Coal tar suspended bed hydrocracking method

A hydrocracking and suspended bed technology, which is used in hydrocarbon oil cracking, hydrotreating process, and hydrocarbon oil treatment, etc., can solve the problem of difficult and continuous separation of catalysts and high-temperature heavy oil products, aggravating the coking tendency of high-temperature oil products, Equipment, valve wear and other problems are accelerated, so as to reduce the risk of coking, improve the reaction conversion rate, and avoid coking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

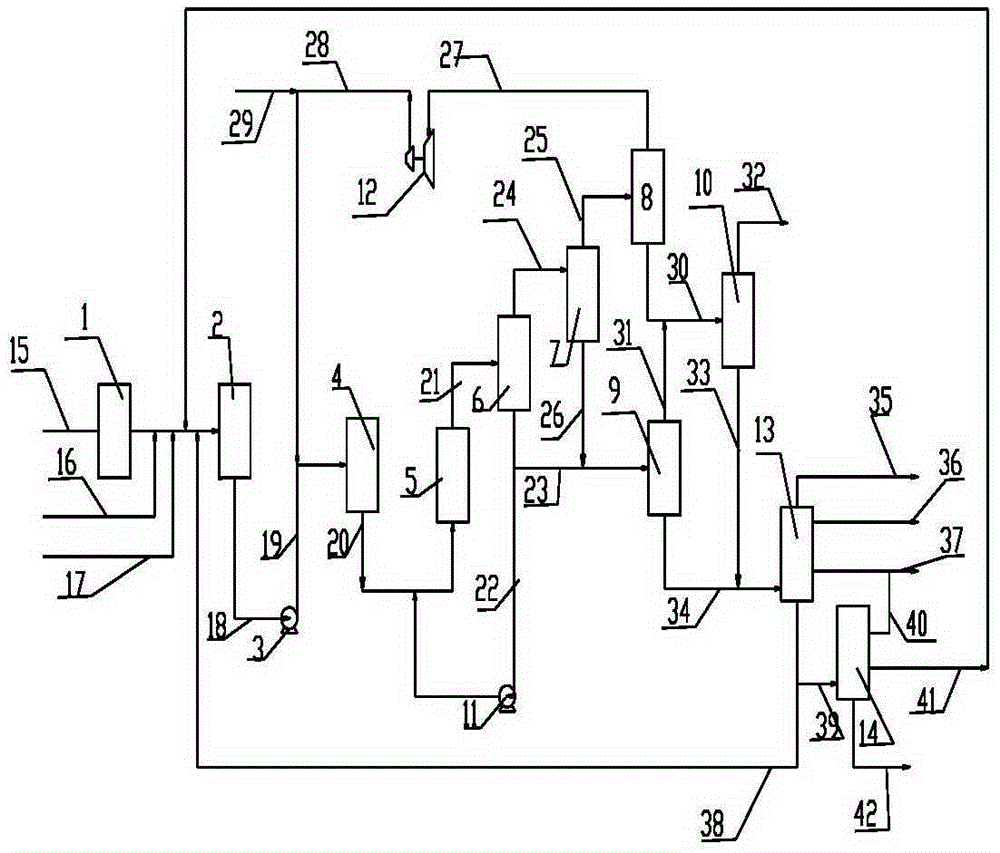

[0041] Coal tar raw material 15 is desalted, dehydrated, and mechanically impurity removed in the raw material pretreatment unit 1, and then mixed evenly with the atmospheric pressure tower bottom circulating heavy oil 38, vacuum wax oil 41, catalyst 16, and co-catalyst 17 in the raw material slurry configuration unit 2 into raw material oil slurry, the raw material oil slurry and hydrogen mixture are merged into mixed feedstock and hot high-separation gas for heat exchange, enter the reaction feed heating furnace 4 to heat up, and mix with the circulating hot high-separation oil 22 at the furnace outlet to meet the reaction requirements The temperature enters the suspension bed reactor 5 for hydrocracking reaction. A suspension bed reactor is set, the reaction temperature is 380°C, and the operating pressure is 10MPa. The reaction product 21 of the suspension bed reactor 5 first enters the hot high-pressure separator 6 for gasification. , liquid-solid separation, the hot high-...

