Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

104 results about "Laser fabrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Visual preview for laser fabrication

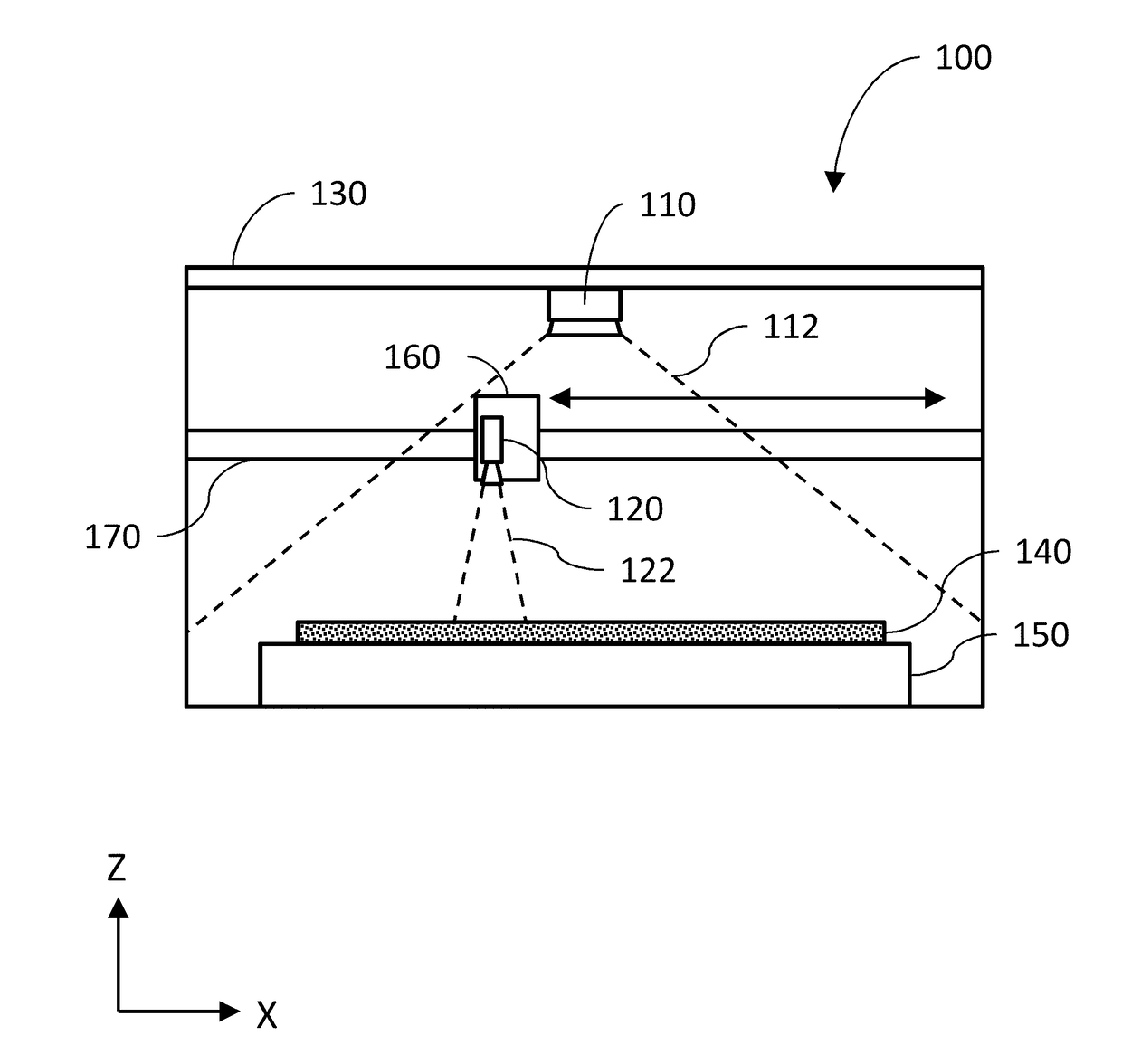

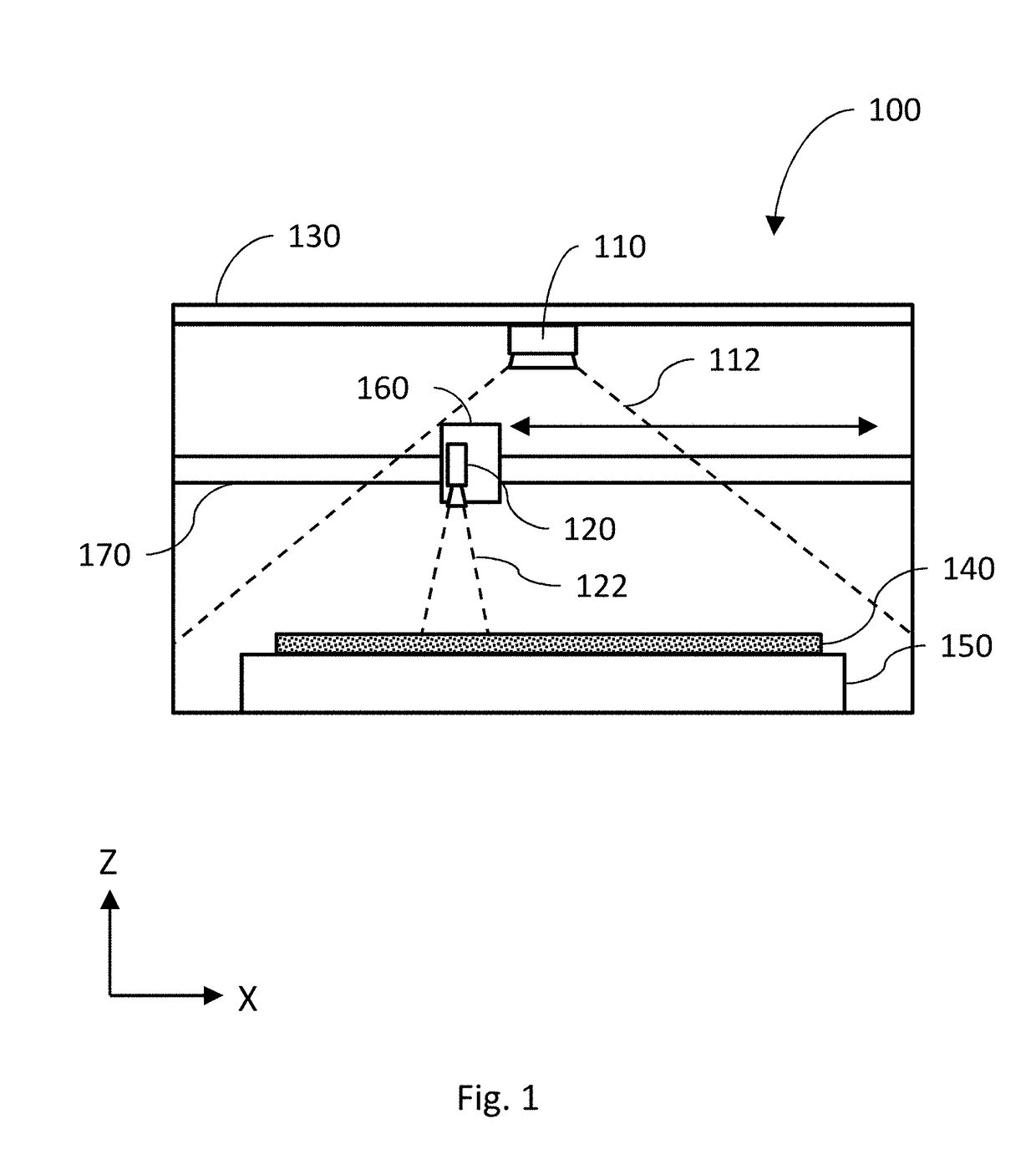

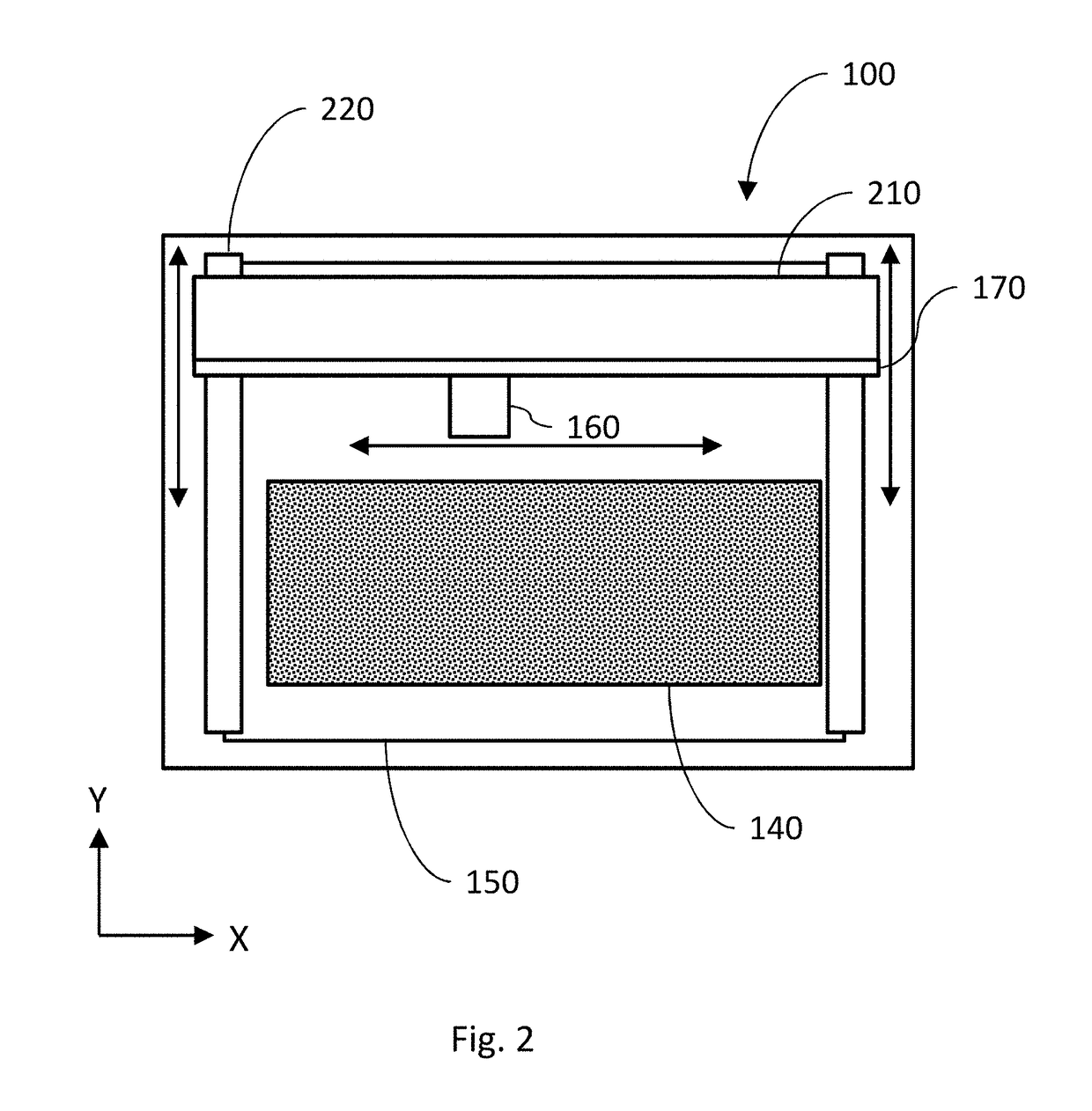

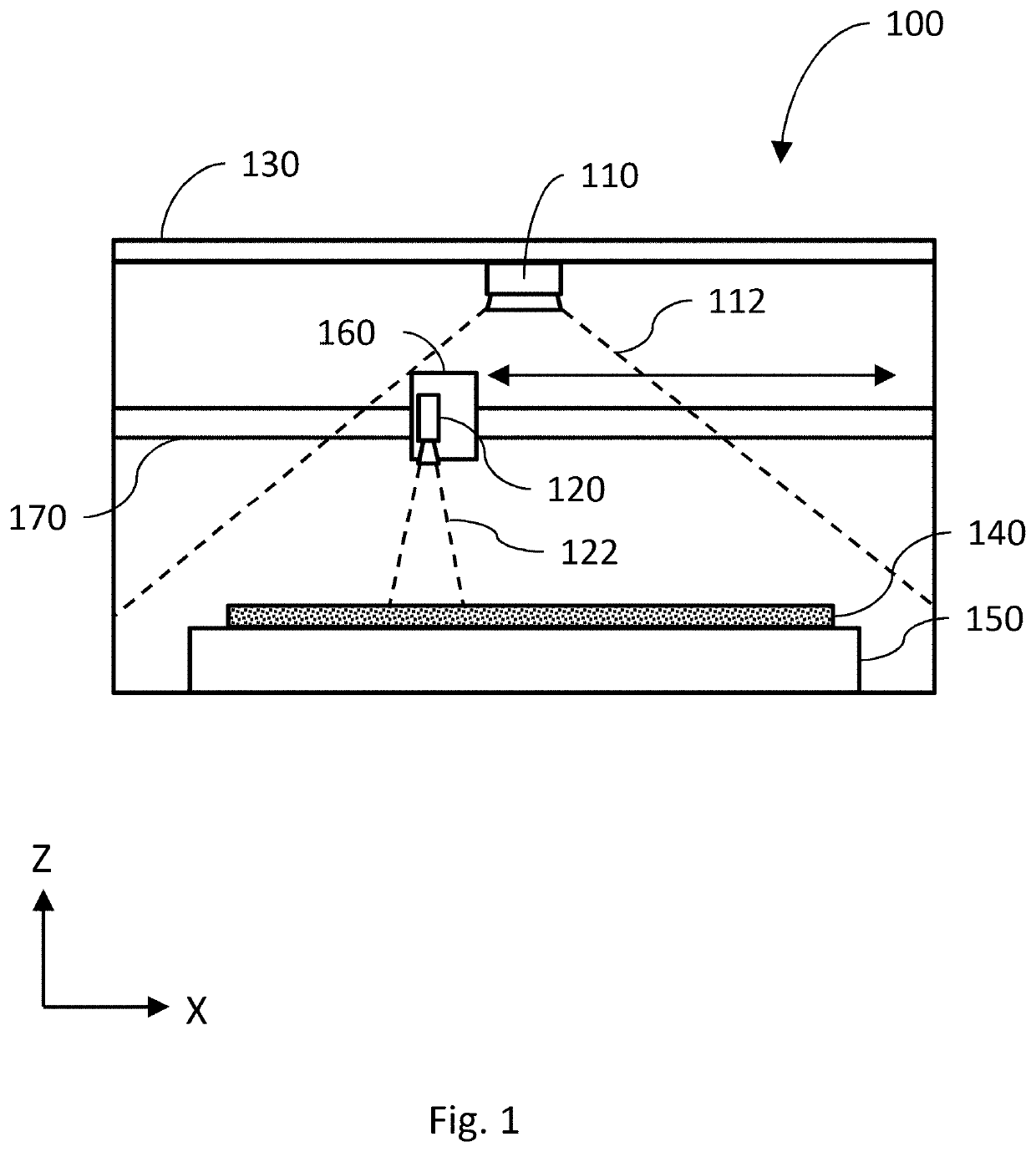

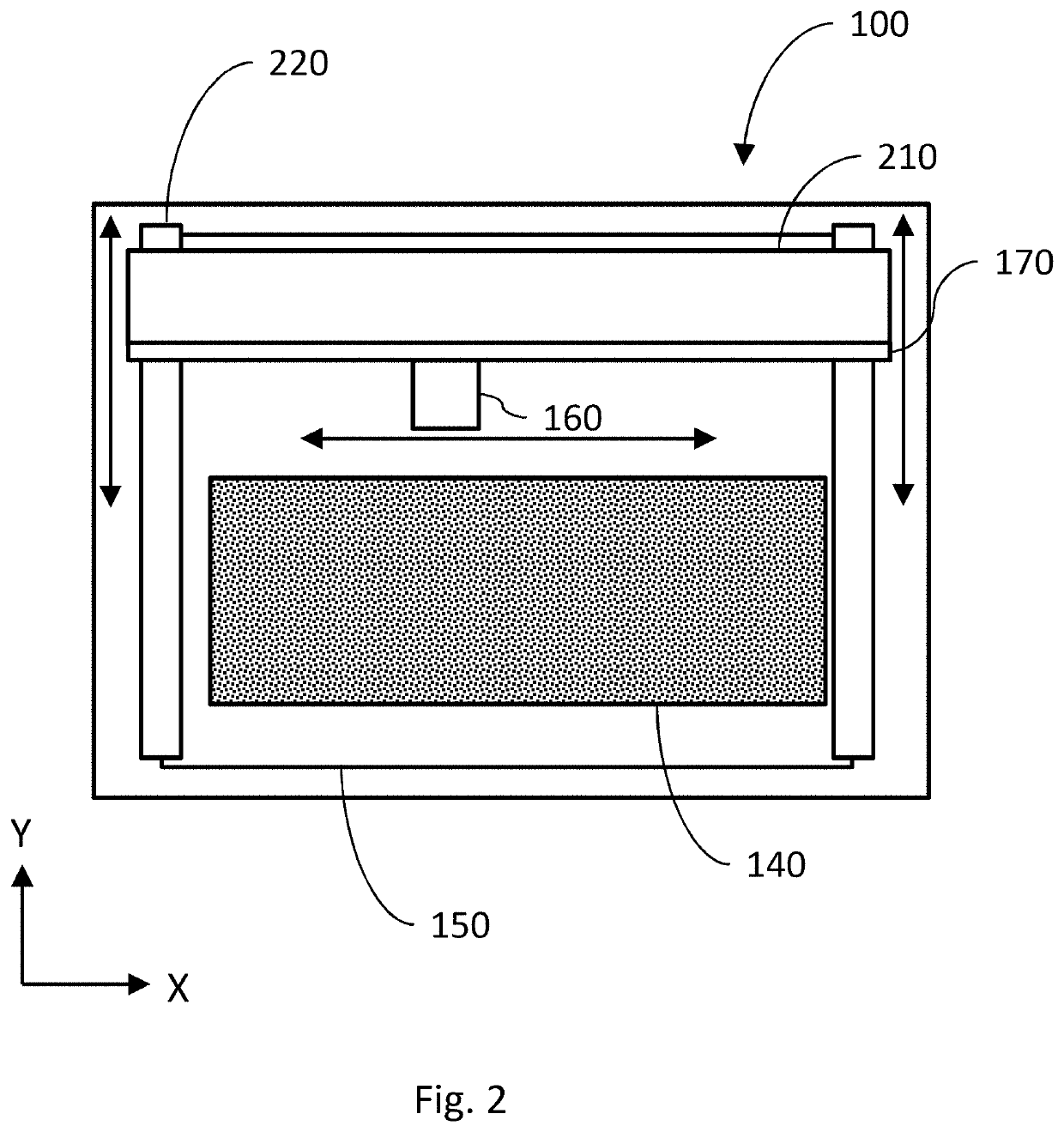

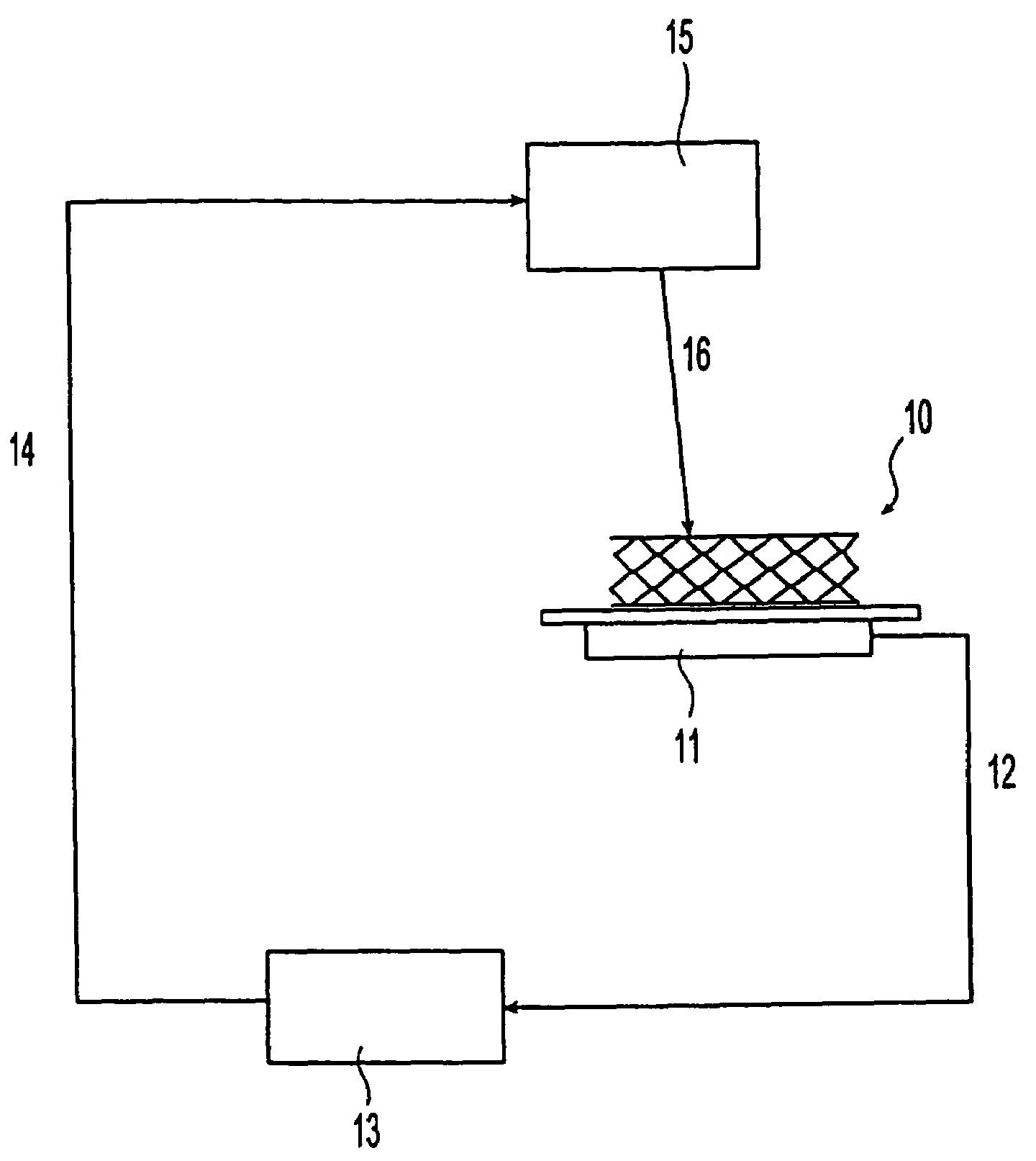

ActiveUS20170045877A1Prevent electromagnetic emissionAvoid emissionsWelding/cutting auxillary devicesWood working apparatusInterior spaceInterlock

