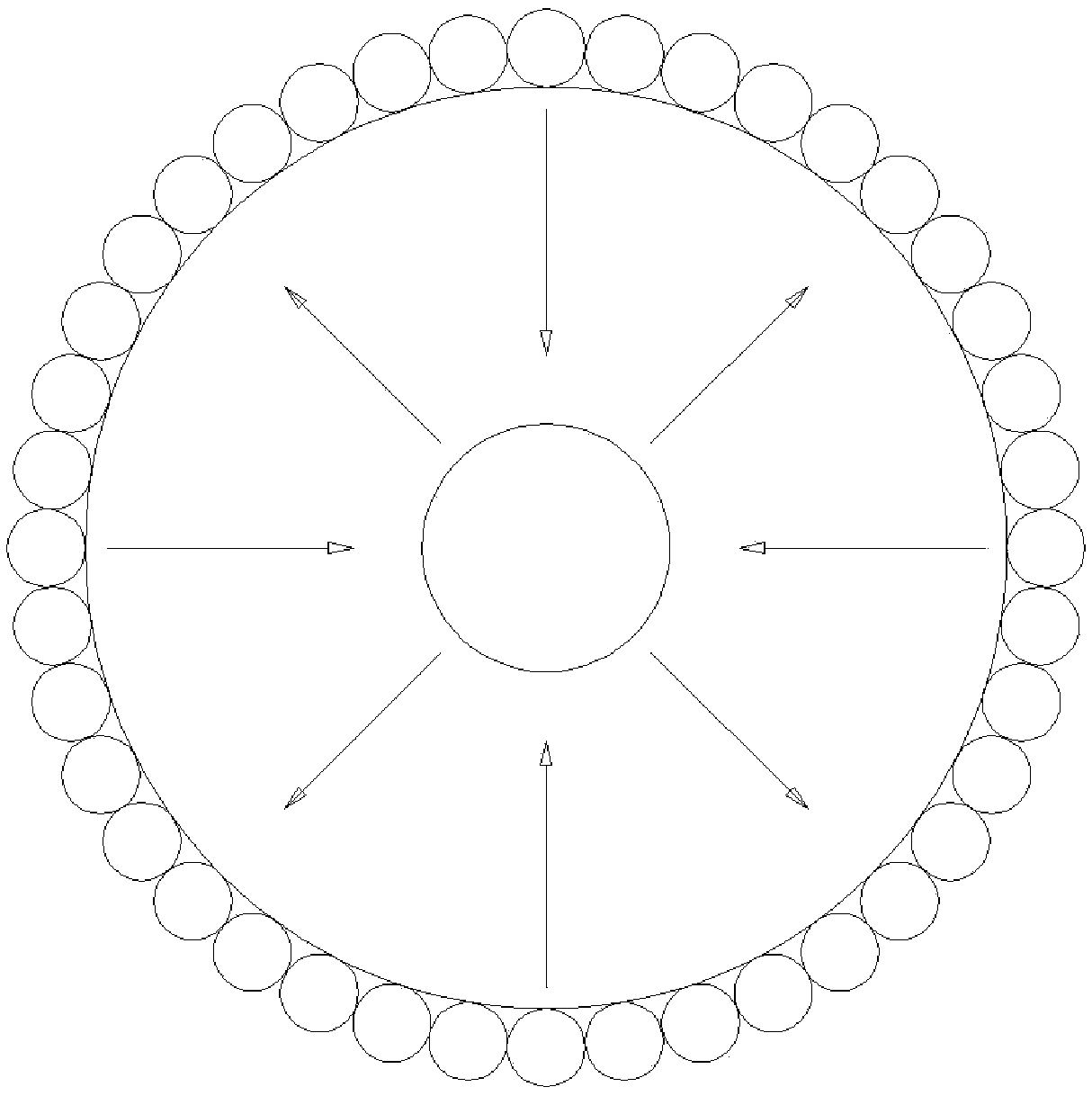

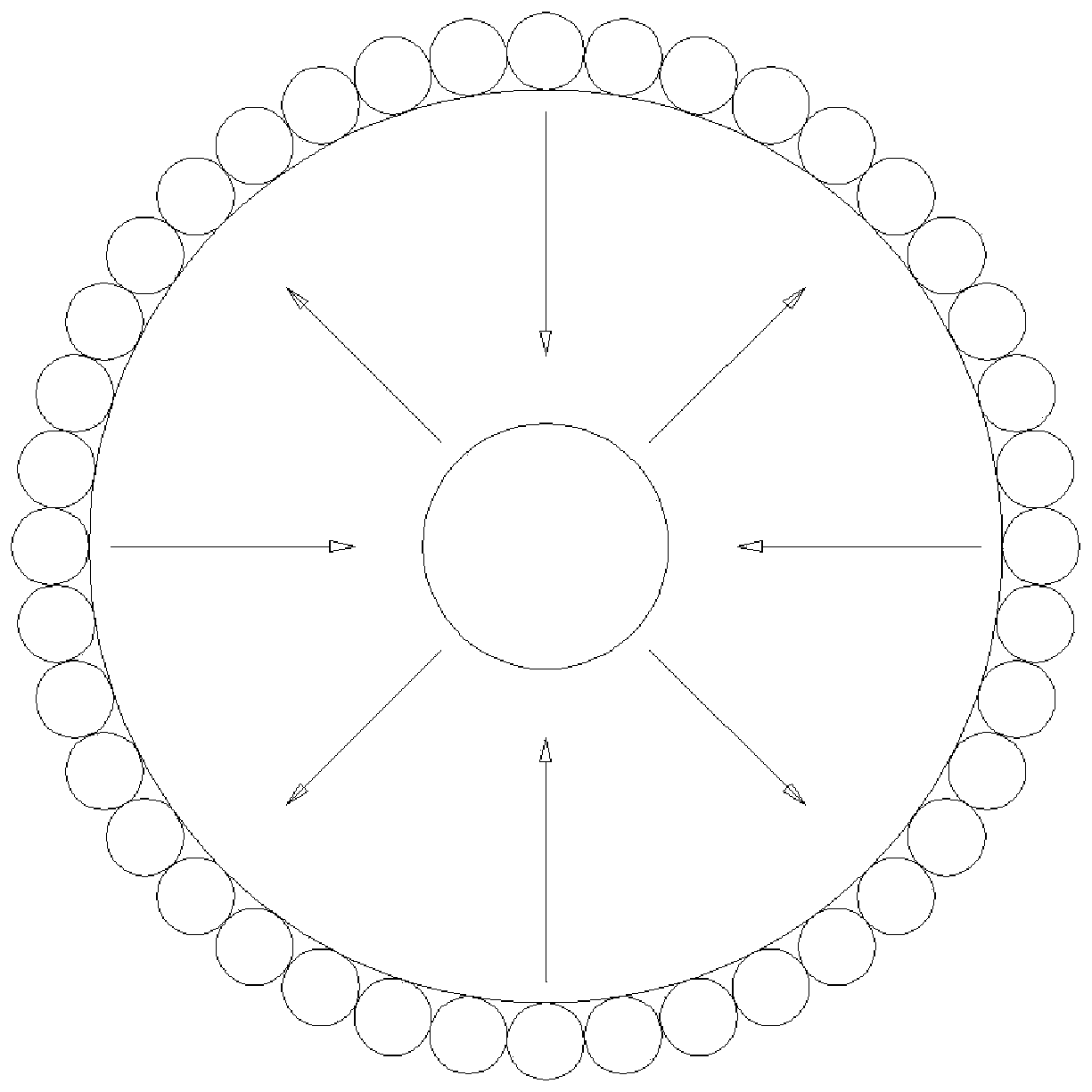

Device for processing aluminum oxide ceramic by fiber laser and method thereof

ActiveCN104384727APromote absorptionAchieve laser convergenceLaser beam welding apparatusLight spotFiber disk laser

The invention relates to a device for processing aluminum oxide ceramic by fiber laser and a method thereof. The device comprises a laser, a collimating mirror, an optical rotation system and a focusing mirror which are sequentially arranged along an optical path, wherein laser is emitted by the laser, runs through the collimating mirror and is converted to parallel light beams by divergent light; the collimated light beams are shaped by the optical rotation system; the optical rotation system is used for forming the parallel light beams as circular light rings with uniform energy distribution; the shaped light beams enter the focusing mirror to collect the laser; an auxiliary positioning image system is matched for controlling laser punching positions and is used for punching with high accuracy and monitoring the punching process in real time; the ceramic drilling, marking and cutting functions are implemented; different micorpores (D is smaller than or equal to 1mm) are punched in a single laser point; the device has the advantages of small light spots, high efficiency and low cost.

