Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

161results about How to "Rich mesostructure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of N-P-codoping porous biomass carbon catalyst

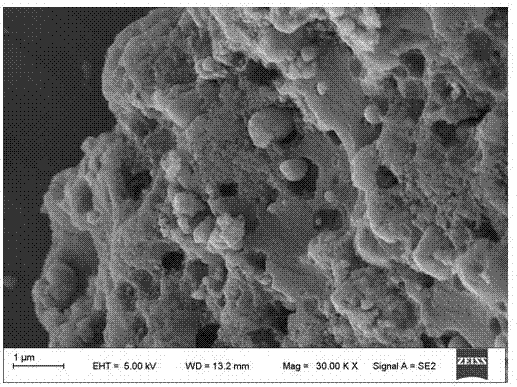

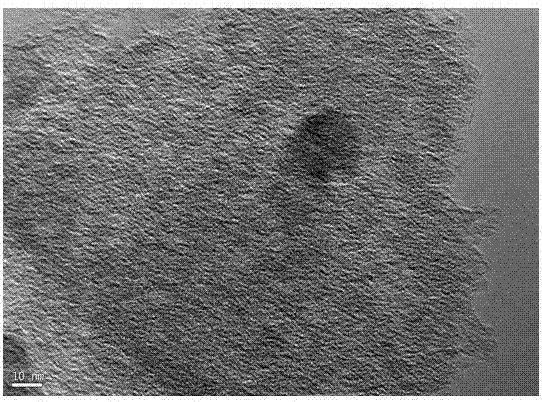

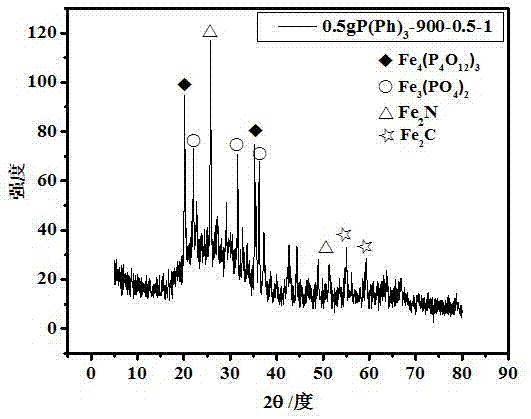

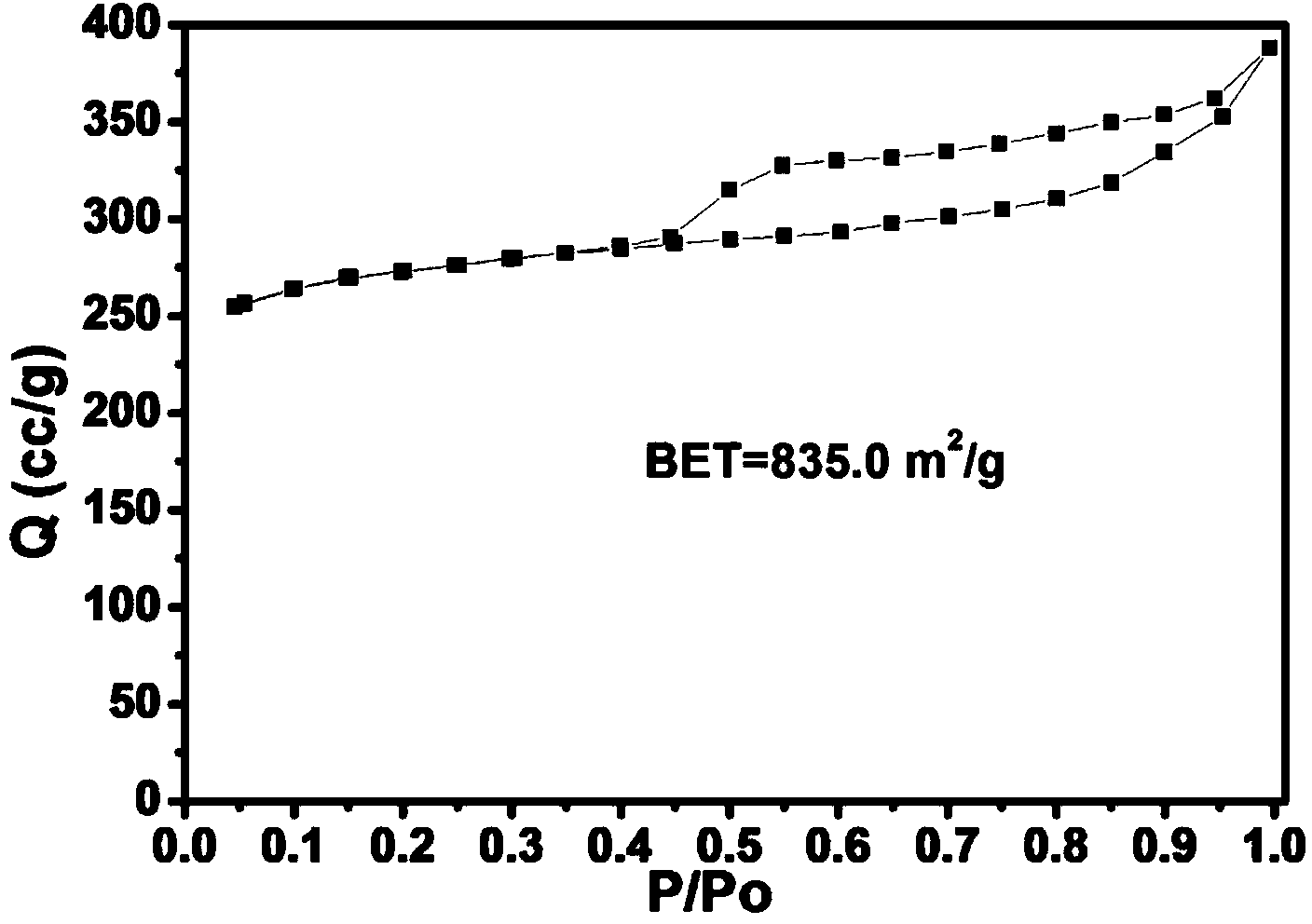

ActiveCN106881138ALarge specific surface areaRich microporous structurePhysical/chemical process catalystsCell electrodesMolecular levelNitrogen gas

The invention provides a preparation method of N-P-codoping porous biomass carbon catalyst. Cheap and easy-to-get biomass chitosan is taken as carbon source and nitrogen source (as nitrogen-containing ligand at the same time), organic phosphorus compound triphenylphosphine is taken as phosphorus-containing ligand, the nitrogen-containing ligand and the phosphorus-containing ligand form a coordination compound together with metal ions in metallic salt solution, ZnCl2 is taken as activating agent, the coordination compound is subjected to high-temperature pyrolysis in a nitrogen atmosphere to form holes, and finally diluted hydrochloric acid is used to remove metals for secondary hole formation, so as to prepare the N-P-codoping porous biomass carbon catalyst with rich micropores and a mesopores structure as well as a high specific surface area. The N-P-codoping porous biomass carbon catalyst is comparable to commercial Pt / C (20%) in catalytic performance in an alkaline environment, has good methanol poisoning resistance and stability, and can regulate components and performance of catalyst in molecular level. The N-P-codoping porous biomass carbon catalyst disclosed by the invention is expected to replace cathode oxygen reduction catalyst of the commercial Pt / C, and has a very good industrial application prospect.

Owner:NORTHWEST NORMAL UNIVERSITY

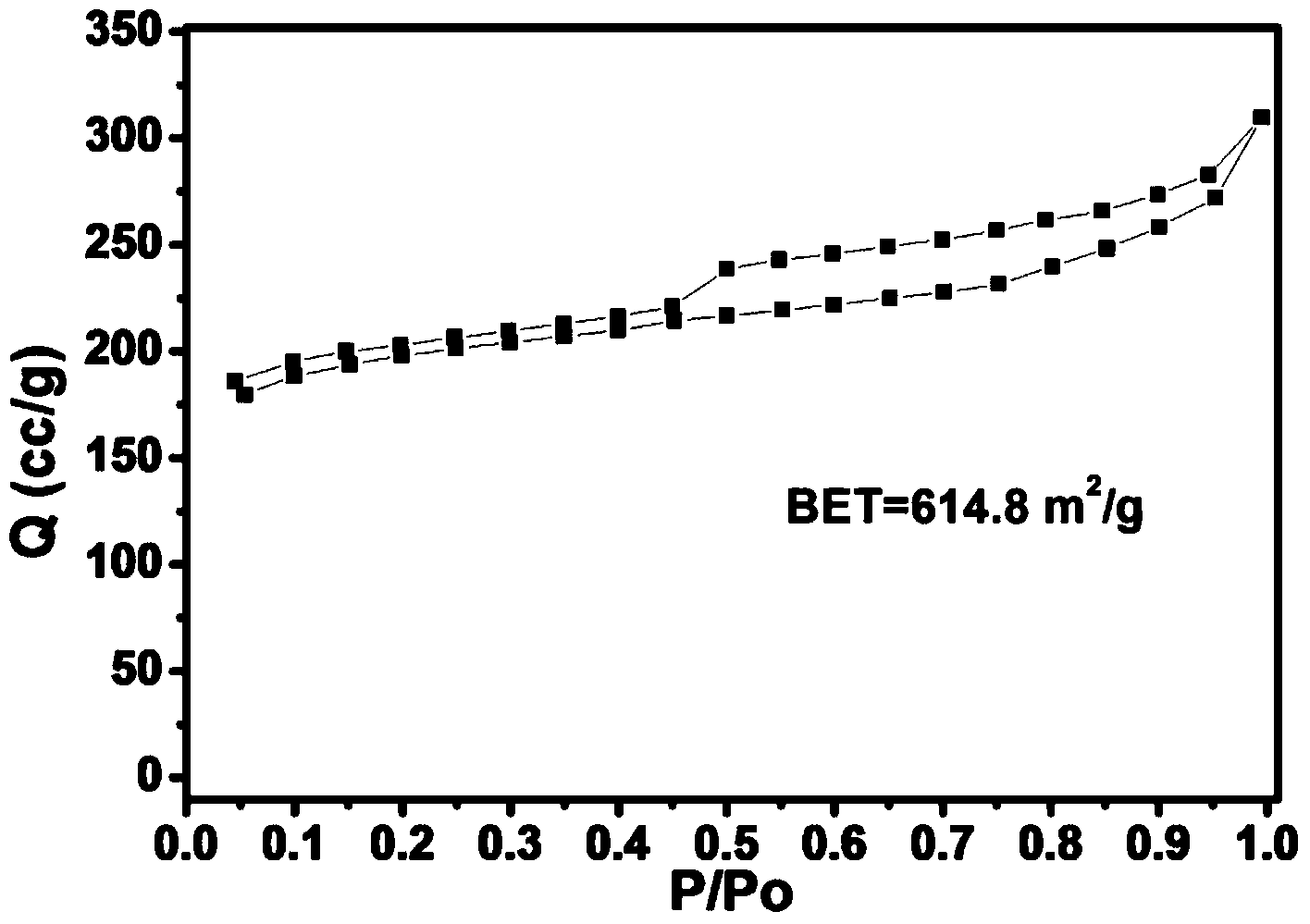

High-specific surface porous carbon fiber, preparation method and application of carbon fiber

ActiveCN103882559ALarge specific surface areaHigh surface areaCatalyst carriersFilament/thread formingFiberCarbon fibers

The invention discloses a high-specific surface porous carbon fiber and a preparation method of the carbon fiber. The method comprises the following steps: spinning through a spinning solution consisting of a pore forming substance, a high polymer and an organic solvent, carbonizing, and carrying out pickling to obtain the high-specific surface carbon fiber. The method has the following advantages that (a) the porous carbon fiber is simple to prepare, high in yield and low in cost; (b) the porous carbon fiber with high specific surface can be prepared through the method; (c) the carbon fiber simultaneously has micro-porous and mesoporous structures.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Preparation and application of MOF-derived porous carbon/graphene composite electrode material

ActiveCN108328706AFully evenly dispersedEvenly dispersedDispersed particle separationWater/sewage treatmentPorous carbonFreeze-drying

The invention discloses preparation and an application of an MOF-derived porous carbon / graphene composite electrode material. The preparation method comprises the steps as follows: (1) a clean container is taken, a graphene or graphene oxide dispersion liquid is added, then, MOFs crystal powder is added, the container is placed on a vortex mixer for continuous mixing after being sealed, the rotating speed is adjusted repeatedly from zero to the highest rotating speed, so that a sample is fully oscillated in the vertical direction, formation of a graphene sheet or graphene oxide sheet self-assembly three-dimensional structure and full and uniform dispersion of MOFs crystals in the three-dimensional frame structure are promoted, and finally, graphene / MOF porous aerogel is obtained through freeze drying; (2) the aerogel is subjected to high-temperature roasting in the N2 atmosphere and a carbonized product is obtained; (3) the carbonized product is subjected to acid treatment and the MOF-derived porous carbon / graphene composite electrode material is obtained. The MOF-derived porous carbon / graphene composite electrode material is applied in CDI or MCDI desalination and has good effects.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of porous carbon fiber with high specific surface area

InactiveCN106521717AHigh specific surface areaLarge specific surface areaArtifical filament manufactureDimethyl formamideElectrospinning

The invention relates to a preparation method of a porous carbon fiber with a high specific surface area. The preparation method comprises the following steps: subjecting a spinning liquid containing polyacrylonitrile, a pore forming agent, and N,N-dimethyl formamide to electrostatic spinning, then carrying out carbonization, and finally performing hot alkali washing and drying to obtain the porous carbon fiber with a high specific surface area. According to the preparation method, nano silica is taken as the pore forming agent, then silica in fibers is removed by hot alkali, and the prepared porous carbon fiber has a high specific surface and is rich in micro pores and mesopores.

Owner:WUYI UNIV

Catalytic cracking fluidized bed catalyst synthesized in situ

ActiveCN102371171AIncrease contentImprove conversion rateCatalytic crackingMolecular sieve catalystsNaphthaMicrosphere

The invention discloses a catalytic cracking fluidized bed catalyst synthesized in situ, which is mainly used for solving the technical problems of low naphtha conversion rate and low yields of ethylene and propylene when the conventional fluidized bed catalyst is used for catalyzing cracking of naphtha for preparing ethylene and propylene. The catalyst comprises the following components in parts by weight: (1) 0.5-15.0 parts of at least one selected from phosphorus, rare-earth or alkali-earth element oxide and (2) 85.0-99.5 parts of catalyst selected from microspheres which are synthesized in situ and contain a ZSM-5 molecular screen and of which the particle sizes are 10-200 mum. Due to the adoption of the technical scheme, the problems are well solved; and the catalyst can be applied to industrial production of preparation of the ethylene and the propylene by the catalytic cracking of the naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

