Real-time prediction method for carbon content and temperature of molten pool for converter steelmaking in whole process

A converter steelmaking and real-time prediction technology, applied in the field of iron and steel metallurgy, can solve the problems of poor adaptability, poor prediction accuracy, and the prediction method cannot provide real-time prediction, etc., and achieves the effect of perfect modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

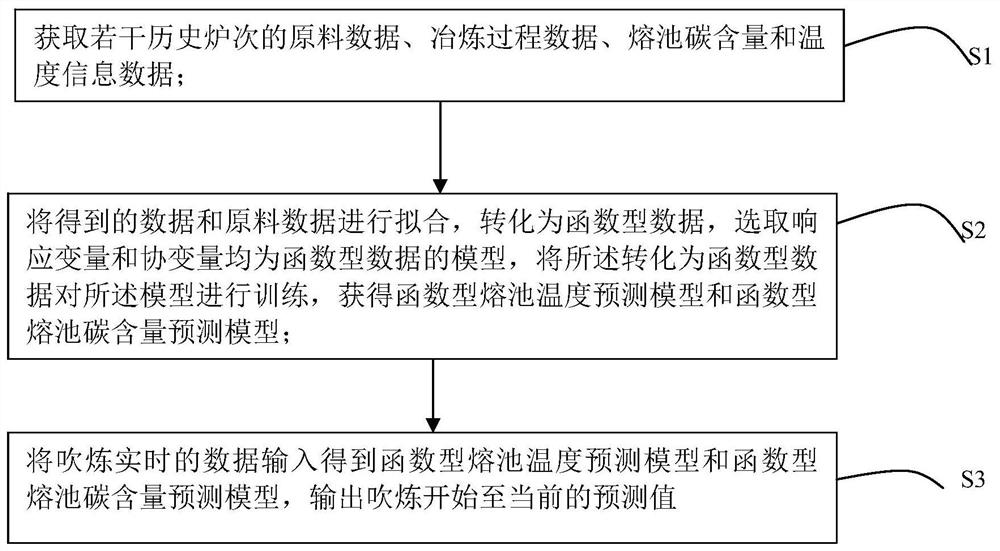

[0096] Firstly: use the production computer network to monitor the oxygen blowing and feeding information, use the flue gas sampling device and infrared gas analyzer to analyze the flue gas composition information, and use the sub-lance to detect the carbon content and temperature information of the molten pool.

[0097] Second: Obtain the raw material data and smelting process data of several historical furnaces, obtain the temperature and carbon content data at the three moments of furnace entry, TSC detection, and TSO detection, and cancel the sub-lance detection device after obtaining historical data.

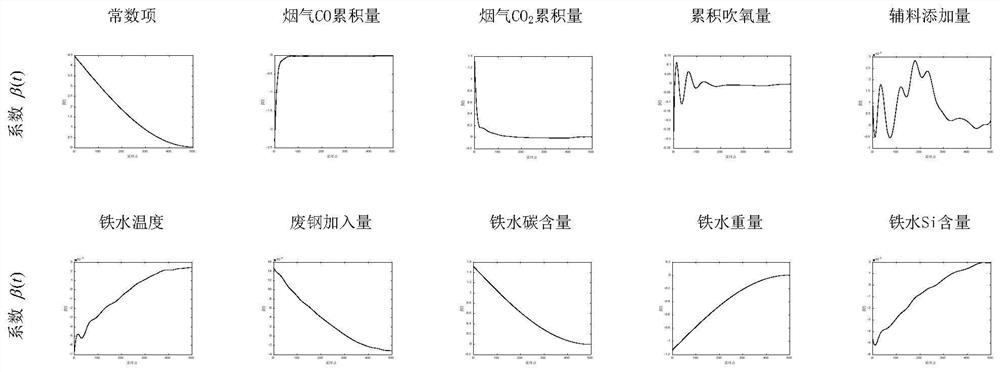

[0098] Then: fit the obtained data into functional data, select the response variable and covariate as a functional data model, use the historical furnace data to train the model, obtain each regression coefficient function, and convert the model to Load computer.

[0099] Finally, the model is used for whole-process prediction, and the real-time blowing data is imported in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com