Three-dimensional metal-graphene composite substrate and preparation method thereof

A graphene composite and graphene layer technology is applied in the field of surface-enhanced Raman substrate and its preparation based on a three-dimensional metal-graphene composite structure, which can solve the problem that the shape and size are difficult to control, the Raman signal is weak, and the signal interference is enhanced. and other problems, to achieve the effect of saving chemical reagents and preparation procedures, enhancing Raman scattering intensity, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this embodiment, the three-dimensional metal-graphene composite substrate of the present invention is prepared according to the following steps:

[0037] (1) The amorphous carbon film was ultrasonically cleaned with acetone, ethanol, and ultrapure water in sequence, each solution was cleaned for 5 minutes, and dried for electrochemical deposition of gold nano-layers.

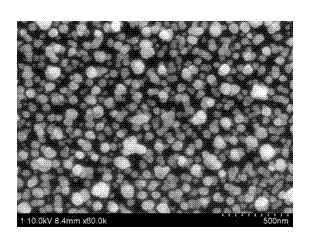

[0038] (2) Deposit a gold nanoparticle layer on the surface of the amorphous carbon film by electrochemical deposition, and the electrodeposition solution used is 20ml 0.6 mmol / L HAuCl 4 with 0.075 mol / L KH 2 PO 4 mixed aqueous solution. A three-electrode system was adopted: the amorphous carbon film was used as the working electrode, the platinum sheet was used as the auxiliary electrode, and the saturated calomel electrode was used as the reference electrode. The model of the electrochemical workstation is CHI630D, the working mode is the constant potential mode, and the deposition is at -0.8V for...

Embodiment 2

[0044] In this embodiment, the three-dimensional metal-graphene composite substrate is prepared according to the following steps:

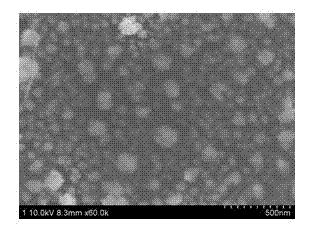

[0045] (1) Electrochemical deposition of silver nano-layers is carried out on the surface of the amorphous carbon film after cleaning in step (1) of Example 1, and the electrodeposition solution is 3mmol / L AgNO 3 with 0.375mol / L KNO 3 Mix the aqueous solution. A three-electrode system is adopted: the amorphous carbon film is used as the working electrode, the platinum sheet is used as the auxiliary electrode, and the saturated calomel electrode is used as the reference electrode. The model of the electrochemical workstation is CHI630D, the working mode is the constant potential mode, and the deposition is at -0.3V for 1200 seconds. Samples were dried for later use.

[0046] (2) Graphene oxide is spin-coated on the above-mentioned prepared sample by using a spin coater. The specific process is as follows: take 80uL of 1mg / mL graphene oxide, dr...

Embodiment 3

[0051] In this embodiment, the three-dimensional metal-graphene composite substrate is prepared according to the following steps:

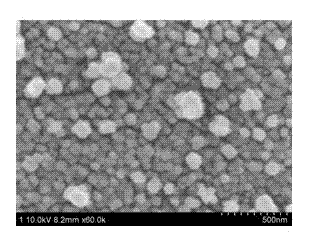

[0052] (1) Deposit a gold nano-layer on the surface of the amorphous carbon film by electrochemical deposition, and the electrodeposition solution is 2.4 mmol / L HAuCl 4 with 0.075 mol / L KH 2 PO 4 mixed aqueous solution. A three-electrode system was adopted: the amorphous carbon film was used as the working electrode, the platinum sheet was used as the auxiliary electrode, and the saturated calomel electrode was used as the reference electrode. The model of the electrochemical workstation is CHI630D, the working mode is the constant potential mode, and the deposition is at -0.5V for 600 seconds. After the deposition is complete, the samples are dried and ready for use.

[0053] (2) Graphene oxide is spin-coated on the above-mentioned prepared sample by using a spin coater. The specific process is as follows: Take 40 μL of 0.5 mg / mL graphene ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com