Owner:SUZHOU DELPHI LASER +1

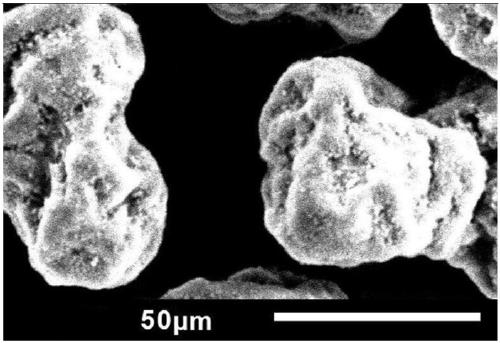

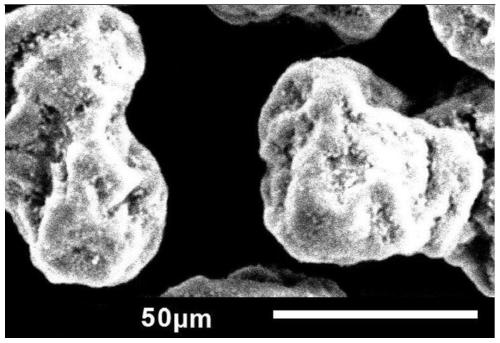

Nylon polymer powder material and preparation method thereof

ActiveCN109517377APrevent carbon black from agglomeratingImprove liquidityAdditive manufacturing apparatusAdditive manufacturing with solidsSolventCarbon black

The invention provides a preparation method of a nylon polymer powder material. The preparation method comprises the following steps: adding the following components into a polymerizing pot in percentage by mass: 85-99.9% of nylon aggregate and 0.1-15% of a thermal medium material, adding a solvent, and preparing a nylon powder material taking the thermal medium as a nucleating agent by adopting asolvent precipitation method; adding 20 parts of nylon powder material and 0.1-1.5 parts of carbon black into a mixing tank, and performing the first high-speed mixing so as to prepare a nylon and carbon black mixed powder material; adding the nylon and carbon black mixed powder material, 0.1-1 part of a flow promoter and 80 parts of the nylon powder material into the mixed powder barrel, performing the second high-speed mixing and screening, thereby obtaining the nylon polymer powder material. By adopting the nylon powder taking the thermal medium material as the nucleating agent and the high-speed mixing, the carbon black is uniformly attached onto the nylon powder surface, so that the nylon powder in the prior art is applied to fiber laser sintering, the surface quality of the parts isexcellent, the structure is fine, and the overall performance is excellent.

Owner:HUNAN FARSOON HIGH TECH CO LTD

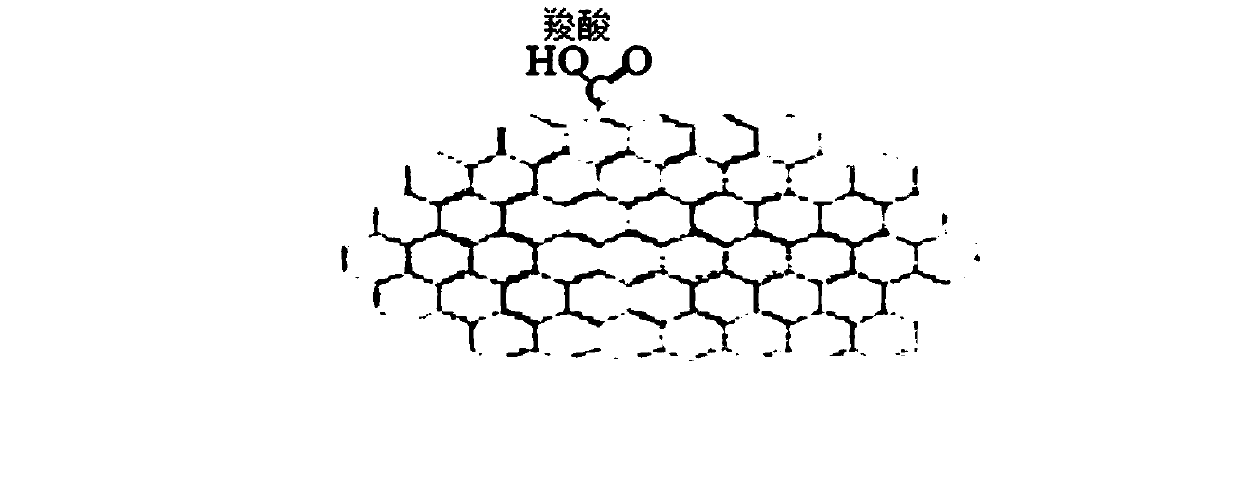

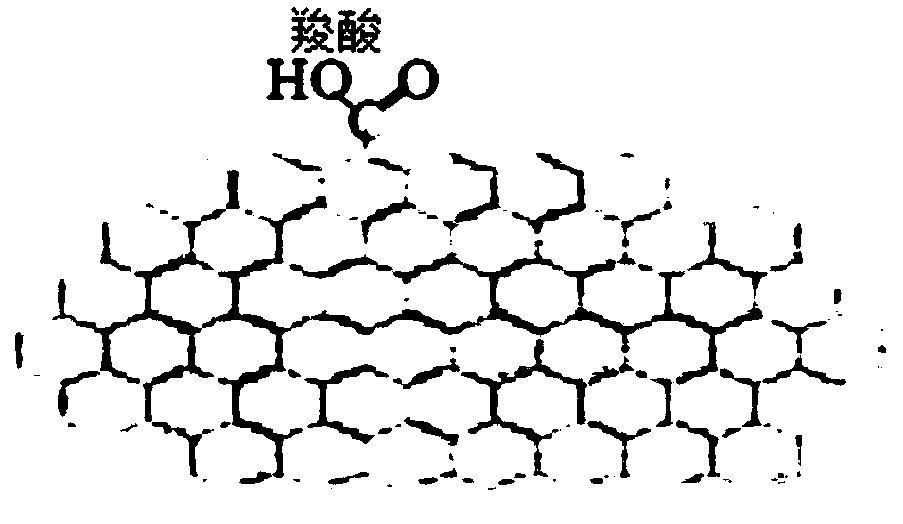

Device and method for etching conducting layer made from graphene on touch screen

InactiveCN103071925AImprove divergence angleSmall spotLaser beam welding apparatusLaser etchingGalvanometer

The invention relates to a device and a method for etching a conducting layer made from graphene on a touch screen. An optical gate is arranged at the output end of a high-frequency short-pulse laser; a beam expanding lens is arranged at the output end the optical gate; a 45-degree full-reflection mirror is arranged at the output end of the beam expanding lens; a dynamic focusing mirror and a scanning field mirror are arranged at the output end of the 45-degree full-reflection mirror; the scanning field mirror is over against a working platform; a blowing device is arranged on one side of the working platform; and a dust collecting device is arranged on the other side of the working platform. High-frequency pulse lasers of different wavelengths are taken as laser sources for performing laser etching on conducting layers made from graphene in different touch screen products, so that the aim of etching graphene conducting layers by gasifying under the action of a high-frequency short-pulse laser is fulfilled; and a high-accuracy dynamic focusing mirror is matched with a galvanometer, so that an etching rang of (500 millimeters)*(500 millimeters) is realized at one time, and a touch screen electronic product having the advantages of no pollution, linear stability and complete functions is processed.

Owner:SUZHOU DELPHI LASER

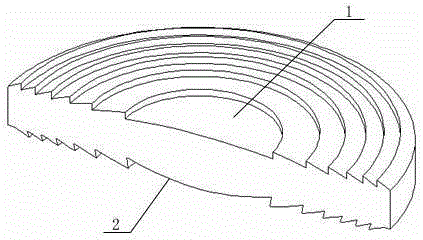

Double-sided Fresnel lens

The invention discloses a double-sided Fresnel lens, which comprises an incident surface and an emergent surface. Both the incident surface and the emergent surface are tooth grooves with multiple depressions; the corresponding tooth surface for light concentrating in each tooth groove has an arc surface structure; and the arc surface contour shape of each tooth groove at the lower part changes along with changes of the contour shape of the corresponding tooth groove at the upper part. Through double-sided structure design, the ratio of the focus of the light concentrator to a caliber of the light concentrator is compressed to 0.7; as the tooth surface in each tooth groove adopts an arc surface structure, a tooth distance can be selected randomly, a small light spot can be acquired, and that is, high light concentrating times can be met while a larger tooth distance is used for improving light effects.

