Optical fiber sensing measurement method of laser plasma shock wave mechanical effect

A technology of laser plasma and measurement method, applied in radiation measurement, measurement device, X/γ/cosmic radiation measurement, etc., can solve the problems of limited measurement accuracy, lack of theoretical model, difficult preparation, etc., to achieve high work efficiency, Wide response frequency, good directivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

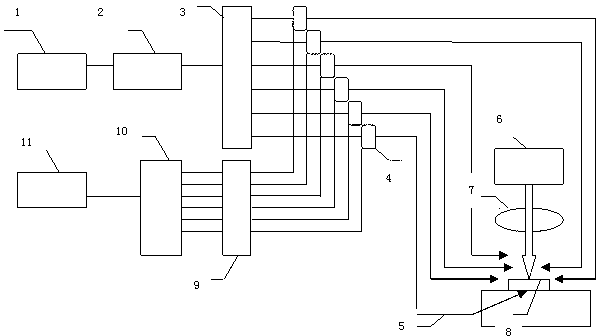

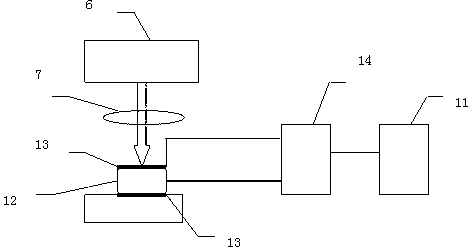

Method used

Image

Examples

Embodiment Construction

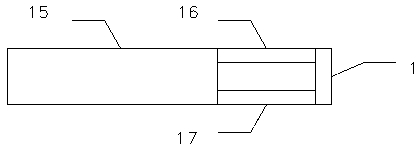

[0023] According to the theory of elastic mechanics, referring to the design principles of related PZT acoustic emission devices, on the basis of simulation analysis, the optical fiber F-P acoustic emission sensing probe is designed and manufactured. In its structure, the capillary glass tube is welded with the optical fiber, and the length of the capillary glass tube is shortened. to 50um, and then weld a thin quartz crystal diaphragm to the end face of the capillary glass tube, and the sensitive element of the probe sensor is a quartz crystal diaphragm. In order to make the sensor capable of responding to both high frequency and high sensitivity, the applicant prepared the sensing head as a probe, and improved the response frequency of the sensor by reducing the quality of the vibrating diaphragm to 0.048ug; The thickness is reduced to 5um to improve the sensitivity of the sensor; in order to reduce the influence of temperature on the performance of the sensor, the probe adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com