A computer numerically controlled machine may include a movable head configured to deliver electromagnetic energy to a part of a working area in which the movable head may be commanded to cause delivery of the electromagnetic energy. The interior space may be defined by a housing and may include an openable barrier that attenuates transmission of light between the interior space and an exterior of the computer numerically controlled machine when the openable barrier is in a closed position. The computer numerically controlled machine may include an interlock that prevents emission of the electromagnetic energy when detecting that the openable barrier is not in the closed position. The commanding may result in the computer numerically controlled machine executing operations of a motion plan for causing movement of the movable head to deliver the electromagnetic energy to effect a change in a material at least partially contained within the interior space.

Owner:GLOWFORGE

Safety and reliability guarantees for laser fabrication

Sensor data generated by a sensor of a computer numerically controlled machine can be compared with a forecast. The forecast can include expected sensor data for the sensor, over a course of an execution plan for making a cut with a movable laser cutting head. The sensor data can be generated during execution of the execution plan. During execution of the execution plan, the sensor data can be monitored and a deviation of from the forecast can be detected. It can be determined, based on the detecting, that an anomalous condition of the computer numerically controlled machine has occurred. Based on the determining, an action can be performed.

Owner:GLOWFORGE

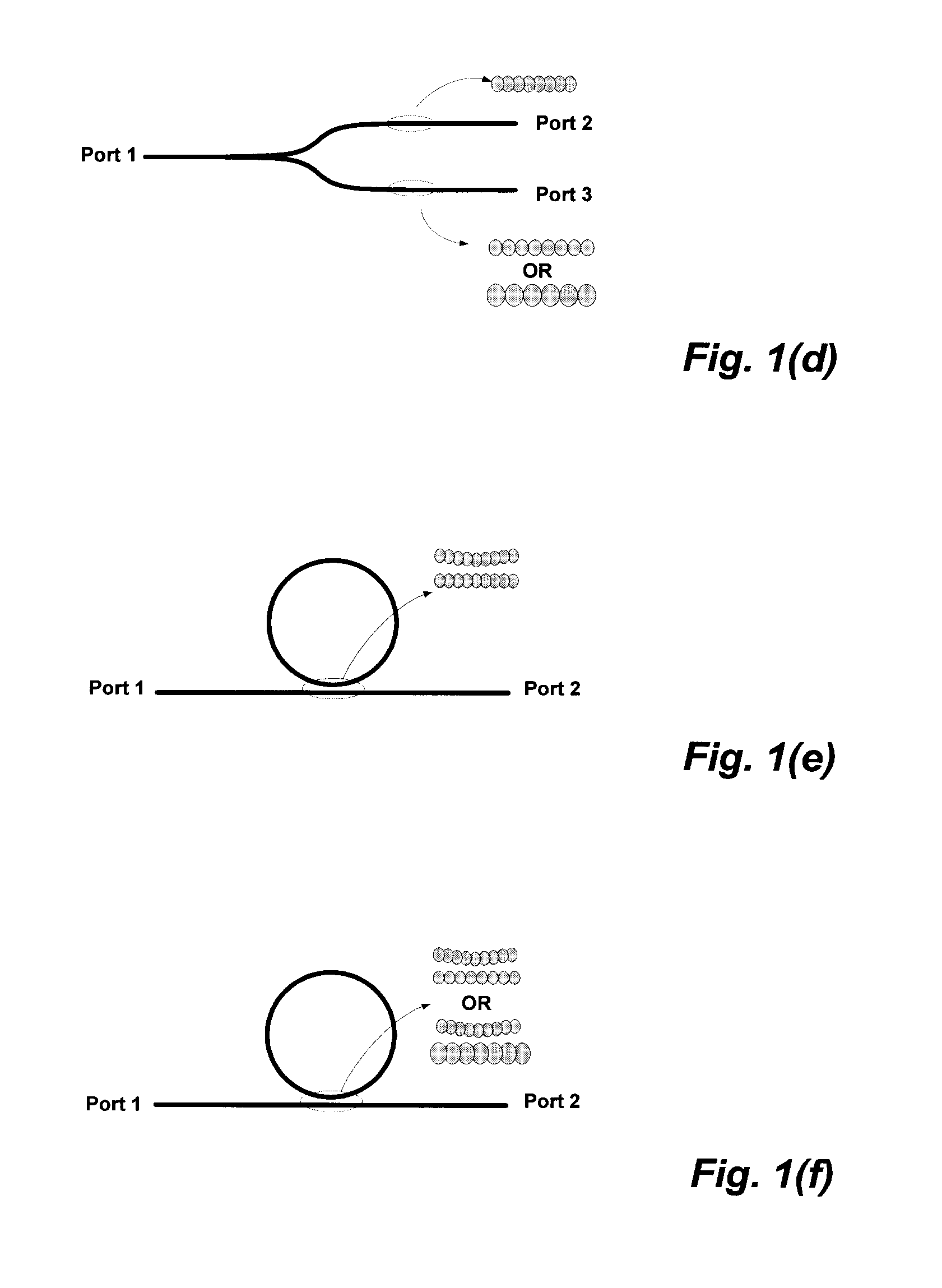

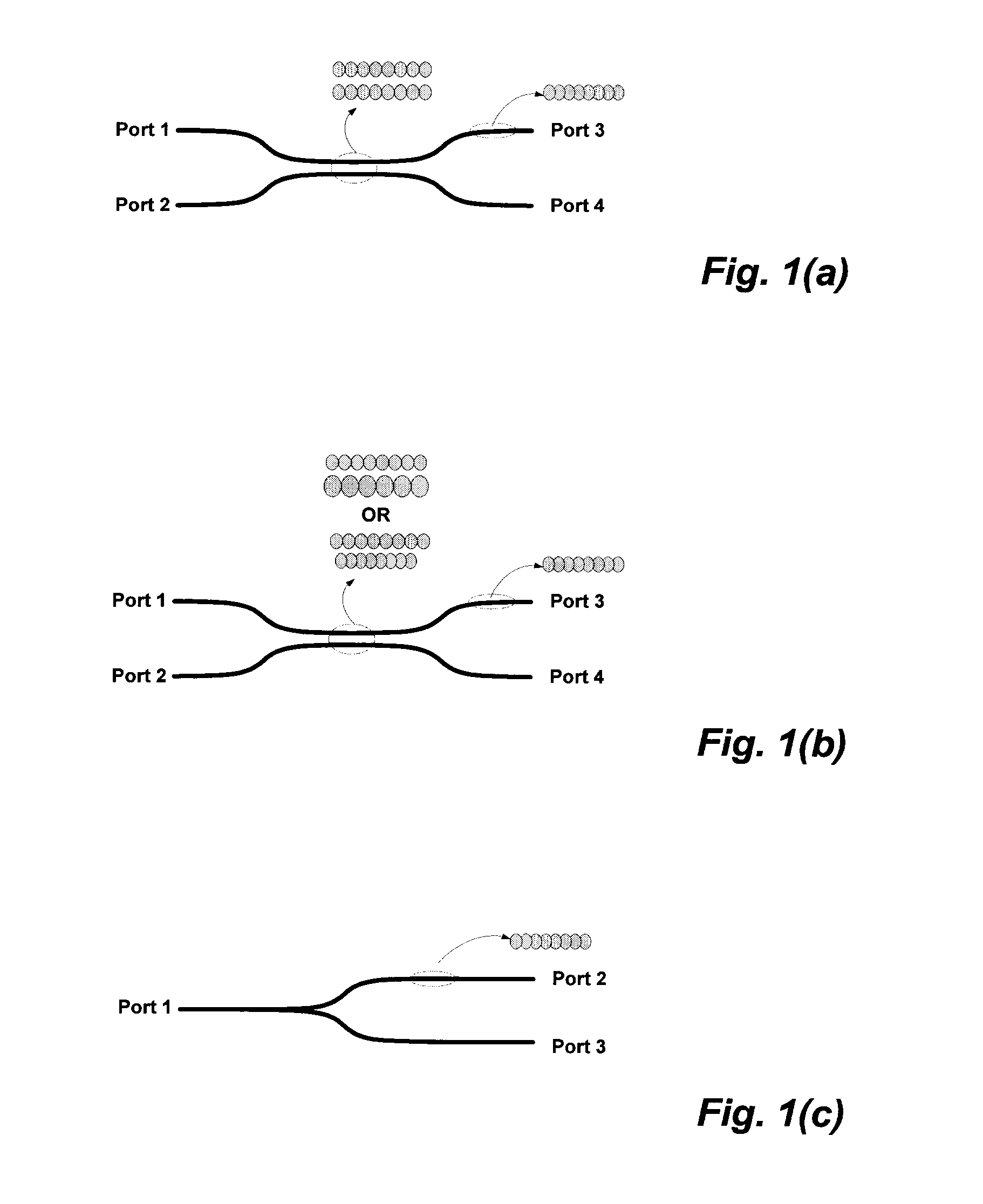

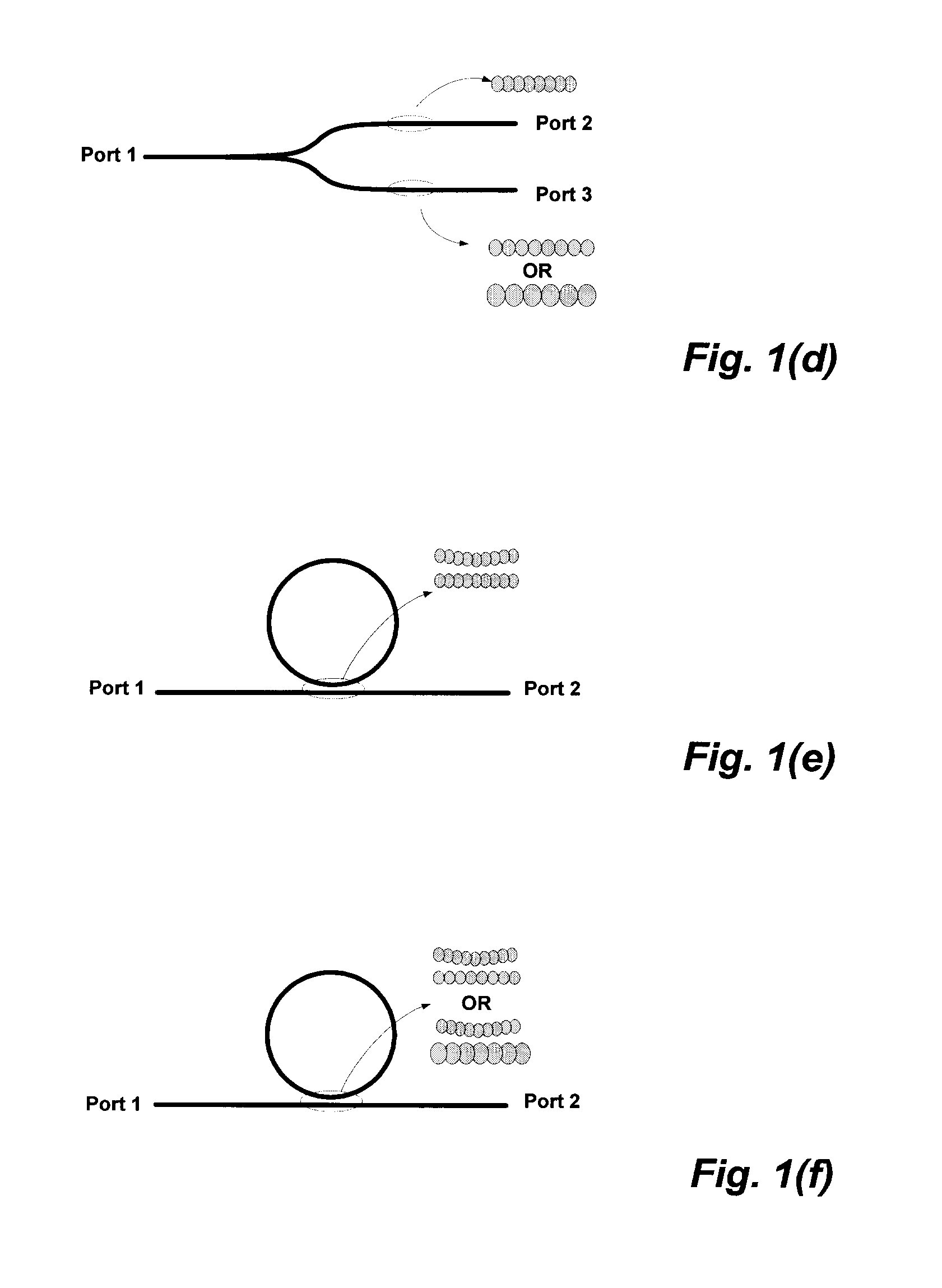

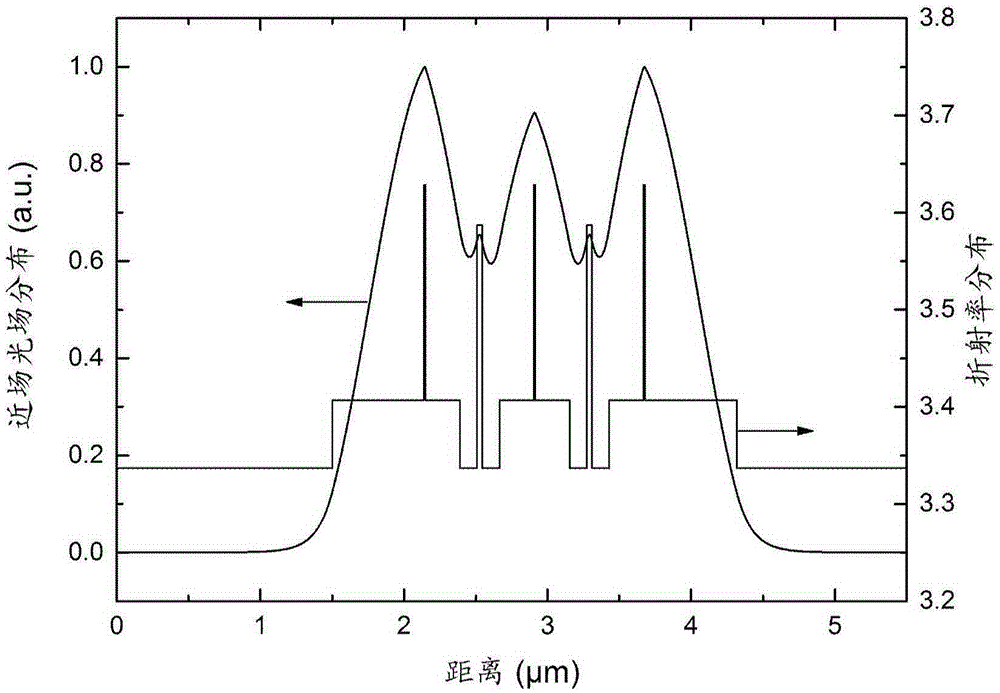

Optical devices and digital laser method for writing waveguides, gratings, and integrated optical circuits

ActiveUS20090304331A1Short timeChange the refractive indexGlass making apparatusOptical articlesGrating couplingLaser fabrication

The invention relates to devices having periodic refractive index modulation structures and fabrication methods for the devices using a laser means. By focusing a pulsed laser beam into a transparent material substrate, a path of laser modified volumes can be formed with modified refractive index compared with the unprocessed material. By selecting appropriate laser parameters and relative scan speed, the laser modified path defines an optical waveguide. Separation distance of the individual modified volumes define a periodic modification pattern along the waveguide path, so that the waveguide structures also exhibit grating responses, for example, as spectral filters, Bragg reflectors, grating couplers, grating sensors, or other devices. This method of direct laser fabrication enables one-step fabrication and integration of periodic or aperiodic refractive-index modulation devices together with optical waveguiding properties to enable low-cost, multifunctional I D, 2D or 3D optical circuit fabrication for simple and complex applications.