Owner:SI CHUAN ZHONG SHUN SOLAR ENERGY DEV

Slab lens for air imaging and air imaging system

PendingCN110794495ASmall diffuse spotReduce spherical aberrationAdvertisingDisplay meansSpherical aberrationLight source

The invention discloses a slab lens for air imaging, comprising a first optical waveguide lens array and a second optical waveguide lens array arranged in parallel, wherein each optical waveguide lensarray comprises a plurality of reflective lenses arranged in parallel, the reflective lenses in the first optical waveguide lens array is orthogonal to the reflective lenses in the second optical waveguide lens array, and the widths of the reflective lenses are reduced from the center to the edge of the optical waveguide lens array. An air imaging system is also disclosed, comprising a light source and a slab lens, wherein the slab lens is any of the above slab lenses for air imaging. The slab lens has the advantages: compared with an ordinary strip reflector, the diffuse spot is smaller after using this solution, so the spherical aberration is smaller, the imaging depth of field is larger, the imaging clarity is effectively improved, this design does not change the size of the original slab lens, and the slab lens can be directly replaced to the original air imaging equipment.

Owner:ZHEJIANG PRISM HOLOGRAPHIC TECH CO LTD

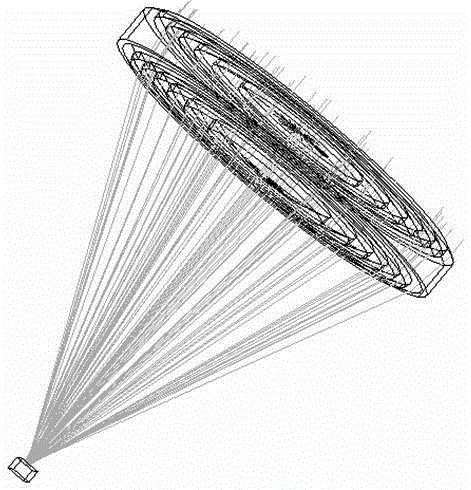

Novel optical lens acquiring long focal depth Bessel gauss light beams through focusing

ActiveCN105607162AWide applicabilityImproving Laser Fine Processing TechnologyLensHigh power densityPeak value

The invention discloses a novel optical lens acquiring long focal depth Bessel gauss light beams through focusing. The novel optical lens comprises a multi-zone curved surface and a focusing curved surface, wherein the multi-ring curved surface and the focusing curved surface are coaxially superposed, the multi-ring curved surface is provided with rings in a concentric-circle structure, surfaces of the rings are spherical surfaces or aspheric surfaces, ring-shaped optical axes are arranged among the adjacent rings, and the focusing curved surface is a spherical surface or an aspheric surface. The single lens is employed for focusing, so the Bessel gauss light beams are acquired, the energy distribution density at the center scope is quite high, quite-low focusing light beam segments are distributed at the edge, the power density scope is high, light spots are quite small, the focal depth is quite long, and light spot peak value power densities in the focal depth segment are similar. According to the novel optical lens, assembly precision requirements of the lens are common, the lens has relatively wide universality for laser beam modes, the fine laser processing technology can be improved and ameliorated, especially for the cutting technology of transparent materials.

Owner:SHANGHAI EMPOWER AUTOMATION TECH CO LTD

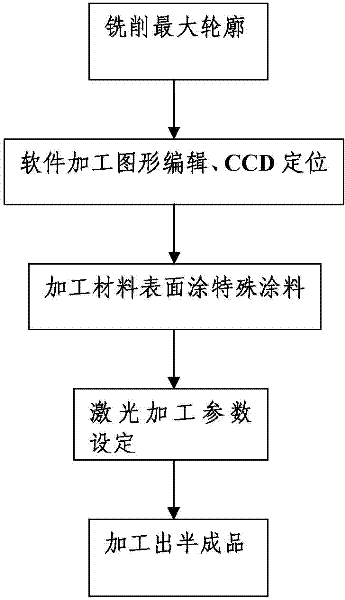

Method for deeply processing metal material by aid of laser

The invention relates to a method for deeply processing a metal material by the aid of laser. A processed area is determined by a CCD (charge coupled device) positioning system, a layer of special material is coated on the surface of the metal material to eliminate influences of processing heat in advance, and after passing through a beam expander with the proper magnification and a lens with the proper focal length, pulse light transmitted by a laser device is focused on the surface of the metal material and matches with selected laser processing parameters so that deep processing is carried out. Compared with other processing modes (such as linear cutting), the method is higher in flexibility, and can be used for processing various patterns which cannot be processed by linear cutting or chemical etching. When products (such as blind holes) do not need to be perforated, laser can be directly used for processing shapes with smaller sharp corners as compared with milling and cutting processing owing to the characteristics of small light spot and high energy density of ht laser. Besides, the surface of the processed material is coated with aqueous compound coating before the material is processed, so that edges processed by the laser are smoother.