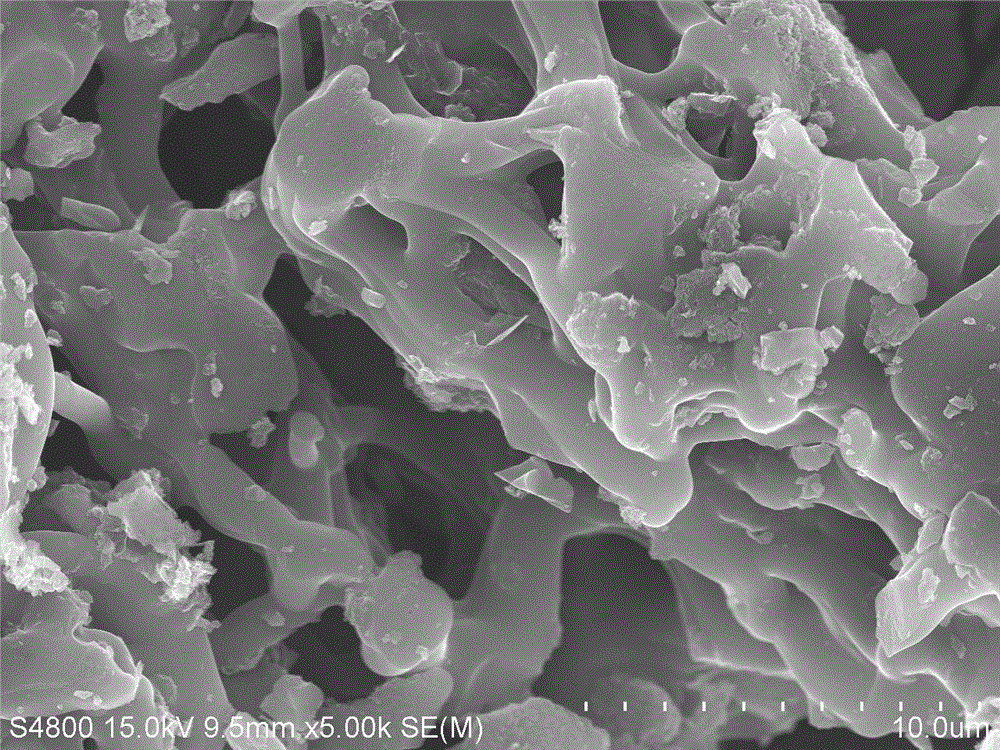

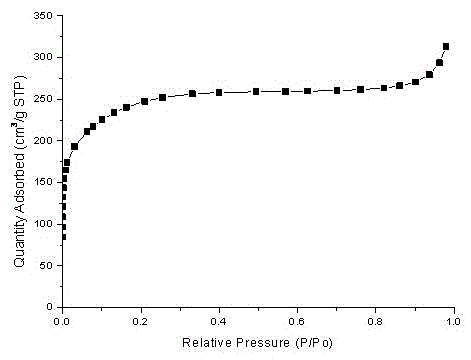

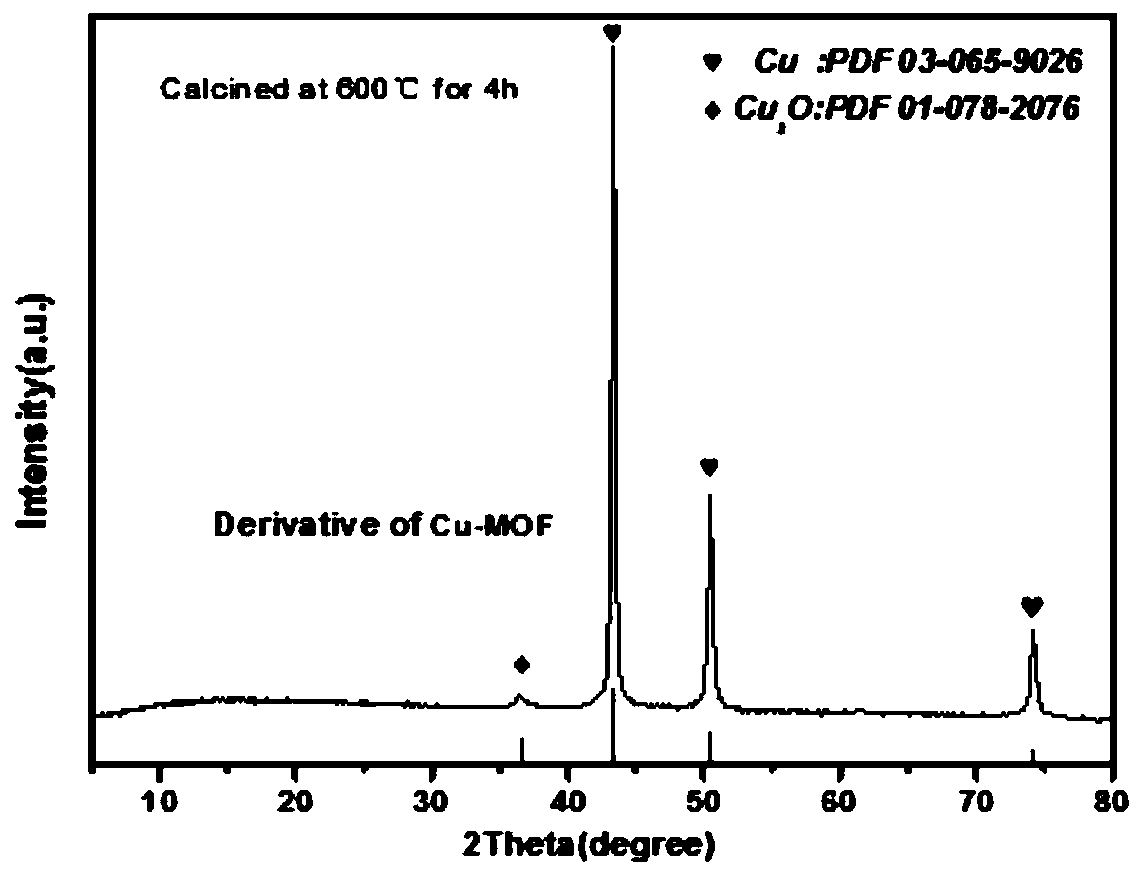

Copper-based MOF carbonization derived catalytic material and preparation method and application thereof

ActiveCN109894154AImprove adsorption capacityLarge specific surface areaOrganic-compounds/hydrides/coordination-complexes catalystsRefining to eliminate hetero atomsCarbonizationHigh surface

The invention belongs to the technical field of heterogeneous catalysis and particularly discloses a copper-based MOF carbonization derived catalytic material and a preparation method and applicationthereof in the field of unsaturated hydrocarbon selective hydrogenation. The copper-based MOF carbonization derived catalytic material and the preparation method have the advantages that by controlling pyrolysis conditions and using organic ligands as the self-sacrificial template to reduce copper ions in an in-situ manner, the metal active center of the prepared catalytic material is highly dispersed, the specific surface area of the catalytic material is larger than that of a traditional supported catalyst, and the catalytic material has rich mesoporous and micropore structures and can provide a sufficient place for hydrogenation reaction; nanoscale, sub-nanometer even atomic-scale metal particles in the structure of the catalytic material have extremely high surface energy, so that theactivity and selectivity of the catalytic material are much better than those of common metal catalysts and even can be on a par with those of precious-metal catalysts; the catalytic material is suitable for activity the carbon-carbon double bonds or triple bonds of unsaturated hydrocarbon and can adsorb free hydrogen to perform selective hydrogenation reaction and the like; the catalytic materialis low in synthesizing cost and can provide a brand new thought for an existing catalytic hydrogenation process.

Owner:WUHAN UNIV OF TECH

A kind of method for preparing mesoporous catalytic composite material

ActiveCN102274742AHigh silica contentIncrease contentMolecular sieve catalystsMolecular sieveAdhesive

The invention discloses a method for preparing a mesoporous catalytic composite material. The method is characterized by taking diatomaceous earth and kaolin as raw materials and comprising the following steps of: A, adding water and a dispersing agent into the diatomaceous earth and kaolin, uniformly stirring to obtain a slurry, adjusting a slurry destination pH value to 4.0-12.0 by using acid or alkali, spraying and drying to form a microsphere, and calcining the microsphere to obtain a mixed clay calcined microsphere; B, adding water and an adhesive into the kaolin and a zeolite molecular sieve, uniformly stirring to form a slurry, spraying and drying to form a microsphere, and calcining the microsphere to obtain a calcined microsphere; and C, adding sodium silicate, alkali liquor and a zeolite guide agent into the mixed clay calcined microsphere obtained in the step A and / or the calcined microsphere obtained in the step B, then putting into a crystallized reaction kettle for hydrothermal crystallization, filtering to remove mother liquor, washing the filter material by using deionized water, filtering again to obtain the washed filter material, and drying the filter material to obtain the mesoporous catalytic composite material containing a NaY zeolite molecular sieve. The method disclosed by the invention is mainly used for preparing the mesoporous catalytic composite material containing the NaY zeolite molecular sieve.

Owner:HUNAN JULI CATALYST

Preparation method of step hole ZSM-5 zeolite composite material-based low-temperature sulfur transfer catalyst for FCC (Fluid Catalytic Cracking) petroleum

InactiveCN102416344ARich mesostructureExcellent sulfur transfer desulfurization rateMolecular sieve catalystsHydrocarbon oils refiningBULK ACTIVE INGREDIENTPetroleum

The invention relates to a preparation method of a step hole ZSM-5 zeolite composite material-based low-temperature sulfur transfer catalyst for FCC (Fluid Catalytic Cracking) petroleum. The method comprises the following steps of: mixing deionized water, an alkali source and a substrate, adding an aluminum source, a microporous template agent and a silicon source, uniformly stirring to obtain aninitial sol mixed system, adding a mesoporous template agent, uniformly stirring, aging, and performing hydrothermal crystallization; cleaning a hydrothermal crystallization product, washing, separating, drying and baking to obtain a step hole ZSM-5 zeolite composite material; performing ammonium exchange treatment on the step hole ZSM-5 zeolite composite material, cleaning, washing, separating, drying and baking to obtain a hydrogen-type step hole ZSM-5 zeolite composite material; and stepwise soaking an aid and active ingredients onto the hydrogen-type step hole ZSM-5 zeolite composite material by adopting an equal-volume soaking method, airing at the room temperature, drying, and baking to obtain the step hole ZSM-5 zeolite composite material-based low-temperature sulfur transfer catalyst for FCC petroleum. The sulfur transfer removing rates of mercaptan and thiophene can be over 90 percent.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

