Reactor for preparing isocyanate and method of reactor for preparing isocyanate

A technology of isocyanate and reactor, which is applied in the field of isocyanate preparation reactor and its use in the preparation of isocyanate, can solve the problems of shortening the operation period of the reactor and deterioration of the flow field of the reactor, so as to improve the quality of the reaction liquid and avoid a large amount of heat release , Improve the effect of the operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

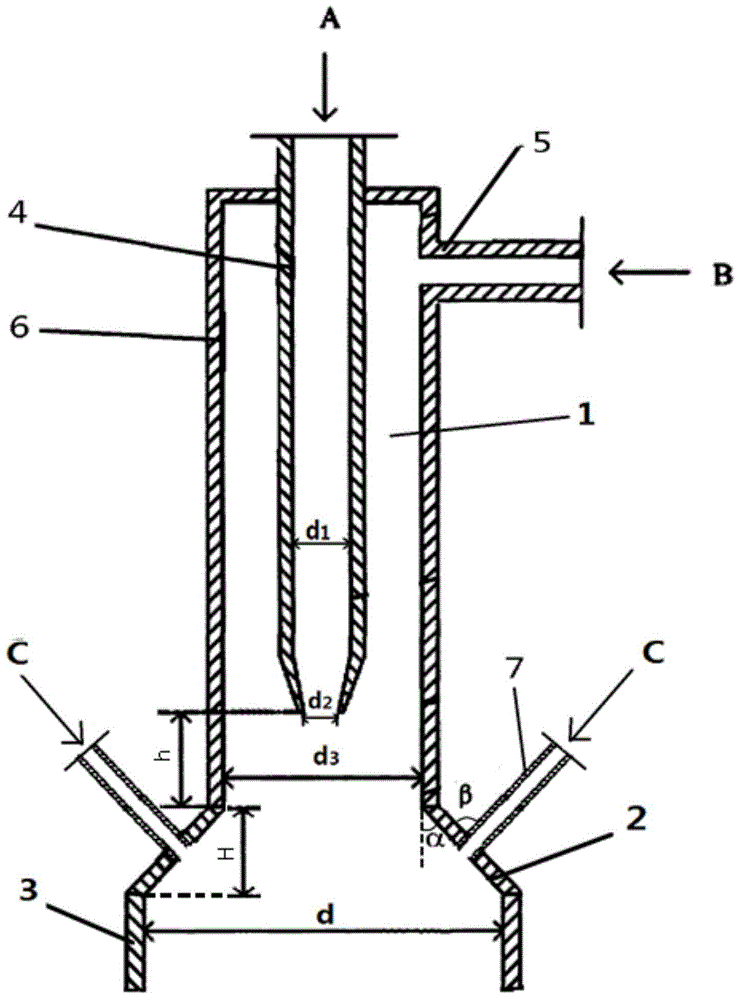

[0045] The reactor comprises an inner feed pipe 4, an outer feed pipe 5, a mixer housing 6, a neck expansion pipe 2, an auxiliary feed pipe 7 and a reaction pipe 3; the inner feed pipe 4, the outer feed pipe 5, The mixer housing 6 constitutes the mixer; the inner feed pipe 4 is arranged inside the mixer, the outer feed pipe 5 is communicated with the mixer through the side wall of the mixer, and the lower end of the mixer is passed through a neck expansion tube 2 is connected to the reaction tube 3, and makes the diameter d of the reaction tube larger than the diameter d3 of the mixer shell, and the auxiliary feed tube 7 is arranged on the side wall of the expansion neck tube 2. The expansion neck is in the shape of a frustum of a cone.

[0046] The diameter d of the reaction tube of the reactor used is 450mm, the diameter d3 of the mixer shell is three times the diameter d1 of the inner feed pipe, the diameter d1 of the inner feed pipe is twice the diameter d2 of the outlet, ...

Embodiment 2

[0054] The diameter d of the reaction tube is 600mm, the diameter d3 of the mixer shell of the reactor used is three times the diameter d1 of the inner feed pipe, the diameter d1 of the inner feed pipe is twice the diameter d2 of the outlet, and the outlet of the inner feed pipe The distance h from the upper bottom surface of the neck expansion tube is twice the inner diameter d1 of the feed pipe, the diameter d of the lower bottom surface of the neck expansion tube is 1.5 times the diameter d3 of the upper bottom surface, and the angle between the busbar 10 of the neck expansion tube and the axis of the reactor α is 30°.