Owner:HERMAN +1

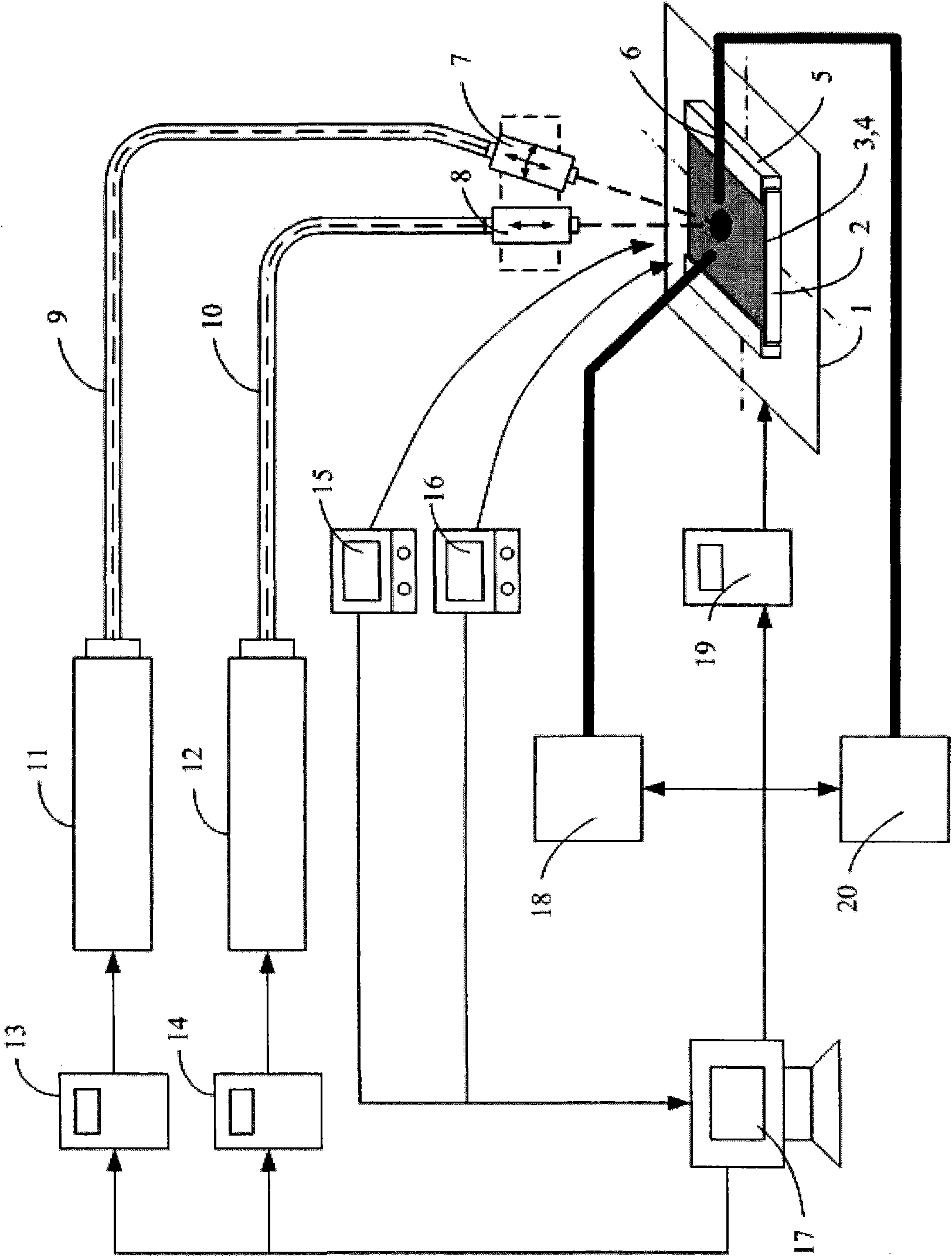

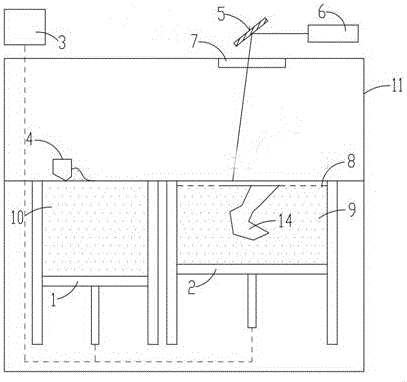

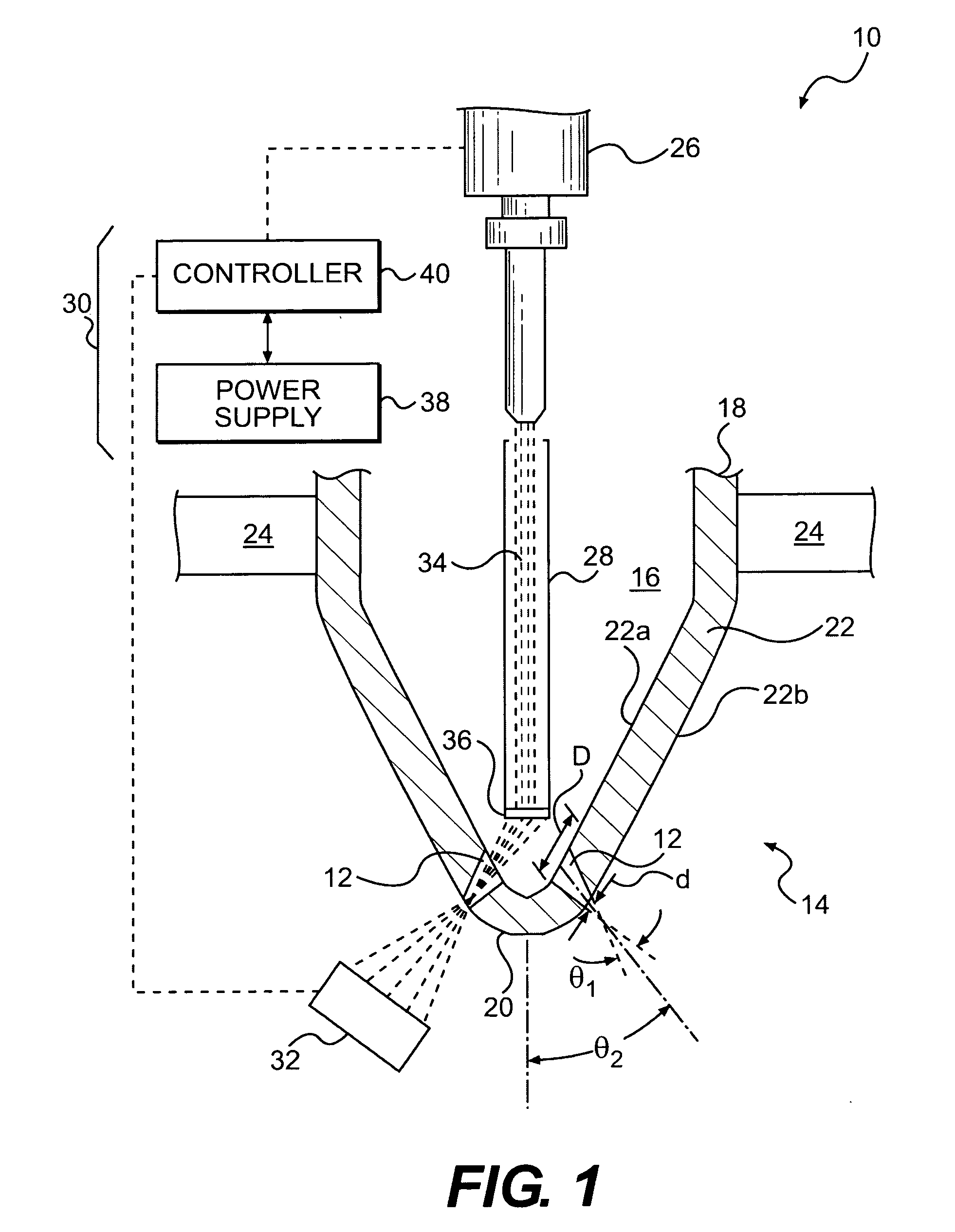

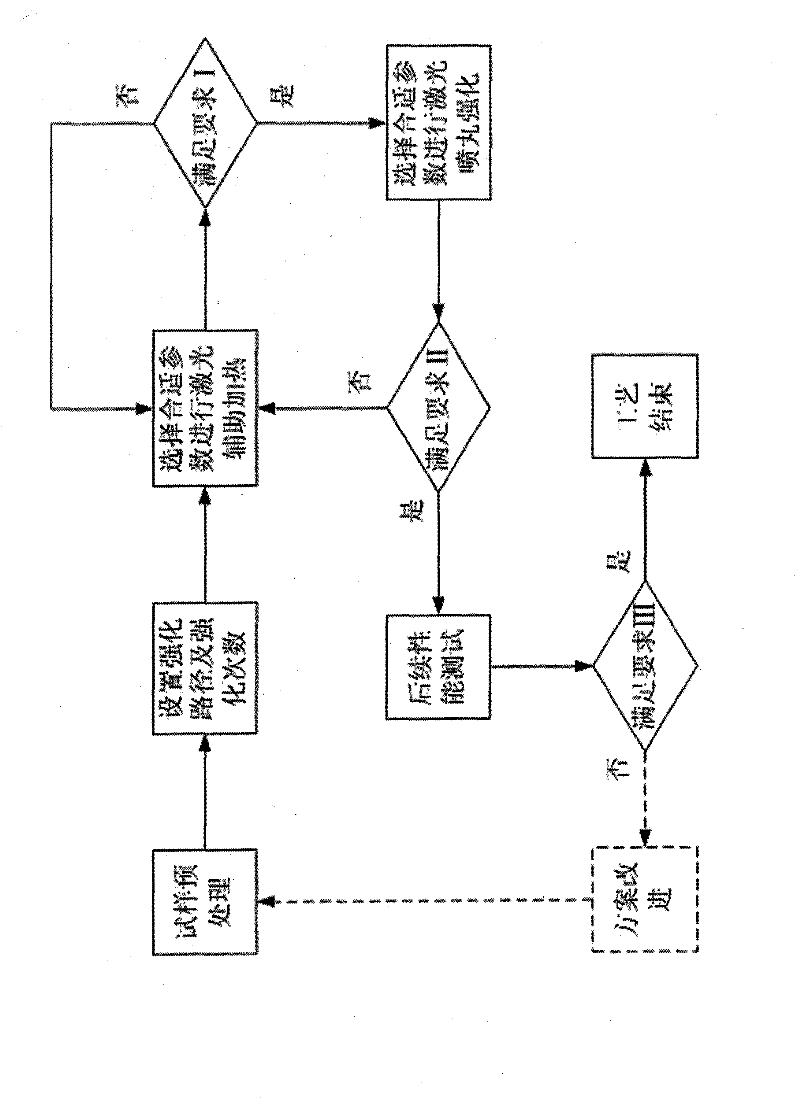

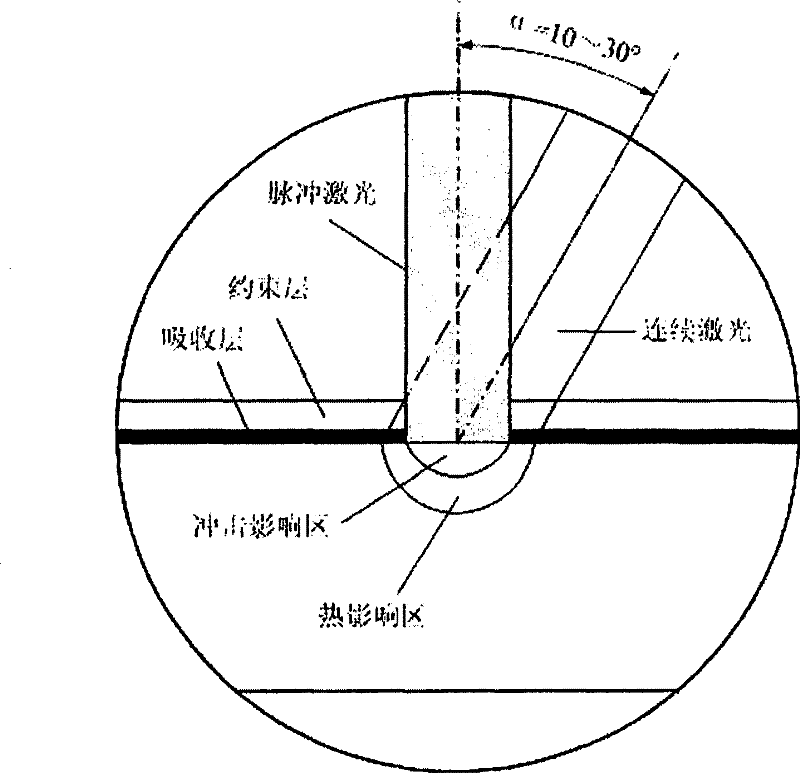

Device and method for laser shot blasting reinforcement of hard and brittle material

The invention discloses a device and a method for laser shot blasting reinforcement of a hard and brittle material, and relates to the field of mechanical manufacture of hard and brittle material processing and laser application. The device comprises a laser aid heating system, a laser shot blasting reinforcement system, a workpiece clamp system, a computer numerical control system, a measurement feedback system and a protective gas circulating system. The method comprises a laser aid heating stage and a laser shot blasting reinforcement stage, namely performing aid heating treatment on the area to be reinforced by adopting high-power continuous laser, wherein for most metal materials, the plastic performance is improved along with the rise of temperature; and after the temperature of the heating area reaches a predetermined heating temperature, implementing laser shot blasting reinforcement treatment by adopting high-power pulse laser. The device and the method can implement the laser shot blasting reinforcement on the hard and brittle material so as to broaden the application range of the laser shot blasting reinforcement technology, and meanwhile compound the advantages of continuous laser and pulse laser so as to broaden the application field and the application prospect of laser manufacture.

