Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Save manufacturing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

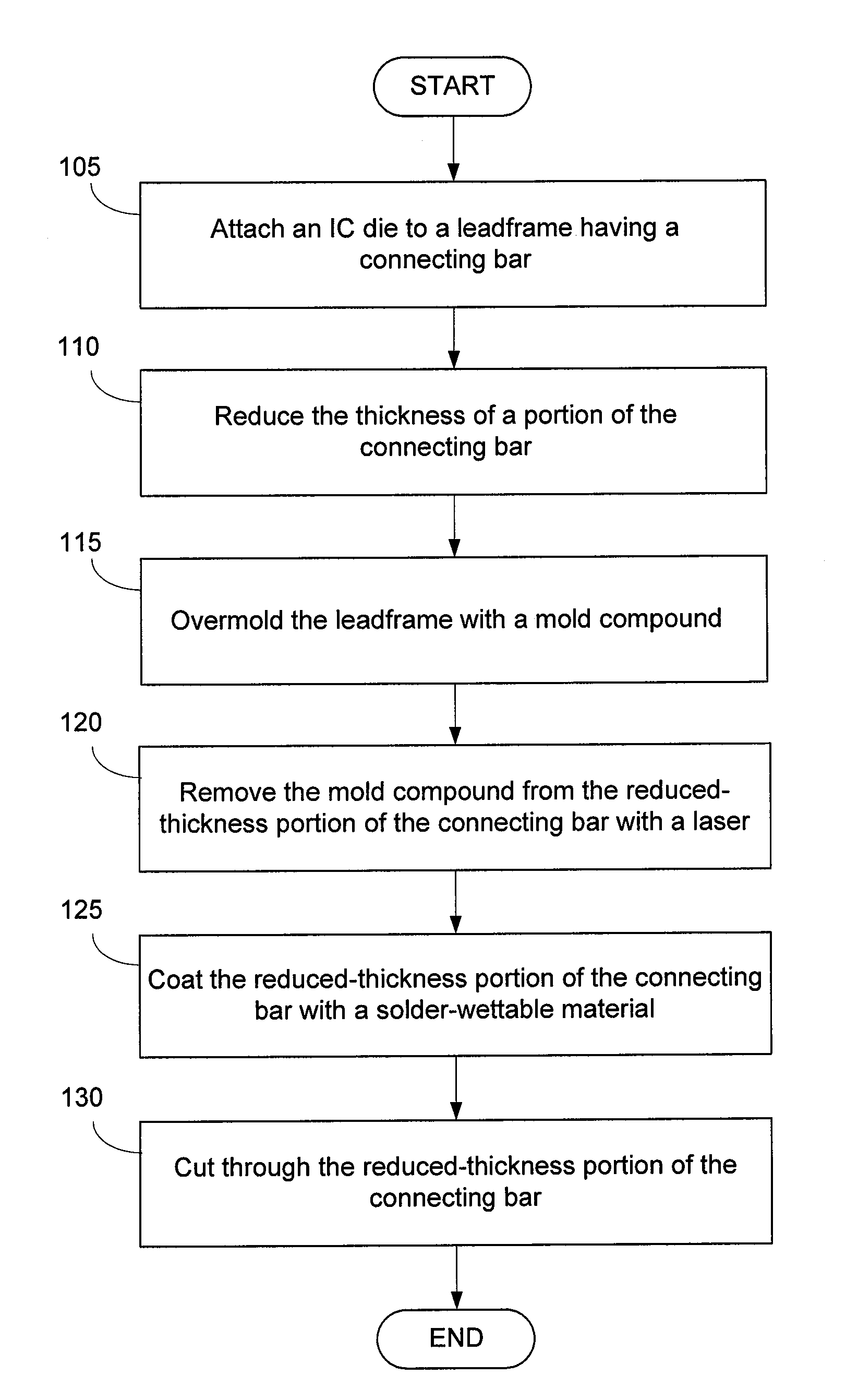

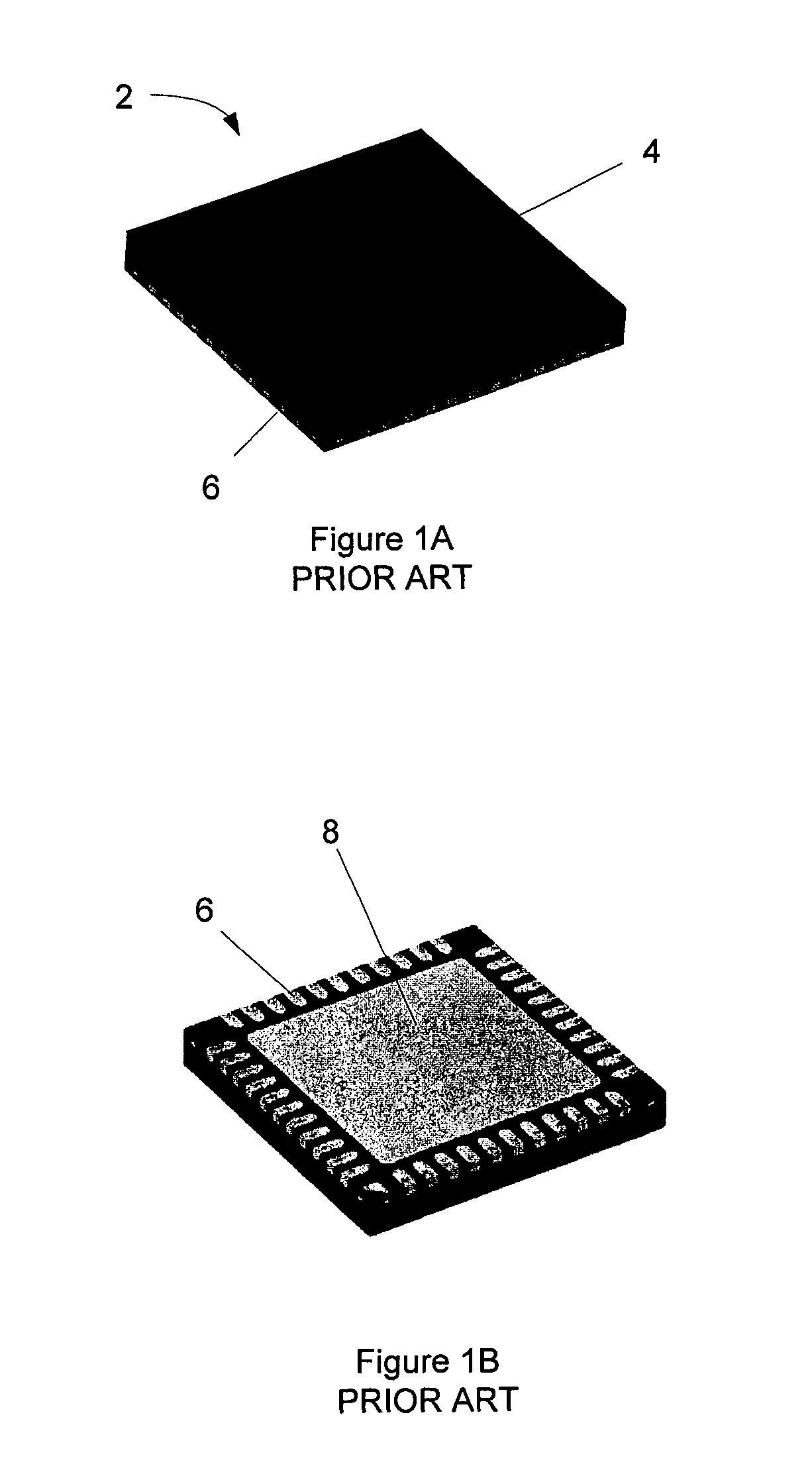

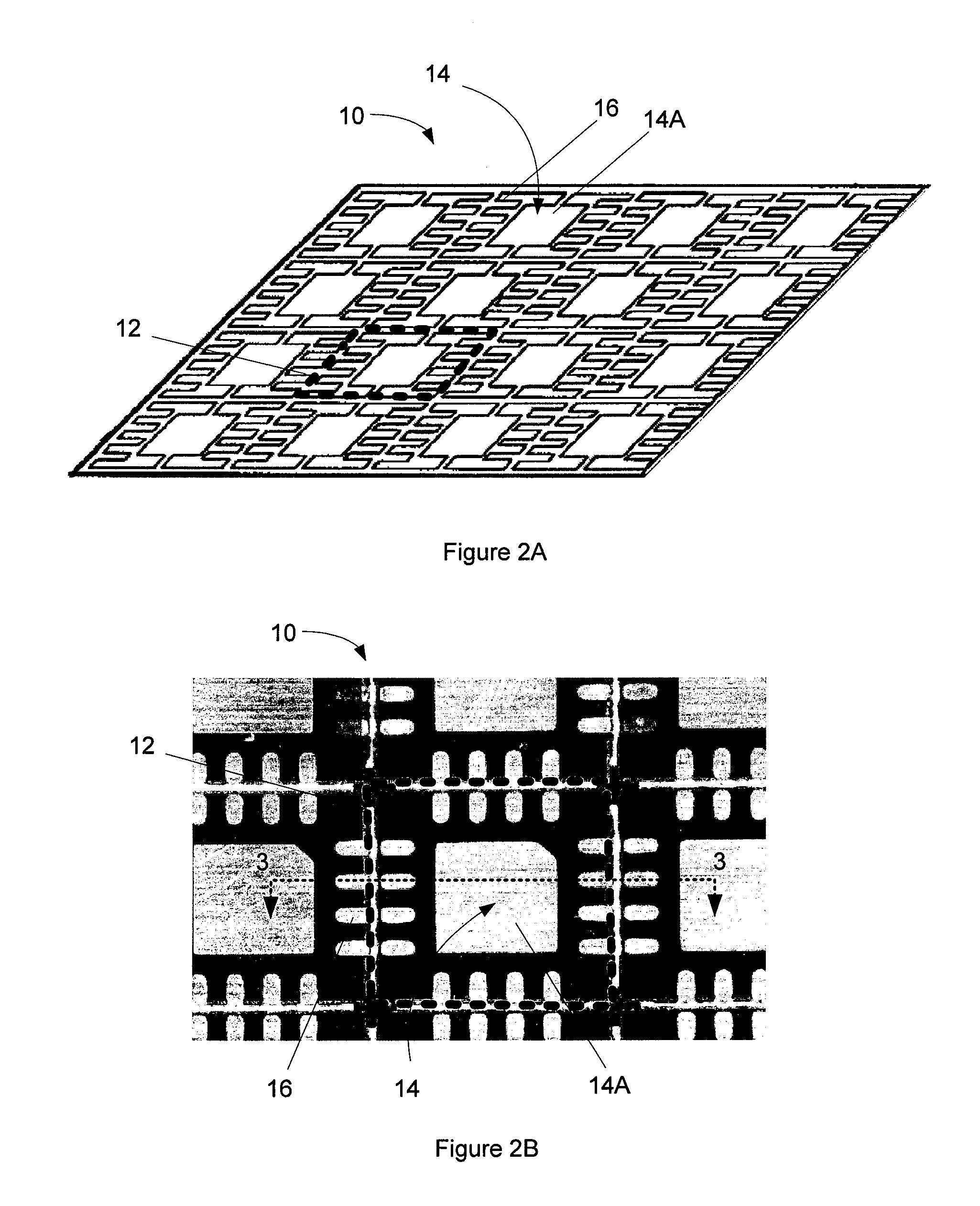

Laser process for side plating of terminals

ActiveUS8017447B1Save manufacturing processEliminate needSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringMechanical engineering

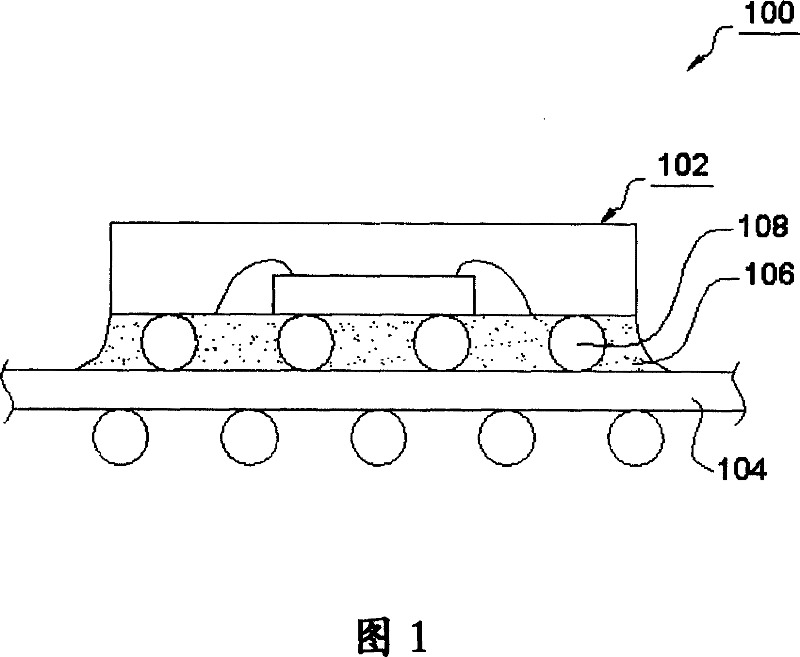

A method of preparing a portion of the side of a terminal of an Integrated Circuit (IC) package for solder is disclosed. The method comprises the steps of attaching an IC die to a leadframe comprising a connecting bar, reducing the thickness of a portion of the connecting bar, overmolding the leadframe with a mold compound, removing the mold compound from the reduced-thickness portion of the connecting bar using a laser, coating the reduced-thickness portion of the connecting bar with a solder-wettable material, and cutting through the thickness of the connecting bar within the reduced thickness portion of the connecting bar, wherein the cut has a width that is less than the width of the reduced thickness portion of the connecting bar.

Owner:ANALOG DEVICES INT UNLTD

Three-dimensional metal-graphene composite substrate and preparation method thereof

InactiveCN103172404AIncreased scattering intensityPlay a protective effectComposite substrateGraphite

The invention discloses a three-dimensional metal-graphene composite substrate and a preparation method thereof. The composite substrate disclosed by the invention is composed of a first nano layer, a graphene layer and a second nano layer, wherein the first nano layer is deposited on the surface of an amorphous carbon underlayer, the graphene layer is arranged on the surface of the first nano layer through spin coating, the second nano layer is deposited on the surface of the graphene layer, and the first nano layer and the second nano layer are gold or silver nano layers. According to the method, an active substrate with a good surface enhanced Raman effect is constructed; and the three-dimensional metal-graphene composite substrate is simple in preparation method, high in efficiency, and low in preparation cost.

Owner:ZHEJIANG SCI-TECH UNIV

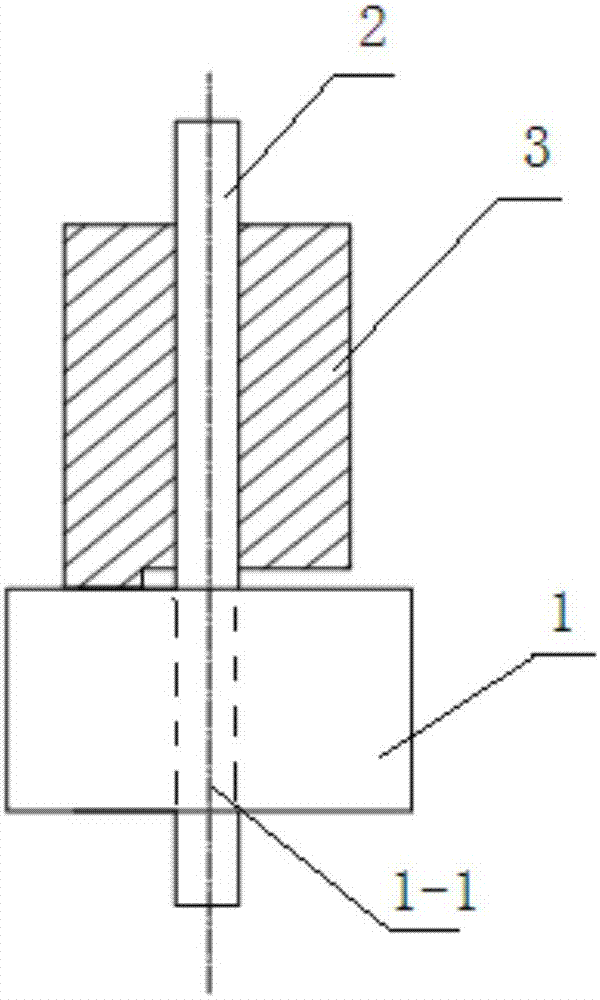

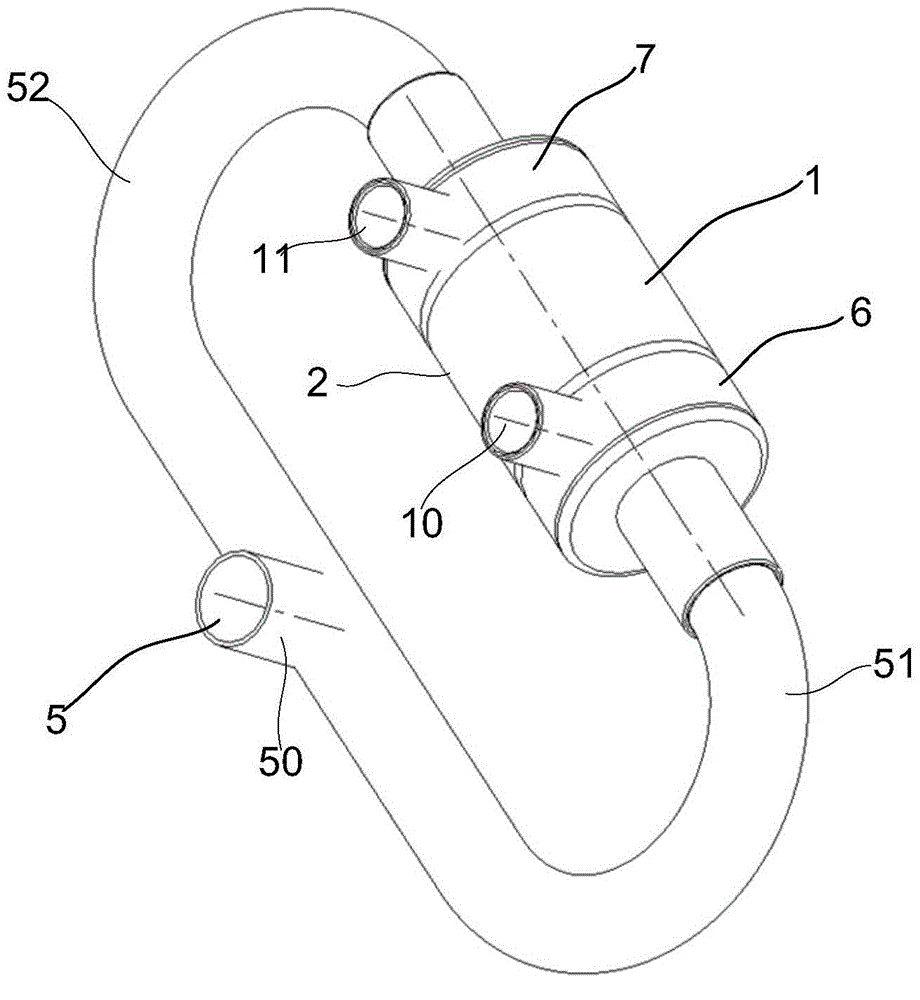

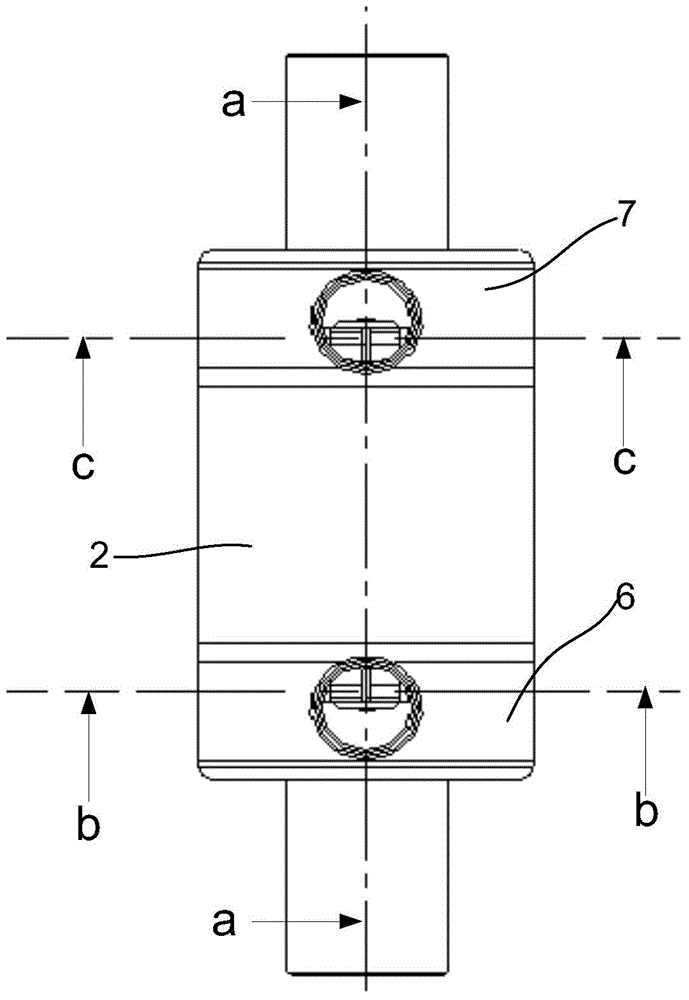

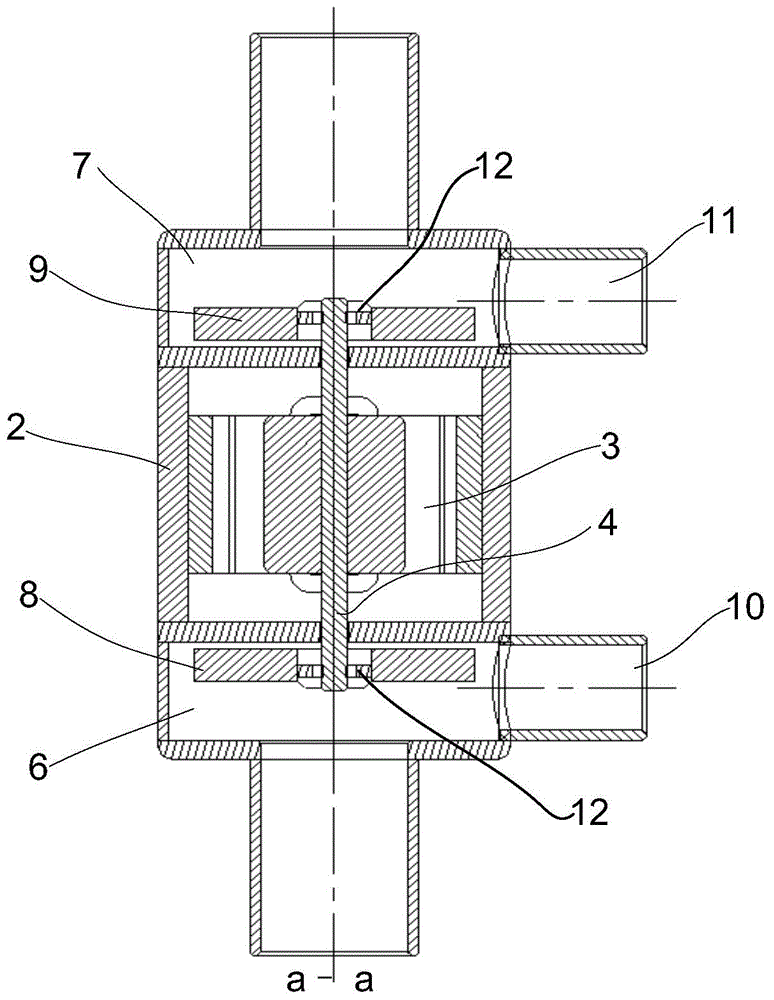

Pressurized gas coupling

InactiveUS20050001194A1Low costHuge savingsValve arrangementsJoints with fluid cut-off meansCouplingEngineering