Embodiment 2

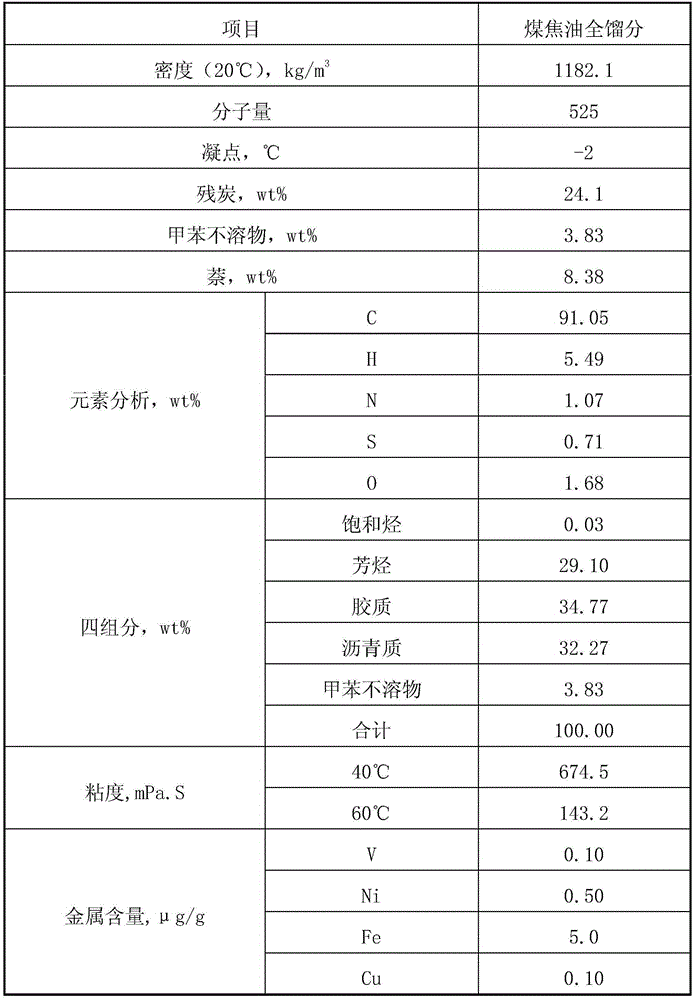

[0043] The high-temperature coal tar in Table 1 is used as the raw material for suspension bed hydrocracking, the reaction conditions are 455°C, 19MPaG, the hydrogen-oil ratio is 1350, and the space velocity is 0.5h -1 , the weight percentage of the high-fraction oil circulation is 50%, the weight percentage of the atmospheric heavy oil circulation is 60%, the vacuum wax oil is all circulated, and the vacuum residue and catalyst residue do not participate in the circulation. The obtained product distribution and yield are shown in Table 2.

[0044] Table 1 Properties of full-fraction high-temperature coal tar

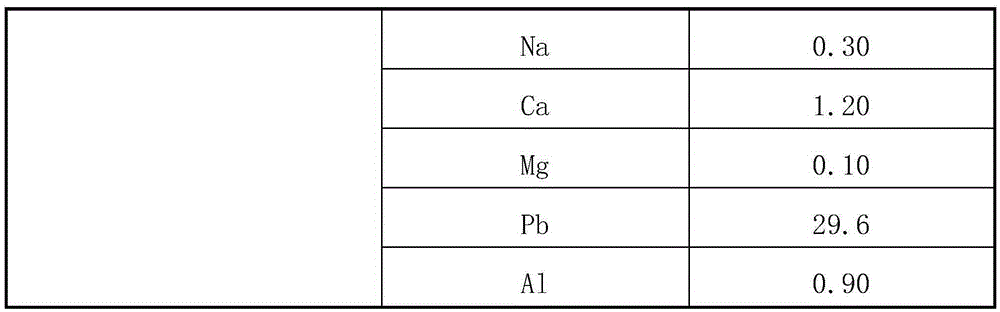

[0045]

[0046]

[0047] Table 2 Properties of a full-fraction high-temperature coal tar

[0048]

Embodiment 3

[0050] The coal tar raw material 15 is desalted, dehydrated, and mechanically impurity removed in the raw material pretreatment unit 1, and then mixed evenly with the atmospheric pressure tower bottom circulating heavy oil 38, vacuum wax oil 41, catalyst 16, and co-catalyst 17 in the raw material slurry configuration unit 2 into raw material oil slurry, the raw material oil slurry and hydrogen mixture are merged into mixed feedstock and hot high-separation gas for heat exchange, enter the reaction feed heating furnace 4 to heat up, and mix with the circulating hot high-separation oil 22 at the furnace outlet to meet the reaction requirements The temperature enters the suspension bed reactor 5 for hydrocracking reaction. A suspension bed reactor is set, the reaction temperature is 500°C, and the operating pressure is 25MPa. The reaction product 21 of the suspension bed reactor 5 first enters the hot high pressure separator 6 for gasification. , liquid-solid separation, the hot h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com