Colored filter and manufacturing method thereof

A technology for color filters and manufacturing methods, applied in the fields of optical filters, optics, nonlinear optics, etc., can solve the problems of unfavorable competitiveness of manufacturers, high prices, increased production costs of color filters, etc., and achieve saving of raw materials And the effect of manufacturing process, simplifying production process and enhancing competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

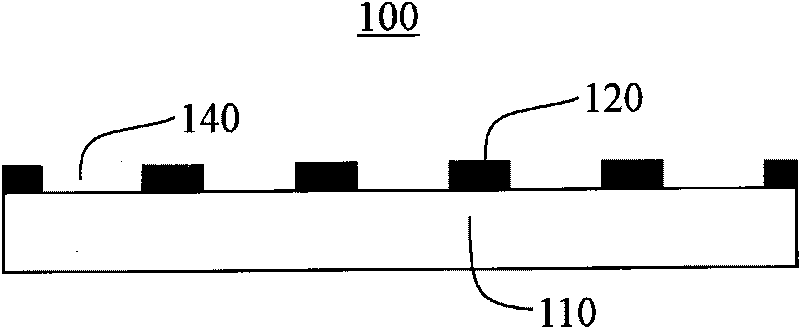

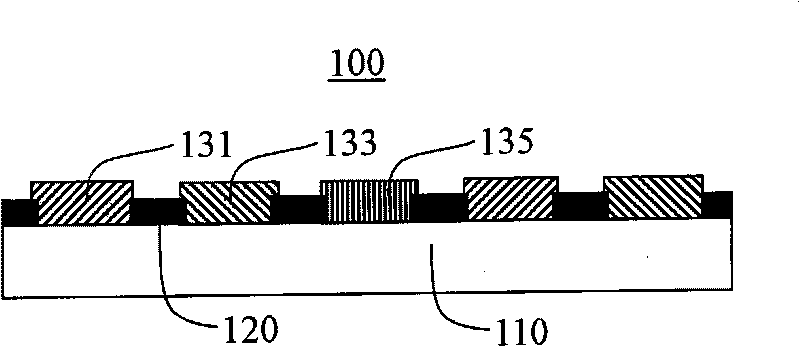

[0030] In order to overcome the problem of high production cost of the color filter in the prior art, the present invention saves the process of making a transparent conductive layer by adding a conductive material to the protective layer. Furthermore, there is no need for professional equipment required for manufacturing the transparent conductive layer and raw materials required for manufacturing the transparent conductive layer, which is beneficial to save costs. At the same time, the process for manufacturing the color filter omits the process of making the transparent conductive layer, which saves the time required for producing a single color filter and is beneficial to improving the production efficiency of the color filter. Therefore, the color filter and the manufacturing method thereof provided by the present invention can effectively save production cost and improve production efficiency at the same time.

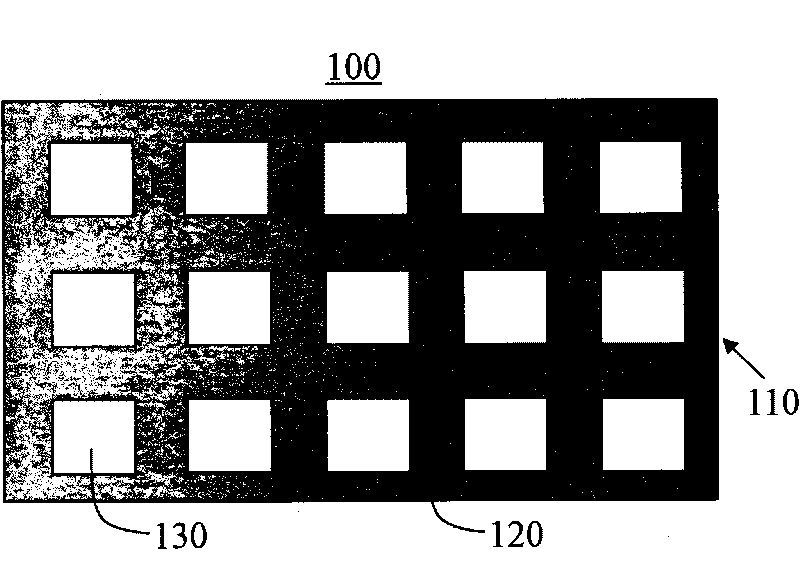

[0031] The color filter provided by the present invention a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com