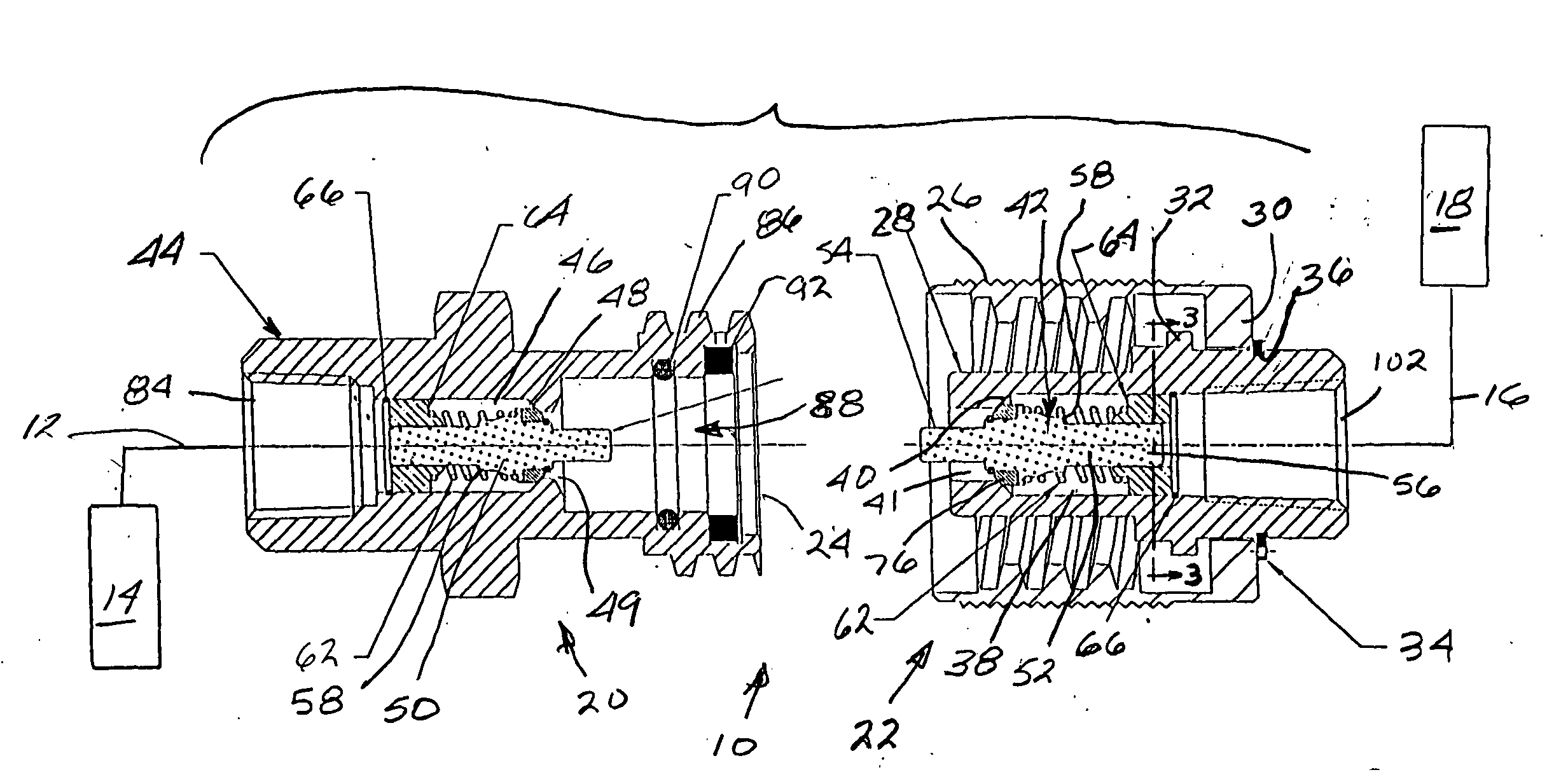

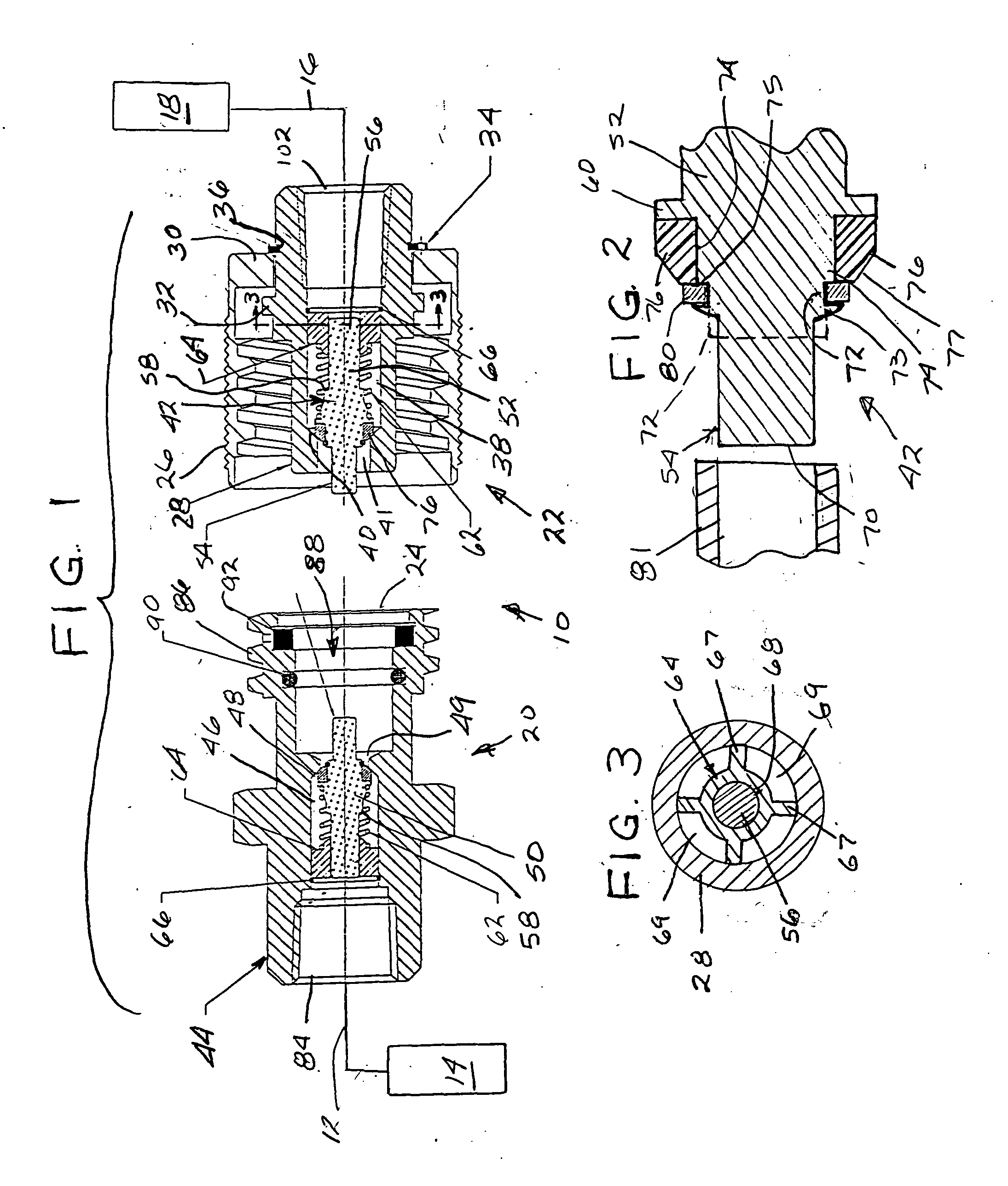

A method for producing a valve holder assembly for an automatic gas shutoff valve in a pressurized gas coupling comprises mounting a compressible annular gasket on a cylindrical portion of the valve holder adjacent an enlarged flange that abuts an outer side of the gasket; mounting a retaining washer on the cylindrical portion adjacent an outer side of the gasket, the cylindrical portion extending outwardly past the retaining washer and terminating at a shoulder; and flaring the shoulder radially outwardly so as to form a retaining cap on an outer side of the retaining washer, thereby locking the gasket on the valve holder, by applying a rotary forming tool against the shoulder on the cylindrical portion. The coupling desirably includes shutoff valves in male and female components, with identical valve holder assemblies being used in both coupling components. A powdered metal guide can be used for a stem on the valve holder.

Owner:MARSHALL EXCELSIOR CO

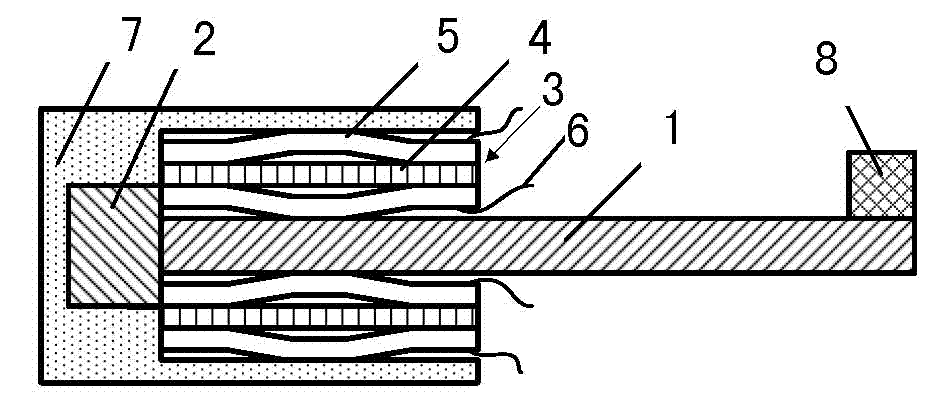

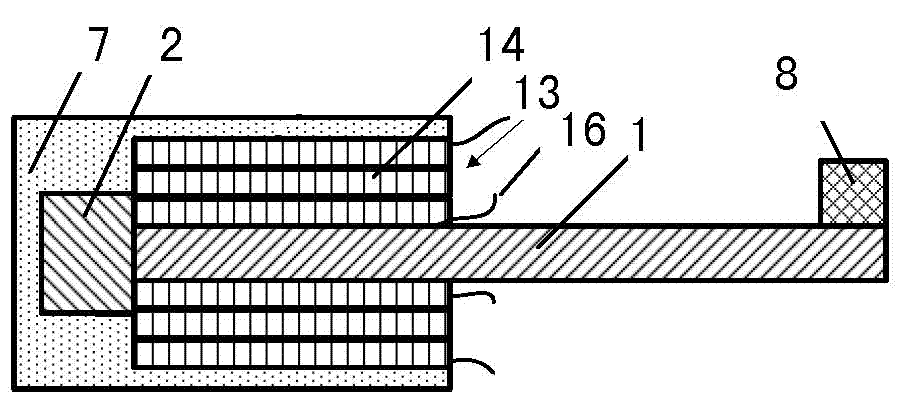

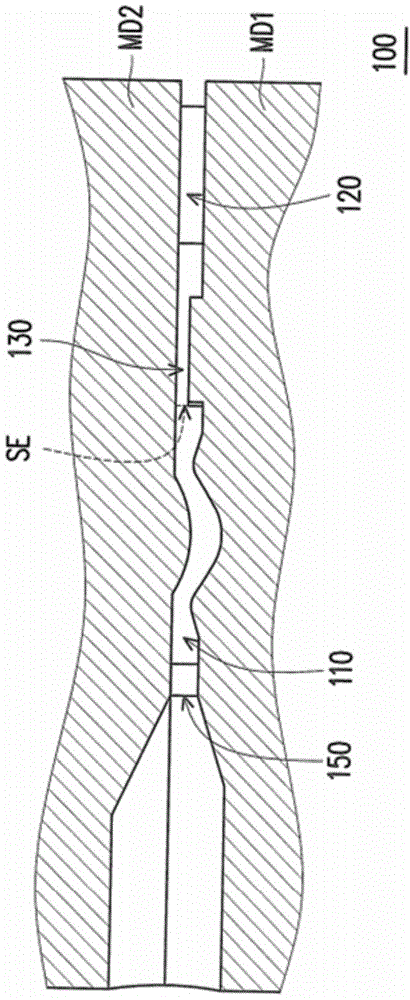

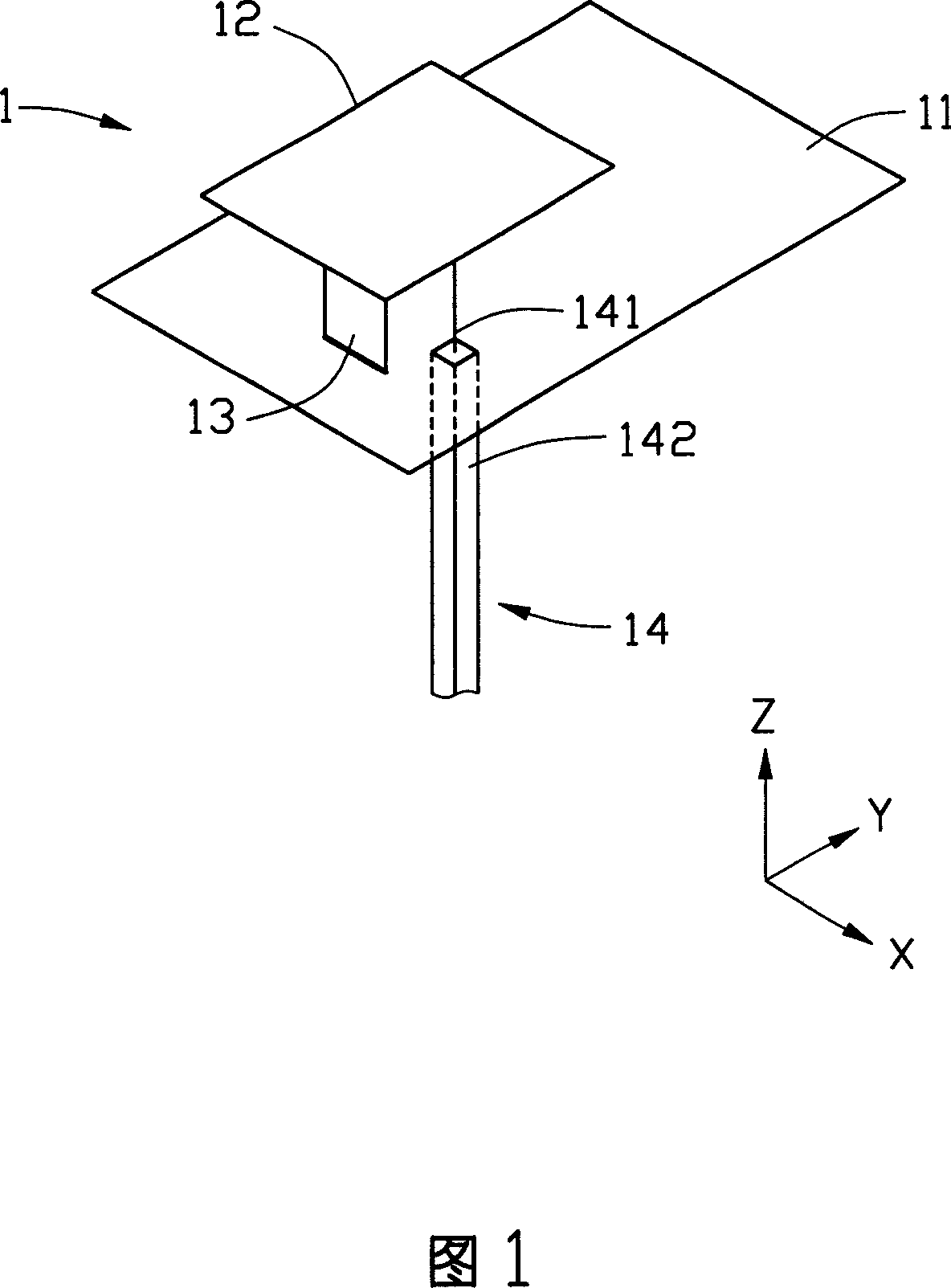

Composite structure piezoelectric energy collector driven by cantilever

InactiveCN103199736ALower resonant frequencyIncrease energy densityPiezoelectric/electrostriction/magnetostriction machinesCantilevered beamEnergy harvester

The invention relates to a composite structure piezoelectric energy collector driven by a cantilever. The energy collector comprises a cantilever member and an output unit used for output of generated electric energy output, one end of the cantilever is a fixed end which is fixed on a base, the other end of the cantilever is a free end, a pair of piezoelectric energy converting units are respectively symmetrically arranged on the portions, near the fixed end of the cantilever member, of the upper surface and the lower surface of the cantilever member, and the piezoelectric energy converting units are driven by vibration of the cantilever member to generate electric energy.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

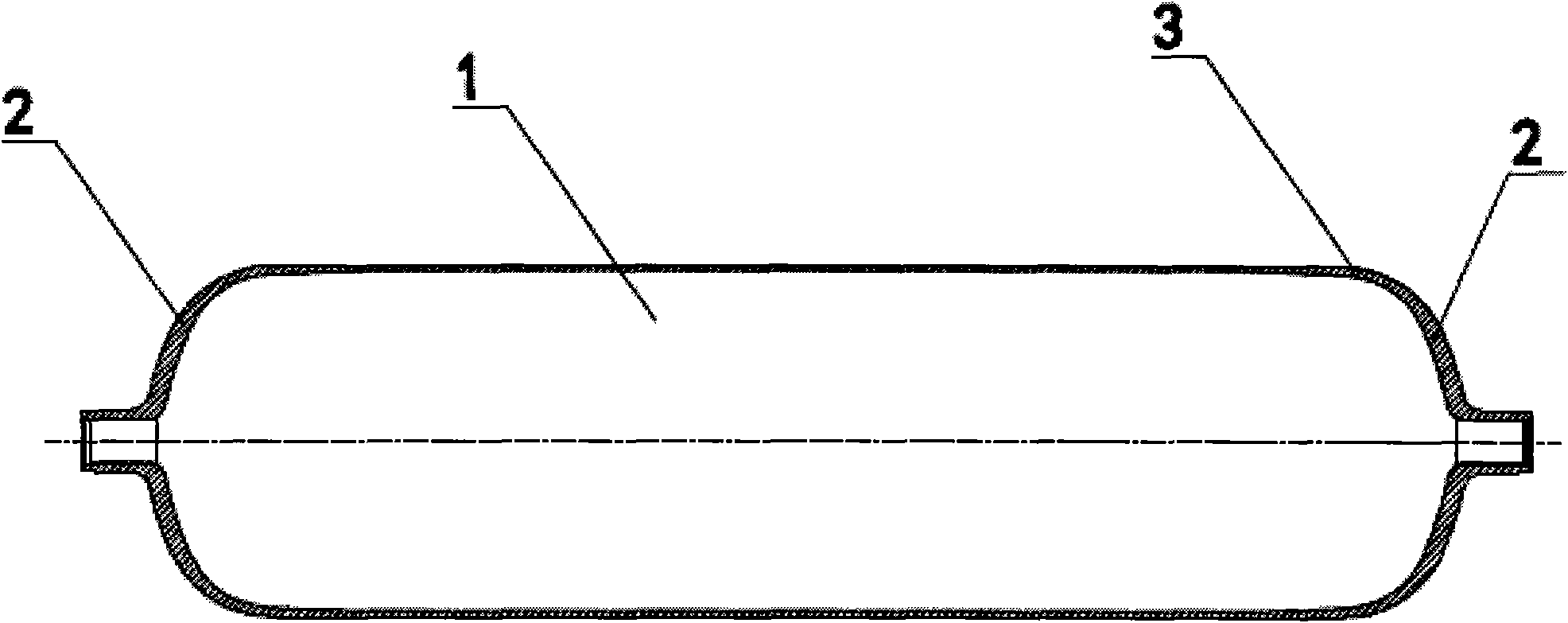

Liner end enclosure molding process of high-pressure hydrogen storage cylinder

ActiveCN101879563ASave manufacturing processSolve the deformationHollow articlesHigh pressure hydrogenEngineering

The invention provides a high-pressure hydrogen storage cylinder, which comprises a liner body, a liner end enclosure and a transition section of the joint of the liner body and the liner end enclosure. A molding process of the liner end enclosure comprises threes steps of clamping processing, billet heating, and neck-spinning. The invention has the beneficial effects that: clamping jaws are designed to clamp during fixing so as to solve the problem that aluminum alloy easily deforms when being tightly clamped, so that the surface of a product has no clamping marks; and the reasonable heating speed and pass number are selected to solve the problem that the aluminum alloy end enclosure is difficult to mold. The process provided by the invention effectively solves the problem of the molding of the transition section of the hydrogen cylinder, and eliminates the manufacturing processes of the gas cylinder.

Owner:SINOMA SCI & TECH CHENGDU CO LTD

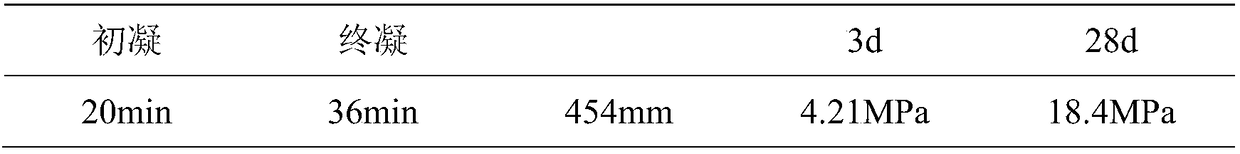

Red mud based rapid-setting grouting material applicable to grouting reinforcement treatment of sandy soil stratum

The invention discloses a red mud based rapid-setting grouting material applicable to grouting reinforcement treatment of a sandy soil stratum. The red mud based rapid-setting grouting material is prepared from components in parts by weight as follows: 60-80 parts of red mud, 20-30 parts of an exciting agent and 5-10 parts of an admixture, wherein the exciting agent is prepared from a sodium hydroxide water solution, sodium silicate and sulphoaluminate cement clinker; the admixture is prepared from a carboxylic acid water reducer, talc powder, hydroxypropyl methyl cellulose and desulfurized gypsum powder. The red mud as a mineral material is supplemented by the exciting agent, the additive and other ingredients for preparation of the grouting material, and the grouting material can be applied to the field of grouting reinforcement of the sandy soil stratum. The gelatinization material is prepared by use of characteristics of high alkalinity and fine particle size of the red mud, and the gelatinization activity of the red mud is improved by use of sulphoaluminate cement clinker and the alkaline exciting agent. The working performance of the red mud based grouting material is adjusted by the additive, so that the red mud based grouting material with excellent engineering performance is prepared.