Owner:江苏华工激光科技有限公司

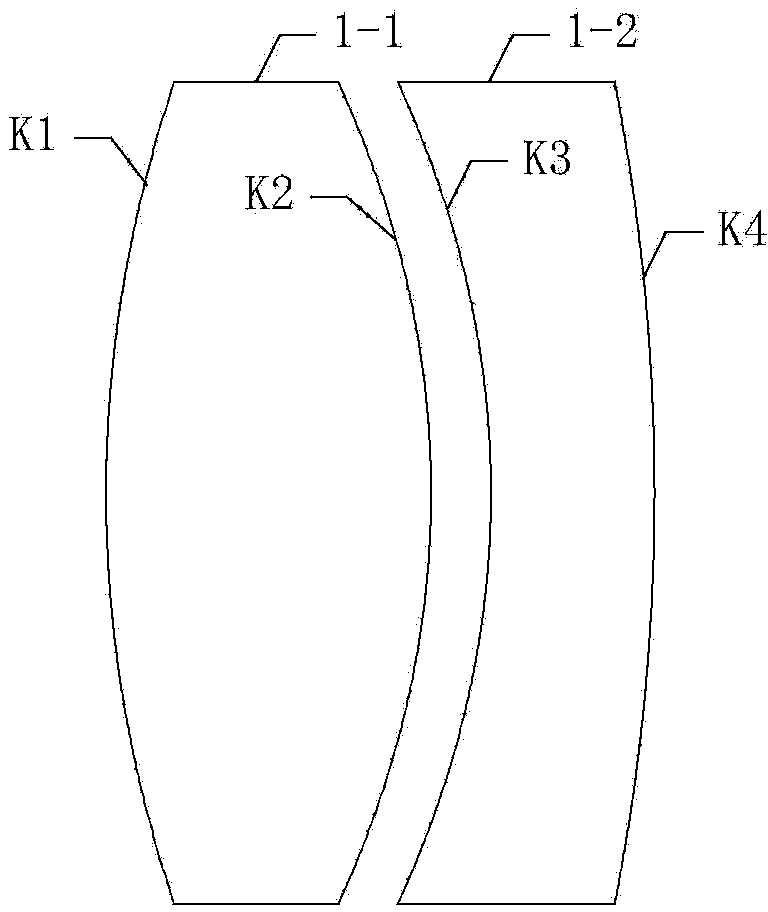

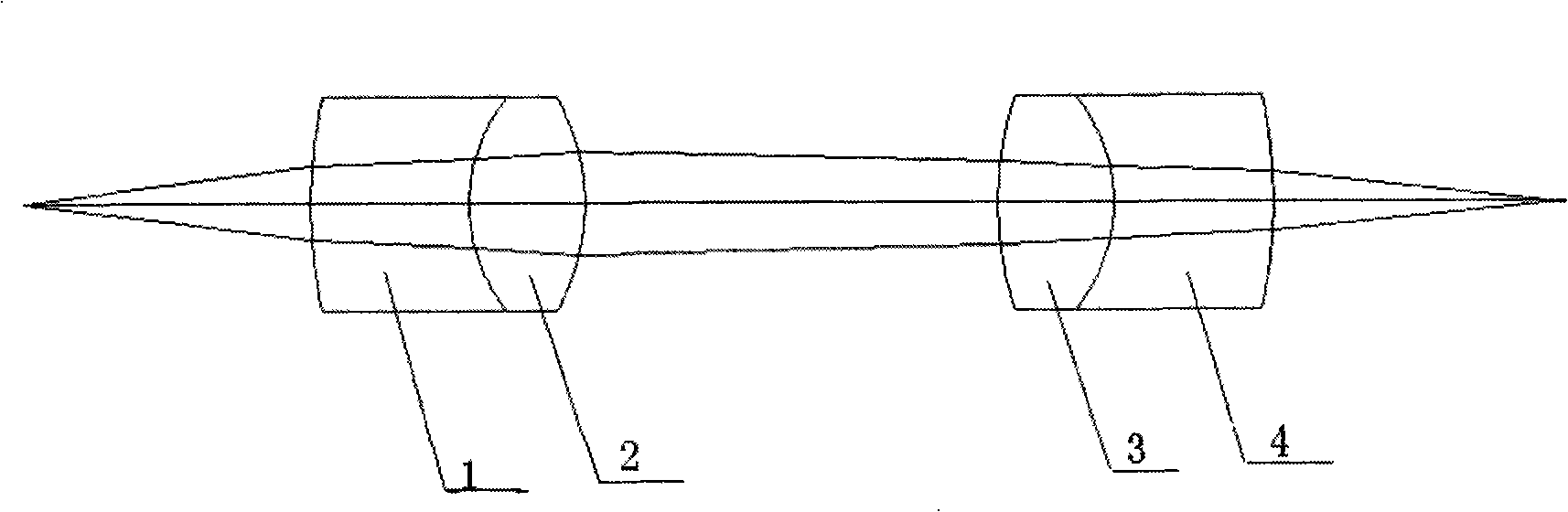

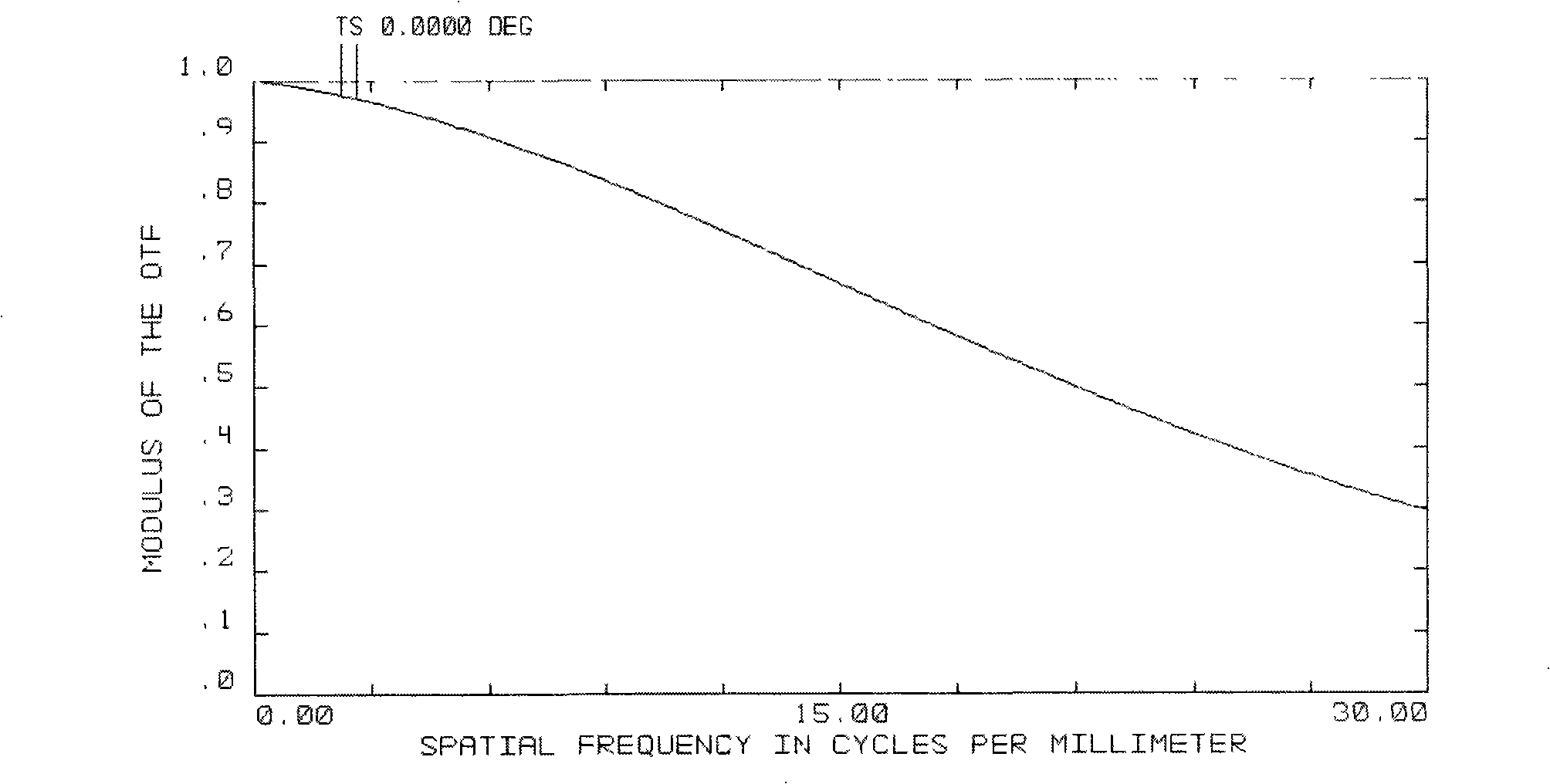

Focusing lens for dual-wavelength OCT system

InactiveCN101354477AHigh-resolutionEasy to correctDiagnostic recording/measuringSensorsCamera lensImage resolution

The invention relates to an amasthenic lens used for a dual wavelength OCT system. The amasthenic lens carries out excellent correction of image differences such as ball difference, can obtain small facula and effectively improves the resolution of the OCT system; more importantly, the amasthenic lens excellently corrects the colour difference and can be used for the OCT system detection imaging of dual wavelength or multi-wavelength. The amasthenic lens has the advantages of simple structure, low cost, small image difference and clear imaging.

Owner:NANKAI UNIV

Electronic component laser welding device and method

InactiveCN110076455AAvoid risk of injuryAvoid damageLaser beam welding apparatusElectronic componentLaser beams

The invention belongs to the technical field of fuse wire production and particularly relates to an electronic component laser welding device. The electronic component laser welding device comprises an electronic component fixing mechanism, a laser fiber lens, a first fixed support and a second fixed support. The electronic component fixing mechanism is used for fixing a main body part and leadingwires of an electronic component; The electronic component fixing mechanism is fixed to the first fixed support. The laser fiber lens is mounted on the second fixed support. A laser beam emitted fromthe laser fiber lens is aligned with the junction between the main body part and the leading wires. Compared with the prior art, the electronic component laser welding device realizes accurate welding, reduces damage to the electronic component and improves the welding quality. In addition, the invention further provides an electronic component laser welding method. Through the electronic component laser welding device and method, operation is easy and convenient, and welding accuracy and welding quality are high.

Owner:DONGGUAN BETTER ELECTRONICS TECH

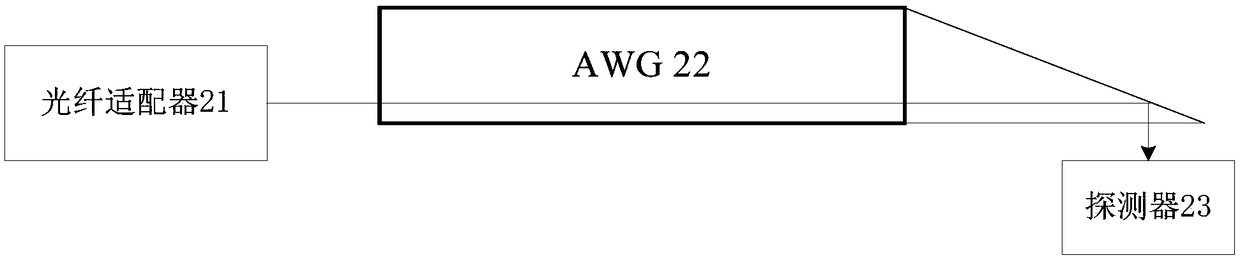

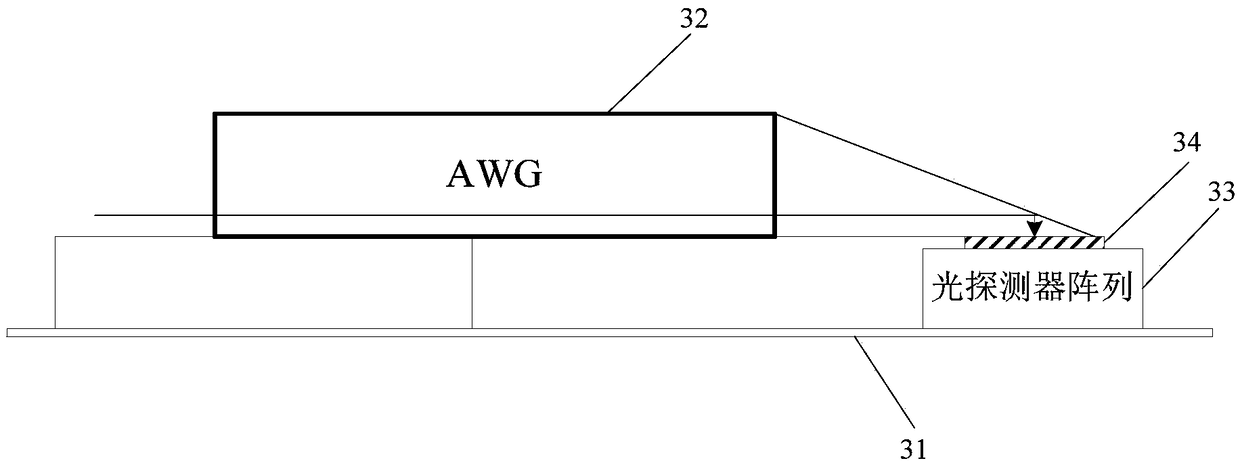

Optical module

InactiveCN109143498AChange direction of propagationImprove coupling efficiencyCoupling light guidesOptical ModuleRefractive index

