Method and device for manufacturing polyamide three-dimensional object by laser

A three-dimensional object, polyamide technology, applied in additive manufacturing, processing and manufacturing, manufacturing tools, etc., can solve problems such as difficult to achieve results, and achieve the effect of fine three-dimensional feature structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

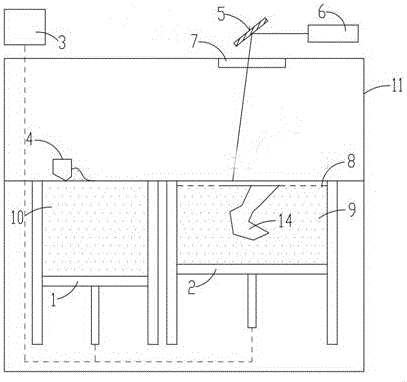

[0038] Embodiment 1: A polyamide three-dimensional part is manufactured by using a Nd:YAG laser with a wavelength of 1064 nm.

[0039] The material used is the polyamide powder material FS3200 of Hunan Farsoon High-Tech Co., Ltd., and it is fully mixed with aluminum powder with a particle size distribution of 5-40 μm. The volume percentage of FS3200 is 90%, and the aluminum powder is 10%. The device used is the selective laser sintering equipment FS403 of Hunan Farsoon High-Tech Co., Ltd. and correspondingly modified. The matching equipment is equipped with a Nd:YAG laser with a wavelength of 1064nm.

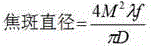

[0040] During the manufacturing process, the layer thickness of the powder coating material is set to 0.1mm, the preheating temperature of the material is about 180°C, the laser power is about 40-80W, the laser spot is controlled at 40-60μm, and the speed is controlled at about 10m / s The laser irradiates the cross-sectional area of the three-dimensional part. When one layer i...

Embodiment 2

[0041] Embodiment 2: Manufacturing carbon fiber-polyamide three-dimensional parts by using a solid-state laser with a wavelength of 532nm.

[0042] The material used is the polyamide powder material FS3400CF of Hunan Farsoon High-Tech Co., Ltd., which contains polyamide powder with a volume fraction of 80% and carbon fiber powder with a volume fraction of 20%, and the carbon fiber diameter is 50-100 microns. The device used is the selective laser sintering equipment FS403 of Hunan Farsoon High-Tech Co., Ltd. and correspondingly modified. The matching equipment is equipped with a solid-state laser with a wavelength of 532 nm.

[0043] During the manufacturing process, the layer thickness of the powder coating material is set to 0.1mm, the preheating temperature of the material is about 180°C, the laser power is about 40-80W, the laser spot is controlled at 40-60μm, and the speed is controlled at about 12m / s The laser irradiates the cross-sectional area of the three-dimensiona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com