Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

114results about How to "Reduce the cost per ton of steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing tire cord steel wire by converter billet continuous casting process

ActiveCN102534094AGuaranteed surface qualityLow costManufacturing convertersMetal rolling arrangementsSlagSilicon alloy

The invention relates to a method for producing a tire cord steel wire according to a converter billet continuous casting process and belongs to the technical field of production of tire cord steel wires in the field of ferrous metallurgy. The method comprises the following process steps: desulfurizing by pre-treating molten iron, namely desulfurizing by spraying magnesium on a foundry ladle; smelting by using a converter, namely deoxidizing and alloying, modifying steel ladle slag, re-carburizing the molten iron and adding low-alkalinity pre-melted slag into the steel ladle after tapping; adding ferro-silicon alloy, manganese iron alloy and micronitrogen carburant in the tapping process and re-carburizing; and in the refining process and after the refining is finished, rolling the wire at high speed by adopting a two-stage steel ladle bottom blowing argon system and adopting billet continuous casting of 130mm*130mm or 160mm*160mm. The method has the advantages that: the production isreduced; the production efficiency is improved; and the method is particularly suitable for development and production of tire cord steel products in steel enterprises without big billet or rectangular billet continuous casting and without vacuum treatment equipment.

Owner:SHOUGANG CORPORATION

Dynamic thickening rolling process of controlling break of cold rolled thin strip steel

InactiveCN1857809AReduced number of broken beltsReduce broken belt rateRoll mill control devicesMeasuring devicesControl breakMultiple frame

The dynamic thickening rolling process of controlling break of cold rolled thin strip steel has weld seam tracking system used in measuring the weld seam position accurately, and features that in the range of 50 m around the weld seam, the strip steel thickness is increased to 1.0-1.5 times the original target thickness. Two wedge rolling processes are used to increase the rolled thickness dynamically, so as to lower the break rate of the thin rolled material. The present invention has the advantages of reduced strip steel breaking rate, high production efficiency, etc. and is suitable for multi-frame continuous cold rolling machine with 4, 5 or 6 frames.

Owner:ANSHAN IRON & STEEL GROUP CORPORATION +1

Method based on high-silicon high-phosphorus molten iron converter low slag material consumption to melt low-phosphorus steel

ActiveCN108624735ASimple and fast operationEasy to masterManufacturing convertersProcess efficiency improvementSlagMaterial consumption

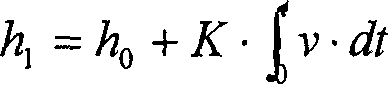

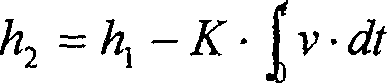

The invention relates to a smelting technology method of a steel technological process and specifically relates to a method based on high-silicon high-phosphorus molten iron converter low slag material consumption to melt low-phosphorus steel. The method comprises the following steps: utilizing single-slag operation under the conditions that Si of molten iron putting into a furnace is larger thanor equal to 0.55% and smaller than or equal to 0.8% and P of molten iron putting into the furnace is larger than or equal to 0.17% and smaller than or equal to 0.22%; making a molten iron temperaturelarger than 1250 DEG C and a scrap steel ratio larger than 25%; utilizing a less-slag material, adding the less-slag material into a melting model and controlling the adding amount of an auxiliary material. When Si of general molten iron putting into the furnace is larger than or equal to 0.6% or P of the general molten iron putting into the furnace is larger than or equal to 0.12%, a duplexing method or a double-slag method is utilized by a converter. Under the situations of molten-iron-free three-removal pretreatment and converter duplexing method dephosphorization, operation of the method disclosed by the invention utilizes a single-slag method; under the premises that converter lime consumption is smaller than 40kg / t and a new slag material consuming total amount is smaller than 70kg / t, the condition that P is smaller than 0.012% when a smelting point C is larger than or equal to 0.065% is ensured at the same time. The method disclosed by the invention can effectively reduce novelslag material consumption of high-silicon high-phosphorus molten iron converter smelting, is favorable for reducing industrial waste generation and reduces production cost of per ton of steel.

Owner:UNIV OF SCI & TECH BEIJING +1

Method for smelting high-phosphorus molten iron to produce steel with converter end point P less than or equal to 0.01% by adopting slagless material

ActiveCN109280731AAvoid going backReduce the temperatureManufacturing convertersProcess efficiency improvementSteelmakingNitrogen

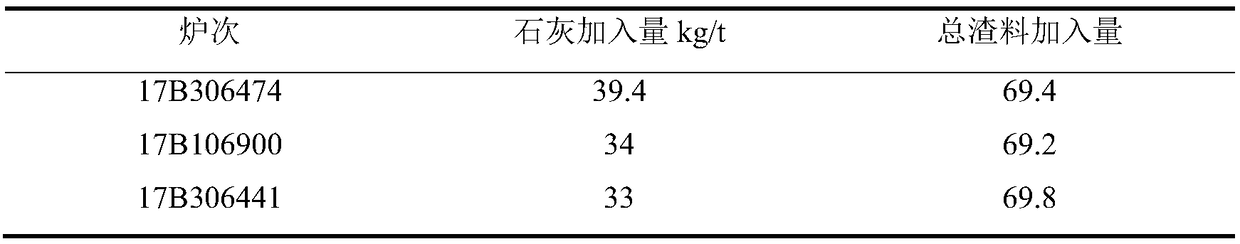

The invention belongs to the technical field of converter steelmaking processes, and particularly relates to a method for smelting high-phosphorus molten iron to produce steel with converter end pointP less than or equal to 0.01% by adopting slagless material. The method comprises the following steps that loading low-silicon high-phosphorus molten iron and steel scrap which are not subjected to triple-removal pretreatment into a converter, a single-slag method is adopted to carry out blowing, a slagging material is added twice in a blowing process and a gun position control mode of high, low, high and low is adopted in the blowing process, and oxygen supply and nitrogen supply are carried out in the blowing process; after the blowing is completed, the steel is discharged, slag splashingis carried out after the steel is discharged, slag is reserved after the slag splashing, and is used for smelting in the next furnace. According to the method, on the premise that lime consumption ofa steel liquid is less than or equal to 30 kg / t, and the consumption of the new slag material is less than or equal to 50 kg / t, dephosphorizing of the molten iron with the following components, by weight, 0.14-0.26% and Si, 0.15-0.20% of P is carried out until P is less than or equal to 0.01%, and a dephosphorization rate is larger than or equal to 94%, so that the problem that low-phosphorus steel is smelted by a low-silicon high-phosphorus molten iron with the few slag material in the single-slag method is solved.

Owner:UNIV OF SCI & TECH BEIJING

Replacing method of converter tap hole

The invention relates to a replacing method of a converter tap hole and belongs to the technical field of steel smelting. The replacing method of the converter tap hole provided by the invention comprises the following steps: 1, placing a whole set of brick in a brick cup channel and adjusting the angle and position; and 2, fixing the whole set of brick on the converter body, filling the gap between the brick cup and whole set of brick with a tapping hole grouting material and sintering the tapping hole grouting material by the waste heat in the converter. The invention has the following beneficial effects of the replace time shortened by about 10 minutes compared with an existing method, the service life of the tapping hole prolonged by about 250 furnace compared with the existing method, the success rate for pushing off the slag improved by 10% compared with the existing method and the cost on per ton of steel reduced by about 0.15 yuan, so as to achieve the purposes of shortening replace time for converter tapping hole, prolonging the service life of tapping hole, improving slag pushing-off rate, reducing production mistake, improving product quality and reducing production cost.

Owner:张家港联峰钢铁研究所有限公司

Method for producing ladle joint material by utilizing waste corundum bricks

The invention discloses a method for producing a ladle joint material by utilizing waste corundum bricks. The method comprises the following steps of: conveying 35 parts of 1-8 mm waste corundum brick granules, 35 parts of 0.1-8 mm white fused alumina granules, 10 parts of powder materials, 10 parts of alumina powder, 3 parts of fused magnesia powder, 1 part of silica powder and 6 parts of calcium aluminate cement into a stirrer, and fully stirring to obtain the ladle joint material finished product. The obtained ladle joint material finished product has the physical and chemical indexes as follows: after the ladle joint material is dried at the temperature of 110 DEG C for 24 hours, the compressive strength is more than 40MPa, and the flexural strength is more than 5MPa; and after the ladle joint material is sintered at the temperature of 1550 DEG C for 24 hours, the bulk density is not less than 3.0 g / cm<3>, the flexural strength is more than 12MPa, and the linear change rate is + / -0.5%. In the method disclosed by the invention, 1 / 3 of waste corundum brick granules are used as aggregates, thus the cost of the ladle joint material and the cost of per ton of steel are greatly lowered; and calcium aluminate cement is used for binding, and alumina, fused magnesia and silica are used as media, thus the problem that the recovered waste corundum brick granules are easy to crack when used in high-grade pouring materials is solved, and the requirements for safety and durability of the ladle are achieved.