Owner:SHANDONG UNIV

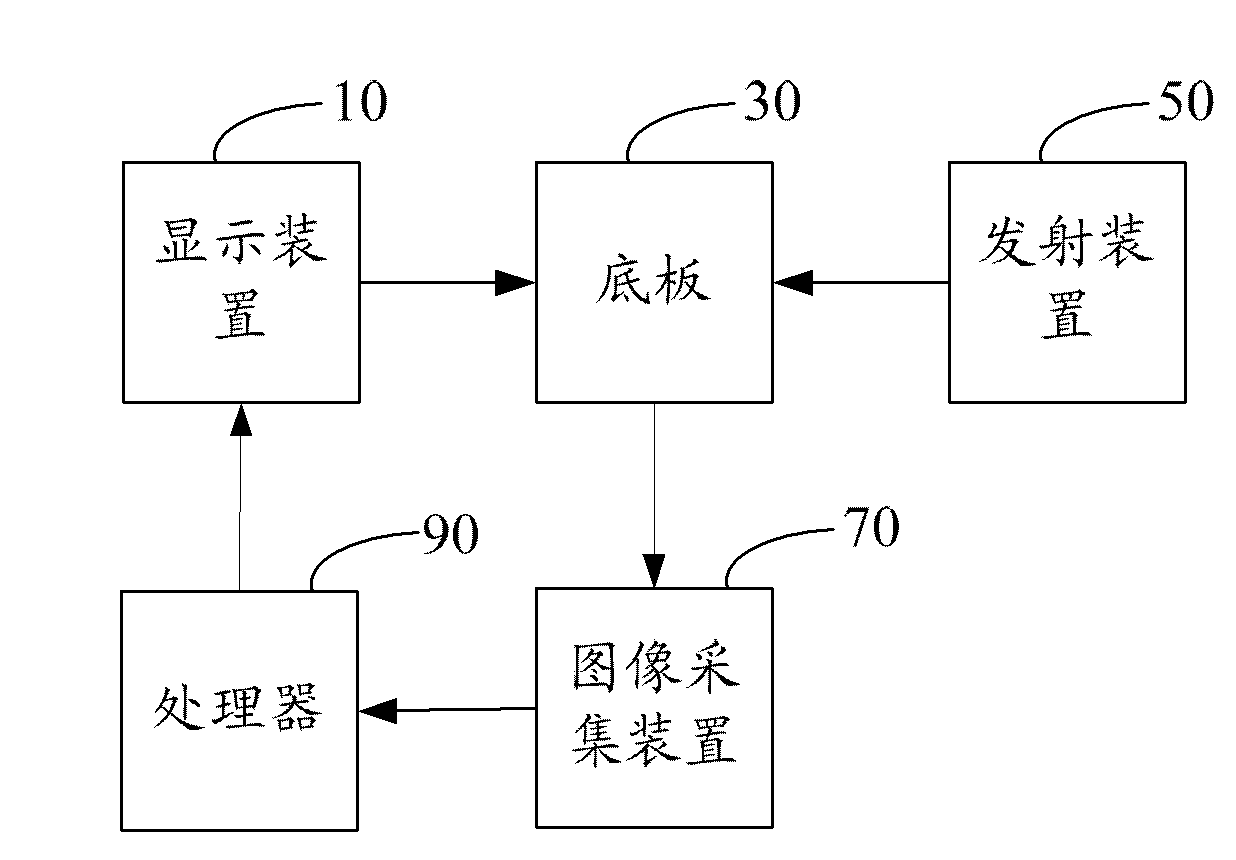

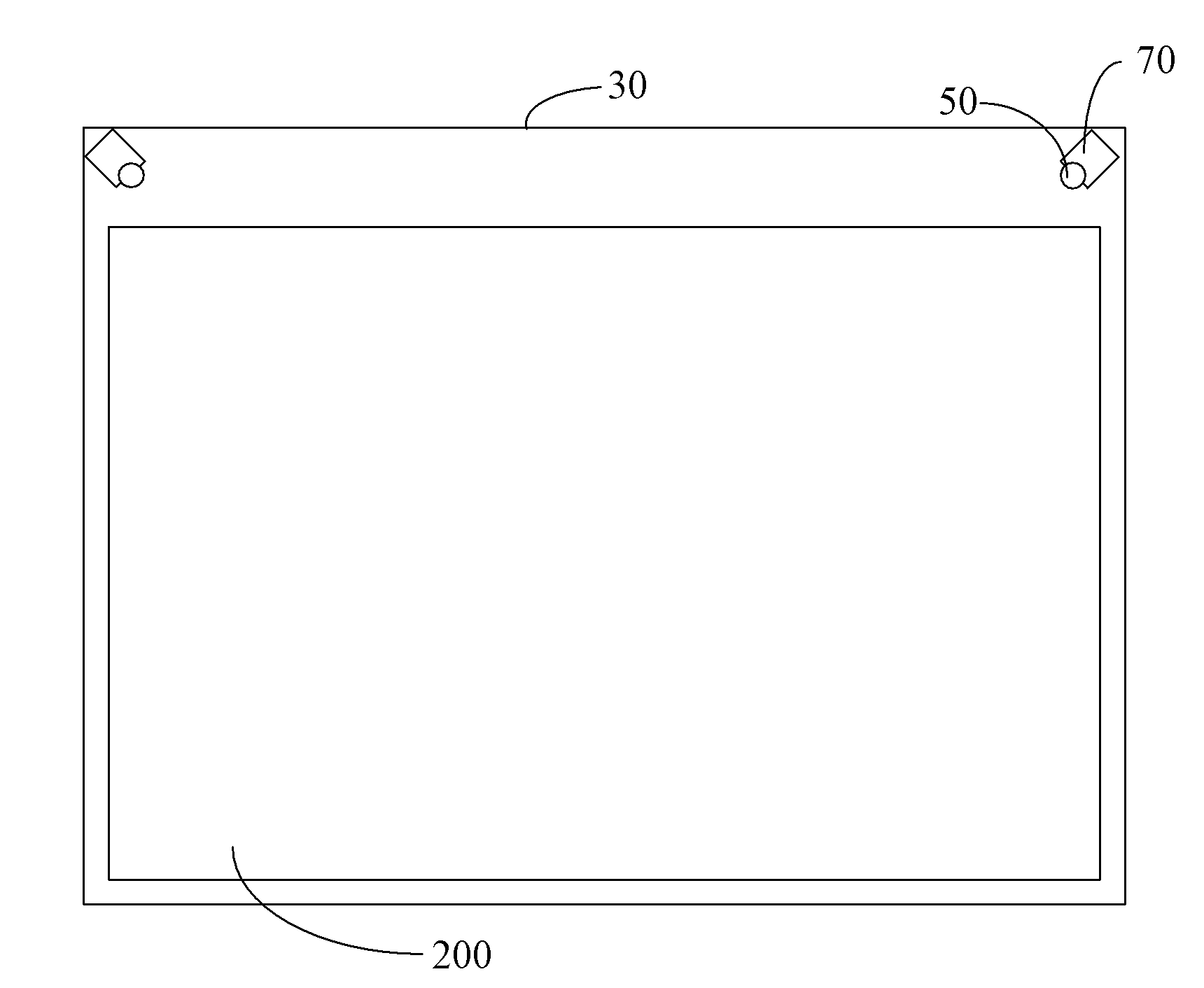

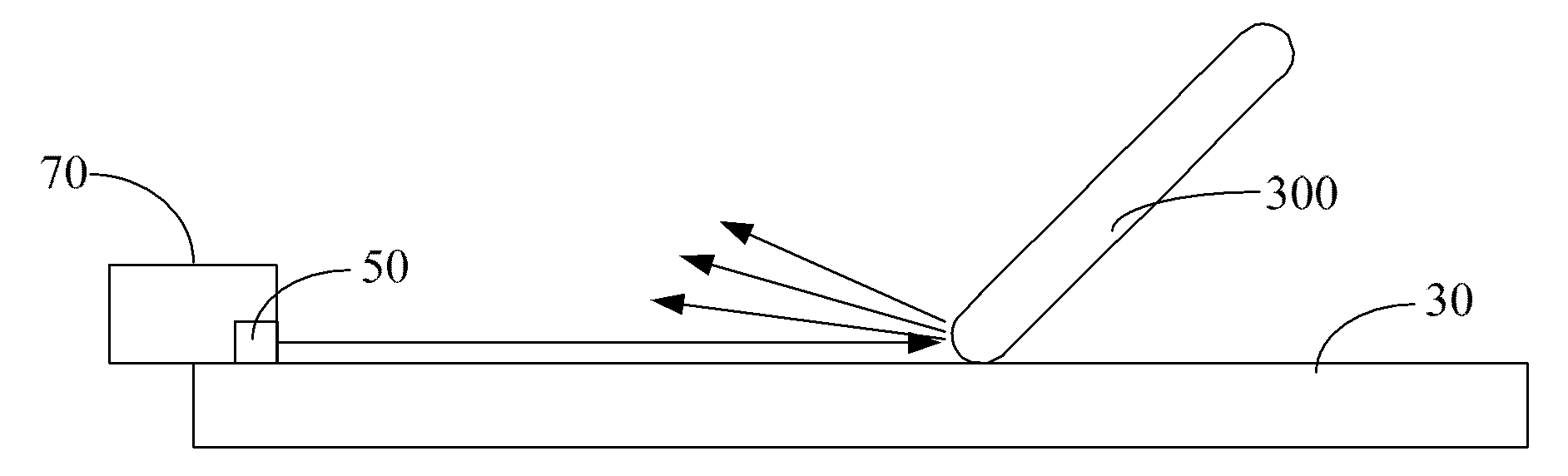

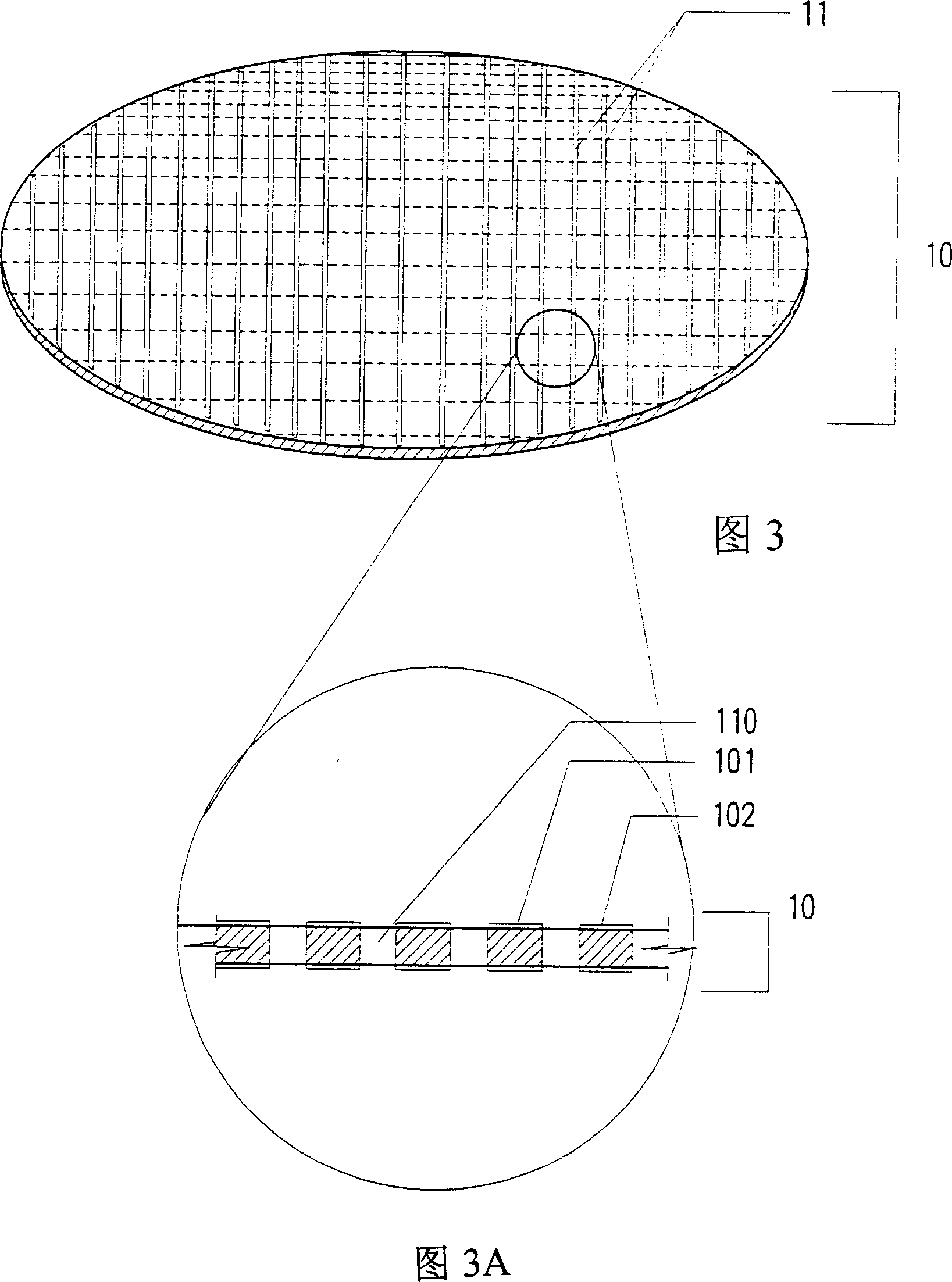

Optical touch screen and touch positioning method thereof

ActiveCN102156593APrecise positioningGood directionInput/output processes for data processingDisplay deviceEngineering

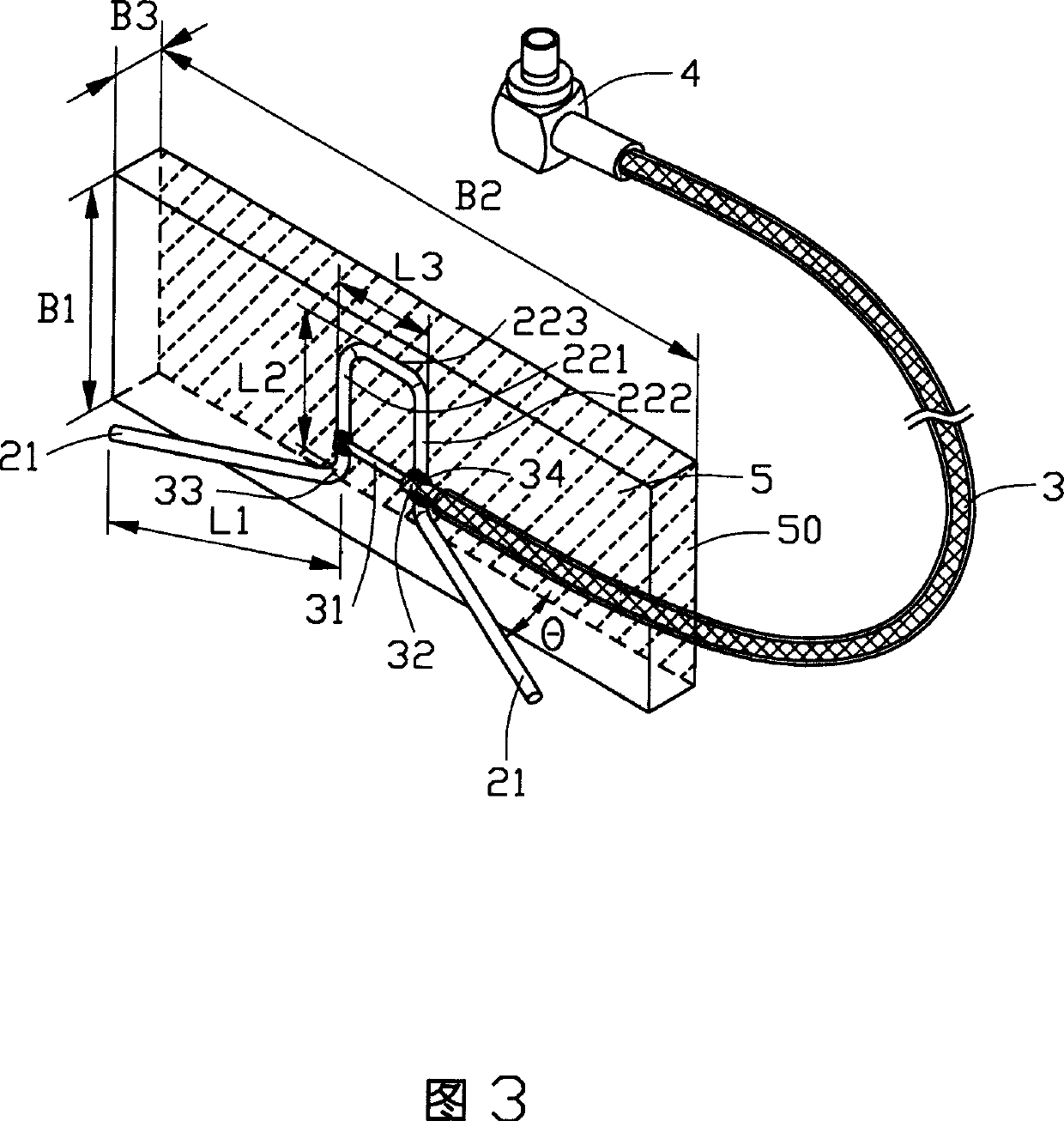

The invention provides an optical touch screen that comprises a display device, a bottom plate, an emitting device, an image collecting device, and a processor, wherein the display device is used for response by the projection according to the clicking position of a sensing object in a touch detection area; the bottom plate is used for exhibiting the touch detection area of the projection; the emitting device is used for emitting laser that is arranged in parallel with the touch detection area and covers the touch detection area; the image collecting device is used for receiving the laser that is reflected by the sensing object in the touch detection area and generating light spot images according to the reflected laser; and the processor is used for obtaining the clicking position of thesensing object in the touch detection area by calculation according to the position of the light spot in the light spot image and the coordinate converting matrix in the touch detection area. By adopting the optical touch screen and the touch screen positioning method thereof, the laser emitted by the emitting device covers the touch detection area; and as the laser has very good directivity, more irregular and uniform light spots can be formed as to the laser that is reflected by the sensing object, thus positioning the position of the sensing object more accurately, and obtaining higher positioning precision.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

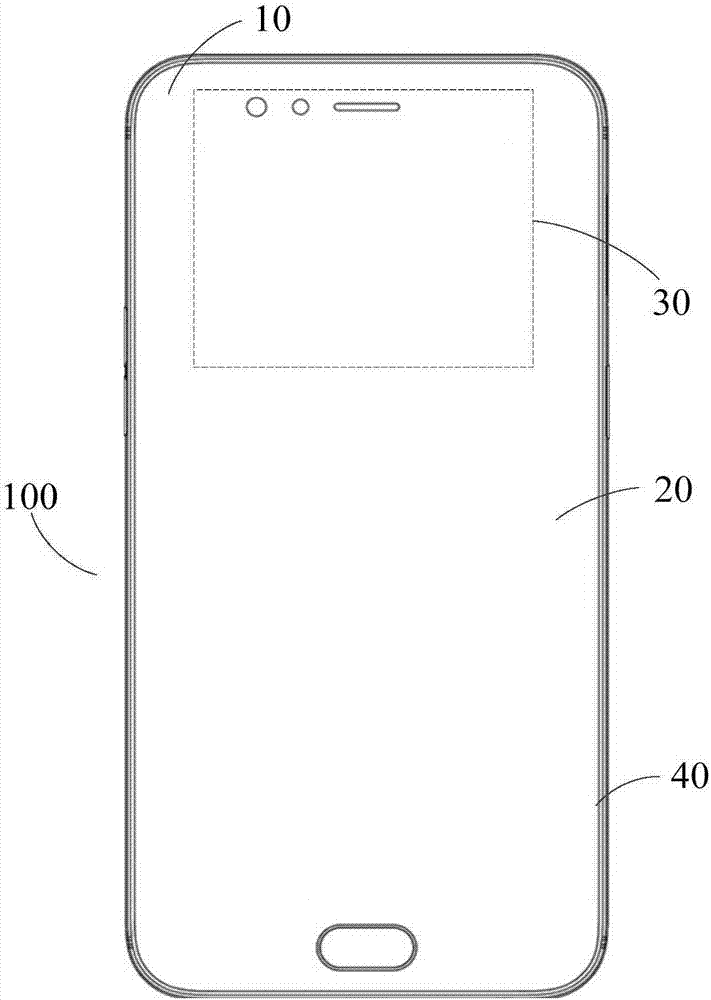

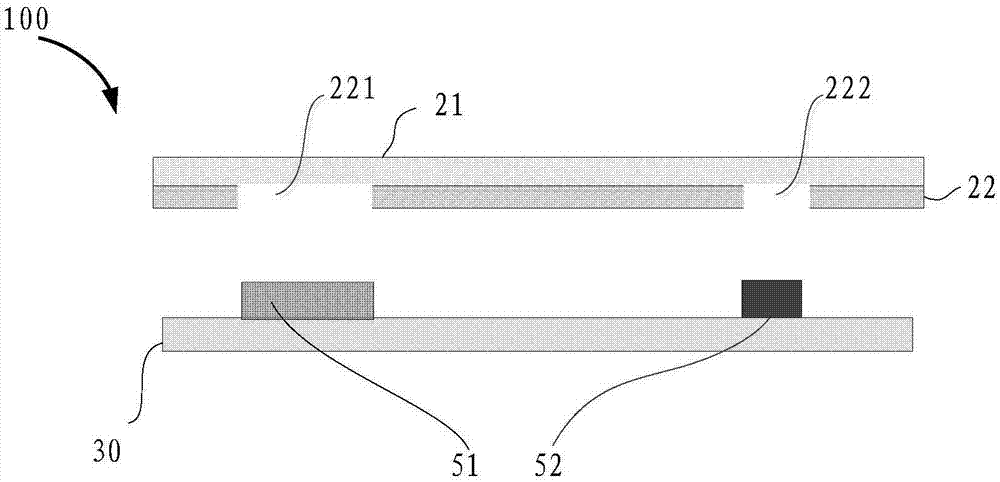

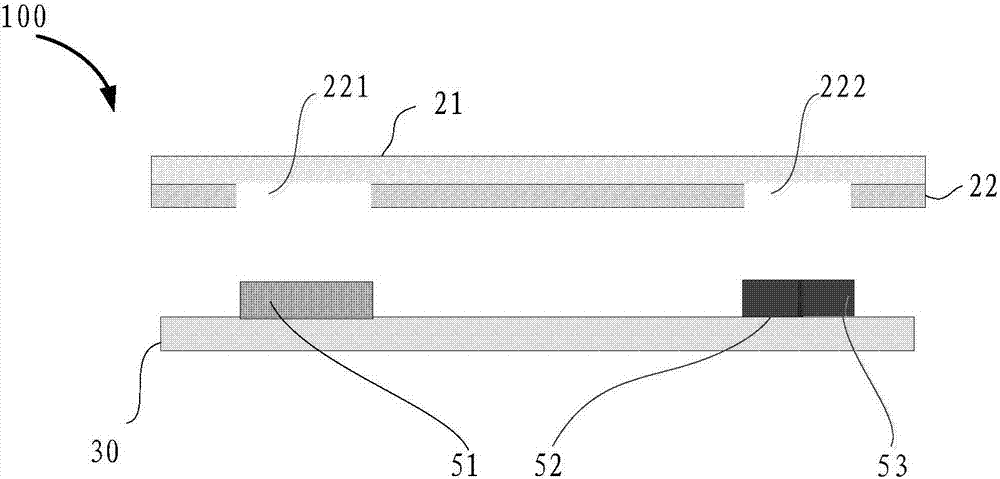

Electronic device

InactiveCN107968854ASave space resourcesReduce the use of space resourcesDigital data processing detailsTelephone set constructionsInfraredDistance sensors

The embodiment of the invention provides an electronic device. The electronic device comprises a display screen, a light shading layer set at one side of the display screen, a sensor assembly and a circuit board. The light shading layer is set between the display screen and the sensor assembly. The sensor assembly is set on a circuit board. The sensor assembly comprises an infrared transmitter andan infrared camera. The infrared transmitter is used for transmitting an infrared signal to the outside world. The infrared signal is reflected by an external object to form a reflection signal. Theinfrared camera is used for receiving the reflection signal. According to the electronic device, a function of a distance sensor can be realized through utilization of the infrared camera in the electronic device. Other hardware device does not need to be increased. The use of a front panel space resource of the electronic device is reduced. The hardware cost is reduced. Production processes are reduced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

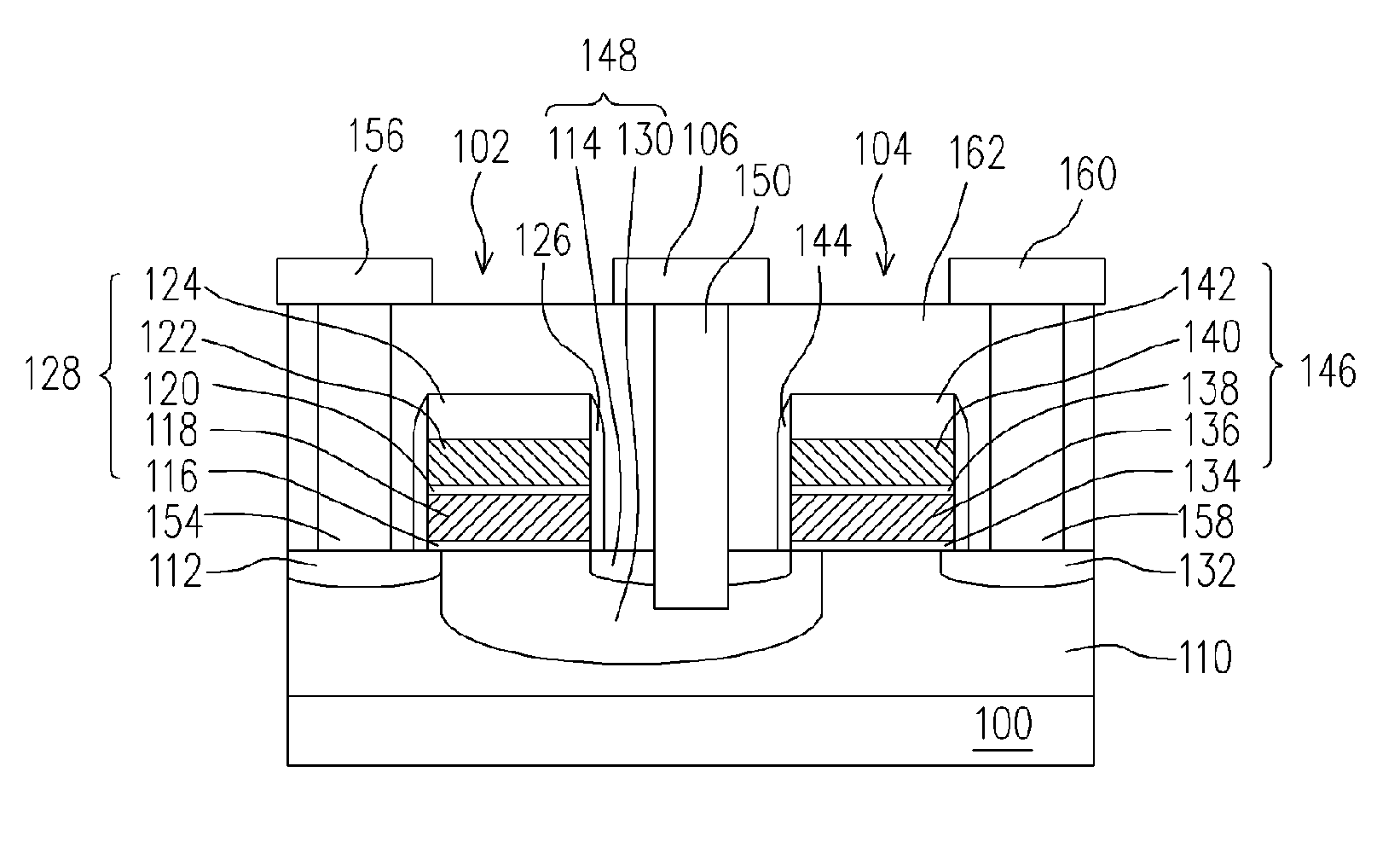

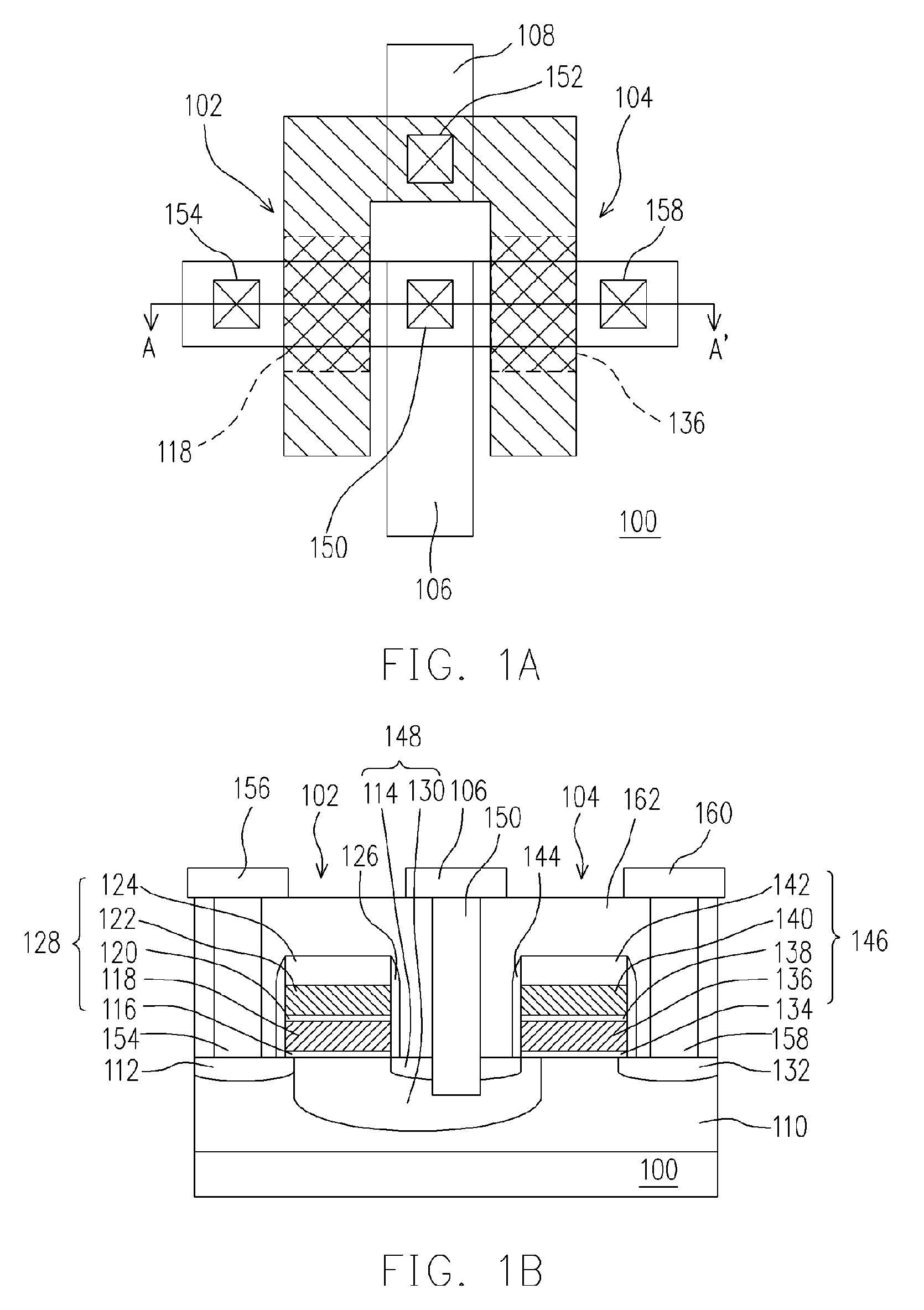

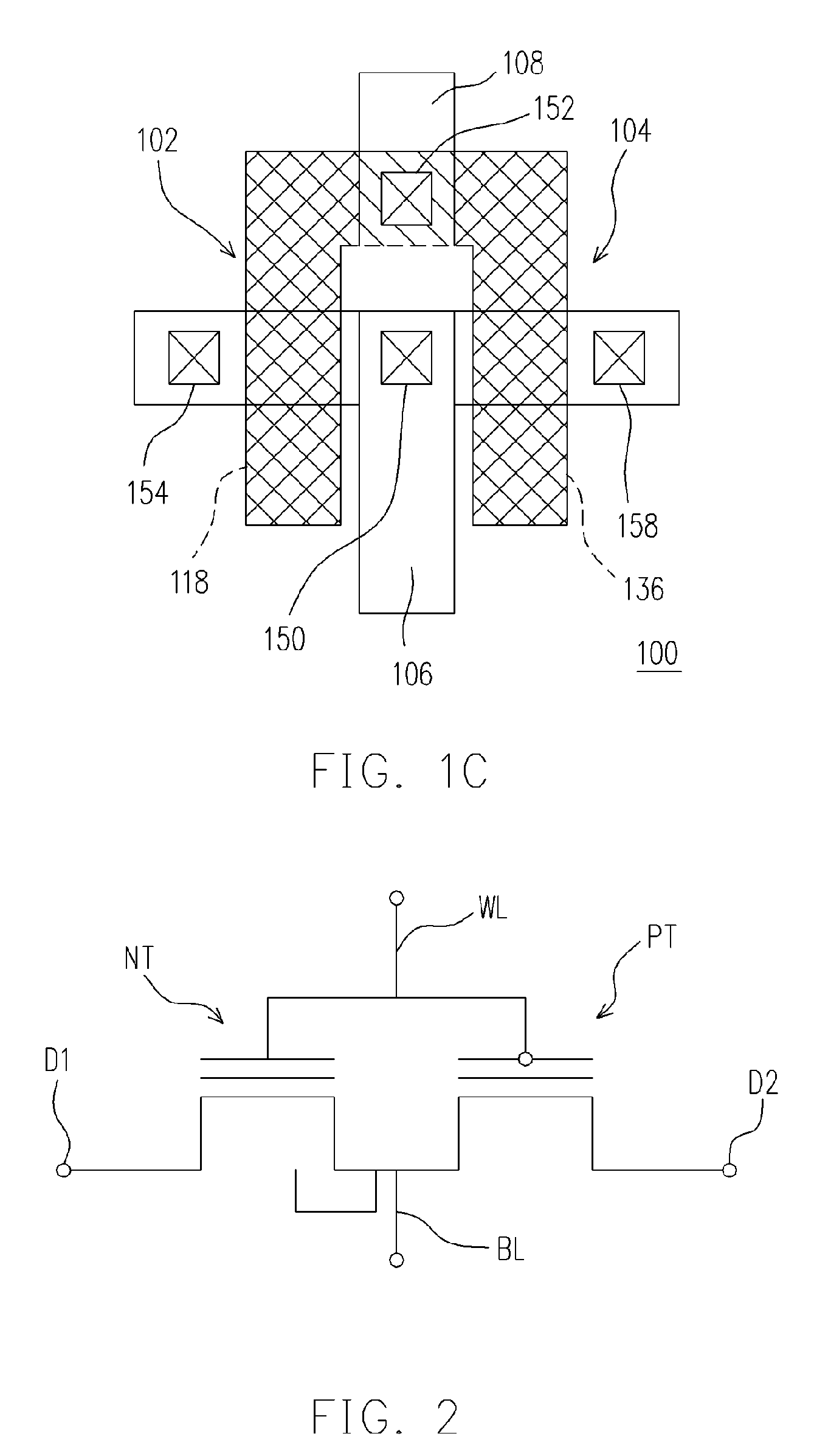

Programmable and erasable digital switch device and fabrication method and operating method thereof

