Preparation method of step hole ZSM-5 zeolite composite material-based low-temperature sulfur transfer catalyst for FCC (Fluid Catalytic Cracking) petroleum

A ZSM-5, composite material technology, applied in molecular sieve catalysts, physical/chemical process catalysts, petroleum industry, etc., can solve the difficulty of conversion and removal of macromolecular thiophene sulfides, the inability to effectively utilize zeolite, and the reduction in utilization rate, etc. problem, to achieve the effect of excellent sulfur transfer desulfurization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] At 60°C, 0.53g NaOH, 5.0g of the substrate prepared in Comparative Example 1 and 70mL of deionized water were stirred and mixed uniformly, and 0.35g of Al was added. 2 (SO 4 ) 3 ·18H 2 O, 2.62g TPABr and 6.54g TEOS are mixed uniformly to obtain a mixed system of starting sol;

[0045] Add 1.35g of polyquaternary ammonium salt PCD to the mixing system of the starting sol, stir it evenly, and age for 24h;

[0046] Transfer the obtained final mixture into a stainless steel reactor lined with polytetrafluoroethylene, and perform 72h hydrothermal crystallization at 170°C;

[0047] The hydrothermal crystallization product was ultrasonically cleaned, and the template-containing stepped pore ZSM-5 zeolite composite material was separated, washed with deionized water to pH=7-8, and then dried at 120°C for 12 hours to obtain the template-containing agent The stepped pore ZSM-5 zeolite composite material;

[0048] The above stepped pore ZSM-5 zeolite composite material containing template...

Embodiment 2

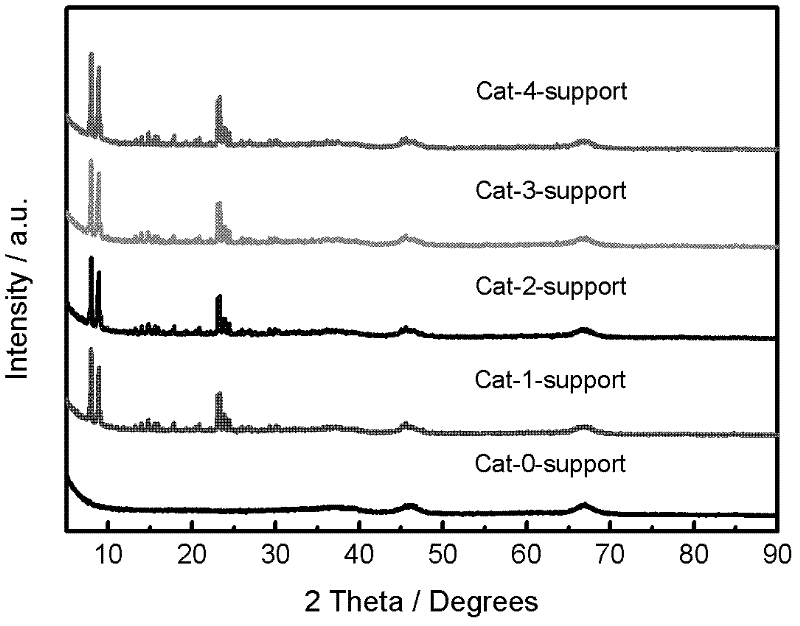

[0052] MoO 3 The impregnation amount is 11.0wt.%, and other preparation conditions are the same as in Example 1. The template-free stepped pore ZSM-5 zeolite composite material prepared is marked as Cat-3-support. The powder XRD pattern is shown in figure 1 , The pore structure parameters are shown in Table 1. The final FCC gasoline low-temperature sulfur transfer catalyst based on the stepped pore ZSM-5 zeolite composite material is recorded as Cat-3. by figure 1 It can be seen that the material not only has the characteristic diffraction peak of typical ZSM-5 molecular sieve, but also the characteristic diffraction peak of γ-alumina.

Embodiment 3

[0054] MoO 3 The impregnation amount of the zeolite is 13.0wt.%, and the other preparation conditions are the same as in Example 1. The template-free stepped pore ZSM-5 zeolite composite material prepared is marked as Cat-4-support. The powder XRD pattern is shown in figure 1 , The pore structure parameters are shown in Table 1. The final FCC gasoline low-temperature sulfur transfer catalyst based on the stepped pore ZSM-5 zeolite composite material is recorded as Cat-4. by figure 1 It can be seen that the material not only has the characteristic diffraction peak of typical ZSM-5 molecular sieve, but also the characteristic diffraction peak of γ-alumina.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com