Owner:ZHENGZHOU ZHENDONG TECH

Method for producing flaw detection and performance guaranteed Q235B steel plate with 80-100mm in argon station

InactiveCN102345050AGuarantee the quality of flaw detectionGuaranteed performanceChemical compositionIngot

The invention discloses a method for producing a flaw detection and performance guaranteed Q235B steel plate with 80-100mm employing argon station steel. The produced steel plate of the specification comprises chemical components of 0.10-0.19% of C, 0.15-0.30% of Si, 0.50-0.80% of Mn, P no more than 0.023%, S no more than 0.015%, Als no more than 0.020% and N no more than 0.005%. The invention employs a 250mm continuous casting billet; and a production process flow comprises steps of: molten iron desulphurization, treatment in 120t top-bottom combined blown converter, continuous casting, casting blank insulation and slow cooling, rolled steel plate stack cooling, finishing, examination and warehouse entering. Compared with a prior art, the invention employs argon station steel to produce flaw detection guaranteed steel plate, cancels a routine LF refining production, shortens a production flow and reduces costs per ton of steel; meanwhile, a 250mm thickness section is adopted in the production to increase production rhythm and substantially reduce production costs, compared with a routine section thicker than 250mm or mold ingot.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

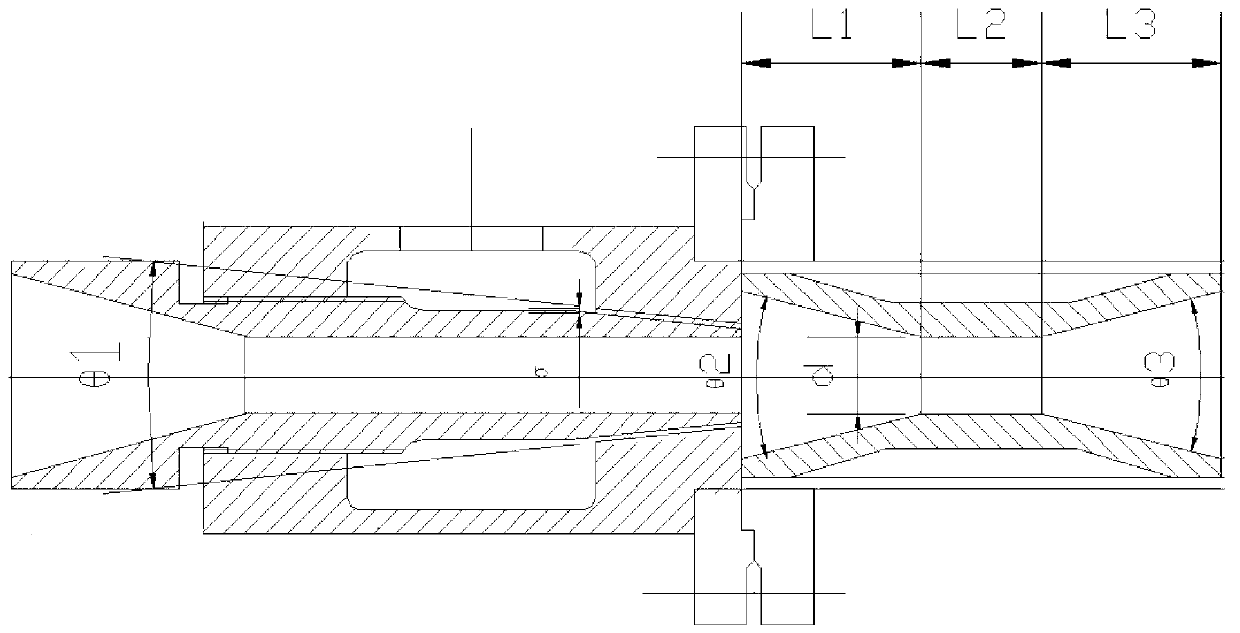

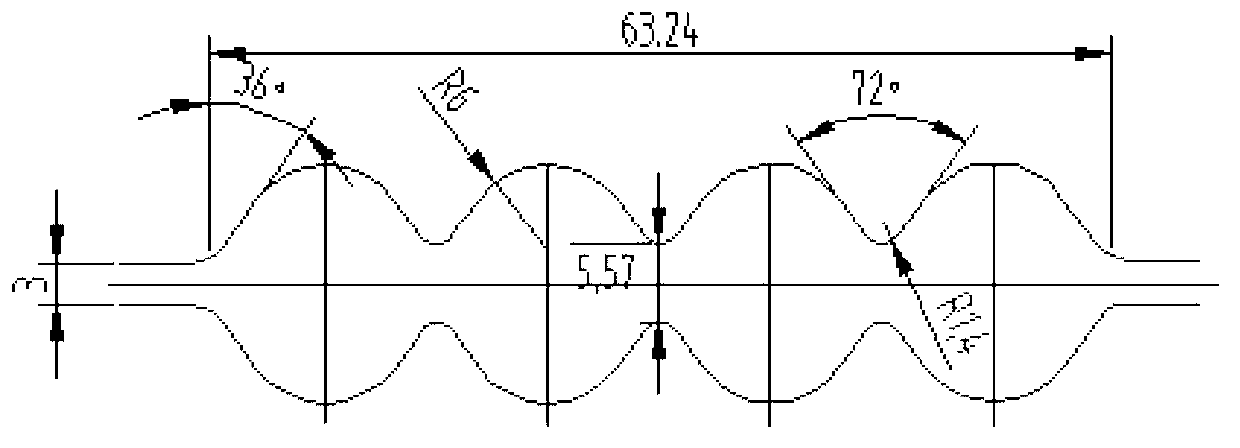

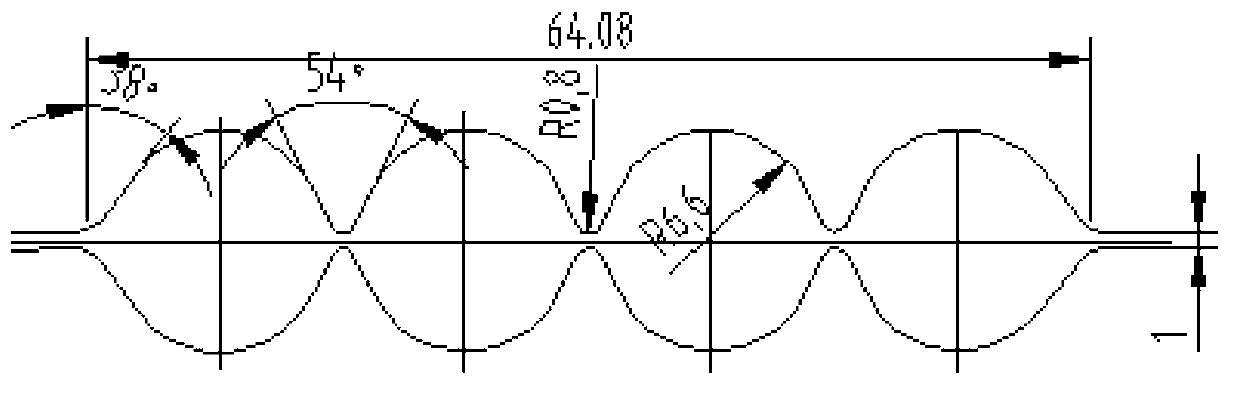

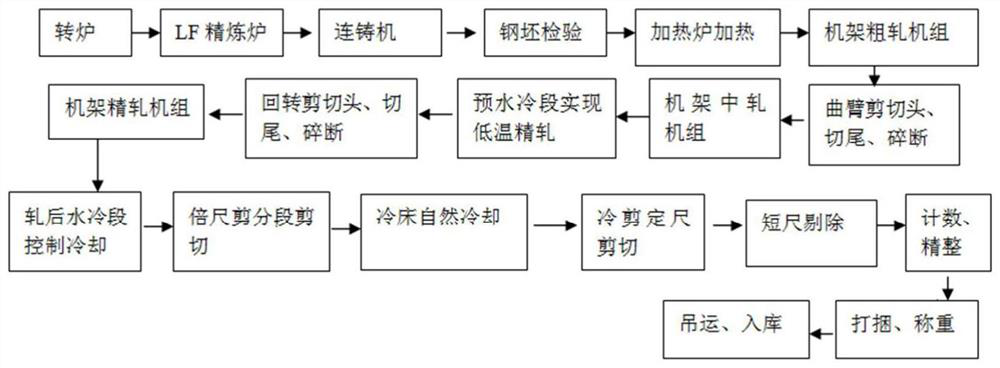

Production method of four-segment high-strength aseismic reinforcement

ActiveCN102989763AImprove stabilityAvoid bendingTemperature control deviceWork treatment devicesProof constructionRebar

The invention discloses a production method of four-segment high-strength aseismic reinforcement, and belongs to the technical field of steel for earthquake proof construction. Controlled rolling and controlled cooling processes are low-temperature initial rolling of a heating furnace, water cooling before pre-segmentation, four-line pre-segmentation, four-line segmentation, finally rolling, and two-stage control cooling after rolling. The production method has the advantages that minimization of micro-alloy elements of four-line segmentation of phi12mm and phi14mm under the condition that the edge organization of a basic circle is P+F is achieved; and the problems of low-temperature phase change organization, four-line line difference, poor mechanical property and the like caused by bending and water cooling in the four-line low temperature segmentation and water cooling processes are avoided.