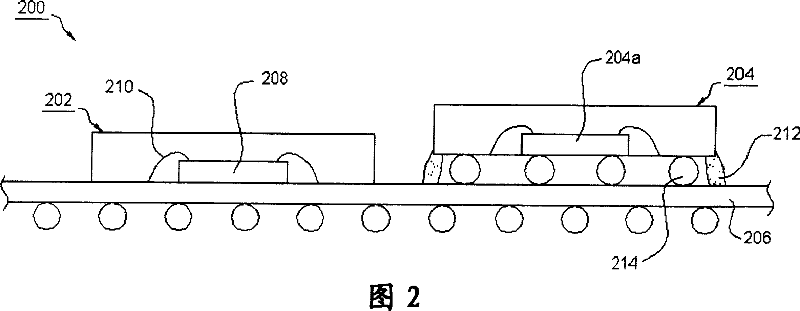

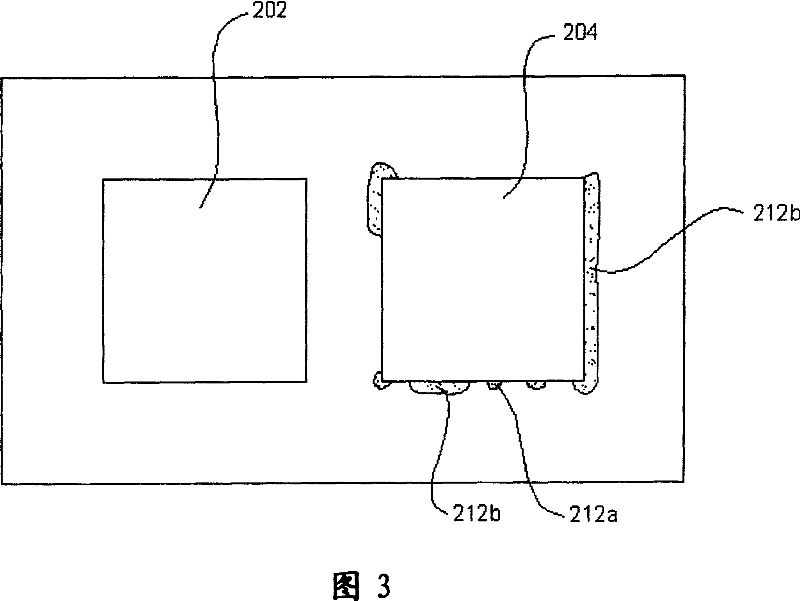

ActiveUS7291882B2Easy to switchSave manufacturing processTransistorSolid-state devicesBit lineComputer science

A programmable and erasable digital switch device is provided. An N-type memory transistor and a P-type memory transistor are formed over a substrate. The N-type memory transistor includes a first N-type doped region, a second N-type doped region, a first charge storage layer and a first control gate. The P-type memory transistor includes a first P-type doped region, a second P-type doped region, a second charge storage layer and a second control gate. A common bit line doped region is formed between the N-type memory transistor and the P type memory transistor and electrically connects the first N-type region to the second P-type doped region. A word line electrically connects the first control gate to the second control gate.

Owner:POWERCHIP SEMICON MFG CORP

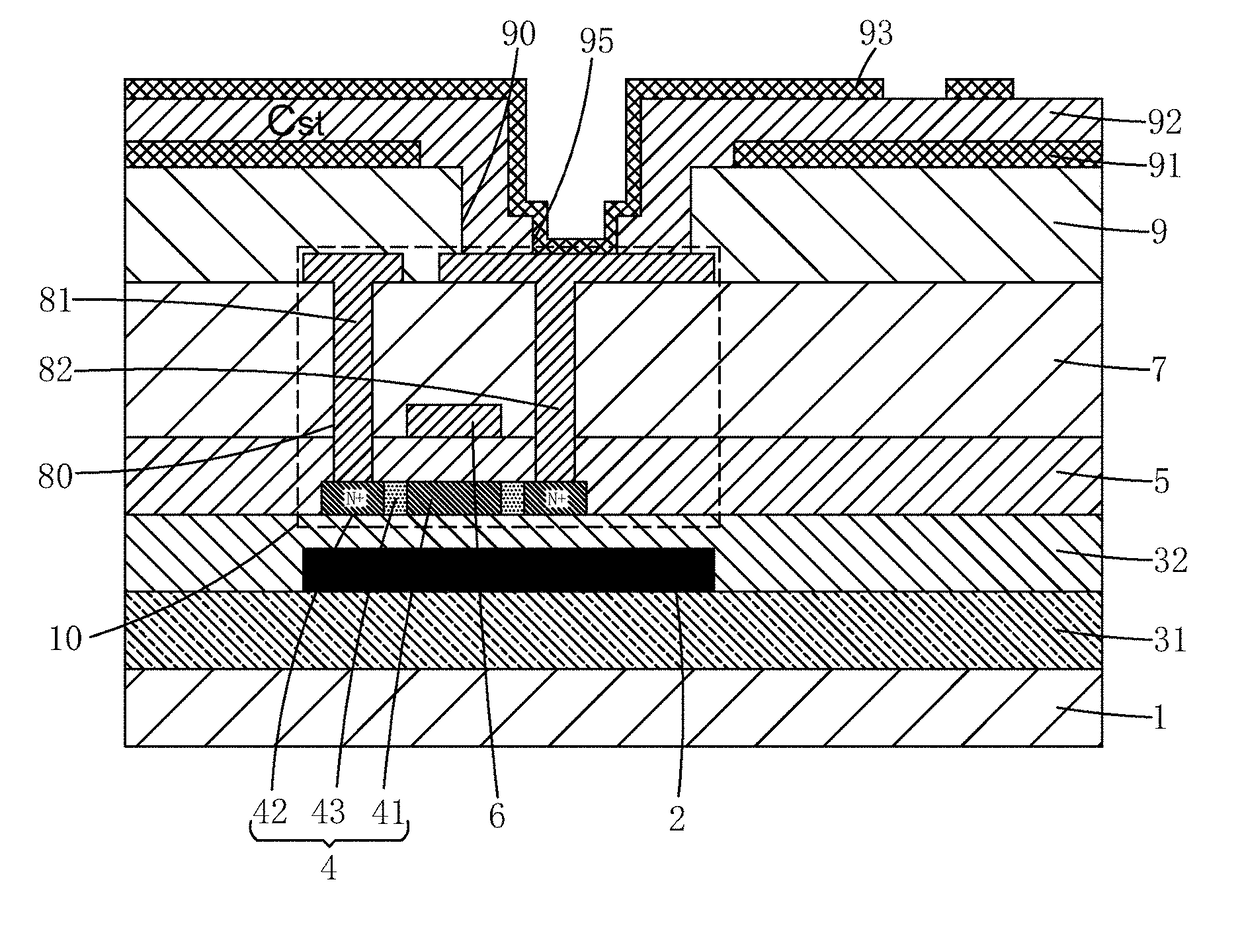

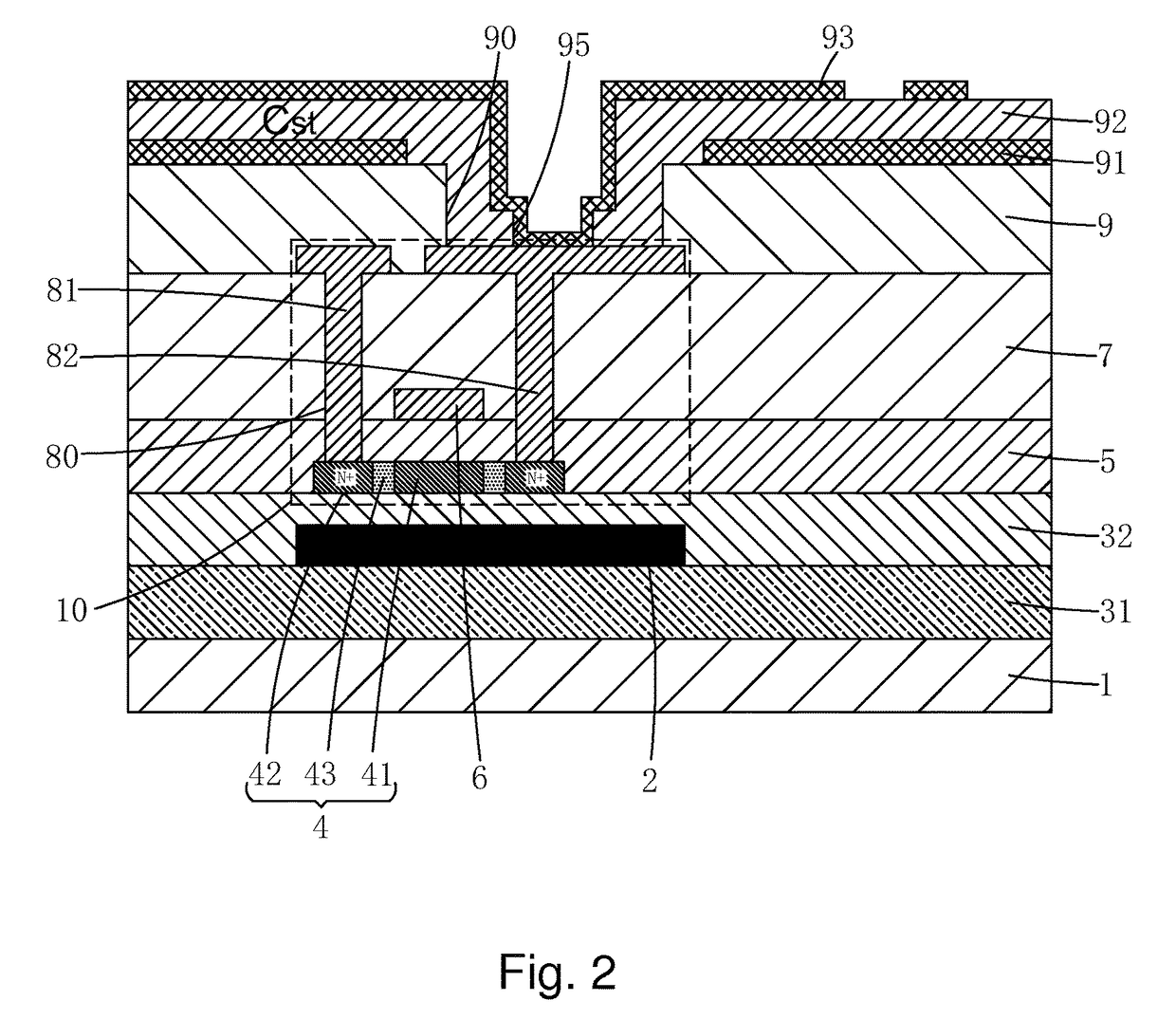

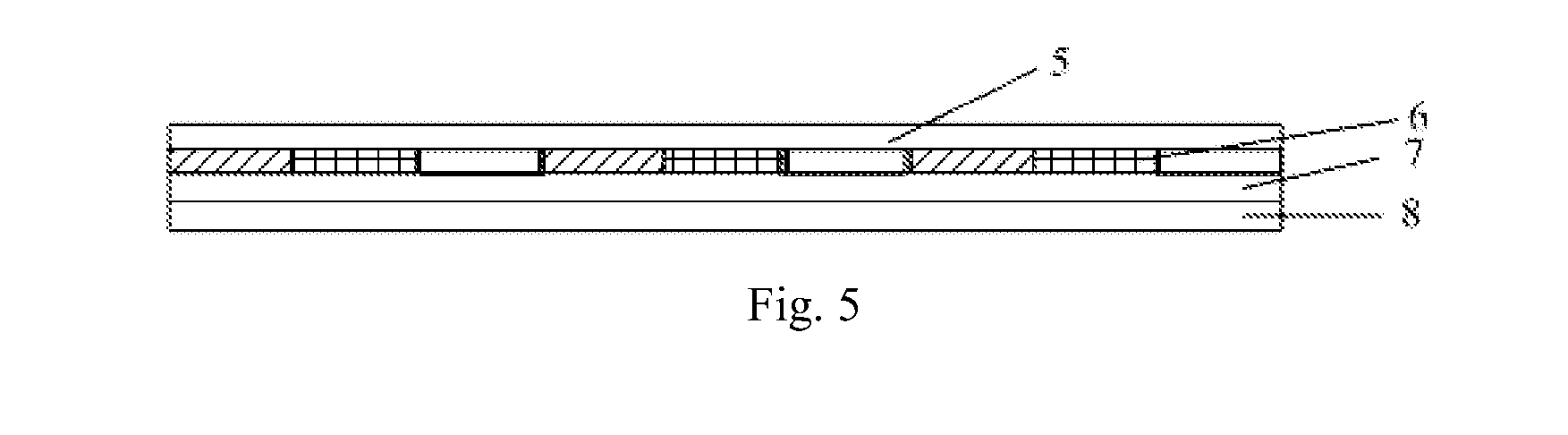

Low temperature poly-silicon TFT substrate

ActiveUS9869912B2Keep performance stableReduce manufacturing costTransistorSolid-state devicesLight irradiationEngineering

The present invention provides a LTPS TFT substrate, which includes a black matrix arranged on a first buffer layer of the LTPS TFT substrate to have an area where a TFT device is located is shielded by the black matrix thereby preventing the TFT device from being influenced by light irradiation, maintaining stability of the TFT device; and also saving the manufacturing process of a shielding metal layer, reducing one photo-mask, and lowering down manufacturing cost so as to allow the black matrix, in achieving the functionality of its own (shielding leaking light of the pixel), to also take the place of a shielding metal layer that is commonly adopted in the prior art to shield light for the TFT device and thus providing duality of functionality.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD +1

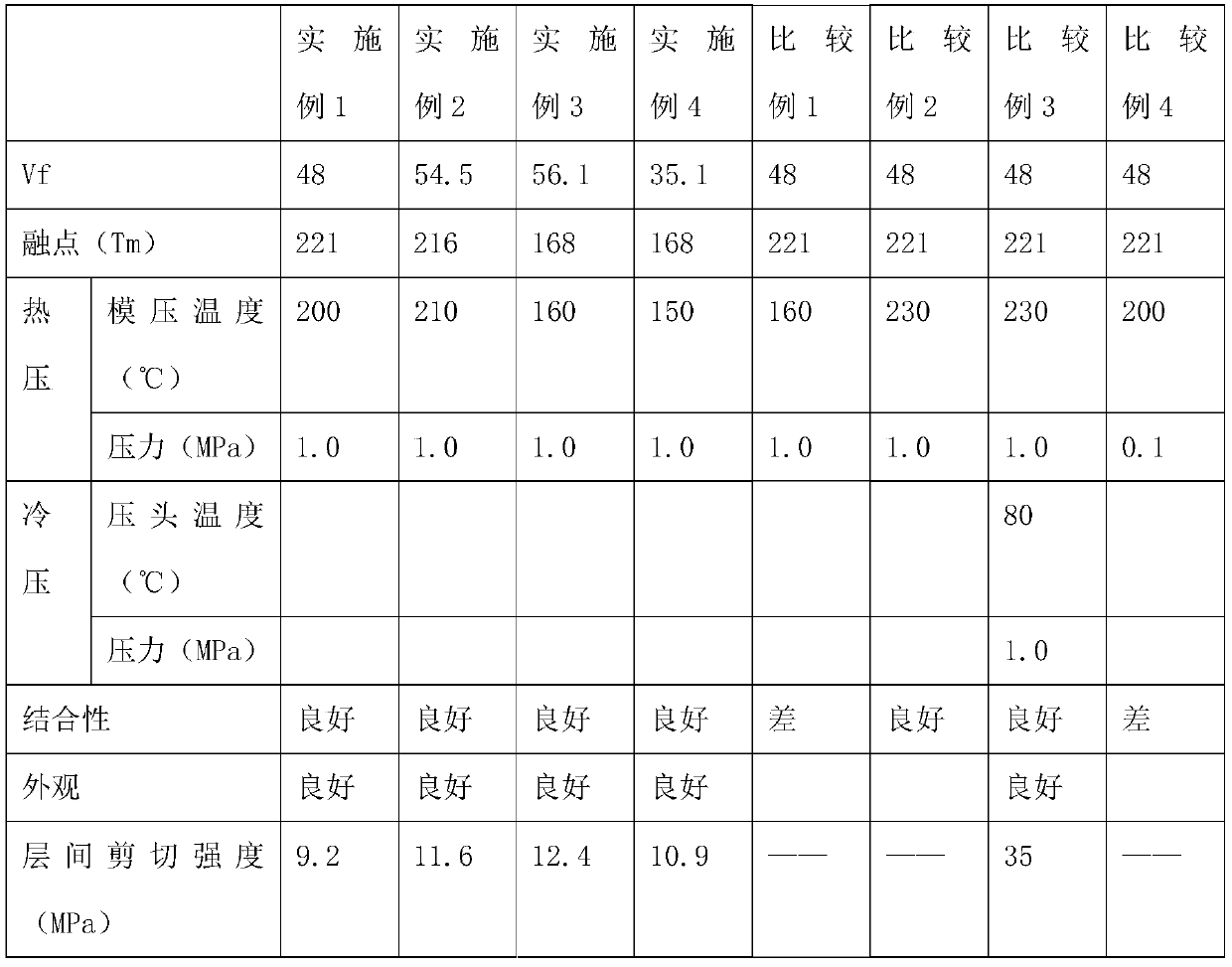

Carbon fiber reinforced thermoplastic resin plate and manufacturing method thereof

InactiveCN110712379ASave manufacturing processSave costsFlat articlesCompression moldingPolymer science

The invention discloses a carbon fiber reinforced thermoplastic resin plate and a manufacturing method thereof. The manufacturing method comprises the following steps: (1) blending carbon fibers and thermoplastic resin to prepare carbon fiber prepreg; and (2) after laying the carbon fiber prepreg, directly carrying out compression molding at a compression molding temperature without preheating toobtain the carbon fiber reinforced thermoplastic resin plate. In the process of laying the carbon fiber prepreg composed of the carbon fibers and the thermoplastic resin and then carrying out compression molding to prepare the carbon fiber reinforced thermoplastic resin plate, after the carbon fiber prepreg is laid, compression molding is directly carried out between the crystallization temperature and the melting point of the thermoplastic resin base material under the pressure of 0.5MPa or above without preheating, so that the manufacturing process and the cost are saved.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

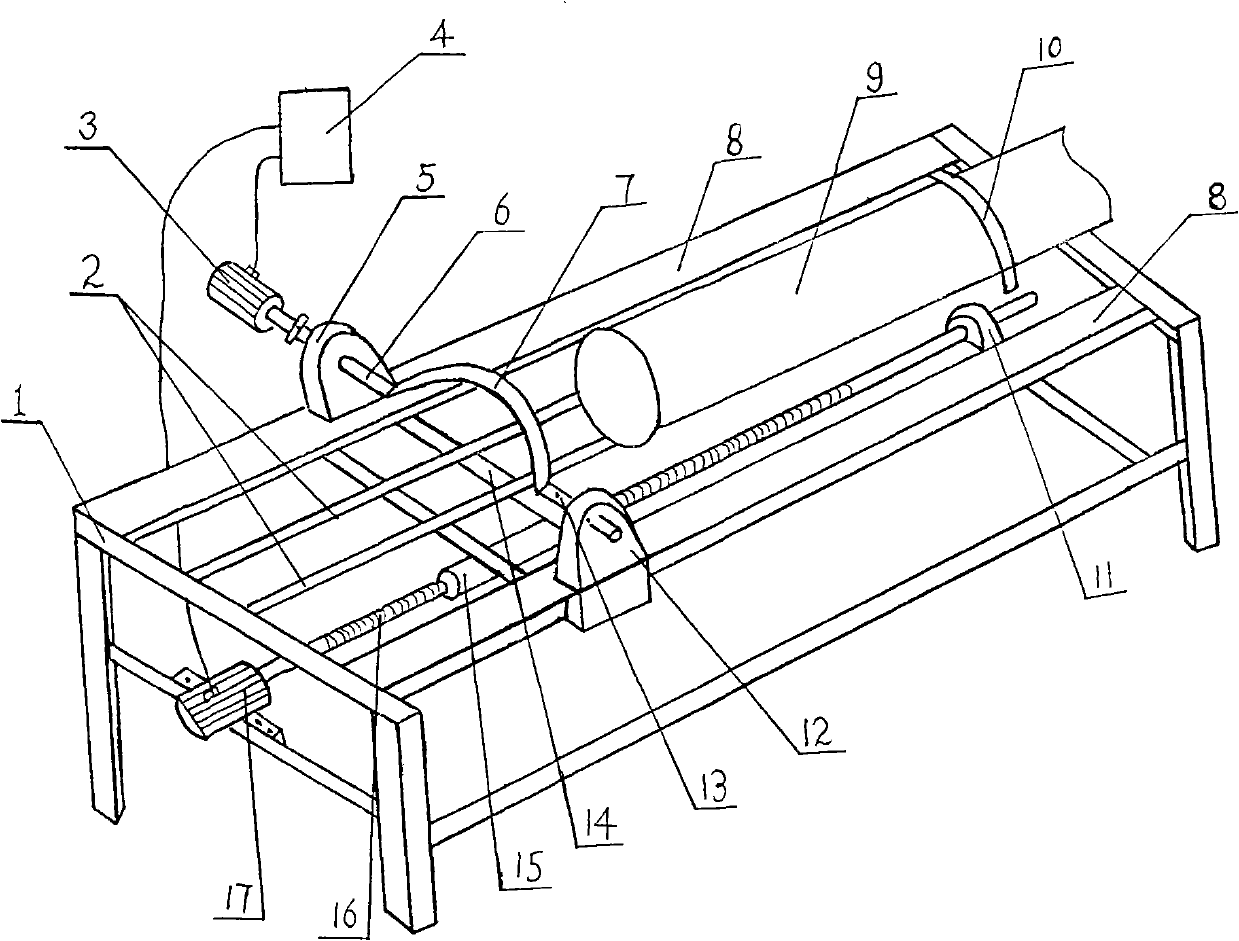

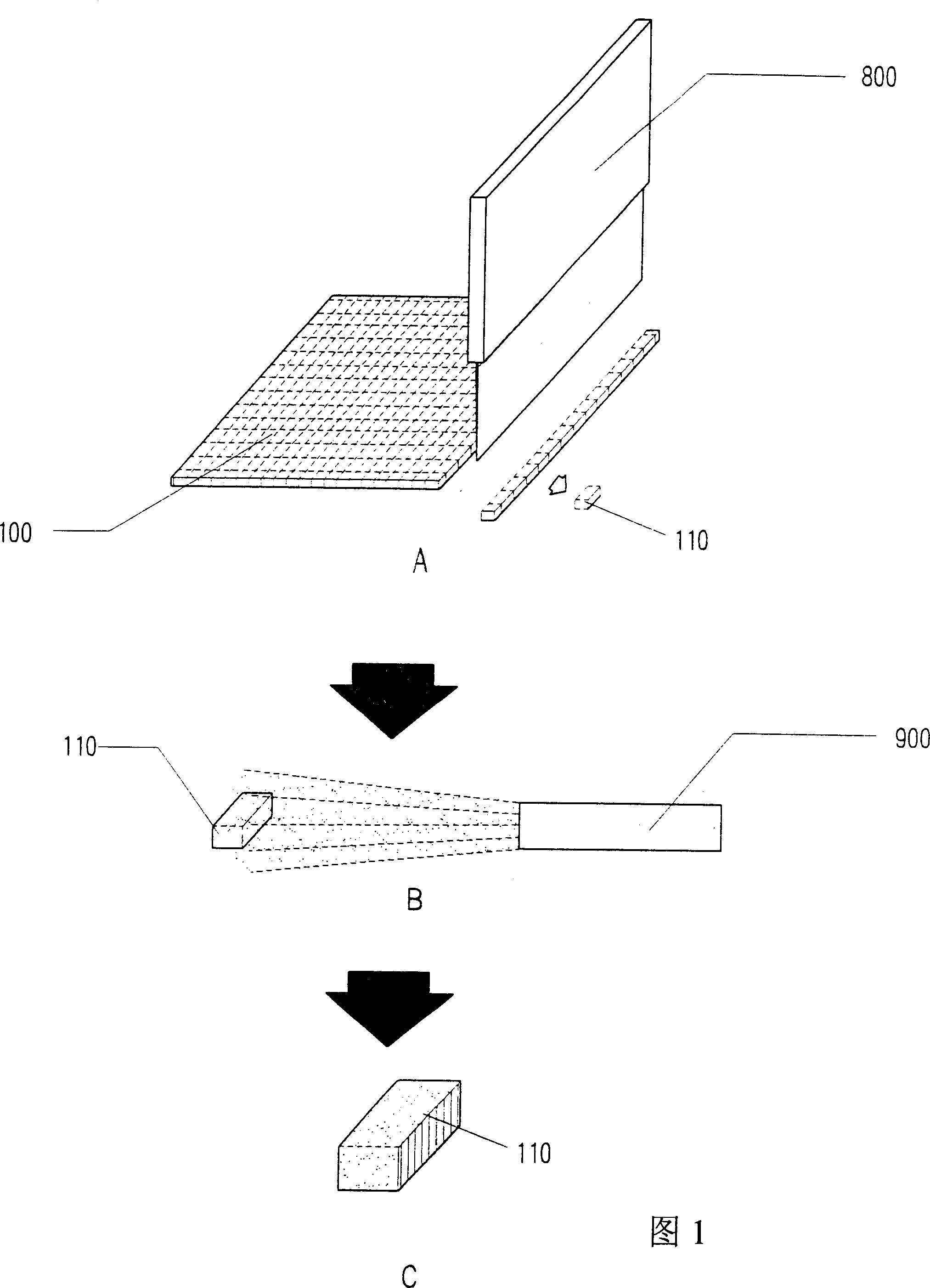

Device and method for manufacturing disposable wooden tableware and liner

InactiveCN102001118AAddress health and safety issuesNo secondary pollutionWood working apparatusAutomatic controlPublic place

The invention relates to a device and a method for manufacturing disposable wooden tableware and a liner. The device comprises a hot press, a drying plant, and a wood slice digging and cutting machine, wherein the wood slice digging and cutting machine consists of a machine frame, a digging and cutting mechanism, a feed mechanism, and an automatic control part; the machine frame is provided with a log support and a sliding rail; a digging and cutting tool rest is arranged on the sliding rail; a cutter shaft and a digging and cutting cutter connected with the cutter shaft are arranged on the tool rest through a bearing pedestal; the cutter shaft is connected with a digging and cutting stepping motor; the feed mechanism consists of a feed stepping motor and a feed screw rod matched with a travelling nut; and an output end of the feed stepping motor is linked with the feed screw rod. The disposal wooden tableware and the liner manufactured through the manufacturing device and the manufacturing method of the invention can effectively solve the problem of health security of tableware in public places, are disposal and can be directly recovered; the recovered waste can be used as raw materials for paper making and is used furthest; and secondary pollution is avoided and the resources are saved.

