Method for welding nuclear main pump shielding can

A welding method and shielding sleeve technology are applied in the welding field of nuclear main pump shielding sleeves, which can solve the problems of complicated welding equipment control and process parameter adjustment, increased welding process and welding equipment complexity, and decreased physical and mechanical properties. Defect-free precision welding, small deformation, energy concentration effect

Active Publication Date: 2011-06-15

DALIAN UNIV OF TECH

View PDF5 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

First of all, the heat-affected zone of the weld seam is large, which can easily lead to deformation of the workpiece, and the diameter is not easy to control. Correction treatment is required after welding, which greatly increases the complexity of the welding process and welding equipment, and affects production efficiency.

Secondly, the large grain size of the weld leads to a decrease in physical and mechanical properties relative to the base material. At the same time, the heat-affected zone is easily damaged, and the size of the weld is large, and thermal deformation is likely to cause residual stress accumulation. Without subsequent heat treatment Under the condition of

Thirdly, if a tungsten argon arc welding process with a reserved weld spacing of 2 mm and a welding wire diameter of 0.508 mm is used, not only the weld size is wider, but also a welding shape must be achieved at a higher welding speed. , so the control of welding equipment and the adjustment of process parameters during the welding process will be quite complicated and even very harsh

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

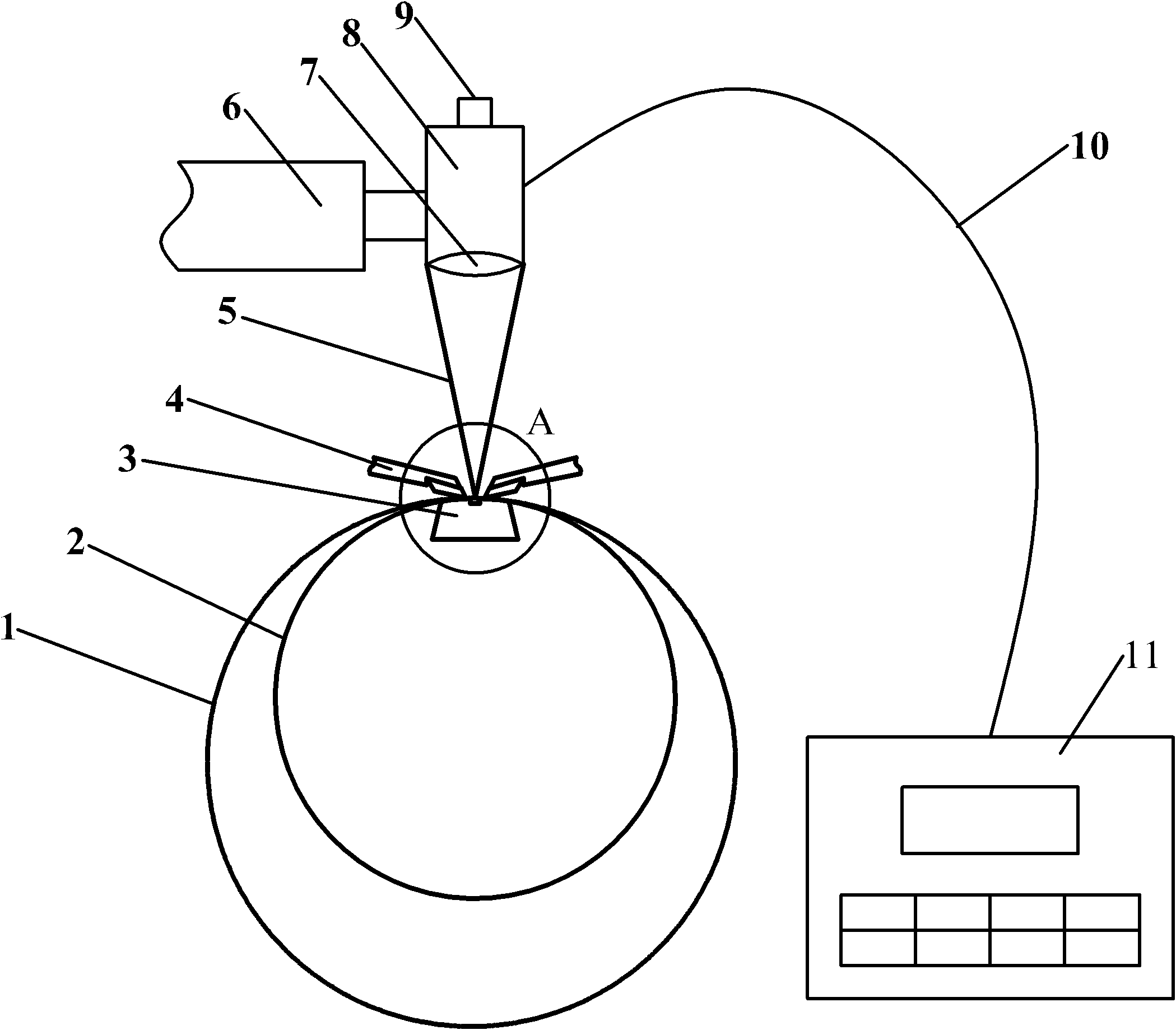

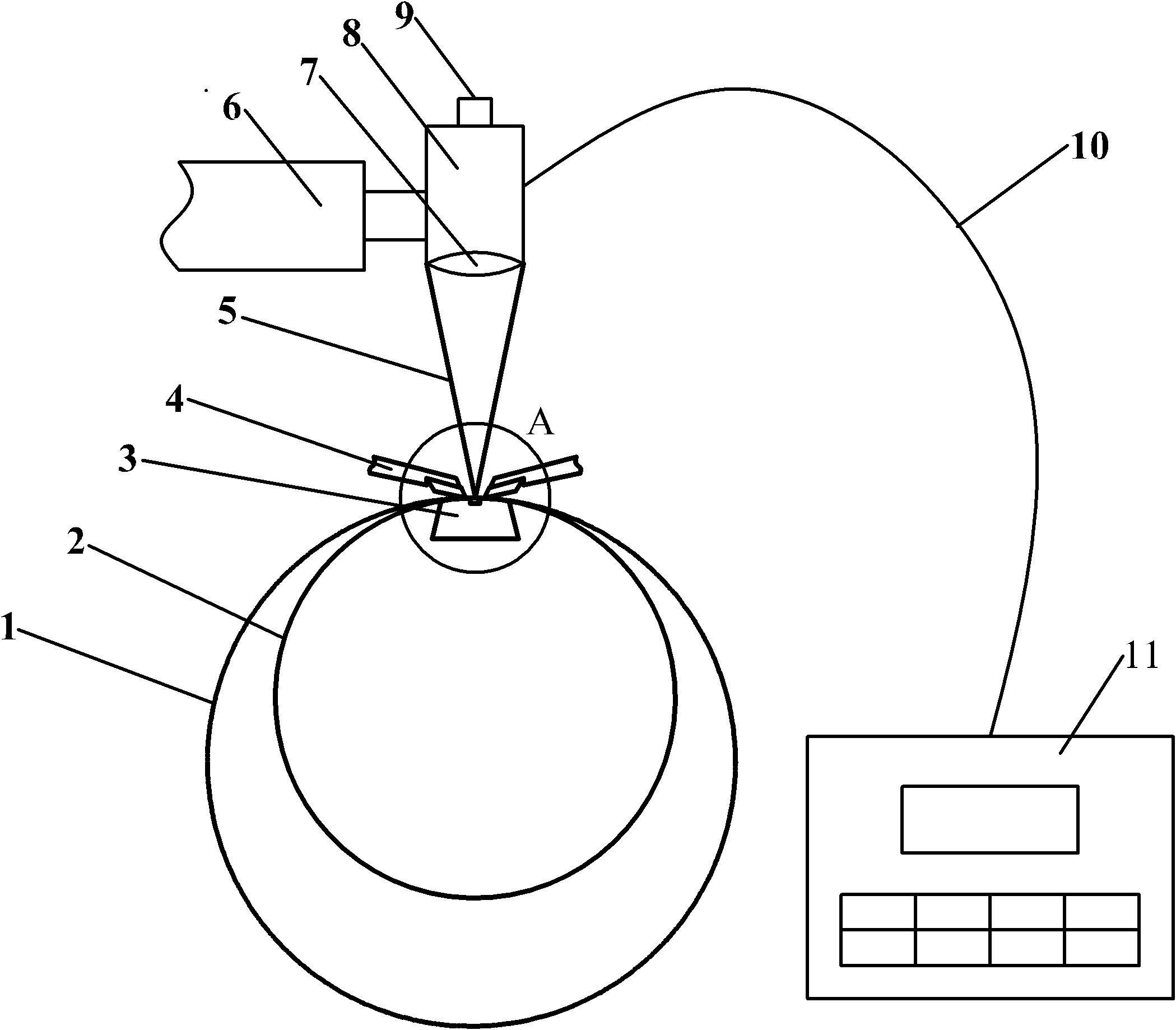

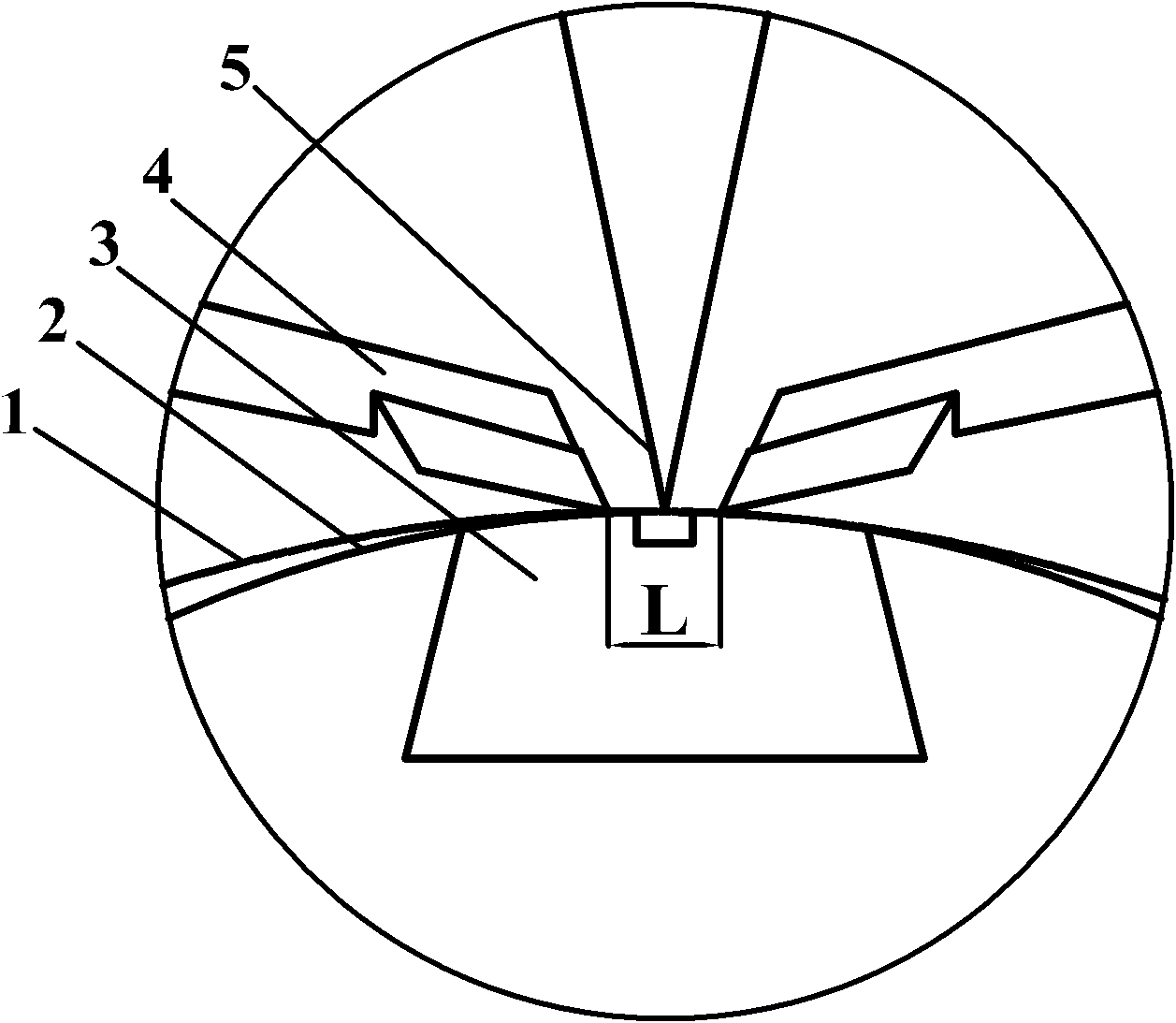

The invention discloses a method for welding a nuclear main pump shielding can. A laser welding machine is utilized to perform pulse laser welding on the nuclear main pump shielding can. The method comprises the following steps of: bending and rolling a Hastelloy C-276 alloy sheet into a drum, arranging into a special welding fixture, protecting the front and back of a welding line by using inertgas, connecting a laser welding head with a Nd:YAG solid pulse laser through a transmission fiber, and welding a longitudinal seam of the nuclear main pump shielding can by controlling the accurate positioning and continuous movement of a laser welding head. By the method, on the one hand, a weld heat-affected zone of the nuclear main pump shielding can is small, a workpiece is not deformed, the diameter is high in precision, the correction treatment is not needed after welding, and the influence on the physical and mechanical properties of materials can be reduced to the minimum; on the other hand, a welding wire is not needed to be filled in the welding process, the size of the welding line is narrow, the complexity of controlling welding equipment and adjusting process parameters is simplified, and the production efficiency is improved.

Description

A welding method for nuclear main pump shielding sleeve technical field The invention relates to the manufacturing technology of the nuclear main pump in the field of nuclear power, in particular to a welding method for the shielding sleeve of the nuclear main pump. Background technique In recent years, nuclear power has been more and more favored by countries due to its advantages of safety, high efficiency, energy saving and environmental protection. In nuclear power plants, the nuclear reactor coolant main circulation pump, referred to as the nuclear main pump, is the only rotating equipment on the nuclear island of the nuclear reactor, and is one of the pressure boundaries of the primary loop circulation system. The occurrence and deterioration of the accident is extremely important, so the nuclear main pump is often referred to as the "heart" of the nuclear power plant. In the third-generation passive pressurized water reactor, the nuclear main pump adopts a canned p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K26/02B23K26/42B23K26/035B23K26/70

Inventor 吴东江郭玉泉郭东明马广义

Owner DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com