Owner:SHOUGANG CORPORATION +1

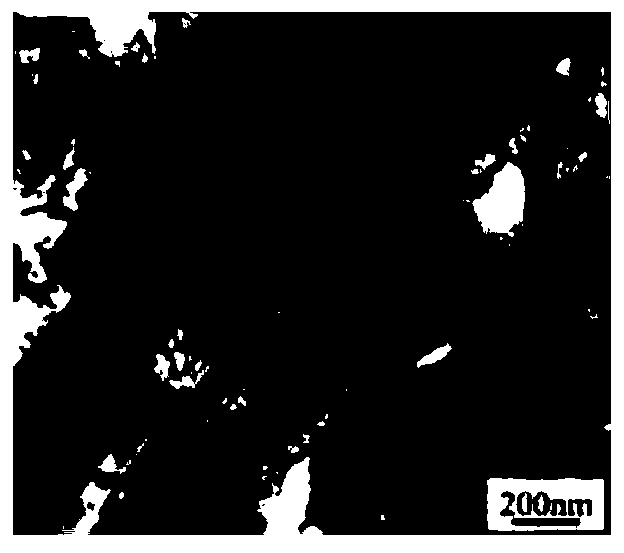

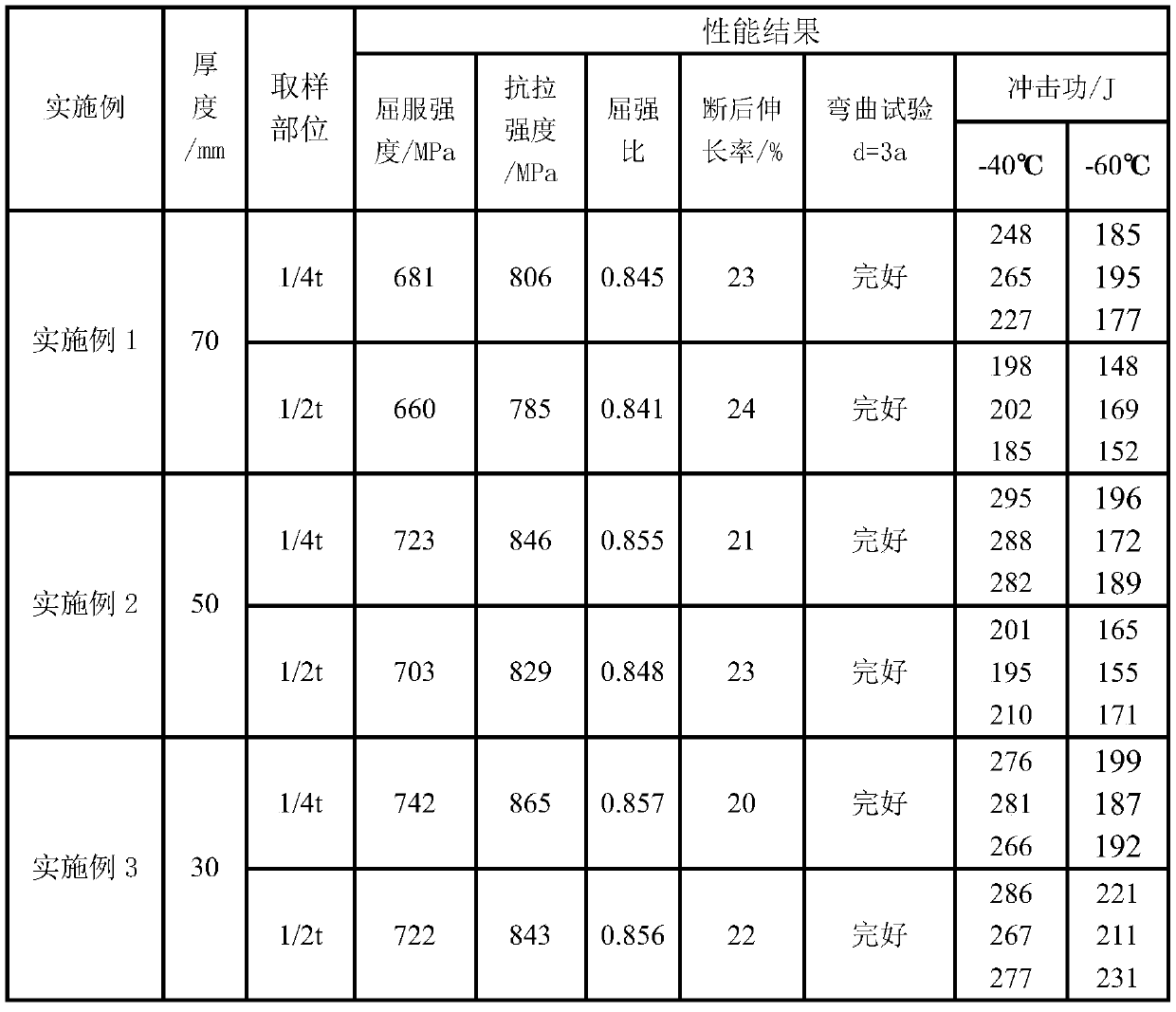

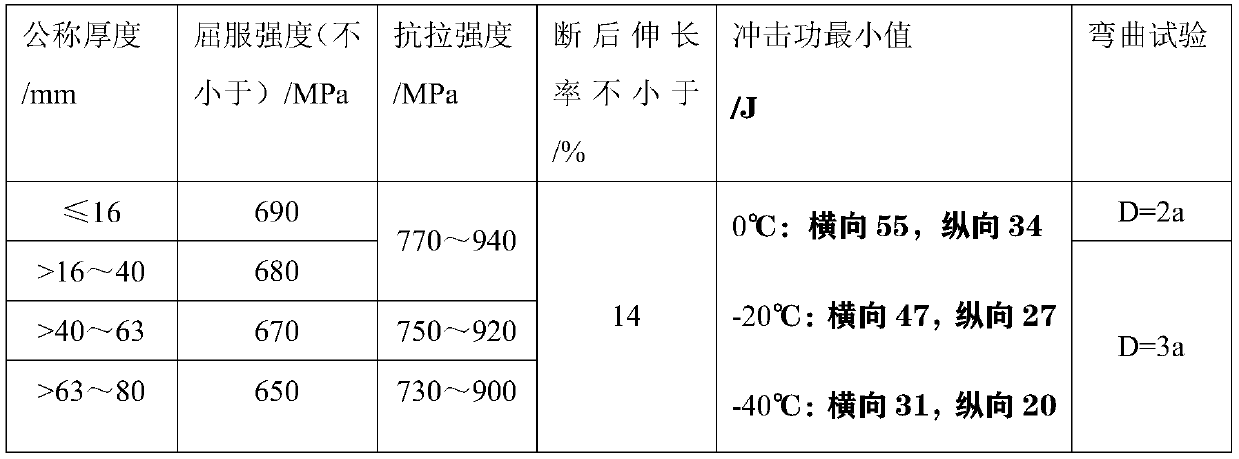

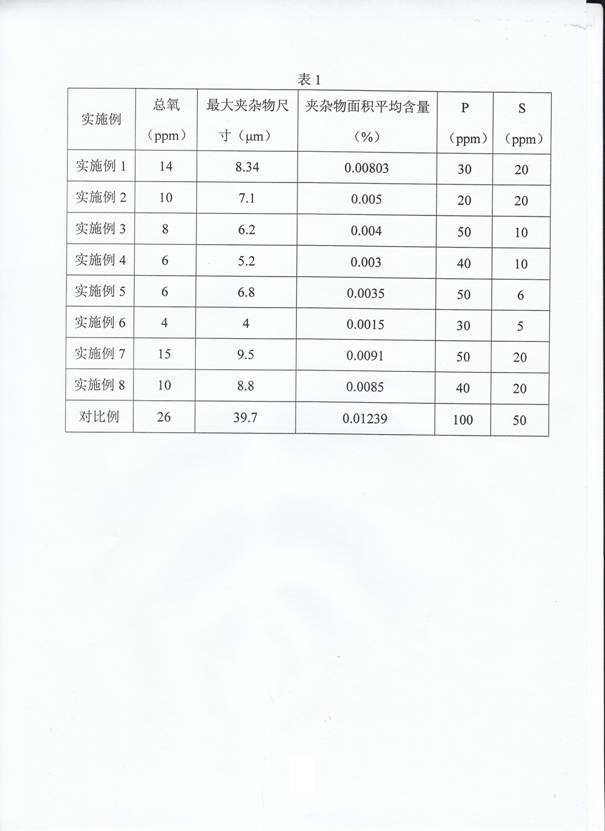

690 MPa grade high-strength low-yield-ratio medium-manganese steel medium-thickness steel and manufacturing method

The invention discloses 690 MPa grade high-strength low-yield-ratio medium-manganese steel medium-thickness steel and a manufacturing method, and relates to the technical field of steel smelting. Thesteel comprises the following chemical components of, in percentage by mass, 0.05%-0.10% of C, 4.1%-4.7% of Mn, 0.15%-0.4% of Si, less than or equal to 0.010% of P, less than or equal to 0.003% of S,0.01%-0.05% of Ti, less than or equal to 0.6% of Ni + Cr + Mo, and the balance Fe and inevitable impurities. The requirements of ultra-high strength steel safety performance and construction cost in acomplex environment in the field of engineering machinery can be met.

Owner:NANJING IRON & STEEL CO LTD

Production method for low-cost clean steel

InactiveCN102586547ASimple processEasy to operateProcess efficiency improvementSmelting processAlloy

The invention discloses a production method for low-cost clean steel, which comprises the following steps of initial desulfuration of liquid iron; initial desulfuration in iron folding processes in a blast furnace casting trough and between folded iron, and adding liquid iron desulfuration spheres into liquid iron in blast furnace casting or iron folding processes; dephosphorization and sulphur control; dephosphorization and sulphur control in a smelting process of a converter to guarantee that in a steel tapping process, phosphorus (P) is smaller than or equal to 0.014%, and sulphur (S) is smaller than or equal to 0.004%; quick slagging and dephosphorization; controlling a converter end point between 0.02-0.10%, adding dephosphorization spheres through an alloy runner in a converter tapping process, and simultaneously blowing argon to stir; purifying liquid steel in a Rockwell hardness (RH) refining process; adding purification spheres in later of RH refining treatment when the vacuum degree is 66.7-500Pa; and adopting whole course protection to pour in continuous casting. The production method effectively improves quality of steel materials and reduces smelting cost. Compared with the traditional process, raw materials of the production method are cheap, and cost of a ton of steel can be reduced by 5 to 10 yuan RMB.

