Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Fast pace of production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

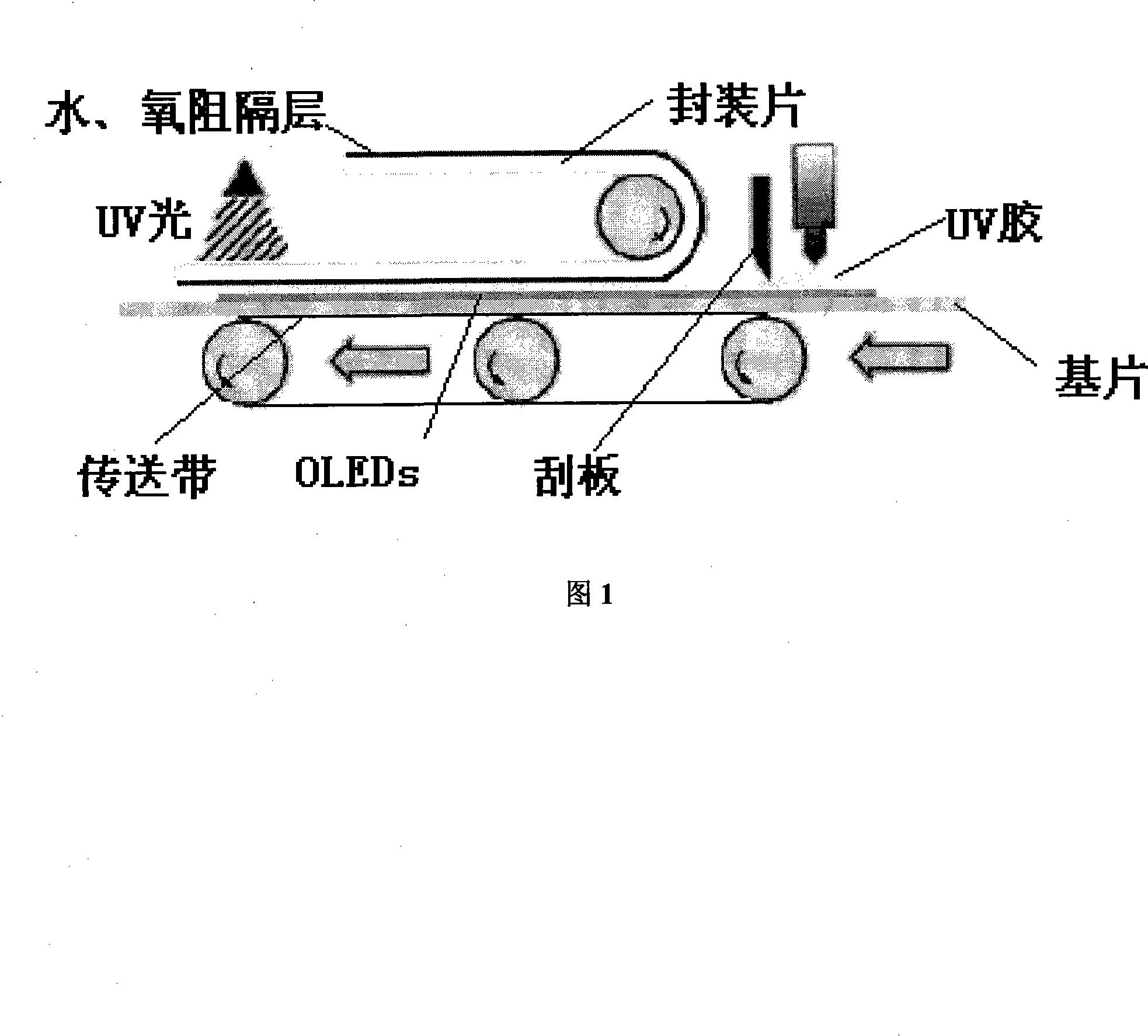

An organic EL part and its making method

InactiveCN101080121AContinuous production rhythmAvoid deformationElectrical apparatusElectroluminescent light sourcesDistortionOrganic electroluminescence

This invention relates to a package structure of an organic electroluminescent device and its manufacturing method, in which, the organic electroluminescent device includes a package structure with a flat packaged cover made of glass, polymer, metal or alloy material and its composite film material, and the flat package cover can be prepared by a roller extrusion method. The package structure is especially suitable for large size or soft OLED, since no gas space exists during the packaging process, the device can be made thinner and distortion of the cover can be avoided.