Owner:朱文华

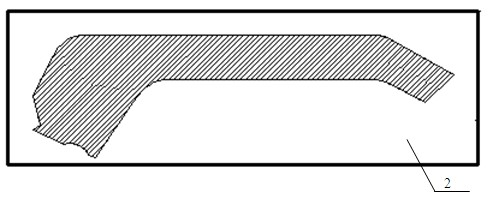

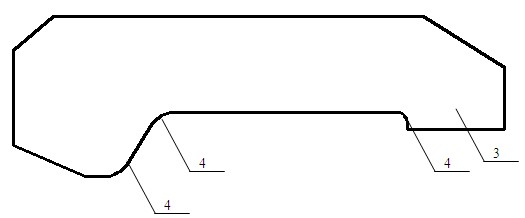

Blank of automotive front pillar inner plate part and machining method

InactiveCN102581169AEliminate the step of monomer blankingHigh precisionVehicle componentsSheet steelStructural unit

Disclosed are a blank of an automotive front pillar inner plate part and a machining method. The blank is integrally similar to the appearance of the front pillar inner plate part, the middle of the blank is straight, one end of the blank is wide, the other end of the blank is narrow, two ends of the blank are bent towards the same side, bent positions are in arc transition, the blank comprises two pieces distributed on an online blanking and machining structure unit, and the two pieces of the blank are in central symmetry. The machining method includes the steps: using two stamping dies with cavities in central symmetry for online blanking on an uncoiling blanking line; uncoiling a steel plate coil, and leading the steel plate coil to correspond to one blanking and machining structure unit when conveying the steel plate coil by the length of a blanking unit; and using an online process for blanking once to manufacture the two pieces of the steel plate blank of the front pillar inner plate, wherein the two pieces are arrayed in central symmetry. By the aid of the front pillar inner blank with the structure, material utilization rate can be increased, and cost can be reduced. Besides, the step of single blanking for rectangular blanks in subsequent machining is omitted, manufacturing procedures can be simplified, cost can be saved, control links are decreased, and precision and quality of final parts are improved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

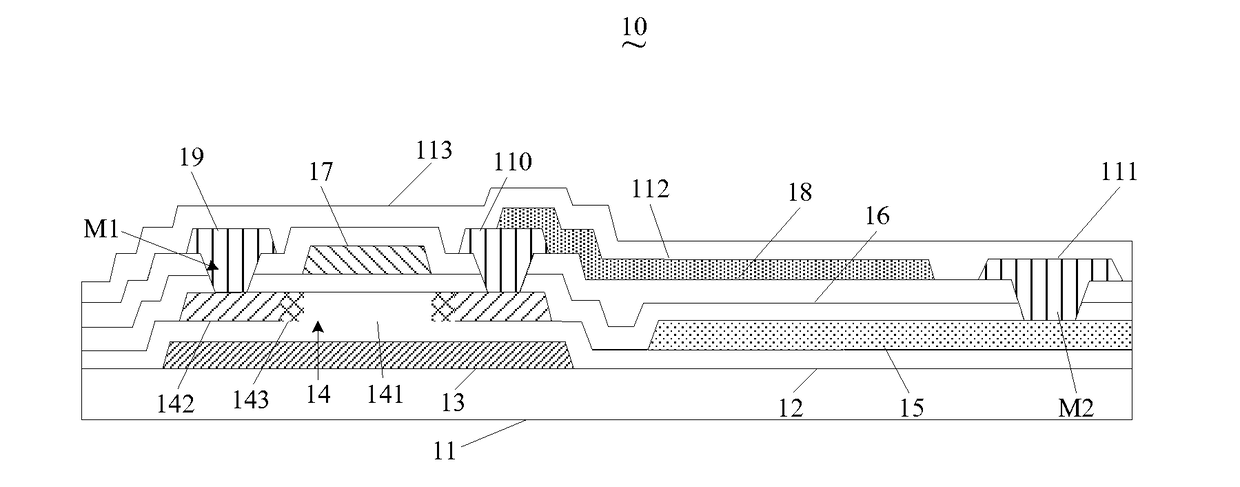

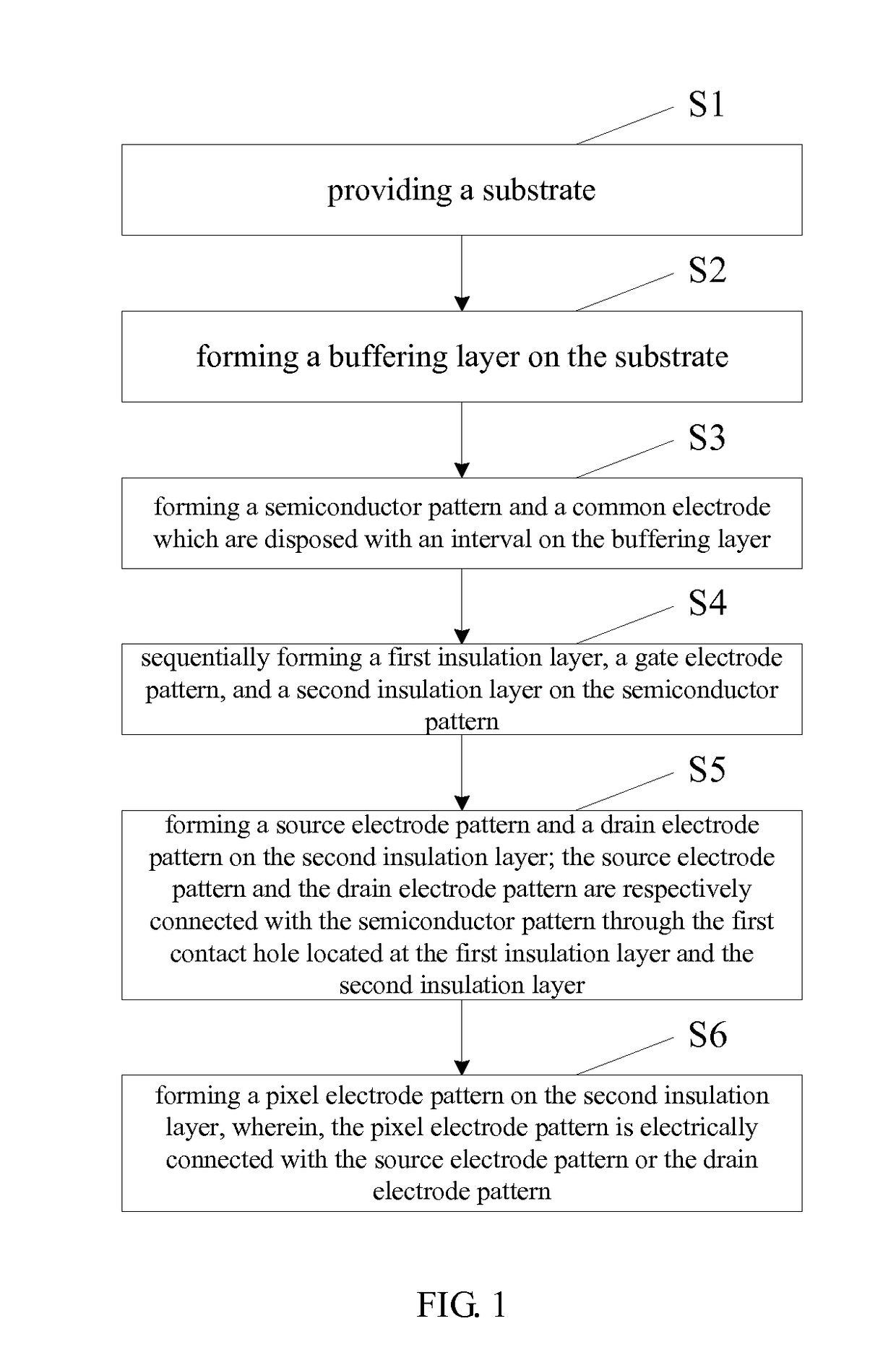

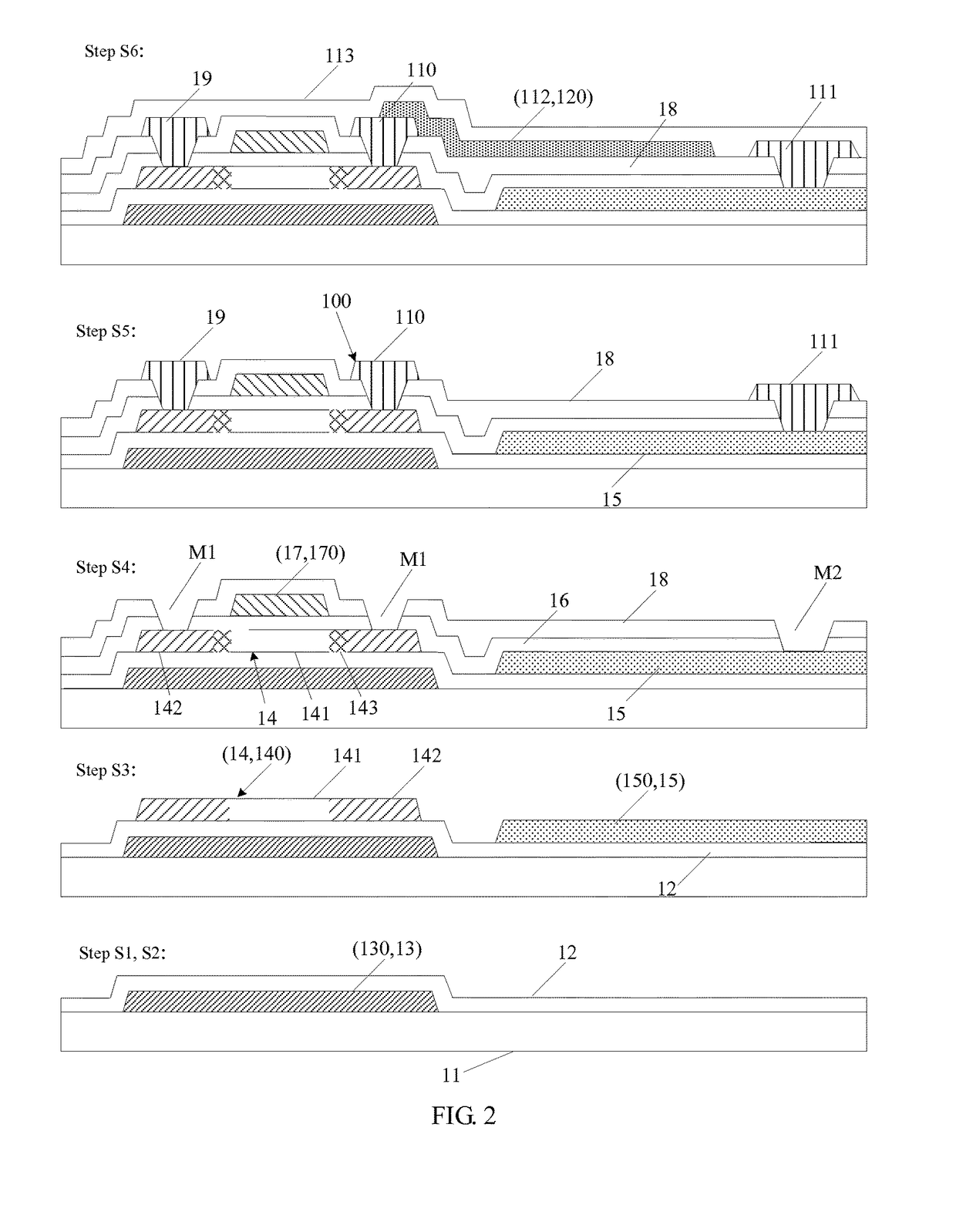

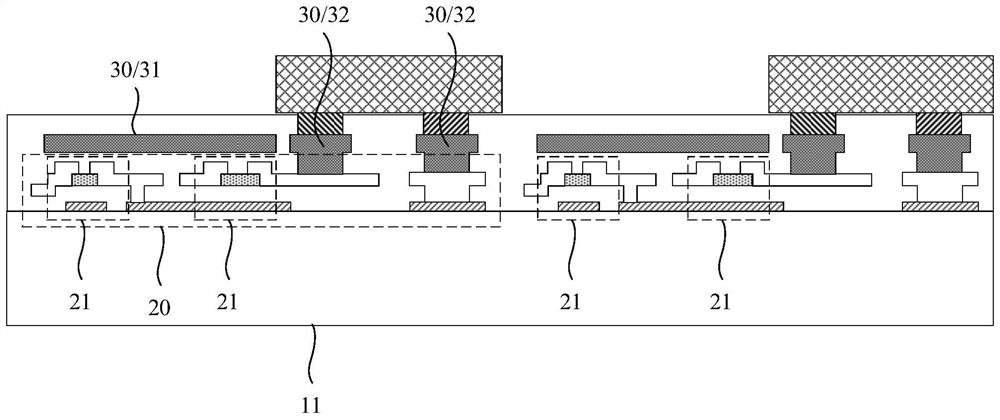

Ltps pixel unit and manufacturing method for the same

InactiveUS20170301705A1Save manufacturing processImprove production yieldTransistorSolid-state devicesInsulation layerEngineering

An LTPS pixel unit and a manufacturing method. The method includes following steps: forming a buffering layer on the substrate; forming a semiconductor pattern and a common electrode pattern which are disposed with an interval on the buffering layer; sequentially forming a first insulation layer, a gate electrode pattern and a second insulation layer on the semiconductor pattern; forming a source electrode pattern and a drain electrode pattern on the second insulation layer, wherein, the source electrode pattern and the drain electrode pattern electrically contact with the semiconductor pattern through a first contact hole at the first insulation layer and the second insulation layer; and forming a pixel electrode pattern on the second insulation layer, wherein, the pixel electrode pattern electrically contacts with the source electrode pattern or the drain electrode pattern. Accordingly, the present invention can save the cost and increase process yield.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

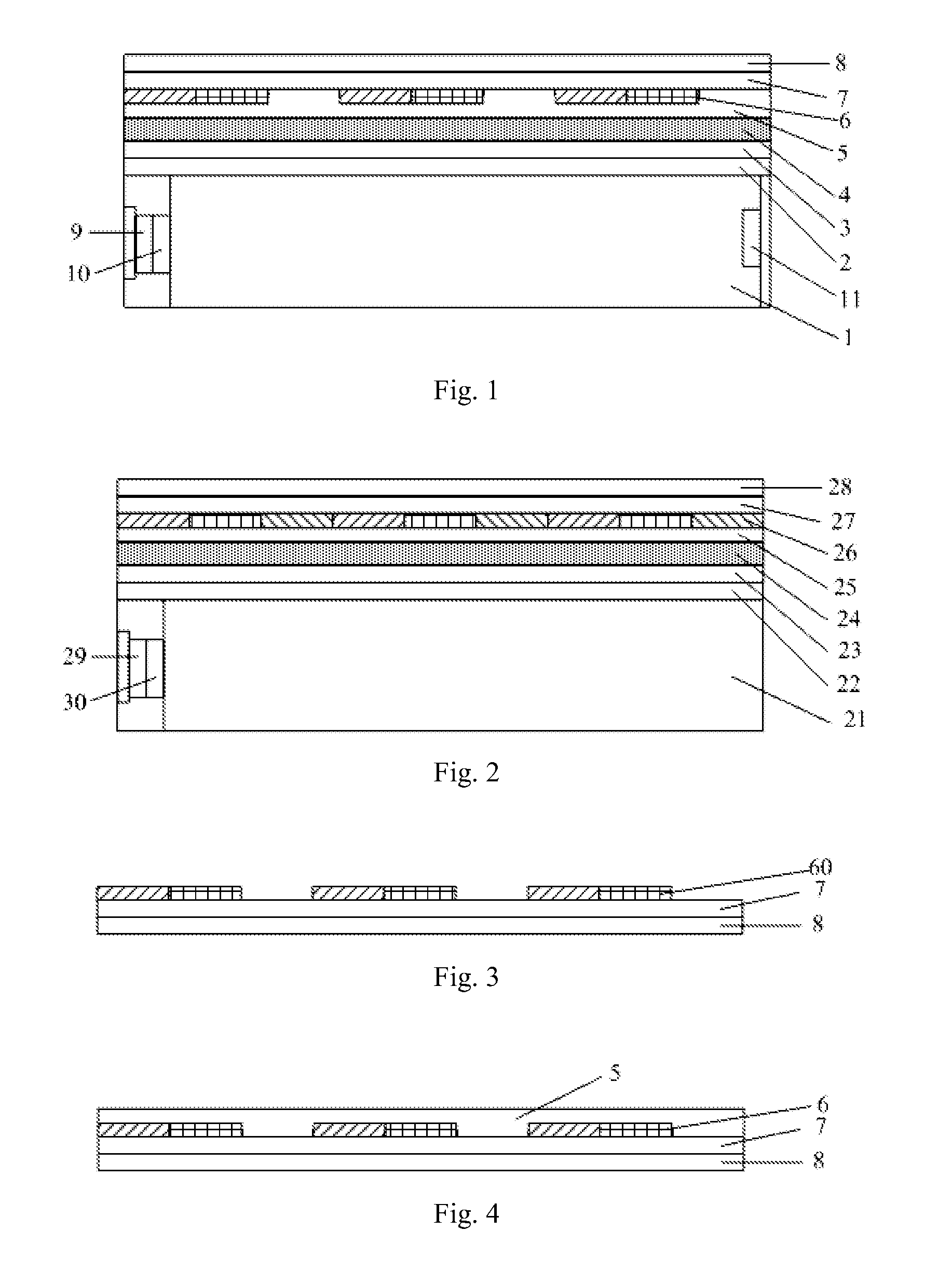

Display device

InactiveUS20150062201A1Enhanced brightnessReduce fabrication costCathode-ray tube indicatorsInput/output processes for data processingBlue filterLight filter

The present invention relates to a display device, including a display panel, a backlight module under the display panel and a driving circuit, wherein, a filter substrate of the display panel includes a plurality sets of filters each of which includes a red filter, a blue filter and a transparent filter; the backlight module includes a white backlight and a green backlight; and the driving circuit drives the white backlight to emit light and drives a red and blue pixels corresponding to the red and blue filters respectively to display at odd frames (or even frames), and drives the green backlight to emit light and drives a transparent pixel corresponding to the transparent filter to display at even frames (or odd frames). With the above technical solution, the Adobe RGB color coordinates can be met while a color of a mixed light can be adjusted and brightness can be enhanced.

Owner:BOE TECH GRP CO LTD +1

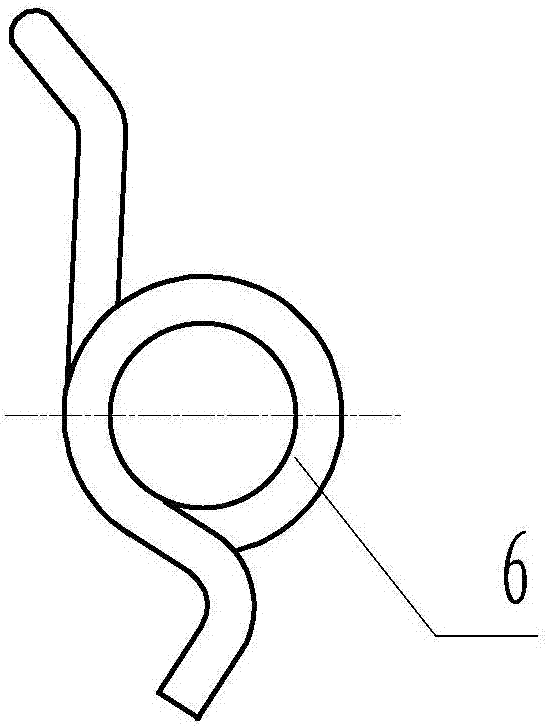

Double-body torsional spring forming device

PendingCN107486514AReduce labor intensityImprove pass rate and production efficiencyWind energy generationScrew thread

The invention provides a double-body torsional spring forming device. The longitudinal thickness of a base adapts to the length of a middle torsional arm of a double-body torsional spring; one side of the base is provided with a through groove which is through up and down and is matched with a spring wire of the double-body torsional spring in shape and diameter; the length of a forming shaft body of a forming shaft adapts to the length of a left spring body and a right spring body of the double-body torsional spring; the diameter of a smooth shaft body of the forming shaft adapts to the inner diameter of the left spring body and the right spring body of the double-body torsional spring; the bottom of a forming sleeve is provided with a longitudinal through hole with the hole diameter corresponding to the inner diameter of the left spring body and the right spring body of the double-body torsional spring and slightly greater than the diameter of the smooth shaft body of the forming shaft; a connection portion is arranged outside the bottom of the forming sleeve; the forming shaft body of the forming shaft is sleeved with the forming sleeve; a thread on a threaded hole of the forming sleeve is engaged with a matched thread on the periphery of the forming shaft body; the lower end of the smooth shaft body of the forming shaft downwards penetrates through the longitudinal through hole in the bottom of the forming sleeve and a longitudinal connection through hole of the base; the lower portion of the smooth shaft body is fixedly assembled in the longitudinal connection through hole; and a handle is connected to the outer portion of the forming sleeve.