Owner:ANGANG STEEL CO LTD

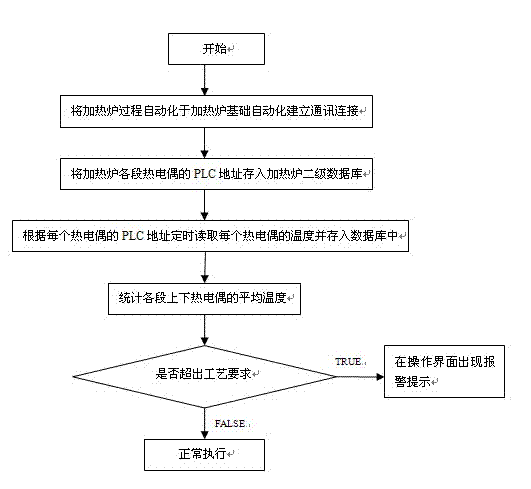

Monitoring method of heating time and heating temperature of heating furnace

InactiveCN103045847APrevent increased oxidative burning lossAvoid oxidation burnFurnace typesHeat treatment process controlLoss rateHeating temperature

The invention relates to a monitoring method of the heating time and the heating temperature of a heating furnace on a hot rolling production line, and belongs to the field of automation of the metallurgical hot rolling production line. According to the technical scheme, the method comprises the following steps: reading steel billet ID (Identification) signals sent to PLC (Programmable Logic Controllers) at the first stage in the heating furnace continuously; establishing a tracking of steel billets in the furnace by tracking the positions of the steel billets on a roller bed outside the furnace; reading the position of each steel billet in the heating furnace every three minutes from a secondary database of the heating furnace and accumulating the reading results; calculating the heating time of the steel billets at each stage in the heating furnace; contrasting the heating time with a technological requirement and alarming if the heating time exceeds the time specified by the technological requirement; storing the PLC address of each thermocouple in the heating furnace in the secondary computer database of the heating furnace; reading an average value of the temperature at each stage in the heating furnace; and finally, contrasting the heating temperature with the technological requirement and alarming if the heating temperature exceeds the temperature specified by the technological requirement. With the adoption of the method provided by the invention, the occurrence of inferior-quality products caused by an incomplete phosphorus removal on the surface of strip steel due to the long heating time and the high heating temperature at each stage in the heating furnace is avoided; the oxidation burning loss rate is decreased; the yield is increased; the cost of the steel per ton is reduced; and therefore the economic benefit is improved.

Owner:TANGSHAN GUOFENG IRON & STEEL

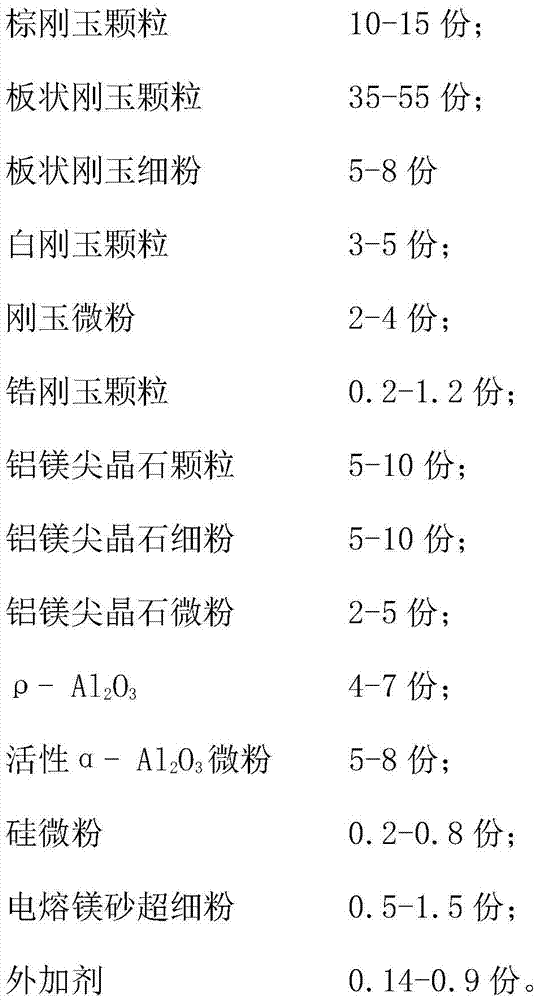

Castable for large steel ladle

InactiveCN105439586AImprove structural strengthImproved thermal shock stabilitySpinelUltimate tensile strength

The invention discloses castable for a large steel ladle. The castable comprises brown corundum granules, tabular corundum granules, fine tabular corundum powder, white corundum granules, corundum micropowder, zirconia corundum granules, alumina-magnesia spinel granules, fine alumina-magnesia spinel powder, alumina-magnesia spinel micropowder, Rho-Al2O3, active alpha-Al2O3 micropowder, silica powder, ultrafine fused magnesite powder and an additive. The castable for the large steel ladle can be well used on a refined steel ladle which weighs more than 150 tons, has good thermal shock stability, good safety and long service life, can be used for repeated pouring and also has excellent cost performance, the production efficiency is improved, the labor intensity of an operator is reduced, the cost of steel per ton is reduced, and discharge of solid waste is reduced.

Owner:WUHAN RUXING TECH CO LTD

Composite alloy of Al - Mg - Ca - Fe with lower carbon, silicon, phosphor, and sulfur in use for final steelmaking deoxidizer

This invention relates to a final deoxidizer for steelmaking, which is low-C, low-Si, low-P and low-S Al-Mn-Mg-Ca-F alloy. The alloy can be used as the final deoxidizer for steelmaking with good effect, and does not need further refinery of steel. The alloy comprises: C less than or equal to 0.2 wt.%, Si less than or equal to 1.0 wt.%, P less than or equal to 0.02 wt.%, S less than or equal to 0.02 wt.%, Al 40-50 wt.%, Mn 1.0-10 wt.%, Mg 0.1-10 wt.%, Ca 0.1-10 wt.%, and Fe as balance. This invention adopts main frequency induction furnace smelting to produce the final deoxidizer. The final deoxidizer has such advantages as high specific gravity, low melting point, no pulverization, good deoxidation and desulphurization effects, high yield, high fluidity of deoxidized molten steel, no nodulation, easy suspension of deoxidized product, low inclusion total content, high molten steel purity, good steel quality, fine grains, good mechanical properties, and long service life.

Owner:李兴有

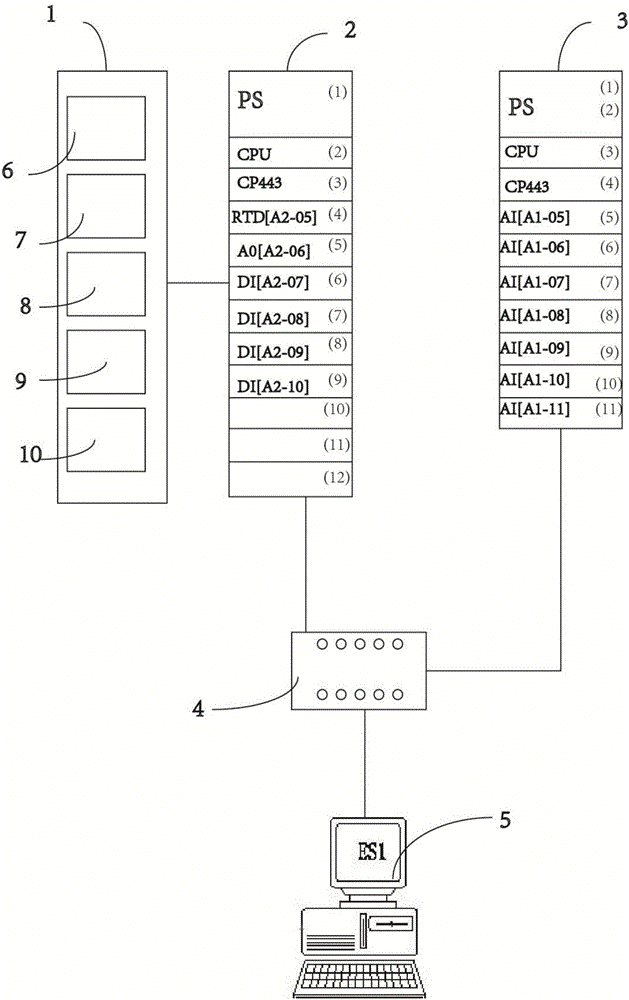

Zero-clearance rolling system and method based on PLC (Programmable Logic Controller) control

InactiveCN107520254AThere will be no long and short phenomenonHigh yieldRolling mill drivesTension/compression control deviceProduction lineProgrammable logic controller

The present invention proposes a non-gap rolling system and method based on PLC control, including an original rolling line control cabinet, a switch, a non-gap control cabinet, and a rolling production line. The rolling production line is connected to the original rolling line control cabinet. The rolling line control cabinet is connected to the switch, and the output ends of the switch are respectively connected to the operation station and the gapless control cabinet, wherein the rolling production line includes a rough rolling unit, a flying shear unit, an intermediate rolling unit, a looper unit, and a finishing rolling unit , the rough rolling unit, the flying shear unit, the intermediate rolling unit, the looper unit, and the finishing rolling unit are connected in sequence, and each includes a multi-stand rolling mill. The present invention controls the different gathering speeds of two continuous steel slabs by establishing a two-stage gathering relationship to realize seamless steel feeding.

Owner:天津天合共创科技有限公司

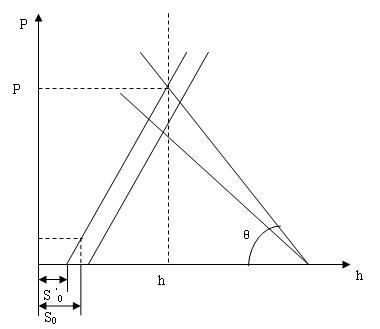

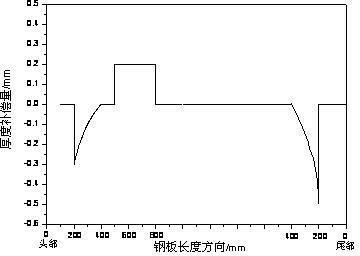

Method for rolling wide and thick steel plate by adopting complete negative allowance

ActiveCN102145346AHigh yieldImprove uniformityRoll mill control devicesMetal rolling arrangementsThick plateSheet steel

The invention discloses a method for rolling a wide and thick steel plate by adopting a complete negative allowance. The method is used for thickness compensation in the length direction of the steel plate on the basis of an automatic thickness control system, so that the allowance of the whole steel plate containing the head and the tail of the steel plate is controlled between minus 0.3 mm and 0 mm. The main thickness compensation parameters are as follows: when X=400-800, T'=0.2; when X=200-400, T'=0.3-(0.3*400) / X; and when Y=200-400, T'=0.5-(0.5*400) / X. The thickness allowance of the wide and thick plate rolled by adopting the method is controlled within the range of minus 0.3-0mm, and the percent of pass is not less than 90%, therefore, the lumber recovery of the steel plate and the thickness uniformity of the whole plate can be effectively improved, the cost of steel per ton can be reduced, and the load capacity can be improved.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Dynamic thickening rolling process of controlling break of cold rolled thin strip steel

InactiveCN100411760CReduced number of broken beltsReduce broken belt rateRoll mill control devicesMeasuring devicesControl breakMultiple frame

The dynamic thickening rolling process of controlling break of cold rolled thin strip steel has weld seam tracking system used in measuring the weld seam position accurately, and features that in the range of 50 m around the weld seam, the strip steel thickness is increased to 1.0-1.5 times the original target thickness. Two wedge rolling processes are used to increase the rolled thickness dynamically, so as to lower the break rate of the thin rolled material. The present invention has the advantages of reduced strip steel breaking rate, high production efficiency, etc. and is suitable for multi-frame continuous cold rolling machine with 4, 5 or 6 frames.