Owner:TSINGHUA UNIV +2

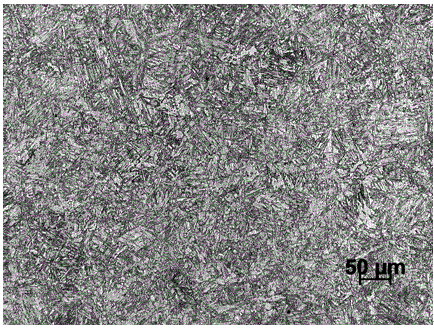

Ultra-thick high temperature-resistant steel for pressure vessel and preparation method thereof

ActiveCN102094150AProportion design is reasonableIncrease productivityTemperature control deviceMetal rolling arrangementsChemical compositionMetallurgy

The invention relates to an ultra-thick high temperature-resistant steel for a pressure vessel and a preparation method thereof. After smelting and refining, the steel is subjected to continuous casting, hot rolling, normalizing and tempering. The steel comprises the following controlled chemical components in percentage by mass: 0.08-0.15% of C, 0.15-0.40% of Si, 0.40-0.70% of Mn, 0.90-1.20% of Cr, 0.15-0.30% of V, 0.25-0.35% of Mo, at most 0.025% of P, at most 0.010% of S and the balance of Fe and inevitable inclusions. The preparation method provided by the invention comprises the steps of smelting, heating, rough rolling, finish rolling, normalizing and tempering. The invention has the characteristics of appropriate design and proportion of the chemical components, simple manufacturing process, large thickness dimension (80mm), good heat resistance, stable product performance and the like.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

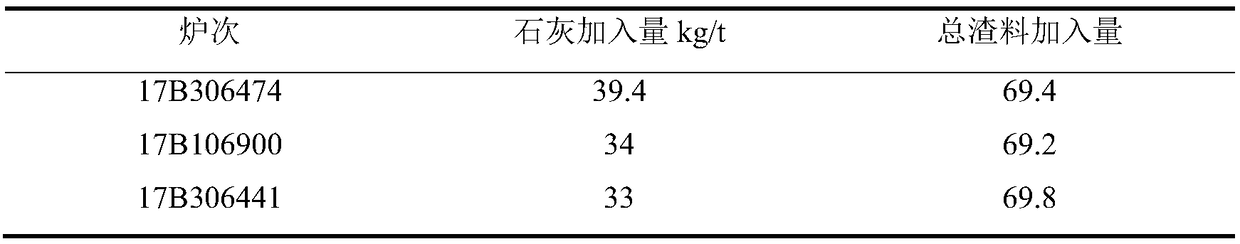

Method based on high-silicon high-phosphorus molten iron converter low slag material consumption to melt low-phosphorus steel

ActiveCN108624735ASimple and fast operationEasy to masterManufacturing convertersProcess efficiency improvementSlagMaterial consumption

The invention relates to a smelting technology method of a steel technological process and specifically relates to a method based on high-silicon high-phosphorus molten iron converter low slag material consumption to melt low-phosphorus steel. The method comprises the following steps: utilizing single-slag operation under the conditions that Si of molten iron putting into a furnace is larger thanor equal to 0.55% and smaller than or equal to 0.8% and P of molten iron putting into the furnace is larger than or equal to 0.17% and smaller than or equal to 0.22%; making a molten iron temperaturelarger than 1250 DEG C and a scrap steel ratio larger than 25%; utilizing a less-slag material, adding the less-slag material into a melting model and controlling the adding amount of an auxiliary material. When Si of general molten iron putting into the furnace is larger than or equal to 0.6% or P of the general molten iron putting into the furnace is larger than or equal to 0.12%, a duplexing method or a double-slag method is utilized by a converter. Under the situations of molten-iron-free three-removal pretreatment and converter duplexing method dephosphorization, operation of the method disclosed by the invention utilizes a single-slag method; under the premises that converter lime consumption is smaller than 40kg / t and a new slag material consuming total amount is smaller than 70kg / t, the condition that P is smaller than 0.012% when a smelting point C is larger than or equal to 0.065% is ensured at the same time. The method disclosed by the invention can effectively reduce novelslag material consumption of high-silicon high-phosphorus molten iron converter smelting, is favorable for reducing industrial waste generation and reduces production cost of per ton of steel.

