Production method for low-cost clean steel

A production method and clean steel technology, which is applied in the field of metallurgy, can solve problems such as increased production costs, and achieve the effects of reduced cost per ton of steel, easy operation, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

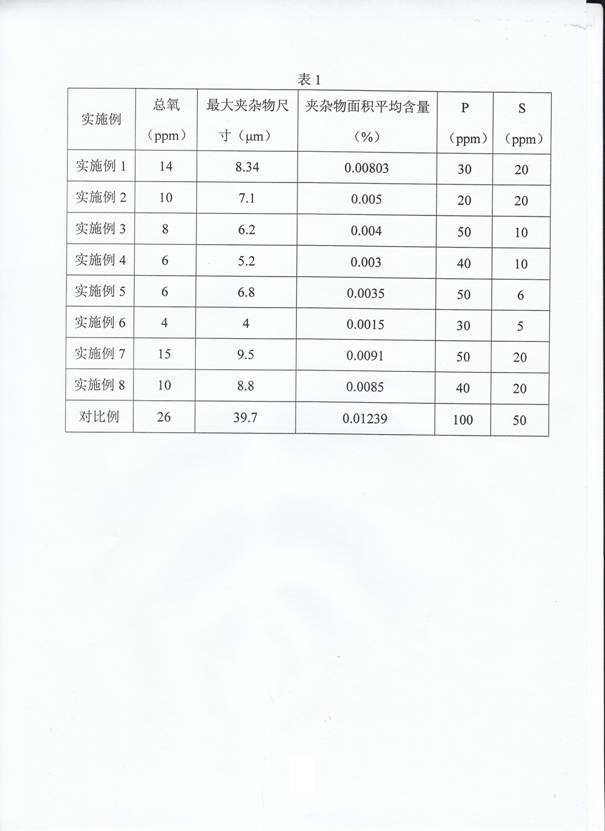

Examples

Embodiment 1

[0031]A production method of low-cost clean steel, the steps are as follows:

[0032] (1) Initial desulfurization of molten iron: In the process of iron folding in the blast furnace iron ditch and in the iron folding room, a kind of molten iron desulfurization sphere is added to the molten iron during the blast furnace tapping or iron folding process. The amount of the desulfurization sphere It is 2-8kg / t to ensure that S≤0.01% in weight percentage in molten iron after initial desulfurization.

[0033] (2) Desulfurization of molten iron pretreatment: use mixed CaO and Mg powder desulfurizers to carry out deep desulfurization of molten iron injection, and use a slag scraper to remove desulfurization slag. After deep desulfurization of molten iron, ensure that the molten iron before entering the converter is S≤ 0.0015%.

[0034] (3) Dephosphorization and sulfur control: dephosphorization and sulfur control in the converter smelting process to ensure that P≤0.014% and S≤0.004% i...

Embodiment 2

[0043] For the preparation of the desulfurization sphere, 55 kg of white slag, CaO 20 kg, CaF 2 5kg, CaCO 3 5kg of which CaO, CaF 2 , CaCO 3 And the particle size of the white slag recovered from the LF furnace is ≤100mm; it is made by dry pressing balls, the size of the balls is between 5-25mm, the compressive strength of the balls is between 5-35MPa, and the 1600℃ delayed burst reaction time is in 1~35s.

[0044] For the preparation of the dephosphorization spheres, 10 kg of white slag, CaO 65 kg, CaF 2 15 kg, CaCO 3 30 kg, including CaO, CaF 2 , CaCO 3 And the particle size of the white slag recovered from the LF furnace is ≤100mm; it is made by dry pressing balls, the size of the balls is between 5-25mm, the compressive strength of the balls is between 5-35MPa, and the 1600℃ delayed burst reaction time is in 1~35s.

[0045] For the preparation of the purified sphere, 60 kg of white slag, 15 kg of MgO, 15 kg of CaF 2 1kg, MgCO 3 5kg, Mg 1kg, of which CaF 2 ...

Embodiment 3

[0047] For the preparation of the desulfurization sphere, 35 kg of white slag, CaO 35 kg, CaF 2 10kg, CaCO 3 10kg of which CaO, CaF 2 , CaCO 3 And the particle size of the white slag recovered from the LF furnace is ≤100mm; it is made by dry pressing balls, the size of the balls is between 5-25mm, the compressive strength of the balls is between 5-35MPa, and the 1600℃ delayed burst reaction time is in 1~35s.

[0048] For the preparation of the dephosphorization spheres, 38 kg of white slag, 38 kg of CaO, 38 kg of CaO, 38 kg of CaO, and 38 kg of CaO are taken from LF refining process waste slag, that is, LF furnace cold recovery white slag according to the formula ratio. 2 10 kg, CaCO 3 12 kg, of which CaO, CaF 2 , CaCO 3 And the particle size of the white slag recovered from the LF furnace is ≤100mm; it is made by dry pressing balls, the size of the balls is between 5-25mm, the compressive strength of the balls is between 5-35MPa, and the 1600℃ delayed burst reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com