Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about How to "Reduce the severity of the reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

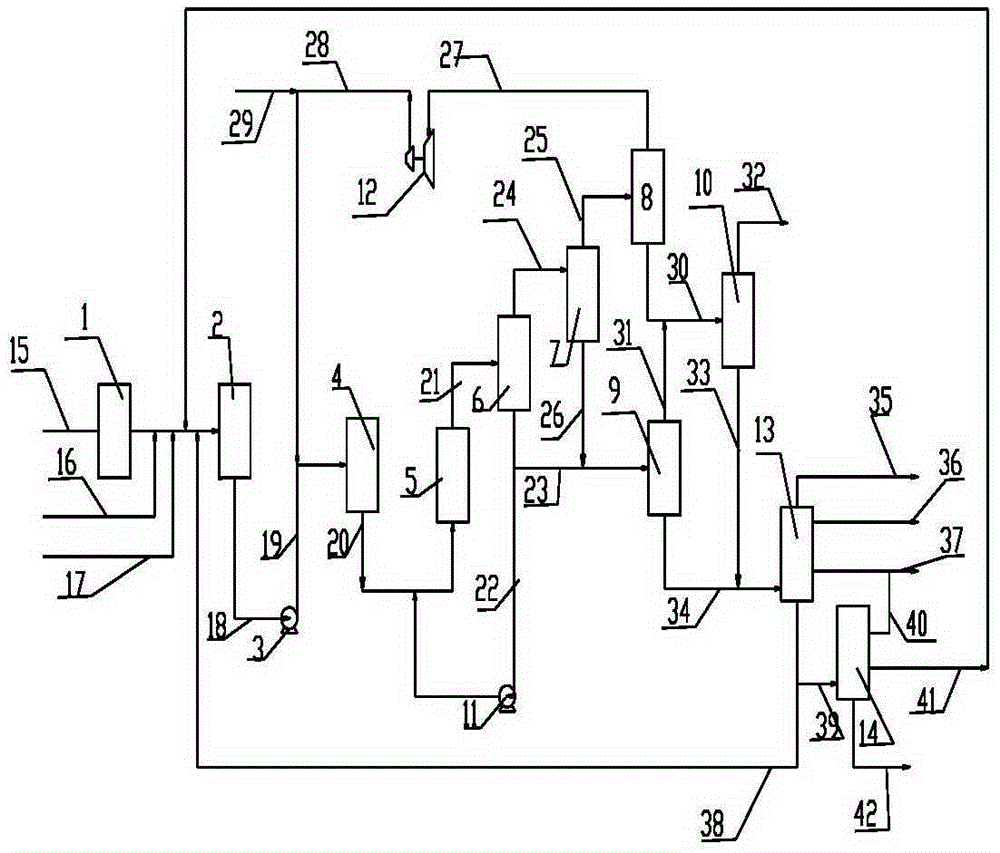

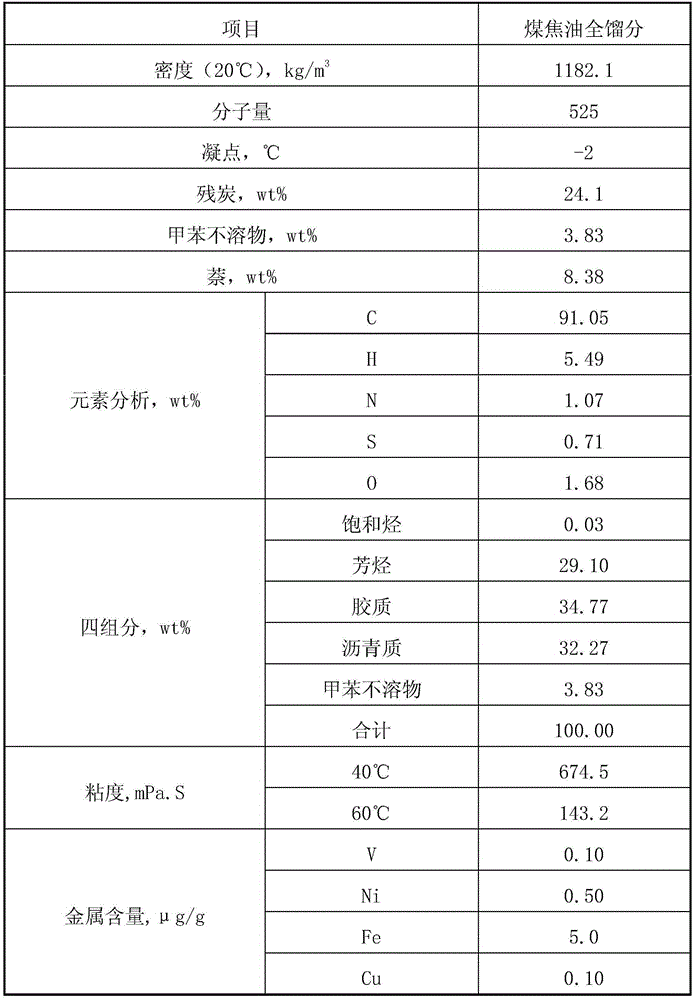

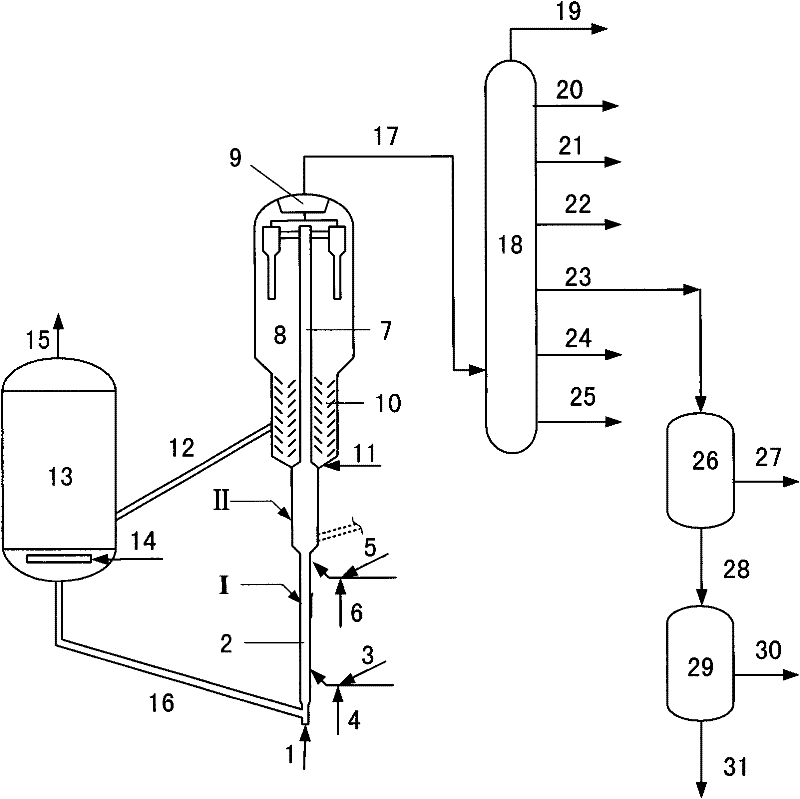

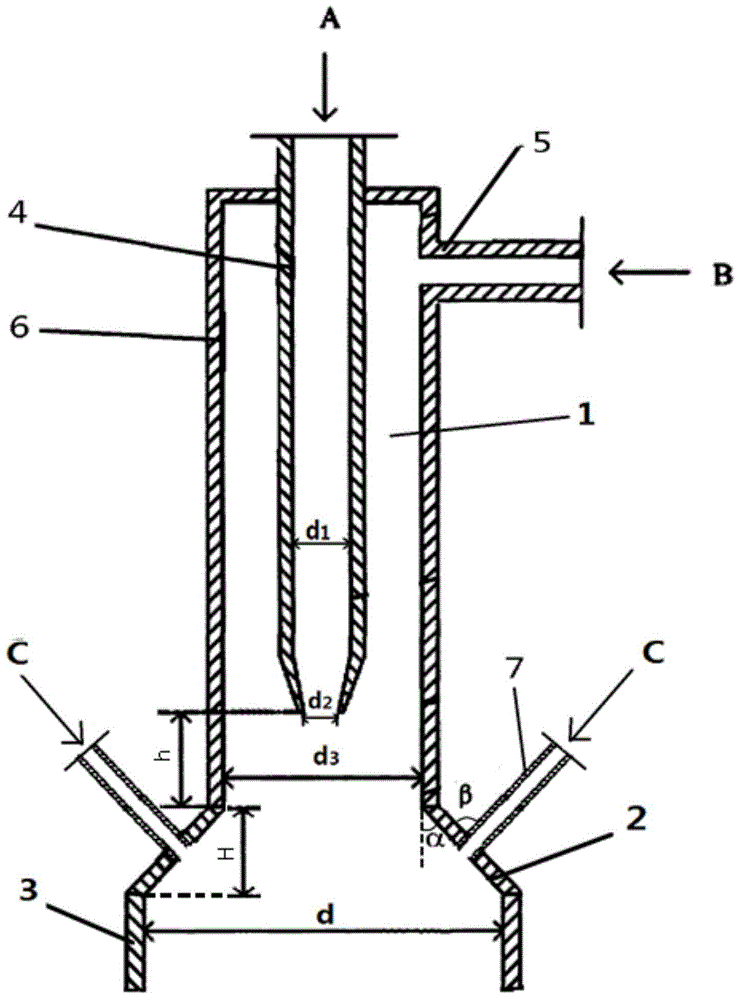

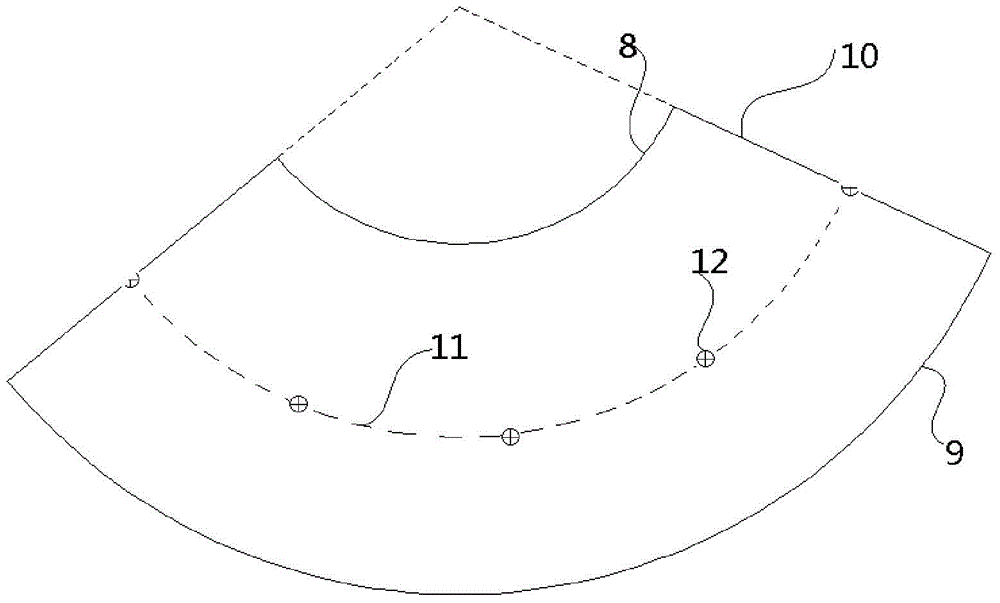

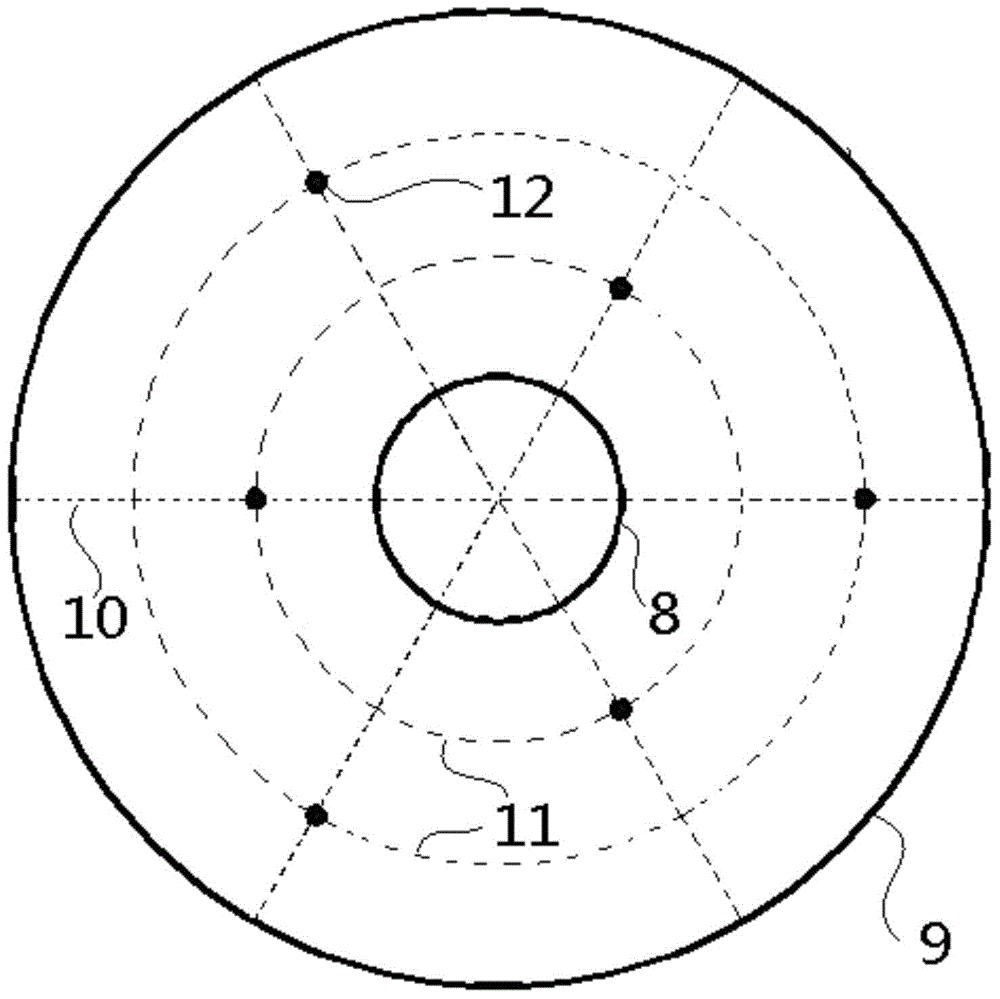

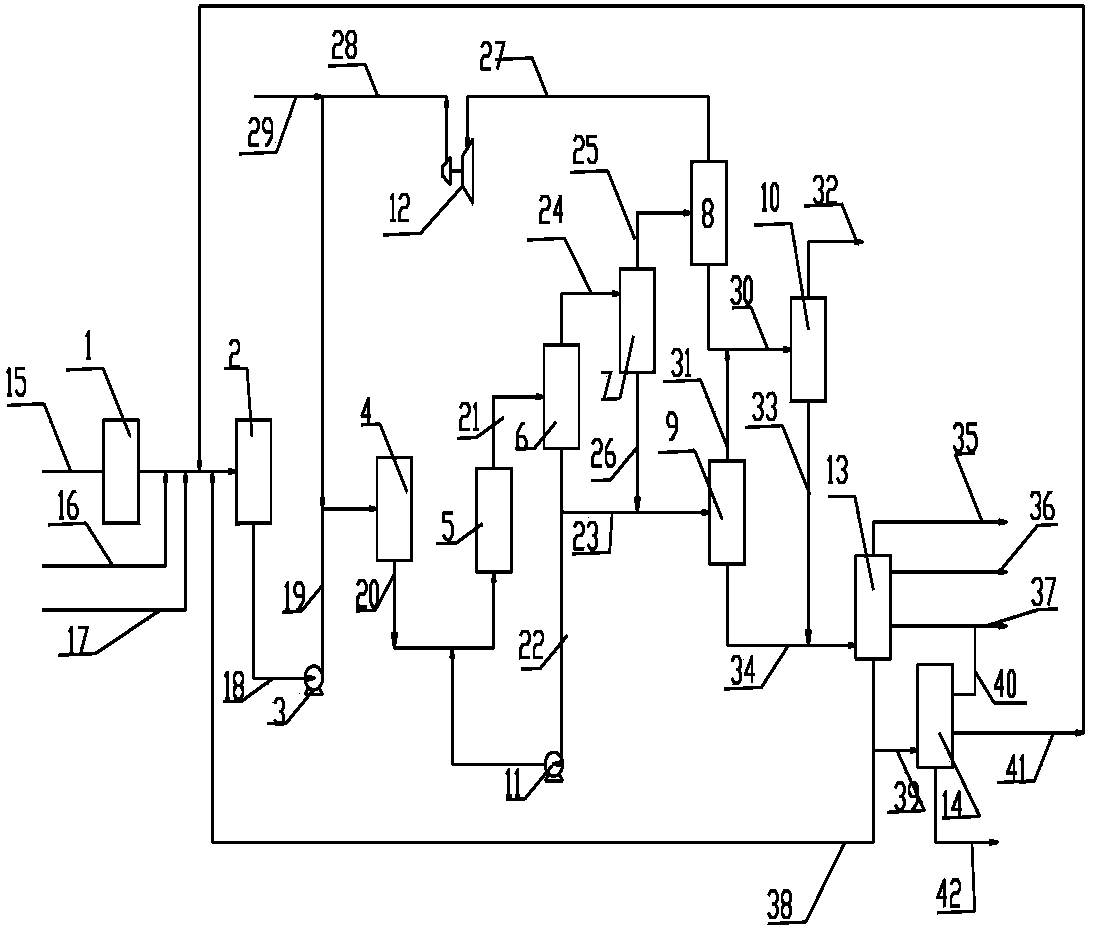

Coal tar suspended bed hydrocracking method

ActiveCN106701178ASimple structureGuaranteed long-term operationHydrocarbon oil crackingTreatment with hydrotreatment processesHydrogenEngineering

