Carbon fiber reinforced thermoplastic resin plate and manufacturing method thereof

A technology that enhances thermoplasticity and thermoplastic resin, applied in the field of carbon fiber, can solve problems such as product cost increase, complex equipment, production capacity limitation, etc., and achieve the effect of saving manufacturing process and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

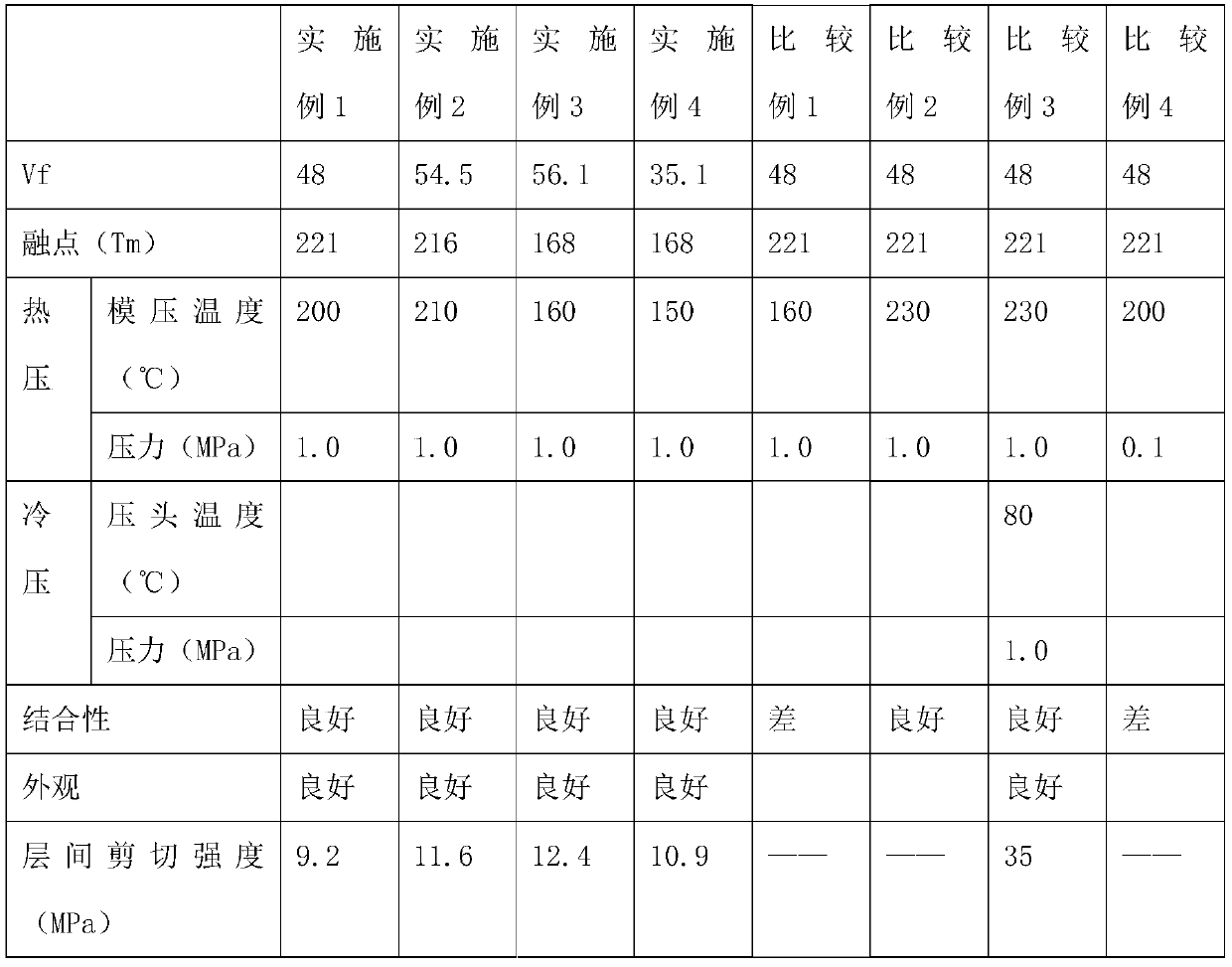

Embodiment 1

[0041] Using carbon fiber (domestic T700 grade carbon fiber, 12K) and nylon 6, the melting point measured by nylon 6 is 221°C. Arranged individually, the surface density is 100g / m 2 The carbon fiber spreading sheet is clamped by 30μm nylon 6 film on both sides, heated to 250°C, pressurized at 1MPa to integrate the carbon fiber and the resin film, and then cooled to 80°C to obtain a carbon fiber reinforced nylon prepreg. The thickness of the prepreg is 114 μm, and the volume content of carbon fiber is 48.0%.

[0042] Lay up the prepreg according to (0 / 45 / 90 / -45°), the thickness of the ply is 16 sheets, and an approximately isotropic laminate is obtained. Clamp it with two layers of 1.5mm thick stainless steel plates, place it on a molding machine with a pressure head temperature of 200°C, apply a pressure of 1.0 MPa, press for 8 minutes, and take it out directly to obtain a carbon fiber reinforced thermoplastic resin sheet.

[0043] Each layer of prepreg in the sheet is well ...

Embodiment 2

[0045] Carbon fiber (Toray T700 24K, Japan) and nylon 610 were used, and the measured melting point of nylon 610 was 216°C. The prepreg has a thickness of 132 μm and a carbon fiber volume content of 54.5%. Molding temperature is changed into 210 ℃, and others are identical with embodiment 1.

Embodiment 3

[0047] Carbon fiber (domestic T700 grade, 12K) and polypropylene (PP) are used as the base material, and the measured melting point of PP is 168°C. The thickness of the single-layer PP film in the prepreg is 25 μm, the thickness of the prepreg is 104 μm, and the volume content of carbon fiber is 56.1%. Molding temperature is changed into 160 ℃, and others are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com