Owner:ANSHAN IRON & STEEL GROUP CORPORATION +1

High-temperature bolt steel BG25Cr2MoVA and preparation method thereof

InactiveCN108531815ARealize continuous casting productionReduce the cost per ton of steelProcess efficiency improvementElectric furnaceMechanical propertyImpurity

The invention discloses high-temperature bolt steel BG25Cr2MoVA and a preparation method thereof. The high-temperature bolt steel BG25Cr2MoVA comprises the following components of, by weight, 0.23-0.27% of C, 0.20-0.35% of Si, 0.54-0.62% of Mn, 0-0.015% of P, 0-0.012% of S, 1.64-1.72% of Cr, 0.28-0.32% of Mo, 0.20-0.24% of V, 0-0.15% of Ni, 0-0.15% of Cu, 0.020-0.040% of Alt, and the balance Fe and inevitable impurities. The high-temperature bolt steel BG25Cr2MoVA is high in steel purity degree, resistant to high temperature and fatigue, and stable in mechanical property. The preparation method is simple and practical, and the technology is stable.

Owner:BENGANG STEEL PLATES

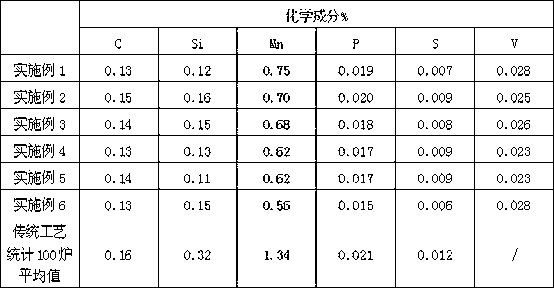

New process for producing low-alloy structural steel by adding ferro-vanadium-nitride

InactiveCN103320688ARational component control technologyMn element content decreasedChemical compositionVanadium nitride

The invention discloses a new process for producing low-alloy structural steel by adding ferro-vanadium-nitride. The new process comprises the following steps: (1) smelting in a converter; (2) refining in a ladle furnace; (3) performing continuous casting; (4) performing hot rolling. Compared with the prior art, the new process has the following advantages: 1, a Q345B hot-rolled steel strip chemical composition system is designed innovatively, and a reasonable composition control technology is realized; the content of element Mn is reduced by 0.45 percent at least; meanwhile 0.015 to 0.030 percent of the element V is added, so that the cost of the steel per ton is further reduced; 2, the conventional high-manganese alloying is replaced by ferro-vanadium-nitride micro-alloying, the adding amount of alloying elements is reduced; the reducing production is realized, and meanwhile refined crystalline strengthening and precipitation strengthening are played better.

Owner:SHANDONG TAISHAN STEEL GROUP

Rolling method for negative common difference steel plate

The invention discloses a rolling method for a negative common difference steel plate, which adopts hydraulic gauge control, temperature control, rolling schedule making and roll crown design to produce the negative common difference steel plate. The main technological parameters are as follows: the roll-bending force is set to 1000-2800KN, the basic cooling water of a working roll is regulated to 50-70%, the added water is regulated to 10-40%, the roll crown ranges from -0.15 to +0.15, and the like. The pass of rate of rolled ship steel plates the thickness negative common difference of which ranges from -0.3 to 0mm, is more than or equal to 90%, thereby improving the yield of the steel plates, reducing the cost of steel per ton and the self-weight of a ship and increasing the dead weight capacity.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

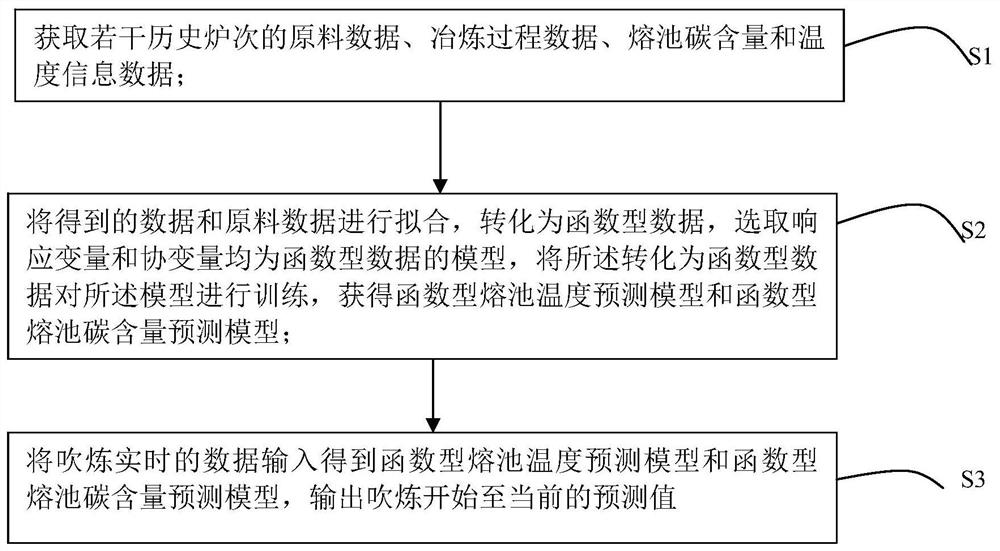

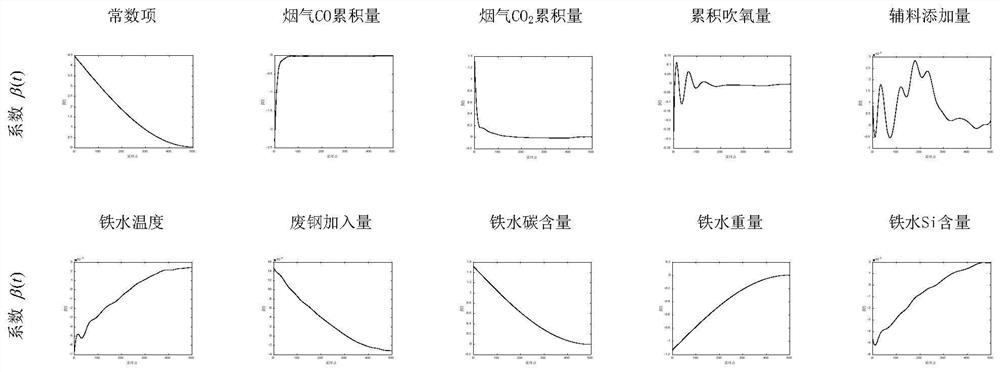

Real-time prediction method for carbon content and temperature of molten pool for converter steelmaking in whole process

ActiveCN111893237AOvercome the disadvantage of limited prediction accuracyOvercome the shortcoming that it is difficult to provide real-time dynamic blowing process dataManufacturing convertersDesign optimisation/simulationSteelmakingFunctional data analysis

The invention belongs to the field of iron and steel metallurgy, and particularly relates to a real-time prediction method for carbon content and temperature of a molten pool for converter steelmakingin the whole process. The real-time prediction method includes the following steps that raw material data, smelting process data and molten pool carbon content and temperature information data of a plurality of historical heats are obtained; the obtained data and the raw material data are fitted and converted into functional data, both response variables and concomitant variables are selected asfunctional data models for training, a functional molten pool temperature prediction model and a functional molten pool carbon content prediction model are obtained, and converting real-time data aresent to the functional molten pool temperature prediction model and the functional molten pool carbon content prediction model to get predicted values. A model which can be used for predicting the carbon content and temperature of the molten pool in real time in the whole process of smelting is established by means of functional data analysis, the internal rules of the raw material data and the smelting process data are fully excavated, and the real-time prediction method has good adaptability to an actual production process and good accuracy and can replace traditional carbon content and temperature prediction methods.