The invention discloses a coal tar suspended bed hydrocracking method which comprises the steps of pretreating coal tar; mixing the coal tar with a catalyst and a catalyst promoter to form even raw material oil slurry; putting the raw material oil slurry into a suspended bed reactor; enabling a reaction product to enter a hot high-pressure separator, a warm high-pressure separator, a cold high-pressure separator and a cold low-pressure separator; separating the reaction product; circulating separated hydrogen; enabling separated liquid and catalyst to enter an atmospheric vacuum device to distill out a product and a catalyst, wherein the catalyst can be used circularly. The method has the advantages of low back mixing degree of materials in the reactor, wide raw material adaptability and flexibility in operation.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

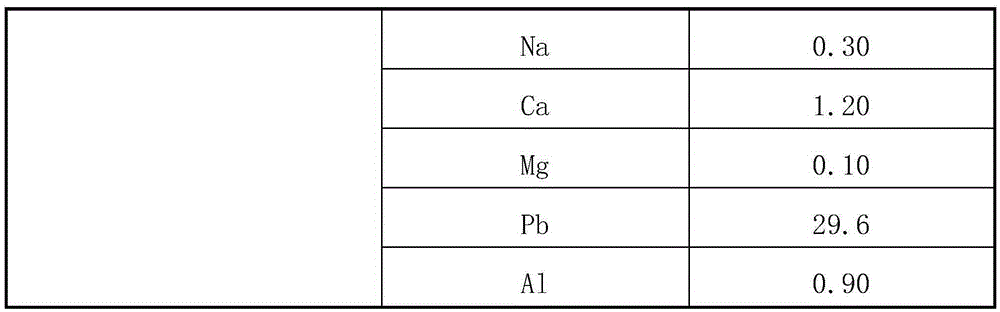

Petroleum hydrocarbon catalytic conversion method

ActiveCN102344831AHigh yieldHigh selectivityTreatment with hydrotreatment processesChemical recyclingCatalytic transformationGasoline

The invention discloses a petroleum hydrocarbon catalytic conversion method. The petroleum hydrocarbon catalytic conversion method comprises the following steps that raw oil contacts a mesoporous zeolite-rich catalyst in a first reaction zone of a reactor and undergo a cracking reaction; a reactant flow and a part of the raw oil are fed into a second reaction zone of the reactor and further undergo a cracking reaction; reaction oil gas and a catalyst needing to be regenerated are separated out, wherein the catalyst needing to be regenerated is subjected to steam stripping and burning regeneration and then is fed back to the reactor; the reaction oil gas is subjected to separation to form a desired ethane product, propylene and aromatic hydrocarbon-rich catalytic gasoline; the aromatic hydrocarbon-rich catalytic gasoline is subjected to selective hydrogenation and then is fed into a aromatic hydrocarbon extraction device to produce a desired light aromatic hydrocarbon product by separation; and the extract oil obtained by the previous step is fed back to the first reaction zone of the reactor. Through petroleum hydrocarbon catalytic conversion method, an ethene yield is 22.43 wt%; a propylene yield is 33.22 wt%; and a benzene-toluene-xylene mixture yield is 25.28 wt%.