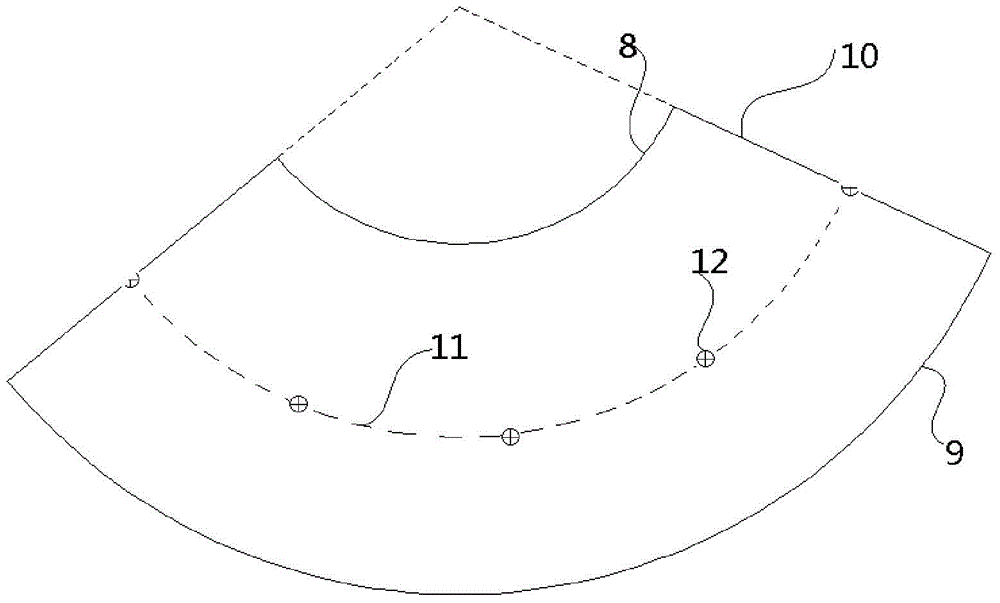

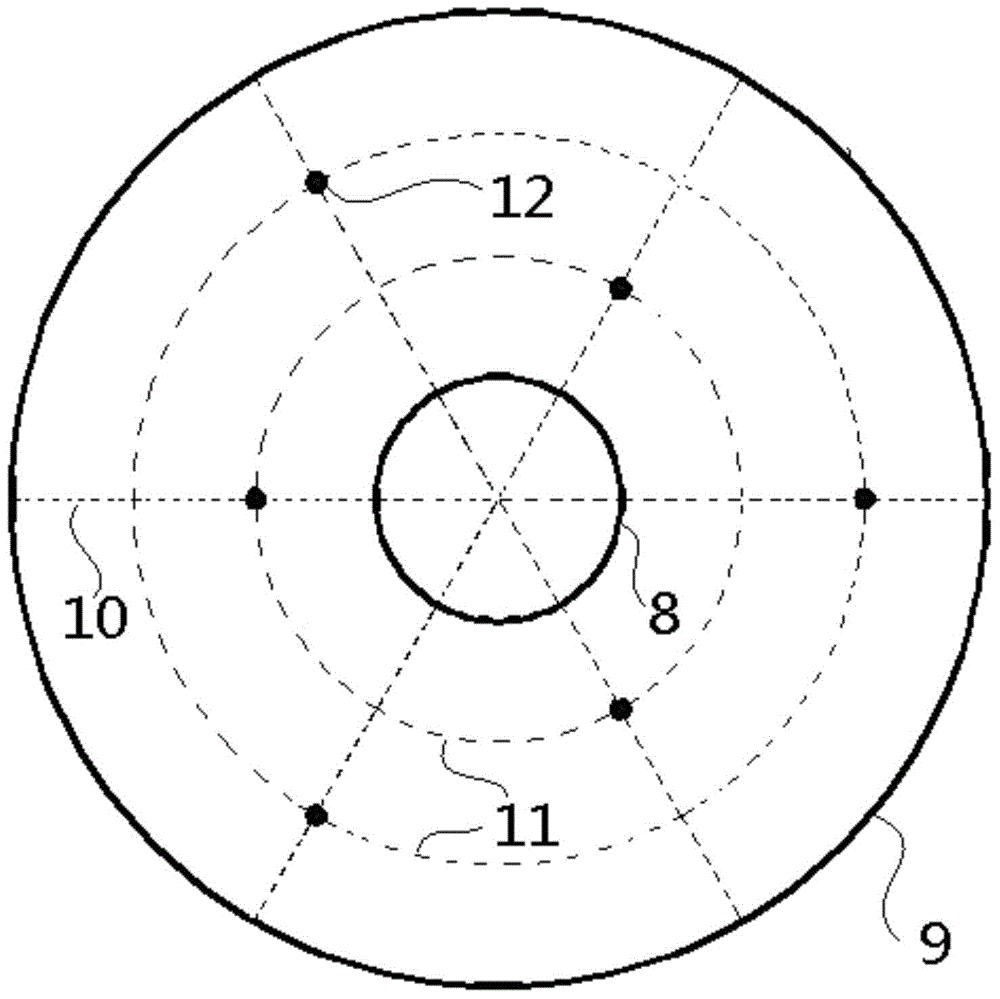

[0055] The neck expander top view of the reactor adopted in embodiment 2 is shown in image 3 . Among them, 8: the round edge of the upper bottom surface of the neck expansion tube, 9: the round edge of the bottom surface of the neck expansion tube, 10: the bus bar of the neck expansion tube, 11: the round edge of the section where the outlet of the auxili...

Embodiment 3

[0063] The diameter d of the reaction tube is 450mm, the diameter d3 of the mixer shell of the reactor used is three times the diameter d1 of the inner feed pipe, the diameter d1 of the inner feed pipe is twice the diameter d2 of the outlet, and the outlet of the inner feed pipe The distance h from the upper bottom surface of the neck expansion tube is twice the inner diameter d1 of the feed pipe, the diameter d of the lower bottom surface of the neck expansion tube is 1.5 times the diameter d3 of the upper bottom surface, and the angle α between the busbar of the neck expansion tube and the reactor axis is 45°.

[0064] A total of 8 auxiliary feed pipes are evenly distributed on the two sections, and the outlets of the 4 auxiliary feed pipes are evenly distributed on the round edge of the first section parallel to the bottom surface of the neck expansion tube. The distance from the bottom surface is 1 / 3H; the outlets of the other 4 auxiliary feed pipes are evenly distributed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com