The invention provides an optical module. The optical module comprises a circuit board, an arrayed waveguide grating AWG and an optical detector array which is arranged on the surface of the circuit board. Glue is coated on the surface of the optical detector array. The end of the AWG is an inclined surface. The glue is in contact with the AWG. The absolute value of the difference between the refractive index of the glue and the refractive index of the AWG is less than 10%. The light is reflected on the inclined surface of the AWG and incident to the surface of the optical detector array through the glue. According to the technical scheme, the glue is coated on the surface of the optical detector array, and the coupling efficiency can be improved and the coupling time can be shortened by using the simple optical path system, and the position accuracy requirement for each device in the optical path system can be reduced.

Owner:HISENSE BROADBAND MULTIMEDIA TECH

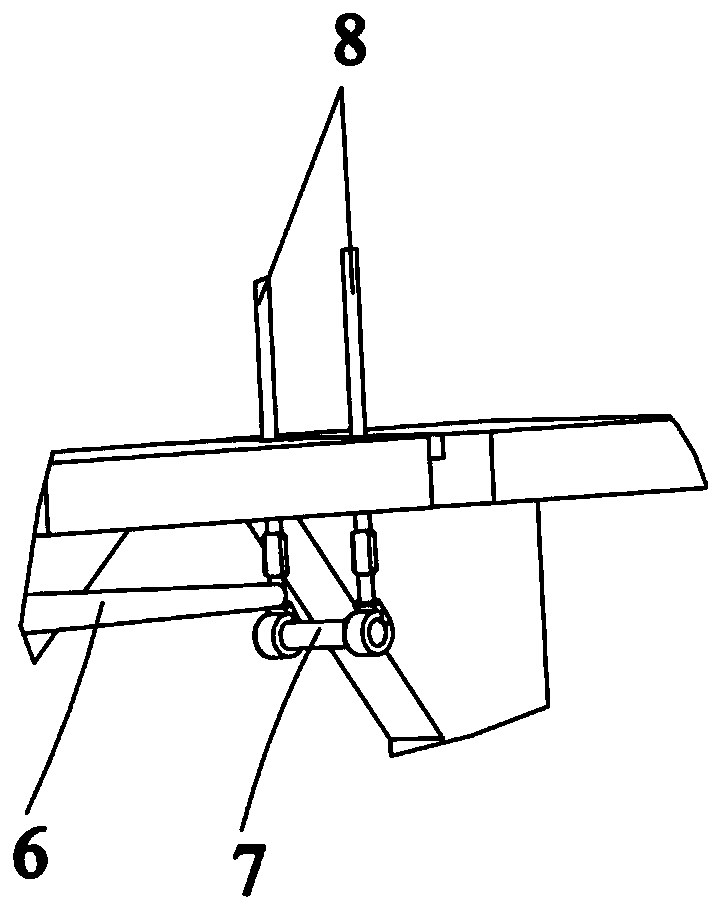

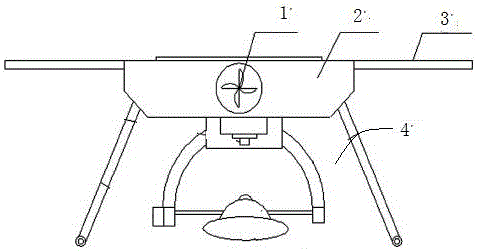

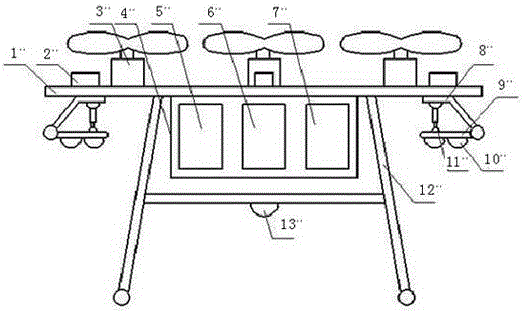

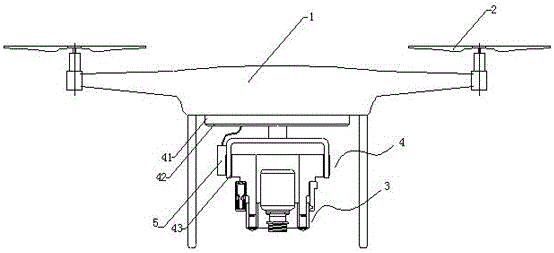

Illumination unmanned aerial vehicle

ActiveCN106628216AAdjustable angleSmall spotAircraft componentsProjectorsEngineeringHelicopter rotor

The invention relates to an illumination unmanned aerial vehicle which comprises an unmanned aerial vehicle body, a rotor wing, a pan-tilt and a photographing and illumination integrated assembly. The rotor wing is installed on the unmanned aerial vehicle body and located at the top end of the unmanned aerial vehicle body. The pan-tilt is installed on the unmanned aerial vehicle body and located at the bottom end of the unmanned aerial vehicle body. The photographing and illumination integrated assembly is fixedly connected with the pan-tilt and located at the lower end of the pan-tilt. The photographing and illumination integrated assembly comprises a base, a lens cover, an adjusting base and a photographing assembly fixedly arranged in an inner cavity of the base through a support. The illumination unmanned aerial vehicle has the advantages that the pan-tilt is adopted for fixedly connecting illumination and photographing devices to the unmanned aerial vehicle body, and the angle is adjusted in an omnibearing mode; meanwhile, by additionally arranging a guiding positioning pin and a guiding chute matched with the guiding positioning pin, the photographing assembly can stretch and retract back and forth to be adjusted; in addition, a heat dissipation region is further arranged on a lens base of the lens cover, and excessive heat can be effectively avoided.

Owner:NANTONG ZHONGTIE HUAYU ELECTRICS

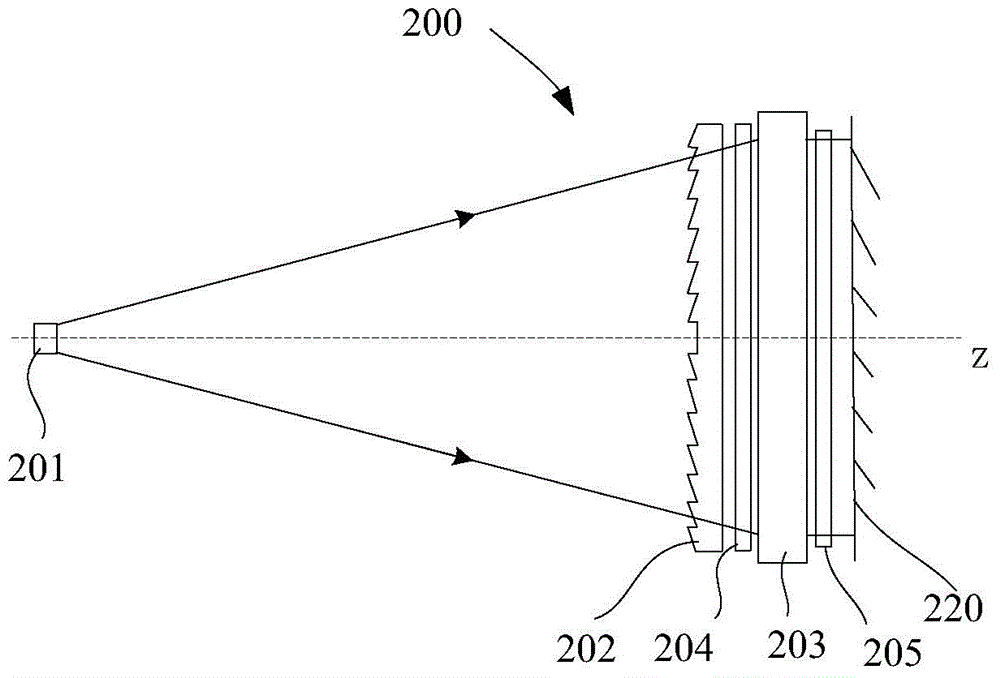

Photocurable 3D (three-dimensional) printing device and imaging system thereof

ActiveCN104669622AAvoid distortionSmall spotAdditive manufacturing apparatusOptical elementsCamera lensLight beam