Owner:CHINA PETROLEUM & CHEM CORP +1

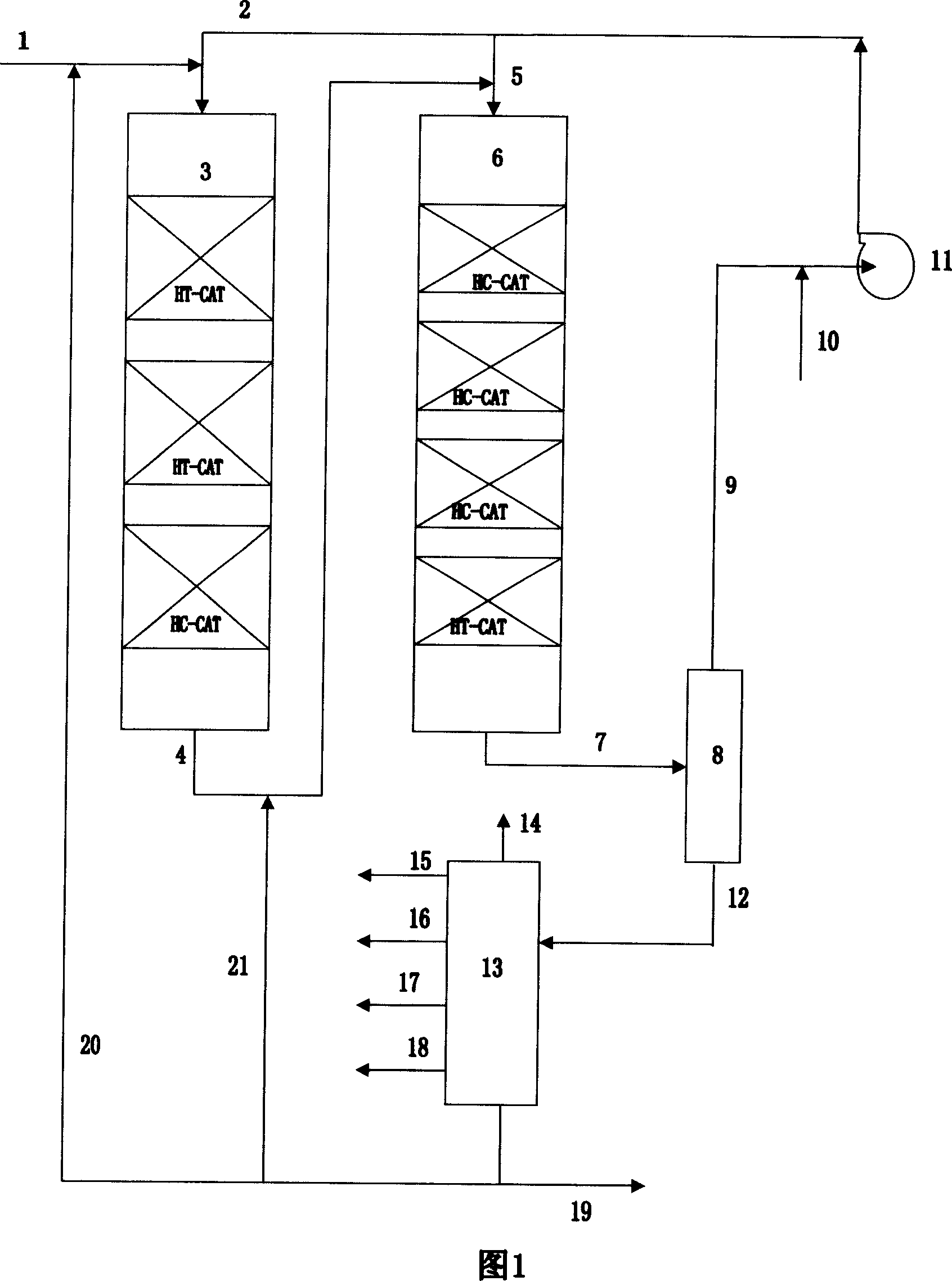

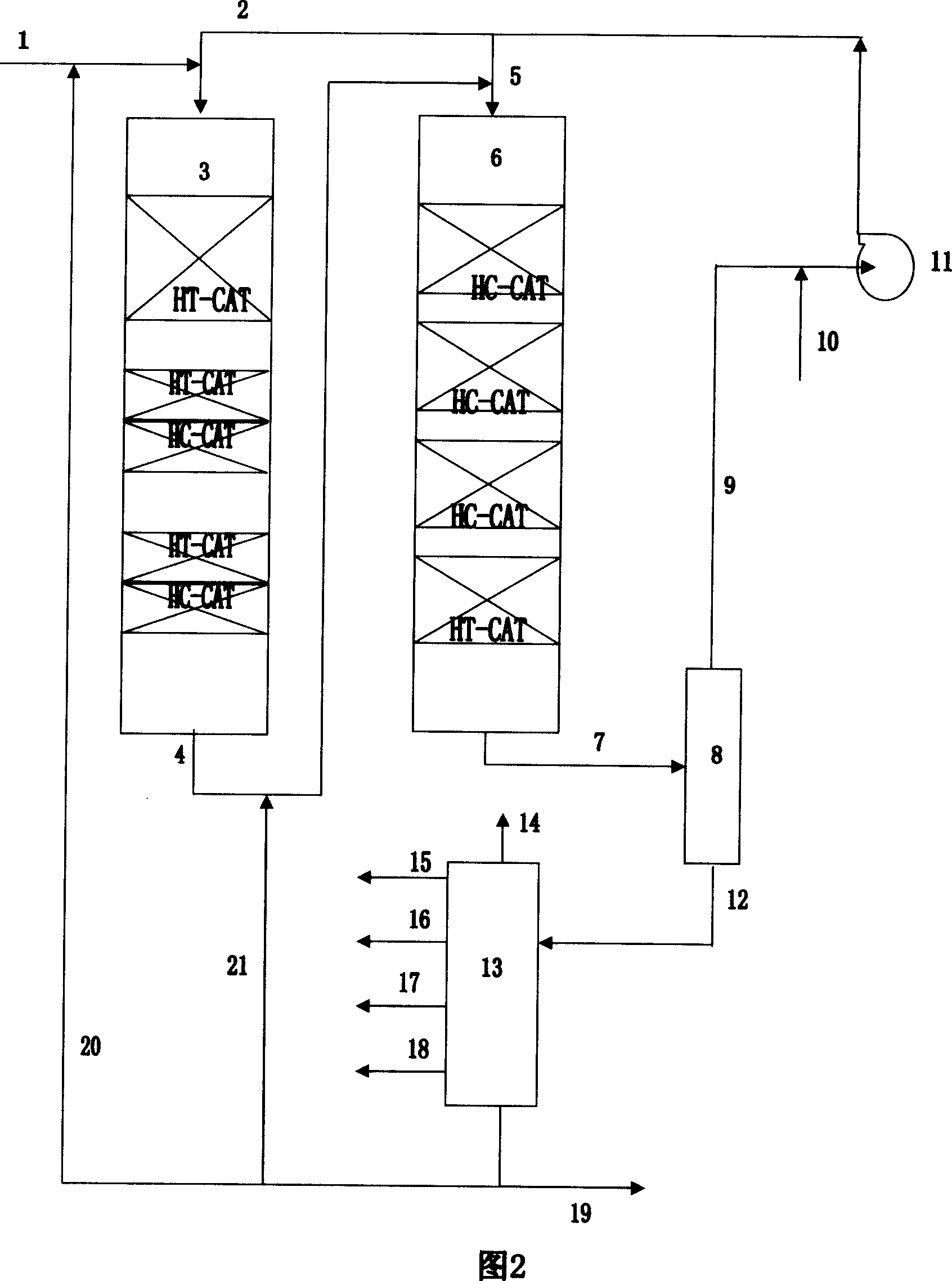

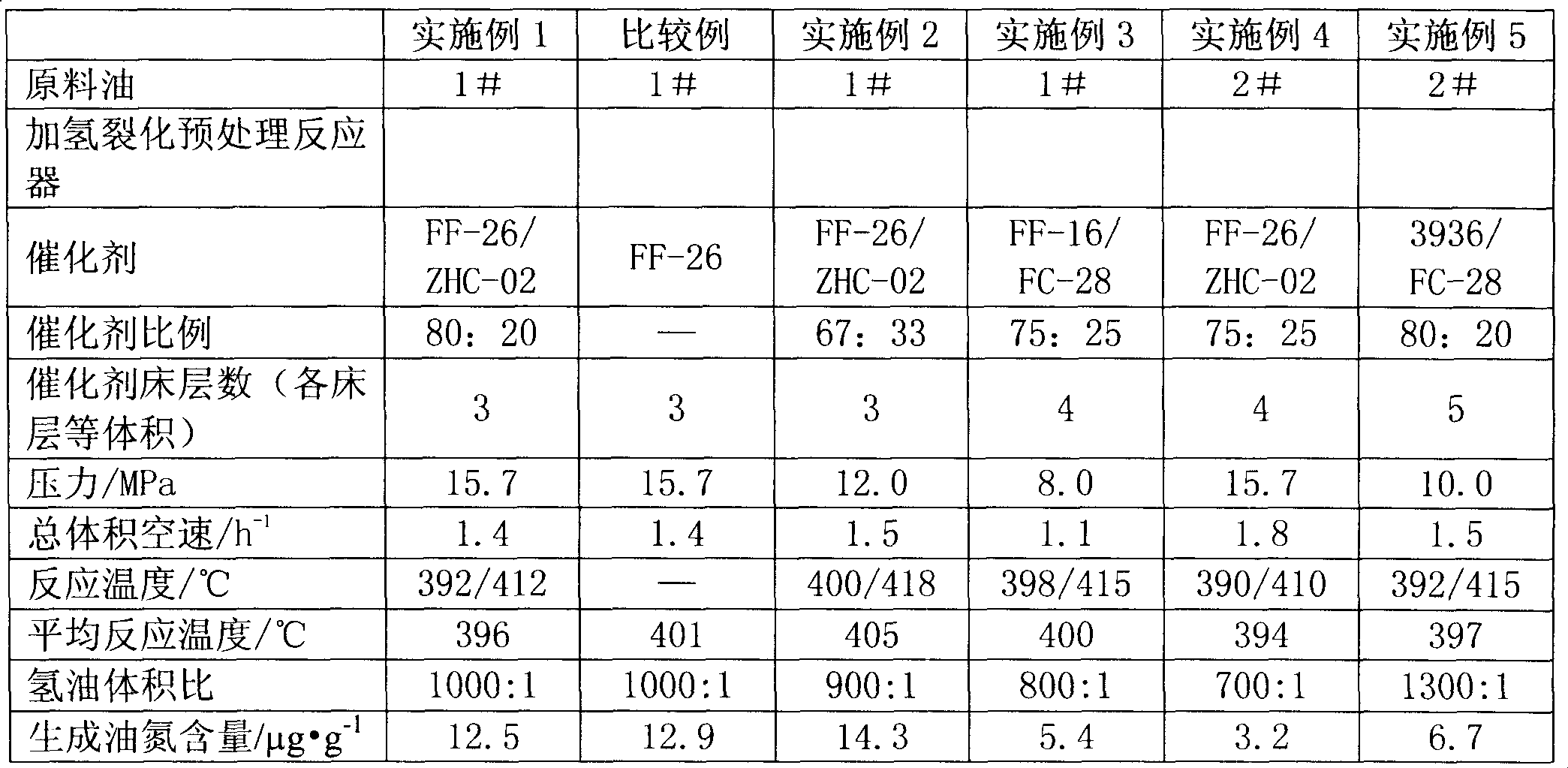

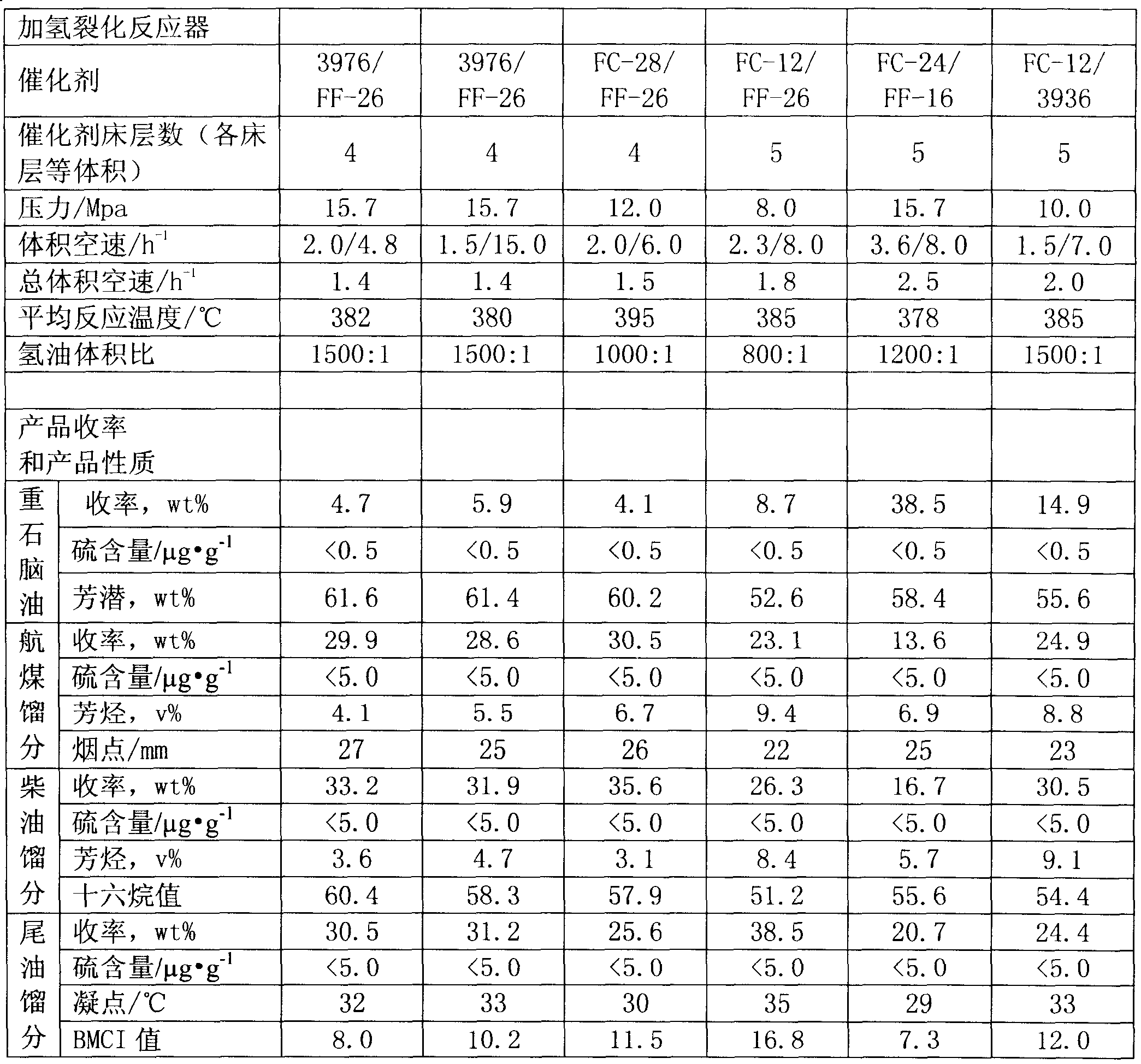

One-stage serial hydrocracking method

ActiveCN101148614AReduce concentrationReduce contentTreatment with hydrotreatment processesEngineeringPre treatment

The present invention discloses one-section cascade hydrocracking process, and features the hydrocracking unit comprising one hydrocracking pre-treating reactor filled with pre-treating catalyst and hydrocracking catalyst and one hydrocracking reactor filled with hydrocracking catalyst and post-hydrotreating catalyst connected serially. Compared with available technology, the hydrocracking unit of the present invention has the advantages of raised integral activity, increased treating capacity or increased operation period, and raised product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

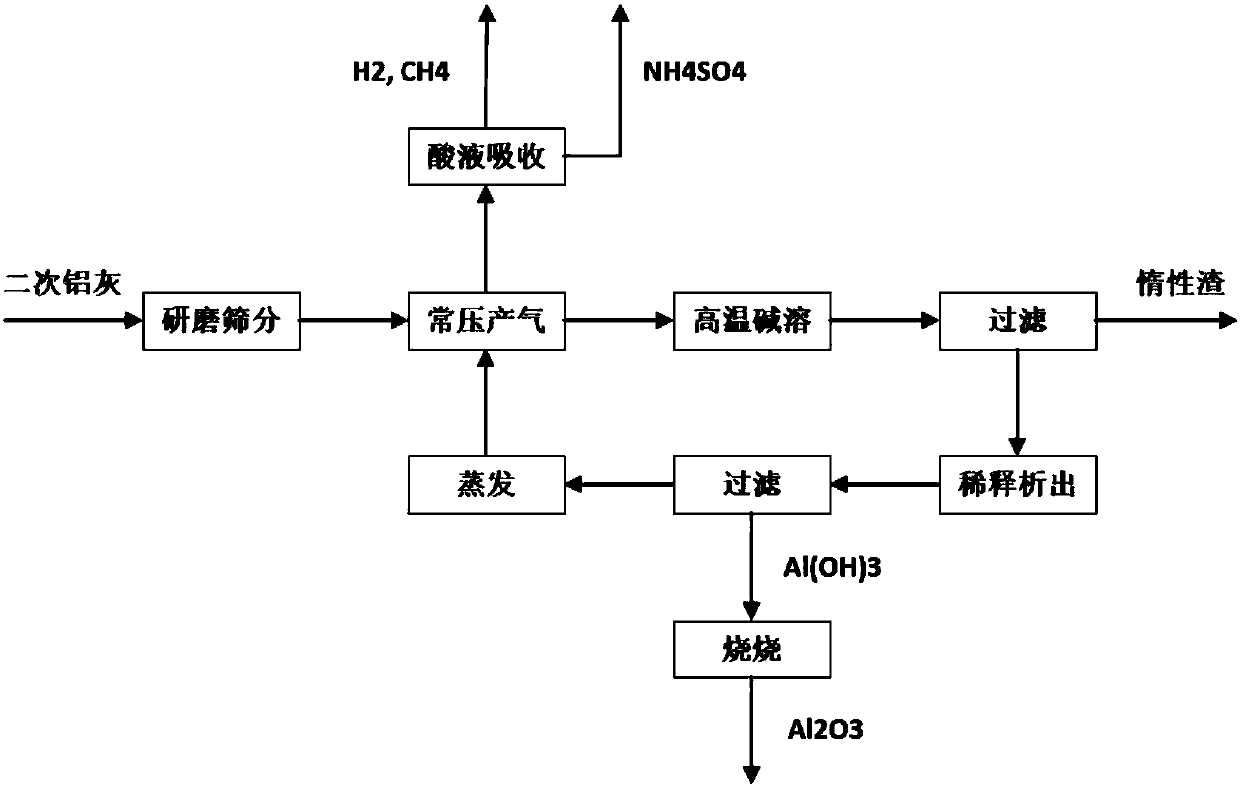

Method for secondary aluminum ash recycling

ActiveCN109678186AImprove practicalityHigh utility valueHydrogen productionHydrocarbonsHydrogenRoom temperature

The invention relates to the field of resources and environments, in particular to a method for secondary aluminum ash recycling. The method comprises the following steps that S1, secondary aluminum ash is ground and then sieved, a caustic soda (NaOH) solution and an anti-boiling agent are added into a sieved object, a full reaction is conducted at the normal pressure till no bubble is generated,and ammonia, hydrogen and methane are collected; and S2, under the condition of the high temperature and high pressure, filtrate obtained after filtering is diluted, the diluted filtrate is cooled tothe room temperature, and aluminum hydroxide crystals are separated out; and aluminum hydroxide obtained after filtering is calcined and dehydrated to obtain aluminum oxide. The method for efficientlyrecycling the secondary aluminum ash is provided.

Owner:SHANGHAI JIAO TONG UNIV

Preparing method for cyclohexane-1,2-dibasic diformate

ActiveCN106554278AGuaranteed complete hydrogenationReduce hot spot temperatureOrganic compound preparationCarboxylic acid esters preparationHydrogenation reactionDibasic ester

The invention relates to the field of hydrogenation for preparing cyclohexane-1,2-dibasic diformate, and discloses a preparing method for cyclohexane-1,2-dioctyl phthalate dibasic ester. The method comprises the steps that firstly, hydrogenation raw materials containing phthalic acid dibasic ester and H2 are subjected to first contact in a main hydrogenation reactor in the presence of a first catalyst, and first gas-liquid mixing fluid is obtained; secondly, the first gas-liquid mixing fluid is subjected to gas-liquid separation; thirdly, hydrogen is injected into main hydrogenation reaction liquid through holes with the average hole diameter being the nanometer size, the main hydrogenation reaction liquid is separated out in the second step, and second gas-liquid mixed fluid is obtained; fourthly, the second gas-liquid mixed fluid is subjected to second contact in a rear hydrogenation reactor in the presence of a second catalyst, and third gas-liquid mixed fluid is obtained; and fifthly, the third gas-liquid mixed fluid is subjected to gas-liquid separation. The method has the beneficial effects that the raw material conversion rate, the product selectivity and the cis-structure product content are high.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

Online chemical tempering method of aluminosilicate glass

InactiveCN102531364AImprove wear resistanceImprove impact resistanceGlass tempering apparatusGlass productionManufacturing cost reductionProduction line

The invention discloses an online chemical tempering method of aluminosilicate glass. An online chemical tempering region which is hermetically connected with a pre-annealing region and an annealing region is additionally arranged between the pre-annealing region and the annealing region, and the online chemical tempering temperature is not more than the outlet temperature of the pre-annealing region. The online chemical tempering method comprises the following steps: enabling a glass substrate which is formed by melting to enter into the online chemical tempering region for performing surface spray-coating of a tempering solution after passing through the pre-annealing region, so as to form a pressure stress layer on the glass substrate, and then enabling the glass substrate to enter into the annealing region for completing online chemical tempering during the annealing process of the glass substrate. According to the online chemical tempering method disclosed by the invention, the online chemical tempering can be directly completed during the annealing process of a glass production line, the production efficiency of products can be greatly improved, the manufacturing cost can be reduced and large-scale benefits can be further realized; and furthermore, the online chemical tempering method disclosed by the invention can be directly applied to the existing glass production line without performing large-scale technical transformation, so that the technical application threshold and technical development risk can be further reduced.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