Owner:UNIV OF SCI & TECH BEIJING

Process for rolling 170 mm specification of flaw detection satisfying steel plate with 300 mm section

The invention discloses a production process for rolling a 170 mm specification of flaw detection satisfying steel plate with a 300 mm section. The process is mainly characterized by comprising the following steps of molten iron desulphurization, furnace converting, argon station, LF refining, continuous casting, cooling in heap, casting blank cleaning, casting blank heating, rolling, cooling in heap, destacking finishing, flaw detection and storage control. The process can overcome the defects in the mould ingot casting production adopted for producing the 170 mm extremely-thick flaw detection satisfying steel plate, has the characteristics of low cost, short flow, high efficiency and low energy consumption, and is matched with the reasonable process route, the reasonable parameters and drawing speed under light pressure, the reasonable casting blank heating time and rolling reduction, the reasonable casting blank cooling in heap and steel plate cooling in heap time, thus, the 170 mm specification of flaw detection satisfying steel plate produced by adopting the 300 mm section meets the level 1 standard of national phi 5 flaw detection, the purpose of cost reduction is realized, and the market competitiveness is improved.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

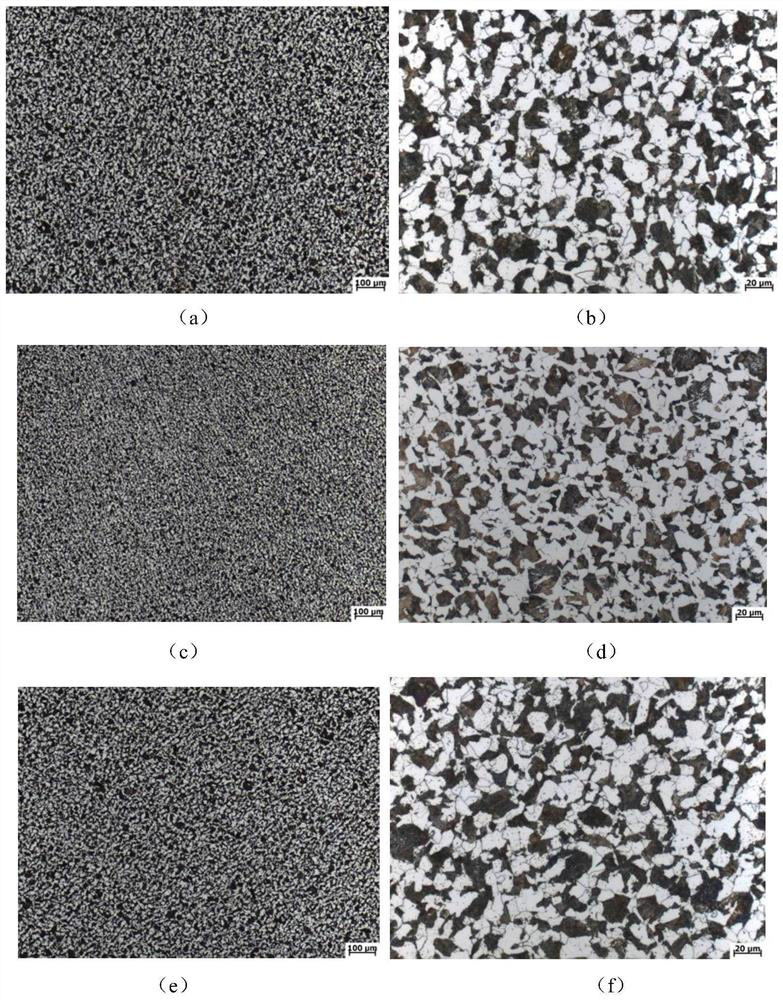

One-steel dual-purpose cold-rolled high-strength steel based on carbon partitioning process and manufacturing method thereof

ActiveCN110964882ASimplify operabilitySimplify the management processFurnace typesHeat treatment furnacesManufacturing technologyUltimate tensile strength

The invention belongs to the cold-rolled high-strength steel production and manufacturing technology field and and relates to one-steel dual-purpose cold-rolled high-strength steel based on a carbon partitioning process and a manufacturing method thereof. Chemical components comprise, by weight, 0.20%-0.30% of C, 1.5%-2.5% of Si, 2.0%-3.0% of Mn, 0.2%-0.4% of Cr, 0.03%-0.06% of Nb, 0.02%-0.10% ofTi, 0.02%-0.40% of Al, 0.002%-0.005% of B, S being less than 0.015%, P being less than 0.010% and the balance being Fe and inevitable inclusions. According to the method, production of TRIP780 and QP980 steel type and strength level products is completed through process control by using one component. The method provided by the invention is is suitable for industrial production, easy in process control and capable of reducing cost and increasing efficiency for enterprises.

Owner:BENGANG STEEL PLATES

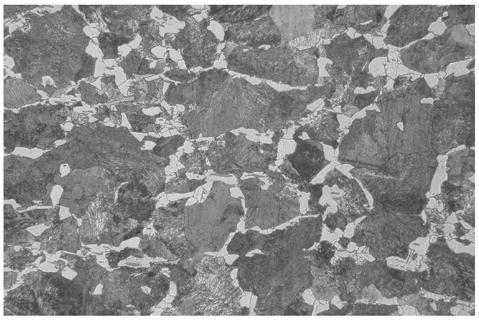

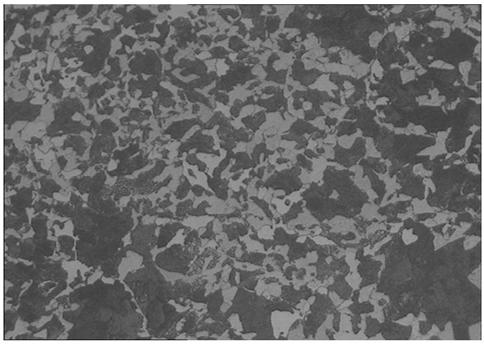

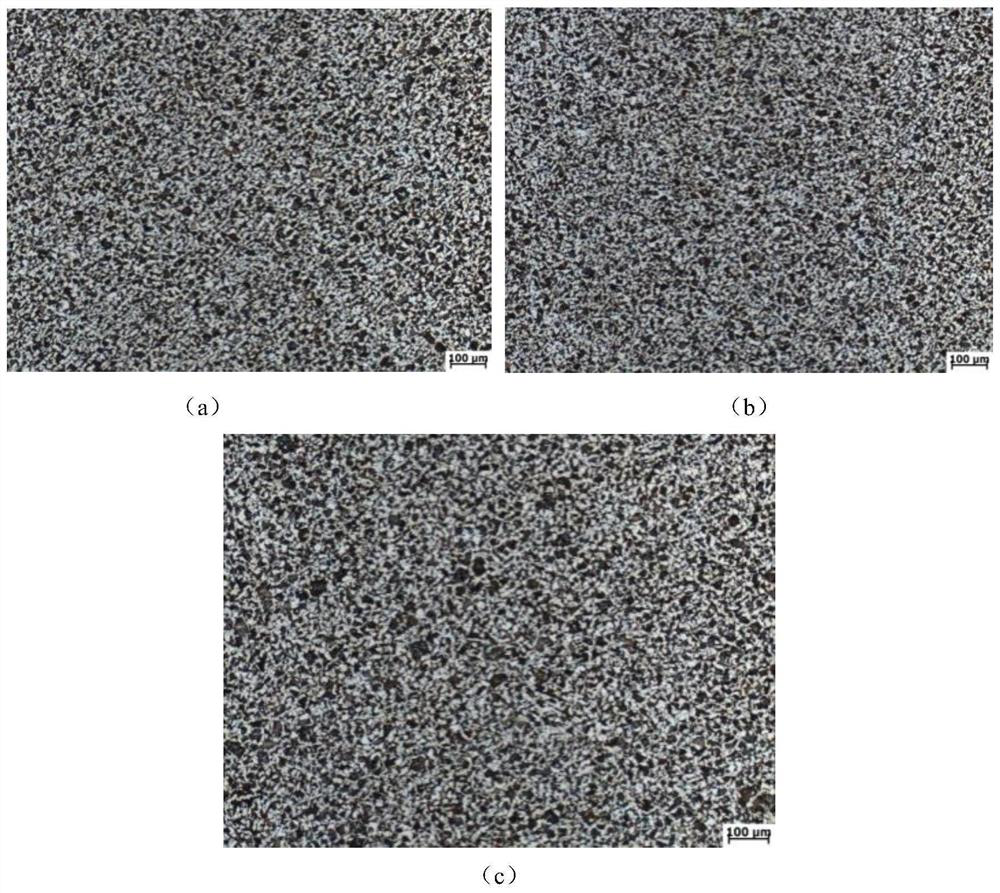

Low-cost non-quenched and non-tempered crankshaft steel 48MnV-C and production method thereof

InactiveCN108998627AReduced dimensional accuracyEasy production organizationTemperature control deviceFurnace typesUltimate tensile strengthCrankshaft

The invention belongs to the technical field of production of non-quenched and non-tempered crankshaft steel, and particularly relates to a low-cost non-quenched and non-tempered crankshaft steel 48MnV-C. The low-cost non-quenched and non-tempered crankshaft steel 48MnV-C comprises the main microalloying elements of, by weight, 0.05%-007% of V, 0.02%-0.03% Alt, 150-180ppm of N and the remaining elements of 0.44%-0.48% of C, 0.17%-0.25% of Si, 0.90%-1.00% of Mn, less than or equal to 0.020% of P, 0.010%-0.015% of S, 0.10%-0.15% of Cr and the balance Fe. The invention also provides a productionmethod of the steel. The method comprises the following steps of converter, RH refining, LF refining, rectangular billet continuous casting, 800 rolling mill rolling, and the converter-RH-LF-continuous casting process is used for producing the non-quenched and non-tempered crankshaft steel 48MnV-C, the steel has high strength and hardness, good machinability, uniform organization and high purity,machined finished steel is almost free of magnetic trace defects, and the finished crankshaft steel is at the leading level in the domestic industry.

Owner:BENGANG STEEL PLATES

Waste magnesia carbon brick black smearing material

The invention discloses a waste magnesia carbon brick black smearing material which is composed of waste magnesia carbon bricks, forsterite, magnesite fine powder, newspaper fibers and binding agents, wherein the binding agents are formed by mixing sodium tripolyphosphate, calcium lignosulphonate, a-Al2O3, SiO and CA-70 cement. The carbon brick black smearing material is prepared on the basis of tundish continuous pouring time, environment temperature and environmental protection use requirement, the waste magnesia carbon brick and forsterite are taken as main raw materials, the rational utilization and the cyclic utilization of the resource are realized, and the cost is also reduced.

Owner:浙江琰大新材料有限公司

Preparation method of waste magnesia carbon brick black smearing material

The invention discloses a preparation method of a waste magnesia carbon brick black smearing material which is prepared on the basis of tundish continuous pouring time, environment temperature and environmental protection use requirement, waste magnesia carbon bricks and forsterite are taken as main raw materials, the rational utilization and the cyclic utilization of the resource are realized, and the cost is also reduced; besides, the product construction is convenient, the construction body structure is compact, and no hazardous gas is discharged.

