Red mud based rapid-setting grouting material applicable to grouting reinforcement treatment of sandy soil stratum

A grouting material and grouting reinforcement technology, which is applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of not meeting the requirements of green ecology, the high price of ultra-fine cement, and the high energy consumption of the cement industry, achieving high additional The effect of value resource utilization, saving preparation process and cost, and solving engineering problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Components and mass ratio: 65 parts of red mud, 28 parts of activator, and 7 parts of admixture. The activator consists of 26 parts by mass of 8M sodium hydroxide aqueous solution, 12 parts by mass of water glass and 62 parts by mass of sulphoaluminate cement clinker. The admixture is composed of 25 parts by mass of carboxylic acid water reducer, 25 parts by mass of talcum powder, 15 parts by mass of hydroxypropyl methylcellulose and 35 parts by mass of desulfurized gypsum powder.

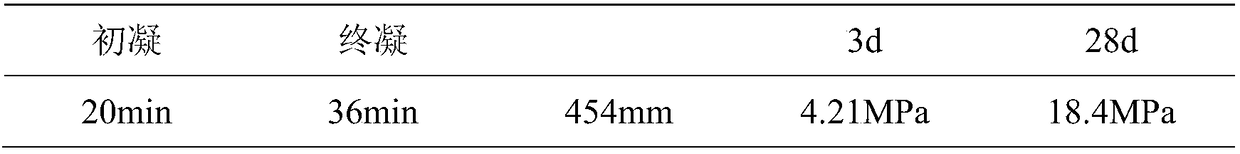

[0028] 2. Preparation method: grind until the specific surface area is 550-600m 2 / Kg of red mud powder with a specific surface area of 350-400m 2 / Kg of sulphoaluminate cement clinker and water are mixed at a water-cement ratio of 1:1, stirred evenly, and then other components in corresponding proportions are added to it, and stirred for five minutes. The relevant properties of the prepared grouting materials are shown in Table 1:

[0029] Table 1

[0030]

[0031] This product ...

Embodiment 2

[0033] 1. Components and mass ratio: 70 parts of red mud, 25 parts of activator, and 5 parts of admixture. The activator consists of 27 parts by mass of 8M aqueous sodium hydroxide solution, 9 parts by mass of water glass and 64 parts by mass of sulphoaluminate cement clinker. The admixture consists of 23 parts by mass of carboxylic acid water reducer, 20 parts by mass of talcum powder, 15 parts by mass of hydroxypropyl methylcellulose and 42 parts by mass of desulfurized gypsum powder.

[0034] 2. Preparation method: grind until the specific surface area is 550-600m 2 / Kg of red mud powder with a specific surface area of 350-400m 2 / Kg of sulphoaluminate cement clinker and water are mixed at a water-cement ratio of 1:1, stirred evenly, and then other components in corresponding proportions are added to it, and stirred for five minutes. The relevant properties of the prepared grouting materials are shown in Table 2:

[0035] Table 2

[0036]

[0037]

[0038] This ...

Embodiment 3

[0040] 1. Components and mass ratio: 80 parts of red mud, 30 parts of activator, and 8 parts of admixture. The activator consists of 30 parts by mass of 8M sodium hydroxide aqueous solution, 15 parts by mass of water glass and 70 parts by mass of sulphoaluminate cement clinker. The admixture is composed of 30 parts by mass of carboxylic acid water reducing agent, 25 parts by mass of talcum powder, 15 parts by mass of hydroxypropyl methylcellulose and 45 parts by mass of desulfurized gypsum powder.

[0041] 2. Preparation method: grind until the specific surface area is 550-600m 2 / Kg of red mud powder with a specific surface area of 350-400m 2 / Kg of sulphoaluminate cement clinker and water are mixed at a water-cement ratio of 1.2:1, stirred evenly, and then other components in corresponding proportions are added to it, and stirred for five minutes. The relevant properties of the prepared grouting materials are shown in Table 3:

[0042] table 3

[0043]

[0044] This...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com