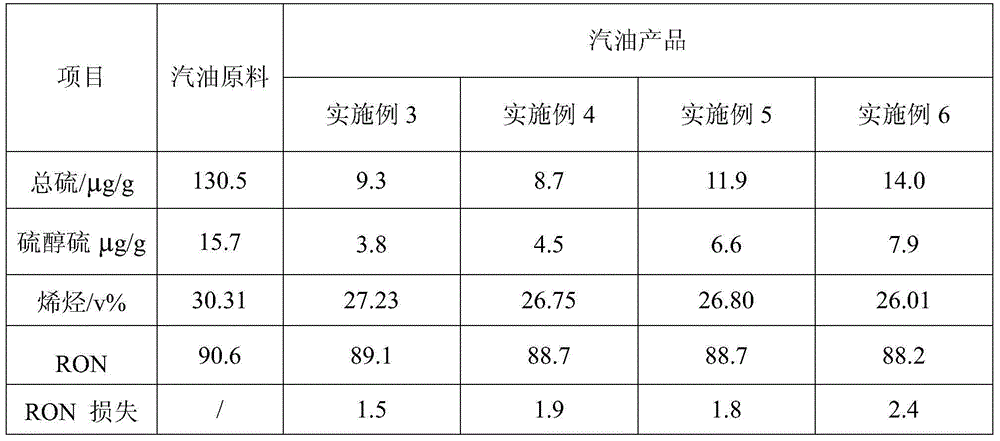

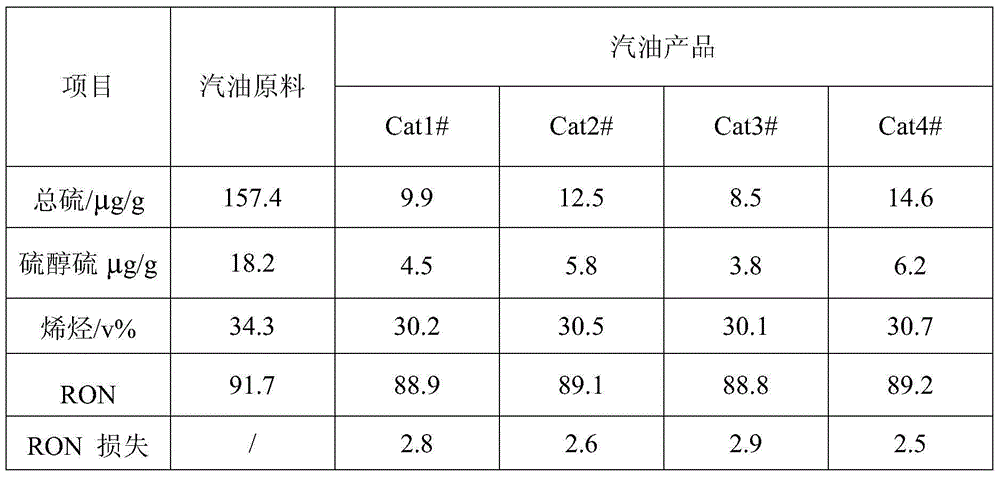

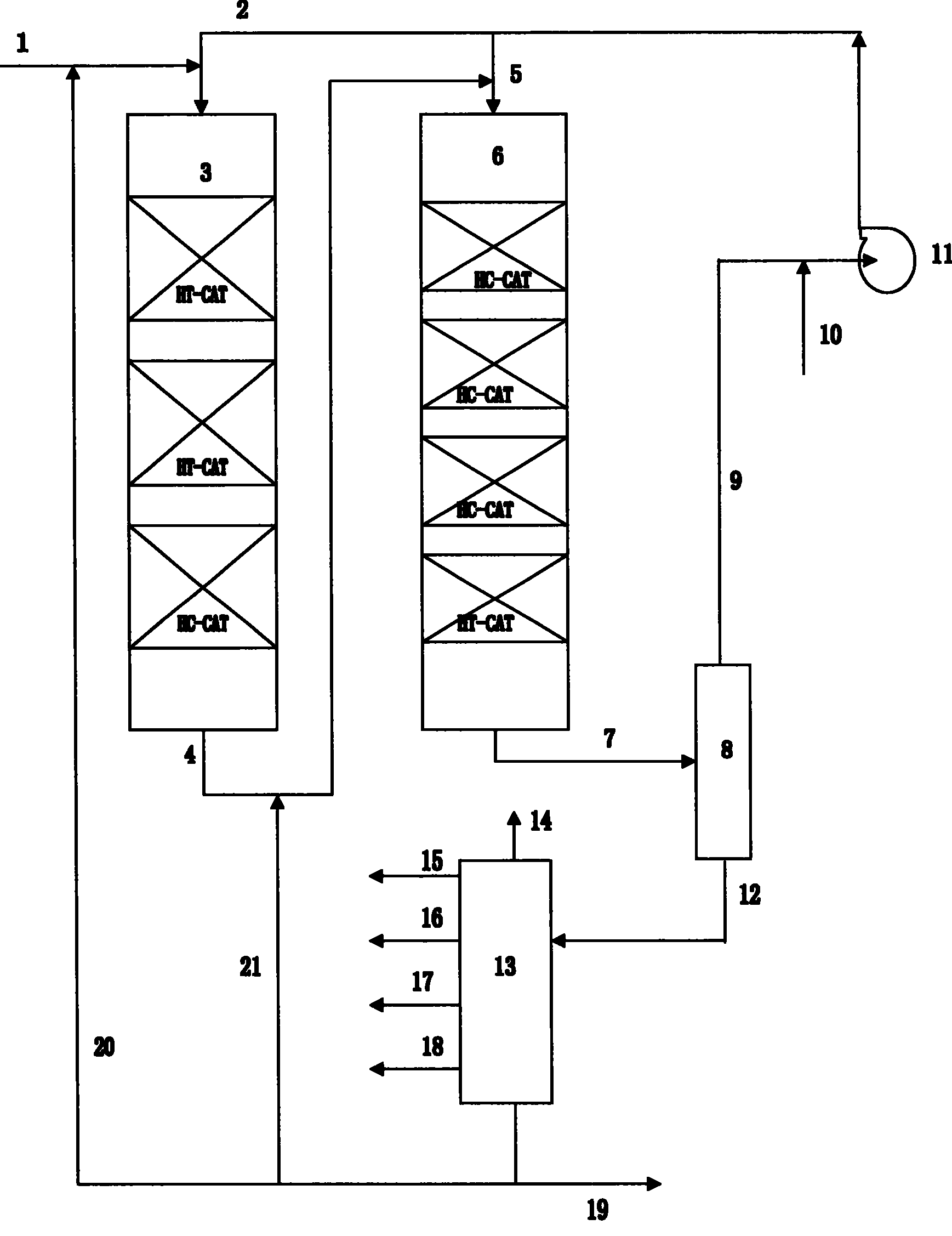

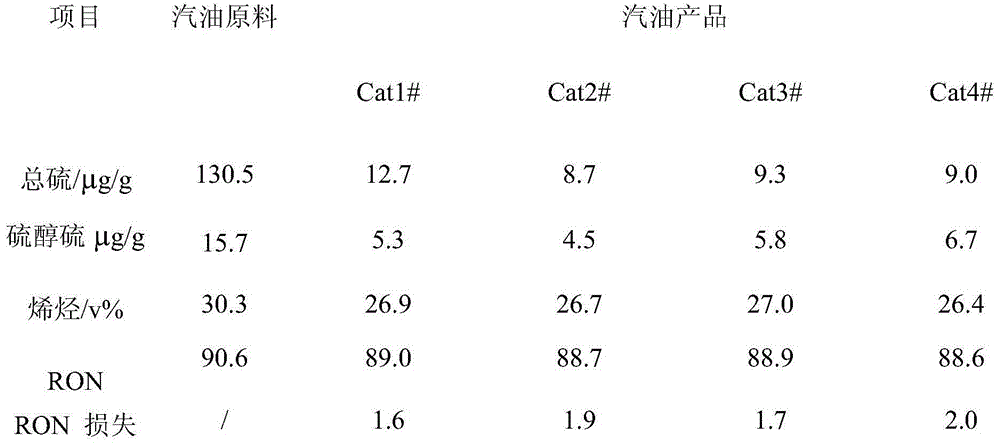

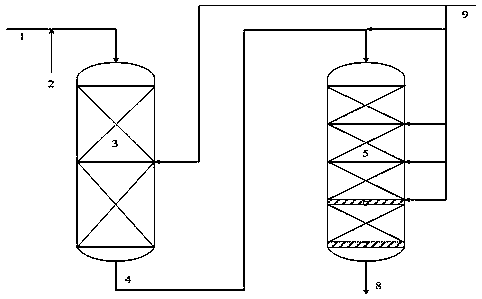

Deep desulfurization method of gasoline

ActiveCN104650975AReduce the severity of the reactionReduce lossesTreatment with hydrotreatment processesHydrodesulfurizationGasoline

The invention relates to a deep desulfurization method of gasoline. A gasoline raw material firstly enters a first reactor to remove dialkene and simultaneously mercaptan becomes heavier; the gasoline raw material then enters a fractionating tower to be cut and fractioned into light and heavy gasoline; heavy gasoline enters a second reactor to remove the vast majority of sulfide, and a reaction product enters a third reactor to further undergo desulfurization; and a heavy gasoline hydrodesulfurization product obtained is mixed with the light gasoline so as to obtain a qualified gasoline product. By additionally arranging the third reactor after the second reactor, further deep desulfurization is realized. Meanwhile, reaction severity of the second reactor is remarkably reduced, and octane number loss and hydrogen-consumption optimization are realized.

Owner:PETROCHINA CO LTD

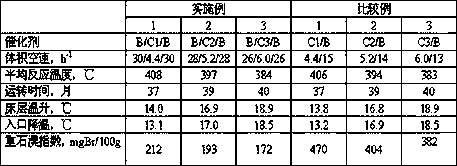

Method for catalyzing gasoline deep desulfurization with Ni-Mo-Co containing catalyst

ActiveCN104650965AReduce the severity of the reactionExtended operating cycleTreatment with hydrotreatment processesMetal/metal-oxides/metal-hydroxide catalystsGasolineHydrogen consumption

The invention relates to a method for catalyzing gasoline deep desulfurization with an Ni-Mo-Co containing catalyst. Specifically, a gasoline raw material enters a first reactor to undergo selective hydrodesulfurization and then enters a second reactor to further undergo deep desulfurization. The hydrodesulfurization catalyst adopted by the second reactor is the Ni-Mo-Co containing catalyst. The catalyst has certain desulfurization activity, and at the same time has little olefin saturation, after combination with the first reactor, further deep desulfurization can be realized, and simultaneously the reaction severity of the first reactor can be significantly reduced, so that the octane number loss and hydrogen consumption can be optimized.

Owner:PETROCHINA CO LTD

Production process of biological diesel

ActiveCN1861749AAvoid pollutionGood miscibilityBiofuelsLiquid hydrocarbon mixture productionBiodieselTriglyceride

This invention relates to the preparation of the biological diesel fuel from the fat acid triglyceride, and special from the animal, vegetable tallow and oil. This invention takes the solid alkali as the catalyst, and the addition of the amine is as the third component. It can gain the high ratio of conversion and the lifetime of the catalyst is long. Comparing to the existing technology, the process of this invention is simple, the condition is moderate, the conversion is high, the by-product is less, and the lifetime of the catalyst is long. The diesel fuel can be produce from the animal and vegetable tallow and oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

One-stage serial hydrocracking method

ActiveCN101148614BReduce contentPreferential adsorptionTreatment with hydrotreatment processesEngineeringPre treatment

The present invention discloses one-section cascade hydrocracking process, and features the hydrocracking unit comprising one hydrocracking pre-treating reactor filled with pre-treating catalyst and hydrocracking catalyst and one hydrocracking reactor filled with hydrocracking catalyst and post-hydrotreating catalyst connected serially. Compared with available technology, the hydrocracking unit of the present invention has the advantages of raised integral activity, increased treating capacity or increased operation period, and raised product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

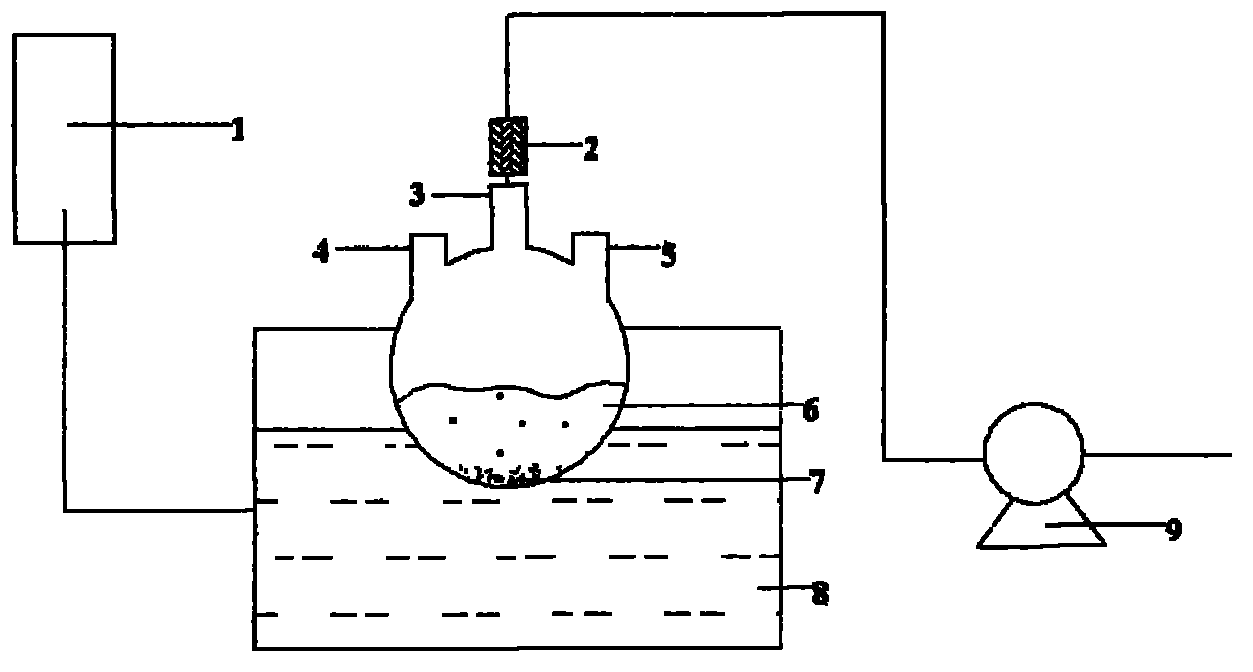

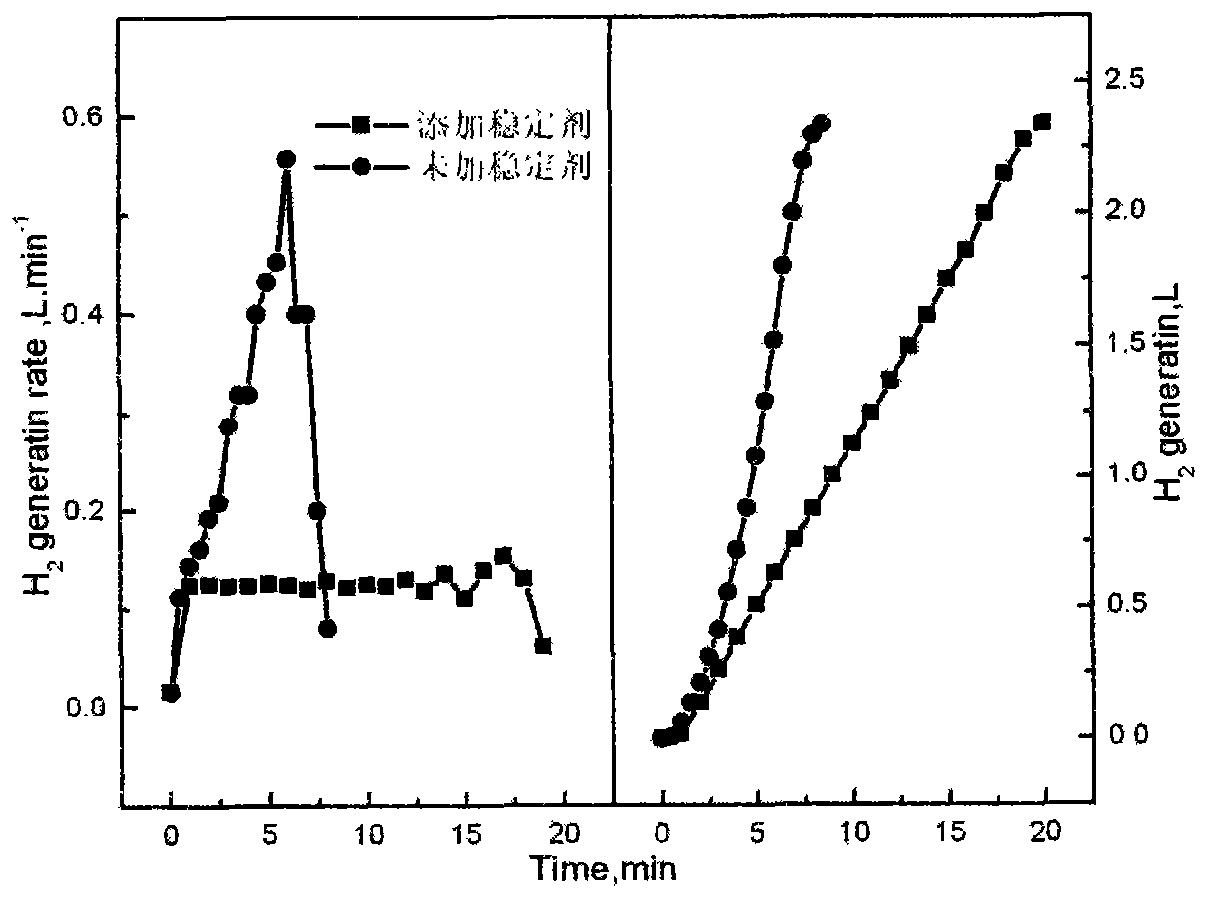

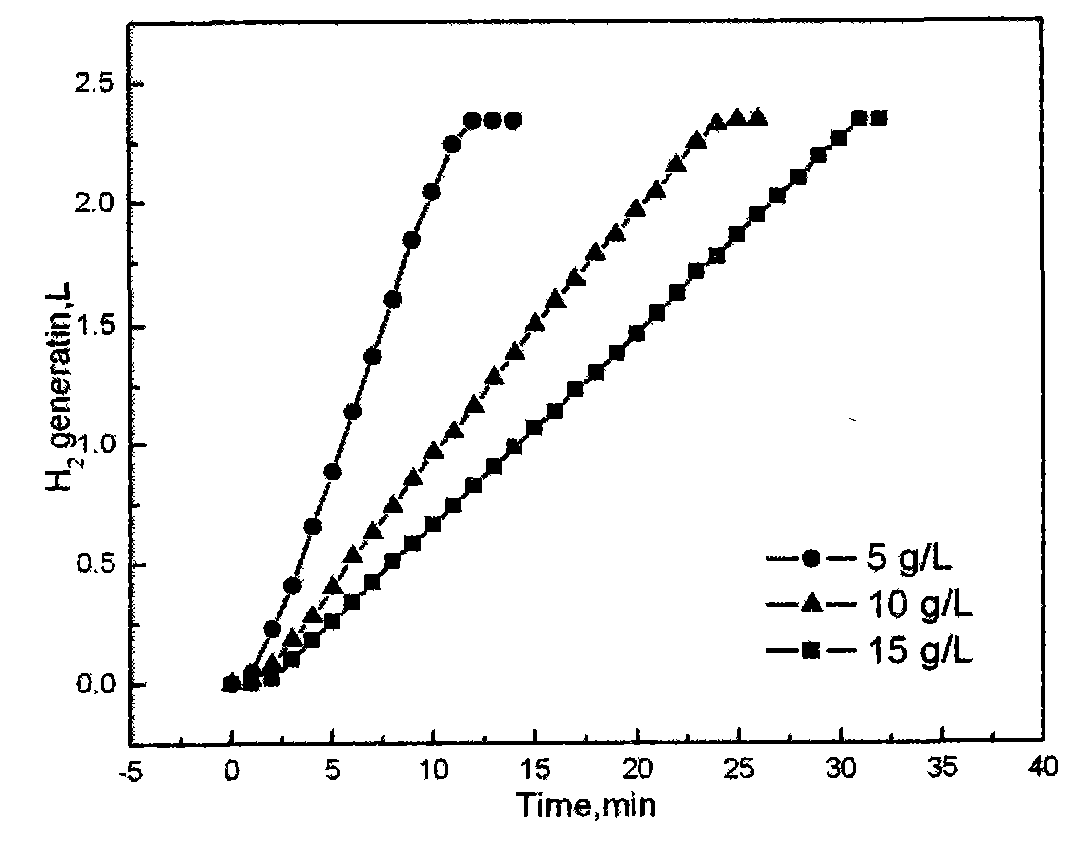

Method and device for preparing hydrogen by hydrolysis of hydroboron, and application

The invention provides a method and a device for preparing hydrogen by hydrolysis of hydroboron, and an application. The method comprises the steps of preparing hydrogen by hydrolysis of hydroboron under an alkaline condition; loading metal cobalt and metal cerium or zirconium to a molecular sieve as a bimetallic catalyst; and adding urea as a reaction stabilizer. By adopting the method and the device, hydrogen production by hydrolysis of hydroboron known at present is selected as an efficient hydrogen production system; a novel stabilizer is added to control the intense degree of the reaction and keep the hydrogen production rate stable; the reaction is more efficient by adopting a homemade catalyst; and simple purification is carried out in a hydrogen collection process. The hydrogen production method can be directly applied to a miniature fuel cell with certain powder; and extra storage, purification and drying devices are not needed.