The invention provides an imaging system of a photocurable 3D (three-dimensional) printing device. The imaging system comprises a light source, a liquid crystal panel, a first polarized light filter and a second polarized light filter. A light beam is emergent from the light source. The liquid crystal panel is positioned on a light outlet path of the light source, the liquid crystal panel contains a plurality of pixels, and each pixel comprises a light transmissible region and a light-proof region. The first polarized light filter is arranged on the incident side of the liquid crystal panel. The second polarized light filter is arranged on the emergent side of the liquid crystal panel, and the first polarized light filter and the second polarized light filter are matched with one part of the liquid crystal panel blocking the light beam to form a light beam image, wherein the distance from the liquid crystal panel to the surface of a photosensitive material is close enough, and the size of the liquid crystal panel is basically equal to the size of the image formed by the surface of the photosensitive material to allow the image of the light beam to be directly projected to the surface of the photosensitive material without passing through a projection lens.

Owner:PRISMLAB CHINA +1

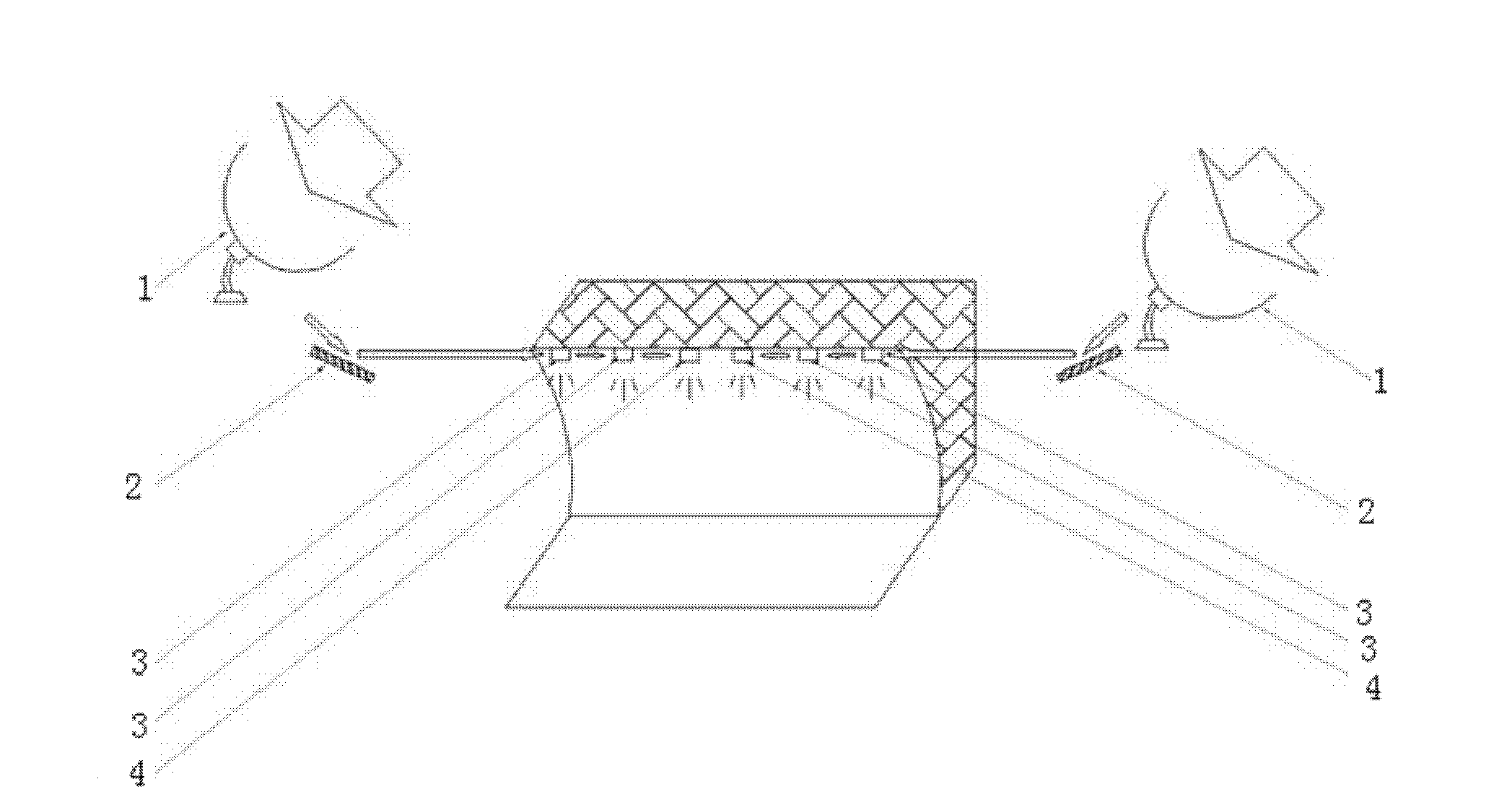

Tunnel sunlight illuminating system using reflection-type collecting lens

InactiveCN103133975ASmall spotIncrease brightnessOutdoor lightingEnergy efficient lightingLight spotLight beam

The invention discloses a tunnel sunlight illuminating system using a reflection-type collecting lens. The tunnel sunlight illuminating system using the reflection-type collecting lens comprises the reflection-type collecting lens. After passing through the reflection-type collecting lens, incident light passes through a light path regulating lens, then sequentially passes through a plurality of semi-reflective semi-transparent type lamps arranged in parallel, and shoots on a full reflection-type lamp in an incident mode. The reflection-type collecting lens and the light path regulating lens are arranged outside a tunnel, and the semi-reflective semi-transparent type lamps and the full reflection-type lamp are arranged on the inner top portion of the tunnel. The tunnel sunlight illuminating system uses the reflection-type collecting lens to directly collect sunlight and gathers the sunlight to a parallel light beam which is small in light spots and high in brightness, the parallel light beam shoots the tunnel in an incident mode and is gradually converted into illuminating light by the semi-reflective semi-transparent type lamps and the full reflection-type lamp, energy conversion does not occur in the whole process, and solar energy utilization efficiency is high.

Owner:XIAN ELITE ELECTRONICS IND

A kind of nylon polymer powder material and preparation method thereof

ActiveCN109517377BIncrease coverageAvoid reunionAdditive manufacturing apparatusAdditive manufacturing with solidsErbium lasersPolymer

The invention provides a preparation method of a nylon polymer powder material. The preparation method comprises the following steps: adding the following components into a polymerizing pot in percentage by mass: 85-99.9% of nylon aggregate and 0.1-15% of a thermal medium material, adding a solvent, and preparing a nylon powder material taking the thermal medium as a nucleating agent by adopting asolvent precipitation method; adding 20 parts of nylon powder material and 0.1-1.5 parts of carbon black into a mixing tank, and performing the first high-speed mixing so as to prepare a nylon and carbon black mixed powder material; adding the nylon and carbon black mixed powder material, 0.1-1 part of a flow promoter and 80 parts of the nylon powder material into the mixed powder barrel, performing the second high-speed mixing and screening, thereby obtaining the nylon polymer powder material. By adopting the nylon powder taking the thermal medium material as the nucleating agent and the high-speed mixing, the carbon black is uniformly attached onto the nylon powder surface, so that the nylon powder in the prior art is applied to fiber laser sintering, the surface quality of the parts isexcellent, the structure is fine, and the overall performance is excellent.