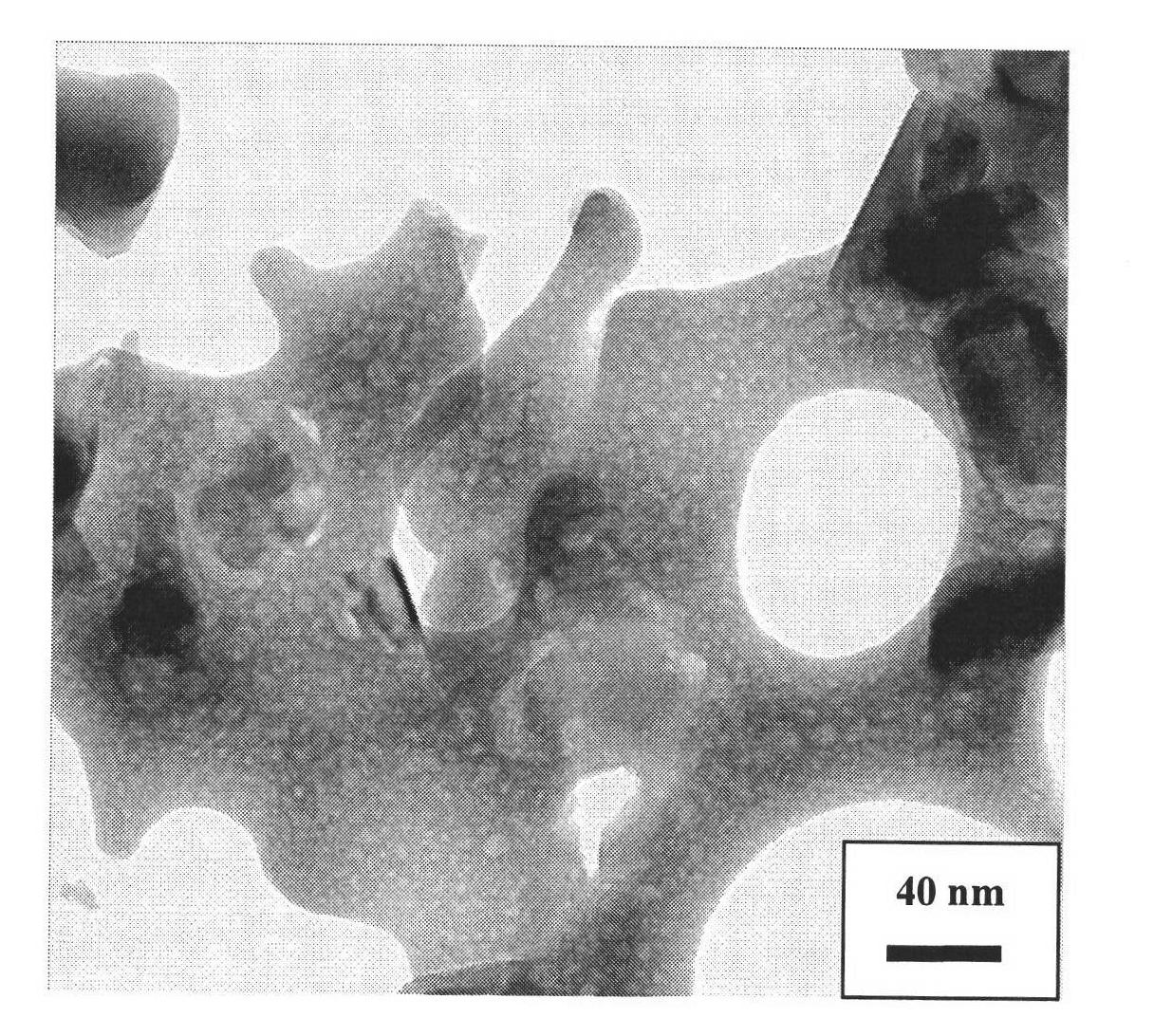

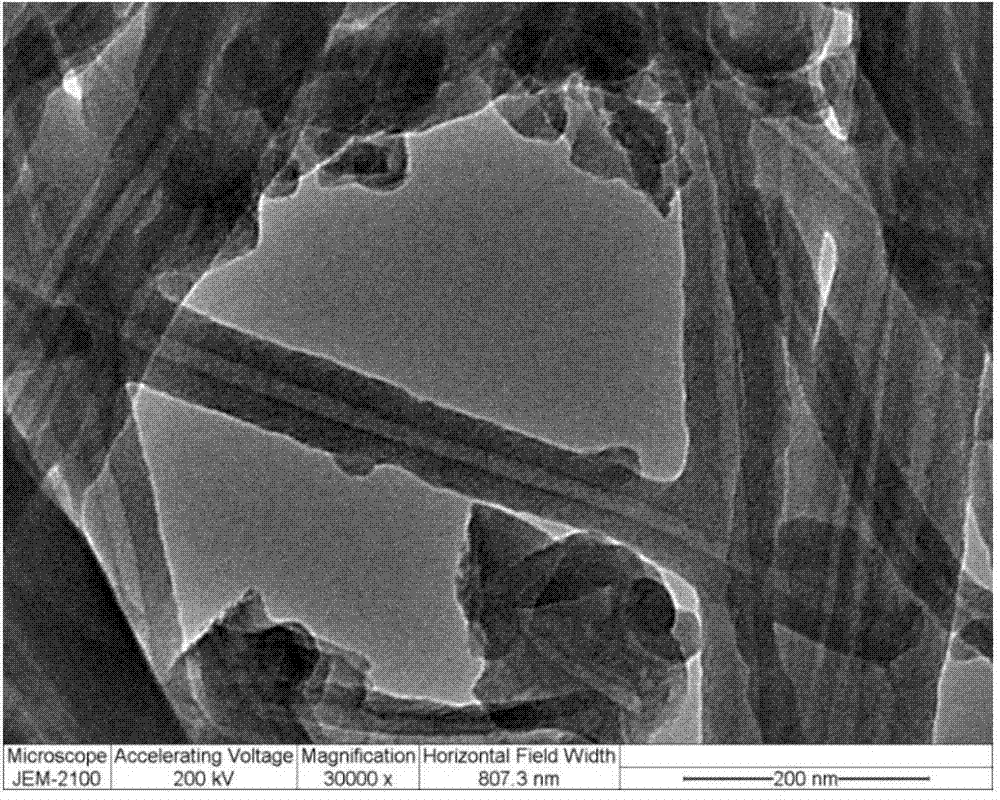

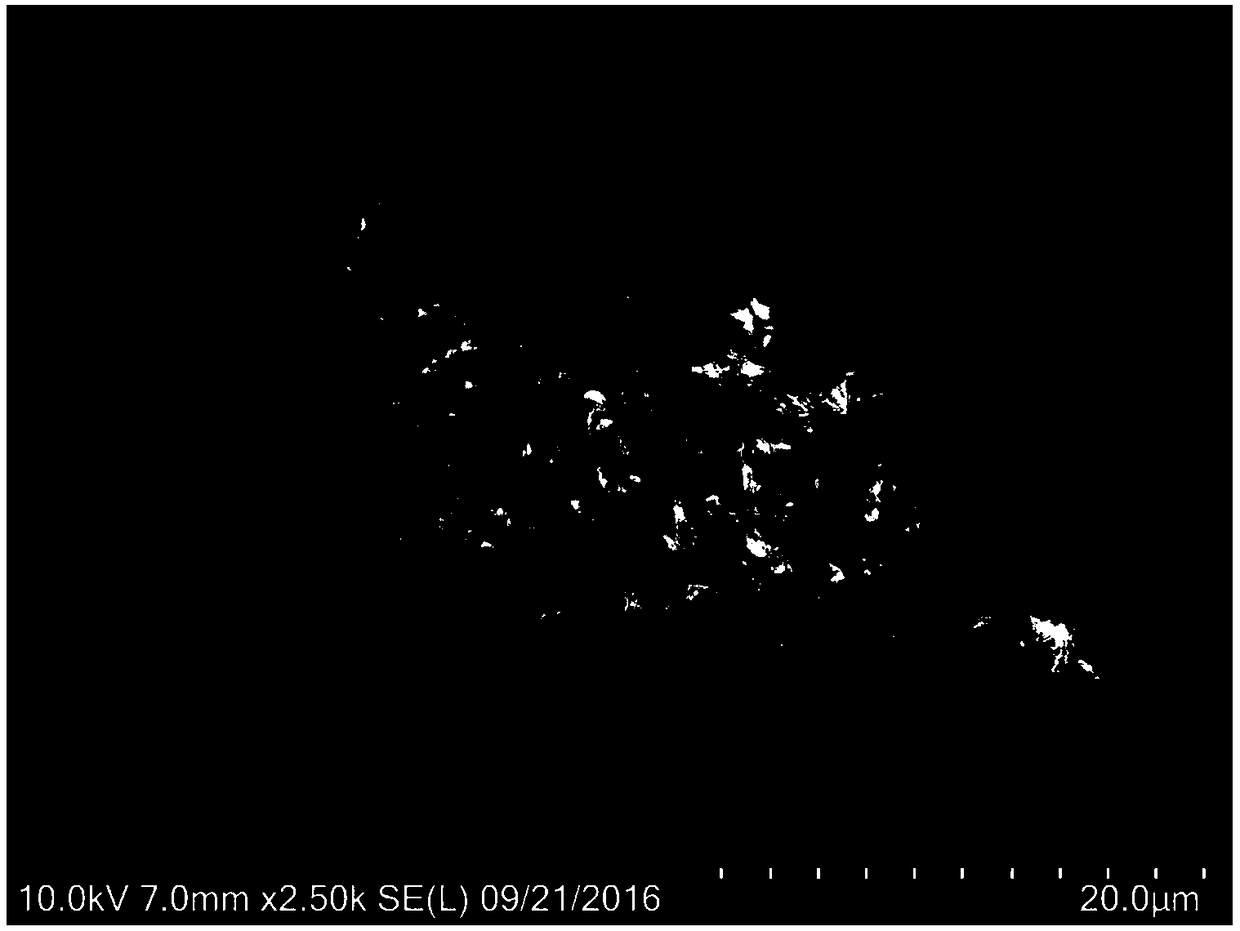

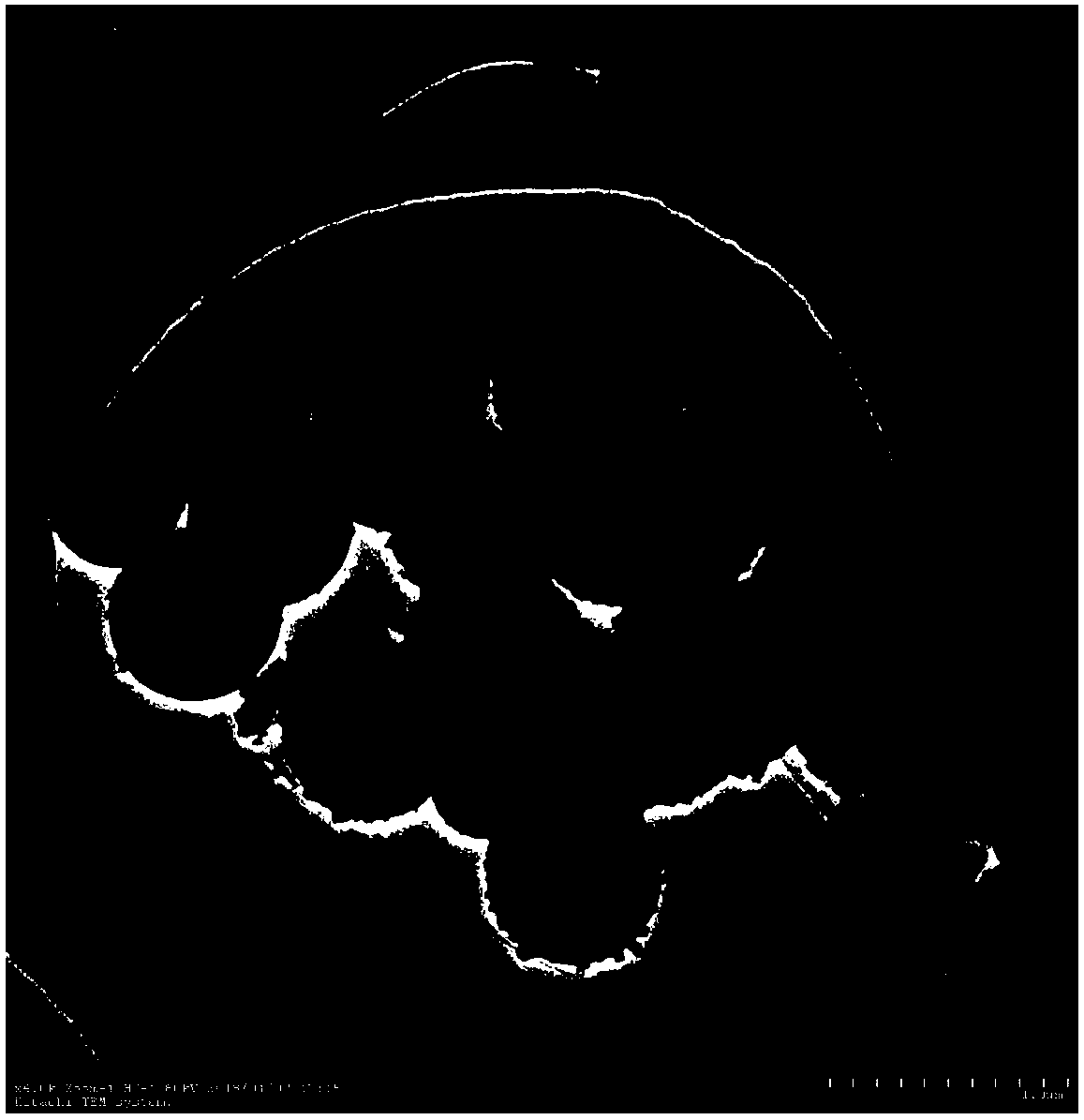

Three dimensional graphene/hollow carbon sphere/sulfur composite material, preparation method thereof, and application in lithium-sulfur batteries

ActiveCN104916828AHigh specific capacityImprove cycle performanceMaterial nanotechnologyCell electrodesLithium–sulfur batteryLithium sulfur

The invention discloses a three dimensional graphene / hollow carbon sphere / sulfur composite material, a preparation method thereof, and an application in lithium-sulfur batteries. The three dimensional graphene / hollow carbon sphere / sulfur composite material comprises nanometer elemental sulfur and a three dimensional graphene-hollow carbon sphere nano-compound, and the nanometer elemental sulfur is distributed in the three dimensional graphene-hollow carbon sphere nano-compound. The preparation method comprises the following steps: dispersing the three dimensional graphene-hollow carbon sphere nano-compound in an alcohol and water mixed solvent to obtain a suspension; and adding an aqueous solution of Na2S.9H2O and Na2SO3 into the suspension, adding an acidic solution, and reacting to obtain the three dimensional graphene / hollow carbon sphere / sulfur composite material. The composite material has the advantages of high specific capacity, stable cycle performances, and excellent rate performance and coulombic efficiency, the preparation method has the advantages of simplicity, convenience and good effect, and the composite material can be applied in the preparation of lithium-sulfur battery positive electrode materials.

