Production technology of sandwich core-spun yarn

A production process, cored wire technology, applied in the field of sandwich cored wire production process, can solve the problems of increased magnesium oxide, uneven powder, reduced effective magnesium content, etc., to achieve the effect of increased magnesium absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

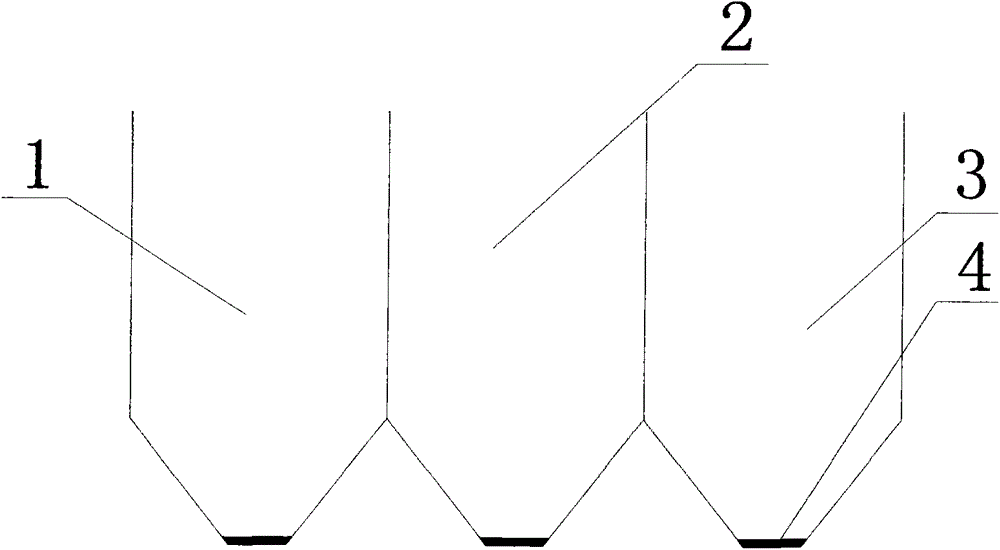

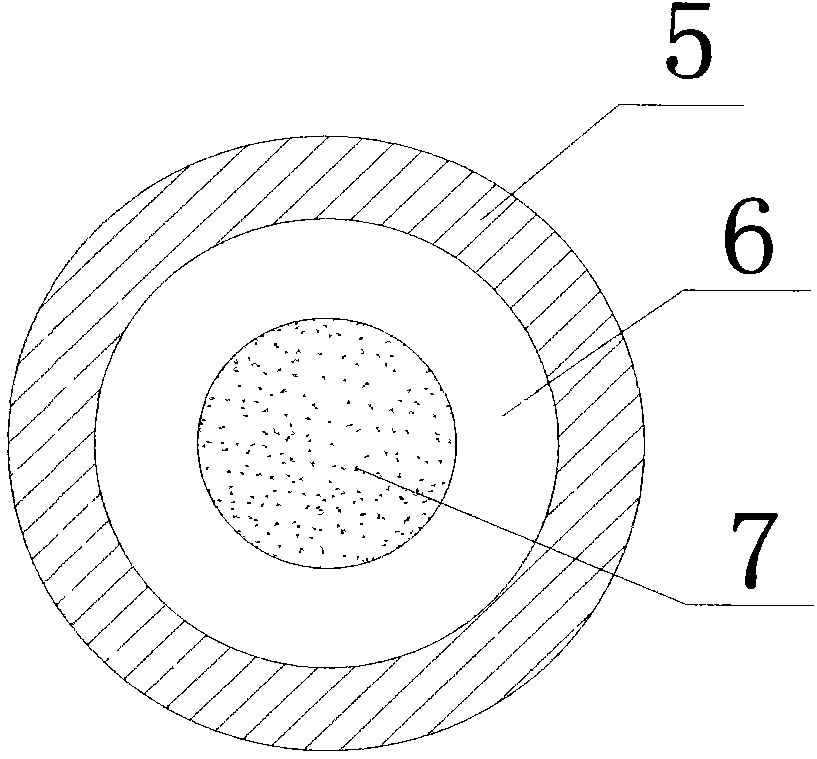

[0020] Such as figure 1 and figure 2 Shown: the manufacturing process of the present invention comprises the first hopper 1, the second hopper 2 and the third hopper 3, the bottoms of the first hopper 1, the second hopper 2 and the third hopper 3 are equipped with a flow regulating device 4, the first The hopper 1 and the third hopper 3 respectively place ferrosilicon powder, silicon calcium powder and rare earth ferrosilicon powder mixed powder 6 mixed by a mixing device, and the second hopper 2 places pure magnesium granules 7 . Practical embodiment: the proportion of ferrosilicon powder in the mixture 6 is 35%, the proportion of calcium silicon powder is 10%, the proportion of rare earth ferrosilicon powder is 10%, the proportion of pure magnesium grain 7 is 45%, use 0.8mm thick The low-carbon steel strip is rolled into a cored wire by the core wrapping unit through t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com