Owner:QINGDAO UNIV OF SCI & TECH

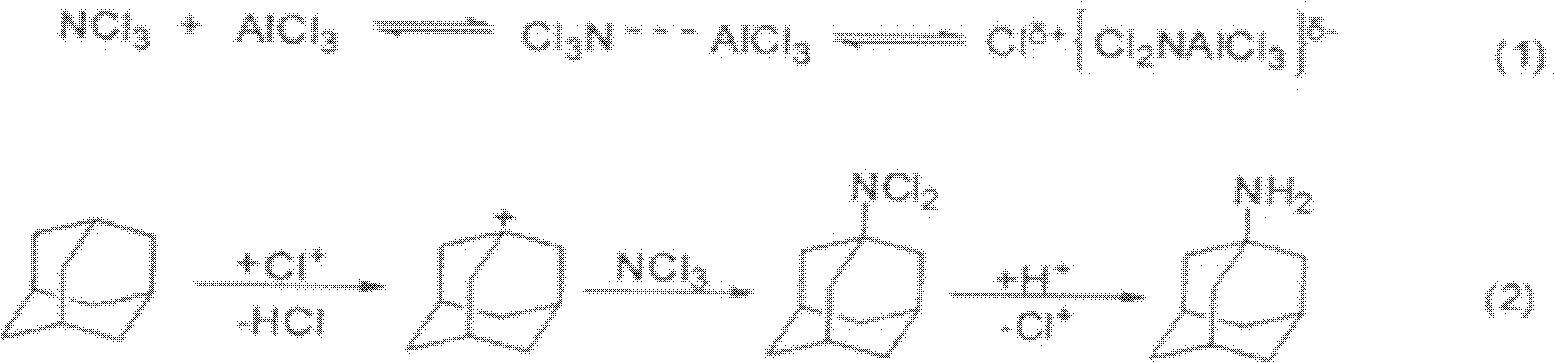

Synthesis method for Amantadine Hydrochloride

ActiveCN102050744AAvoid it happening againReduce the severity of the reactionOrganic compound preparationAmino compound preparationIsomerizationSynthesis methods

The invention discloses a synthesis method for Amantadine Hydrochloride, which comprises the steps of hydrogenation, isomerization and amination, hydrolysis, refining, etc. to get Amantadine Hydrochloride finished product. Compared with the prior art, Trichloro ethane is adopted as solvent in the isomerization and amination steps, and bromination is cancelled, so that atmospheric pollution is lessened remarkably, and environmental pollution in the traditional process in Amantadine Hydrochloride synthesis is effectively solved. The invention has the advantages of no pollution, environmental friendliness, and better market application prospect.

Owner:GUIZHOU MAQIKA PHARMA

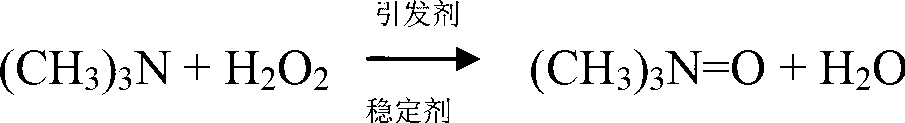

Preparation method for trimethylamine oxide

The invention discloses a preparation method for trimethylamine oxide. The technical scheme that hydrogen peroxide which is more than trimethylamine or stabilizing agent and / or initiating agent is added is adopted to enable the trimethylamine and the hydrogen peroxide to be reacted totally so as to avoid the raw material loss and to reduce the cost; the stabilizing agent is adopted in the reaction, so that the reaction system can be effectively stabilized, the excessive loss of reaction raw materials is controlled, and the yield is improved; the initiating agent is adopted in the reaction, so that the reaction activation energy can be reduced, and the reaction can be initiated at a lower temperature and can be implemented smoothly. The method reduces the raw material cost, reduces the equipment investment, largely decreases the acute reaction degree, stabilizes the reaction progress, and enables the reaction process to be easily controlled; and mother liquor can be recycled, so that the product yield and quality can be improved.

Owner:HONGFENG CHEM GUAN COUNTY HEBEI PROV

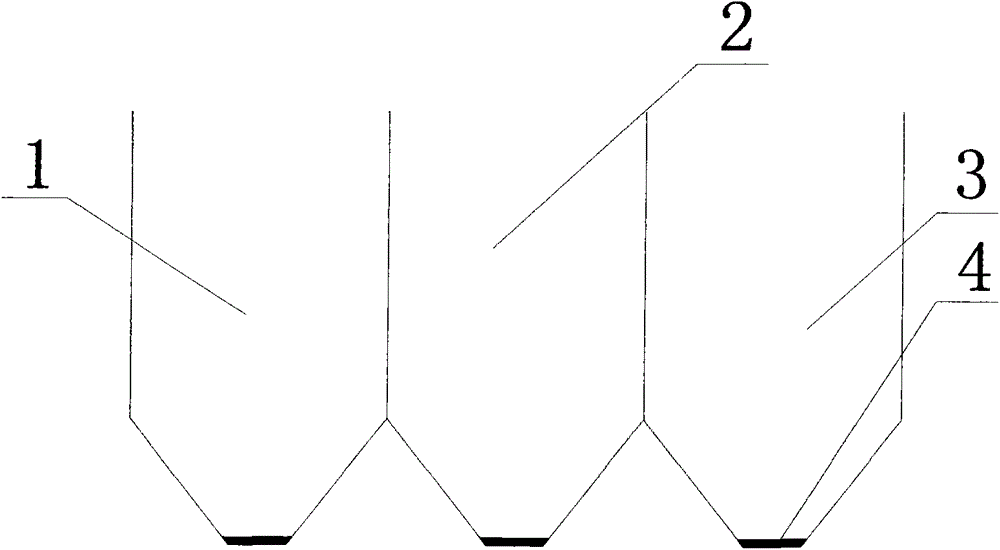

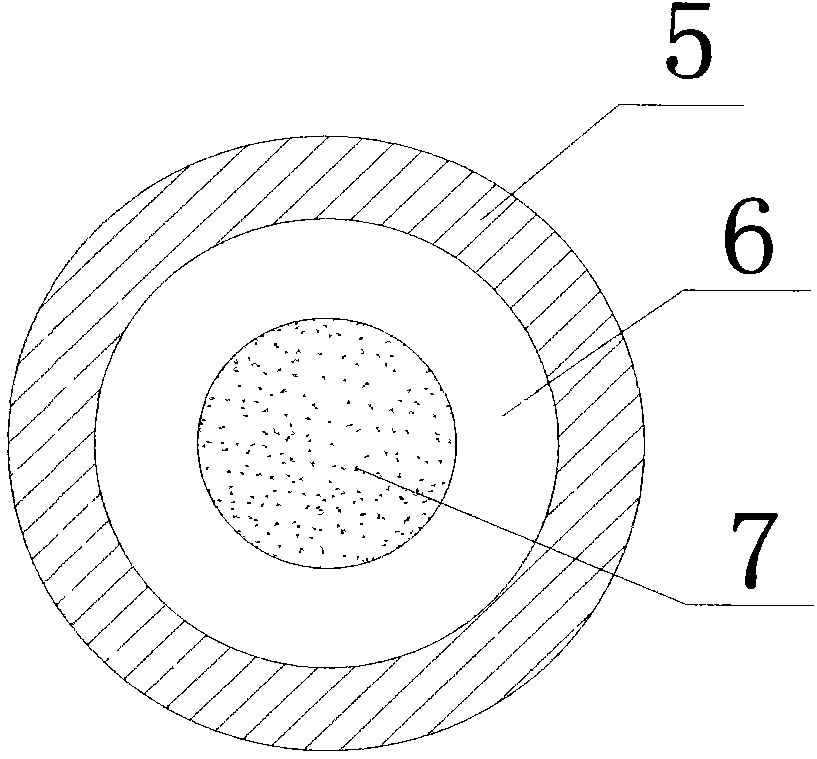

Production technology of sandwich core-spun yarn

The invention discloses a production technology of a sandwich core-spun yarn. The central part of the yarn is composed of 100% pure magnesium pellets, the middle layer is composed of mixed powders, and the outermost layer is formed by rolling a steel strip. According to the technological method, three hoppers capable of regulating flow are used to replace an original single hopper. A second hopper is used for holding the pure magnesium pellets, and a first hopper and a third hopper are used for holding the same mixed powders composed of silicon iron, calcium silicon, rare earth ferrosilicon and the like. The low-carbon steel strip of 0.2-1 mm thick is rolled by a core spinning unit to obtain a sandwich core-spun yarn with the yarn diameter of phi 9-16mm and different magnesium contents. The production technology has advantages as follows: production cost is low; magnesium absorptivity is raised; and the product can be prepared at arbitrary ratio of components.

Owner:北京正大银光科技有限公司

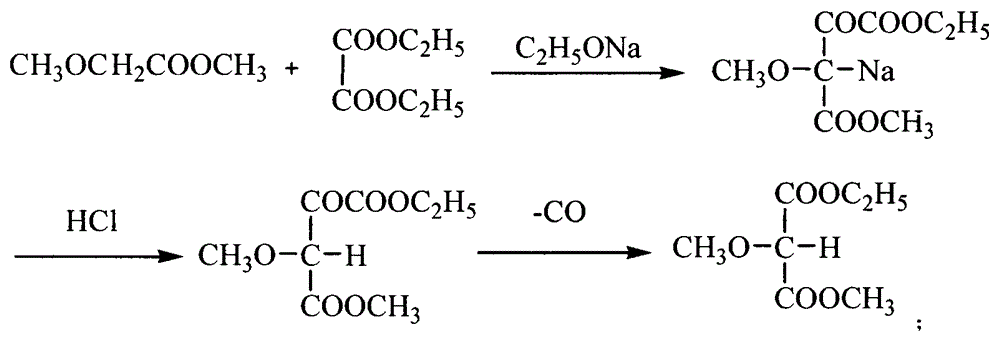

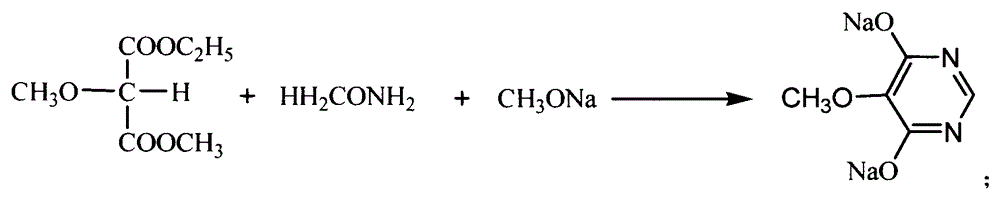

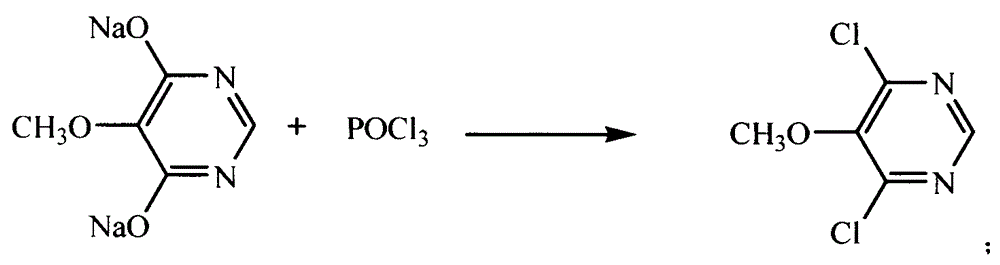

Method used for smooth and steady preparation of 2-methoxypropandioic acid ethyl methyl ester

InactiveCN103910629AHigh yieldSmooth responseOrganic compound preparationCarboxylic acid esters preparationOrganic solventMethyl methoxyacetate

The invention relates to a method used for smooth and steady preparation of 2-methoxypropandioic acid ethyl methyl ester. The method comprises following steps: (a) methyl methoxyacetate and diethyl oxalate are delivered into a reaction container, and a mixed solution is obtained via mixing; (b) solid sodium methylate is dispersed in diethyl oxalate, an obtained mixture is added into the mixed solution dropwise, and an obtained mixed material is reacted for 2 to 8h at a temperature of 50 to 60 DEG C so as to obtain a reaction liquid; (c) an organic solvent, water, and an acid solution are delivered into another reaction container for mixing, the reaction liquid is added, a temperature of an obtained material is controlled below 15 DEG C, pH value is adjusted to 1 to 2, and the material is allowed to stand so as to obtain a water layer and an organic solvent layer; (d) the organic solvent layer is collected and is subjected to distillation so as to remove the organic solvent, and an obtained product is subjected to decarbonylation at a temperature of 178 to 182 DEG C under a vacuum degree of -0.04 to -0.053MPa for 2 to 6h, and fractions obtained under a vacuum degree of -0.095MPa at a temperature above 170 DEG C are collected. According to the method, solid sodium methylate is dispersed in diethyl oxalate which is not too active, and then the obtained mixture is added into the mixed solution dropwise, so that reaction fierce degree of the whole system after adding of solid sodium methylate can be reduced effectively, and smoothness of the reaction is ensured.

