A real-time capture system for simulating the fusion process of metal droplets under microgravity

A technology that simulates microgravity and microgravity. It is used in the improvement of process efficiency, additive manufacturing, and additive processing. It can solve problems such as inability to complete, and achieve the effect of easy operation, high microgravity level, and high vacuum degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

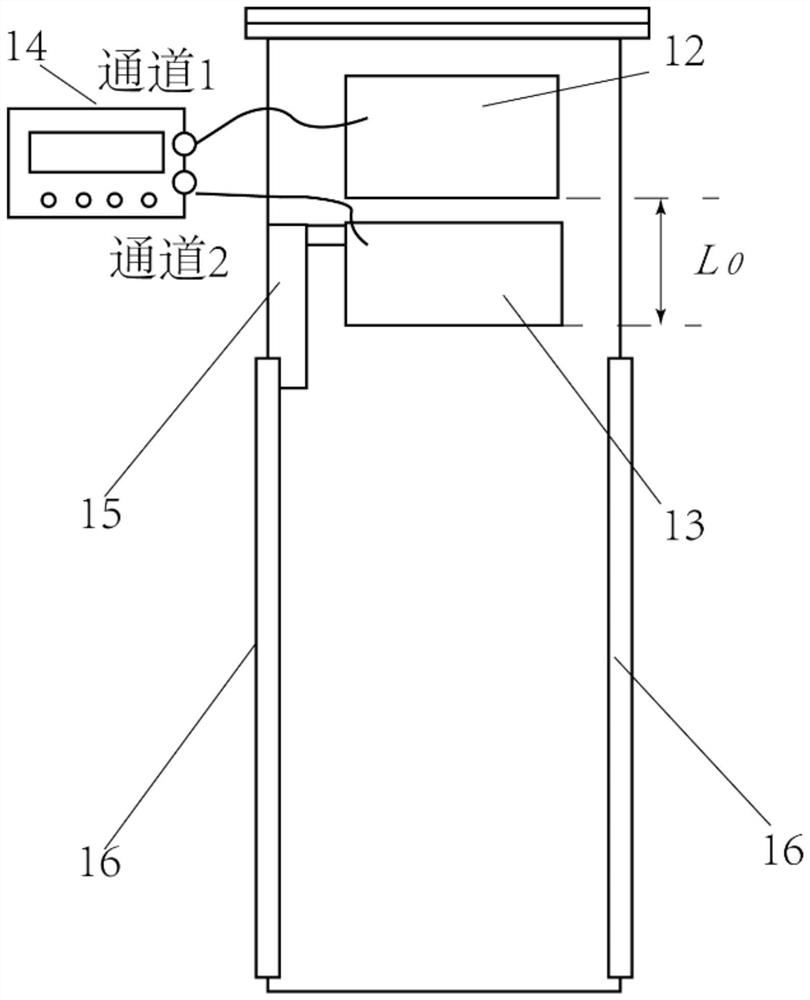

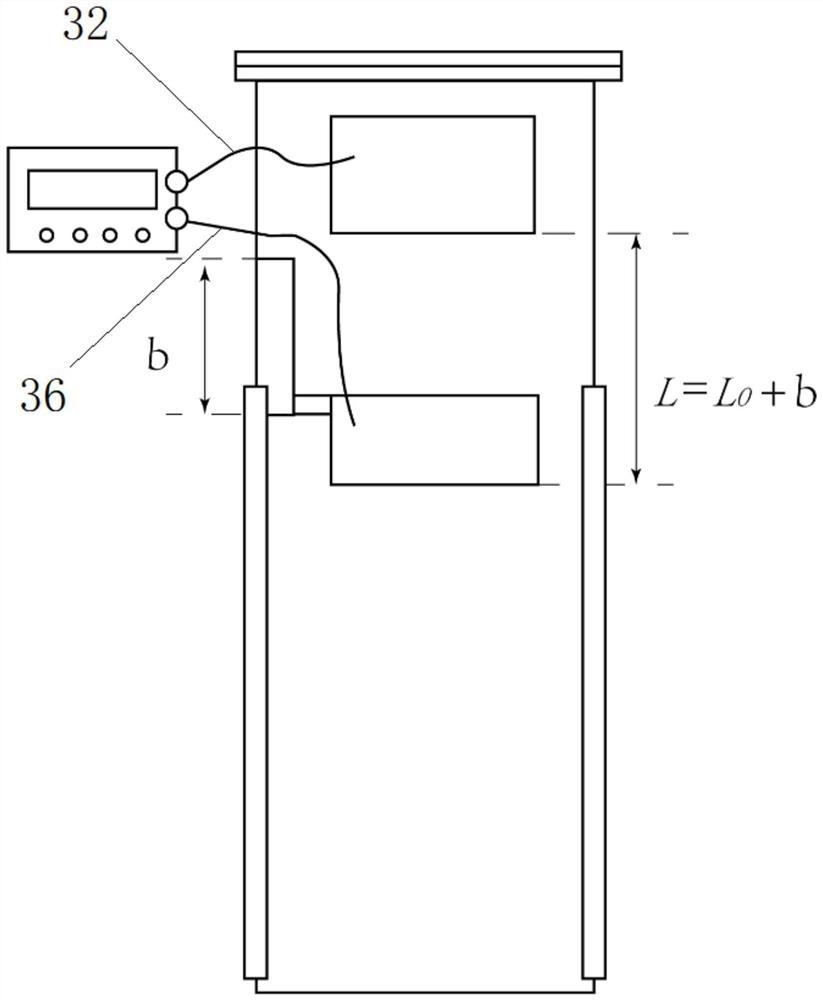

[0077] The content of the present invention is described in further detail below in conjunction with the accompanying drawings and specific embodiments:

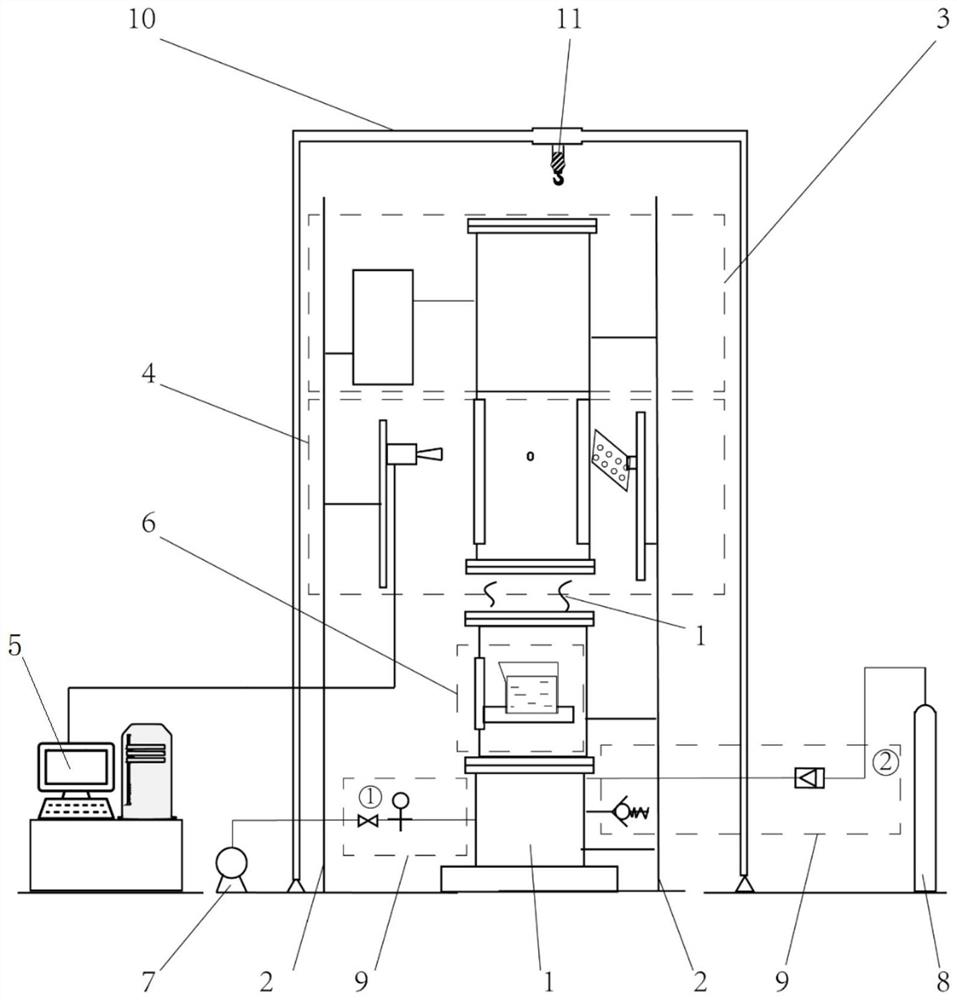

[0078] like Figure 1-Figure 12 As shown, a real-time capture system for simulating the metal droplet pursuit and fusion process under microgravity includes a tube body, a main body support frame, a microgravity droplet pursuit and fusion module, a microgravity droplet pursuit and fusion real-time capture module, an image processing module, and a collection module. , vacuuming and inert gas supplementary modules and hoisting modules.

[0079] The tube body is made of 304 stainless steel, and the height is not less than 3 meters, so as to provide enough falling time to complete the microgravity solidification. The tube body is vertically fixed by the main support frame; the bottom end of the tube body is connected to the vacuum and inert gas supplementary module , to create an inert gas environment in the tube.

[0080] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com