Owner:CHONGQING WANGJIANG IND

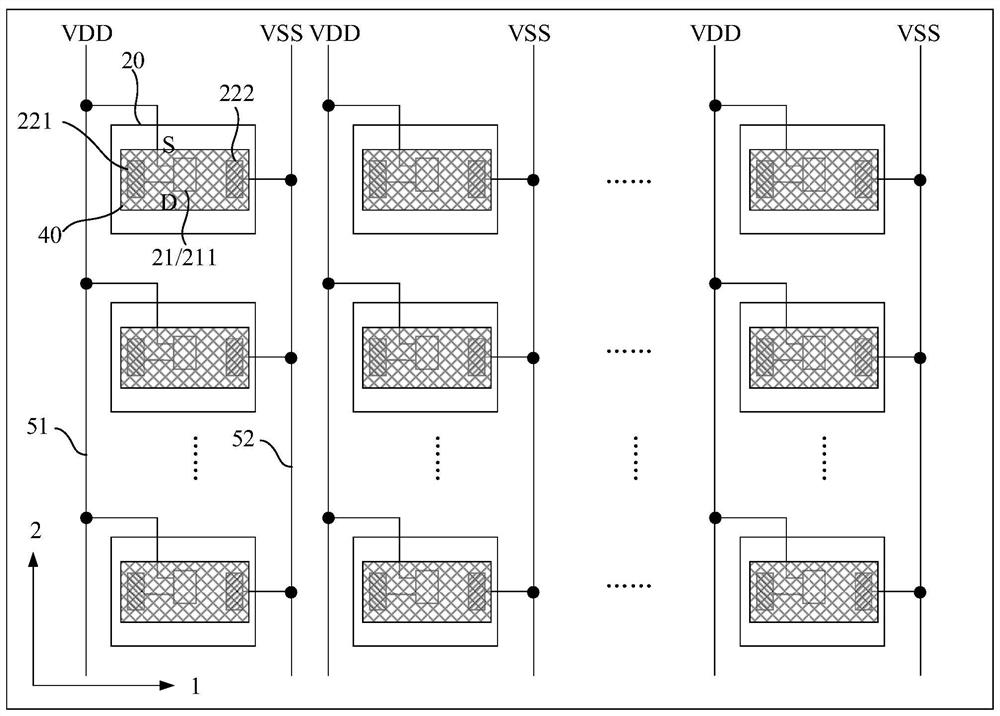

Array substrate, backlight module, display panel, display device and preparation method

ActiveCN111913323ASolve the complex preparation processSimple manufacturing processStatic indicating devicesSemiconductor lamp usageDisplay deviceThin membrane

The embodiment of the invention discloses an array substrate, a backlight module, a display panel, a display device and a preparation method. The array substrate comprises a plurality of driving units. Each driving unit comprises a first electrode, a second electrode and at least one thin film transistor; the first electrode and the second electrode are used for being connected with the anode andthe cathode of a light emitting diode respectively, so that the vertical projection of the light emitting diode on the array substrate can be overlapped with the at least one thin film transistor, andthe thin film transistor is located at the backlight side of the light emitting diode in the light emitting direction of the light emitting diode. The driving unit controls the light-emitting diode to be turned on or off according to the driving signal. According to the embodiment of the invention, the problem that an existing array substrate needs to be additionally provided with a shading layer, so that the preparation process is complex, is solved; the influence of external illumination on the thin film transistor can be avoided, masks and preparation procedures required for preparing theshading layer are saved, the preparation process of the array substrate is simplified, and the manufacturing cost is reduced.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

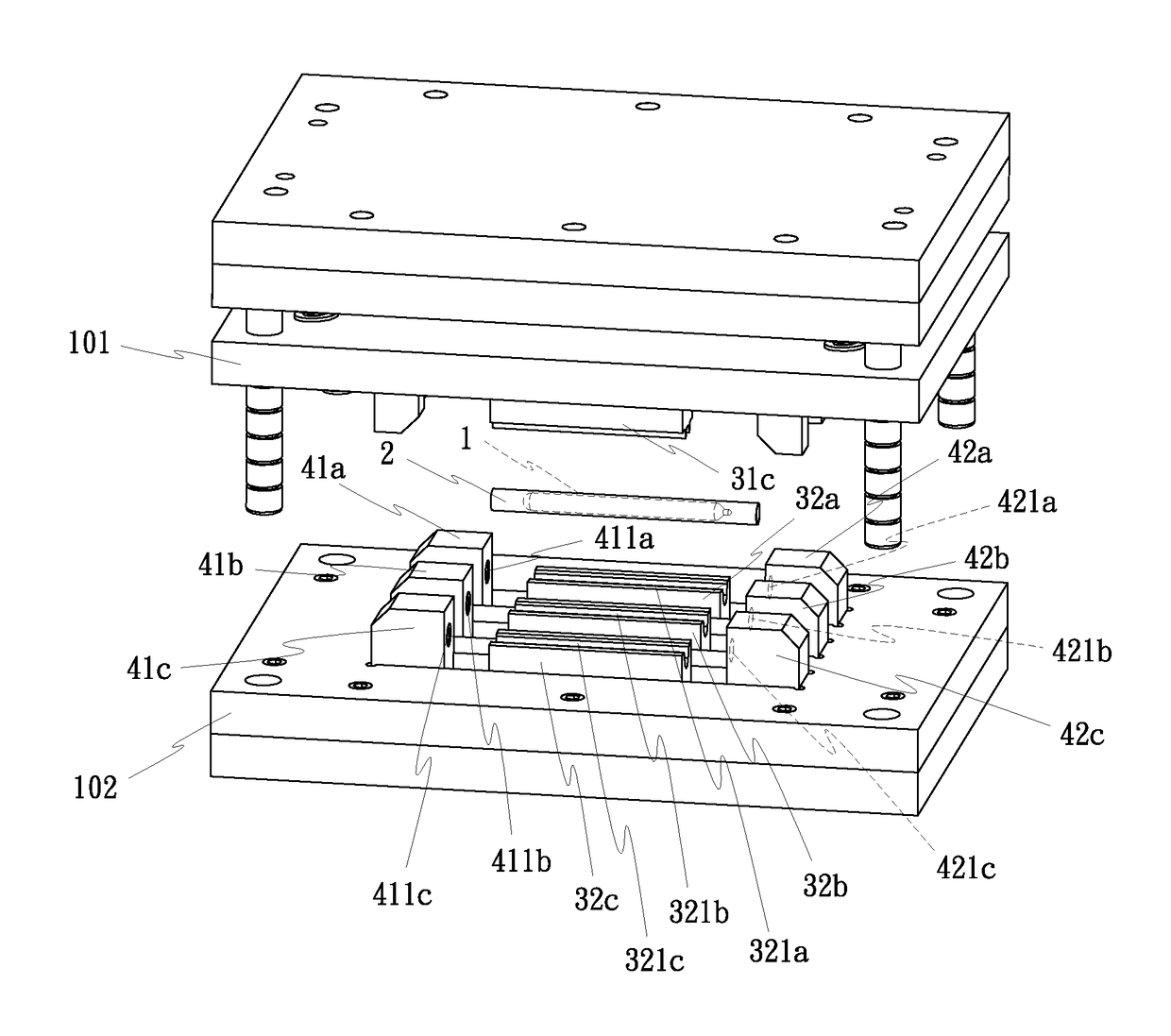

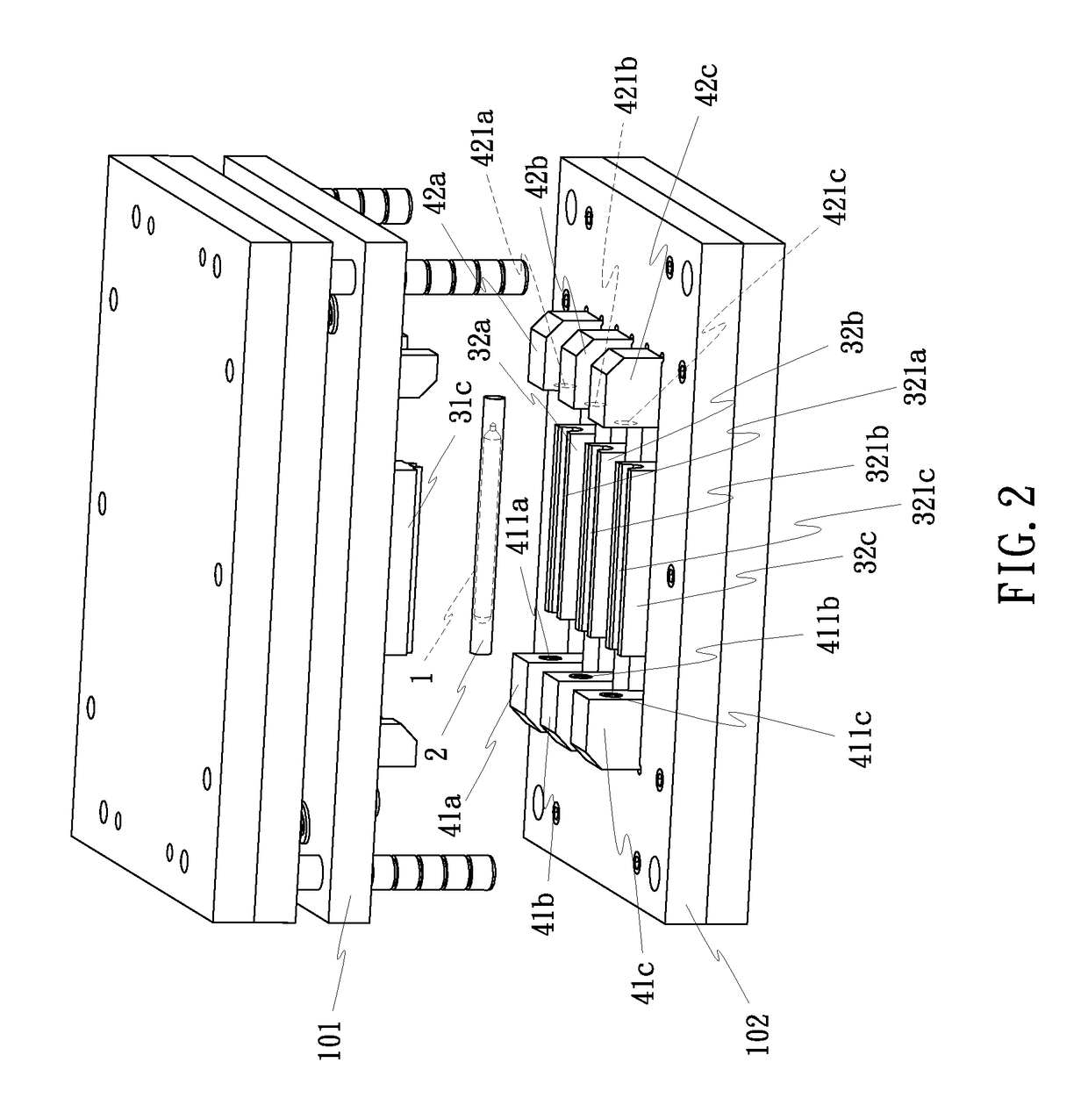

Die for forming lens, lens, and method for manufacturing lens

Owner:E PIN OPTICAL IND

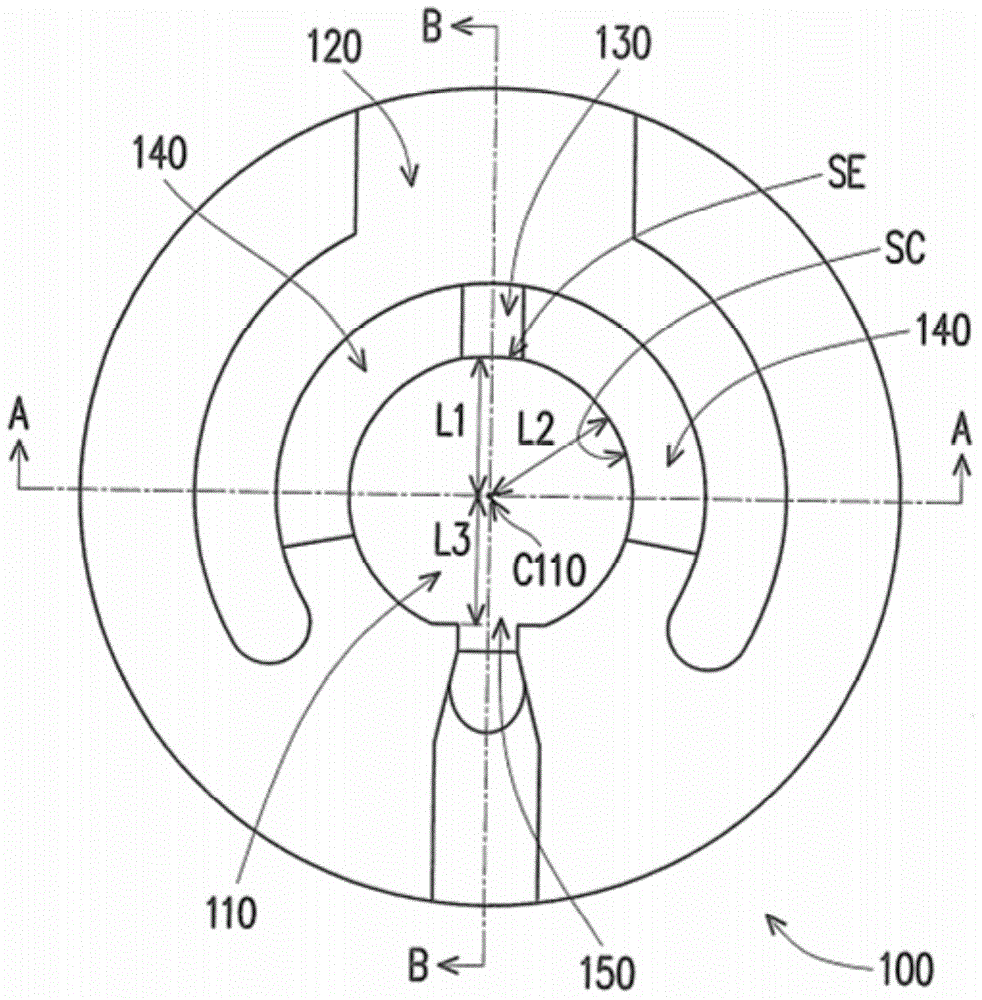

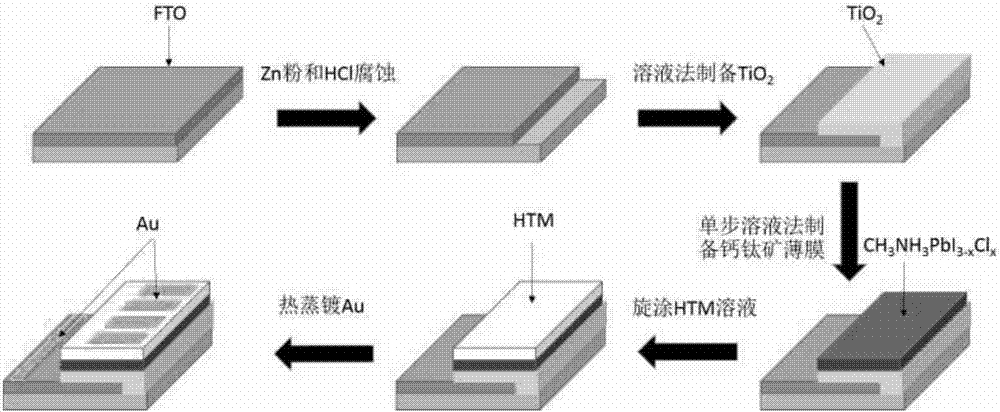

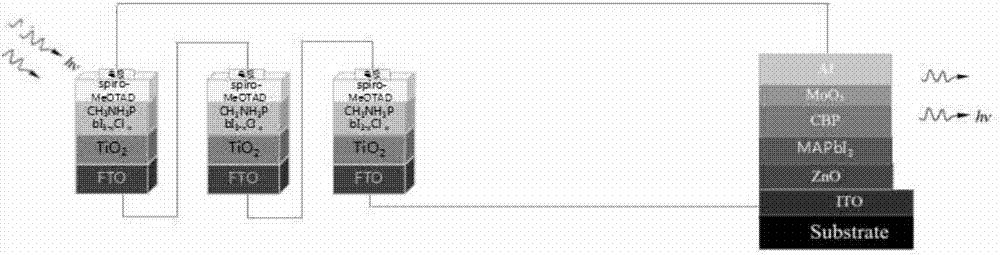

Integrated full perovskite solar energy cell and LED display system and manufacturing method thereof

InactiveCN106981500AReduce energy consumptionFast evaporation rateFinal product manufactureSolid-state devicesElectrical batteryClosed loop

The invention discloses an integrated full perovskite solar energy cell and LED display system and a manufacturing method thereof. A single step solution method is employed to grow a MAPbI3-xClx film, through leads, an anode of a perovskite solar energy cell is connected in series with a cathode of an LED display device, a cathode substrate of the perovskite solar energy cell is connected in series with an anode substrate of the LED display device, a closed loop is formed, solar energy is absorbed by the solar energy cell, electric energy is then emitted to supply power for the LED display device, integrated spin coating manufacturing of the solar energy cell and the LED display device is accomplished, and the full perovskite system is realized. Raw materials are relatively easy to get, the raw materials are saved, and the manufacturing operation has better economic effects The method is further advantaged in that the perovskite solar energy cell and the LED display with high-efficiency are manufactured, integration is lastly carried out, operation is simple, production line manufacturing is convenient, the materials are saved, time and energy are saved, and large-scale production is easy.

Owner:SHANGHAI UNIV

Package method electronic ship made from wafen

The method for packaging electronic chip element made of wafer includes the following steps: 1. making electronic chip elements on the wafer and making them spaced and arranged; 2. in the above-mentioned wafer etching the portion where the electronic chip elements are not formed to obtain slot; 3. utilizing vacuum film-pressing equipment to cover the wafer with etched slot with photo resist film or soaking the whole wafer in the container tank with photoresist, so that the whole wafer is covered with a layer of photoresist; 4. heating wafer and drying the photo resist film or photoresist to make it tightly combined on the wafer; and 5. finally, separating out the electronic chip elements from the wafer so as to obtain the packaged electric chip element unit.

Owner:CYNTEC

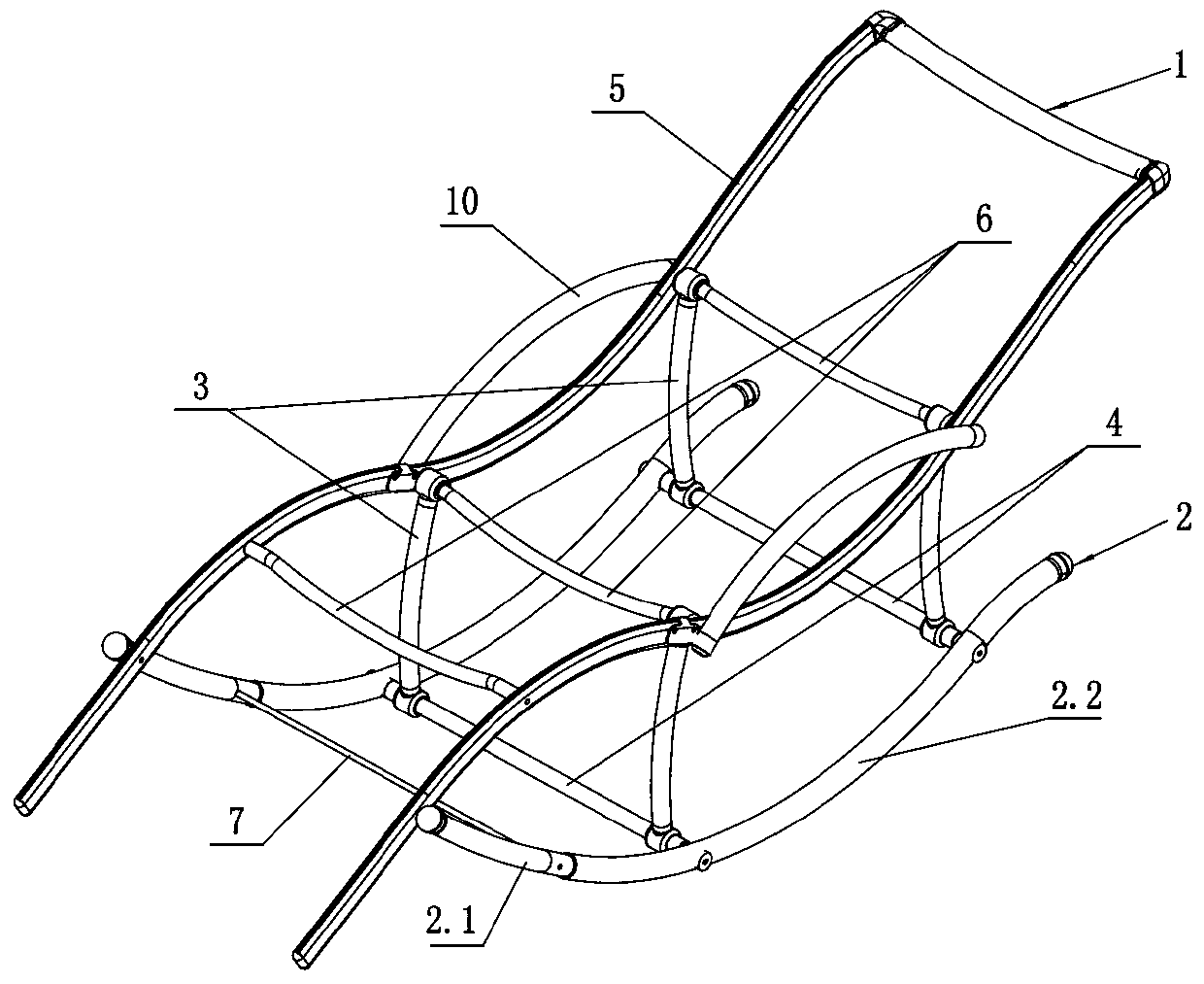

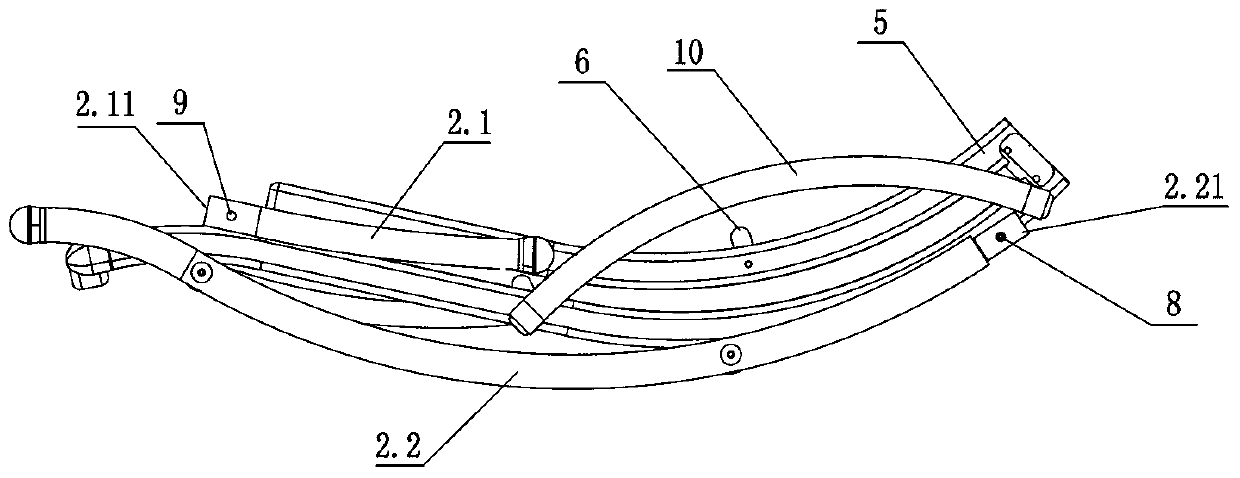

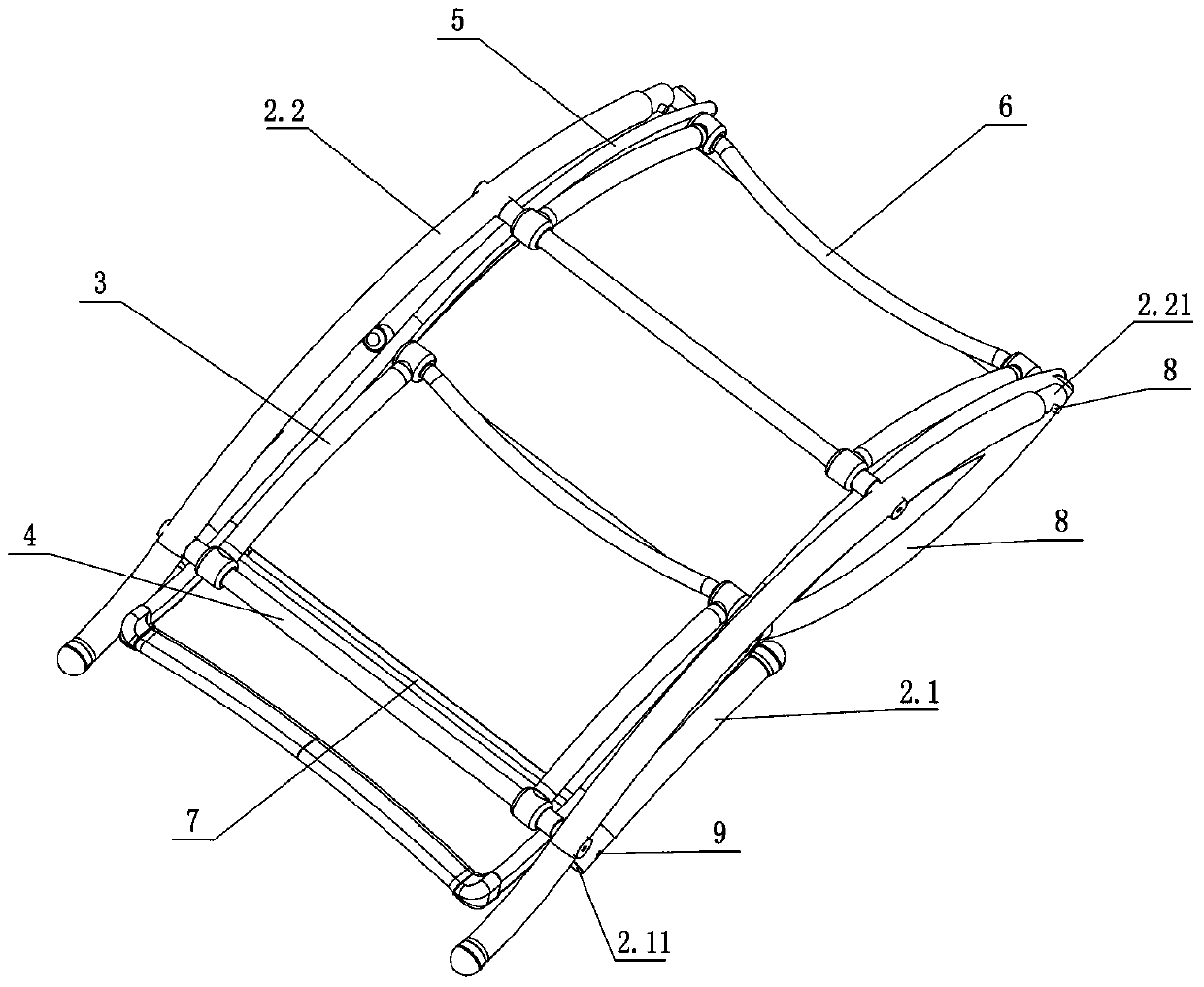

Folded rocking chair

ActiveCN103340524ADoes not affect volumeTo achieve the comfort of useDismountable chairsFoldable chairsEngineering

Owner:宁波蒙恩铝业有限公司

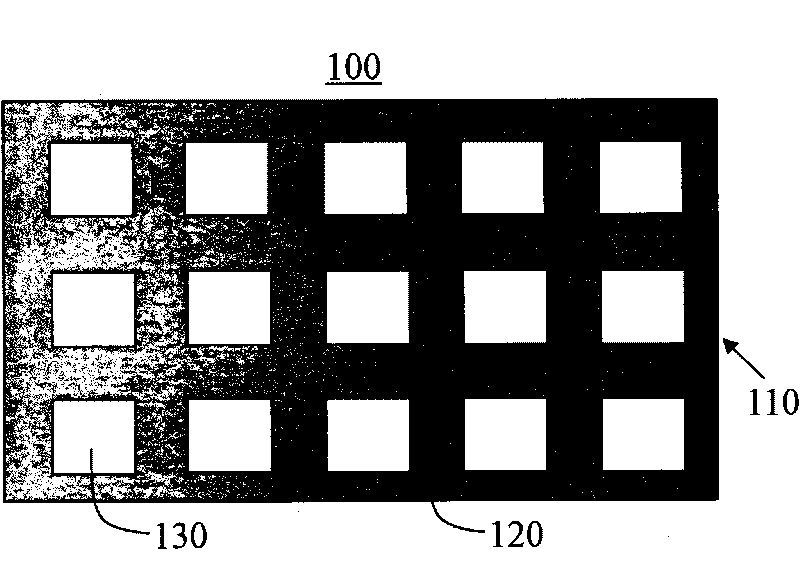

Colored filter and manufacturing method thereof

InactiveCN101702041AReduce manufacturing costIncrease productivityOptical filtersNon-linear opticsColor gelEngineering