Owner:CHANGSHU NANHU INDAL CHEM

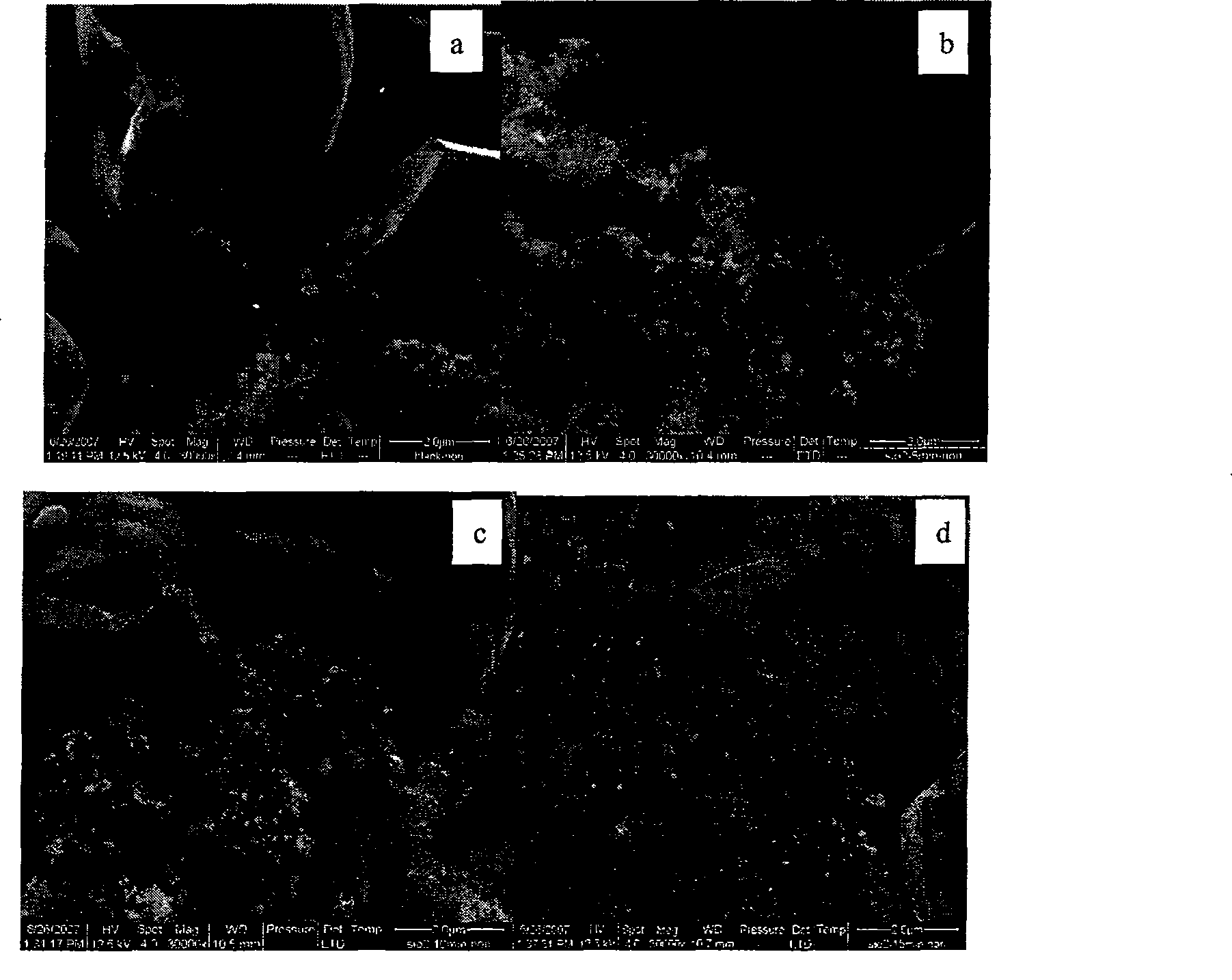

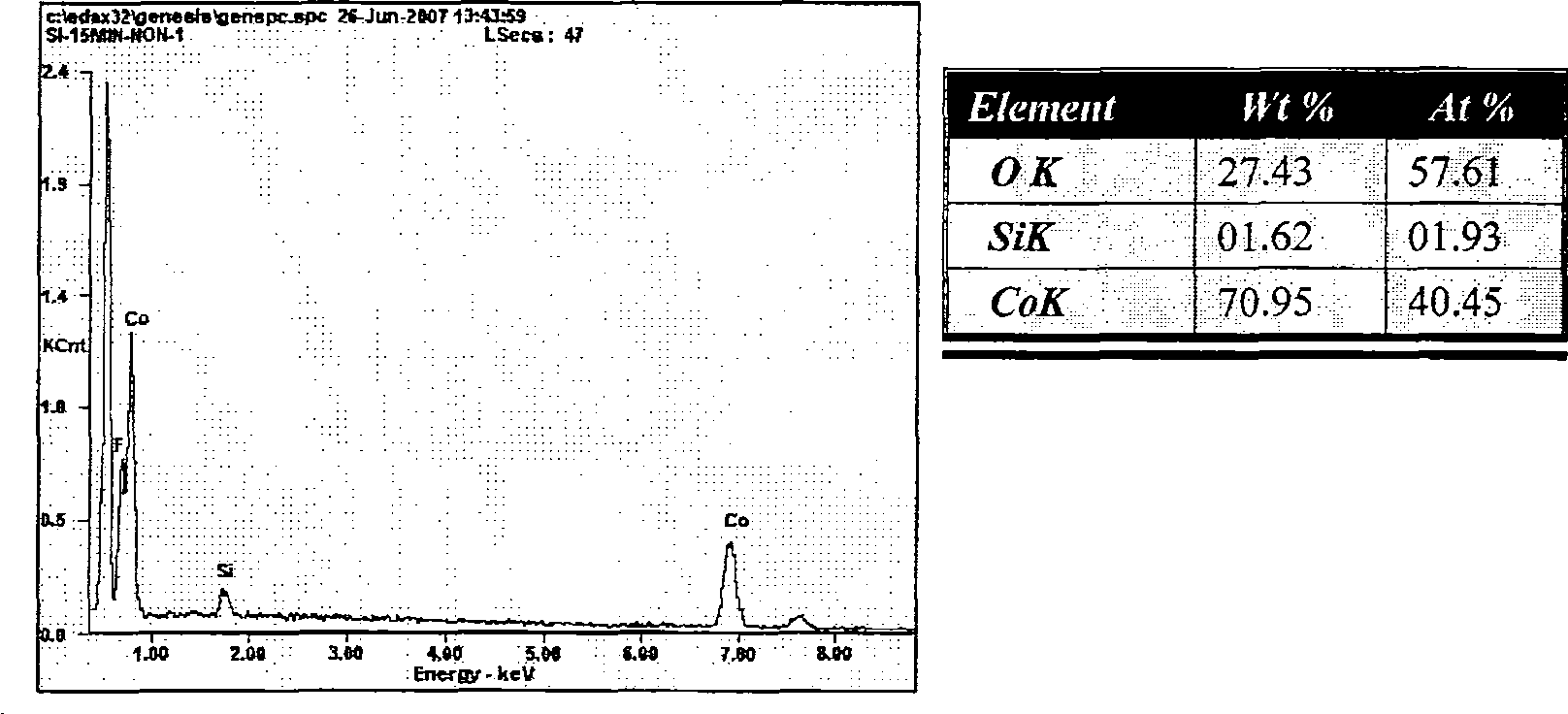

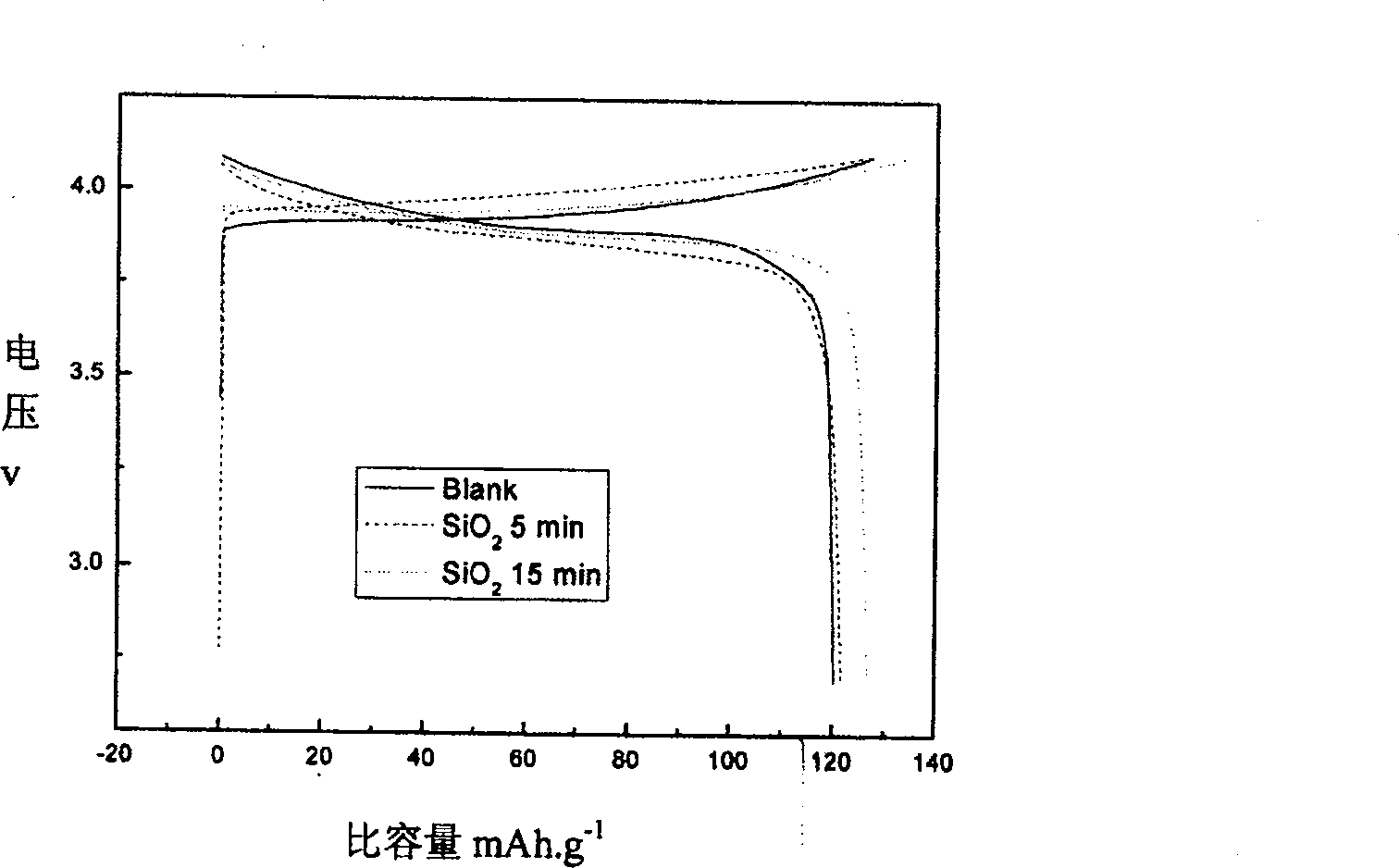

Surface film coating modify method for improving lithium ionic cell positive pole safety

InactiveCN100527483CImprove bindingAvoid damageElectrode manufacturing processesVacuum evaporation coatingElectrical batteryCharge discharge

The present invention relates to a technology of filming on the anode surface of a lithium-ion battery by the magnetic control sputtering method. The positive plate of the common lithium-ion battery is gained through film preparation and is cut into the needed size and put to a sample chamber of a magnetic control sputtering device; a proper target material is put to a sputtering chamber of the magnetic control sputtering device; the sputtering power is set between 40 W and 60 W and the sputtering time is set between 2 min and 30 min and then the positive plate is gained through filming. The positive plate has better cycle performance, charge-discharge capacity and thermal stability, and improves the safety performance of the lithium-ion battery under the conditions of overcharge, overdischarge and misuse.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

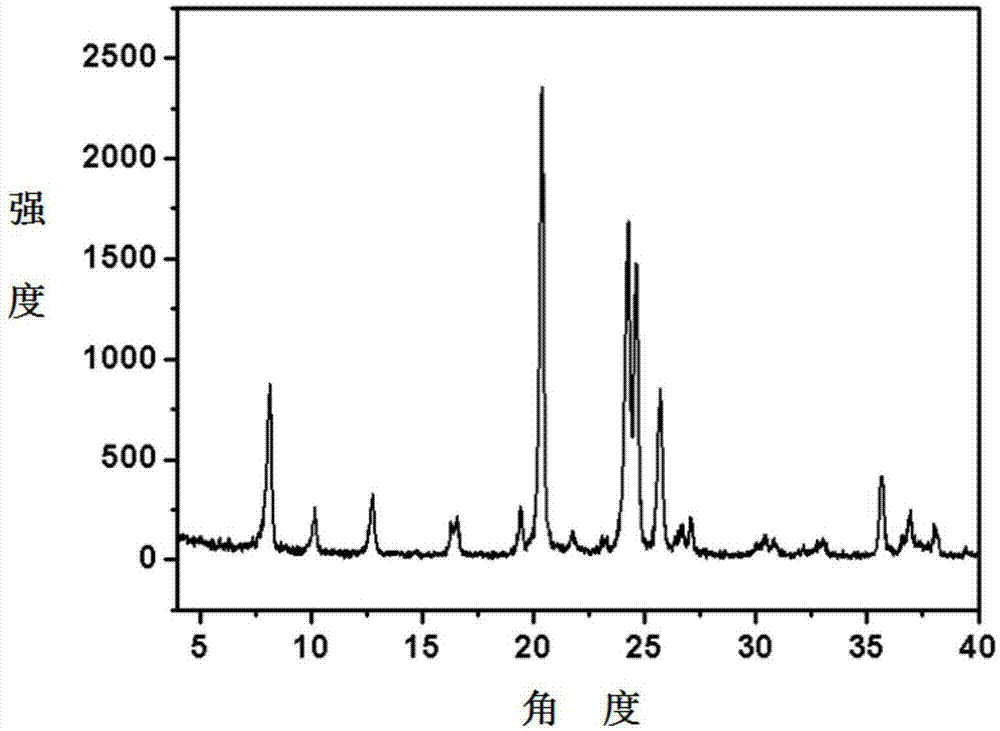

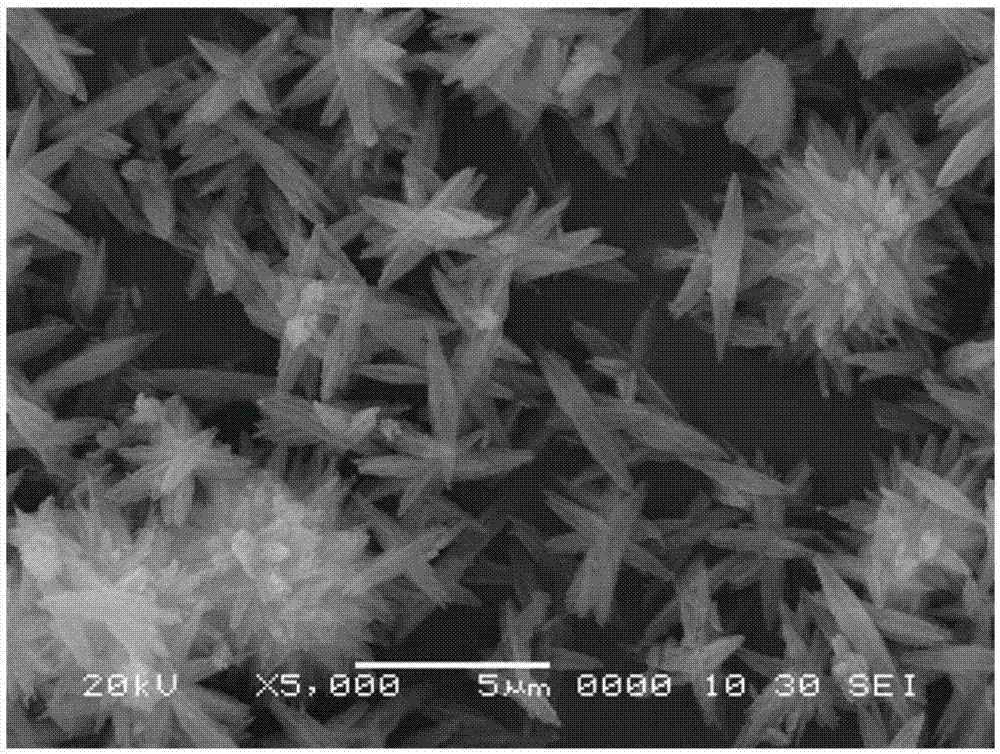

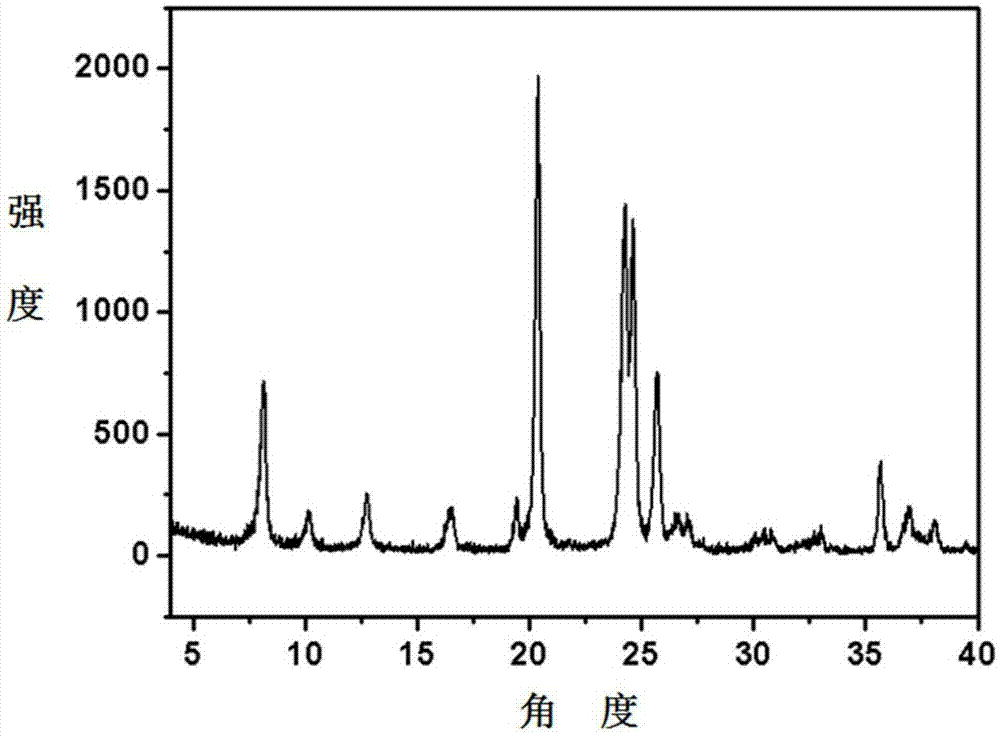

Stable synthetic method for TON zeolite

ActiveCN106853972AImprove the success rate of synthesisHigh purityCrystalline aluminosilicate zeolitesZSM-5Chemistry