Owner:NAT UNIV OF DEFENSE TECH

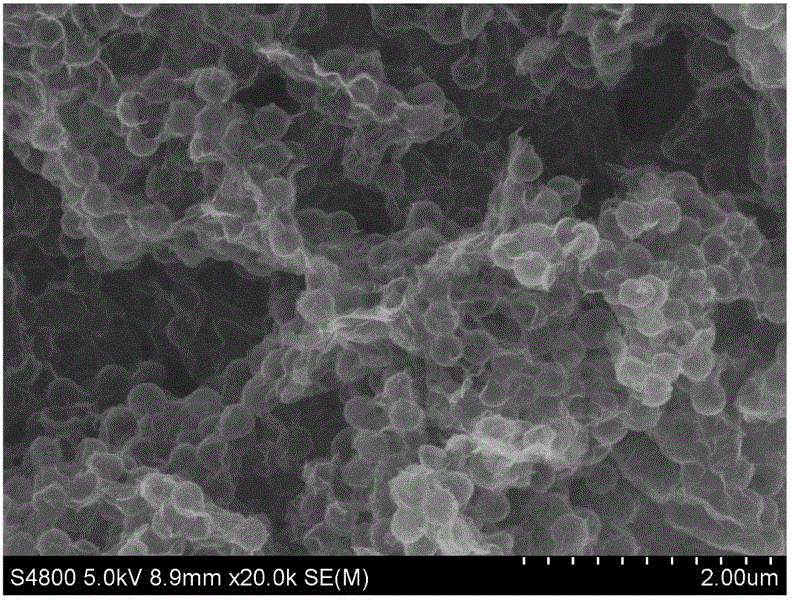

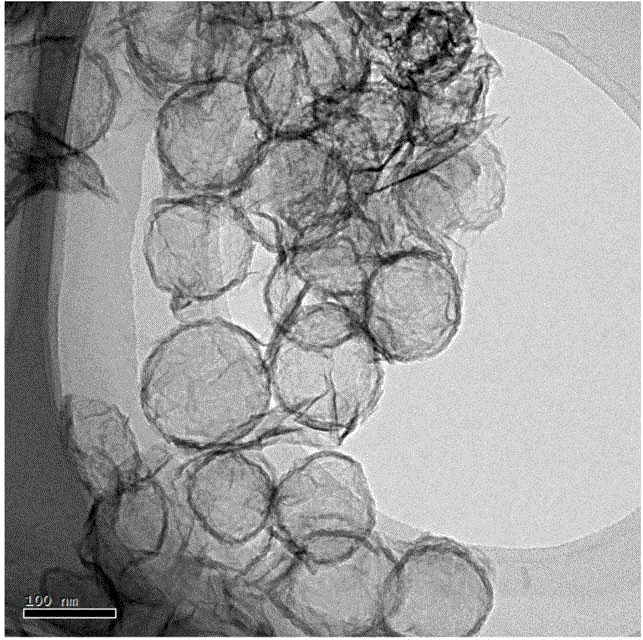

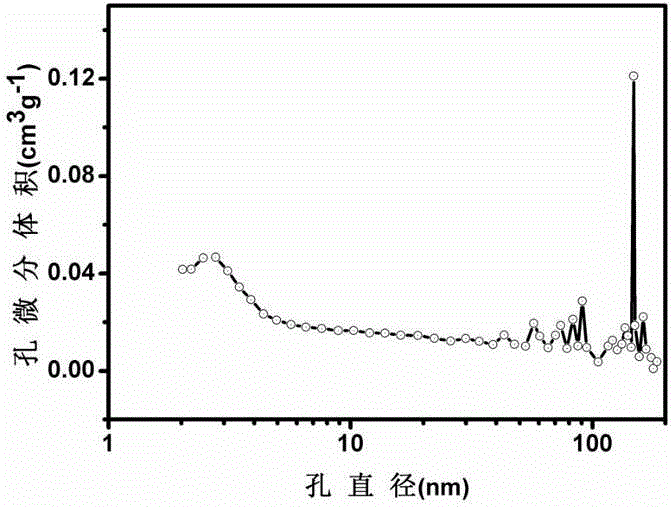

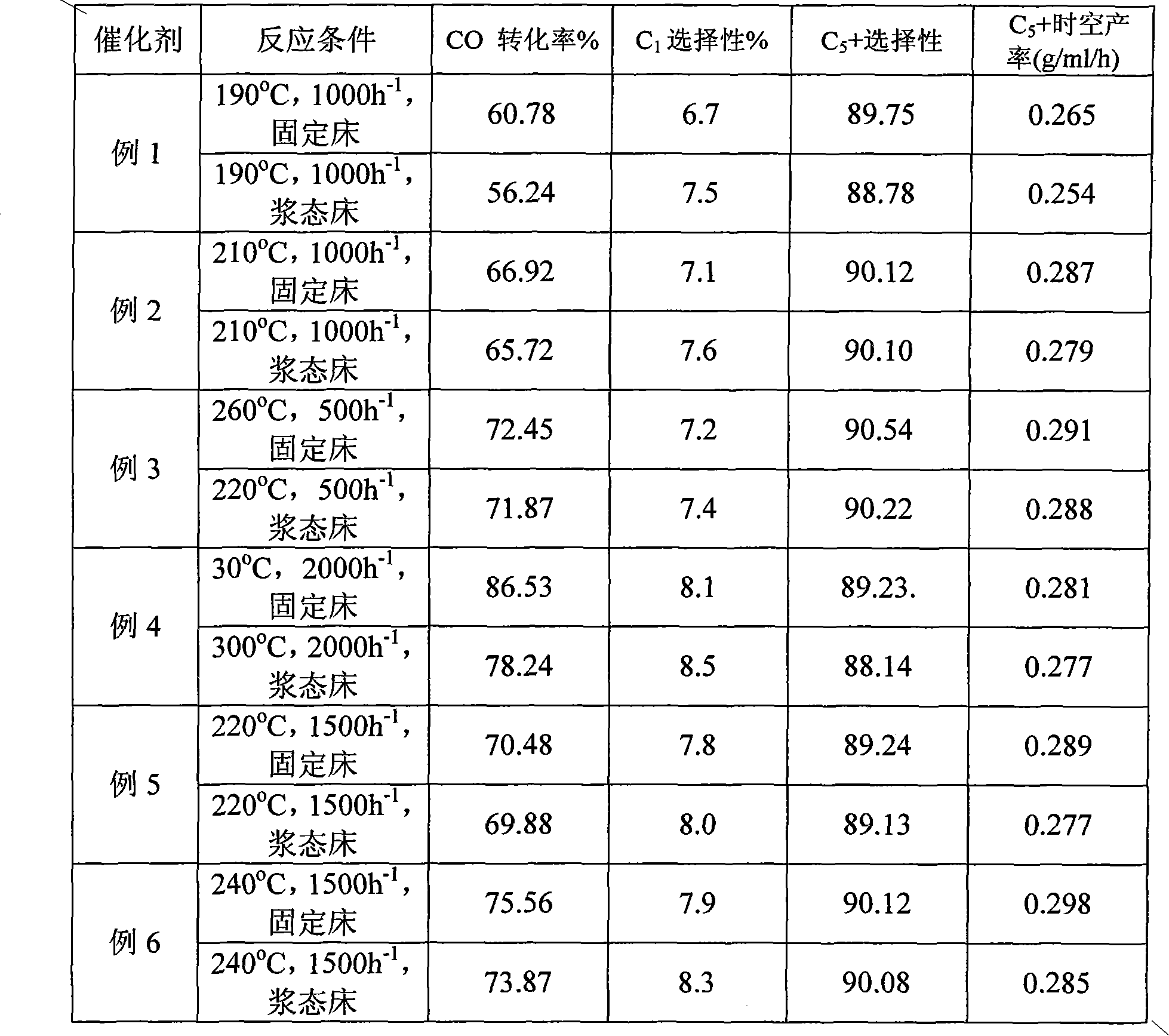

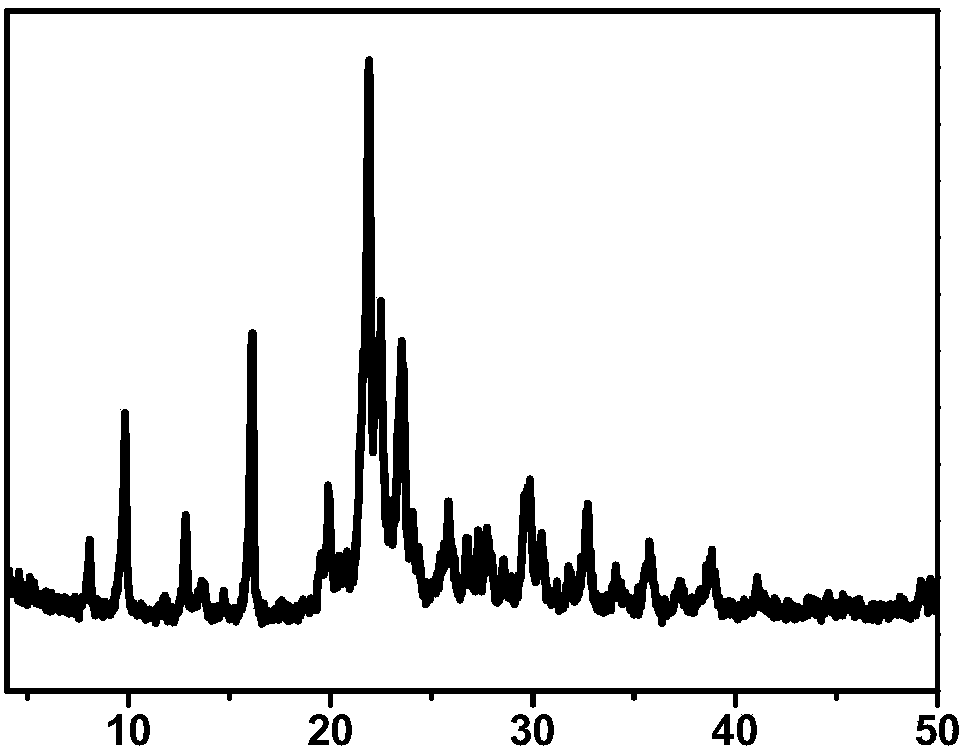

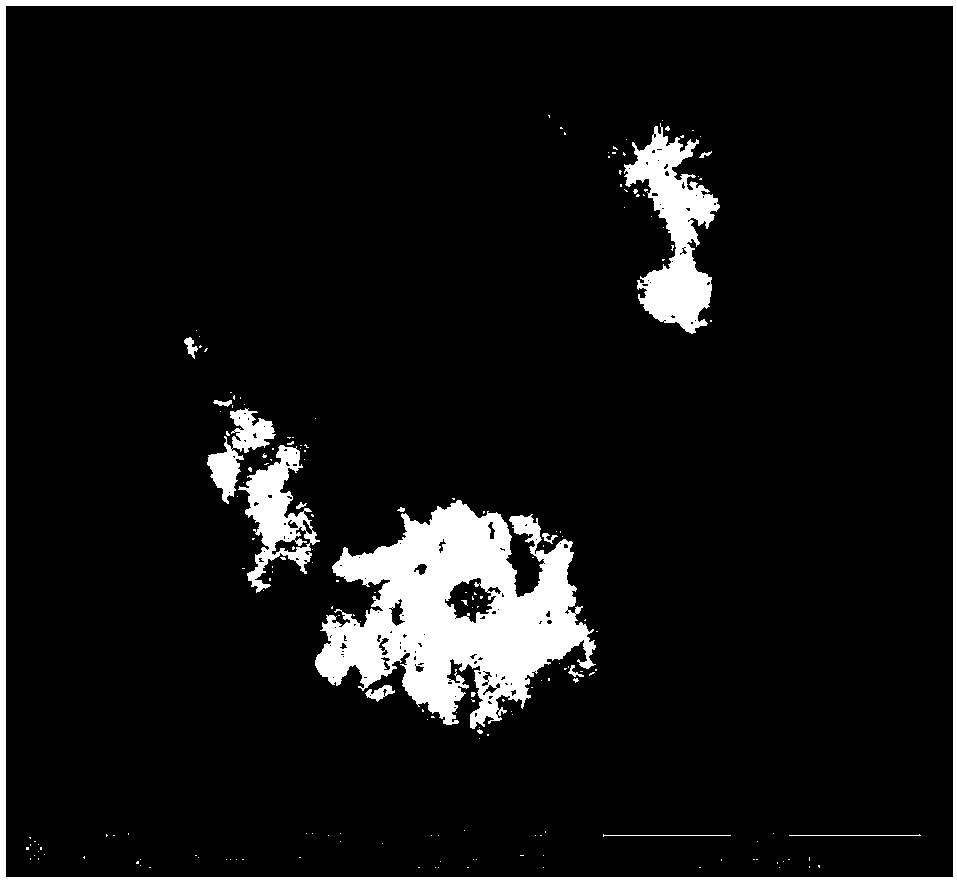

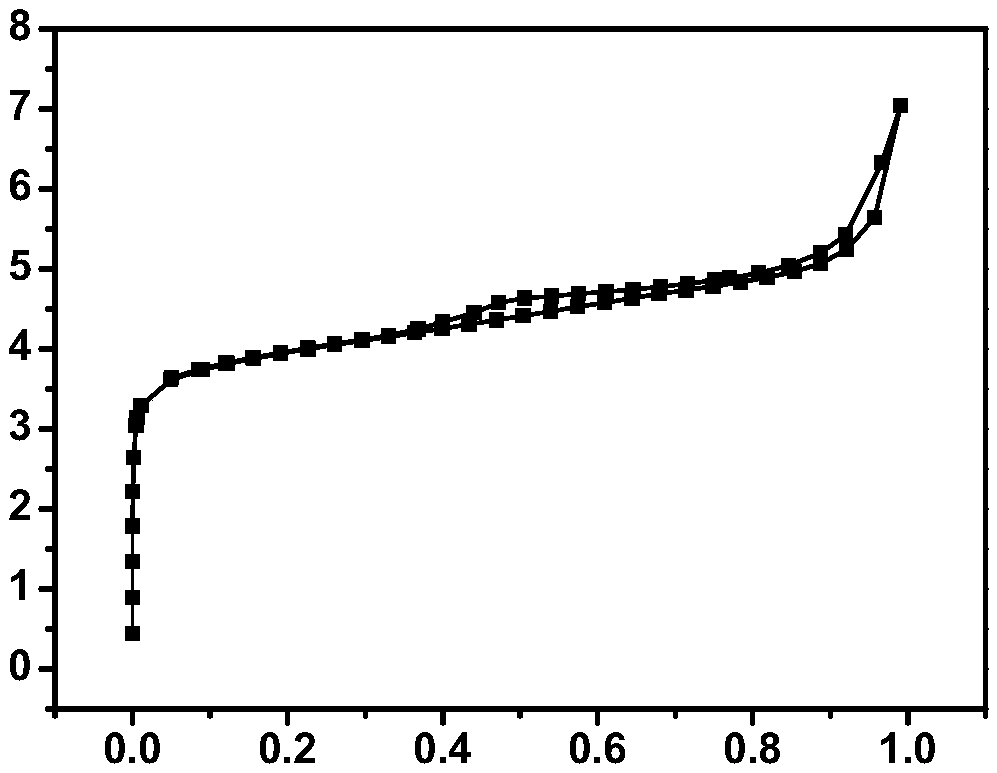

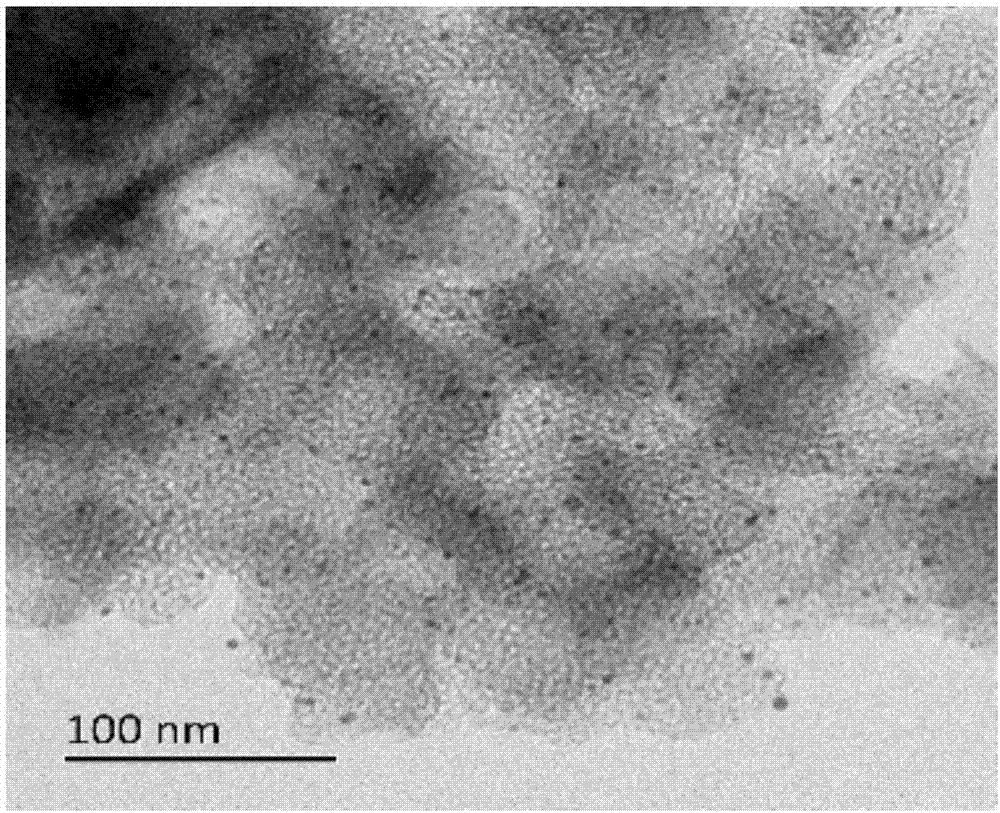

Dual mesoporous cobalt-based catalyst as well as preparation method and application thereof

ActiveCN102059118ARich mesostructureAvoid issues such as proliferation limitationsHydrocarbon from carbon oxidesCatalyst activation/preparationCarbon numberMesoporous silica

The invention disclosed a dual mesoporous cobalt-based catalyst comprising 5-44 percent of metallic cobalt and 56-95 percent of dual mesoporous silicon dioxide, wherein the first pore diameter of the dual mesoporous catalyst is 2.3-2.6nm which accounts for 20-35 percent of the catalyst pore structure; and the second pore diameter of the dual mesoporous catalyst is 10-50nm which accounts for 40-60 percent of the catalyst pore structure. The catalyst can be prepared by adopting a volumetric immersion method. The dual mesoporous cobalt-based catalyst has abundant mesoporous structures; and the catalyst has different double pore canal structures, thus the diffusional limitation and other problems of reactants and products can be avoided. The ratio of pore diameters of 2.3-2.6nm of small pore to 10-50nm of large pore in a carrier can be adjusted by changing the ratio of a pore-expanding agent TMB (Tetramethylbenzidine) and a surfactant CTAB (Cetyltrimethyl Ammonium Bromide) and the ageing temperature, thus the dual mesoporous cobalt-based catalyst has the advantage of facilitating the selective synthesis of long chain hydrocarbons with different carbon numbers.

