Method for preparing hierarchical porous SAPO-11 molecular sieve through ultrasonic assistance

A SAPO-11, ultrasonic-assisted technology, applied in the field of ultrasonic-assisted preparation of multi-stage SAPO-11 molecular sieves, can solve the problem of low mesopore increase, achieve high crystallinity, reduce waste water production, and increase single-pot yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This example provides a method for preparing SAPO-11 hierarchically porous molecular sieves by an ultrasonic-assisted method, which specifically includes: first mixing 4.085g of aluminum isopropoxide and 3.16g of deionized water, and then adding 1.7mL of phosphoric acid and 3.16g of deionized water 0.45mL tetraethyl orthosilicate, 1.6mL di-n-propylamine and 0.018g hexadecyltrimethylammonium bromide were added successively, and then the mixed liquid was ultrasonicated at room temperature for 1h (ultrasonic power was 53KHz , 350W). Continue to stir, dry at 80°C, hydrothermally crystallize at 200°C for 24 hours, and calcine at high temperature (600°C) to remove the template agent.

[0031] The specific surface area of the hierarchical porous SAPO-11 molecular sieve obtained in this embodiment is 296.4m 2 / g, the external specific surface area is 80.6m 2 / g, the total pore volume is 0.225cm 3 / g, the mesopore volume is 0.139cm 3 / g.

Embodiment 2

[0033] This example provides a method for preparing SAPO-11 hierarchically porous molecular sieves by an ultrasonic-assisted method, which specifically includes: first mixing 4.085g of aluminum isopropoxide and 3.16g of deionized water, and then adding 1.7mL of phosphoric acid and 3.16g of deionized water 0.45mL tetraethyl orthosilicate, 1.6mL di-n-propylamine and 0.018g hexadecyltrimethylammonium bromide were added successively, and then the mixed liquid was ultrasonicated at room temperature for 2h (ultrasonic power is 53KHz, 350W). Continue to stir, dry at 80°C, hydrothermally crystallize at 200°C for 24 hours, and calcine at high temperature (600°C) to remove the template agent.

