Liner end enclosure molding process of high-pressure hydrogen storage cylinder

A molding process and liner technology, which is applied to household appliances, hollow objects, other household appliances, etc., can solve the problems of easy deformation of aluminum alloy clamping and difficult forming of aluminum alloy heads, so as to solve the problems of easy deformation, solving molding, The effect of saving steps in the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

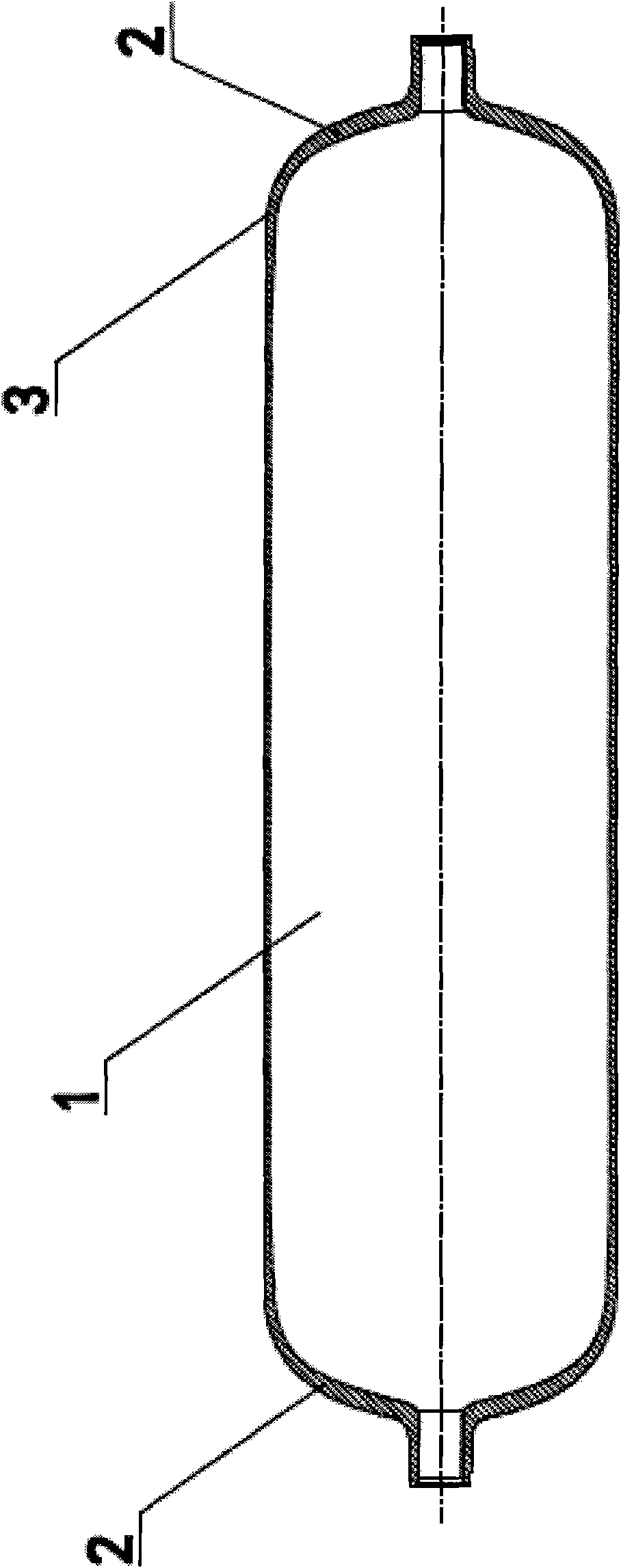

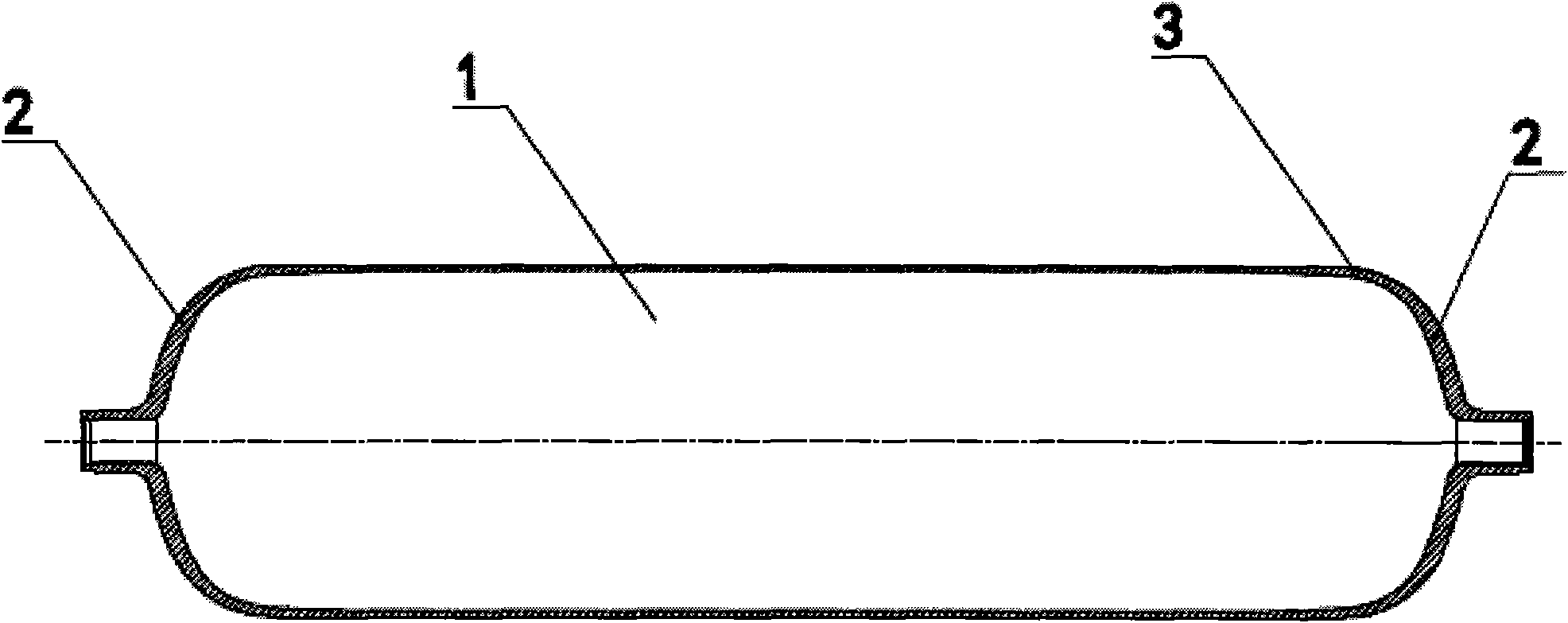

[0021] Combine below figure 1 , figure 2 The present invention is described in detail:

[0022] The present invention provides a high-pressure hydrogen storage cylinder, comprising an inner tank body 1, an inner tank head 2 and a transition section 3 at the junction of the inner tank body 1 and the inner tank head 2, the inner tank head 2 The molding process includes the following steps:

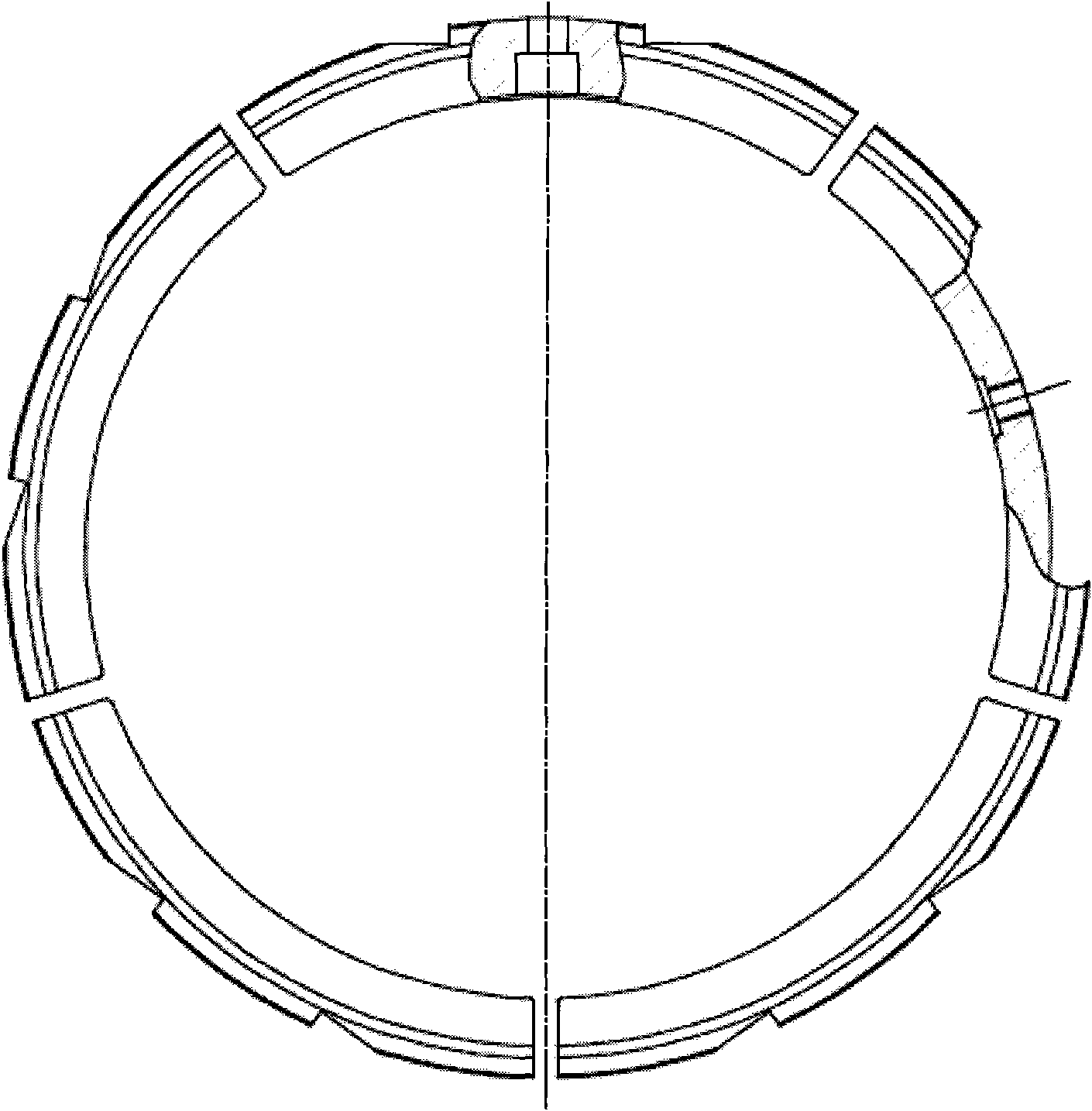

[0023] Step 1: Clamping process, clamping the aluminum alloy pipe blank with claws, the diameter of the aluminum alloy pipe blank is 389mm, the wall thickness is 5.5mm, the claw is composed of five equal claws, and the claw is equipped with a locking screw hole; and must be considered in the design of the claws, so that the claws are circular after clamping, and there is no gap between the five petals.

[0024] Step 2: Heating, preheating the clamped aluminum alloy pipe blank, using a natural gas-oxygen heating device, controlling the heating rate by controlling the distance between the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com