Owner:UNIV OF SCI & TECH BEIJING +1

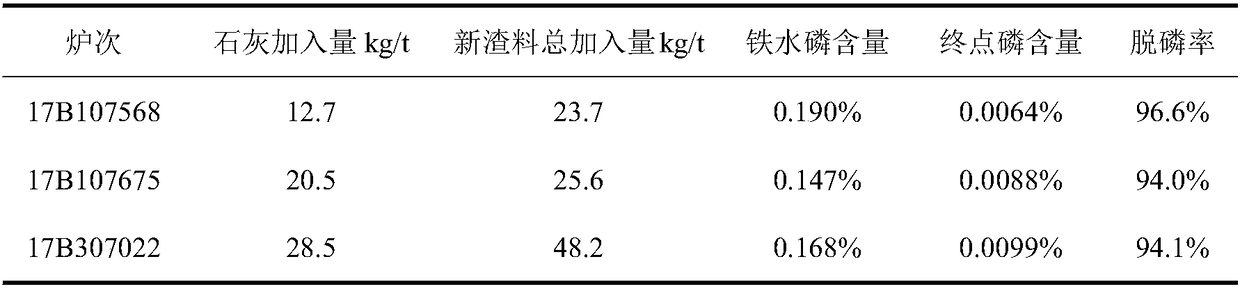

Method for smelting high-phosphorus molten iron to produce steel with converter end point P less than or equal to 0.01% by adopting slagless material

ActiveCN109280731AAvoid going backReduce the temperatureManufacturing convertersProcess efficiency improvementSteelmakingNitrogen

The invention belongs to the technical field of converter steelmaking processes, and particularly relates to a method for smelting high-phosphorus molten iron to produce steel with converter end pointP less than or equal to 0.01% by adopting slagless material. The method comprises the following steps that loading low-silicon high-phosphorus molten iron and steel scrap which are not subjected to triple-removal pretreatment into a converter, a single-slag method is adopted to carry out blowing, a slagging material is added twice in a blowing process and a gun position control mode of high, low, high and low is adopted in the blowing process, and oxygen supply and nitrogen supply are carried out in the blowing process; after the blowing is completed, the steel is discharged, slag splashingis carried out after the steel is discharged, slag is reserved after the slag splashing, and is used for smelting in the next furnace. According to the method, on the premise that lime consumption ofa steel liquid is less than or equal to 30 kg / t, and the consumption of the new slag material is less than or equal to 50 kg / t, dephosphorizing of the molten iron with the following components, by weight, 0.14-0.26% and Si, 0.15-0.20% of P is carried out until P is less than or equal to 0.01%, and a dephosphorization rate is larger than or equal to 94%, so that the problem that low-phosphorus steel is smelted by a low-silicon high-phosphorus molten iron with the few slag material in the single-slag method is solved.

Owner:UNIV OF SCI & TECH BEIJING

Low-alloy high-strength hot-pierced and hot-rolled fully-threaded once-formed bolt

InactiveCN101614014AHigh yield strengthReduce energy consumptionBulkheads/pilesAnchoring boltsHigh energyEngineering

The invention relates to a low-alloy high-strength hot-pierced and hot-rolled fully-threaded once-formed bolt. The fully-threaded bolt is widely used for road side slope support and tunnel, mine and water conservancy and hydropower engineering support and is the most economic and effective important tool for improving geotechnical stability and solving the stability problem of complex geotechnical engineering. The conventional cold rolling or hot rolling production process requires at least two times of heating for producing fully-threaded bolts and is high in energy consumption and low in efficiency. The method thermally roll and pierce low-alloy steel rod through one time of heating, forms the fully-threaded bolt with waste heat after reducing and sizing, integrally normalizes by using residual heat, and directly produces a fully-threaded hollow bolt through on-line once forming. The technology solves the drawbacks of low efficiency, high energy consumption and low quality of the conventional process in fully-threaded bolt production.

