Magnetic climbing robot applied to cleaning and detecting of fan tower barrel

A wind tower and robot technology, applied in the field of climbing robots, can solve problems such as high labor costs, time-consuming and labor-intensive, and potential safety hazards, and achieve the effects of avoiding the risk of casualties, improving economic benefits, and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

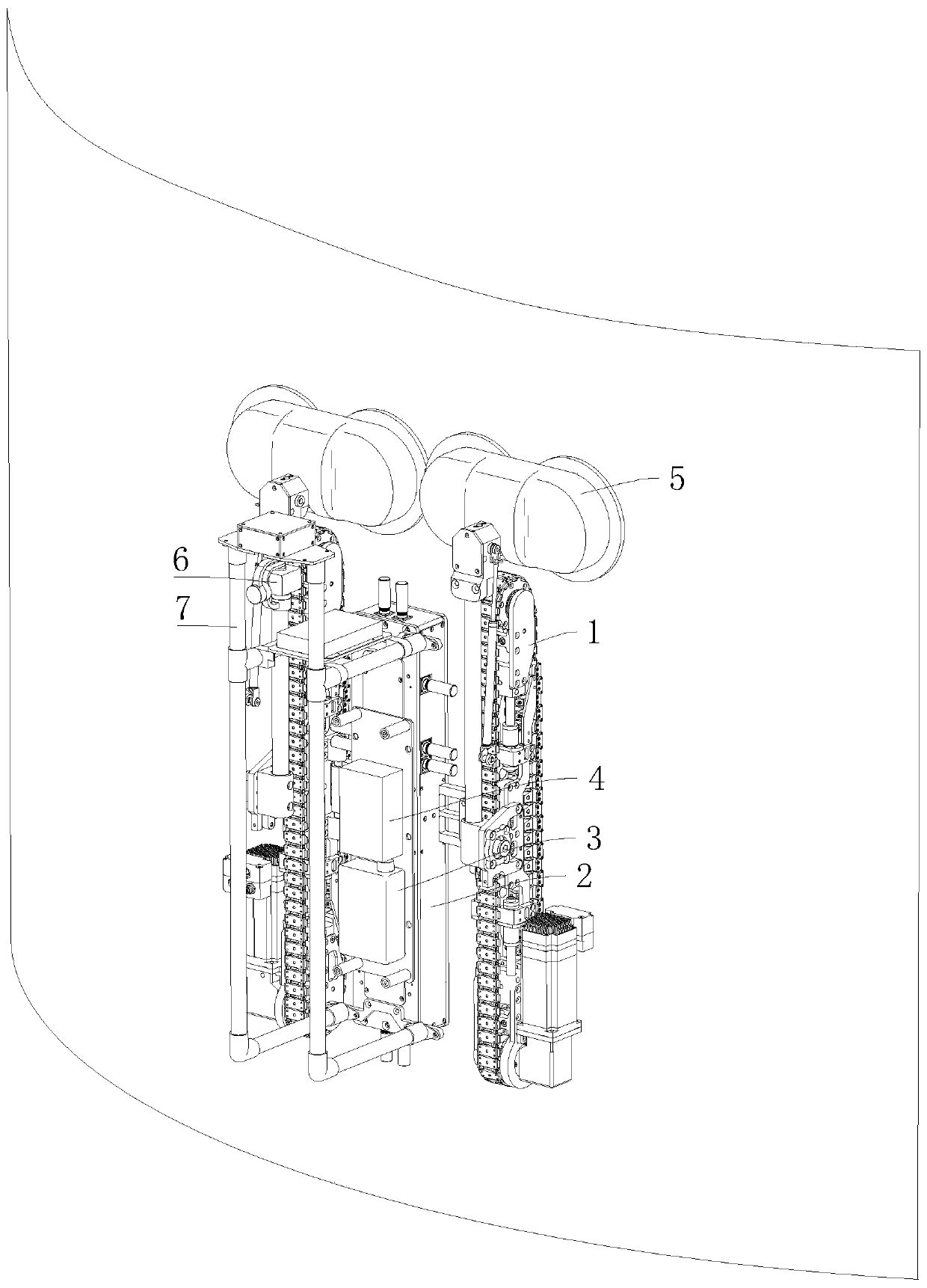

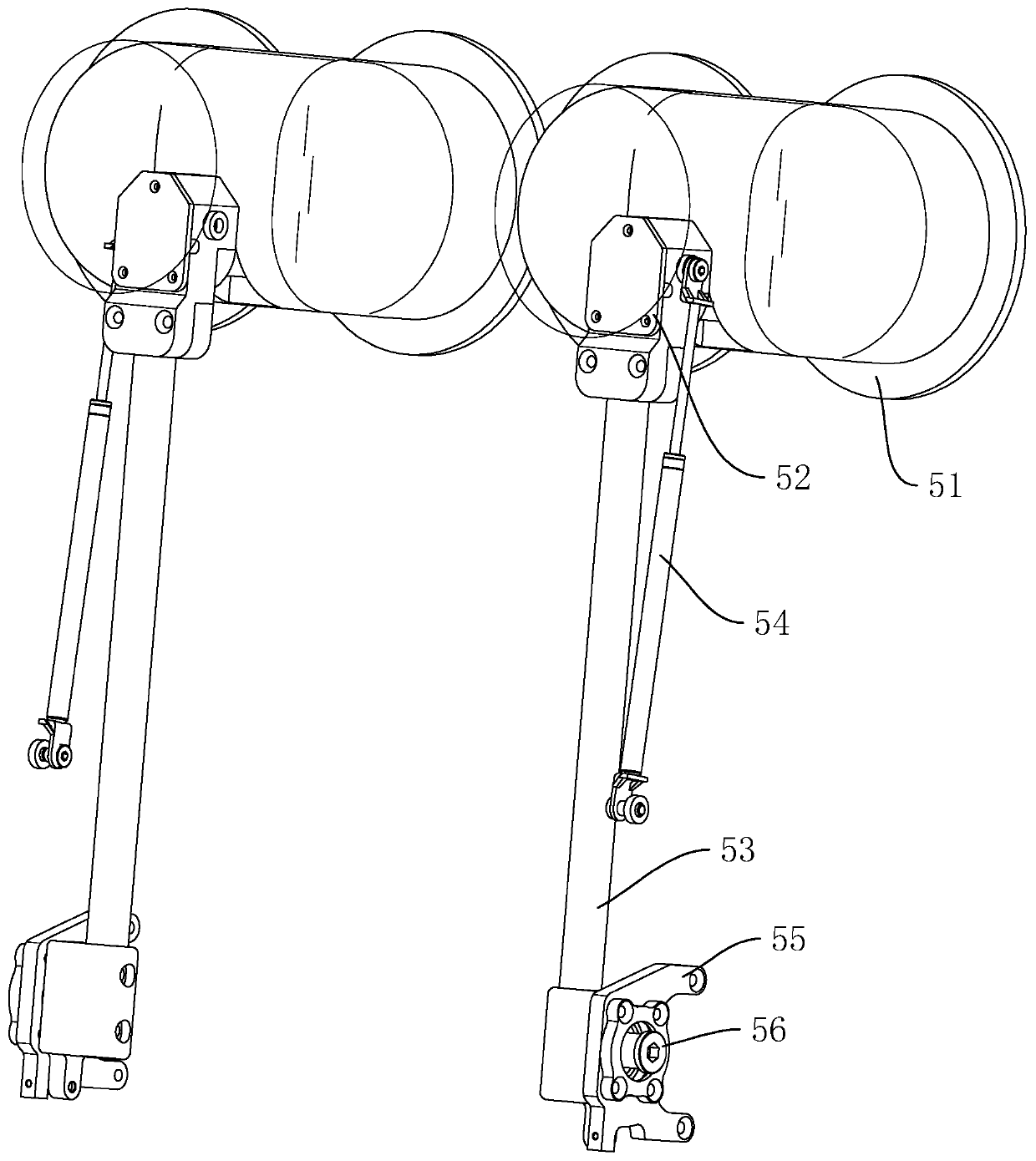

[0031] Such as figure 1 Shown is a magnetic climbing robot applied to the cleaning and detection of fan towers according to the present invention, including: permanent magnet adsorption track assembly 1, central control box 2, water tank 3, water pump 4, cleaning disc brush 5 and camera 6;