Owner:SHENZHEN LAIBAO HI TECH

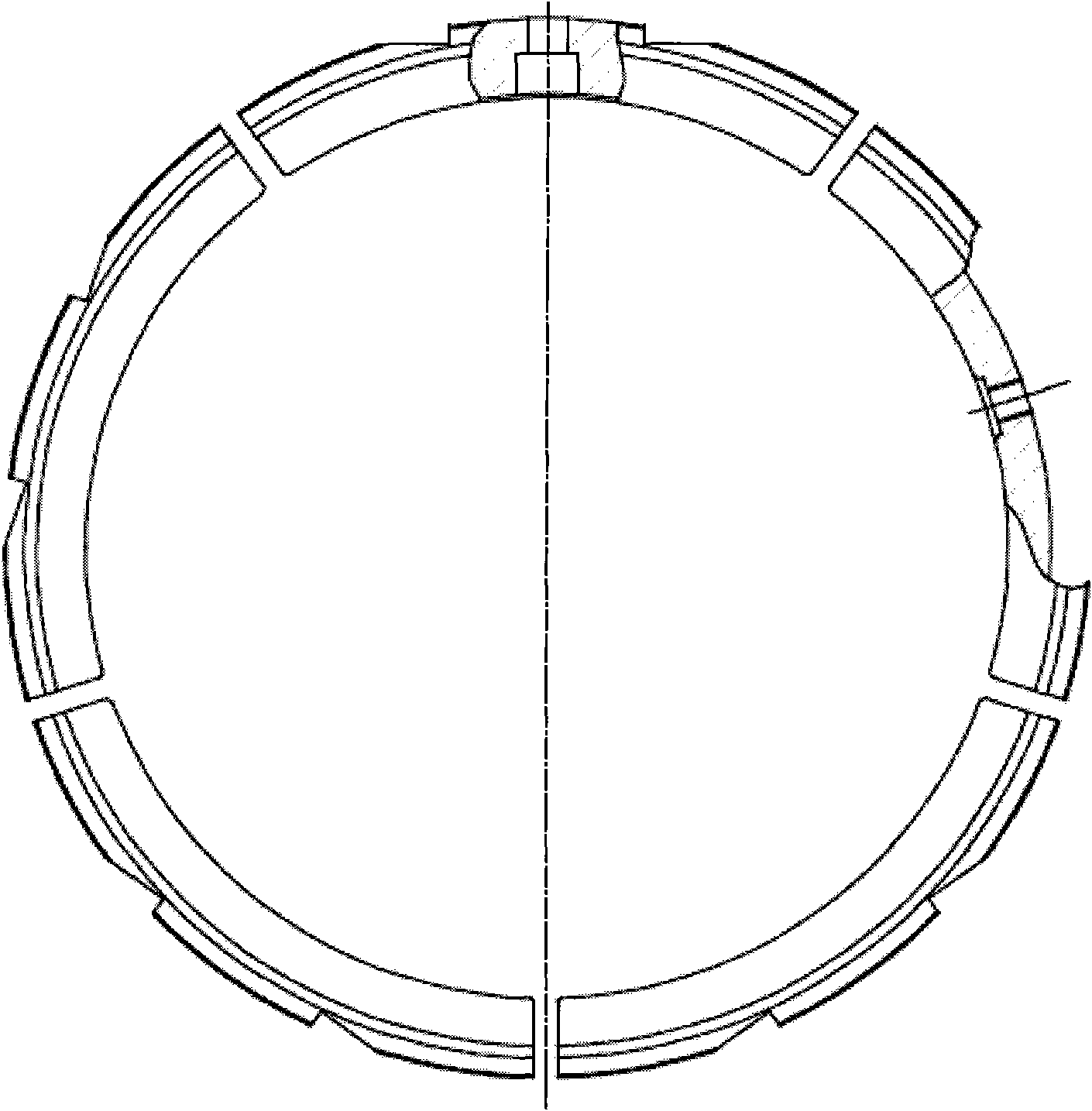

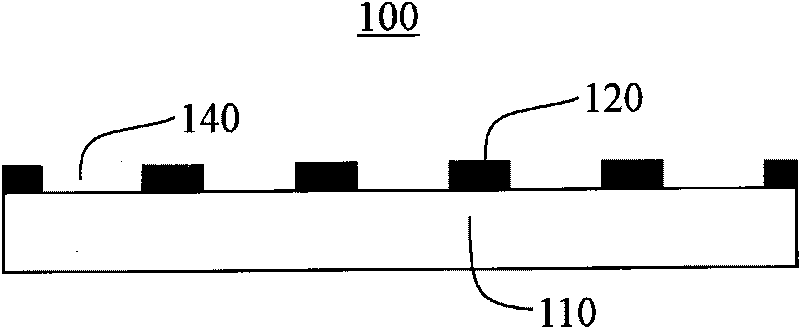

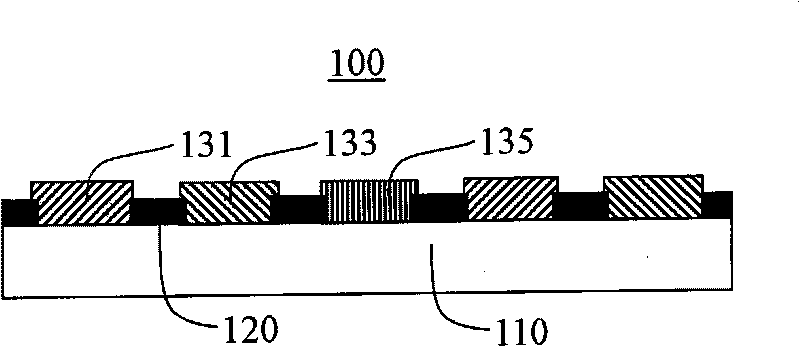

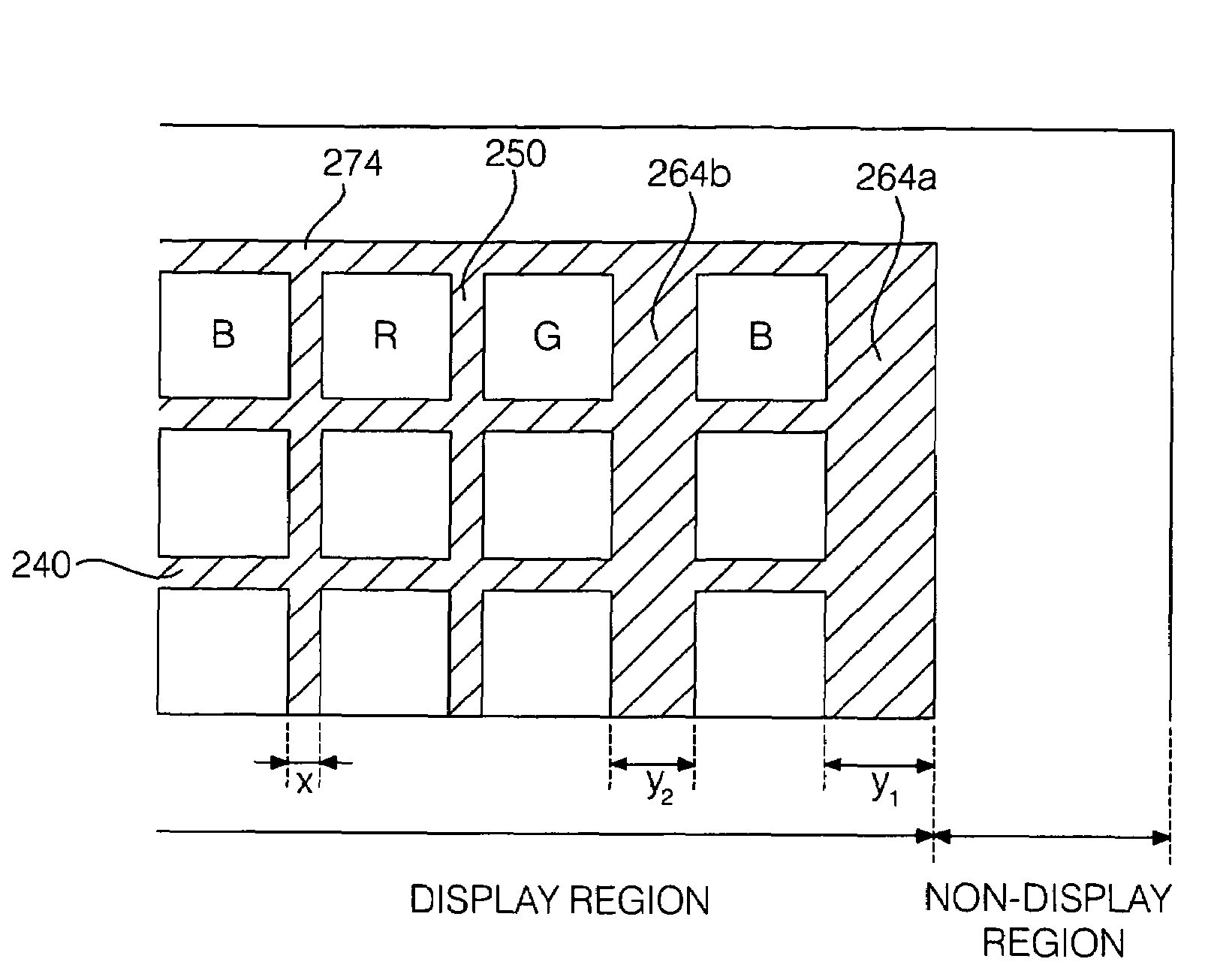

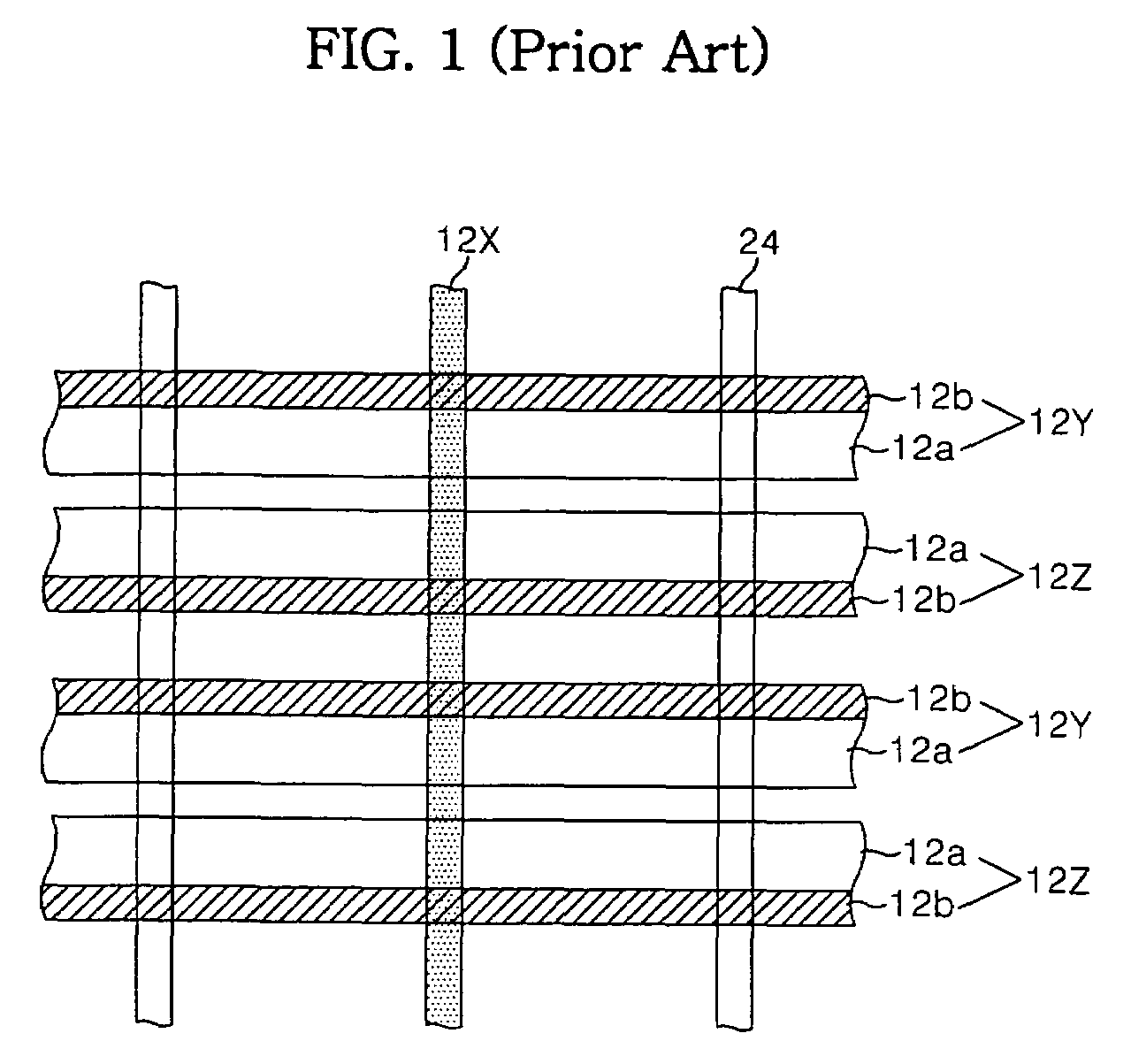

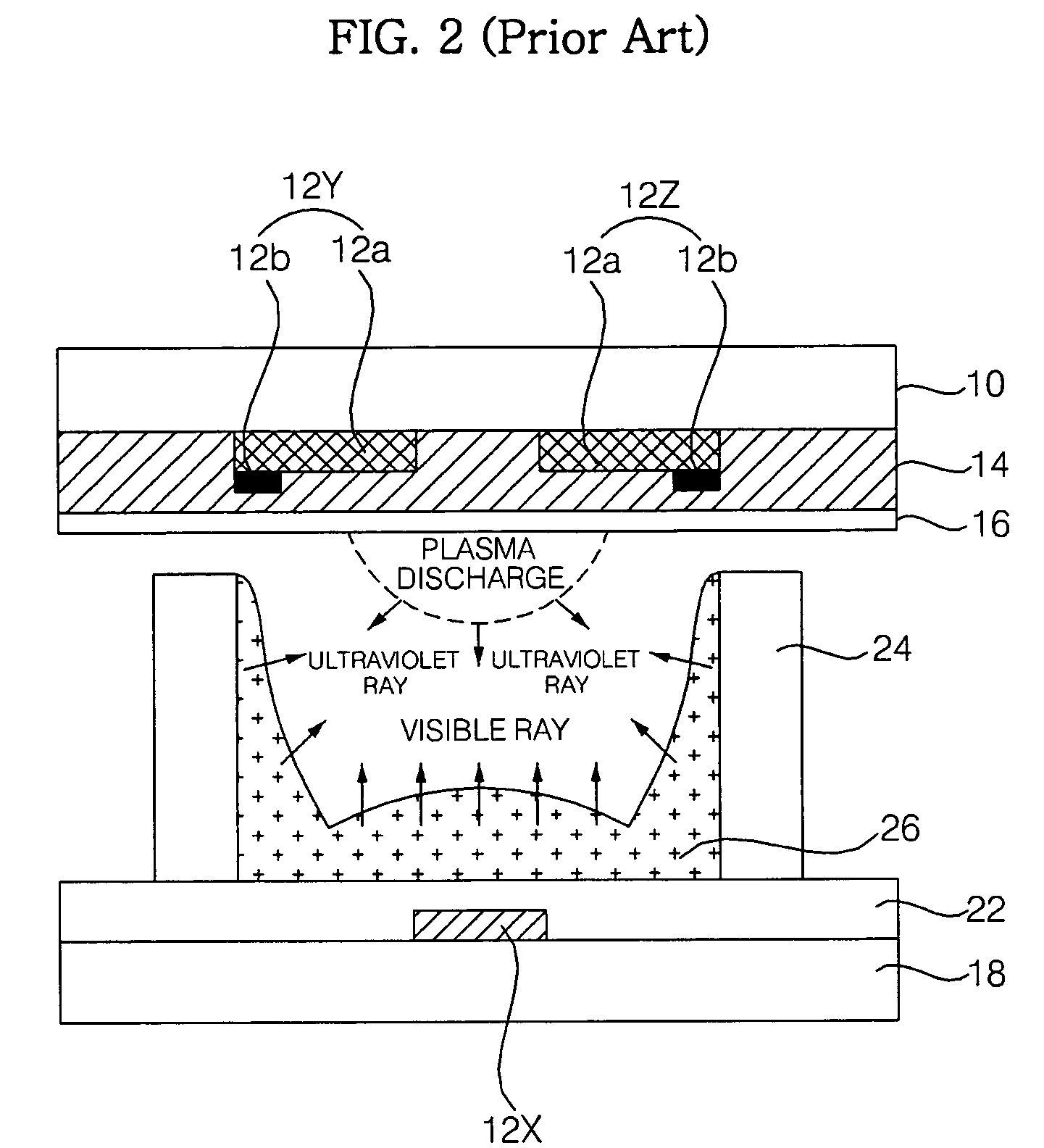

Plasma display panel with improved barrier ribs

InactiveUS7683543B2Save manufacturing processNoise minimizationIncadescent body mountings/supportElectrode assembly support/mounting/spacing/insulationEngineeringPlasma display

The present invention relates to a plasma display panel. According to the present invention, a width of an inner barrier rib formed in an inner region within a display region of a rear substrate is smaller than a width of an outer barrier rib formed in an outer region of the rear substrate. Therefore, the barrier ribs can be prevented from being damaged due to pressure applied when a front substrate and the rear substrate are adhered. Furthermore, a height of the inner barrier rib and a height of the outer barrier rib are substantially the same. It is thus possible to minimize noise incurred by a step between the barrier ribs.