Owner:湖北嘉裕钎具股份有限公司

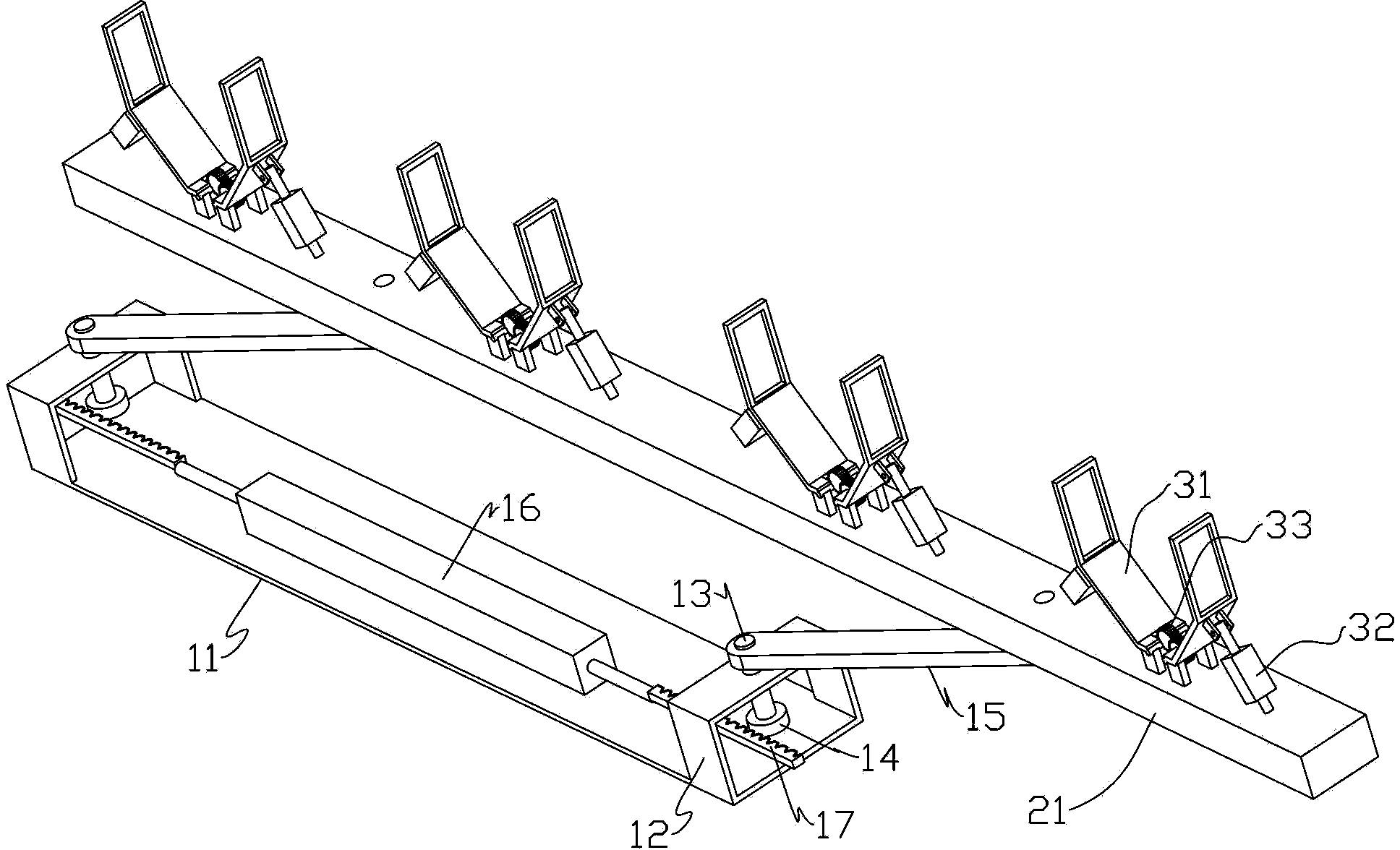