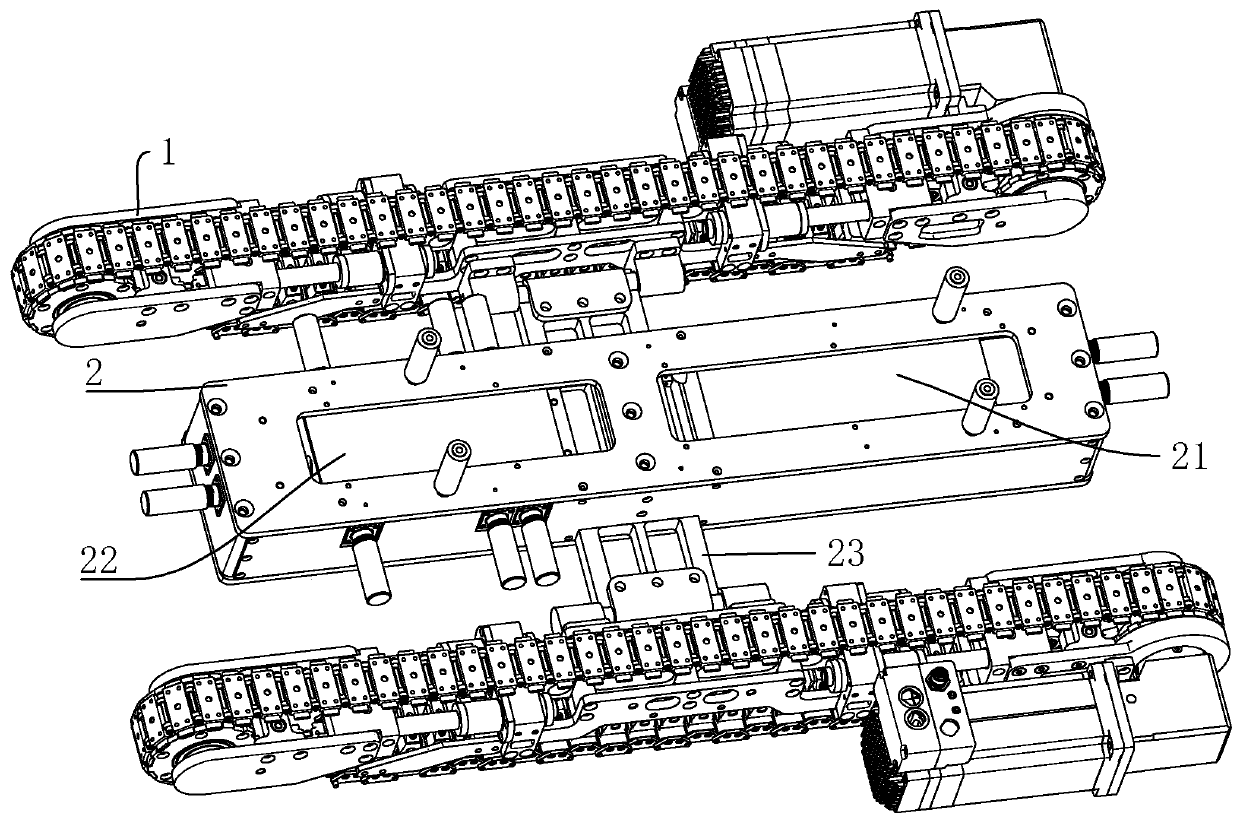

[0032] The permanent magnetic adsorption crawler assembly 1 includes the left permanent magnetic adsorption crawler assembly and the right permanent magnetic adsorption crawler assembly with the same structure, which are respectively installed on the left and right sides of the central control box 2, and the cleaning disc brush 5 also includes two groups, respectively Installed on the front end of the permanent magnetic adsorption track assembly 1 on the left and right sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com