Owner:JIANGSU UNIV

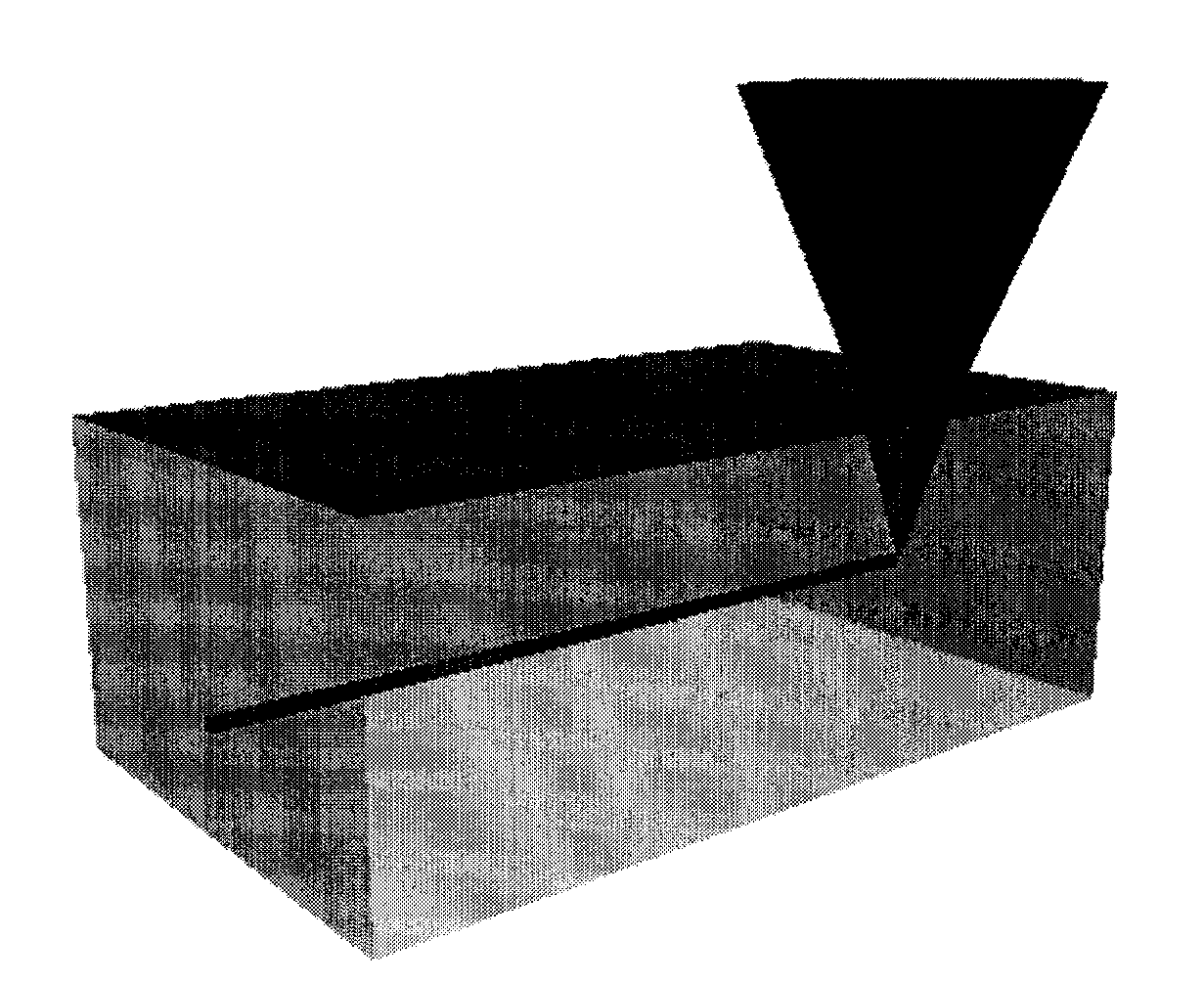

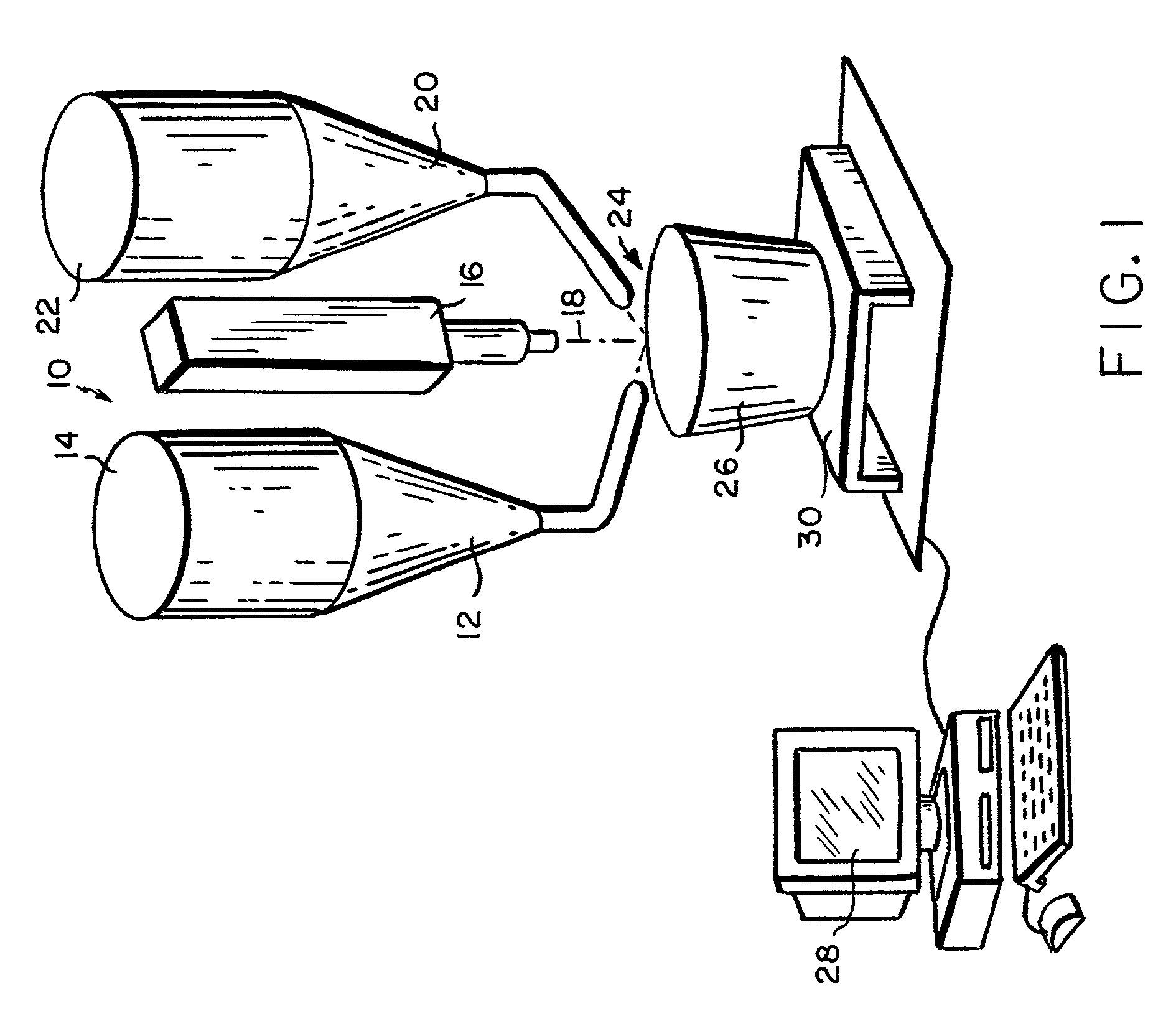

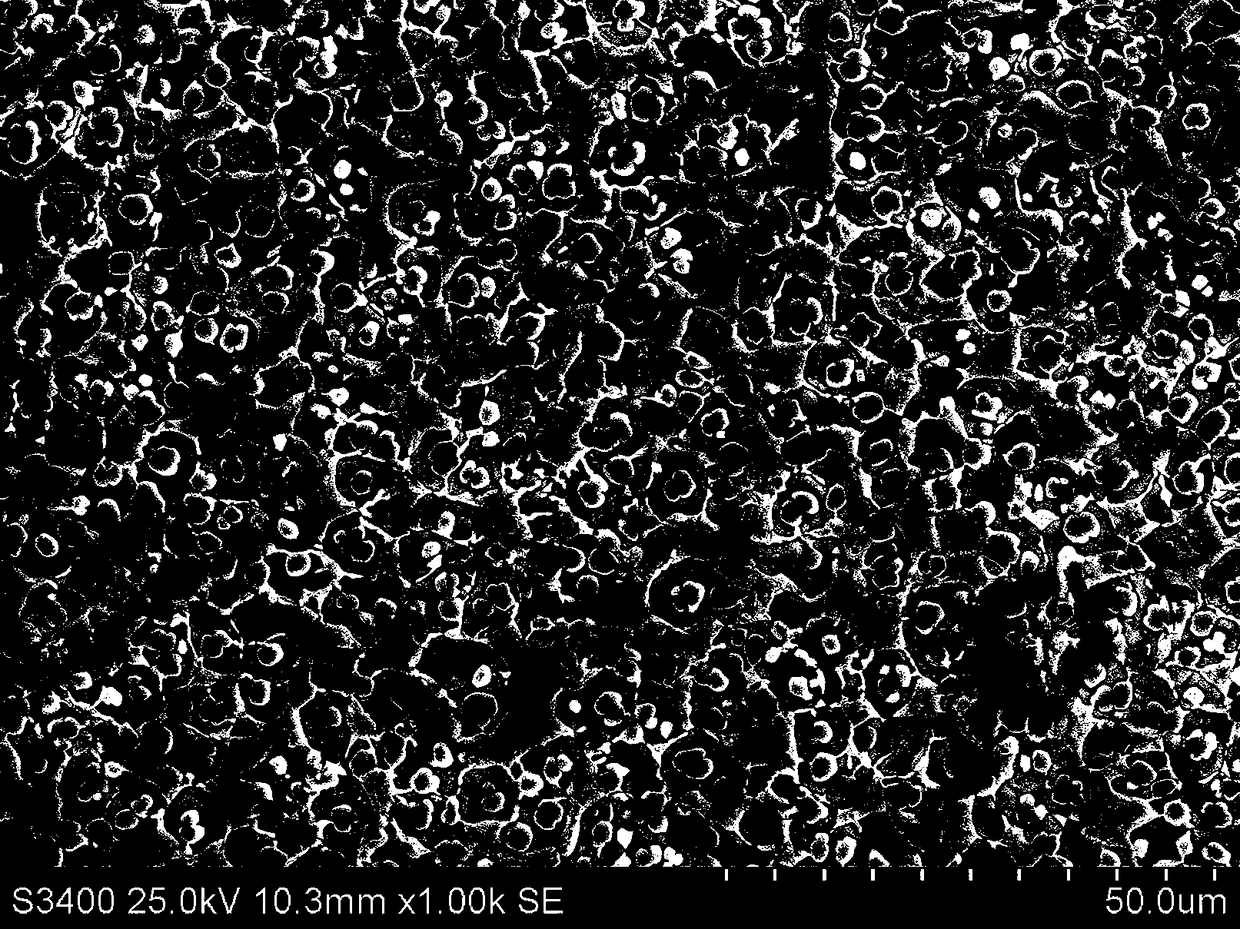

Laser fabrication of discontinuously reinforced metal matrix composites

InactiveUS7521017B2Low costImproved propertyAdditive manufacturing apparatusVacuum evaporation coatingLaser fabricationHardness

Disclosed are reinforced metal matrix composites and methods of shaping powder materials to form such composites. Articles of manufacture are formed in layers by a laser fabrication process. In the process, powder is melted and cooled to form successive layers of a discontinuously reinforced metal matrix. The matrix exhibits fine grain structure with enhanced properties over the unreinforced metal, including higher tensile modulus, higher strength, and greater hardness. In some preferred embodiments, an in-situ alloy powder, a powder metallurgy blend, or independently provided powders are reinforced with boron and / or carbon to form the composite.