Owner:中科潞安能源技术有限公司

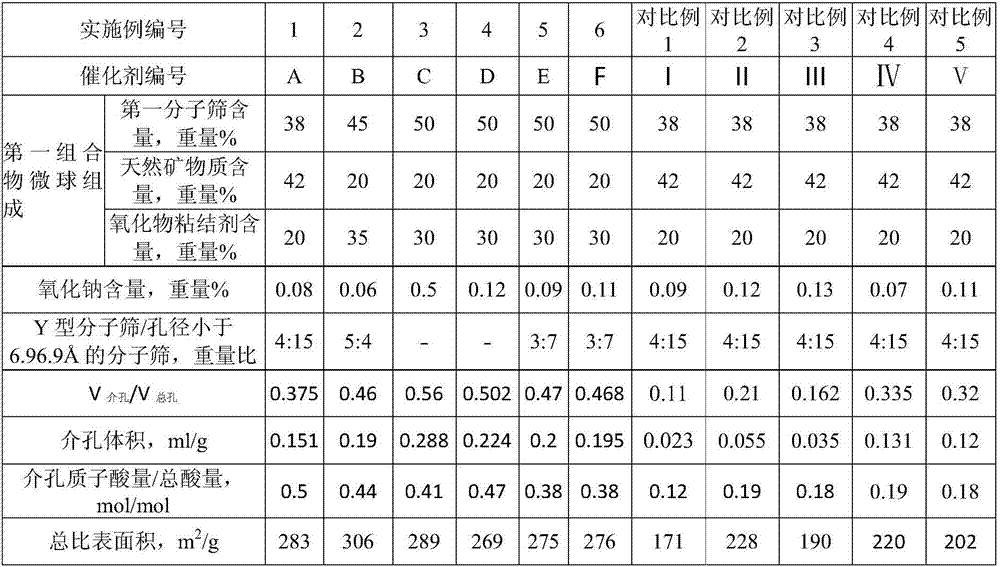

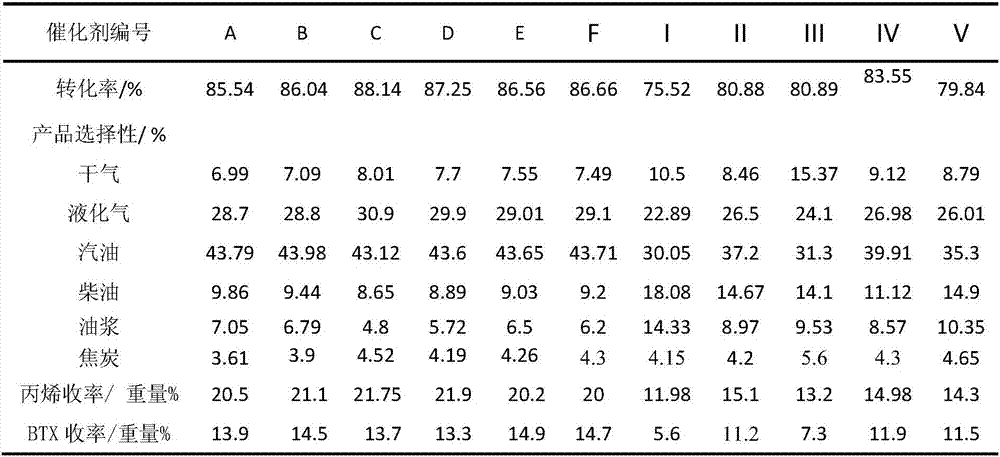

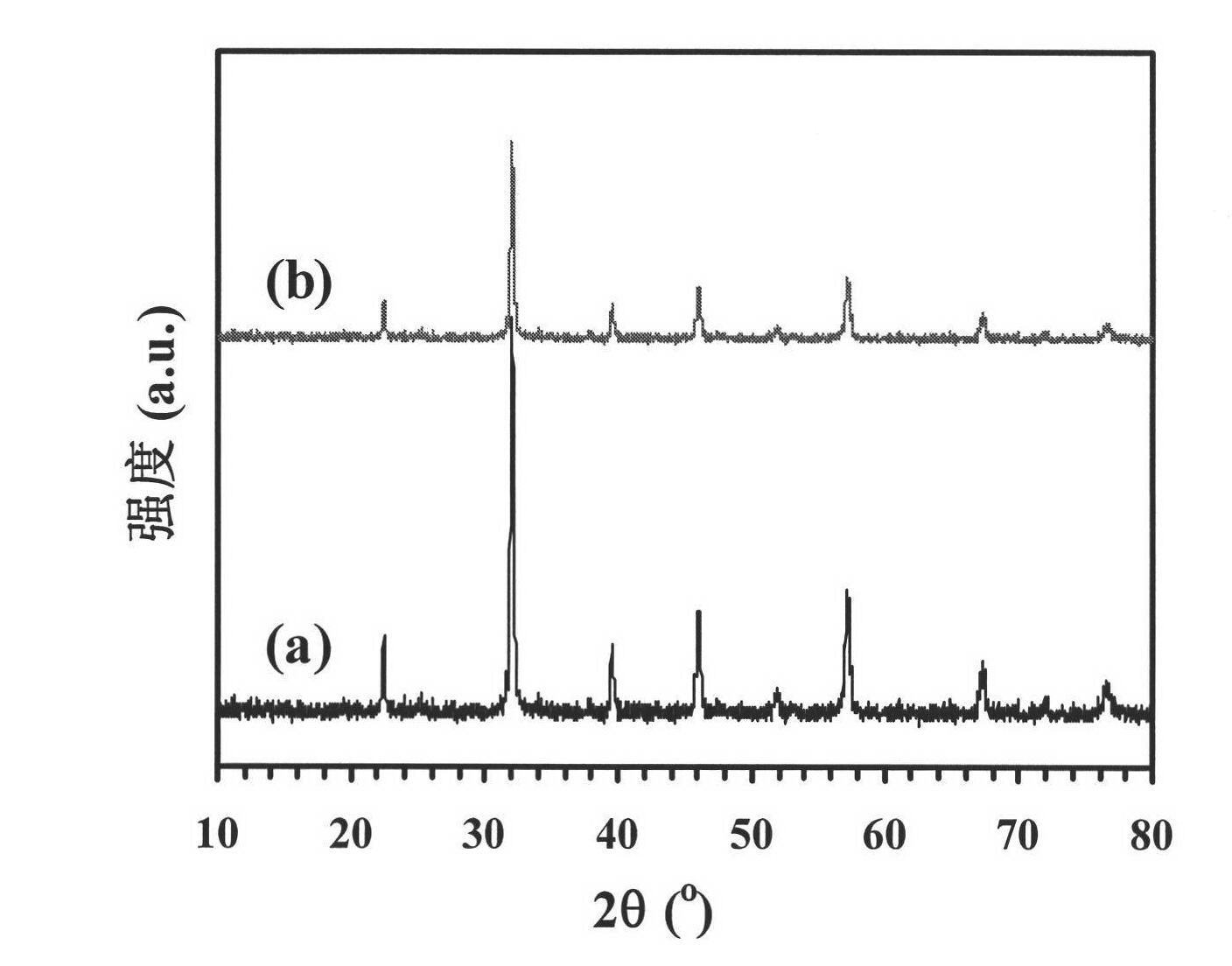

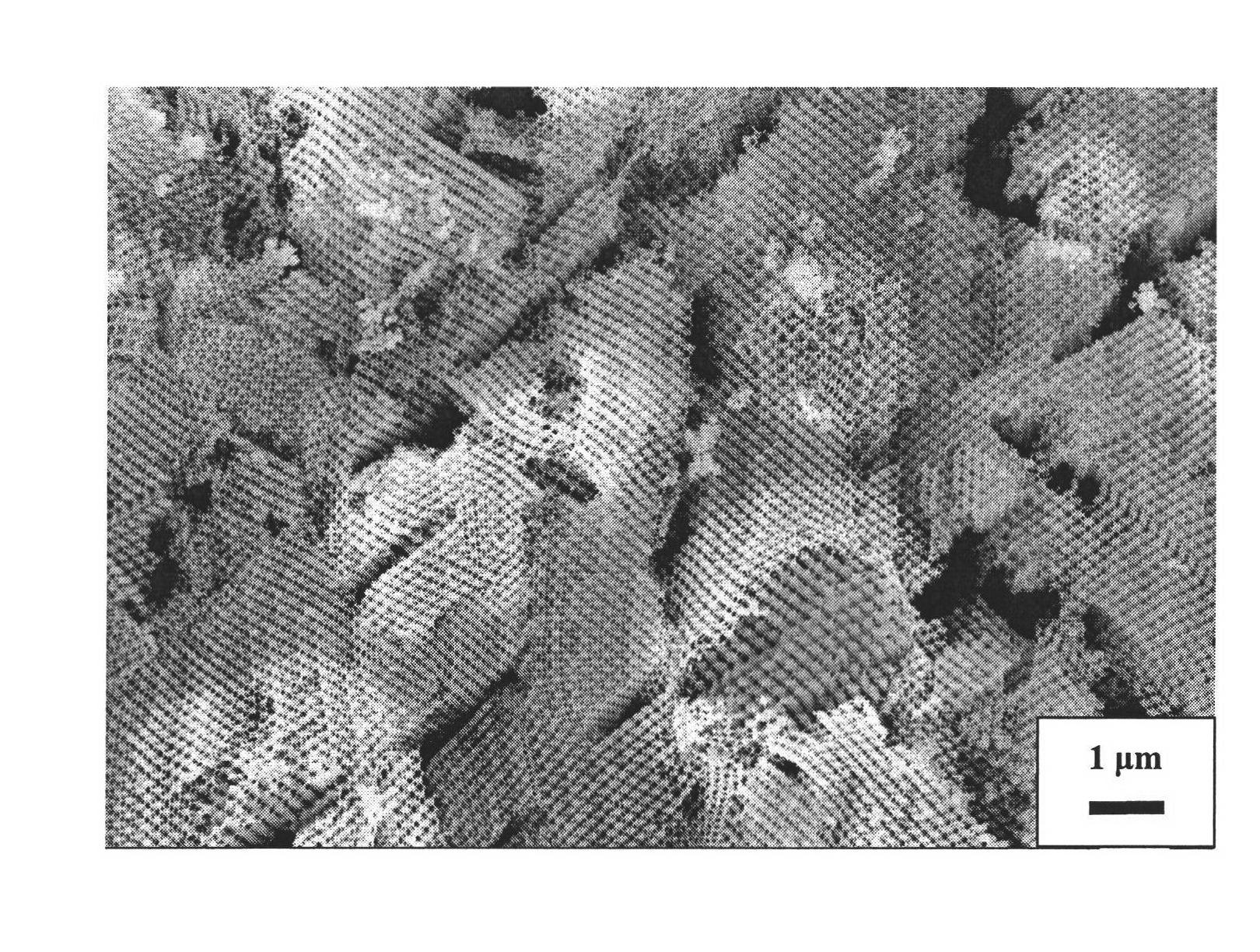

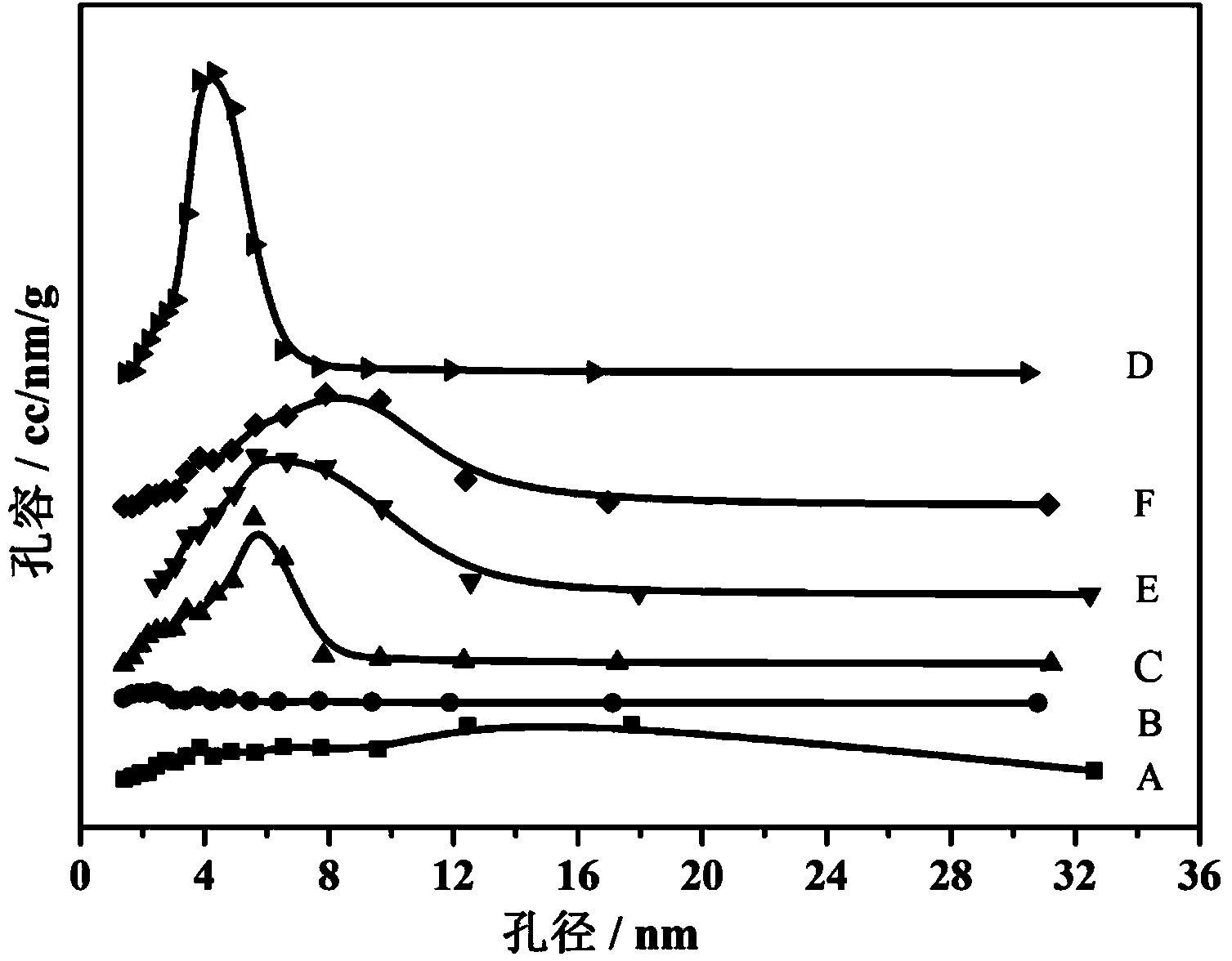

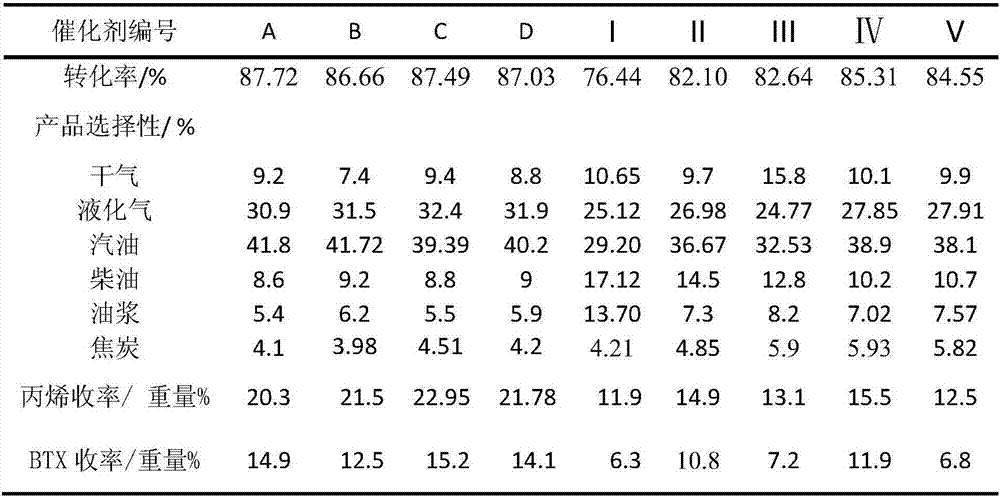

Catalytic cracking catalyst and preparation method thereof

ActiveCN107971018ARich mesostructureHigh hydrothermal stabilityCatalytic crackingMolecular sieve catalystsMolecular sieveSpray dried

The invention provides a catalytic cracking catalyst and a preparation method thereof. The catalyst comprises 5 to 65% of natural mineral matters, 10 to 60% of an oxide binder, 24 to 75% of first molecular sieves, wherein the first molecular sieves are composed of molecular sieves with pore diameters of less than 6.9 angstroms and optional Y type molecular sieves, and the amount of mesoporous protonic acid in the catalyst accounts for 20 to 70% of total acid amount. The preparation method comprises the following steps: formation of slurry including the first molecular sieves, the natural mineral matters and the inorganic oxide binder; spray drying; and treatment with alkali and compound acid. The catalytic cracking catalyst has the advantages of higher propylene yield and BTX yield when applied to catalytic cracking of petroleum hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

Mesoporous chromium-oxide-based catalyst for dehydrohalogenation reaction

ActiveCN104475080ALarge specific surface areaRich mesostructurePreparation by hydrogen halide split-offMetal/metal-oxides/metal-hydroxide catalystsIonic strengthDehydrohalogenation

The invention discloses a mesoporous chromium-oxide-based catalyst for dehydrohalogenation reaction and a preparation method of the mesoporous chromium-oxide-based catalyst, and aims at solving the problems of small specific surface area, narrow porous structure and the like in preparation of the chromium-oxide-based catalyst. The preparation method comprises the following steps: (1) preparing an aqueous solution containing chromium salt, a pH regulating agent, a template agent and an ion-strength regulating agent, flowing back at the temperature of 100 DEG C, roasting under the condition of 350-500 DEG C so as to obtain a mesoporous chromium-oxide base body; and (2) dipping the aqueous solution doped with components into the chromium-oxide base body obtained in the step (1) and finally roasting at the temperature of 400-550 DEG C to prepare the catalyst. The mesoporous chromium-oxide-based catalyst disclosed by the invention can be used for achieving the high-efficiency dehydrohalogenation reaction of fluorochloroalkylene.

Owner:XIAN MODERN CHEM RES INST

Preparation method of three-dimensional ordered macroporous La1-xSrxCrO3 with mesoporous pore wall

The invention discloses a preparation method of three-dimensional ordered macroporous La1-xSrxCrO3 (x=0, 0.4) with a mesoporous pore wall. The preparation method comprises the following steps of: dissolving lanthanum nitrate and chromium nitrate in mixed liquid of polyethylene glycol 400 and absolute methanol in the molar ratio of 1:1 or dissolving lanthanum nitrate, strontium nitrate and chromium nitrate in mixed liquid of polyethylene glycol 400, absolute methanol and deionized water in the molar ratio of 0.6:0.4:1; adding citric acid in the molar ratio of 1:1 of chromium nitrate to citric acid; performing ultrasonic treatment; adding absolute methanol solution of P123 and performing ultrasonic treatment so as to form homogeneous solution; adjusting metal ion concentration to be 2.0 mol / L; and pouring a polymethyl methacrylate (PMMA) microsphere template into the solution, soaking, performing suction filtration, drying and baking the obtained substance in two steps. The La1-xSrxCrO3prepared by the preparation method has high degree of crystallization, controllable particle shape and pore size, readily available raw materials, high product stability, high electrical conductivityand good application prospect.

Owner:BEIJING UNIV OF TECH

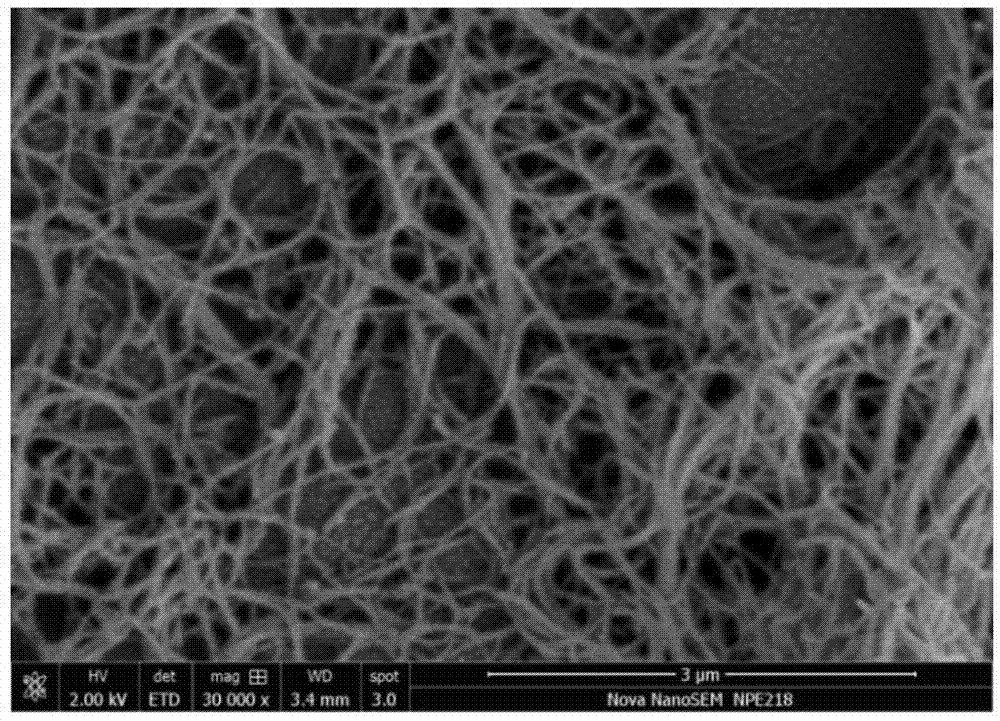

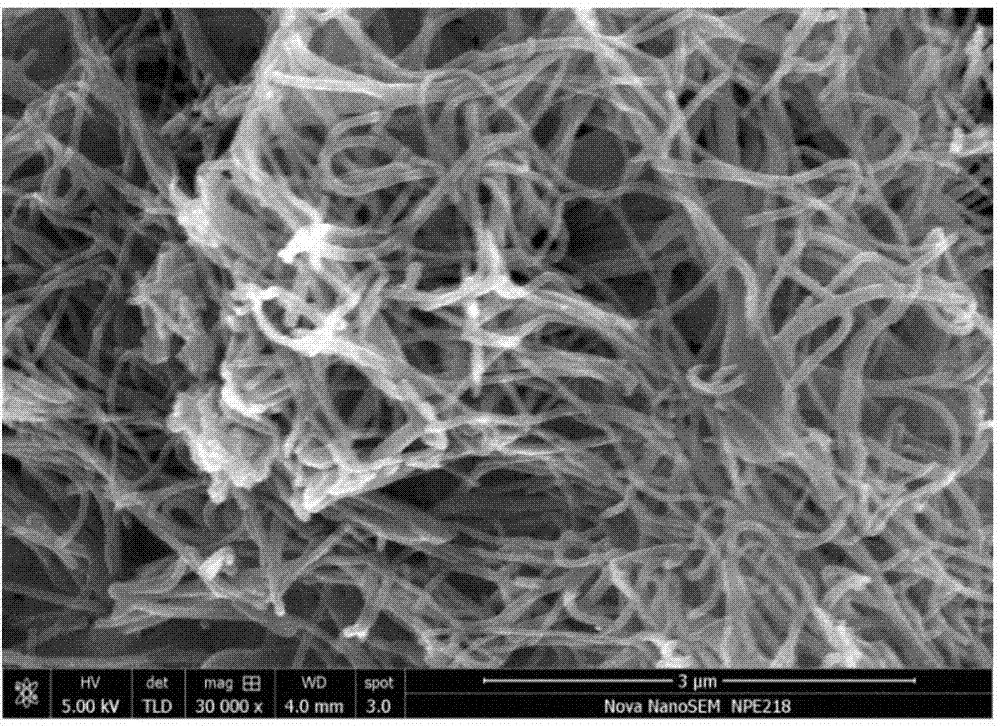

Preparation method and application of heteroatom-doped porous carbon nano-tube

InactiveCN103896246ASimple processHigh yieldMaterial nanotechnologyHybrid capacitor electrodesCapacitancePolyphosphazene

The invention discloses a preparation method and application of a heteroatom-doped porous carbon nano-tube in the technical field of the inorganic carbon nano industry. The carbon nano-tube prepared by using a polyphosphazene nano-tube as a precursor has relatively large specific surface area, and abundant mesoporous structures are formed on the tube wall of the carbon nano-tube. According to the invention, the preparation process is simple in technology and high in yield; the prepared carbon nano-tube is regular in shape and appearance and high in heteroatom content, and has good capacitive performance when being used as an electrode material of a super-capacitor. Charge and discharge tests show that a sample subjected to carbonization at 900 DEG C has the specific capacity of 190F / g and excellent cycling stability.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of ordered mesopore molybdenum carbide

ActiveCN107311176AFacilitated DiffusionHigh activityTungsten/molybdenum carbideDistillationCarbonization

The invention relates to a preparation method of ordered mesopore molybdenum carbide, which belongs to the field of ordered mesopore material preparation. The preparation method comprises the following steps of adopting a hard template method, adopting saccharose as a carbon source and an SBA-15 molecular sieve as a template, stirring, carrying out ultrasound, drying and carbonizing, roasting, and acid pickling to obtain an ordered mesopore carbon material; then soaking the ordered mesopore carbon material into an ammonium molybdate solution (a molybdenum source), stirring, drying by distillation, and roasting to obtain an ordered mesopore carbon / molybdenum trioxide compound; mixing the ordered mesopore carbon / molybdenum trioxide compound with magnesium powder, and carrying out magnesiothermic reduction reaction in a tube furnace to obtain the ordered mesopore molybdenum carbide material. During the preparation process, the carbonization reduction temperature is greatly reduced; the molybdenum carbide prepared at a low temperature condition is concentrated in bore diameter and large in specific surface area; the rich mesoporous structure is beneficial to diffusion of reactants and exposure of active sites, so that the activity and the stability of a molybdenum carbide catalyst are improved. The preparation method is advanced in process, low in cost, easy for getting raw materials, reasonable in match ratio, and stable in products, and is an advanced method for preparing the ordered mesopore molybdenum carbide.