Owner:HUNAN FARSOON HIGH TECH CO LTD

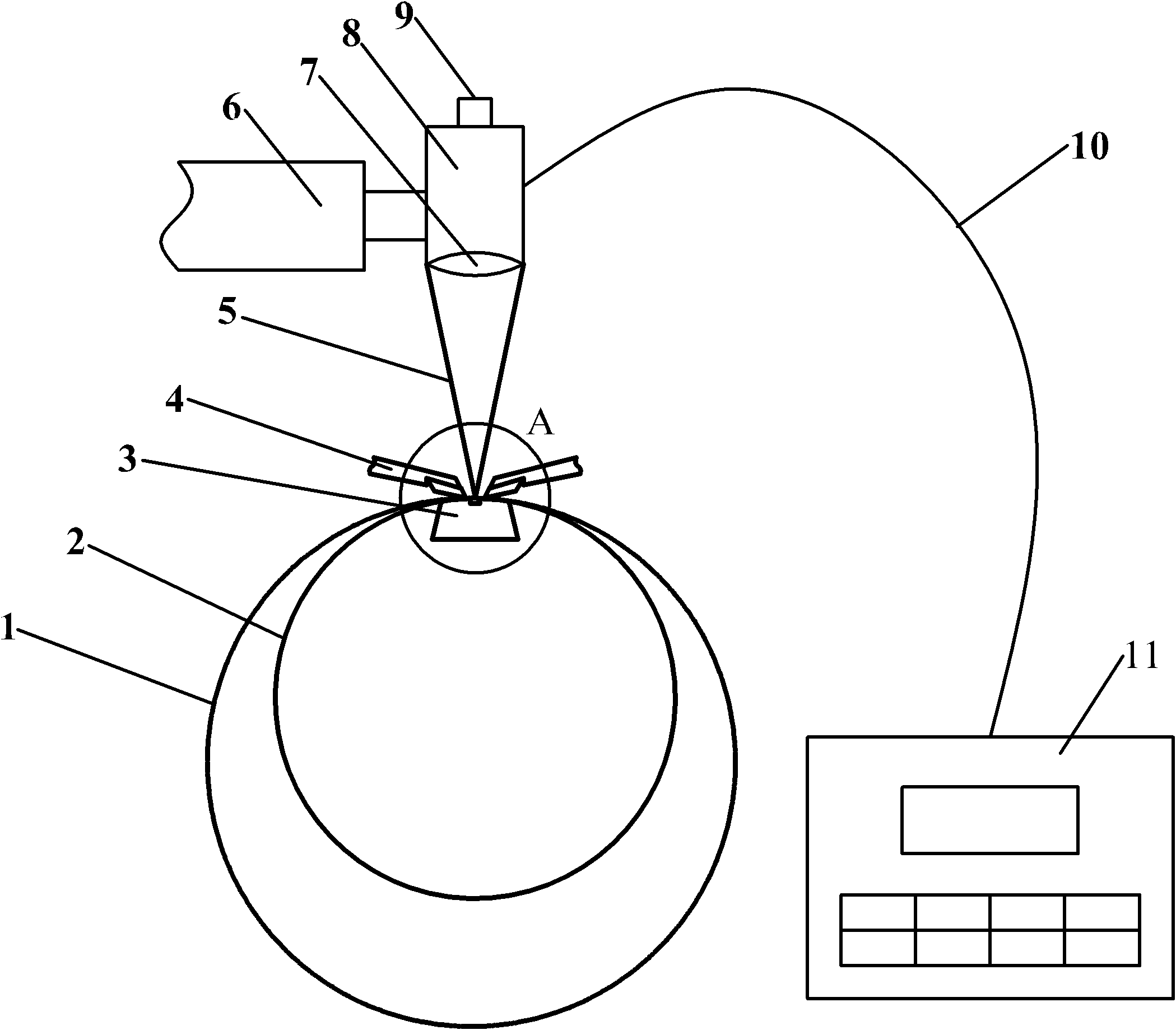

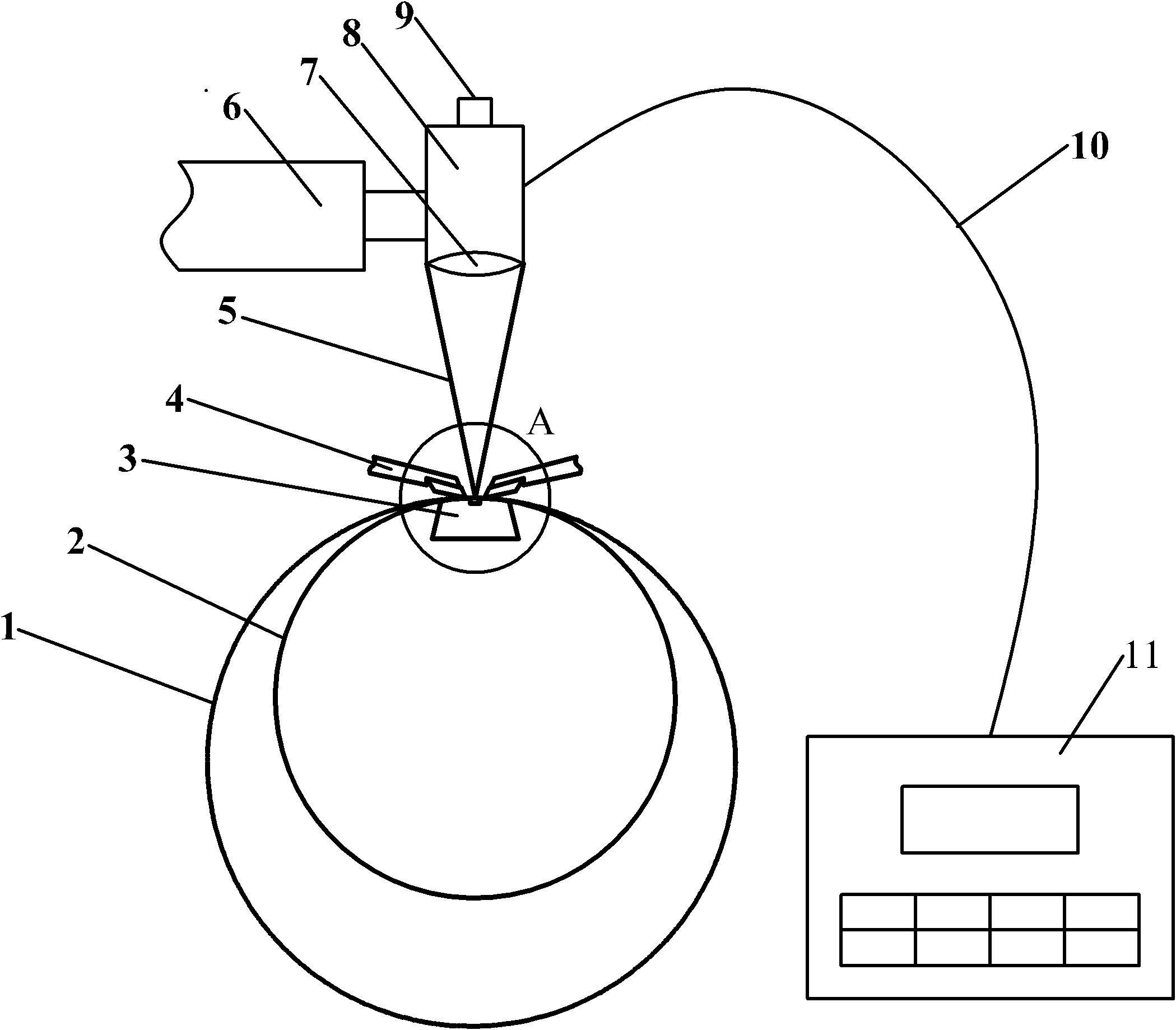

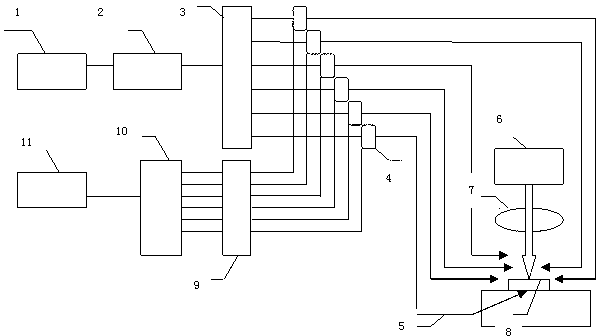

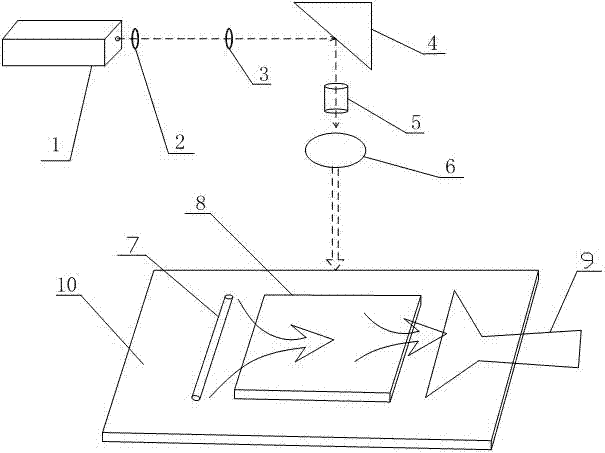

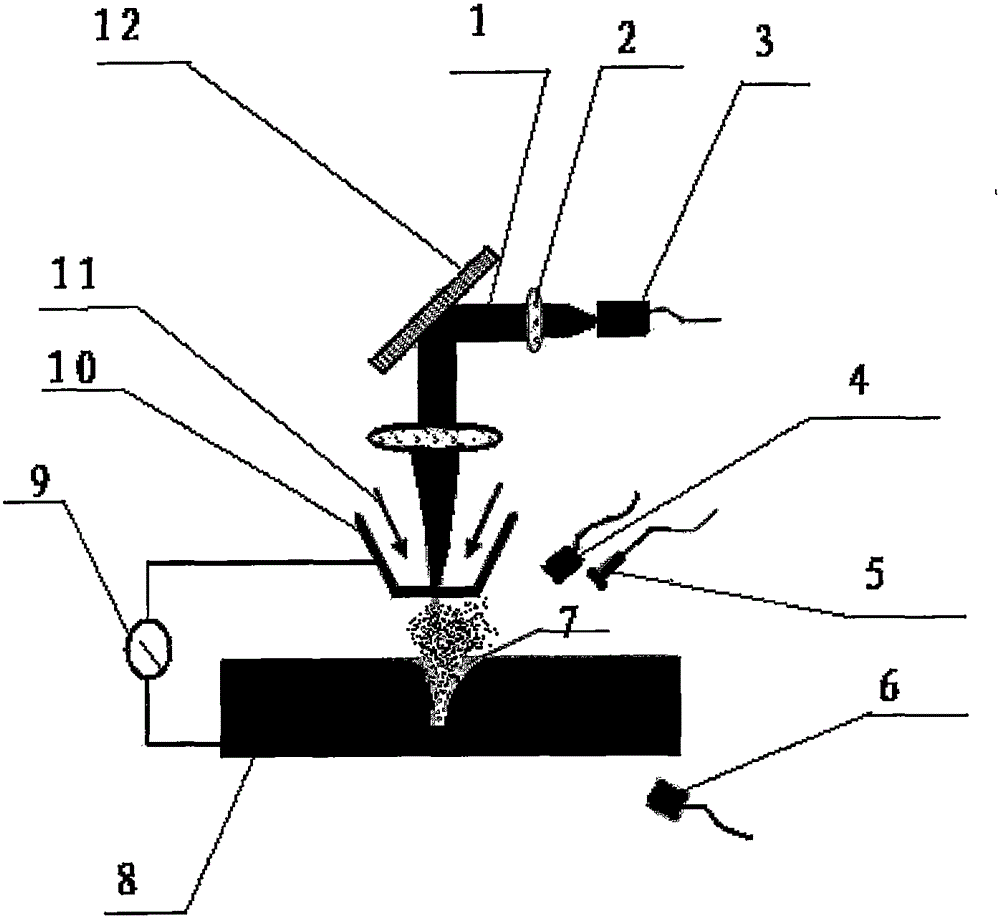

Laser welding device carrying multiple sensors

ActiveCN104999178AQuality improvementGood effectLaser beam welding apparatusCharge detectionCarbon Dioxide / Helium

The invention relates to a laser welding device, particularly to a laser welding device carrying multiple sensors. The device comprises a laser 1, a convex lens 2, a coaxial optical sensor 3, a lateral optical sensor 4, an acoustic sensor 5, a back sensor 6, a welding pool 7, a welded material 8, a charge detection meter 9, a welding nozzle 10, inert shielding gas 11 and a half-reflecting mirror 12, wherein the back sensor 6 is mounted at the back of the welded material 8; the welded material 8 is in series connection with the welding nozzle 10 through a lead; the middle of the lead is also in series connection with the charge detection meter 9. With the adoption of the device, refractory materials such as titanium, quartz and the like can be welded, anisotropic materials can be welded, and the effect is good; the device is exquisite in structure as well as safe and reliable to use and has the certain economical and applicable value, and the equipment manufacturing cost is moderate; the welding quality is good, the automation degree is high, and a large quantity of manpower and material resources are saved.

Owner:广东龙辉科技有限公司

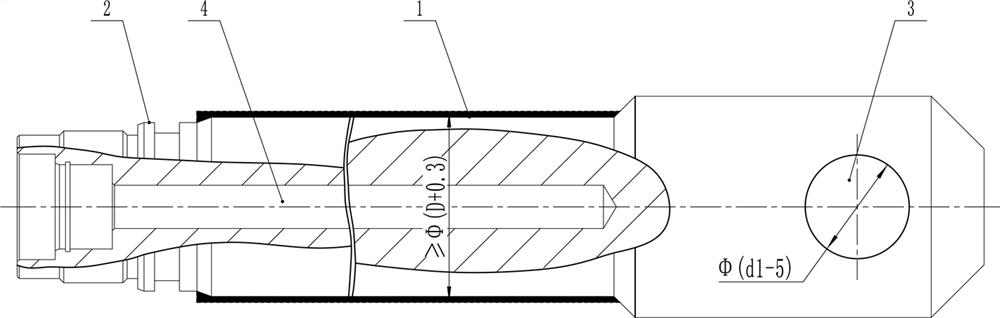