Owner:TRITON SYST INC

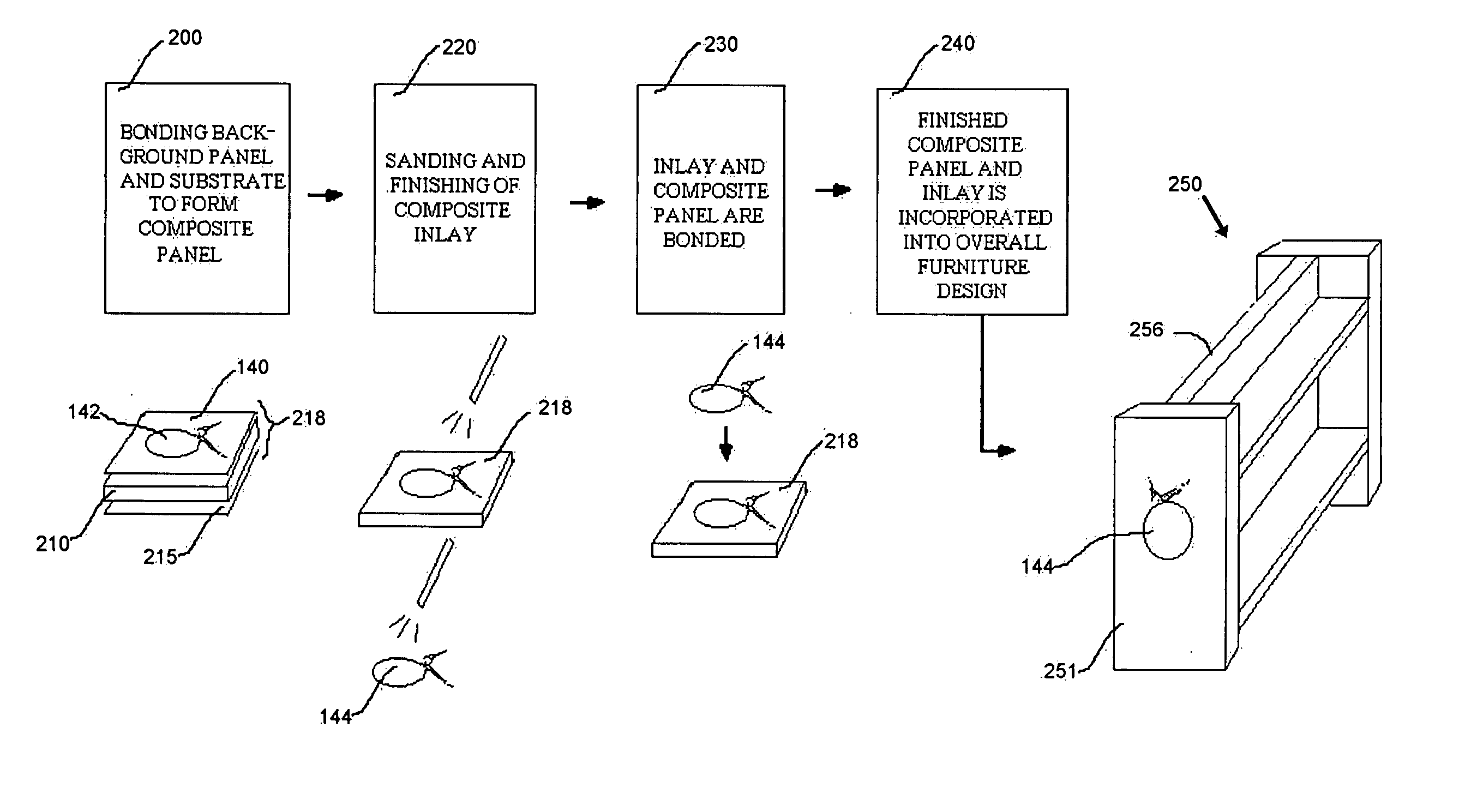

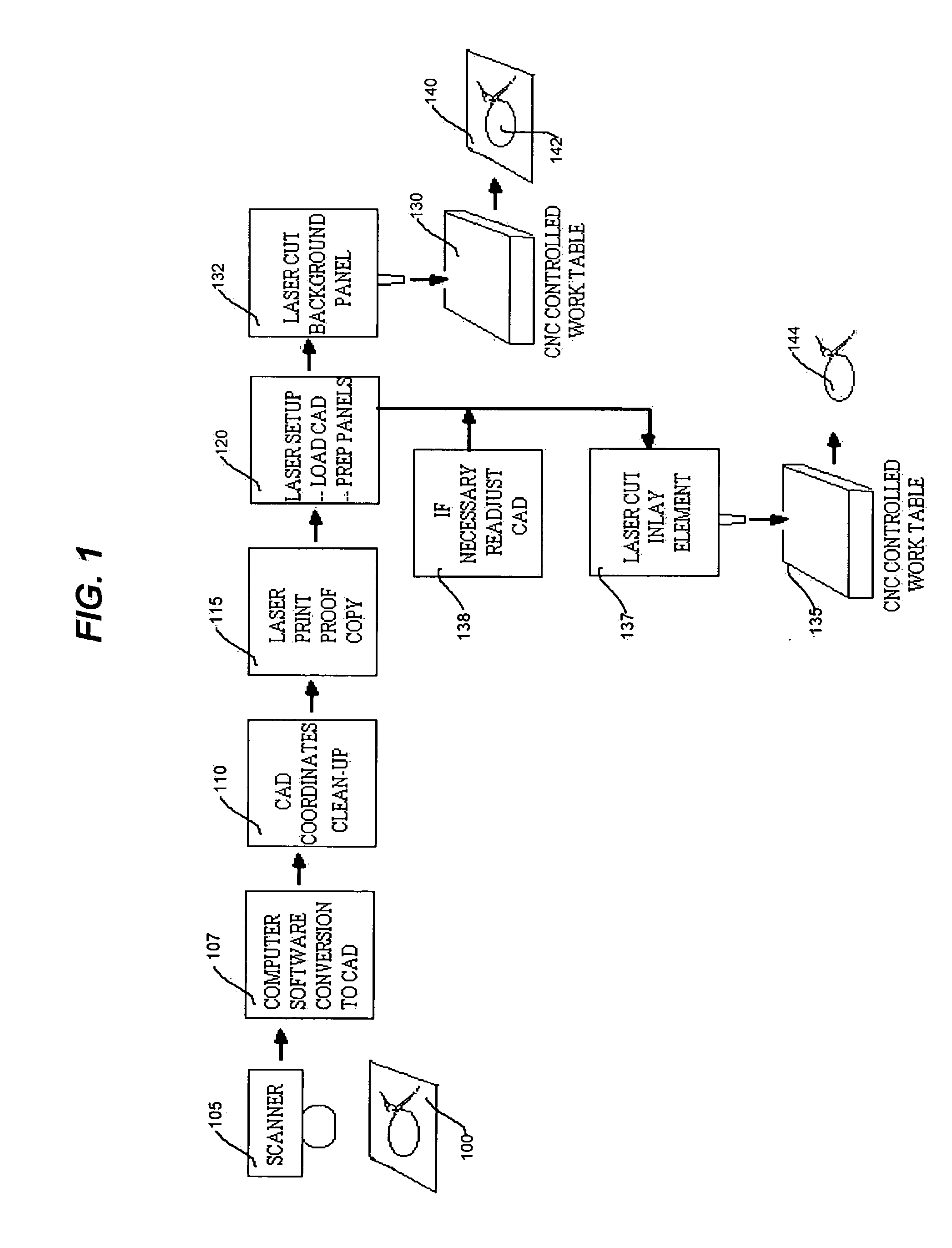

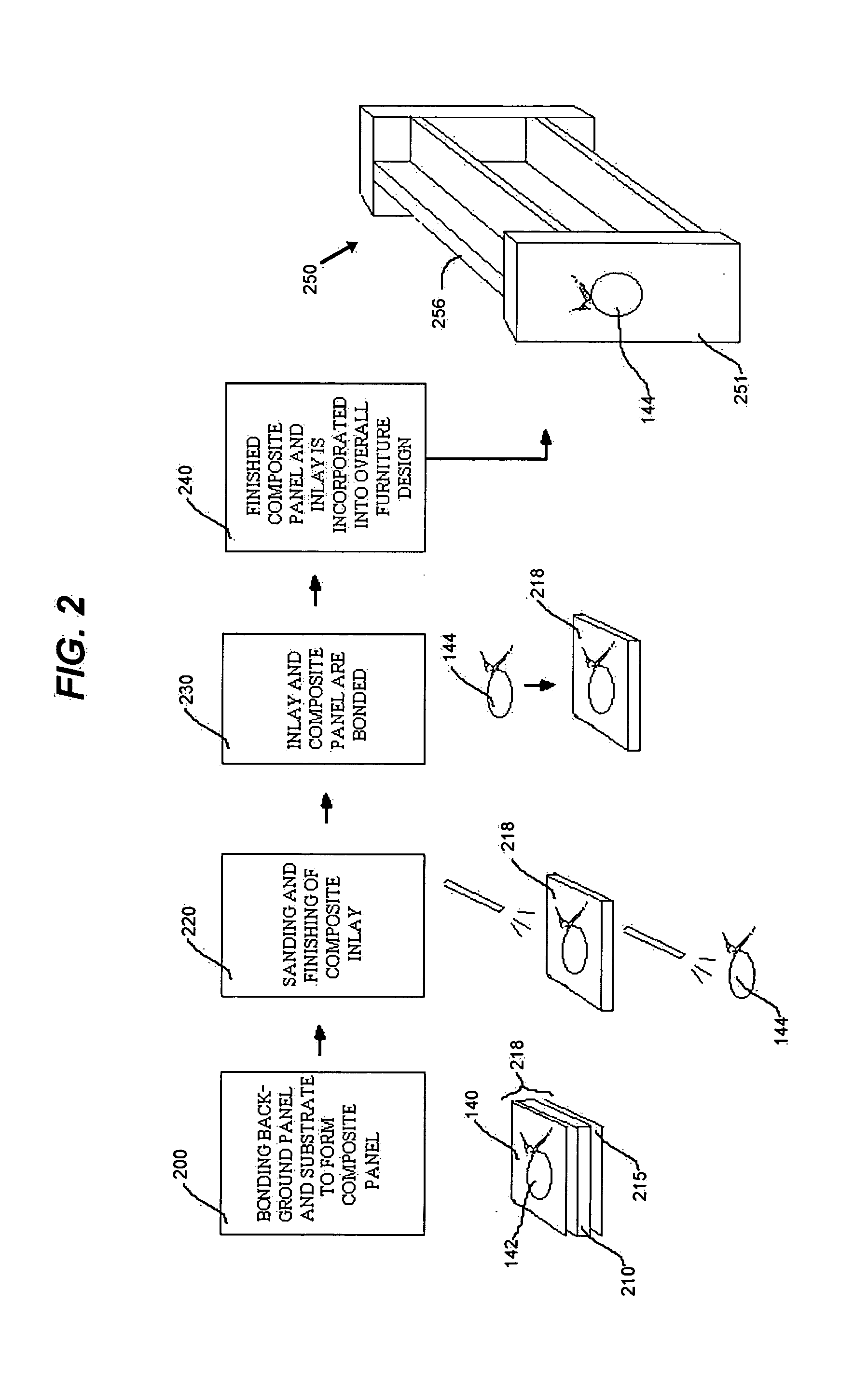

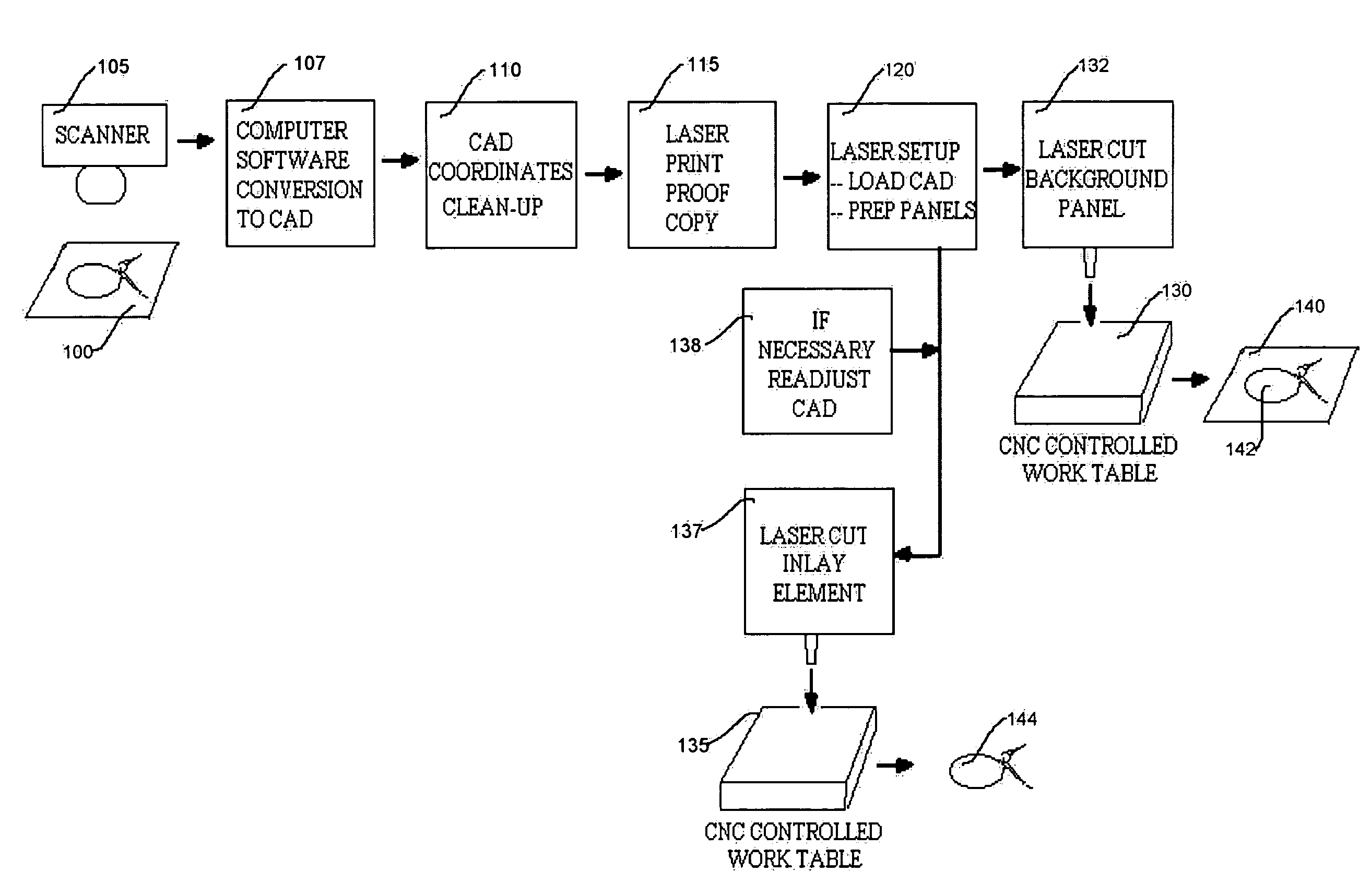

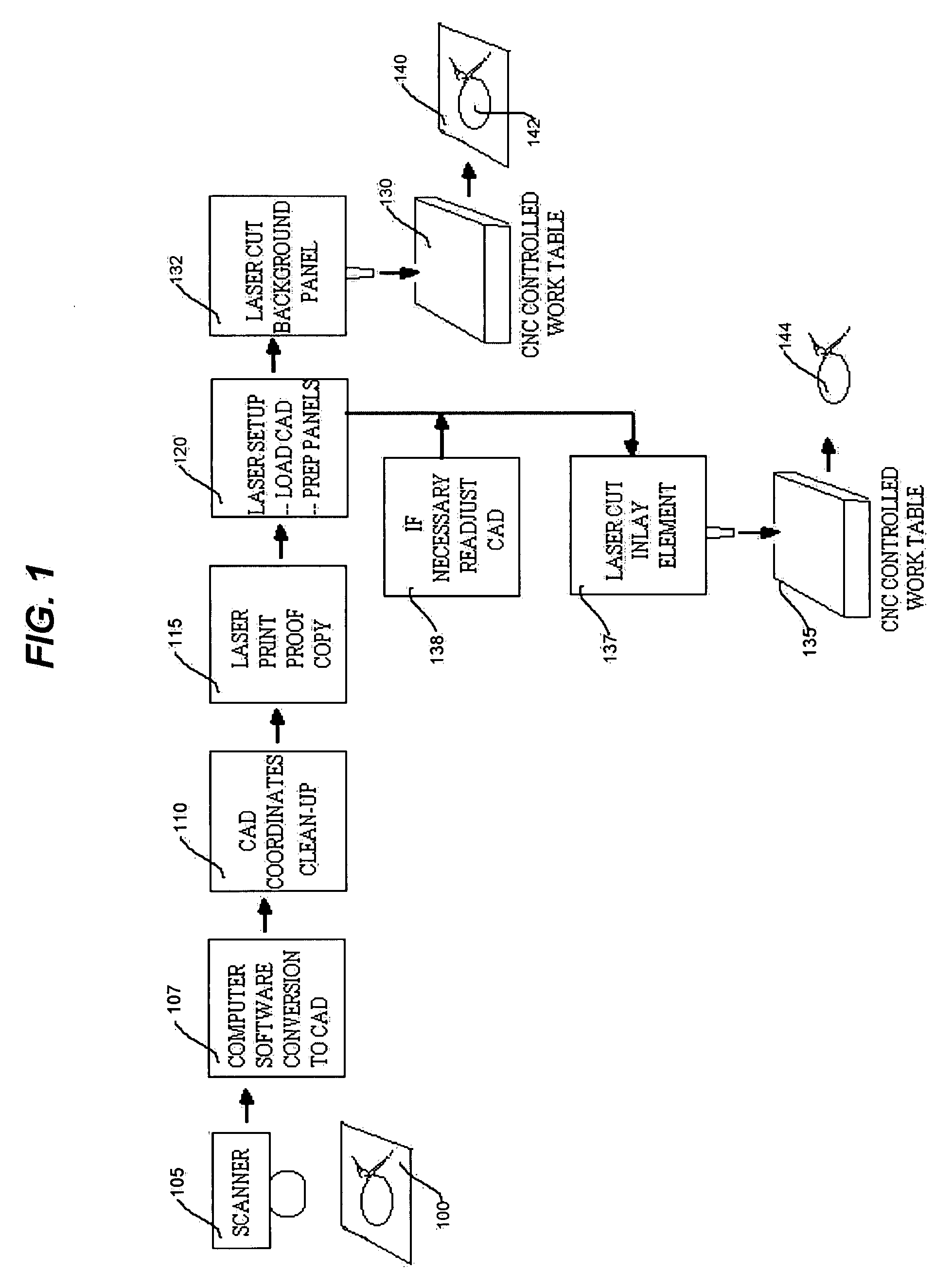

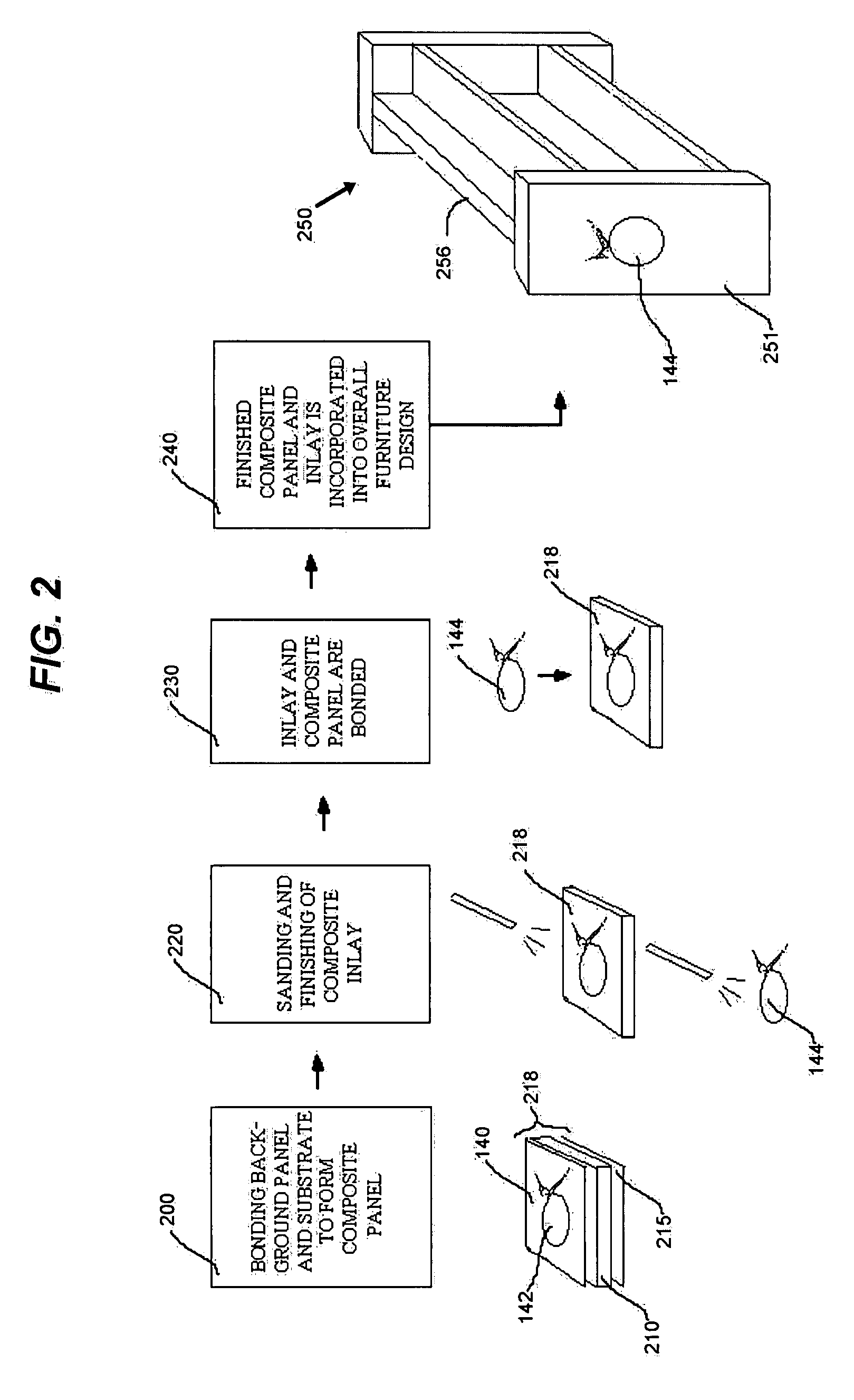

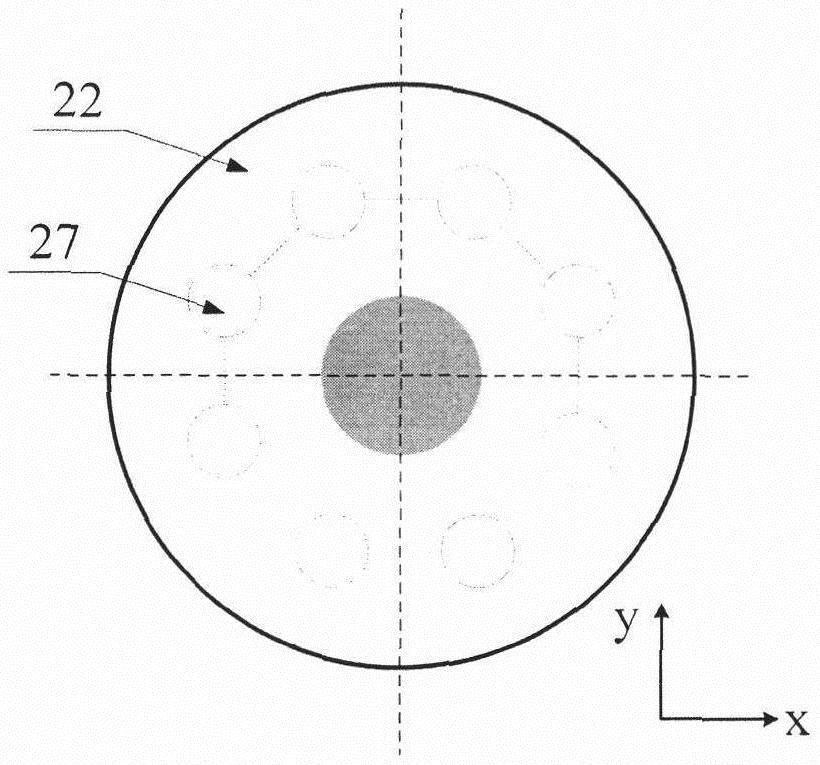

System for manufacturing an inlay panel using a laser

InactiveUS20050006019A1Straightening imperfect linesSimple designLamination ancillary operationsDecorative surface effectsGraphicsSoftware system

A method of manufacturing an inlayed panel uses the steps of providing an art master rendering as constitute a decorative design for the inlaid panel; scanning electronically the art master to form an art master data file; transferring the art master data file to a CAD software system to form an art master CAD file; coordinating a laser beam to cut-through a first background panel and create negative image voids; driving a CNC laser cutting machine in response to the machine code coordinates; coordinating a laser beam to cut through a second panel for forming positive images that become inlay elements; bonding the first background panel and the second panel; placing the inlay element in appropriate voided spaces; and finishing the composite panel and the inlay elements. A decorative panel is also formed of panel portions cut by laser using data inputted directly into a computer graphics system.

Owner:TMC FURNITURE

Optical devices and digital laser method for writing waveguides, gratings, and integrated optical circuits

ActiveUS8270788B2Short timeChange the refractive indexGlass making apparatusOptical articlesSpectral filteringLaser fabrication

The invention relates to devices having periodic refractive index modulation structures and fabrication methods for the devices using a laser means. By focusing a pulsed laser beam into a transparent material substrate, a path of laser modified volumes can be formed with modified refractive index compared with the unprocessed material. By selecting appropriate laser parameters and relative scan speed, the laser modified path defines an optical waveguide. Separation distance of the individual modified volumes define a periodic modification pattern along the waveguide path, so that the waveguide structures also exhibit grating responses, for example, as spectral filters, Bragg reflectors, grating couplers, grating sensors, or other devices. This method of direct laser fabrication enables one-step fabrication and integration of periodic or aperiodic refractive-index modulation devices together with optical waveguiding properties to enable low-cost, multifunctional 1D, 2D or 3D optical circuit fabrication for simple and complex applications.

Owner:HERMAN +1

Laser fabrication of continuous nanofibers

This invention provides a continuous process of making continuous nanofibers of all kinds, such as SiC, BN, AlN, and C. Laser heating a vapor of feed-material made of all atomic elements needed to grow chosen nanofibers results in growth of nanofibers onto seed-nanostructures attached to a filament, which is then pulled up continuously at a rate controlled by a rate of growth of the nanofibers. More feed-material is supplied at a rate sufficient to enable the nanofibers to grow longer continuously without limit. Laser light focused into a doughnut shape provides a photon density gradient, which constrains the nanofibers to grow parallel to each other and in the form of cylinders, so that industrially useful structures like cables and cylinders can be made in one low cost operation and in large quantities.

Owner:SHIMOJI YUTAKA +1

Method and device for manufacturing polyamide three-dimensional object by laser

ActiveCN106626379AAchieve fusionSmall spotAdditive manufacturing apparatus3D object support structuresPolyamideLength wave

The invention discloses a method for manufacturing a polyamide three-dimensional object by laser. The method comprises the steps that a layer of manufacturing material is laid and conveyed onto a bottom plate or a selective fusion layer to form a novel material layer; a laser device emits laser; the laser is guided to selectively irradiate a fusion region on the novel material layer; the fusion region is a cross section position, corresponding the three-dimensional object to be manufactured, on the novel material layer, wherein the laser is generated by the laser device with the wavelength being 400 to 1080nm; the manufacturing material is a mixture of a polyamide powder material and a thermal medium material; the thermal medium material absorbs laser energy and conducts the laser energy to polyamide powder, so that the manufacturing material in the laser irradiation region realizes fusion. The polyamide three-dimensional object with high manufacturing precision can be manufactured according to the method.

Owner:HUNAN FARSOON HIGH TECH CO LTD

Visual preview for laser fabrication

ActiveUS20200089185A1Avoid emissionsWelding/cutting auxillary devicesWood working apparatusInterior spaceInterlock

Owner:GLOWFORGE

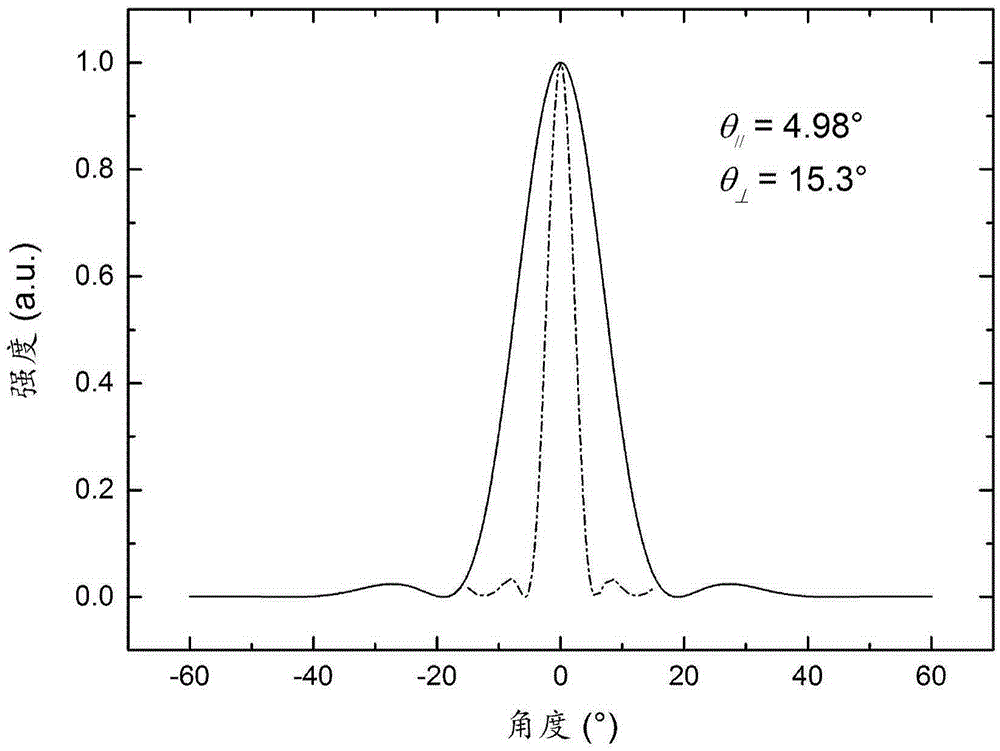

Multi-active zone epitaxial structure, semiconductor laser adopting same and manufacturing method of multi-active zone epitaxial structure

InactiveCN105429004AIncreased cooling burdenReduce power densityLaser detailsSemiconductor lasersSemiconductor packageDivergence angle

The invention relates to a tunnel cascaded multi-active region epitaxial structure. The tunnel cascaded multi-active region epitaxial structure includes a substrate and a plurality of heterostructure active regions which are limited respectively; the plurality of active regions are formed on the substrate sequentially; and the plurality of active regions are connected with each other through reversely-biased PN junctions. The invention also provides a semiconductor laser adopting the epitaxial structure. According to the laser, a buffer layer and an electrode contact layer are sequentially grown on the uppermost active region; and follow-up laser fabrication is completed through using a standard wide-surfaced strip-shaped laser fabrication process. The number of active regions in the epitaxial structure can be adjusted between 2 to 4 according to needs. With the tunnel cascaded multi-active region epitaxial structure and the laser adopting the same adopted, output power and slope efficiency can be improved, and a vertical divergence angle can be greatly reduced.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI +1

System for manufacturing an inlay panel using a laser

InactiveUS20090014118A1Straightening imperfect linesSimple designLamination ancillary operationsDecorative surface effectsGraphicsLaser fabrication

A method of manufacturing an inlayed panel uses the steps of providing an art master rendering as a decorative design for the inlaid panel; entering into a control computer graphical data corresponding to a plurality of laser cutting paths, first laser cutting a panel in accordance with the graphical data; second laser cutting a panel in accordance with the graphical data to produce a plurality of panel portions; and attaching the plurality of panel portions to a substrate to form the decorative panel. One of the plurality of panel portion then is finished. The step of entering graphical data corresponding to the plurality of cutting paths can be performed on a CAD system to produce machine code for controlling the laser beam. The graphical data can be entered, in some embodiments by scanning electronically the art master to form an art master data file.

Owner:RATCLIFFE BLAKE EDWARD

Visual preview for laser fabrication

ActiveUS20200089184A1Avoid emissionsWelding/cutting auxillary devicesWood working apparatusInterior spaceInterlock

A computer numerically controlled machine may include a movable head configured to deliver electromagnetic energy to a part of a working area in which the movable head may be commanded to cause delivery of the electromagnetic energy. The interior space may be defined by a housing and may include an openable barrier that attenuates transmission of light between the interior space and an exterior of the computer numerically controlled machine when the openable barrier is in a closed position. The computer numerically controlled machine may include an interlock that prevents emission of the electromagnetic energy when detecting that the openable barrier is not in the closed position. The commanding may result in the computer numerically controlled machine executing operations of a motion plan for causing movement of the movable head to deliver the electromagnetic energy to effect a change in a material at least partially contained within the interior space.

Owner:GLOWFORGE

Method for manufacturing metallic component by additive laser manufacturing

InactiveCN104511589AExtend your lifeEasy to operateAdditive manufacturing apparatusIncreasing energy efficiencyControl mannerOptoelectronics

The invention refers to a method for manufacturing a three-dimensional metallic article / component made of a Ni-, Co-, Fe-based superalloy or combinations thereof, entirely or partly, by a powder based additive manufacturing process. During the step of performing powder melting by scanning a dual laser setup is used, where two laser beams of different beam properties are combined in the same machine and by adjusted beam profiling and integration of a suitable beam switch in a controlled manner a switching between two different laser beam diameters is performed. In each layer the laser beam with the smaller diameter scans the whole area and in every kth layer, with k>1, the laser beam with the larger diameter scans the area where a coarse grain size is needed thereby remelting the area with fine grain sizes. With such a manufacturing method higher lifetime and operation performances of metallic parts and prototypes can be reached.