Owner:TAIYUAN UNIV OF TECH

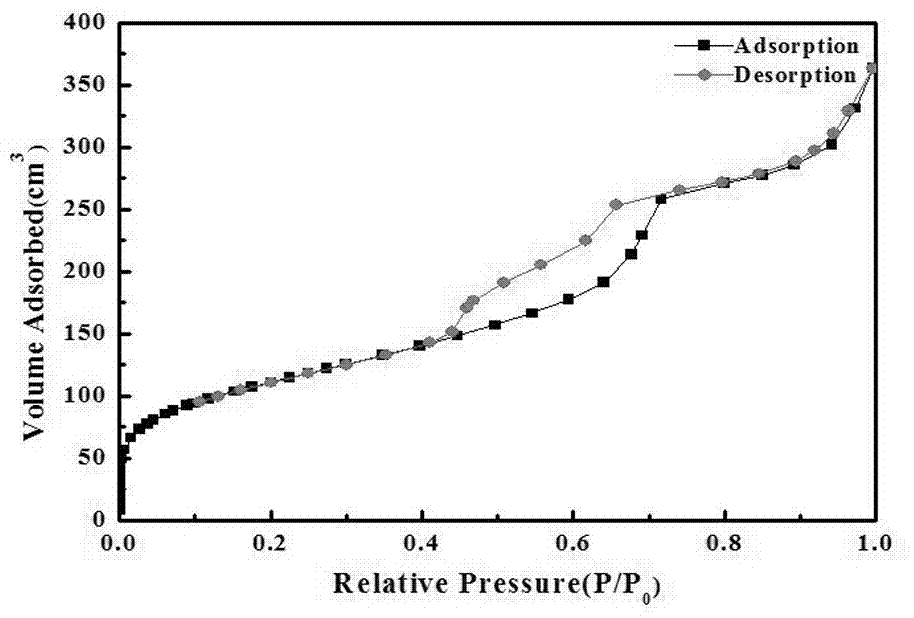

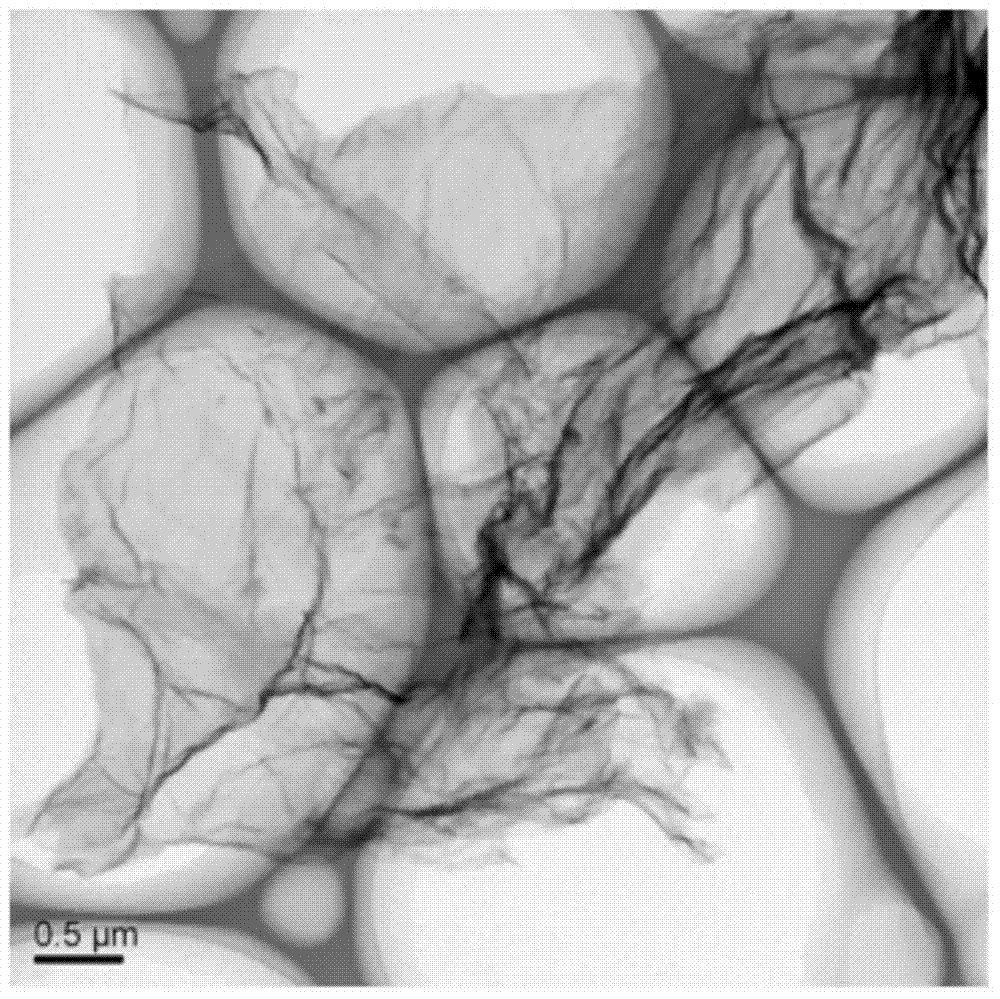

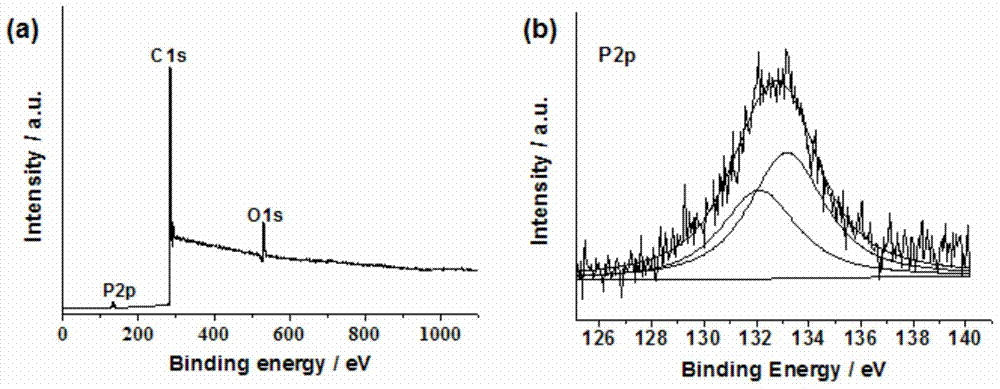

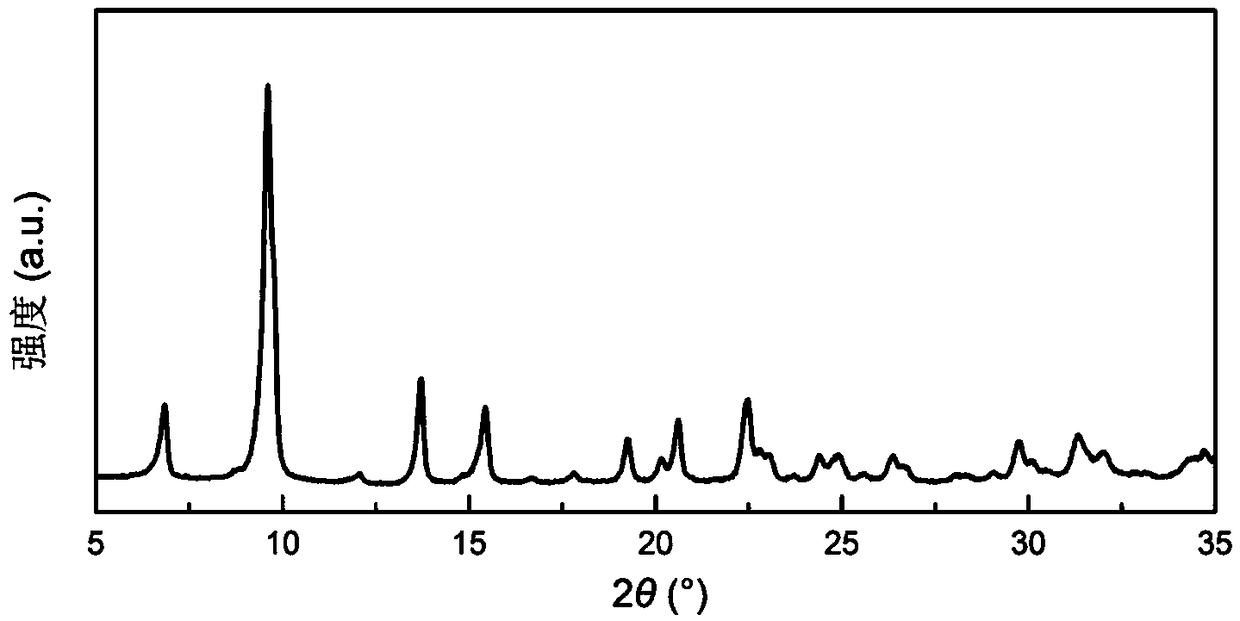

Phosphorus-doped graphene oxygen reduction electro-catalyst and preparation method and application thereof

InactiveCN103495430AIncrease contentEvenly distributedPhysical/chemical process catalystsCell electrodesCarbon monoxide poisonElectrochemical biosensor

The invention relates to a catalyst, in particular to phosphorus-doped graphene oxygen reduction electro-catalyst and a preparation method and application thereof. The phosphorus-doped graphene oxygen reduction electro-catalyst contains oxidized graphene substrate and active phosphorus doped or attached to the surface and inside of the oxidized graphene substrate. The preparation method includes the steps of 1, preparing the oxidized graphene; 2, mixing the oxidized graphene with phosphorus-bearing precursor; 3, drying; 4, performing pyrolysis. The phosphorus-doped graphene oxygen reduction electro-catalyst is good oxygen reduction electro-catalyst, is high in catalytic activity and resistant to methanol poisoning and carbon monoxide poisoning, good in stability and capable of serving as electro-catalyst for fuel cells and metal-air cells and serving as electrode active material for electrochemical energy storage and conversion devices such as lithium ion cells, sodium ion cells, lithium-sulfur cells and supercapacitors, and is also applicable to the fields such as electrochemistry / biosensors.

Owner:CHINA WEST NORMAL UNIVERSITY

Flocculating agent for impurity removal process of steviol glycosides

ActiveCN105037460AIncrease in sizeSettling fastSugar derivativesSugar derivatives preparationWater bathsFiltration

The invention discloses a flocculating agent for an impurity removal process of steviol glycosides. The flocculating agent comprises, by weight, 10-20 parts of modified chitosan, 15-25 parts of modified lignin, 30-40 parts of polymeric ferric sulfate, 25-35 parts of aluminium citrate, 10-15 parts of magnesium sulfate, 20-30 parts of polymeric ferric silicate-sulfate, 3-5 parts of porous pearlite powder and 4-6 parts of zeolite powder. A preparation method of the modified chitosan comprises the steps that carboxymethyl chitosan is added into a sodium hydroxide aqueous solution, after heating and heat preservation are conducted, a 3-chloro-2-hydroxypropyltrimethylammonium chloride aqueous solution is dropwise added, the heat preservation is continuously conducted, and then the mixture is adjusted to be neutral to obtain a first material; the first first material is added into ethyl alcohol, filtration is conducted, and a second material is obtained after drying; the second material is added into distilled water to be evenly stirred, water-bath heating is conducted, acrylamide and an initiating agent are sequentially and dropwise added, and a third material is obtained after the heat preservation is conducted; the third material is added into acetone, the filtration is conducted, and the modified chitosan is obtained after drying is conducted.

Owner:BENGBU HUADONG BIOLOGICAL TECH

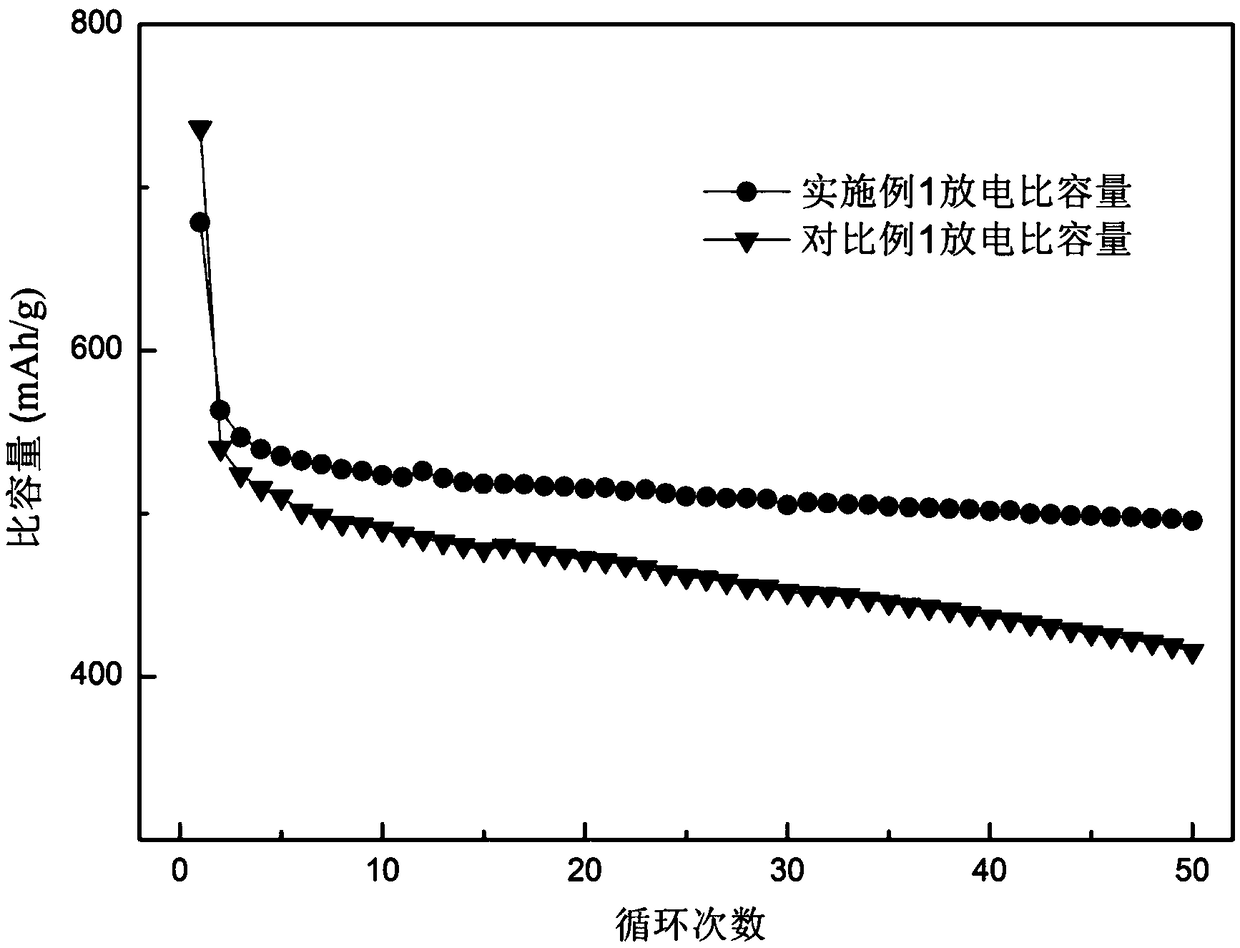

A preparation method of silicon-carbon negative electrode material for lithium ion battery

The invention discloses a preparation method of a silicon-carbon negative electrode material of a lithium ion battery, comprising the following steps: adding a proper amount of nano-silicon powder, adispersant, zinc nitrate hexahydrate, terephthalic acid and CNTs to a sufficient amount of N, N- A mixed solution is prepared from dimethylformamide, and then the mixed solution is uniformly dispersed; A suitable amount of triethylamine reagent is slowly and uniformly adde into that mixture prepared in the first step, aft full reaction, the precipitate is washed, filtered and dried to obtain CNTs / MOF- 5, coat that nano Si precursor; The precursor was put into a tubular furnace protected by inert gas and carbonized at high temperature to obtain silicon-carbon composites. Silicon-carbon anode materials for lithium ion batteries were prepared by mixing the prepared silicon-carbon composite and artificial graphite homogeneously. CNTs is adde into that preparation process of the silicon-carbonnegative electrode material of the lithium ion battery, and the CNTs can be use as a conductive network structure, the electronic conductivity of the silicon-carbon negative electrode is greatly improved, and the first effect and the multiplicity of the charge-discharge cycle of the silicon-carbon negative electrode are improved.

Owner:江西中汽瑞华新能源科技有限公司

Method for preparing noble metal hollow micro capsule

InactiveCN1683066AReduce breakage rateRich mesostructureMicroballoon preparationMicrocapsule preparationPolyelectrolyteMicrosphere

The present invention relates to the preparation process of a kind of hollow noble metal microcapsule. After mesoporous silica microball as template is amino group modified, nano noble metal particle is filled into the microball hole canal and one layer of polyelectrolyte is adsorbed to the surface, and silica is finally leached out through treatment in alkali solution condition to prepare the hollow noble metal microcapsule. Said process is simple, has adjustable shell material and is suitable for the preparation of most kinds of functional microcapsule. The microcapsule product has fine appearance and excellent performance, and may find its wide application in different fields, such as medicine preparation, catalyzing, electrochemistry, etc.

Owner:FUDAN UNIV

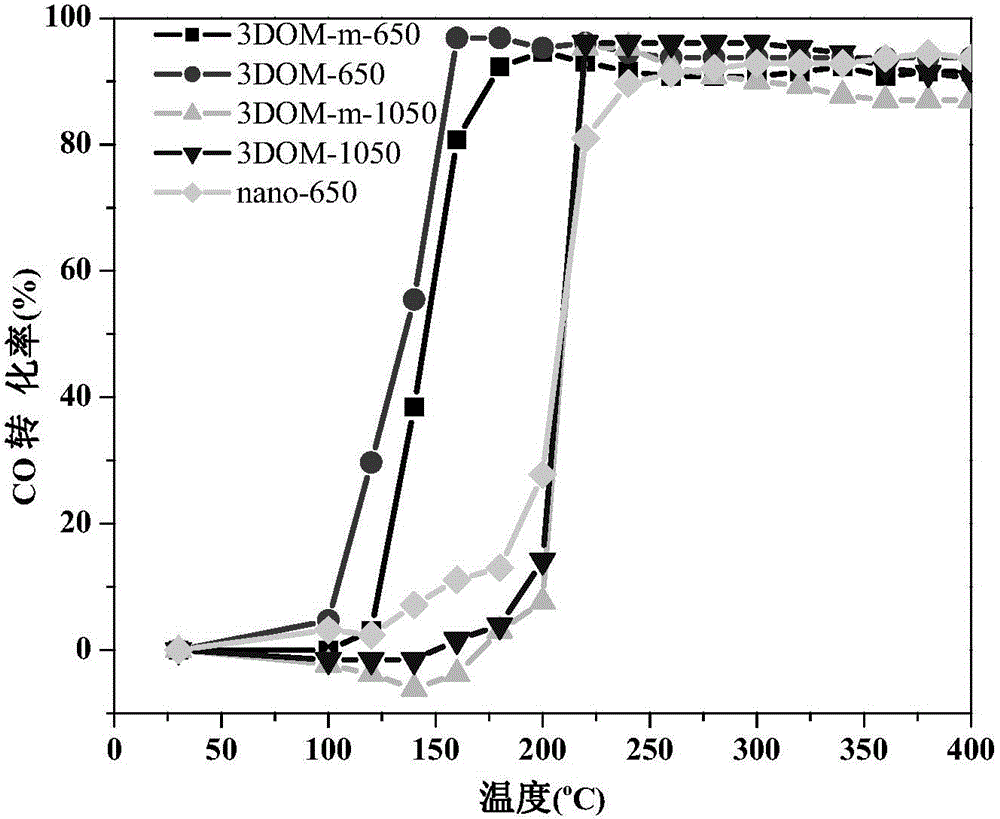

Thermally stable precious metal-doped three-dimensional ordered macroporous-mesoporous three-way catalyst as well as preparation method and application thereof

ActiveCN104607187AGood dispersionHigh specific surface areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMicrosphereCerium

The invention relates to a thermally stable precious metal-doped three-dimensional ordered macroporous-mesoporous three-way catalyst as well as a preparation method and application thereof, and belongs to the technical field of heterogeneous catalysis. The molecular formula of the catalyst is Ce(0.7-x)Zr0.3MxO2, wherein x is greater than 0 but less than 0.1 and M is a precious metal element which enters cerium-zirconium solid solution lattices. The catalyst has a three-dimensional ordered macroporous-mesoporous structure and the pore wall of the macropore is formed by vermiform mesopores. The preparation method comprises the following steps: firstly by taking polymethyl methacrylate microspheres as a hard template, a triblock copolymer as a soft template, ethanediol as an additive and absolute methanol as a solvent, dipping a PMMA hard template by virtue of a mixed solution containing the soft template, the additive, the solvent and soluble metal salt; crystallizing and drying in a constant temperature humidity chamber; and raising the temperature in a programmed manner and roasting to obtain a product. The catalyst provided by the invention has good three-way catalytic activity and high-temperature thermal stability and has a good application prospect in the field of catalysis and purification of motor vehicle exhaust.