The invention relates to a stable synthetic method for TON zeolite. According to the method, zeolite crystallization mother liquor with a TON structure is used as an inductive agent for synthesis of zeolite with the TON structure. The method comprises the following steps: adding the TON zeolite crystallization mother liquor into initial gel in proportion and carrying out a hydro-thermal reaction under sealing conditions so as to obtain a TON zeolite product with a crystallization degree of more than 97%. According to the method, mother liquor produced in primary crystallization of TON zeolite is recovered and utilized; the TON zeolite product with high purity can be obtained in a short period of time under the condition of standing or nonviolent stirring; so the success rate of synthesis of the zeolite is increased, and growth of crystal phases like ZSM-5 and cristobalite is prevented.

Owner:PETROCHINA CO LTD

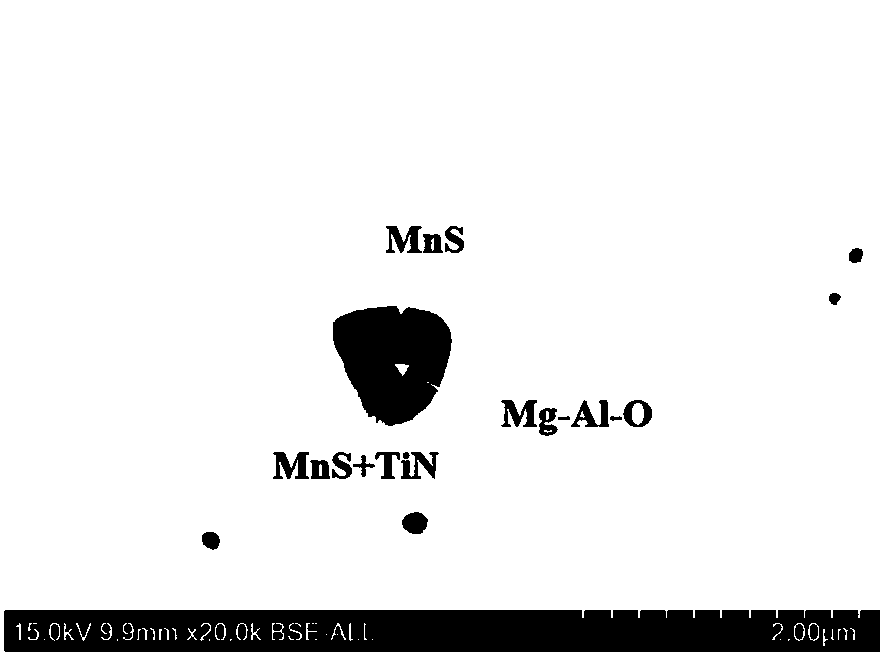

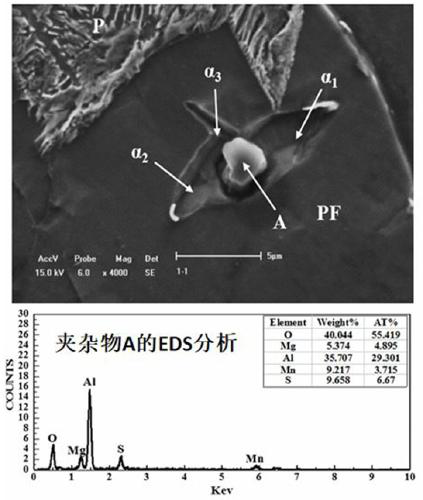

Low-cost magnesium-treated microalloyed steel and preparation method thereof

The invention discloses low-cost magnesium-treated microalloyed steel and a preparation method thereof. The preparation method for the low-cost magnesium-treated microalloyed steel comprises working procedures of steel smelting, alloying, cored wire feeding, continuous casting, rolling and the like. After Ruhrstahl-Heraeus (RH) refining is finished, a magnesium-aluminum-iron alloy is fed to moltensteel at a certain speed and used for partially replacing elements such as niobium, vanadium and titanium which are used for alloying in the refining working procedure. Large-amount precipitation ofsecond-phase particles of steel in solidifying and rolling processes can be promoted. The microalloying function of niobium, vanadium and titanium is replaced partially, and the structure and propertyof steel are improved. Because metal magnesium is lower in price, expensive alloying elements such as niobium, vanadium and titanium are replaced, and the production cost of steel can be effectivelylowered. The property of the magnesium-treated low-carbon microalloyed steel acquired with the preparation method is close to or exceeds the property of standard steel without addition of magnesium, the alloying cost of a ton of steel is lowered by more than twenty-five RMB, and the preparation method for the low-cost magnesium-treated microalloyed steel is a novel steel microalloying technology.

Owner:SUZHOU UNIV

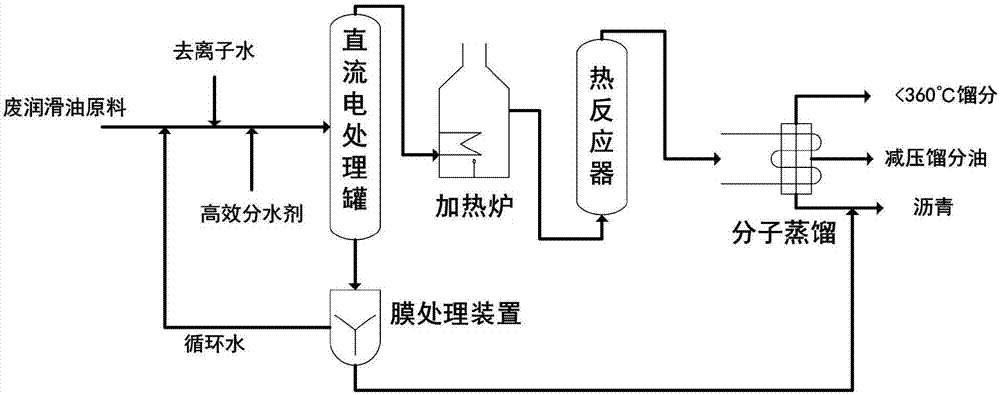

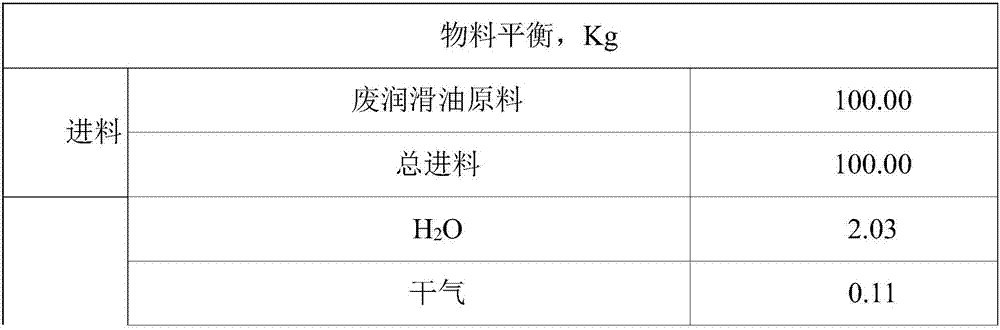

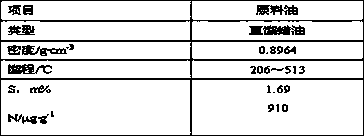

Waste lubricating oil treatment method

ActiveCN107254329AHigh yieldReduce the severity of the reactionLubricant compositionHydrocarbon oils treatmentDistillationEngineering

The invention provides a waste lubricating oil treatment method. The waste lubricating oil treatment method comprises the following steps: (1) performing direct current treatment, namely injecting water into waste lubricating oil, adding a water separating agent, and performing direct current treatment to separate oil from water to obtain upper oil and lower water; (2) performing mild heat conversion treatment, namely, performing a heat conversion reaction on the upper oil obtained in the step (1) in a mild heat conversion reactor to obtain a product which is subjected to the heat conversion treatment; and (3) performing molecular distillation, namely, performing molecular distillation on the product which is subjected to the heat conversion treatment in the step (2) to obtain the fraction less than 360 DEG C, the fraction greater than or equal to 360 DEG C and less than or equal to 500 DEG C, and the fraction greater than 500 DEG C, wherein the fraction greater than or equal to 360 DEG C and less than or equal to 500 DEG C serves as lubricating oil base oil or a hydro-upgraded raw material. According to the method, non-prime components, such as water, metals and ash, in the waste lubricating oil are removed more easily; and the lubricating oil fraction yield is high.

Owner:NINGBO ZHONGXUN ENVIRONMENTAL TECH CO LLC

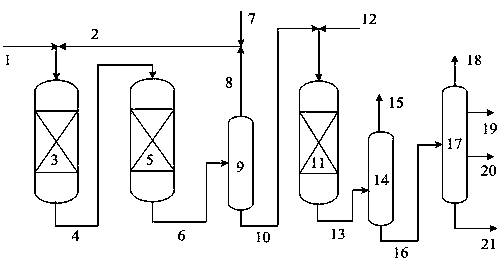

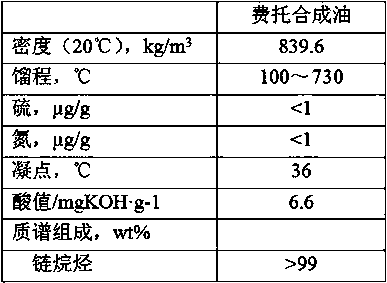

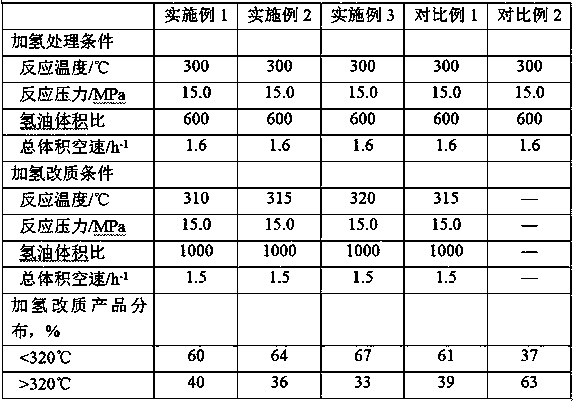

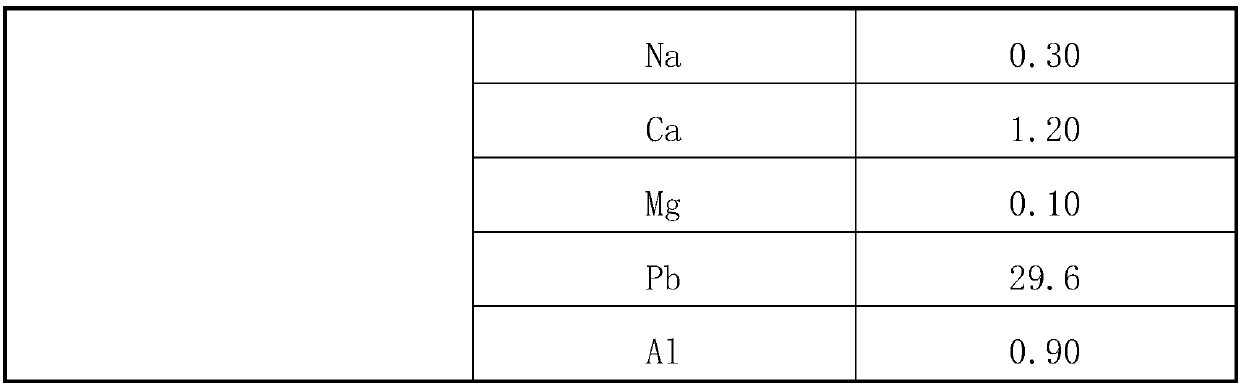

Hydrogenation method for producing API III <+> base oil from Fischer-Tropsch synthetic oil

ActiveCN111378495ASlow cokingLowering the freezing pointTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenation processProcess engineering

The invention discloses a processing method of Fischer-Tropsch synthetic oil. Fischer-Tropsch synthetic oil is used as a raw material, and a two-stage hydrogenation process of hydrofining-hydro-upgrading-isodewaxing is adopted to produce API III <+> lubricating oil base oil. Generated oil obtained through separation of a hydrofining-hydro-upgrading reaction effluent enters an isodewaxing reactionzone, and different types of API III <+> lubricating oil base oil products are obtained through separation and fractionation of an isodewaxing reaction effluent. The method has the advantages of simple process flow and wide raw material adaptability, and can be suitable for the process of producing special oil products with good stability by Fischer-Tropsch synthetic oil fraction hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing 2-ethylhexyl alcohol sulfate salt

InactiveCN105541669ARemove in timeHigh specific areaSulfuric acid esters preparationMicroreactorFluid phase

The present invention discloses a method for producing 2-ethylhexyl alcohol sulfate salt. The method is as below: injecting different inlet 2-ethylhexyl alcohol and a liquid sulfonating agent into a micro-reactor from different inlets of the micro-reactor, mixing and conducting a sulfonation reaction; controlling the reaction temperature at 5-50 DEG C, staying the reaction products in the micro-reactor for 0.5 milliseconds to 5 seconds, and then sending the reaction products into a micro-mixer connected with the micro-reactor to neutralize with a neutralizing agent, and aging for 0-30 min after neutralization, so as to obtain a transparent light yellow 2-ethylhexyl alcohol sulfate salt liquid. The method uses liquid-liquid phase reaction for synthesis of 2-ethylhexyl alcohol sulfate salt, not only obtains a high yield of 100%, but also does not produce any waste gas and waste requiring subsequent treatment. The method simplifies the production process, and improves the production effectiveness.

Owner:GUANGZHOU LONKEY INDAL +1

Reactor for preparing isocyanate and method of reactor for preparing isocyanate

InactiveCN104874335AAvoid it happening againImprove conversion rateIsocyanic acid derivatives preparationOrganic compound preparationPhosgeneReaction tube

The invention provides a reactor for preparing isocyanate and a method of the reactor for preparing isocyanate. The reactor comprises an inner feeding pipe, an outer feeding pipe, a mixer shell, a neck expanding pipe, an auxiliary feeding pipe and a reaction tube, wherein phosgene enters the reactor from the outer feeding pipe and the auxiliary feeding pipe. A coking material in a phosgenation reaction process can be effectively reduced; the running period of the reactor is improved; the conversion rate of the reaction process is improved; and the purity of a reaction liquid is improved.