Owner:ANSALDO ENERGIA IP UK LTD

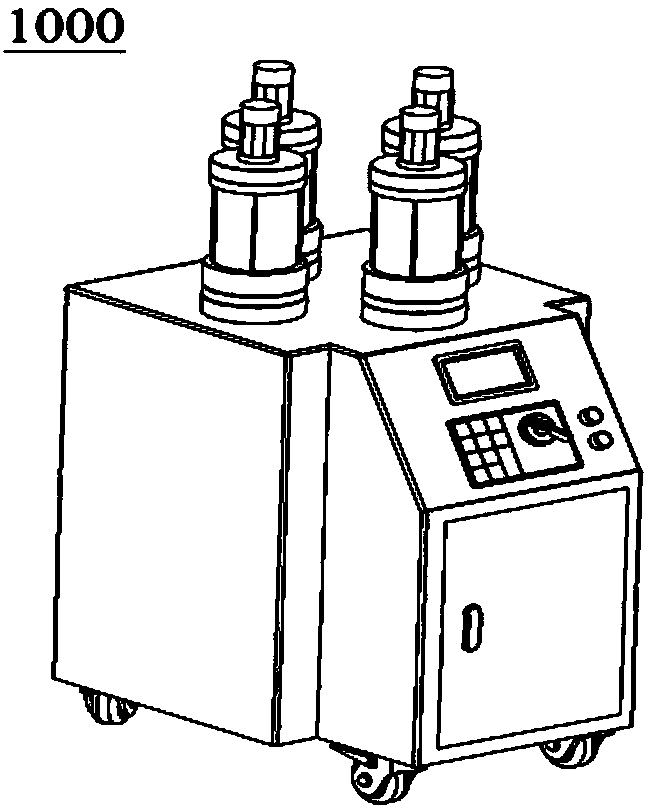

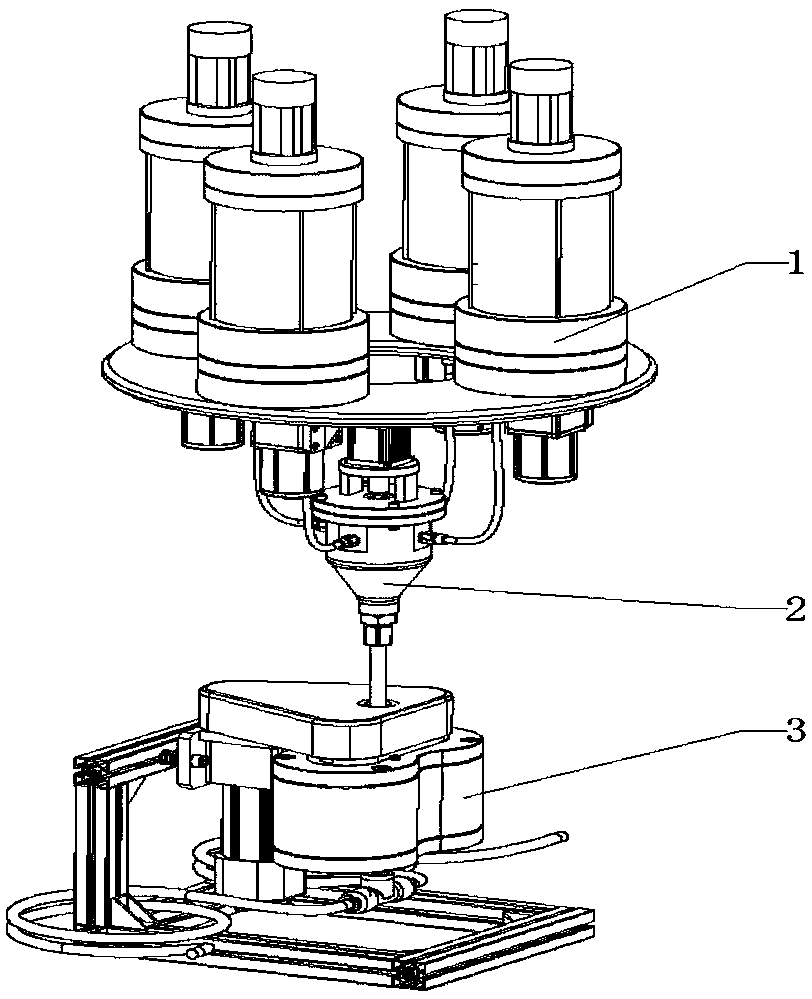

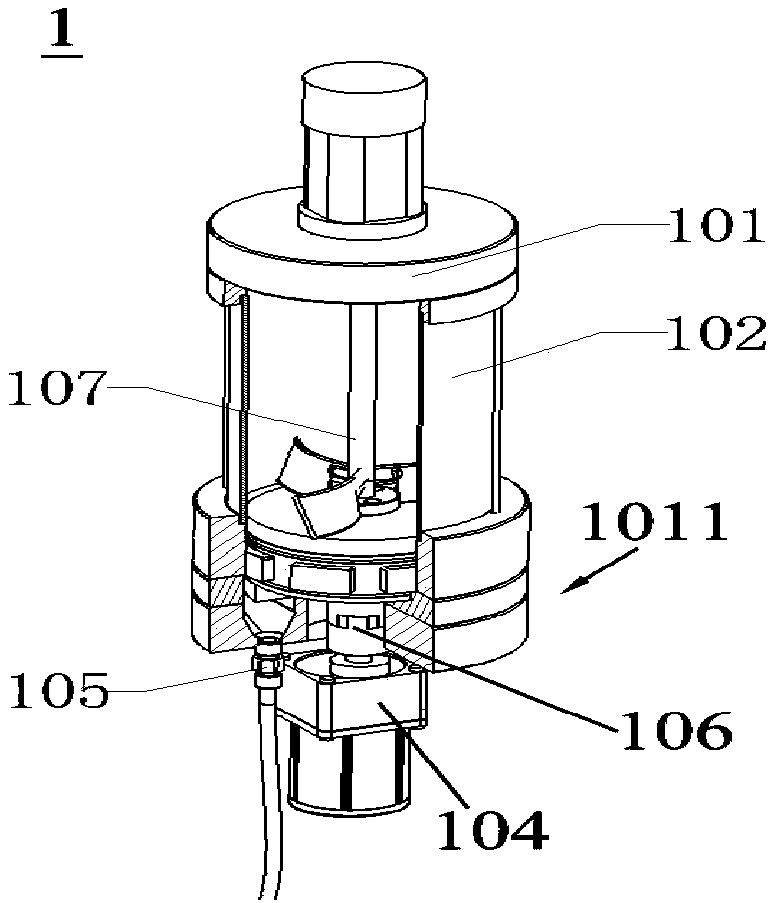

Powder matching dynamic powder-feeding device for large complex gradient functional component direct laser fabrication and machining equipment

PendingCN108097956ADynamic mixingMixed real timeAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgyLaser fabrication

The invention provides a powder matching dynamic powder feeding device for large complex gradient functional component direct laser fabrication and machining equipment and belongs to the field of direct laser fabrication. The powder feeding device comprises a ratio controllable powder feeding device body, a multi-component powder pre-mixing device body and a double-screw component fine mixing device body. The ratio controllable powder feeding device body comprises a powder conveyor and a powder feeding controller which are mutually matched, the powder feeding controller is constructed to receive powder output by the powder conveyor and release the powder received from the powder conveyor in a quantity controllable mode, and the multi-component powder pre-mixing device body is constructed to receive and pre-mix the powder output by the powder feeding controller and output pre-mixed powder materials. The double-screw component fine mixing device body is constructed to receive and finelymix the pre-mixed powder materials. Through the powder-feeding device, powder raw materials can be adjusted and conveyed according to the requirement so that the multi-component raw materials can be better applied to direct laser fabrication.

Owner:INST OF LASER & OPTOELECTRONICS INTELLIGENT MFG WENZHOU UNIV

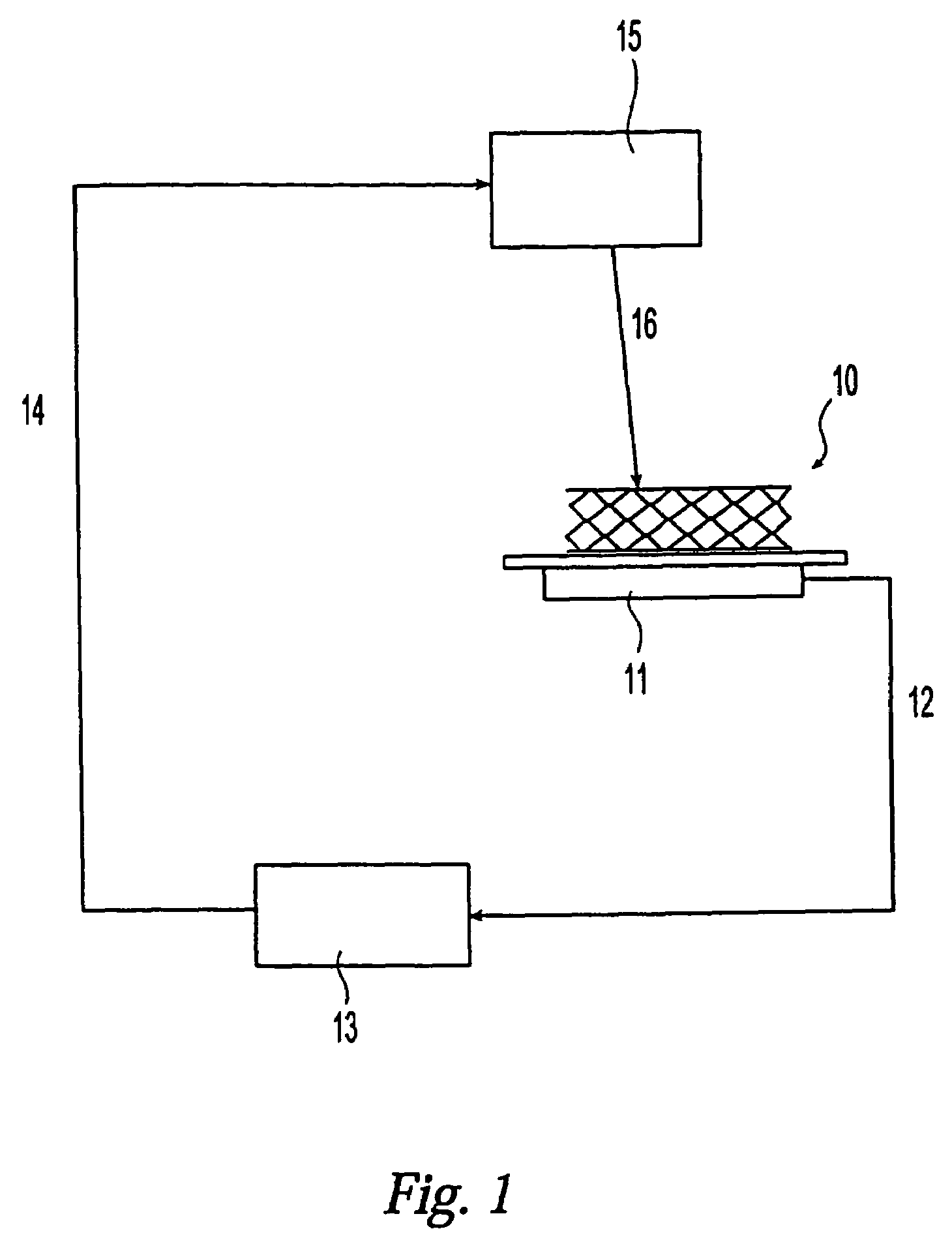

Diffractive optical element changer for versatile use in laser manufacturing

A DOE array apparatus includes a plurality of different interchangeable DOEs for use with lasers in manufacturing for versatile tasks such as drilling holes or vias of various sizes and shapes and multiple ablation or material transformation patterns in a surface of an object. A method of using the apparatus in laser processing systems includes: determining a specification for the number of patterns and / or the number of layers to be patterned, designing the appropriate number of DOEs according to the product specification, assembling the DOEs into an array to be used in a laser processing system, ablating the layer on the object through laser processing, determining whether more patterns on the layer are to be processed, determining whether more layers are to be patterned, and changing and aligning the DOE for the next laser ablation or material transformation pattern to be processed.

Owner:PANASONIC CORP

Laser-manufacturing-technology-based conformal cooling device making method

The invention discloses a laser-manufacturing-technology-based conformal cooling device making method, first, a continuous cooling passage with a preset-shape is processed on a position close to mold cavity or / and mold core surface on a mold by means of mechanical processing method, and the cooling passage is nearly parallel to the mold cavity or / and mold core surface and surrounds the mold cavity or / and mold core surface in the manner of a band; the continuous cooling passage is covered with a strip or plate-shaped metal cover plate, the metal plate is fixed on the cooling passage by laser welding technology, and a sealed channel is formed in the cooling passage; and finally, the metal plate is layer-by-layer fusion-covered with a metal by laser material increase manufacturing technology to form a finally-required mold. According to the method, conformal cooling device making can be realized, and not limited by the shape of macro parts. In addition, the method also has more simple preparation property and more efficient production efficiency, at the same time, the prepared mold has a long service life.

Owner:金鑫 +3

Iron-based alloy powder used for laser manufacturing of high-speed railway switch bedplates

InactiveCN106555127AWith wear and corrosion resistanceImprove performanceBallastwayMetallic material coating processesCrack resistanceLaser fabrication

The invention discloses an iron-based alloy powder used for laser manufacturing of high-speed railway switch bedplates. The iron-based alloy powder comprises, by mass, 1.0-1.2% of C, 12-15% of Cr, 3-4.8% of W, 1-2% of Ti, 4-6% of Ni, 2.1-4.1% of B, 0.2-0.3% of Si, 0.1-0.15% of Y2O3, 0.12-0.19% of Hf, and the balance of Fe. The proportions of all elements are adjusted to improve the crack resistance, the formability, the technologic stability and the component uniformity of the alloy powder in a laser cladding layer in order to meet the high-speed railway switch bedplates' requirements of the corrosion resistance, the wear resistance, the fatigue resistance and other comprehensive performances.

Owner:沈阳大陆激光工程技术有限公司

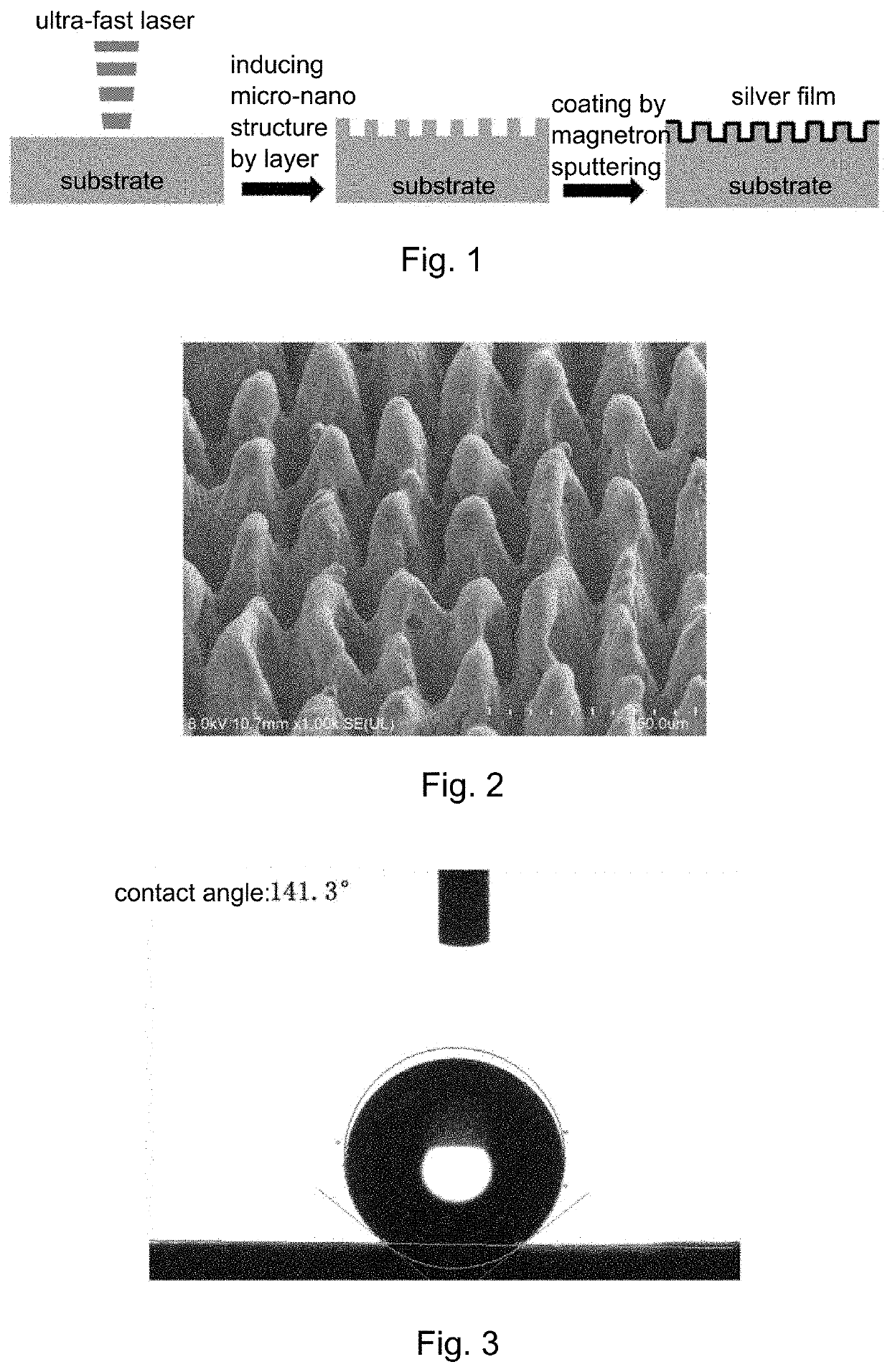

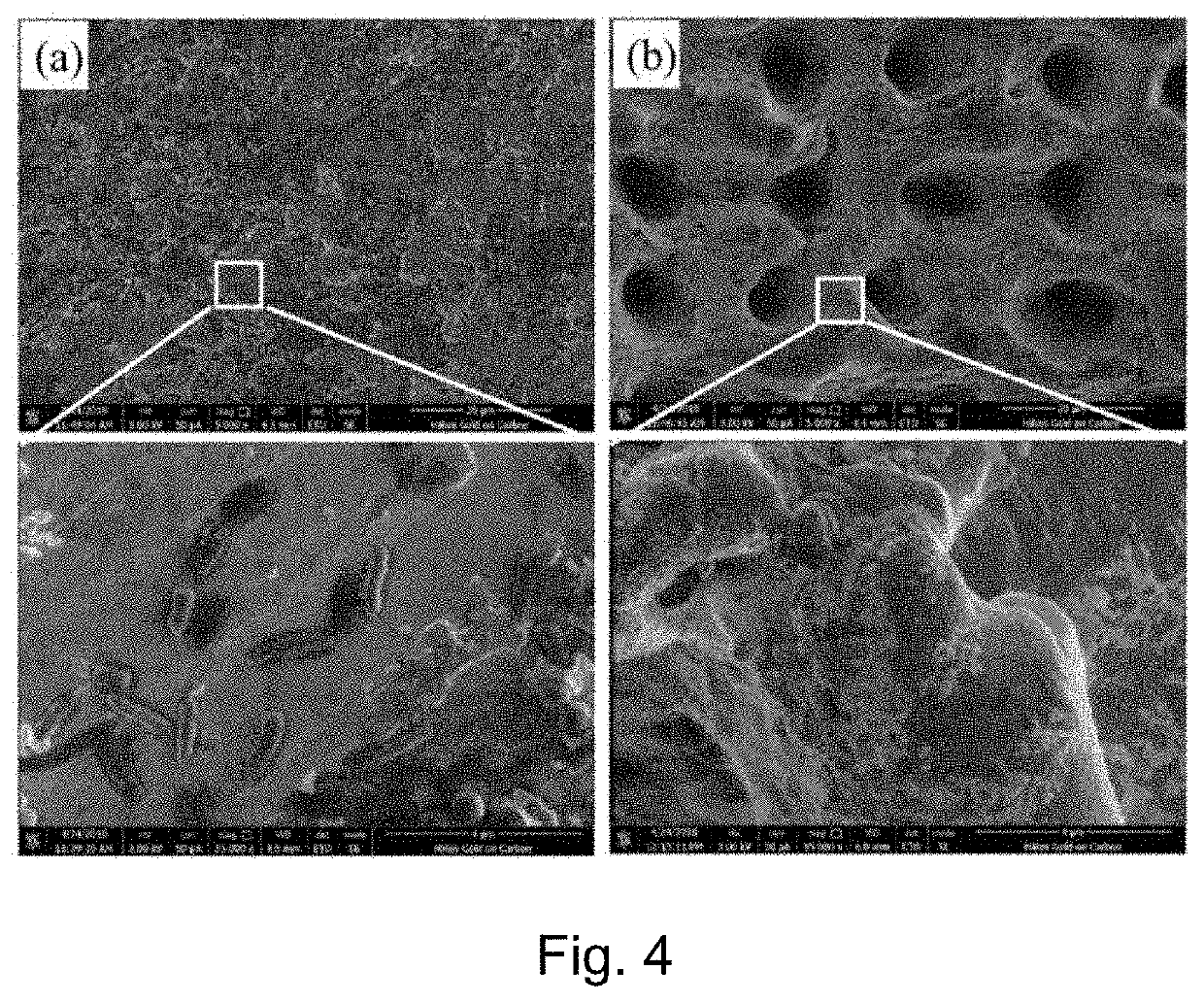

Preparation of antimicrobial surface for medical devices

ActiveUS20200009687A1Precision productionLittle thermal damageBiocideAnimal repellantsBacterial AdhesionsAntimicrobial surface

A method of preparing antimicrobial surface on medical devices: first, producing multi-functional surface with bacterial anti-adhesion and self-cleaning functions through single-stop ultrafast laser fabrication approach for development of micro / nano patterns, then producing bactericidal thin film through depositing metal nanoparticles on those micro / nano patterned surfaces. The combination of bacterial anti-adhesion and bactericidal film can inhibit initial bacterial adhesion and release heavy metal ions to kill the bacteria simultaneously. Meanwhile, the multi-functional surface with self-cleaning function can prevent the killed bacteria from accumulating at the substrate surface, thereby obtaining long-lasting antibacterial effect.