Owner:浙江攀盛冶金材料有限公司

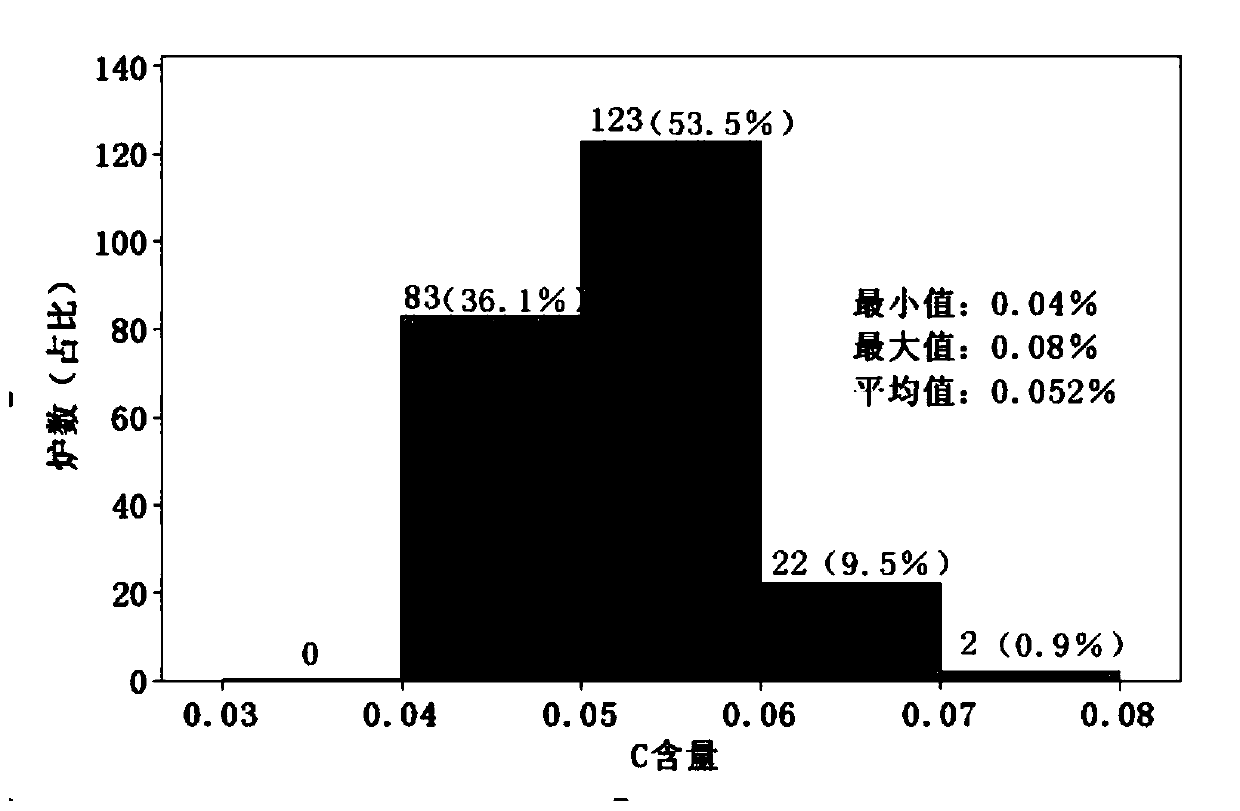

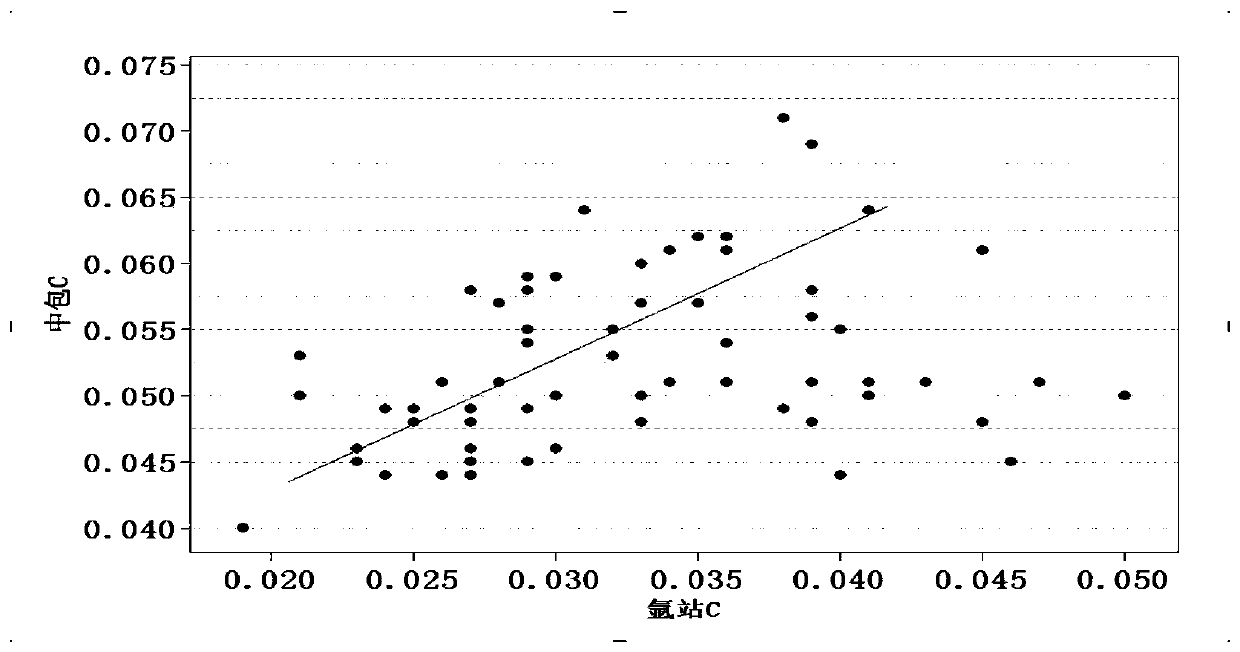

Low-carbon steel carbon content stably-controlled smelting method

ActiveCN110468335AReduce tap carbon contentIncrease tapping temperatureManufacturing convertersSmelting processProcess capability

The invention discloses a low-carbon steel carbon content stably-controlled smelting method. The smelting method includes converter smelting, LF refining and continuous casting. According to the method, by reasonably optimizing process parameters and enhancing process capability control, the carbon content can also be stably controlled within 0.05% without RH vacuum processing, the finished product carbon fluctuation range is small and is controlled at 0.03%-0.05%, the target value hit rate is high, product quality stability is facilitated, and judgement amending or scrapping caused by errantcomponents is reduced. The RH decarburization working procedure is not needed; by means of regulation and cooperation of all step conditions, the carbon steel carbon content is stably controlled at 0.03%-0.05%, and the inclusion content is low; and compared with frequently-used smelting process converter-RH decarburization-LF treatment-continuous casting, operation is easy, the production efficiency is high, and the cost of each ton of steel is effectively reduced.