Owner:WANHUA CHEM GRP CO LTD

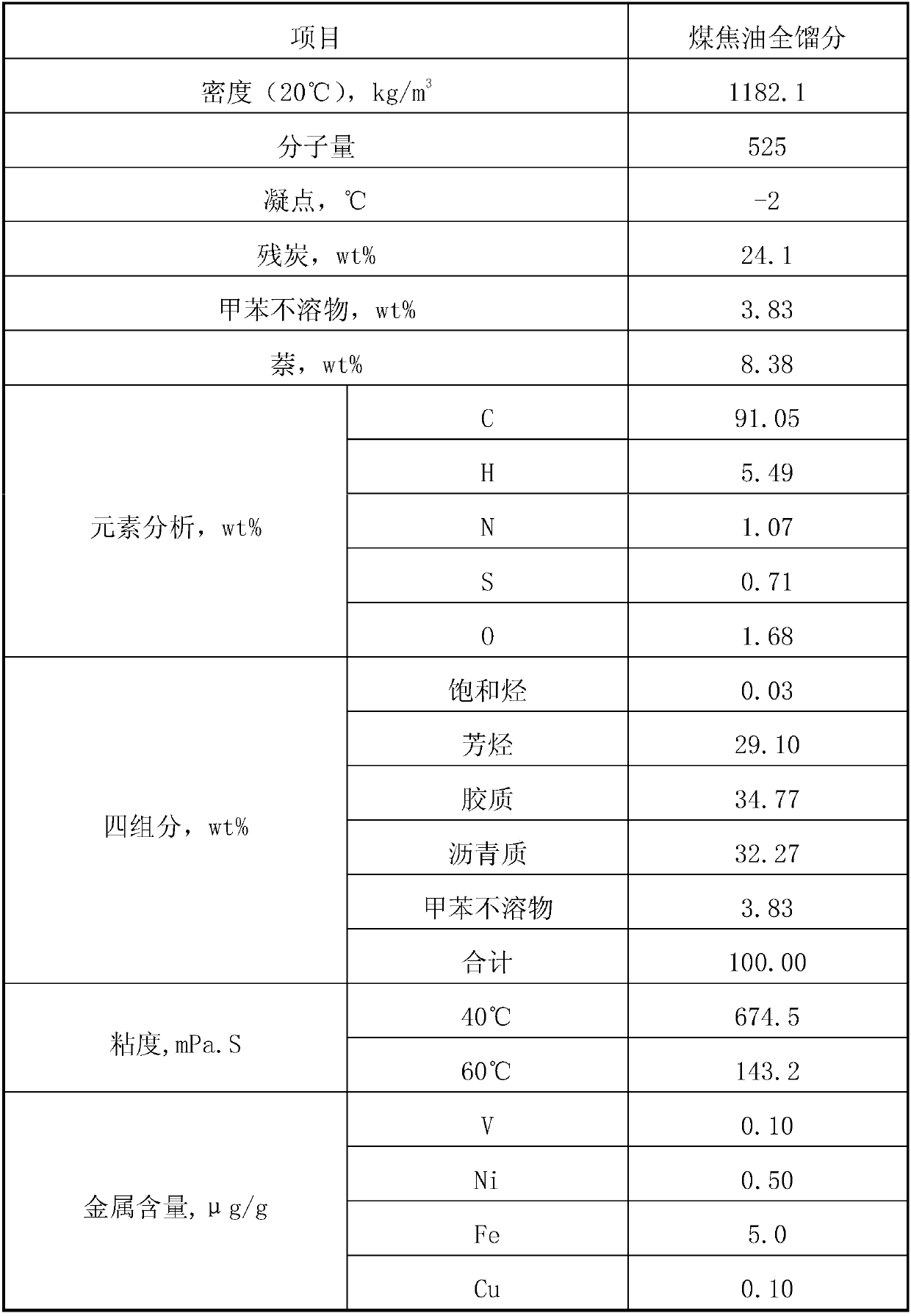

A kind of coal tar suspended bed hydrocracking method

ActiveCN106701178BSimple structureGuaranteed long-term operationHydrocarbon oil crackingTreatment with hydrotreatment processesHydrogenSlurry

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP +1

Processing method of Fischer-Tropsch synthetic oil

ActiveCN111378494ASlow cokingLowering the freezing pointTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenation processProcess engineering

The invention discloses a processing method of Fischer-Tropsch synthetic oil. Fischer-Tropsch synthetic oil is used as a raw material, and a two-stage hydrogenation process of hydrofining-hydro-upgrading-isodewaxing is adopted to produce API III <+> lubricating oil base oil. Heavy distillate oil generated oil obtained through hydrofining-hydro-upgrading reaction effluent separation enters an isodewaxing reaction zone, and an isodewaxing reaction effluent is subjected to separation and fractionation to obtain different types of API III <+> lubricating oil base oil products. The method has the advantages of simple process flow and wide raw material adaptability, and can be suitable for the process of producing special oil products with good stability by Fischer-Tropsch synthetic oil fractionhydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for catalyzing gasoline deep desulfurization with Ni-Co containing catalyst

ActiveCN104650966AHas a relay desulfurization effectExcellent hydrodesulfurization selectivityTreatment with hydrotreatment processesMetal/metal-oxides/metal-hydroxide catalystsHydrodesulfurizationGasoline

The invention relates to a method for catalyzing gasoline deep desulfurization with an Ni-Co containing catalyst. Specifically, a gasoline raw material enters a first reactor to undergo selective hydrodesulfurization and then enters a second reactor to further undergo deep desulfurization. The second reactor adopts a highly selective hydrodesulfurization catalyst, which is an Ni-Co containing catalyst. The catalyst has certain desulfurization activity, and at the same time has little olefin saturation, after combination with the first reactor, further deep desulfurization can be realized, and simultaneously the reaction severity of the first reactor can be significantly reduced, so that the octane number loss and hydrogen consumption can be optimized.

Owner:PETROCHINA CO LTD

Method for prolonging quality stability of hydrocracking product

ActiveCN109777482ATendency to delay coking inactivationReduce acidityTreatment with hydrotreatment processesHydrogenPre treatment

The invention discloses a method for prolonging the quality stability of a hydrocracking product. The method comprises the following steps that hydrocracking raw materials and hydrogen gas are mixed to enter a hydrocracking pretreatment reactor for refining reaction; reaction effluents enter a hydrocracking reactor for hydrocracking reaction; four hydrocracking catalyst bed layers are arranged inthe hydrocracking reactor; when the conversion rate of fractions higher than 350 DEG C in hydrocracking raw materials is 90 to 99 percent, a hydrogenation posttreatment catalyst bed layer is arrangedat each of the top and the bottom of any one hydrocracking catalyst bed layer; the volume ratio of posttreatment catalysts filled along the material flow direction is (3 to 7):(5 to 15):(5 to 25):(20to 40):(30 to 50); the volume ratio of the hydrogenation posttreatment catalysts in the hydrocracking reactor to hydrocracking catalysts filled in the hydrocracking reactor is 1:(6 to 8); after hydrocracking products are separated, various products are obtained. By the method, the stability of the hydrocracking products can be obviously improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for improving quality of hydrocracking products

ActiveCN109777485ATendency to delay coking inactivationReduce acidityTreatment with hydrotreatment processesNaphthaHydrogen

The invention discloses a method for improving the quality of hydrocracking products. The method comprises the following contents: a hydrocracking material and hydrogen are mixed and then enter a hydrocracking pretreatment reactor, so as to be subjected to refining reaction; a reaction effluent enters a hydrocracking reactor, so as to be subjected to hydrocracking reaction; a hydrogen aftertreatment catalyst is filled between the bottom of the hydrocracking reactor and beds of a hydrocracking catalyst; and a hydrocracking product is separated, so that various products are obtained. The methodcan solve the ubiquitous problems of high heavy naphtha bromine index, high mercaptan and excess aviation fuel product sulphur in middle and later stages of reaction in the process of hydrocracking reaction of aftertreatment catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

Recovery device for valuable metals in waste foamed nickel

ActiveCN110699549AImprove leaching rateReduce productionMeasurement devicesProcess efficiency improvementSodium chlorateMonitoring system

The invention provides a recovery device for valuable metals in waste foamed nickel, and is suitable for the field of heavy metal recovery. The recovery device comprises a material barrel, a pure water inlet, a sodium chlorate solution inlet, a dilute sulfuric acid inlet, a feeding port and a safety valve are formed in the top of the material barrel, a material stirring barrel is arranged inside the material barrel, and a collecting box is arranged below the material barrel. According to the recovery device, the material stirring barrel is partitioned, continuous oxidation acid leaching operation can be carried out, the reaction time is greatly shortened, the reaction efficiency is improved, the leaching rate of metal is obviously improved, the nickel leaching rate can reach 99% or above,the treatment effect is obvious, in addition, an online monitoring system is introduced for flammable and explosive hydrogen gas, it is guaranteed that the reaction can be conducted safely and continuously, the reaction safety coefficient is improved, and the possibility of accident occurring is reduced.

Owner:JINGMEN GEM NEW MATERIAL

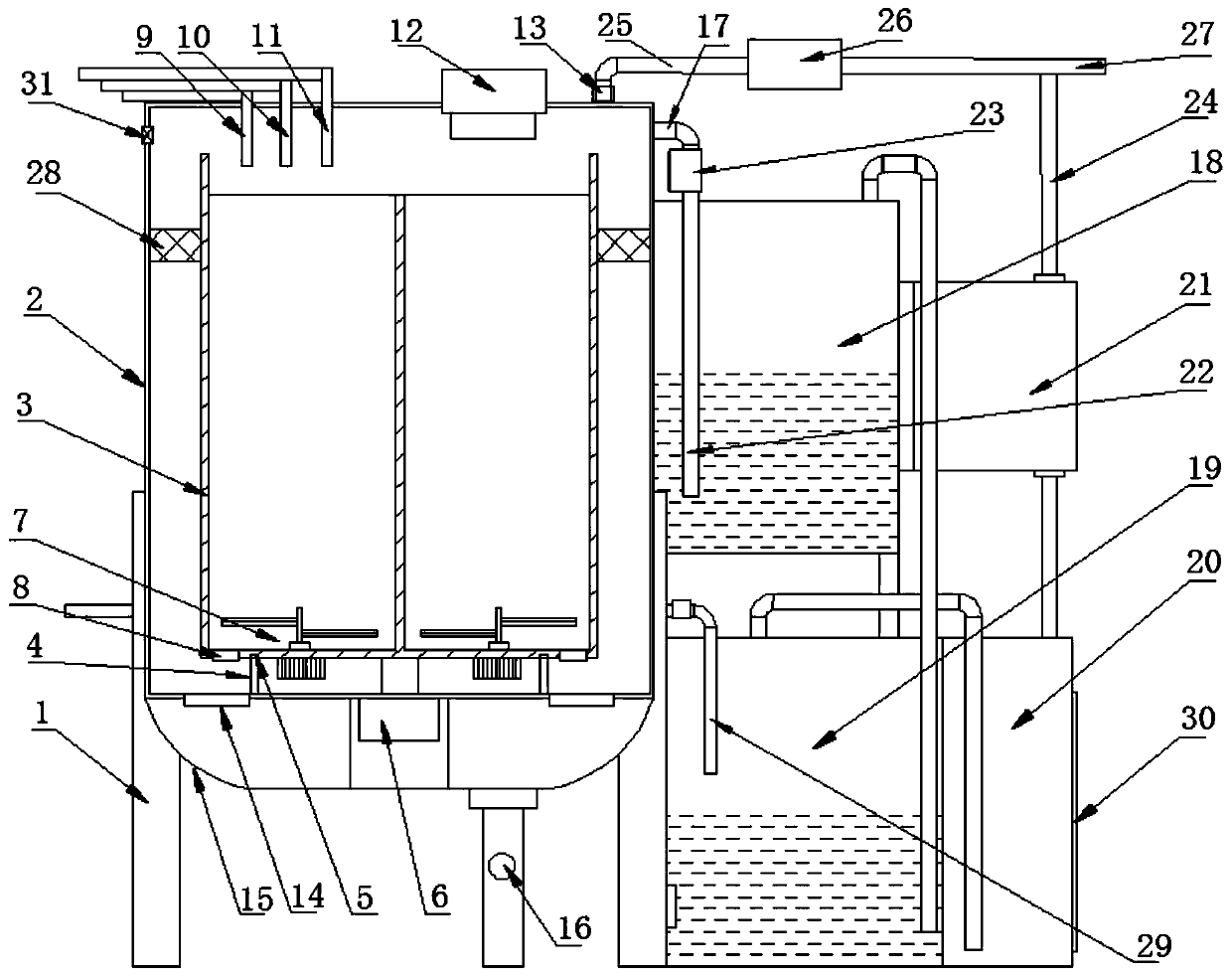

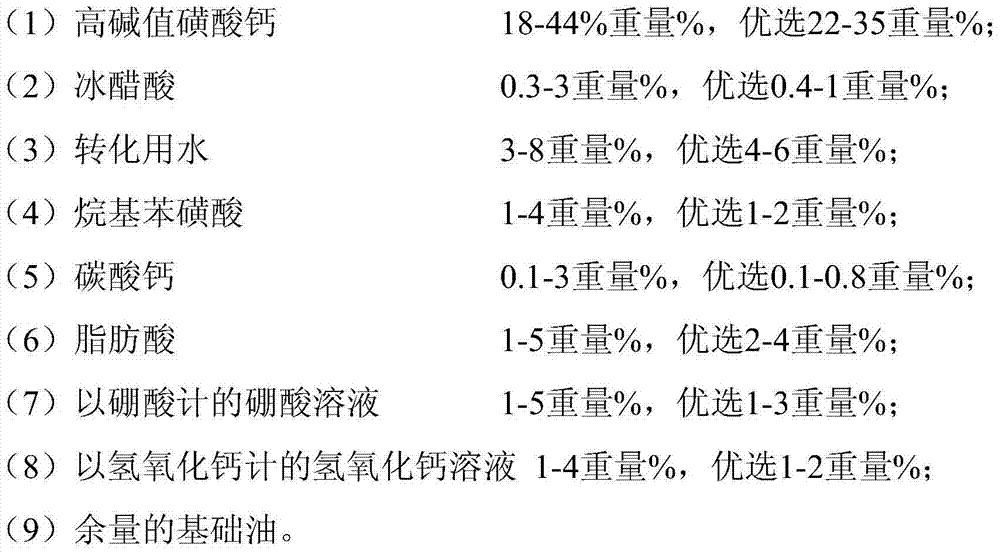

Composite calcium sulfonate lubricating grease composition and preparation method thereof

ActiveCN103740435BGood extreme pressure antiwear agentDrop point highThickenersFatty acidBase Number

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

Surface modification treatment method for titanium metal implant material

PendingCN113981429AEnhance induction activityIncreasing the thicknessMetallic material coating processesOsseointegrationSkeletal tissue

The invention discloses a surface modification treatment method for a titanium metal implant material. According to the method, titanium metal is subjected to reduction treatment to obtain the surface characteristic rich in surface oxygen vacancies, so that the osseointegration capacity of the titanium metal and a matrix is promoted. According to the titanium metal surface rich in oxygen vacancies, the proportion of the oxygen vacancies is 5% to 40%. The prepared titanium metal rich in oxygen vacancies on the surface has the excellent capability of accelerating osseointegration of an implant and the matrix. The adopted treatment and preparation method is simple, high in controllability and suitable for industrial preparation and treatment of bone tissue repair titanium metal materials for biomedicine.

Owner:THE STOMATOLOGIAL HOSPITAL OF ZHEJIANG UNIV SCHOOL OF MEDICINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com