Double-body torsional spring forming device

A forming device and torsion spring technology, applied in the field of double-body torsion spring forming devices, can solve the problems of reducing the service life of double-body torsion springs 6, easily scratching spring wires, and greatly changing the distance between spring wires and deformation, so as to save production Process and production equipment, improve production efficiency and pass rate, and improve the effect of overall service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

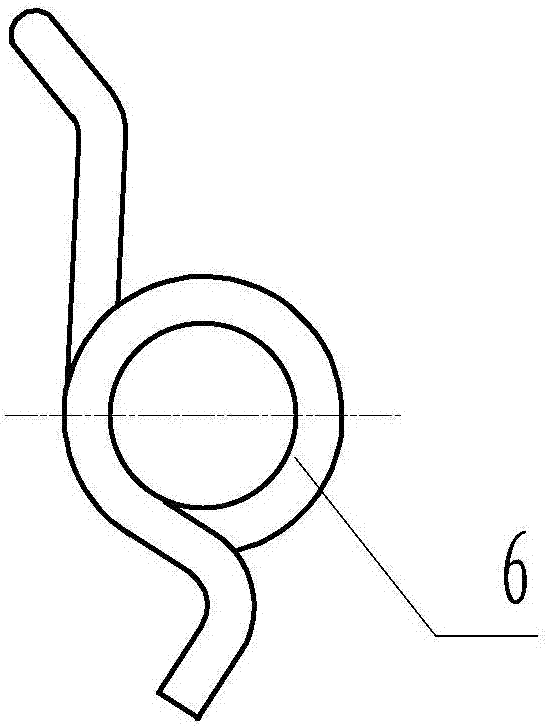

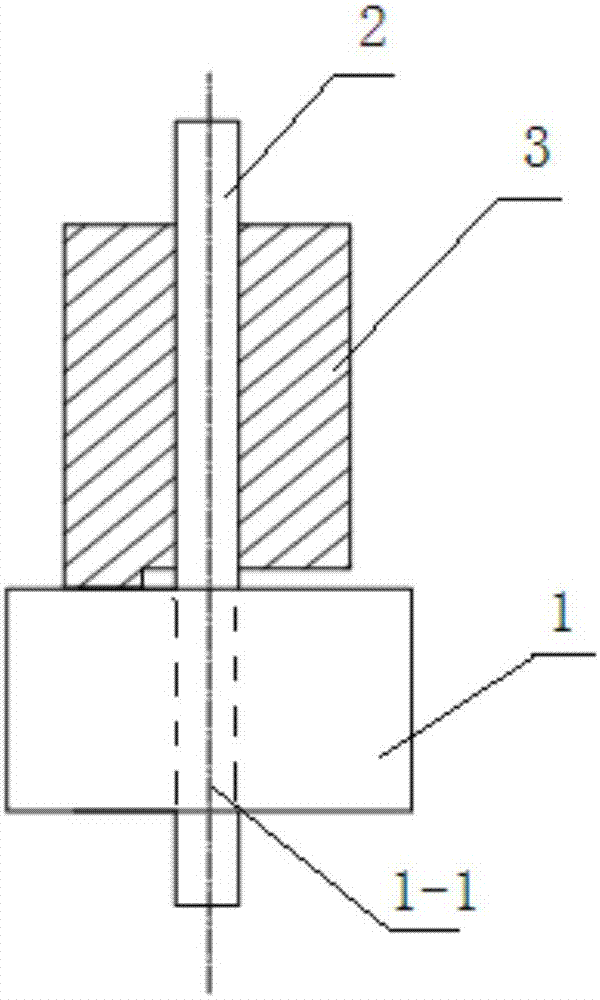

[0025] see Figure 4 to Figure 7 , the dual-body torsion spring forming device of the present invention includes a base 1 , a forming shaft 2 and a forming sleeve 3 . Depend on Figure 4 to Figure 7 It can be seen that the present invention also includes a handle 4, the longitudinal thickness of the base 1 is adapted to the length L1 of the middle torsion arm 6-4 of the double-body torsion spring 6, and a longitudinal connection through hole 1-1 is provided on it, and one side thereof There is a through groove 1-3 that runs through the top and bottom and matches the shape and diameter of the spring wire of the double-body torsion spring 6. The forming shaft 2 includes the forming shaft body 2-1 on the upper part and the smooth shaft body 2 on the lower part. -2, the length of the forming shaft body 2-1 is adapted to the length of the left s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com