Owner:LG ELECTRONICS INC

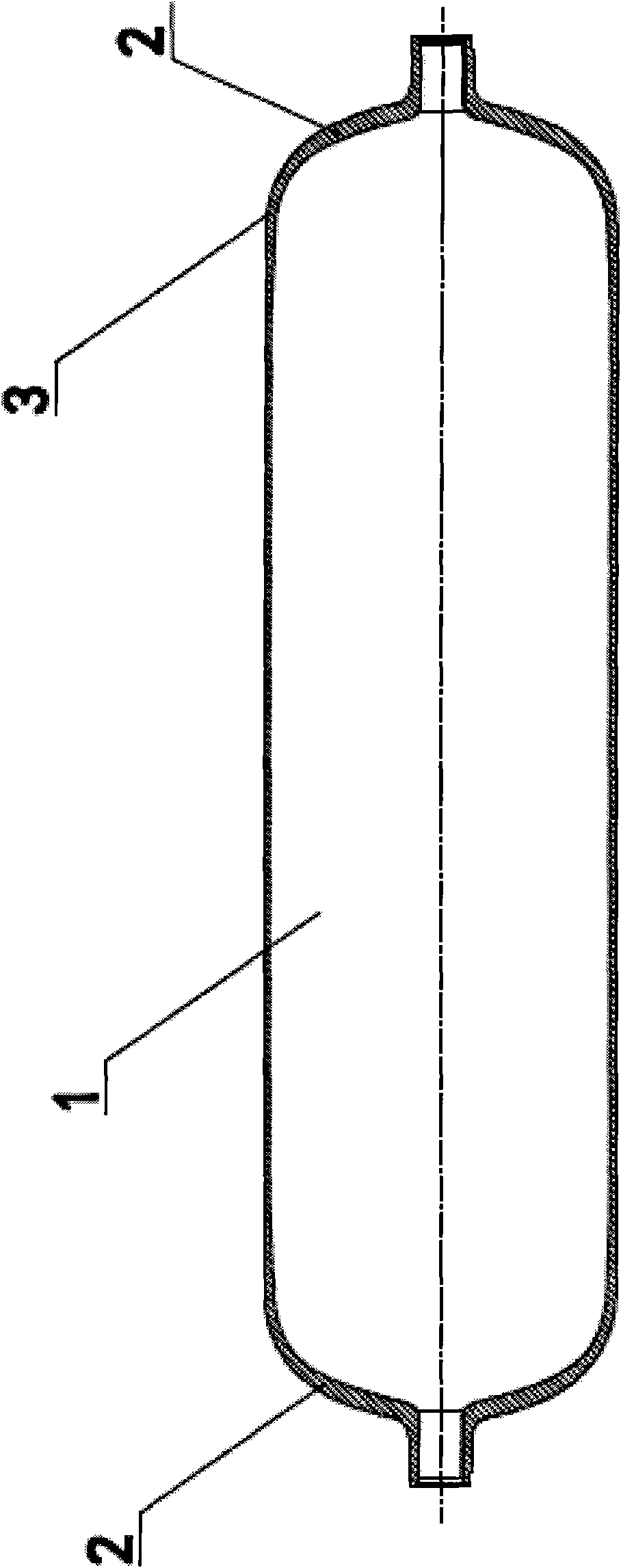

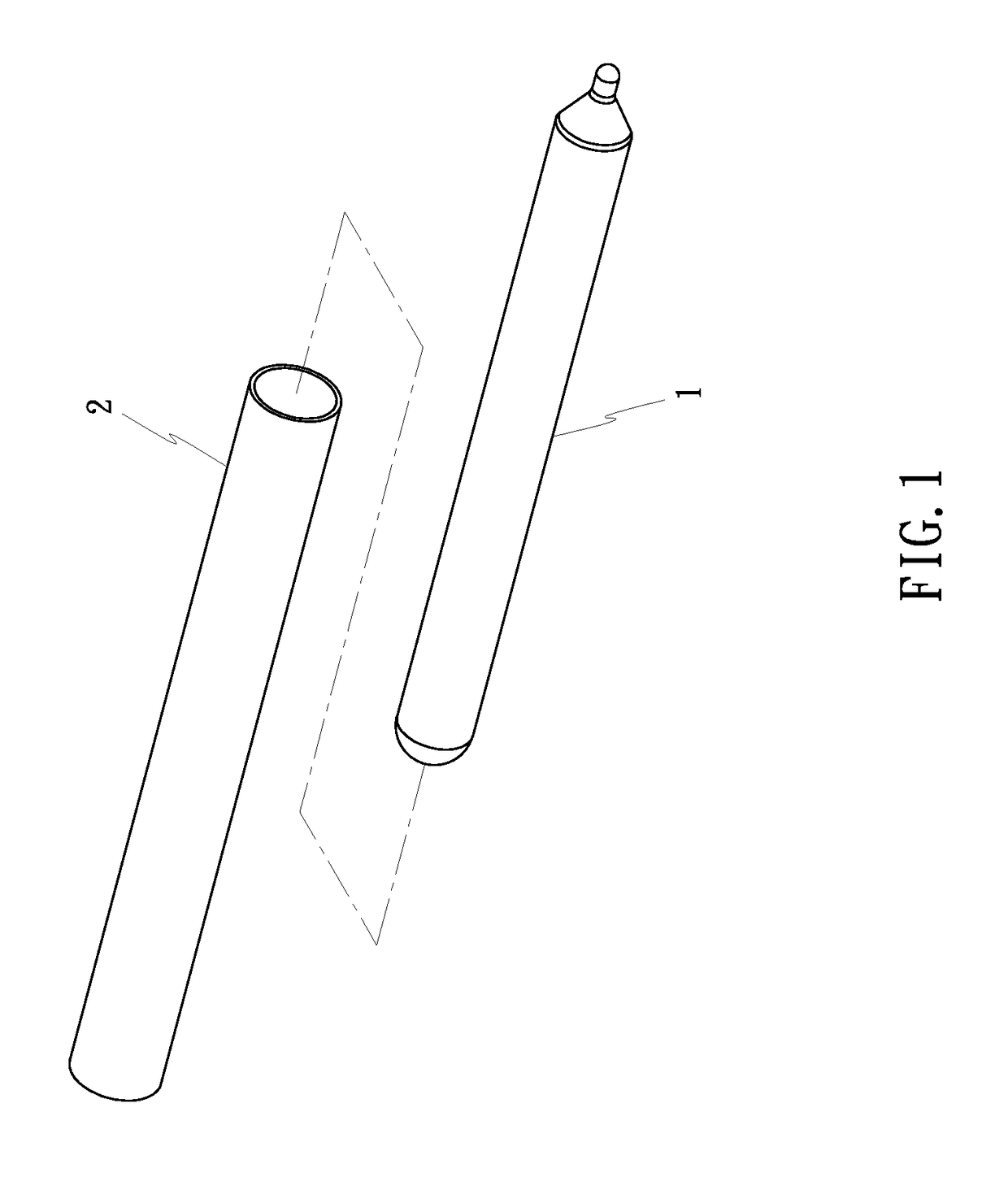

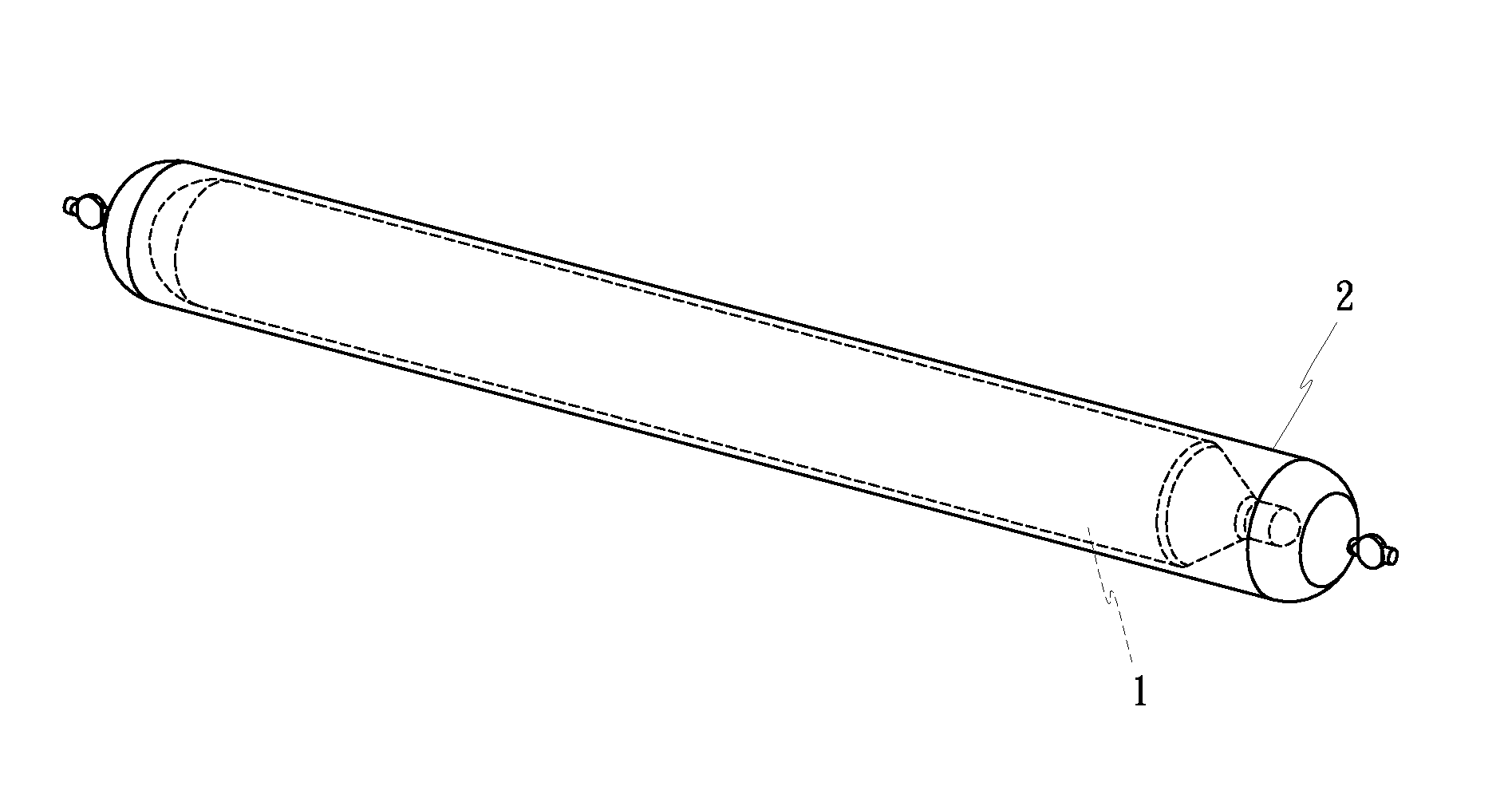

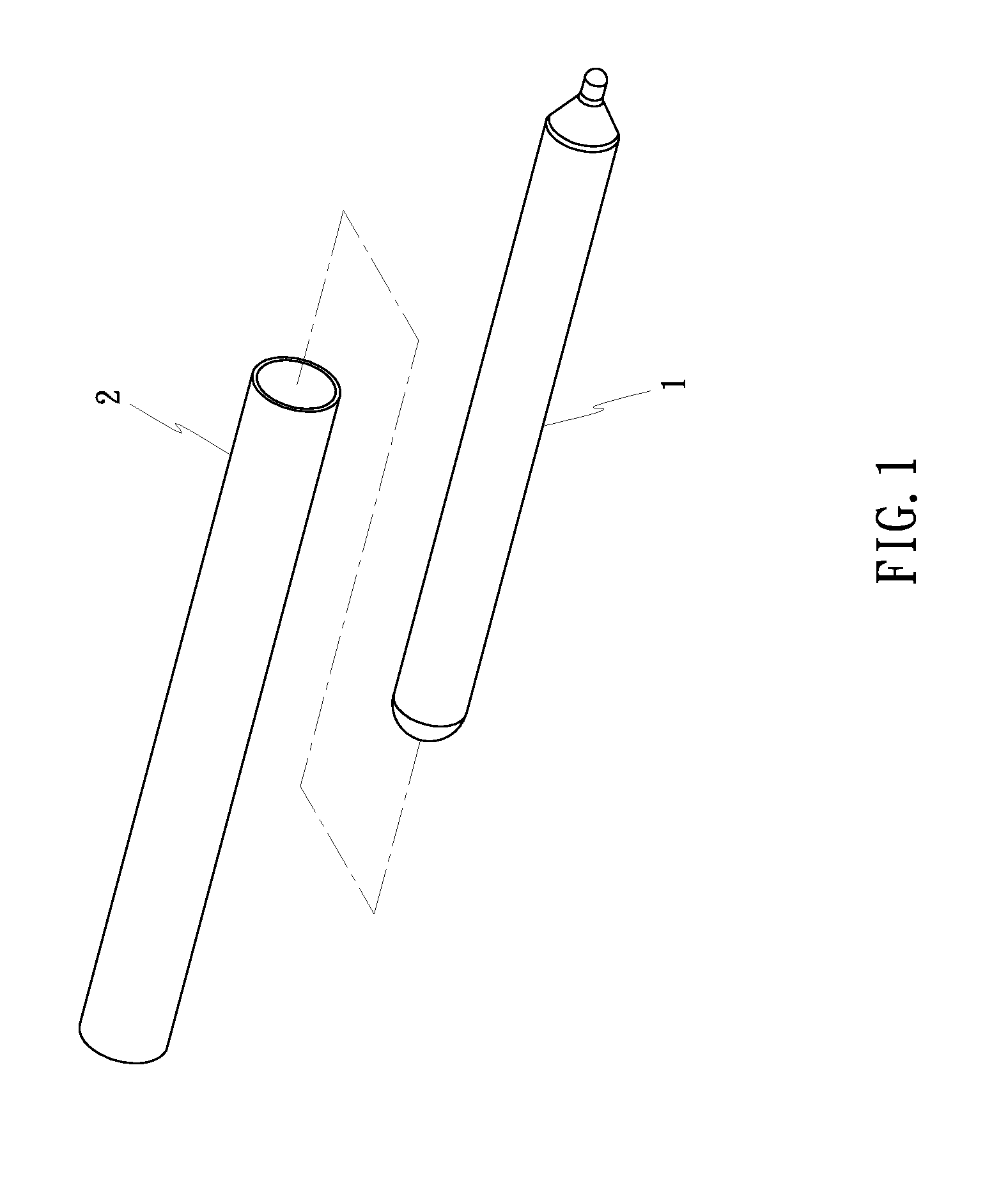

Aluminum pipe and heat pipe package and its packaging method

ActiveUS9664453B2Simple processSave manufacturing processIndirect heat exchangersHeat exchange apparatusMetallurgyShell molding

An aluminum pipe and heat pipe package is formed by inserting a heat pipe into a hollow aluminum pipe, and then processing the combination of the heat pipe and hollow aluminum pipe through a series of extrusion molding steps. The extrusion molding steps are performed by means of opposing top and bottom extrusion dies and opposing left and right necking dies to reduce the gap between the hollow aluminum pipe and the heat pipe. Consequently, the hollow aluminum pipe and the heat pipe are peripherally tightly fitted together, and the two opposite open ends of the hollow aluminum pipe are completely blocked up.

Owner:HUANG TSUNG HSIEN

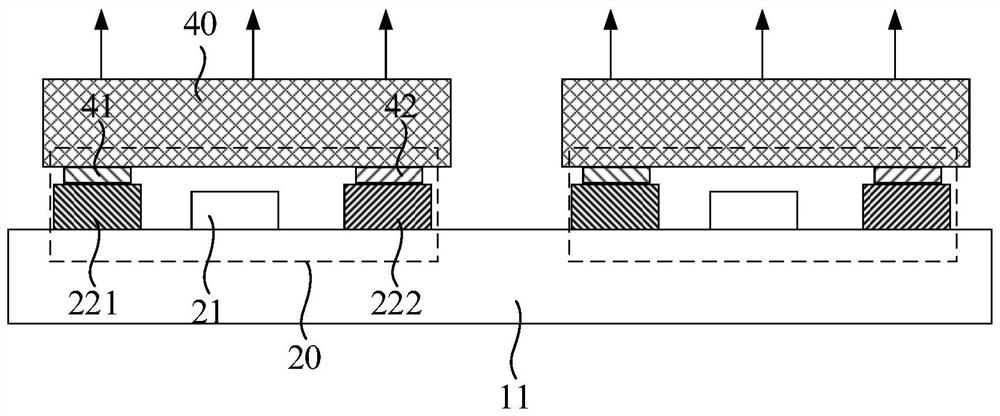

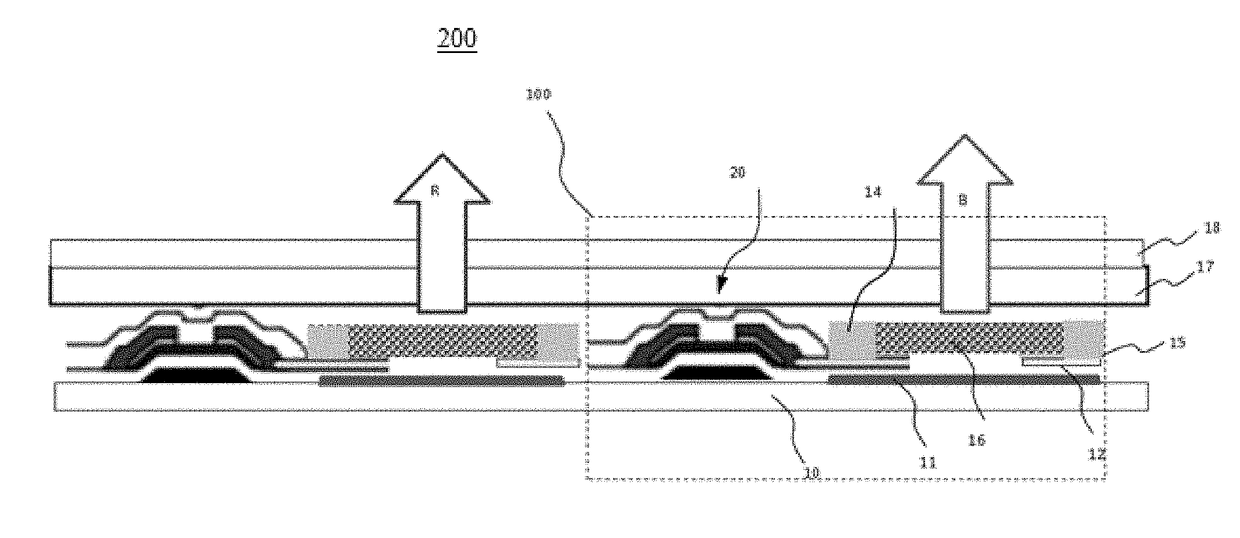

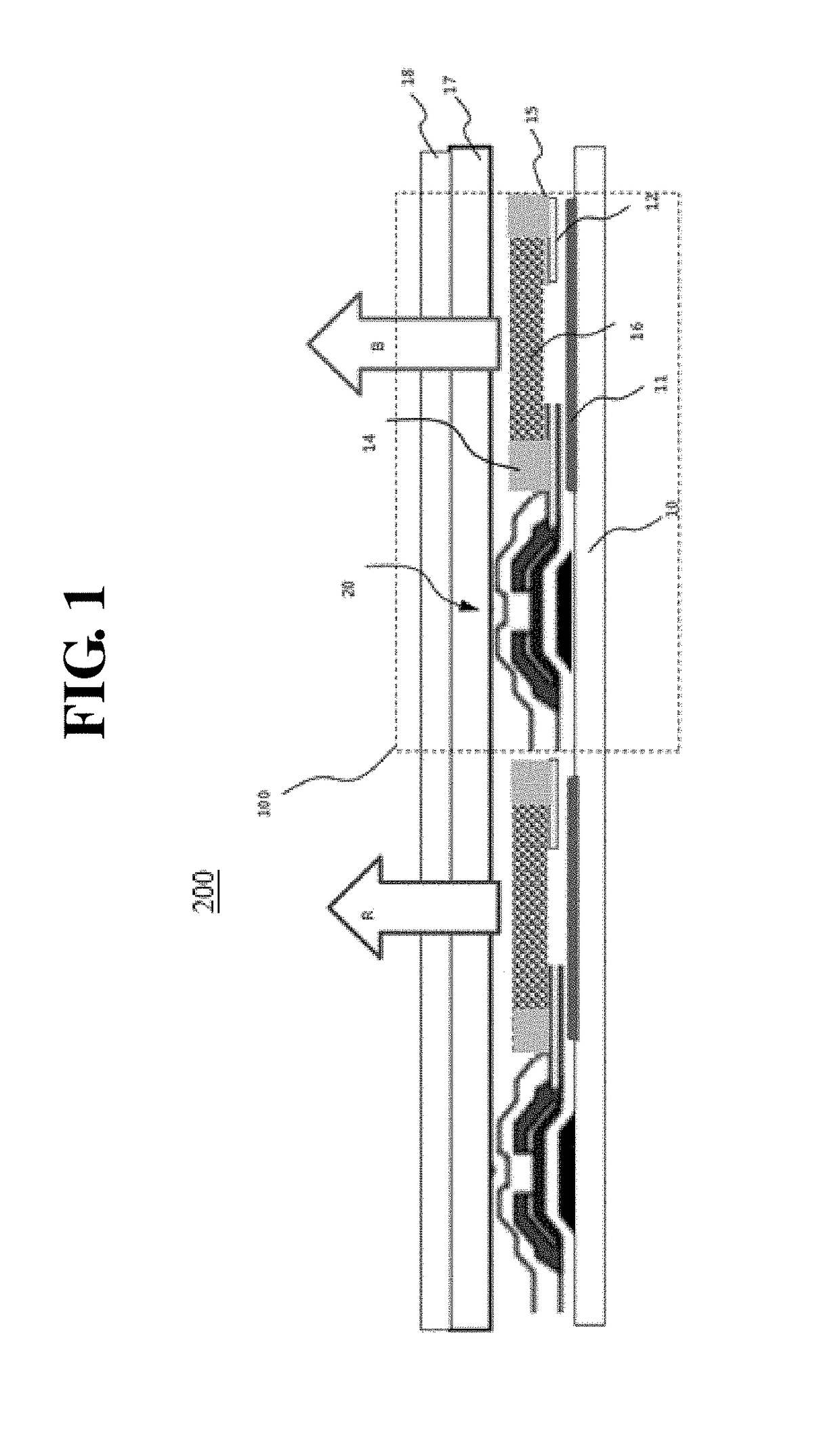

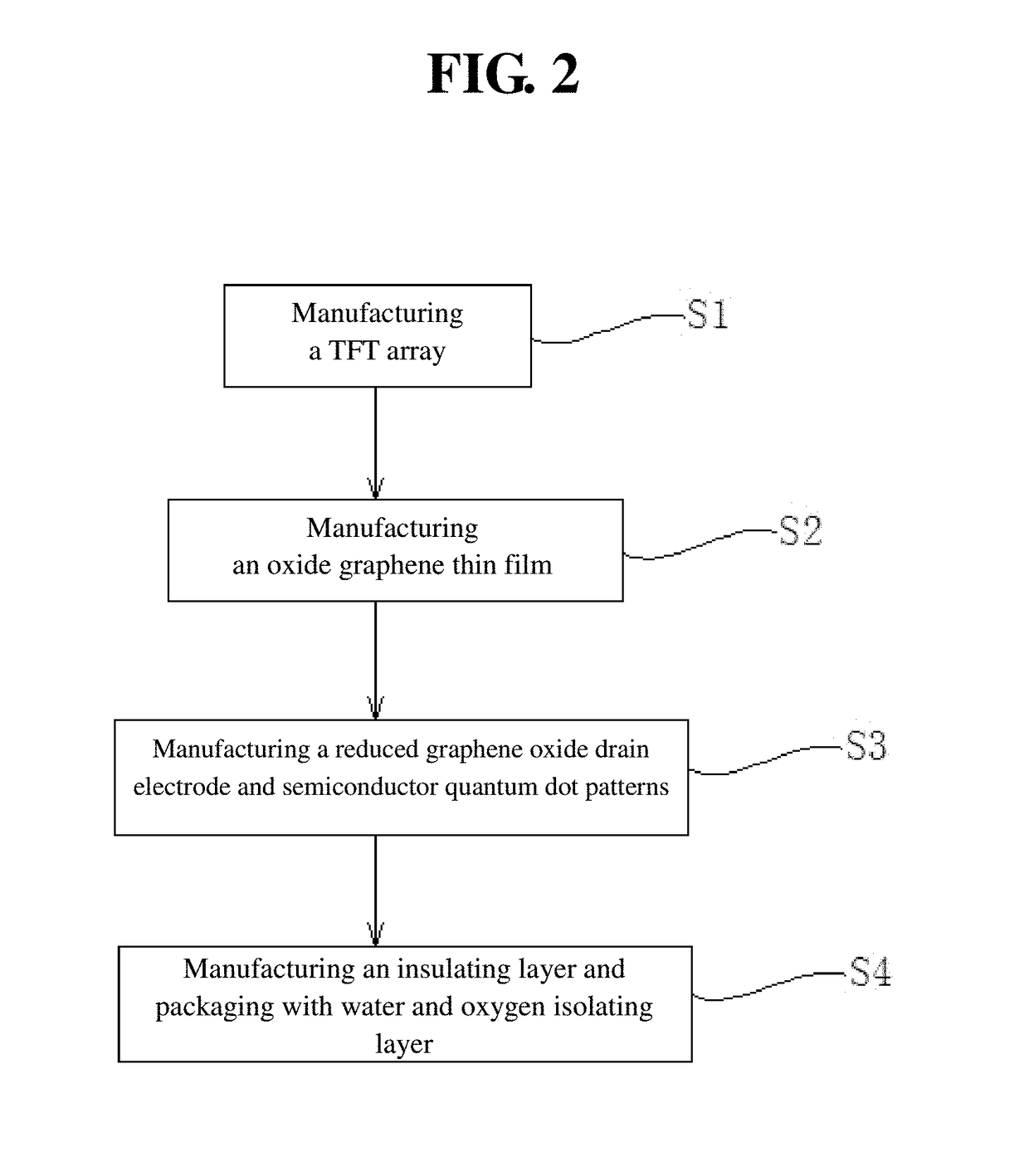

Graphene light emitting display and method of manufacturing the same

InactiveUS20180294377A1Increase the areaIncrease brightnessSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

A graphene light emitting display and a method of manufacturing the same are disclosed. The method comprises: manufacturing a graphene oxide (GO) thin film on a surface of a substrate with a thin film transistor formed thereon; providing a photomask corresponding to the GO thin film to form a source electrode, a drain electrode and a graphene quantum dot layer of a graphene light emitting transistor; and wherein the photomask includes: a complete transparent part corresponding to the region in which the source electrode and the drain electrode are located; a light blocking part corresponding to the region in which the thin film transistor is located; and a semitransparent part corresponding to the region in which the graphene quantum dot layer is located; wherein an insulating layer and a water and oxygen isolating layer are formed sequentially on a surface of the substrate with the graphene light emitting transistor formed thereon.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

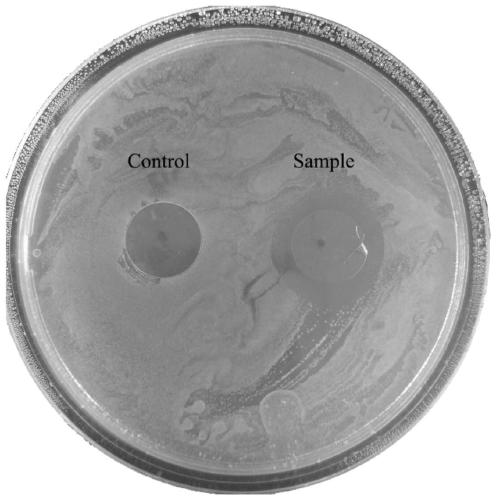

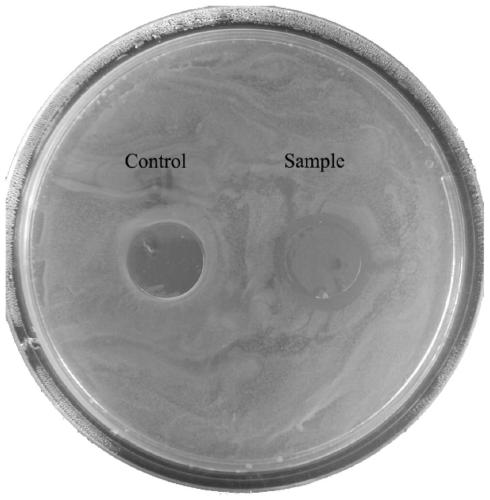

In-situ preparation method of antibacterial cellulose film, antibacterial cellulose film prepared with method and application of antibacterial cellulose film

The invention relates to an in-situ preparation method of an antibacterial cellulose film, the antibacterial cellulose film prepared with the method and an application of the antibacterial cellulose film. The method comprises steps as follows: cellulose pulp boards are crushed, and cellulose powder is obtained; the cellulose powder is dissolved in a compound solvent formed by an ionic liquid and zinc chloride, and a cellulose solution is obtained; the cellulose solution is left to stand for defoaming and applied to a substrate material to form a cellulose solution layer, and the cellulose solution layer is levelled; the substrate material coated with the cellulose solution layer is put in a sodium hydroxide solution, so that cellulose is solidified and regenerated; a coagulating bath is subjected to ultrasonic treatment, and nano zinc oxide modified wet cellulose film is obtained and cleaned; the cleaned wet film is aired at the room temperature, and nano zinc oxide modified dry cellulose film is obtained; the dry cellulose film is put in an oven to be heated, and the antibacterial cellulose film is obtained. The antibacterial cellulose film overcomes the defects of long manufacturing time and poor antibacterial performance of zinc oxide modified dry cellulose films in the prior art and is more practical.

Owner:BEIJING FORESTRY UNIVERSITY

Water pump and clothes caring machine provided with water pump

ActiveCN106256949ASolve the occupied spaceSolve the costOther washing machinesTextiles and paperImpellerInlet channel

The invention discloses a water pump and a clothes caring machine provided with the water pump. The water pump comprises a pump body, a motor arranged in the pump body, a motor shaft and a water inlet channel connected with the pump body. The water pump further comprises a first pump cavity and a second pump cavity which are formed in the pump body and communicated with the water inlet channel, a first impeller and a second impeller which are arranged in the first pump cavity and the second pump cavity respectively and connected with the motor shaft, and a circulating water channel and a drainage channel which are communicated with the first pump cavity and the second pump cavity respectively. When the first impeller rotates, the first pump cavity discharges water in the first pump cavity into the circulating water channel. When the second impeller rotates, the second pump cavity discharges water in the second pump cavity into the drainage channel. The water pump solves the problems that in the prior art, a circulating drainage pump occupies large space and is high in cost; on one hand, the circulating drainage function is achieved through the motor, energy is saved, and water discharge is reduced; on the other hand, compared with a traditional one-way circulating drainage pump, space is saved, material cost is reduced, and the process is saved.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

Aluminum pipe and heat pipe package and its packaging method

ActiveUS20160146544A1Simple processSave manufacturing processLayered productsIndirect heat exchangersHeat pipeComposite material

An aluminum pipe and heat pipe package formed by inserting a heat pipe into a hollow aluminum pipe, and then processing the combination of the heat pipe and hollow aluminum pipe through a series of extrusion molding steps by means of opposing top and bottom extrusion dies and opposing left and right necking dies to reduce the gap between the hollow aluminum pipe and the heat pipe, and to have the hollow aluminum pipe and the heat pipe to be peripherally tightly fitted together, and the two opposite open ends of the hollow aluminum pipe to be completely blocked up.

Owner:HUANG TSUNG HSIEN

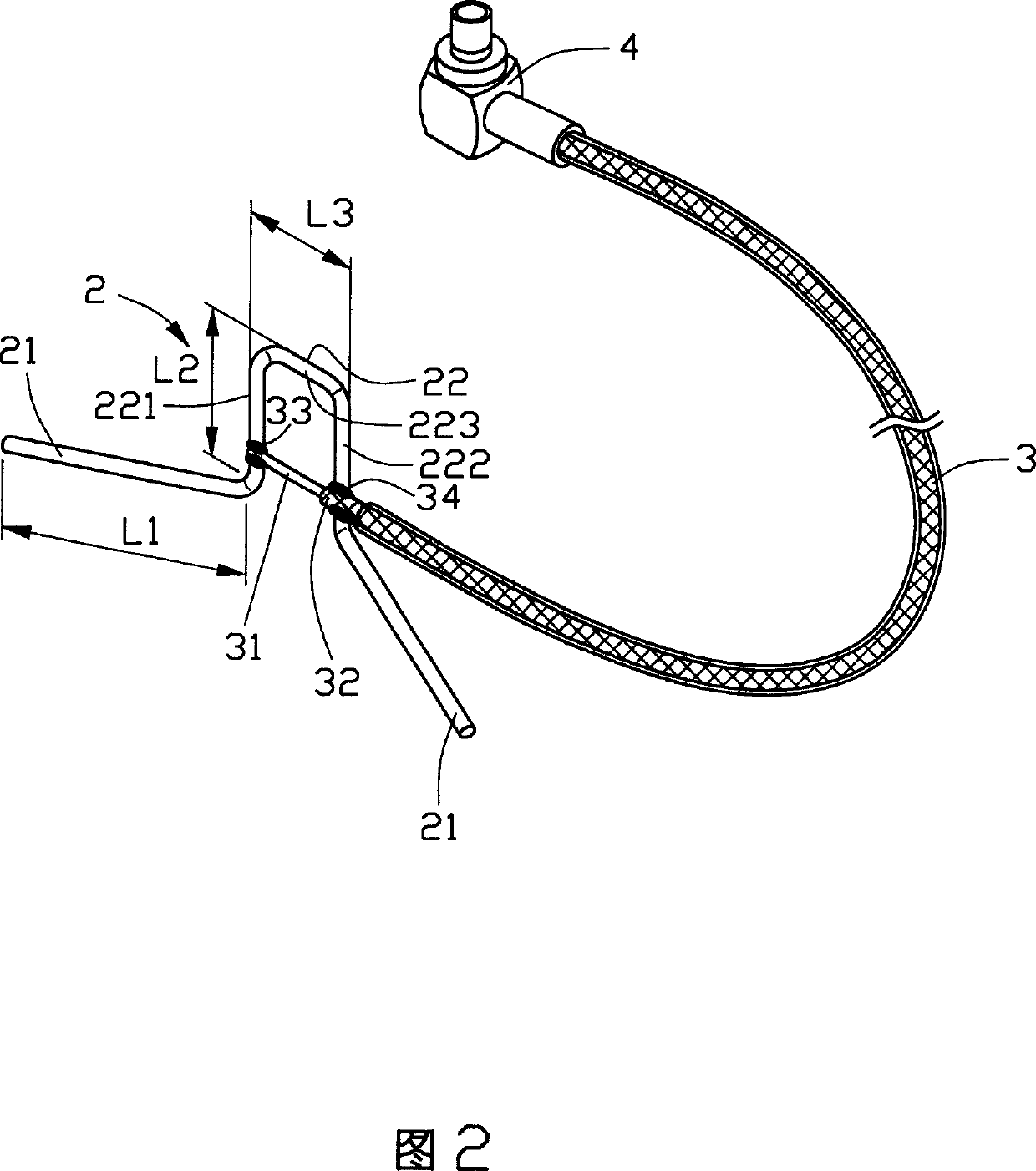

Antenna

InactiveCN1159799CSavings in antenna manufacturing and assembly processesAchieve connectionAntenna supports/mountingsRadiating elements structural formsDipole antennaEngineering

The antenna set inside some electronic equipment includes dipole antenna and feeder line, the dipole antenna includes connecting part with at least one first side wall and one second side wall and two metal arms, and the feeder line includes two conductors. The two metal arms extends separately beyond the first side wall and the second side wall and the two conductors are connected separately to the first side wall and the second side wall to form the first joint point and the second joint point. The said mode can simplify the connection between feeder line and the dipole antenna and thus the manufacture and assembly of the antenna.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com