Owner:BEIJING UNIV OF TECH

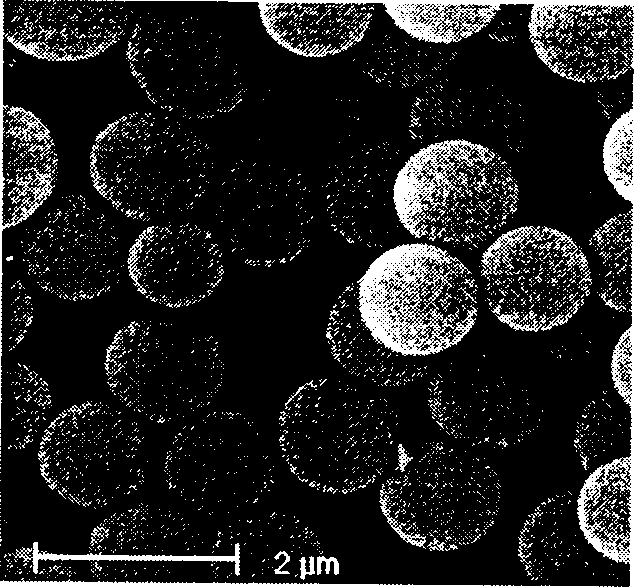

Preparation method of nitrogen and sulfur co-doping micropore-mesopore carbon microspheres

InactiveCN106492749ALarge specific surface areaRich mesostructureOther chemical processesWater contaminantsMicrosphereCarbonization

The invention relates to a preparation method of nitrogen and sulfur co-doping micropore-mesopore carbon microspheres, and belongs to the scientific and technical field of materials. The method comprises the steps that 3-aminophenol, a formaldehyde solution, an L-cysteine, a surface active agent, silica soil, ethyl alcohol and water are taken on the basis of the mass ratio being 1:(1.2-1.8):(0.5-1.5):(0.5-1.5):(1-3):(32-82):(40-100); the water and ethyl alcohol are mixed to be uniform under the temperature of 20-35 DEG C, and the other raw materials are added into the mixture in sequence, the reaction is performed for 24 h, hydrothermal treatment is performed under the temperature of 100 DEG C for 24 h, under the nitrogen atmosphere, the room temperature is increased to 600-900 DEG C at the heating rate of 2-10 DEG C / min for carbonization, NaOH is used for removing SiO2, and nitrogen and sulfur co-doping mesoporous carbon microspheres are obtained. The obtained carbon microspheres, KOH and water are taken on the basis of the mass ratio being 1:(1-4):(20-50) and mixed to be uniform, after drying, in the nitrogen atmosphere, the room temperature is increased to 600-900 DEG C at the heating speed of 2-10 DEG C / min for activation, and the nitrogen and sulfur co-doping micropore-mesopore carbon microspheres are obtained. The technology is simple, the obtained nitrogen and sulfur co-doping micropore-mesopore carbon microspheres are wide in application prospect on the aspect of adsorption and removal of heavy metal ions in wastewater.

Owner:TONGJI UNIV

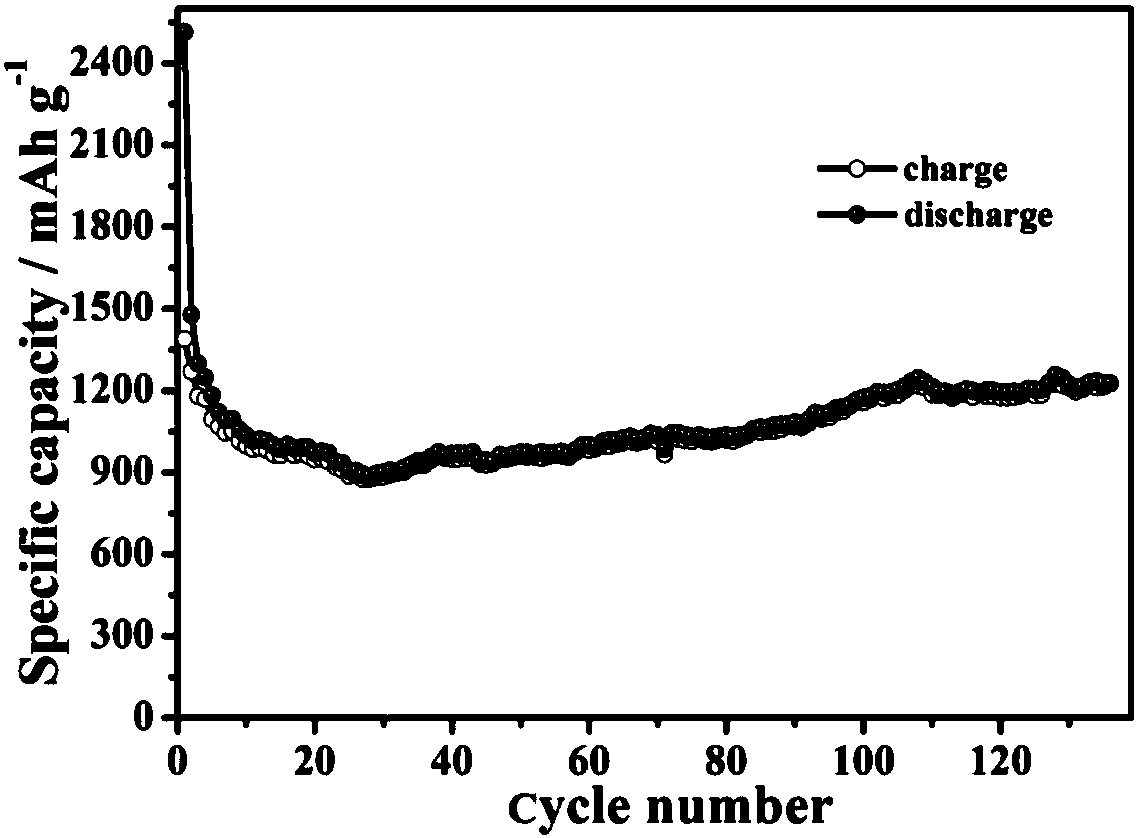

Amino functional carbon-sulfur composite material of porous structure and preparation method and application of material

ActiveCN106159205ASimple processGood reproducibilityNon-aqueous electrolyte accumulator electrodesPolyimideNitrogen atmosphere

The invention belongs to the technical field of carbon-sulfur batteries and particularly relates to an amino functional carbon-sulfur composite material of a porous structure and a preparation method and application of the material. Polyimide serves as the raw material, is pre-oxidized and then synthesized into an amino-containing carbon material precursor of the porous structure by means of a pore forming agent at the nitrogen atmosphere through high-temperature carbonization, the precursor and elemental sulfur are subjected to heat treatment, and the carbon-sulfur composite material is obtained. The process is simple, reproducibility is good, and the prepared composite material has a rich pore structure and can be used for the positive pole of a carbon-sulfur battery. Amino groups in the composite material can enhance constraint to polysulfide anions, dissolution and migration of the polysulfide anions in electrolyte are reduced, electric chemical performance of the positive pole material of the carbon-sulfur battery is improved, and specific discharge capacity, rate capability and cycle performance are good.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

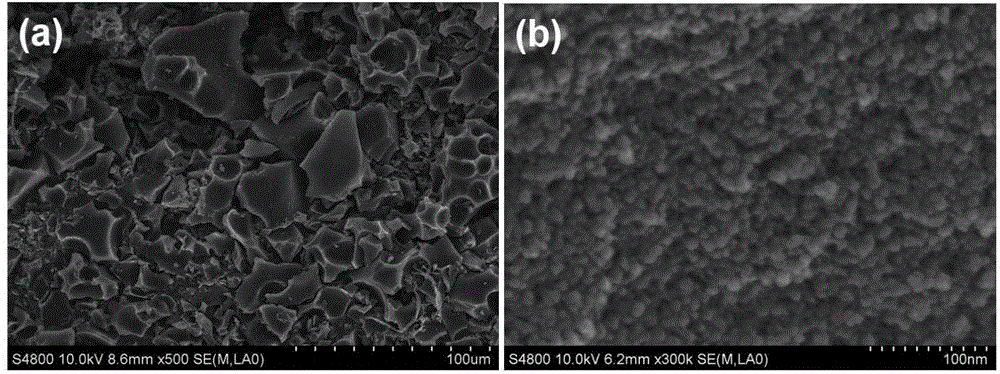

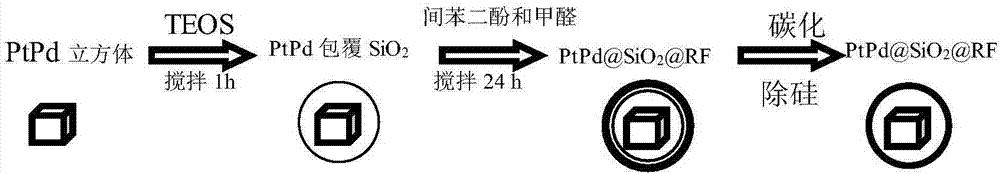

Carbon-coated metal nanocube material and its preparation method

ActiveCN107442111ARich mesostructureMesoporous structure fastMetal/metal-oxides/metal-hydroxide catalystsCarbon layerAlcohol

The invention provides a carbon-coated metal nanocube material and a preparation method thereof. The preparation method comprises the following steps: S1) mixing a metal nanocube and organosilicate in an alcohol solvent, then subjecting the obtained mixture and an alkaline solution to a mixing reaction, adding a phenol compound and an aldehyde compound, carrying out a mixing reaction and then carrying out calcining so as to obtain a carbon sphere; and S2) subjecting the carbon sphere to corrosion with a HF solution or a hot alkaline solution to obtain the carbon-coated metal nanocube material. Compared with the prior art, the method provided by the invention has the following advantages: the surface of the metal nanocube is coated with silica and phenolic resin in a solution via a one-step process, then the metal nanocube coated by silica and a carbon layer is prepared through calcining, and silica in the carbon layer is removed through corrosion in an acid solution, so the method is simple and easily practicable, the thickness of the shell of the hollow carbon sphere is controllable, and the obtained carbon-coated metal nanocube material has abundant mesoporous structures, can provide fast electron conduction and inhibit the aggregation of metal nanocubes and is enhanced in stability.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Preparation method for silicon-phosphorus-aluminum molecular sieve

ActiveCN108557838ARich mesostructureHigh crystallinityMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveDiffusion resistance

The invention provides a preparation method for a silicon-phosphorus-aluminum molecular sieve, belonging to the technical field of molecular sieves. The preparation method mainly overcomes the problems of low mesopore content, great diffusional resistance, low catalytic reaction activity, proneness to inactivation and the like of traditional silicon-phosphorus-aluminum molecular sieves. Accordingto the preparation method in the invention, an aluminum source, a phosphorus source, a silicon source, a template and water are fully mixed, and the silicon-phosphorus-aluminum molecular sieve rich inmesoporous structures is prepared by changing the preparation method and adding a pore expanding agent; so the diffusion resistance of reaction raw materials and a product can be effectively reduced,the catalytic activity of the molecular sieve is improved, the selectivity of the target product is enhanced, and the service life of the catalyst is prolonged. The prepared silicon-phosphorus-aluminum molecular sieve has important application value in hydroisomerization, methanol to olefins, denitration of automobile exhaust gas and the like.

Owner:SHAANXI YANCHANG PETROLEUM GRP

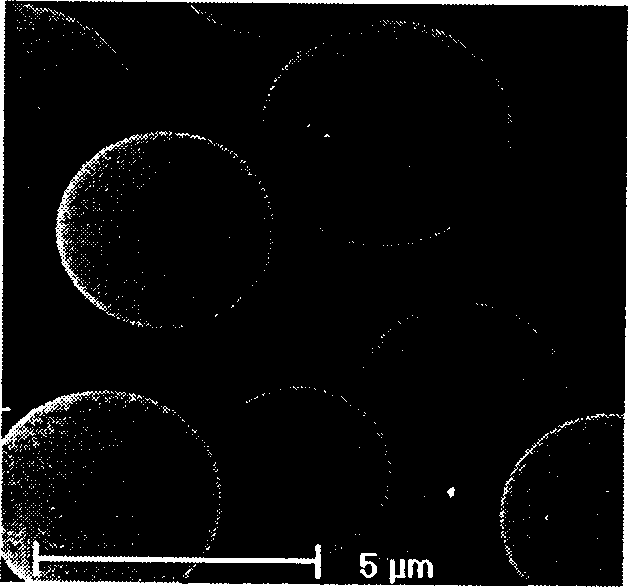

Preparation method of high-performance carbon-silicon composite hollow nano-sphere negative material

InactiveCN108598446AUniform shape and sizeGood dispersionMaterial nanotechnologyCell electrodesCarbon compositesMicrowave method

The invention discloses a preparation method of a high-performance carbon-silicon composite hollow nano-sphere negative material. The method comprises the following steps: taking phenols, aldehydes and orthosilicate organic substances as raw material, preparing through a microwave method to obtain phenolic resin and silicon dioxide composite under the effect of the alkali catalyst and the surfactant; and then obtaining the silicon-carbon composite hollow nano-sphere through high-temperature carbonization and thermal reduction treatment. The preparation method disclosed by the invention is simple in process, convenient for operation, easy in raw material obtaining, low in cost and in favor of industrial production, the prepared material size and morphology are uniform, and the rich mesoporous structure is provided, the ion transmission distance is shortened, the ion diffusion rate of the material is improved, and the conductivity of the material is improved, so that the material has stable cycling and rate performance, and the preparation method has potential application prospect on the negative electrode aspect of the lithium ion battery.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for preparing hierarchical porous SAPO-11 molecular sieve through ultrasonic assistance

ActiveCN108128786ARich mesostructureHigh crystallinityMolecular-sieve and base-exchange phosphatesChemistryMolecular sieve

The invention discloses a method for preparing a hierarchical porous SAPO-11 molecular sieve through ultrasonic assistance. The method comprises the following steps of: mixing an aluminum source, a phosphor source, a silicon source, deionized water, a microporous template agent and a mesoporous template agent in proportion, performing ultrasonic treatment, mixing at the room temperature until a mixture is changed into sol, drying, grinding, performing hydrothermal crystallization, and separating, drying and roasting a product to remove the mesoporous template agent, thereby obtaining the hierarchical porous SAPO-11 molecular sieve. Ultrasonic treatment conditions are as follows: ultrasonic power is 200-400 w, ultrasonic frequency is 20-60 kHz, and ultrasonic time is 0.5-4 hours. The hierarchical porous SAPO-11 molecular sieve prepared by the method has a complete AEL structure of the SAPO-11 molecular sieve and relatively high degree of crystallinity, and has a more mesoporous structures; besides, a very little water is used in a molecular sieve synthesis process; and generation of wastewater in a production process is reduced, and the yield and the single-kettle yield are increased greatly.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