Owner:BEIHANG UNIV

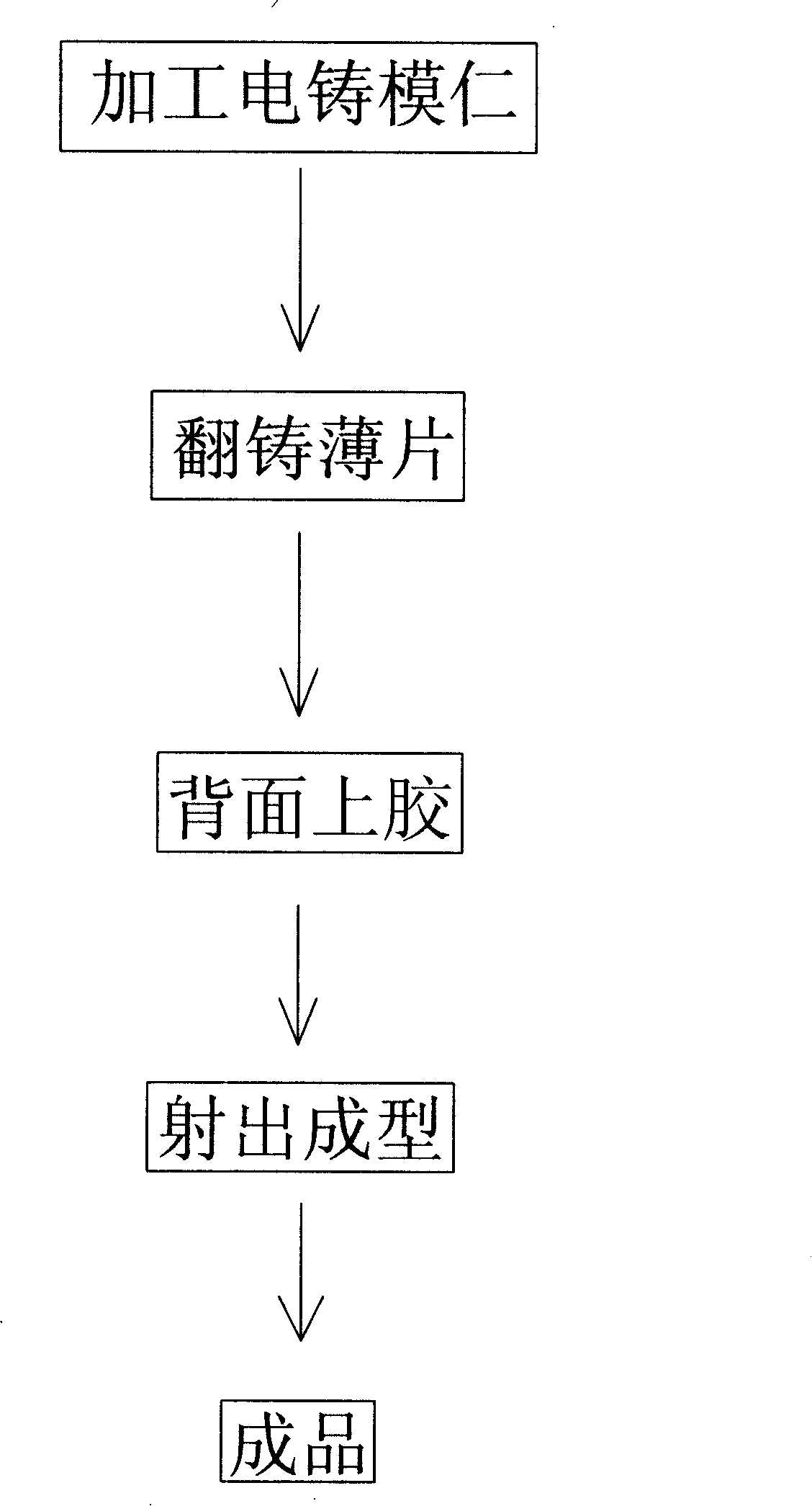

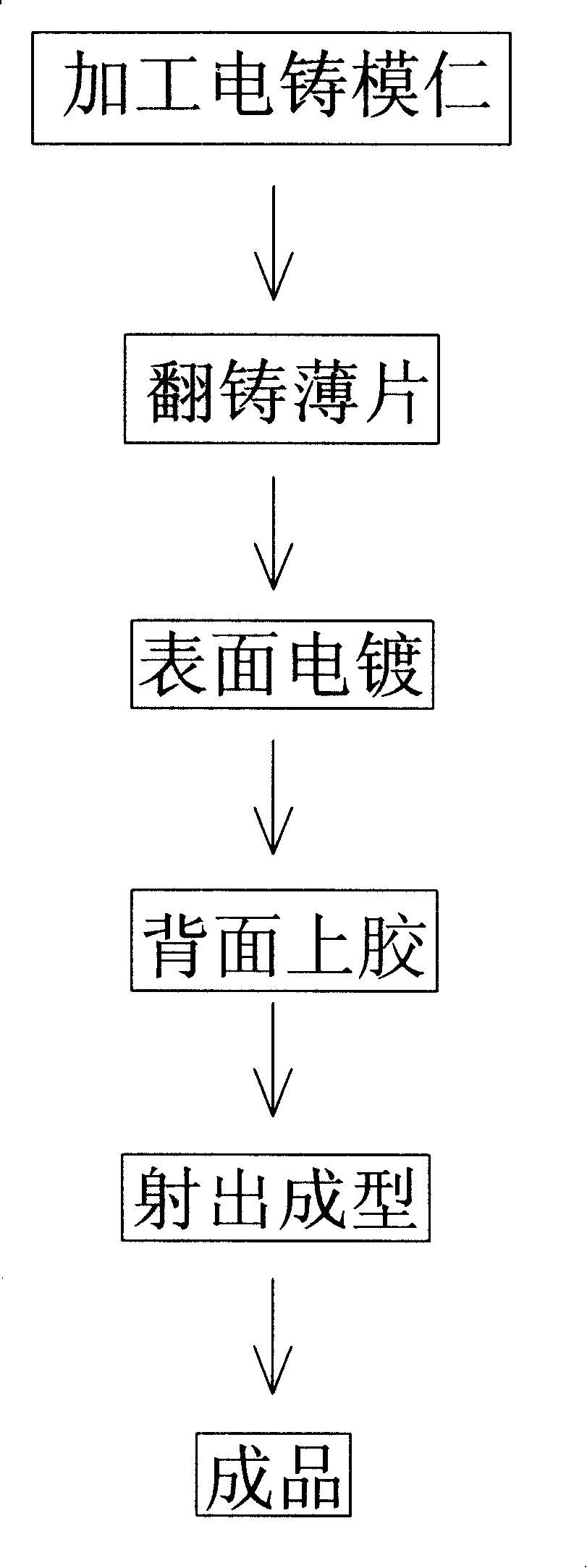

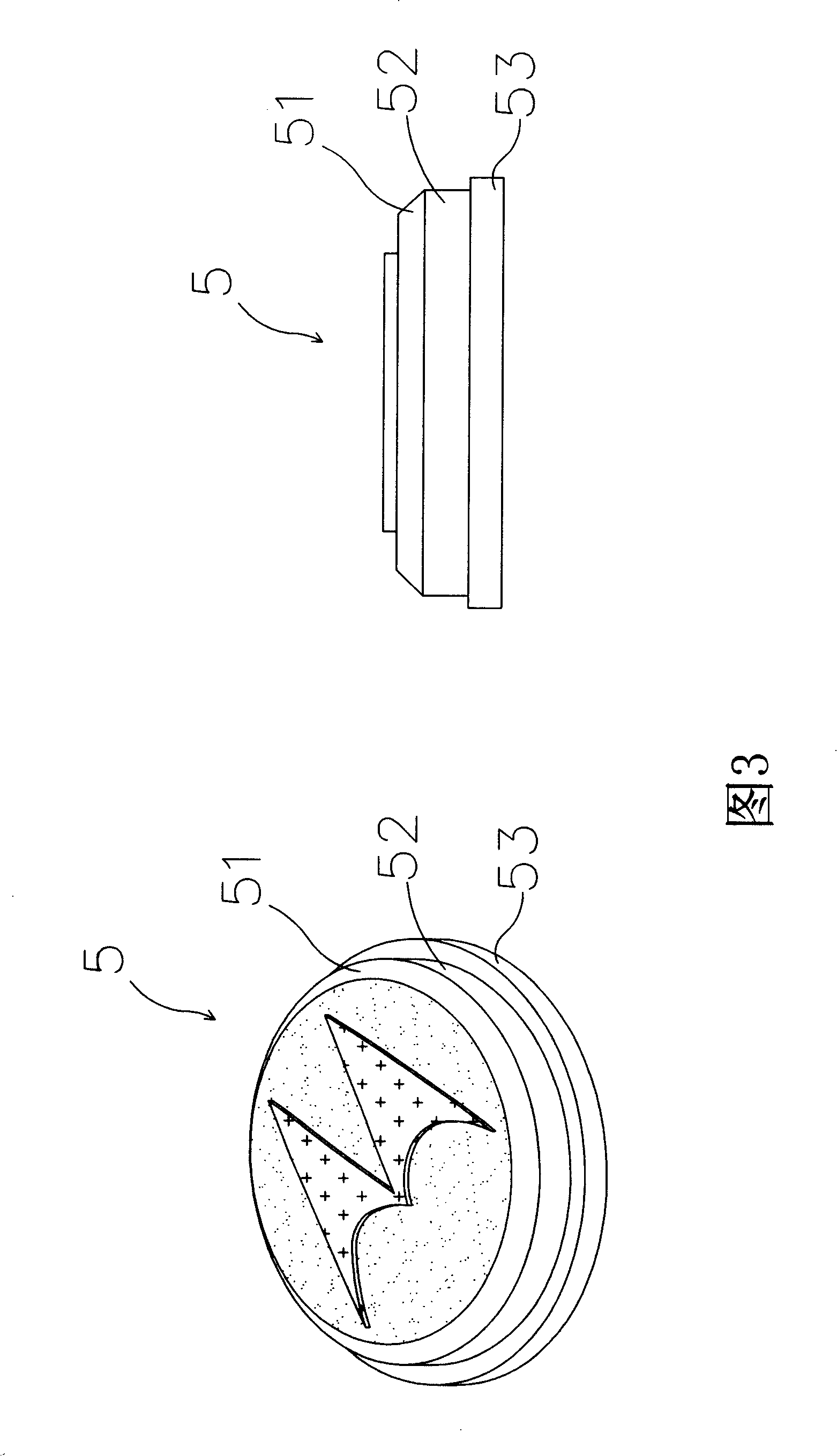

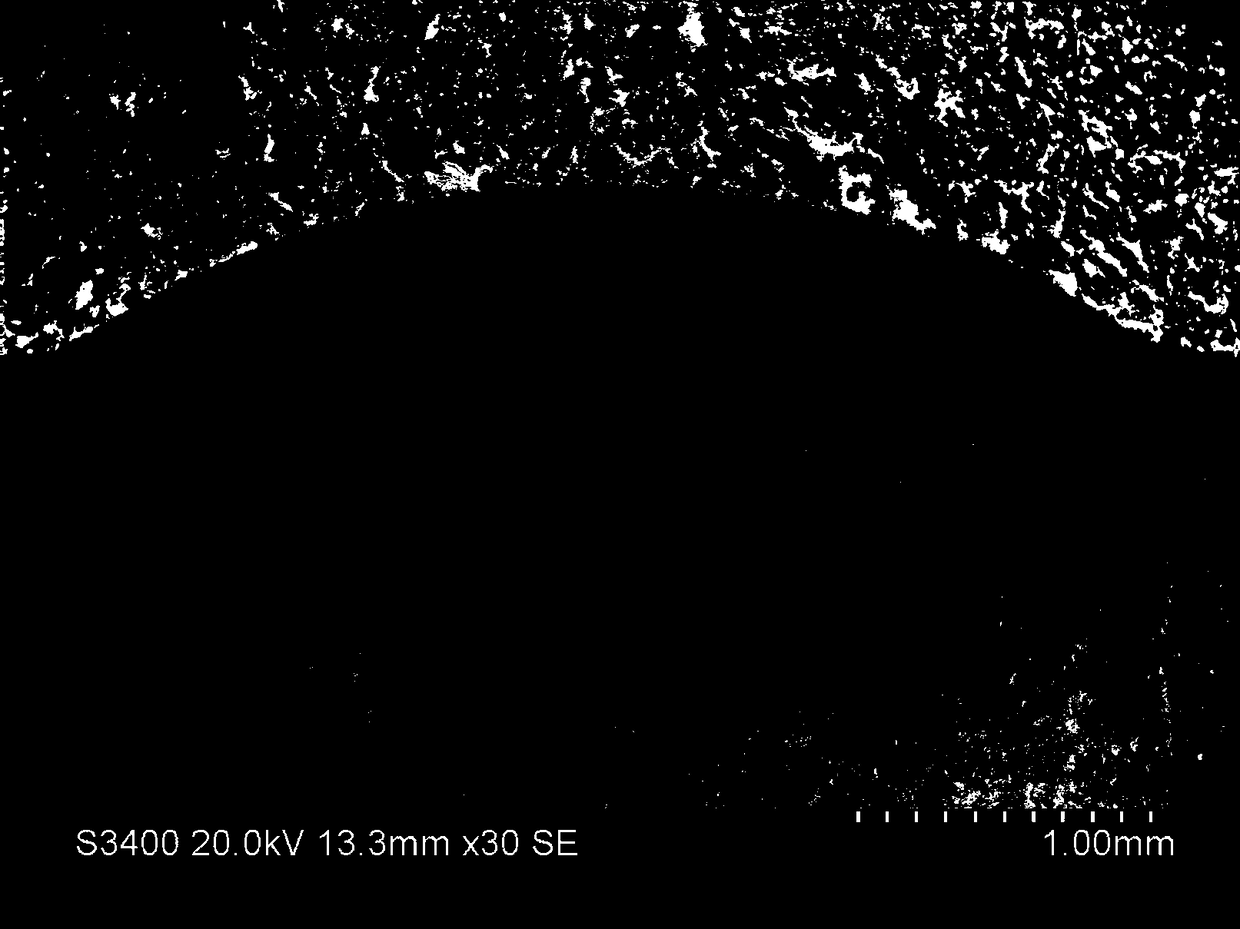

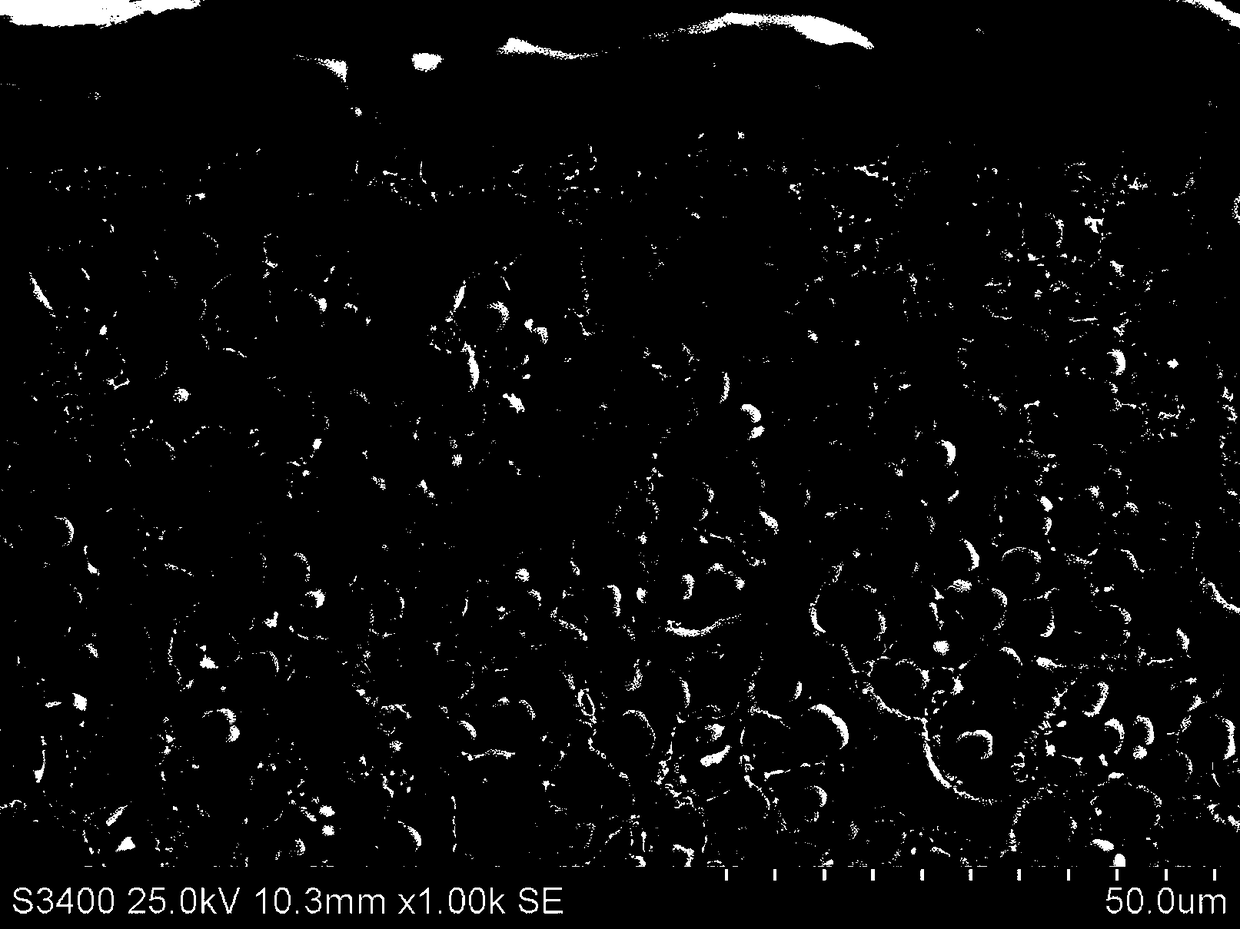

Metal thin sheet sintering plastic outer parts and its manufacture method

InactiveCN101192451AHigh strengthSuitable for mass productionInstrument housingElectrical apparatus casings/cabinets/drawersKey pressingElectric discharge

The invention relates to an external part of metal with plastics and a forming method of electroforming thin plate embedded injection which is particularly suitable for manufacturing various external components of mobile handset, laptop computer, press key pads, etc. The external components have functions and features of special metal surface and plastic internal parts and are suitable for mass production. The processes include the manufacture of laser fabrication, drilling, cutting, surface finish, hairline, electric discharge and etching on the electroform mold before casting the thin plates and manufacturing the thin plates into semi-finished external products; then applying adhesives on the back of the semi-finished external products which are solidified in the plastic molds and processing injection in order to allow the final finished external products to achieve the combination structure of metal plates attached with injected plastic parts.

