Deep desulfurization method of gasoline

A technology for deep desulfurization and gasoline, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems such as unseen, unqualified mercaptan sulfur, unable to meet technical requirements, etc., to reduce the severity of the reaction, The effect of extended operating cycle, octane number and hydrogen consumption optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 100g of pseudo-boehmite, add 2.5g of fenugreek powder, then add 3% nitric acid aqueous solution, knead and extrude, dry at 120°C for 4h, and then roast at 650°C for 4h to obtain the catalyst carrier. Test the water absorption rate of the carrier according to the conventional method, and then follow the equal volume impregnation method to configure the active component impregnation solution according to the water absorption rate of the carrier. First weigh 40ml of ammonia water, then add 35g of nickel acetate and 30g of nickel nitrate and stir until dissolved, and finally use ammonia water to make up the volume. The carrier is impregnated by the equal volume impregnation method, so that the catalyst carrier can fully absorb the impregnation solution of the active component, and after standing for 12 hours, the catalyst is dried at 120°C for 4 hours, and calcined at 500°C for 4 hours to obtain the catalyst sample used in the third reactor Cat-1#.

Embodiment 2

[0030]According to the preparation method of the carrier in Example 1, 100 g of the catalyst carrier was prepared, and then the active component impregnating solution was prepared, and the preparation method was the same as that of Example 1. First weigh 45ml of ammonia water, then add 7g of ammonium molybdate and 58g of nickel nitrate in turn and stir until dissolved, and finally use ammonia water to make up the volume. The impregnation method, drying and roasting conditions of the metal active components were the same as in Example 1, and the catalyst sample Cat-2# was obtained.

Embodiment 3

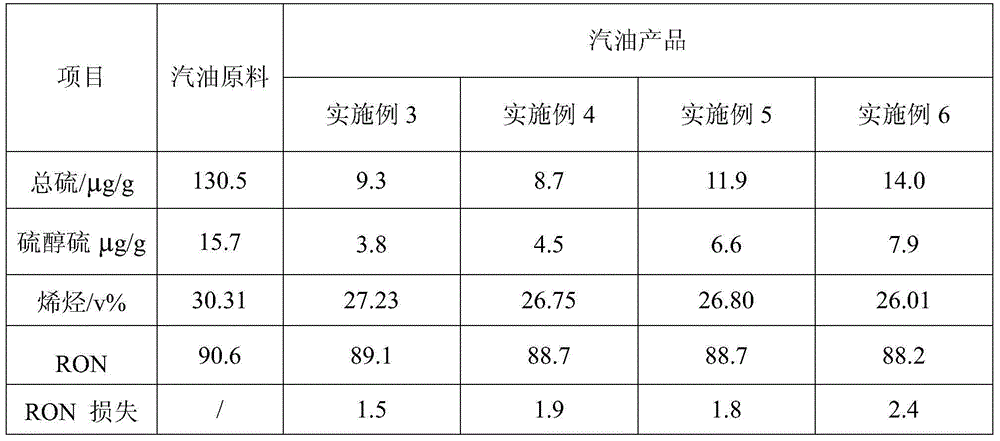

[0032] The used gasoline raw material of embodiment 3 is identical with comparative example. The gasoline raw material first enters the first reactor to remove diolefins while the mercaptan is heavy, and then enters the fractionation tower to cut into light and heavy gasoline (cutting temperature 60°C), and the obtained heavy gasoline passes through the second reactor to remove most After part of the sulfide, it enters the third reactor for further hydrodesulfurization of mercaptans, sulfides, disulfides and thiophene sulfur in the hydrodesulfurization product, and the obtained heavy gasoline hydrodesulfurization product is mixed with light gasoline to obtain Clean gasoline products. Wherein, the catalyst used in the first reactor and the catalyst used in the second reactor are the same as the comparative example, and the catalyst used in the third reactor is Cat-1# developed in Example 1. The operating conditions are shown in Table 3.

[0033] Table 3 Operating process cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com