Owner:ZENITH STEEL GROUP CORP

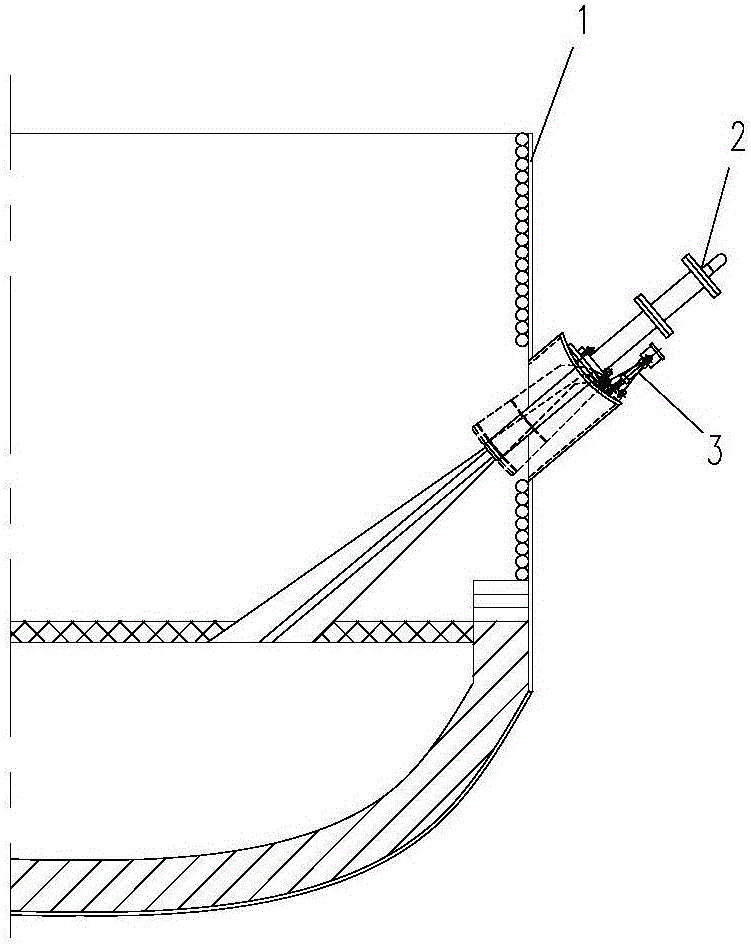

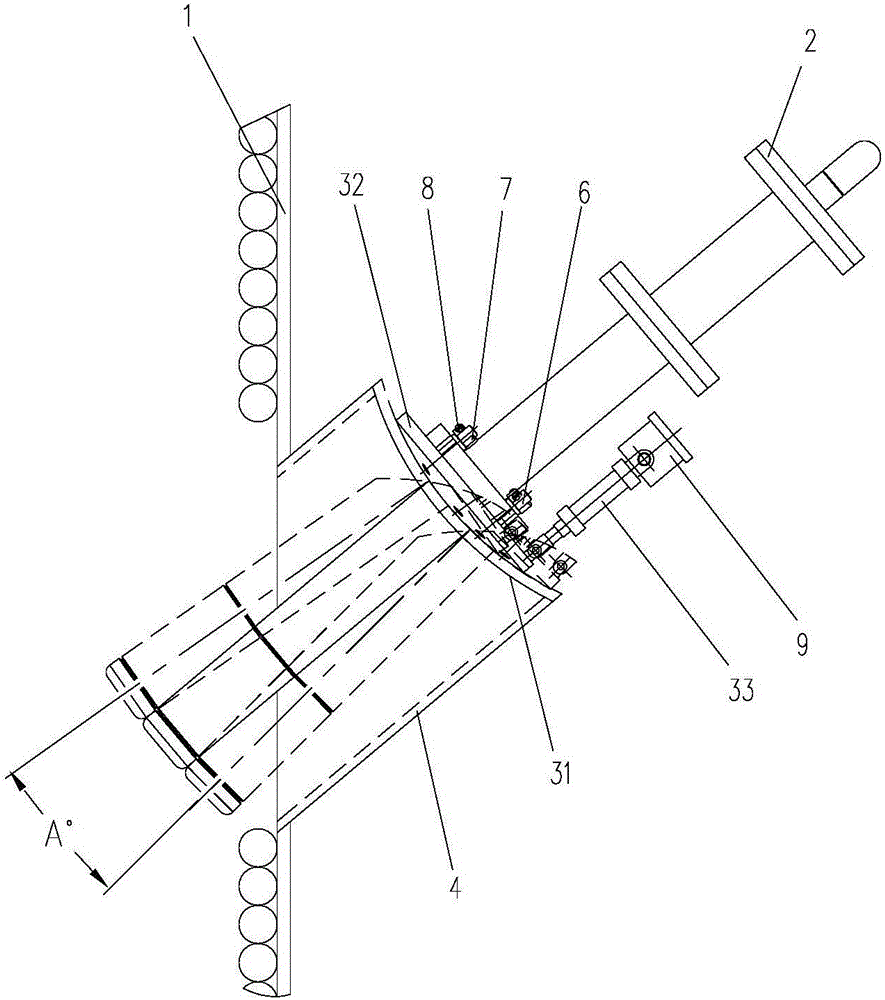

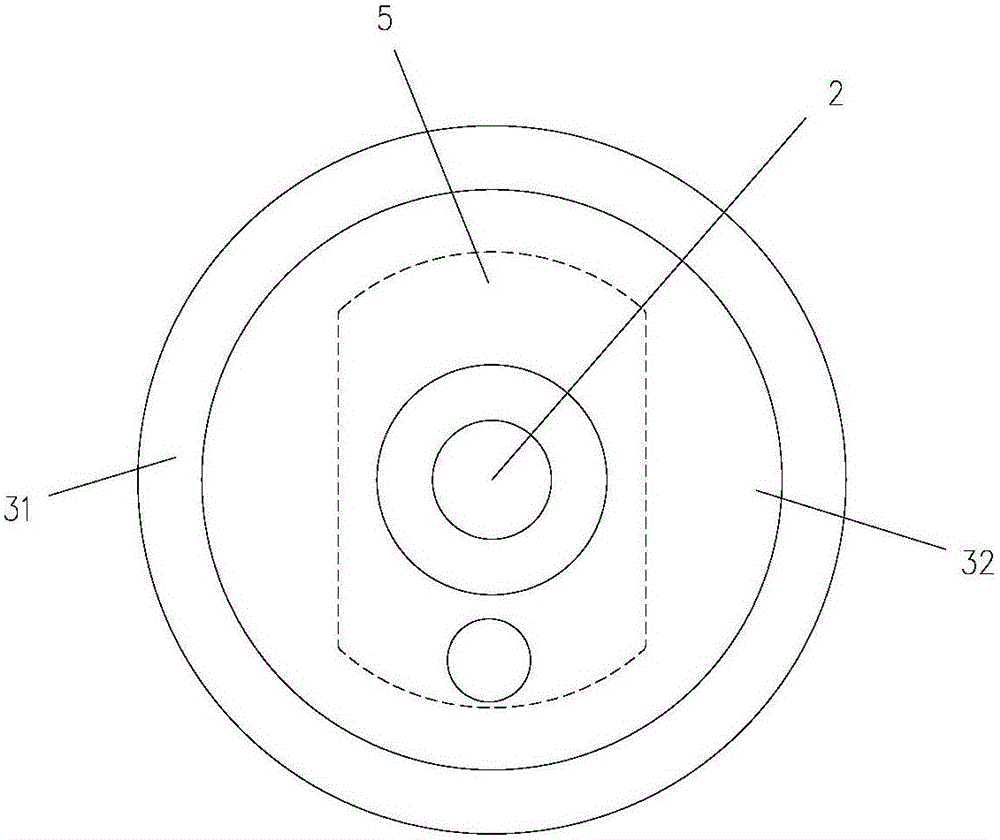

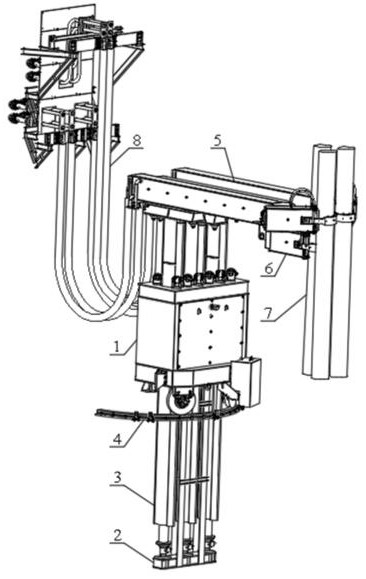

Furnace wall gun swinging device

ActiveCN105838844AFor quick replacementEasy to replaceProcess efficiency improvementElectric furnaceEngineeringCold area

The invention discloses a furnace wall gun swinging device, and belongs to the technical field of metallurgy. The furnace wall gun swinging device comprises a furnace wall gun and a furnace wall gun supporting frame. The furnace wall gun supporting frame is provided with a furnace wall gun swinging cavity. The furnace wall gun swinging device further comprises a swinging mechanism capable of driving the furnace wall gun to swing in the furnace wall gun swinging cavity. The injection covering area of the furnace wall gun in a furnace can be increased through the swinging mechanism, the area of a cold area in the electric furnace is effectively reduced, the smelting period is shortened by sufficiently utilizing chemical energy, and the cost of ton steel is saved.

Owner:CISDI ENG CO LTD

Alloyed aluminum-nickel-chromium-iron composite alloy for final deoxidizing in steel-making

The invention relates to an alloy for steel in the metallurgical field, in particular to an aluminum nickel chrome copper iron composite alloy for final deoxidation and alloying in steelmaking. The aluminum nickel chrome copper iron composite alloy solves the problems that Cr, Ni and Cu are difficult to smash and process and troublesome in use, influence the steelmaking time, has large yield fluctuation, influence the smelting yield of steel grades, etc. The composite alloy simultaneously meets the smelting steel grade needs of a steel grade containing acid-soluble aluminum (Als) and Ni, Cr, Cu and other elements. The aluminum nickel chrome copper iron composite alloy comprises the following compositions in percentage by weight: less than or equal to 0.5 percent of C, less than or equal to 3 percent of Si, less than or equal to 0.05 percent of S, less than or equal to 0.05 percent of P, 3 to 70 percent of Al, 1 to 60 percent of Ni, 1 to 60 percent of Cr, 1 to 65 percent of Cu and the balance being Fe. The aluminum nickel chrome copper iron composite alloy has low melting point, large specific gravity, no pulverization, no impurity, convenient smelting operation, good and stable deoxidation effect, the Ni and Cu yield of 100 percent, the Cr yield of between 90 and 95 percent and high smelting yield of the steel grade.

Owner:李兴有

Application process of Ti microalloying in 400MPa-grade steel bar production

Owner:JIANGSU YONGGANG GROUP CO LTD

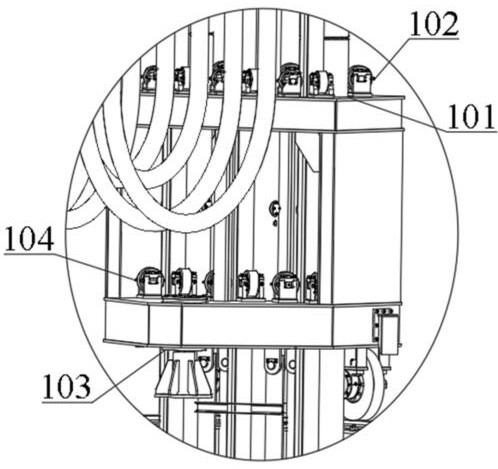

Ladle refining furnace electrode adjusting system

ActiveCN112738937AAchieve independent regulationImprove verticalityElectric discharge heatingProcess efficiency improvementControl systemPower grid

The invention discloses a ladle refining furnace electrode adjusting system, belongs to the technical field of electric furnace control, and particularly relates to an adjusting control system with a three-phase electrode stand column capable of ascending and descending independently and automatically, and a hardware part of the ladle refining furnace electrode adjusting system comprises a rotating base frame, a base, a lifting device, a station adjusting device, a cross arm and a clamping device. The lifting device adopts an independent scheme and can realize free lifting of each electrode stand column, and the station adjusting device can realize integral rotation of the electrode stand columns so as to realize uninterrupted continuous heating of a plurality of steel ladles; the software part of the arc furnace electrode adjusting system adopts an impedance control strategy, and the electrode state can be automatically adjusted according to the optimal working point pre-selected by the power circle diagram. Compared with the prior art, the energy consumption can be remarkably reduced, the production efficiency is improved, and the interference of the electric furnace to a power grid is reduced.

Owner:西安中天冶金工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com