Owner:和久科技有限公司

Self-lubricating wear-resisting coating for laser manufacturing hot rolled strip curling front guide ruler liner plate

InactiveCN106591831AHigh temperature hardnessImprove high temperature oxidation resistanceMetallic material coating processesAlloyStrip steel

The invention discloses a self-lubricating wear-resisting coating for a laser manufacturing hot rolled strip curling front guide ruler liner plate. The self-lubricating wear-resisting coating is characterized in that alloy powder of the laser cladding self-lubricating wear-resisting coating comprises Cr, Co and Si and is characterized by further comprising N, Nb, W and B, wherein the alloy powder includes, by mass percent, 8%-18% of Cr, 5%-10% of Co, 0.1%-0.5% of Si, 0.3%-0.5% of N, 0.1%-0.5% of Nb, 8%-16% of W, 8%-12% of B and the balance Ni. Due to optimal design of technology parameters of laser cladding and the ratio of all element components in the powder material, the high-temperature-wear-resistance hardness of the hot rolled strip curling front guide ruler liner plate obtained after cladding completely conforms to the design index, and in addition, the service life is greatly prolonged and is prolonged by at least 6 times.

Owner:沈阳大陆激光工程技术有限公司

Powder for laser cladding in-situ self-generated vanadium carbide reinforced iron-based alloy and preparation method

ActiveCN108339976AAvoid pollutionAvoid uniformityMetallic material coating processesVanadium carbideCo2 laser

The invention discloses powder for laser cladding in-situ self-generated vanadium carbide reinforced iron-based alloy and a preparation method. The alloy powder prepared by a vacuum gas atomization method comprises, by mass, 4.00%-4.40% of C, 16.00%-18.00% of V, 8.00%-10.00% of Cr, 0.90%-1.30% of Si, 1.00%-2.00% of Mo, 0.90%-1.20% of Mn, 0.40%-0.70% of Ni, 0.30%-0.50% of Al, P, S, less than or equal to 300 ppm of O, and the balance Fe, wherein the total mass fraction of P and S is less than or equal to 0.03%. The preparation method comprises the steps that the alloy powder clads the surface oflow-carbon alloy steel base material through laser by adopting a CO2 laser processing system in a synchronous powder feeding mode, the cladding-layer powder absorbs laser energy to form a molten poolon the surface of the base material, a C element and a V element in the molten pool react to generate an in-situ self-generated V8C7 ceramic reinforced phase, and meanwhile, the cladding layer and the base material form good metallurgical bonding. By preparing the in-situ self-generated V8C7 particle reinforced iron-based alloy laser cladding layer, the hardness and the wear resistance of the surface of a low-alloy steel component can be remarkably improved, and the method can be widely applied to laser manufacturing and remanufacturing of mechanical parts under friction and wear working conditions in the industrial field, and has remarkable economic and social benefits.

Owner:SHENYANG POLYTECHNIC UNIV

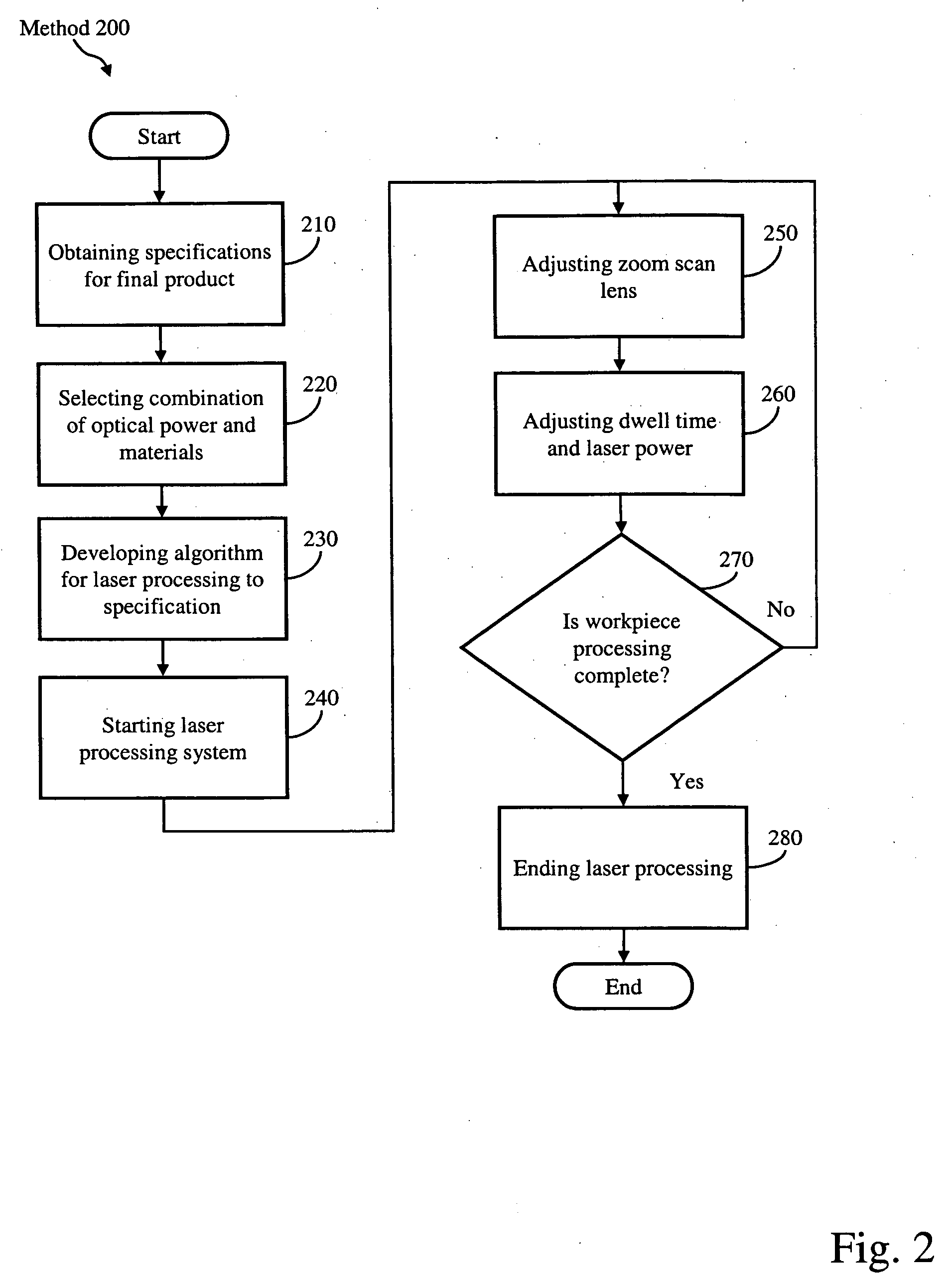

Laser manufacturing system having real-time feedback

A manufacturing system is disclosed. The manufacturing system may have a mount configured to hold a workpiece, a laser source configured to generate a laser beam directed toward a first side of the workpiece, and a sensor located on a second side of the workpiece. The sensor may be configured to sense a characteristic of the laser beam during penetration of the workpiece and to generate a signal in response thereto. The manufacturing system may also have a controller in communication with the laser source and the sensor. The controller may be configured to adjust parameters of the laser beam during penetration of the workpiece based on the signal.

Owner:CATERPILLAR INC

Device and method for laser shot blasting reinforcement of hard and brittle material

The invention discloses a device and a method for laser shot blasting reinforcement of a hard and brittle material, and relates to the field of mechanical manufacture of hard and brittle material processing and laser application. The device comprises a laser aid heating system, a laser shot blasting reinforcement system, a workpiece clamp system, a computer numerical control system, a measurementfeedback system and a protective gas circulating system. The method comprises a laser aid heating stage and a laser shot blasting reinforcement stage, namely performing aid heating treatment on the area to be reinforced by adopting high-power continuous laser, wherein for most metal materials, the plastic performance is improved along with the rise of temperature; and after the temperature of theheating area reaches a predetermined heating temperature, implementing laser shot blasting reinforcement treatment by adopting high-power pulse laser. The device and the method can implement the laser shot blasting reinforcement on the hard and brittle material so as to broaden the application range of the laser shot blasting reinforcement technology, and meanwhile compound the advantages of continuous laser and pulse laser so as to broaden the application field and the application prospect of laser manufacture.

Owner:JIANGSU UNIV

Method for making and measuring a coating on the surface of a medical device using an ultraviolet laser

This invention relates to a method for manufacturing an implantable medical device, having a surface covered with a coating that can include a desired amount of a biologically active material, using an ultraviolet (UV) laser. The invention also pertains to a method for manufacturing an implantable medical device having a surface covered with a coating having more than one layer wherein a desired portion of the top layer is ablated with an ultraviolet (UV) laser. Also, the invention relates to a method for measuring a thickness of a coating applied to an implantable medical device. Furthermore, the invention is directed to a method for manufacturing an implantable medical device having a surface covered with a coating free of webbing or cracking.

Owner:BOSTON SCI SCIMED INC

Additive and subtractive integrated multifunctional system based on machining and laser manufacturing coupling

InactiveCN112008407AEffectively compatible with multi-process manufacturing requirementsHigh degree of automationAdditive manufacturing apparatusOther manufacturing equipments/toolsManufacturing technologyLaser cutting

The invention discloses an additive and subtractive integrated multifunctional system based on machining and laser manufacturing coupling. The additive and subtractive integrated multifunctional system comprises a control system, a machining system, a laser machining system, a movable working platform and an electric arc machining system. The machining system can achieve machining of complex parts, the laser machining system and the electric arc machining system can achieve welding, additive manufacturing and cutting of the complex parts, and specific methods include a laser welding method, alaser-electric arc hybrid welding method, a laser filler wire welding method, a laser additive manufacturing method and a laser cutting method. According to the system, traditional machining and advanced laser manufacturing technologies are integrated, the multi-technology manufacturing requirements of the complex parts can be met, the manufacturing technological process is simplified, the production period is shortened, and efficient manufacturing of the complex parts is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Safety and reliability guarantees for laser fabrication

Sensor data generated by a sensor of a computer numerically controlled machine can be compared with a forecast. The forecast can include expected sensor data for the sensor, over a course of an execution plan for making a cut with a movable laser cutting head. The sensor data can be generated during execution of the execution plan. During execution of the execution plan, the sensor data can be monitored and a deviation of from the forecast can be detected. It can be determined, based on the detecting, that an anomalous condition of the computer numerically controlled machine has occurred. Based on the determining, an action can be performed.

Owner:GLOWFORGE

Transition layer alloy material for laser manufacturing and remanufacturing of crystallizer copper plate

The invention discloses a transition layer alloy material for laser manufacturing and remanufacturing of a crystallizer copper plate. The alloy material is characterized by comprising 1%-10% of Al, 1%-5% of Cu and the balance Ni. A preparation method for a transition layer for laser manufacturing and remanufacturing of the crystallizer copper plate comprises the steps that (1), a layer of transition layer alloy powder with the thickness of 1.0-2.0 mm is prearranged on the surface of the crystallizer copper plate through a powder prearrangement manner; (2), scanning and cladding are conducted through a 6,000 W fiber laser device; and (3), machining is conducted on the clad layer, and the thickness of the transition layer is reserved in the range of 0.5-1.5 mm. The transition layer alloy material has the beneficial effects that the production process is simple, the production efficiency is high, the number of the components of the alloy material is small, no crack is generated in the cladding process, and the metallurgical bonding effect is good.

Owner:沈阳大陆激光工程技术有限公司

Gradient material design process for guiding ruler liner plate used before hot-rolled strip steel coiling through laser manufacturing

ActiveCN106756251AGuaranteed binding stabilityExtended service lifeMetallic material coating processesGradient materialStrip steel

The invention discloses a gradient material design process for a guiding ruler liner plate used before hot-rolled strip steel coiling through laser manufacturing. The process is characterized in that the guiding ruler liner plate comprises a priming layer, a transition layer and a functional layer through gradient design, wherein a priming layer cladding material comprises 3.6-18% of Cr, 5-16% of Mn, 0.2-0.7% of Si, 3-8% of N, 4-18% of W, 8-19% of B and the balance Ni; a transition layer cladding material comprises 3-18% of Cr, 4-15% of Mn, 0.1-0.6% of Si, 3-8% of N, 6-16% of W, 8-15% of B and the balance Ni; and a functional layer cladding material comprises 3-16% of Cr, 5-15% of Mn, 0.1-0.5% of Si, 3-6% of N, 8-18% of W, 8-12% of B and the balance Ni. The service life of the guiding ruler liner plate is prolonged to 5-6 times that of original guiding ruler liner plates.

Owner:沈阳大陆激光工程技术有限公司

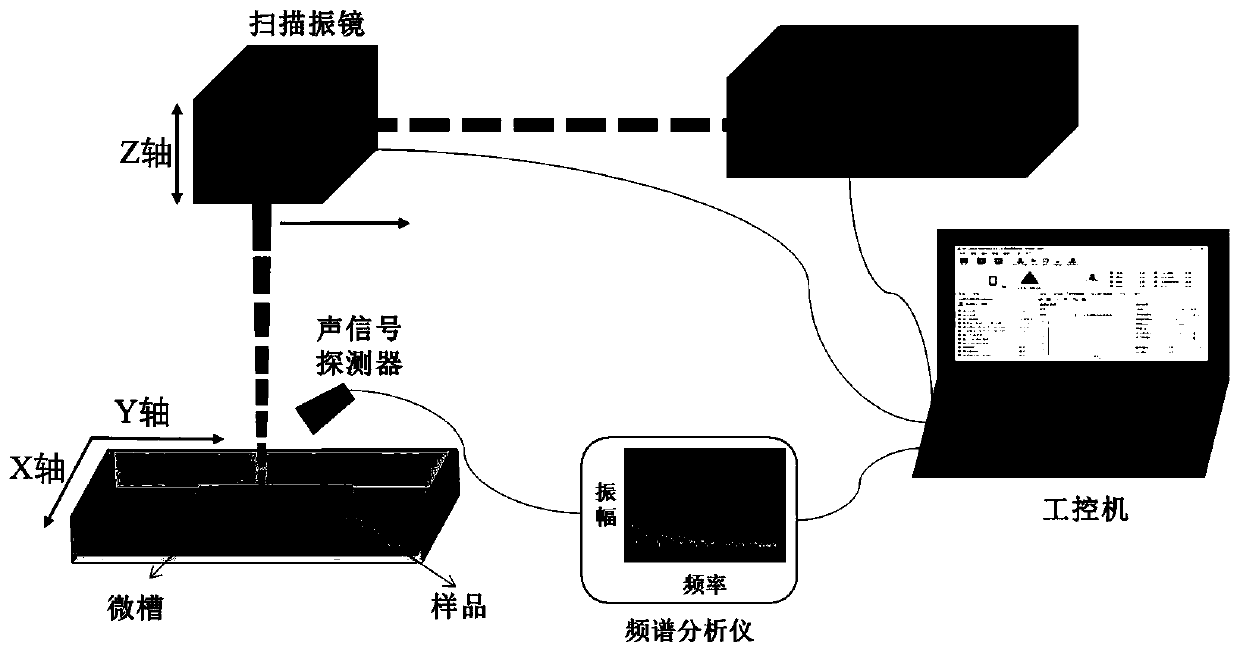

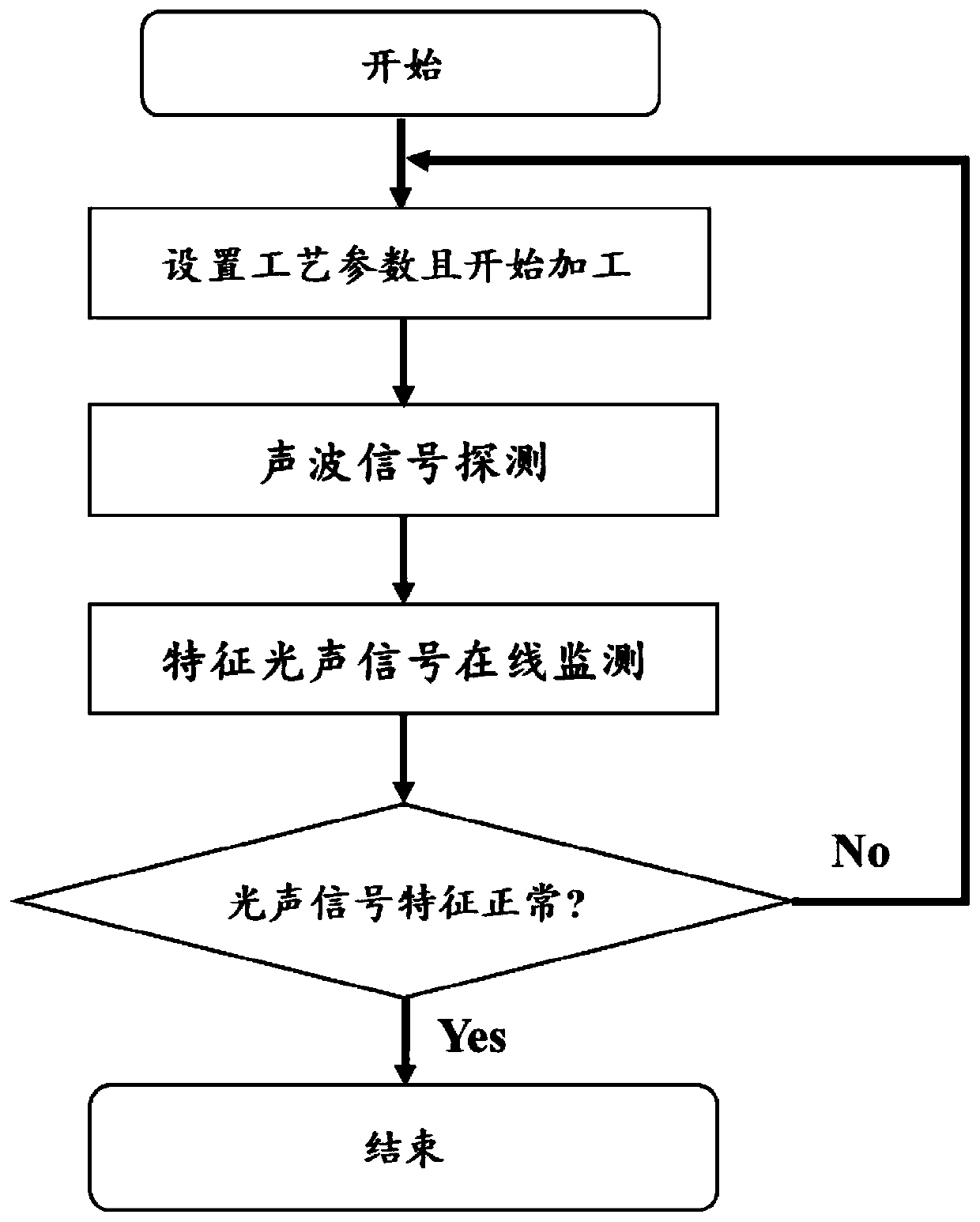

Laser manufacturing process control method based on acoustic wave monitoring

InactiveCN111136382ARealize manufacturing and processingGood repeatabilityWelding/soldering/cutting articlesLaser beam welding apparatusLaser processingEngineering

The invention discloses a laser manufacturing process control method based on acoustic wave monitoring and can solve the technical problems of abnormal component size parameters and shape organizationcaused by instability of a laser system and mismatching of process parameters. The laser process parameters are rapidly optimized by monitoring photo-acoustic signals online, and high-efficiency andhigh-quality laser manufacturing based on photo-acoustic monitoring is realized. The laser manufacturing process control method based on acoustic wave monitoring is implemented through steps as follows: S1, a sample is pretreated; S2, laser processing parameters are set, and processing is started in a specific environment; and S3, photo-acoustic signals are monitored online, the laser processing parameters are rapidly adjusted according to signal features, and the laser processing process is completed. Laser processing abnormity can be monitored in real time based on monitoring of the photo-acoustic signals, the laser processing parameters are rapidly controlled and optimized, and high-efficiency laser manufacture process can be controlled.

Owner:HEFEI INNOVATION RES INST BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com