Electronic component laser welding device and method

An electronic component, laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of damage to electronic components, surface damage of electronic components, etc., to achieve a small spot, reduce damage, and better welding quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

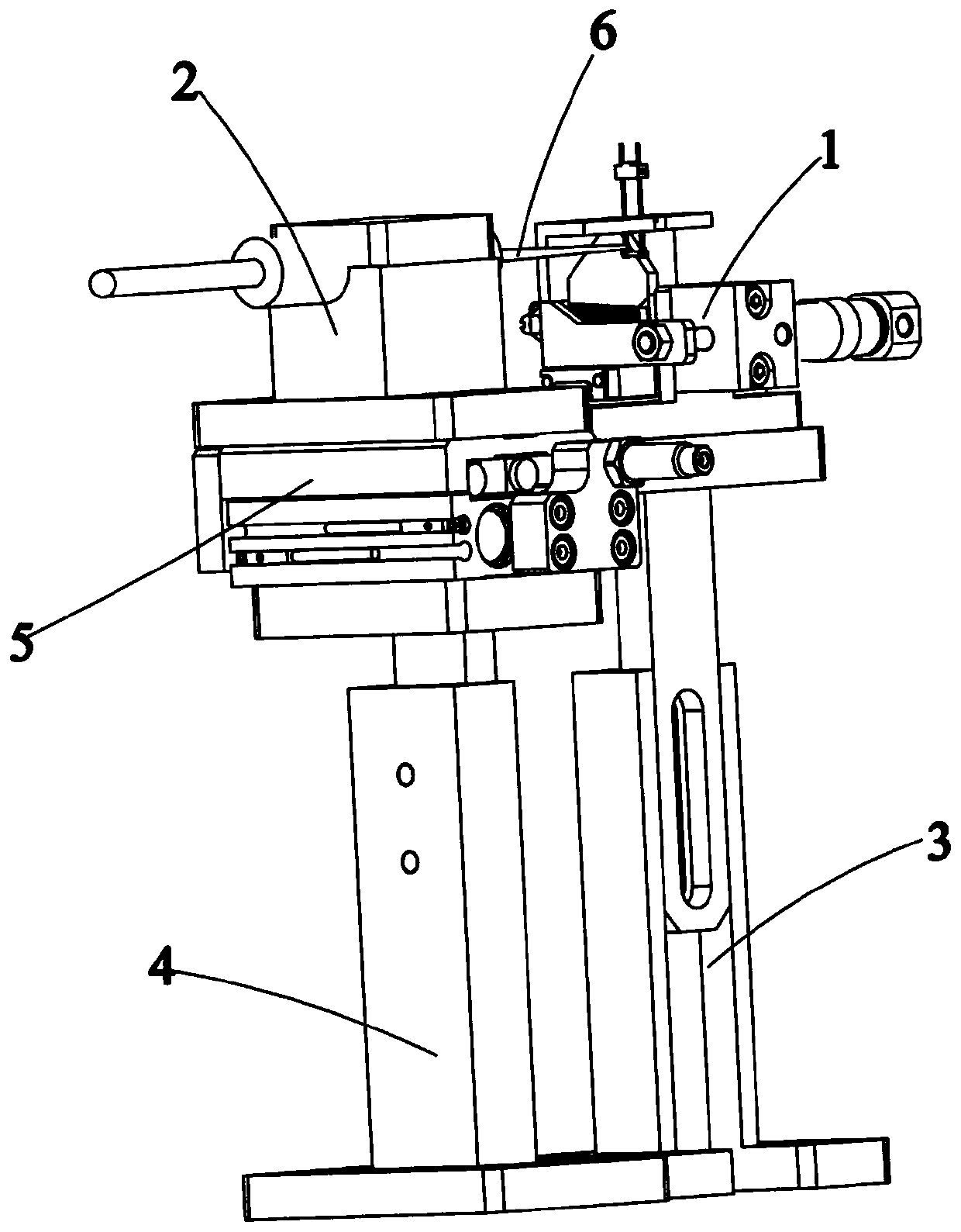

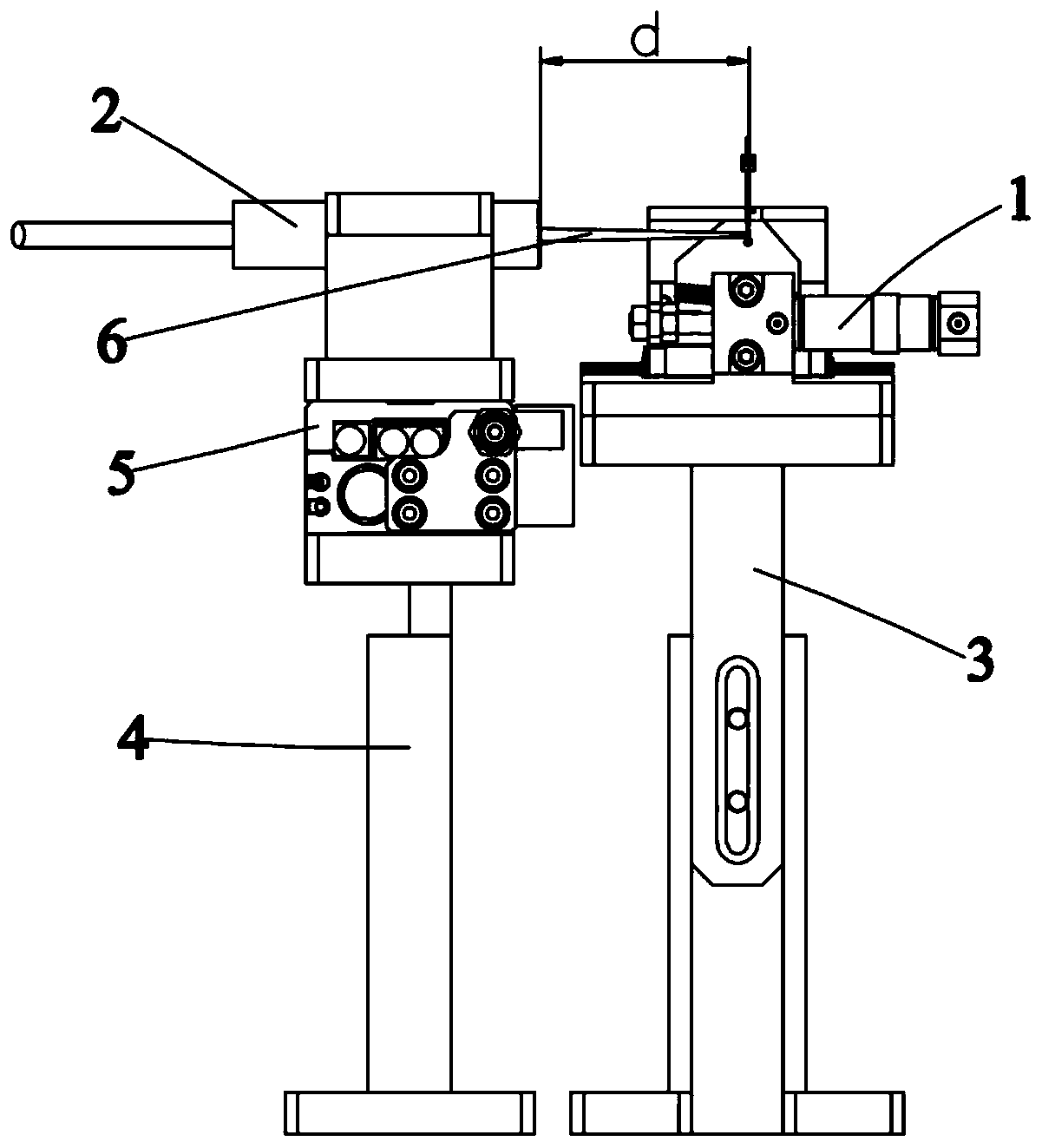

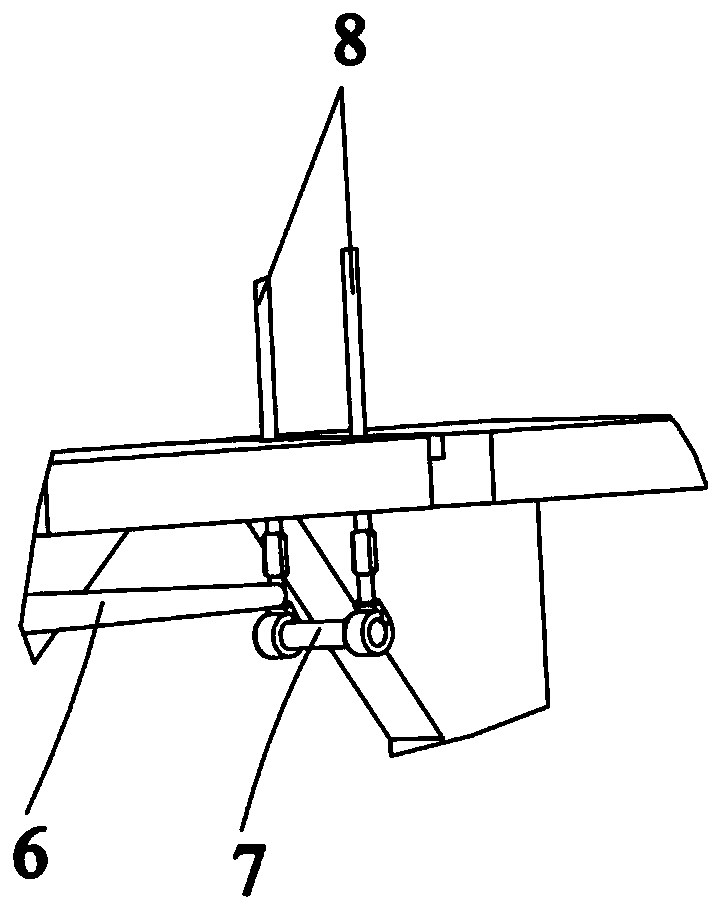

[0026] like Figure 1~3 As shown, a laser welding device for electronic components includes an electronic component fixing mechanism 1, a laser fiber optic lens 2, a first fixing bracket 3 and a second fixing bracket 4, and the electronic component fixing mechanism 1 is used to fix the main body 7 and the The lead wire 8, the electronic component fixing mechanism 1 is fixed on the first fixing bracket 3, the laser fiber lens 2 is installed on the second fixing bracket 4, and the laser beam 6 emitted by the laser fiber lens 2 is aligned with the connection between the main body 7 and the lead wire 8 place.

[0027] Further, the distance between the laser fiber lens 2 and the electronic component fixing mechanism 1 is d, the focal length of the laser fiber lens 2 is f, and d=f±5mm. The focal length f of the laser fiber lens 2 is 30mm.

[0028] Further, the present invention also includes a moving mechanism 5 , the moving mechanism 5 is arranged on the second fixed bracket 4 , ...

Embodiment 2

[0031] The difference from Embodiment 1 is that the focal length f of the laser fiber optic lens 2 is 50 mm.

[0032] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0034] The difference from Embodiment 1 is that the focal length f of the laser fiber optic lens 2 is 100 mm.

[0035] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com