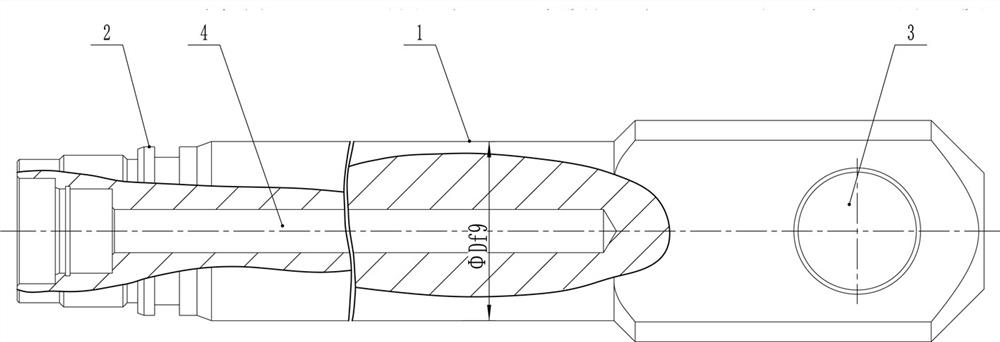

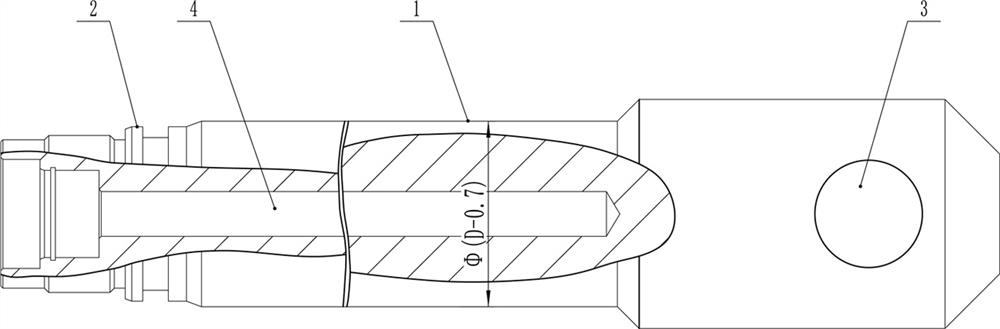

Laser cladding deformation control method for slender piston rod

InactiveCN112059545ANot easy to cause deformationHighlight substantive featuresMetallic material coating processesPolishingDeformation control

The invention provides a laser cladding deformation control method for a slender piston rod. The laser cladding deformation control method comprises the following steps of rough turning, wherein the reserved size is larger than or equal to phi(D+n) mm; drilling a hinge hole; hardening and tempering; straightening, wherein the jerk value of the slender piston rod is less than or equal to 1mm; Semi-finish turning, wherein the reserved size is larger than or equal to phi(D+n1) mm; finish turning, specifically, carrying out further finish machining on the outer circle of the slender piston rod bytaking a semi-finish-turned outer circle as a benchmark; high-speed laser cladding, specifically, detecting the jerk value of a sealing surface; size detection, specifically, detecting the diameter ofeach part of the slender piston rod; and carrying out milling-flattening, excircle grinding and polishing in order to complete the laser cladding process of the slender piston rod. The laser claddingdeformation control method for the slender piston rod has the advantages that severe workpiece deformation caused by excessive heat generated in the laser cladding process is avoided, and the processflow and time are saved.

Owner:ZHENGZHOU COAL MINING MACHINERY GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com