Device and method for etching conducting layer made from graphene on touch screen

A graphene and conductive layer technology, applied in the field of laser micromachining equipment, can solve the problem of high thermal conductivity, and achieve the effect of linear stability and complete function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

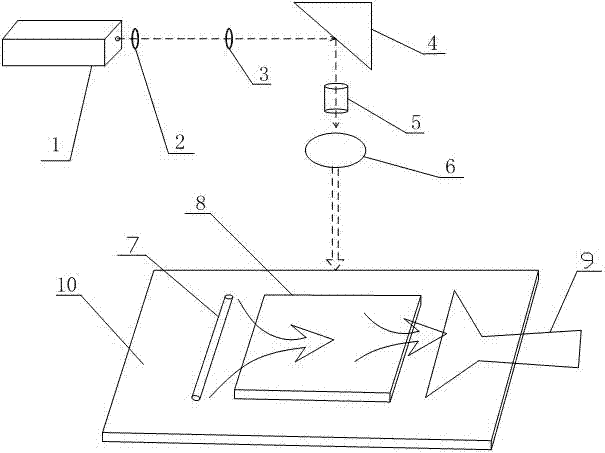

[0013] The invention provides a device and method for laser etching a touch screen with graphene as a conductive layer material. A high-frequency short-pulse laser is used, and the processed material is a high-conductivity conductive film material. The laser passes through a dynamic focusing mirror and a vibrating mirror. Focusing is achieved within the entire 500mm×500mm range with graphene as the conductive layer material, and the graphene conductive layer absorbs pulsed laser gasification with high peak power to achieve the etching effect.

[0014] Such as figure 1 As shown, the device for etching the conductive layer of graphene on the touch screen includes a high-frequency short-pulse laser 1, a dynamic focusing mirror 5, and a scanning field mirror 6. The high-frequency short-pulse laser 1 has a wavelength of 266nm to 1064nm and a For lasers with a width of 100ps-50ns and a frequency of 10KHz-200KHz, the output end of the high-frequency short-pulse laser 1 is arranged wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com