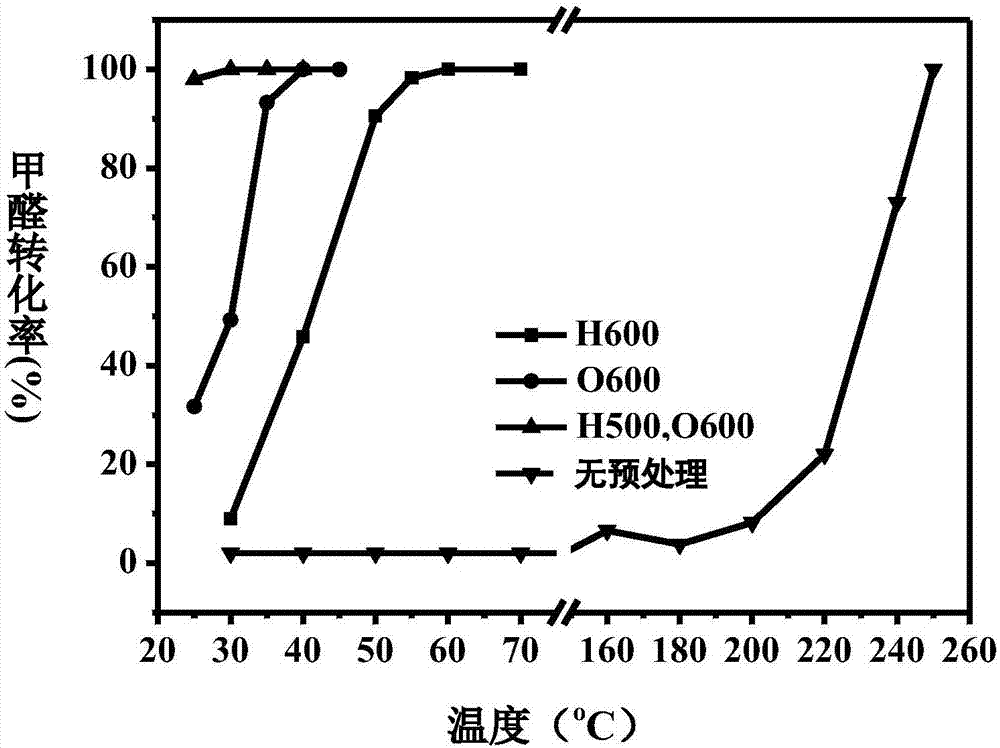

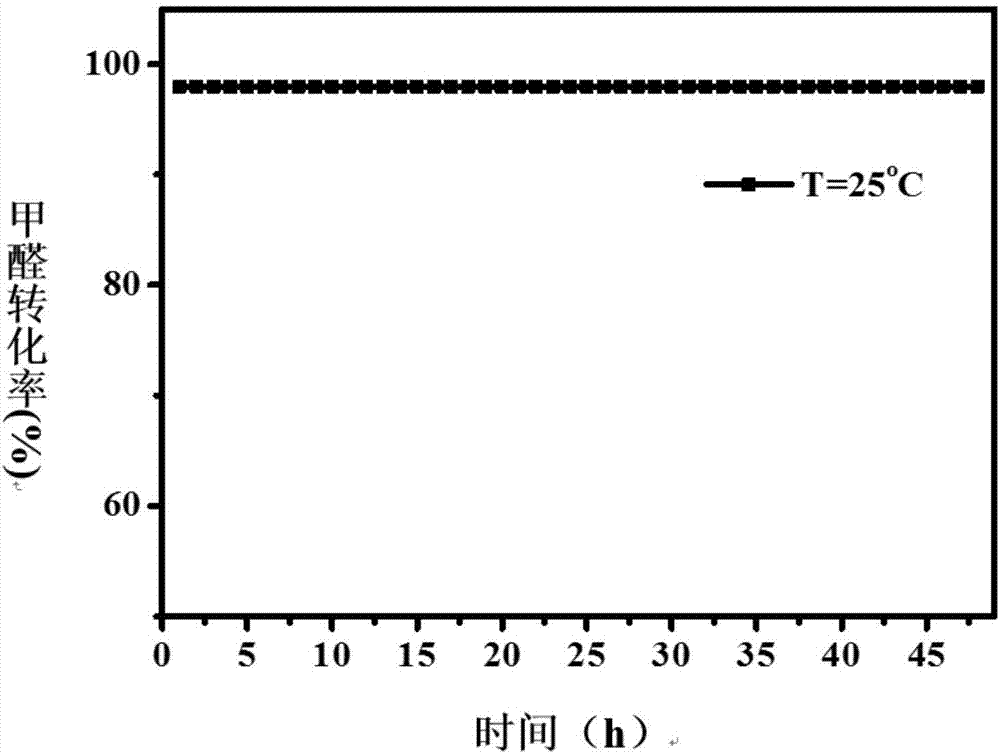

Nanogold-loaded meso-porous silicon material catalyst for formaldehyde room temperature oxidation, preparation and activation method and application

ActiveCN107376982AReduce dosageImprove thermal stabilityGas treatmentMolecular sieve catalystsActivation methodRoom temperature

The invention discloses a nanogold-loaded meso-porous silicon material catalyst for formaldehyde room temperature oxidation, a preparation and activation method and an application, and belongs to the technical field of the indoor environment catalytic purification. The preparation method for the catalyst comprises the following steps: decorating by a silane coupling agent, using an chloroauric acid as a precursor, and using a liquid-phase reduction method to obtain the nanogold-loaded meso-porous silicon material catalyst. The catalyst prepared by the method is applied to the room temperature catalytic formaldehyde reaction, and has the characteristics of high specific surface area, abundant pore structure, higher room temperature activity, and better stability. The product is carbon dioxide and water. The catalyst is suitable for an indoor low-concentration formaldehyde catalytic purification device, and has the extensive practical application prospect.

Owner:DALIAN UNIV OF TECH

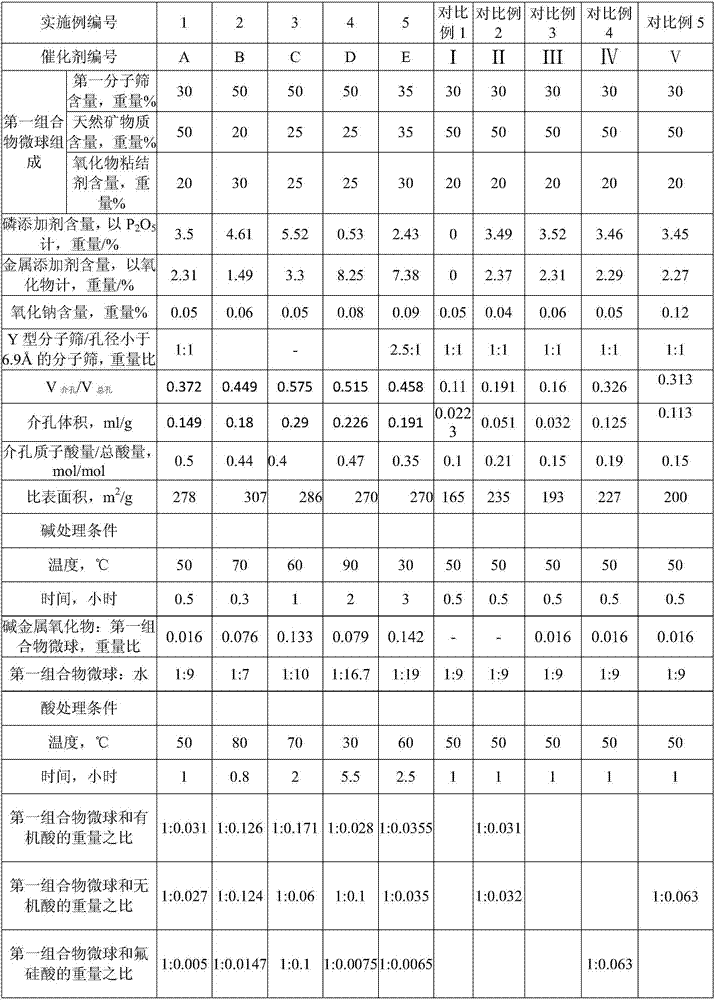

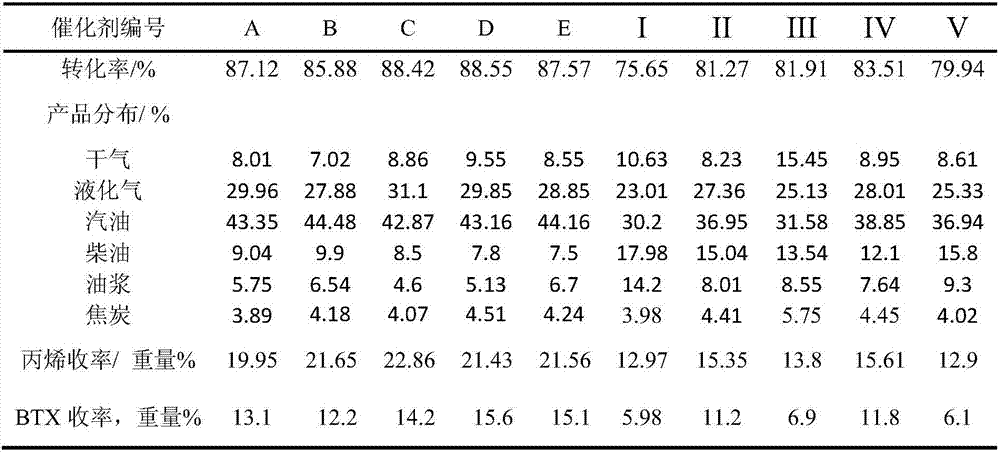

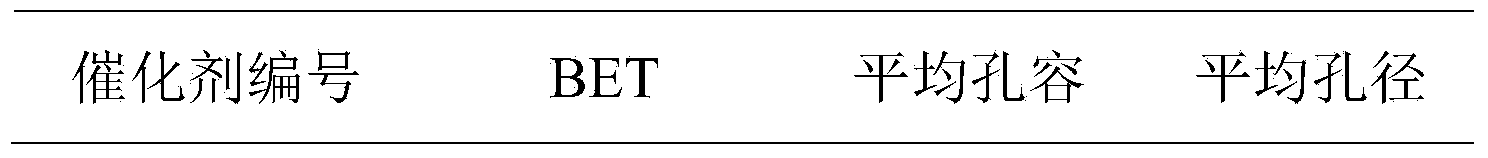

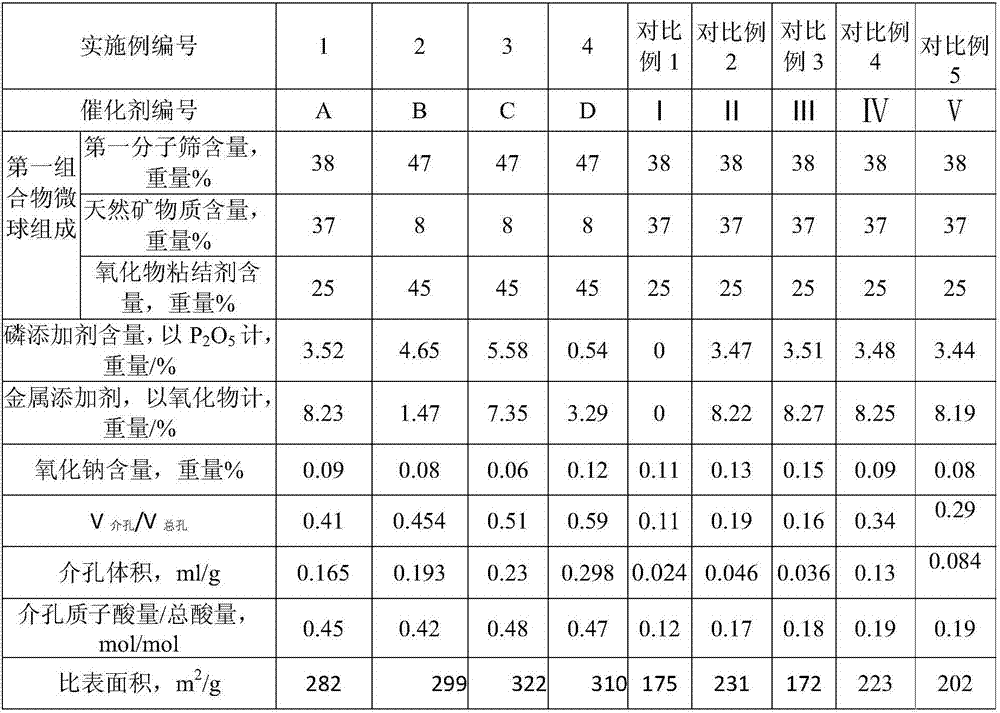

Catalytic cracking catalyst and preparation method thereof

ActiveCN107971017ARich mesostructureSuitable for mesoporous acidityCatalytic crackingMolecular sieve catalystsMolecular sieveBismuth

The invention provides a catalytic cracking catalyst and a preparation method thereof. The catalyst comprises 5 to 65% of natural mineral matters, 10 to 60% of an oxide binder, 24 to 75% of first molecular sieves, 0.1 to 15% of a phosphorus additive and 0.1 to 10% of a metallic additive, wherein the first molecular sieves are composed of molecular sieves with pore diameters of less than 6.9 angstroms and optional Y type molecular sieves or composed of two or more selected from molecular sieves with pore diameters of less than 6.9 angstroms; the metallic additive is at least one selected from agroup consisting of iron, cobalt, nickel, copper, manganese, zinc, tin, bismuth and gallium additives, and the amount of mesoporous protonic acid in the catalyst accounts for 20 to 70% of total acidamount. The preparation method comprises the following steps: formation of slurry including the first molecular sieves, the natural mineral matters and the inorganic oxide binder; spray drying; treatment with alkali and compound acid; and introduction of the phosphorus additive and the metallic additive. The catalytic cracking catalyst has the advantages of higher propylene yield and BTX yield when applied to catalytic cracking of petroleum hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

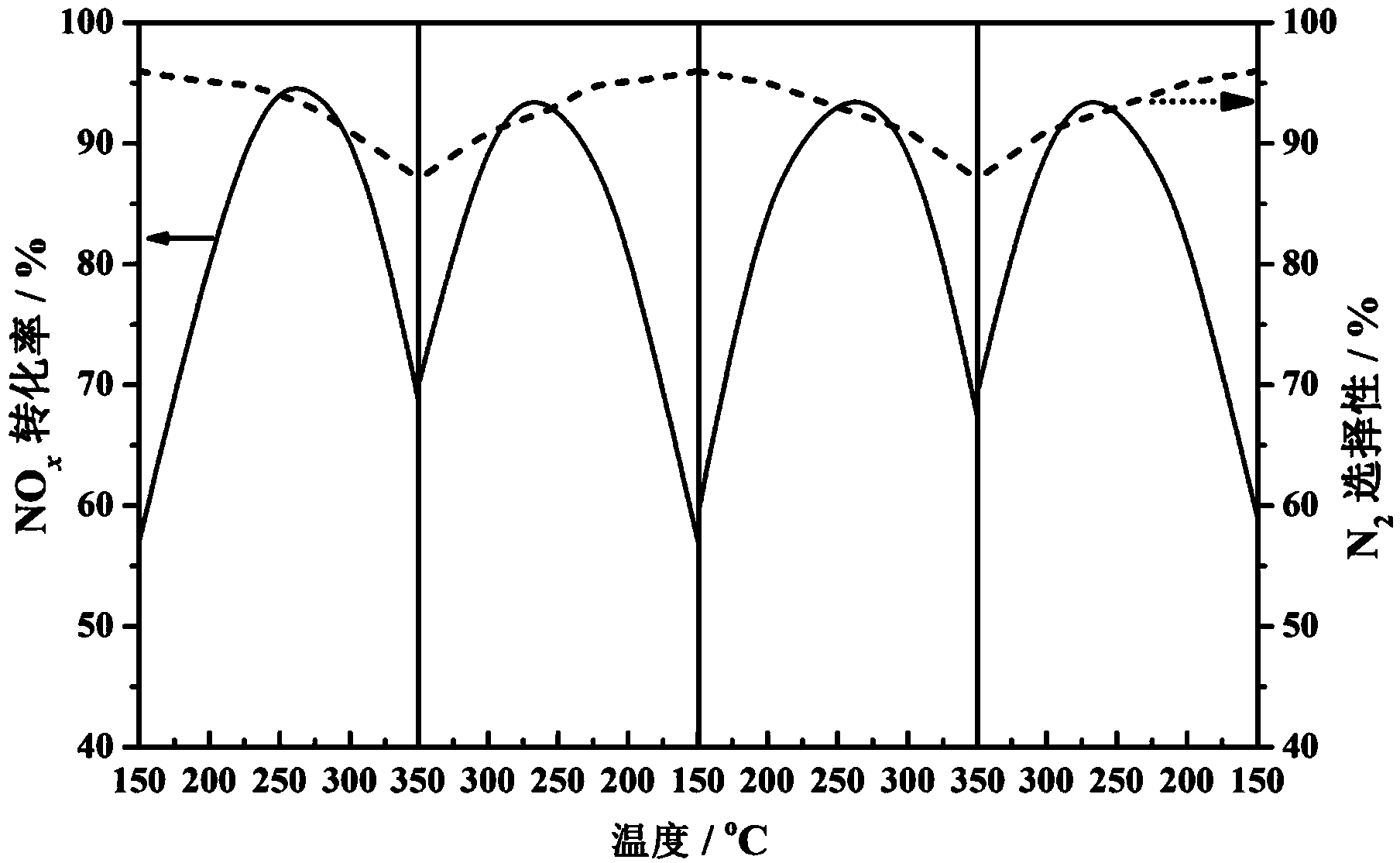

Mesoporous iron-based compound oxide catalyst, preparation method and use thereof to ammonia selective catalytic reduction of nitric oxide

ActiveCN104069861AImprove thermal stabilityImprove sulfur resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFiltrationCerium

The invention discloses a mesoporous iron-based compound oxide catalyst, a preparation method and use of the mesoporous iron-based compound oxide catalyst to ammonia selective catalytic reduction of nitric oxide. The preparation method of the catalyst is a mixed template method, namely comprises the following steps: adding salts corresponding to required iron source and cerium source or copper source in a prepared mixed template solution; with one of sodium hydroxide or ammonium hydroxide as a settling agent, continuously stirring under the condition that the temperature is 80-120 DEG C for 12-36h; and then performing suction filtration, washing, drying and roasting to obtain the catalyst. The catalyst prepared by adopting the preparation method is applied to the ammonia selective catalytic reduction of nitric oxide, has the characteristics of high specific surface area, abundant pore structures, high medium and low temperature catalytic activity, excellent N2 selectivity, wide operation temperature window, good stability and the like, is suitable for a catalytic purifying device for an immobilization source nitric oxide especially smoke of a coal-fired power plant, and is wide in industrialized application prospect.

Owner:DALIAN UNIV OF TECH

Catalytic cracking catalyst and preparation method thereof

ActiveCN107970991ARich mesostructureGood hydrothermal stabilityCatalytic crackingMolecular sieve catalystsManganeseSlurry

The invention provides a catalytic cracking catalyst and a preparation method thereof. The catalyst comprises 5 to 65% of natural mineral matters, 10 to 60% of an oxide binder, 24 to 75% of a MFI-structure molecular sieve, 0.1 to 15% of a phosphorus additive and 0.1 to 10% of a metallic additive, wherein the metallic additive is at least one selected from a group consisting of iron, cobalt, nickel, copper, manganese, zinc, tin, bismuth and gallium additives, and the amount of mesoporous protonic acid in the catalyst accounts for 20 to 70% of total acid amount. The preparation method comprisesthe following steps: formation of slurry including the MFI-structure molecular sieve, the natural mineral matters and the inorganic oxide binder; spray drying; treatment with alkali and compound acid;and introduction of the phosphorus additive and the metallic additive. The catalytic cracking catalyst has the advantages of higher propylene yield and BTX yield when applied to catalytic cracking ofpetroleum hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com