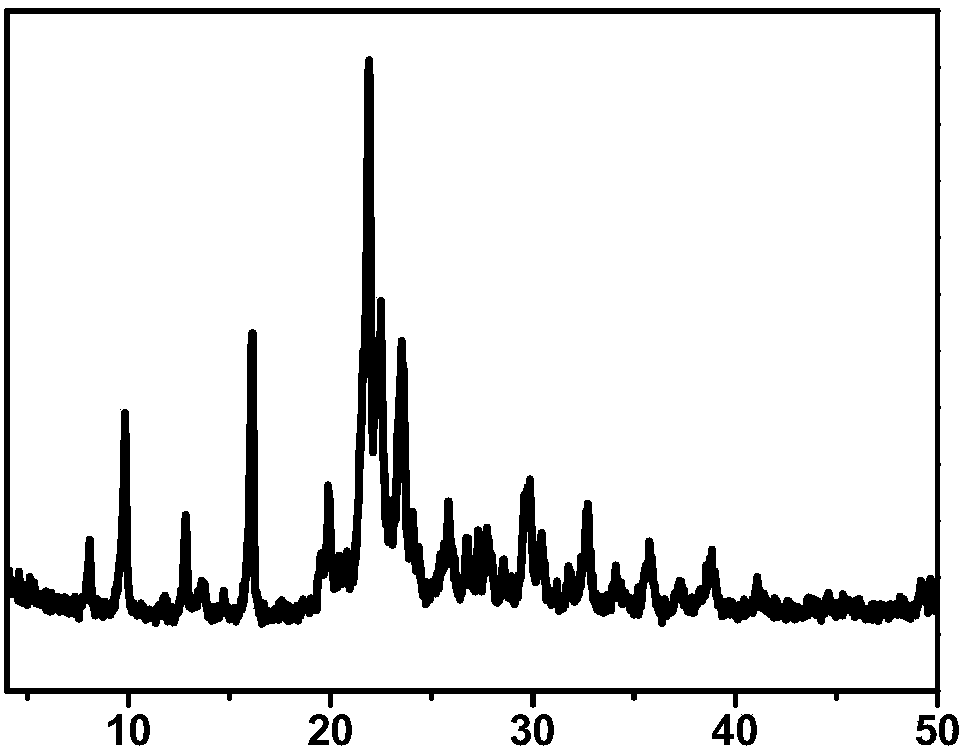

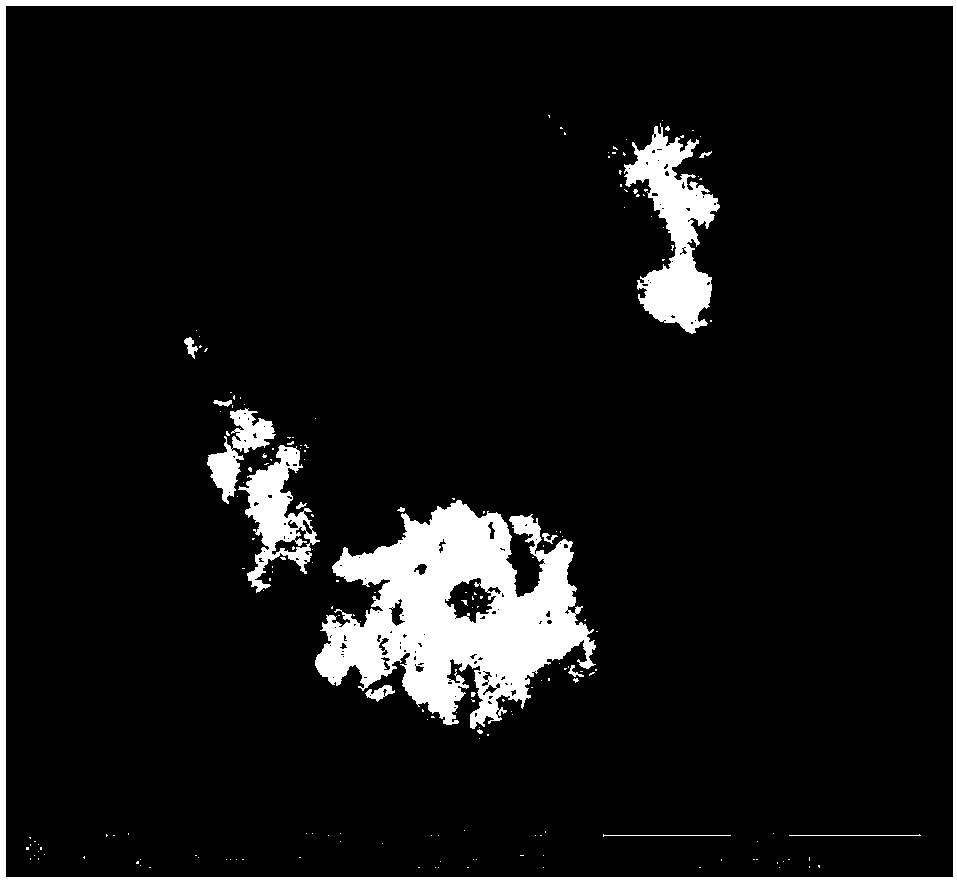

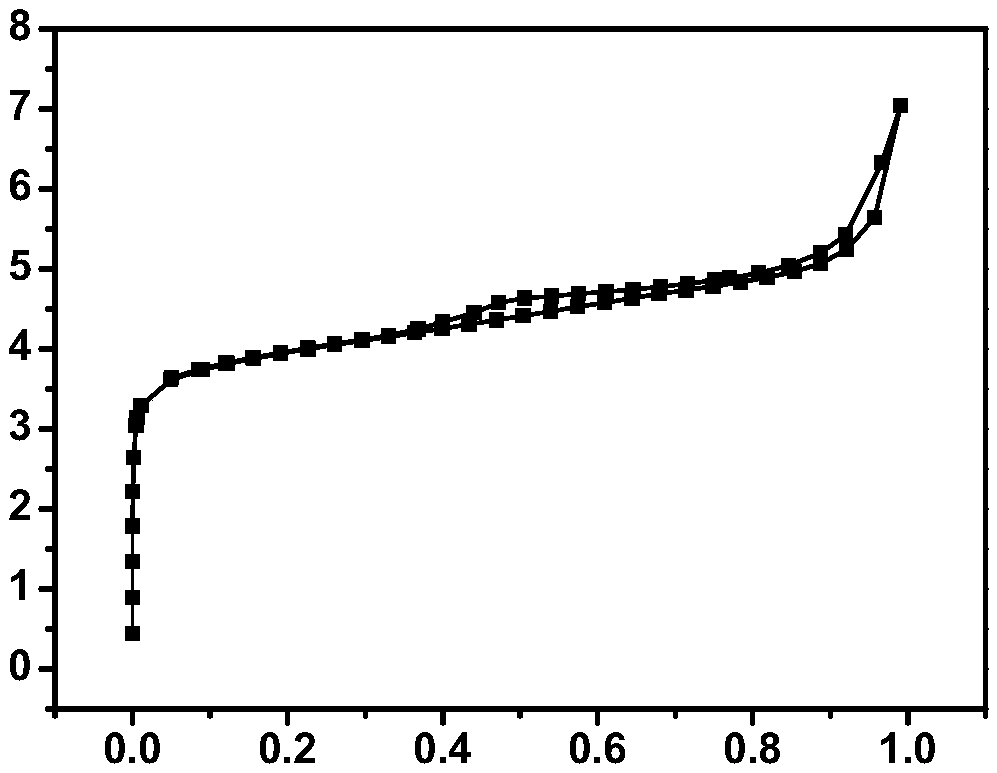

[0034] figure 1 Shown is the XRD characterization result of the hierarchically porous SAPO-11 molecular sieve synthesized in this example. It can be seen that the product has a typical AEL structure and has good crystallinity. figure 2 The scanning electron micrograph of the hierarchically por...

Embodiment 3

[0037] This example provides a method for preparing SAPO-11 hierarchically porous molecular sieves by an ultrasonic-assisted method, which specifically includes: first mixing 4.085g of aluminum isopropoxide and 3.16g of deionized water, and then adding 1.7mL of phosphoric acid and 3.16g of deionized water A mixed solution composed of ionic water; 0.45mL tetraethyl orthosilicate, 1.6mL di-n-propylamine and 0.018g cetyltrimethylammonium bromide were successively added, and then the mixed liquid was ultrasonicated at room temperature for 3h (ultrasonic power was 53KHz, 350W). Continue to stir, dry at 80°C, hydrothermally crystallize at 200°C for 24 hours, and calcine at high temperature (600°C) to remove the template agent.

[0038] The specific surface area of the hierarchical porous SAPO-11 molecular sieve obtained in this embodiment is 286.4m 2 / g, the external specific surface area is 64.8m 2 / g, the total pore volume is 0.231cm 3 / g, the mesopore volume is 0.143cm 3 / g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| External specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com