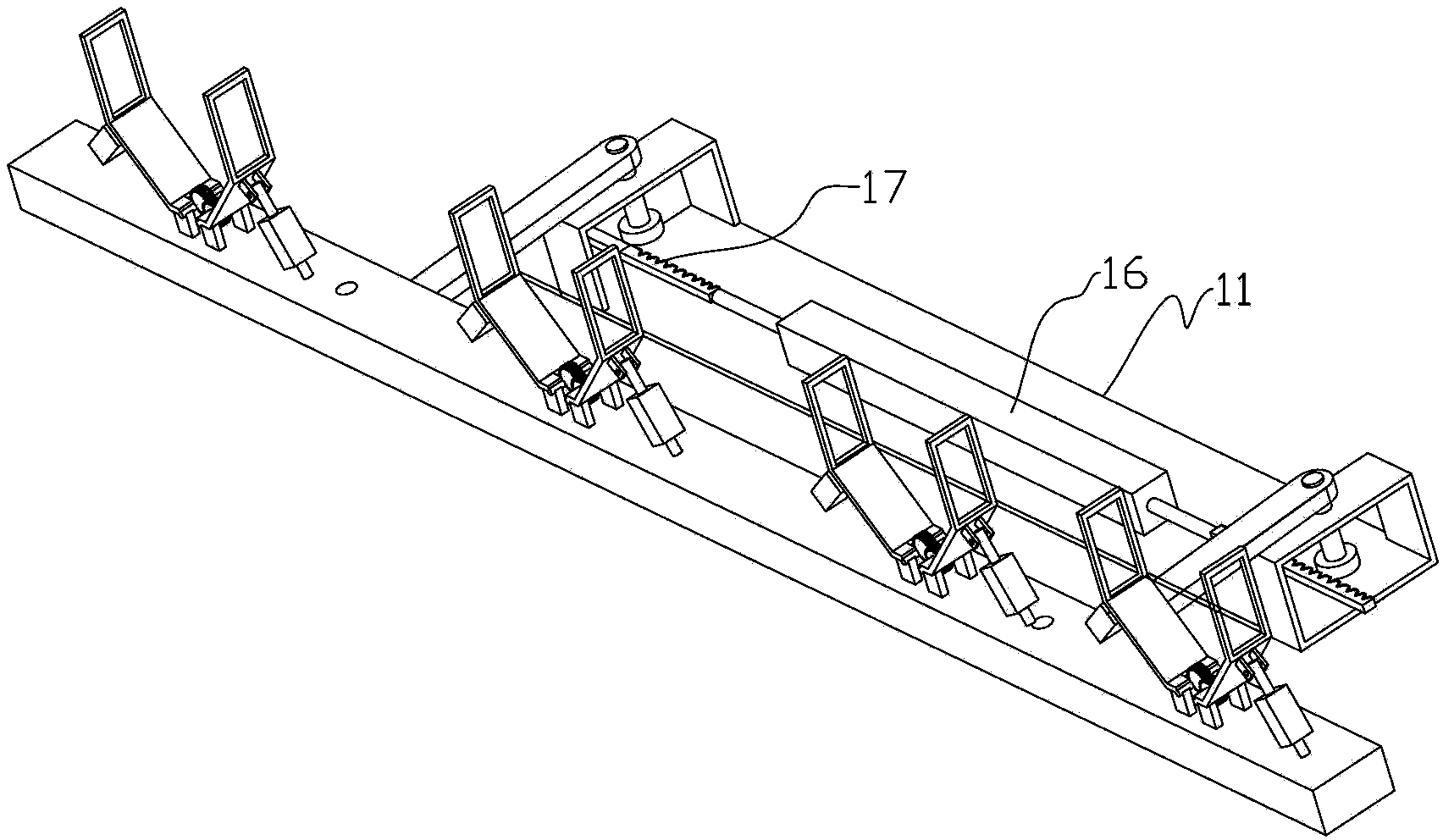

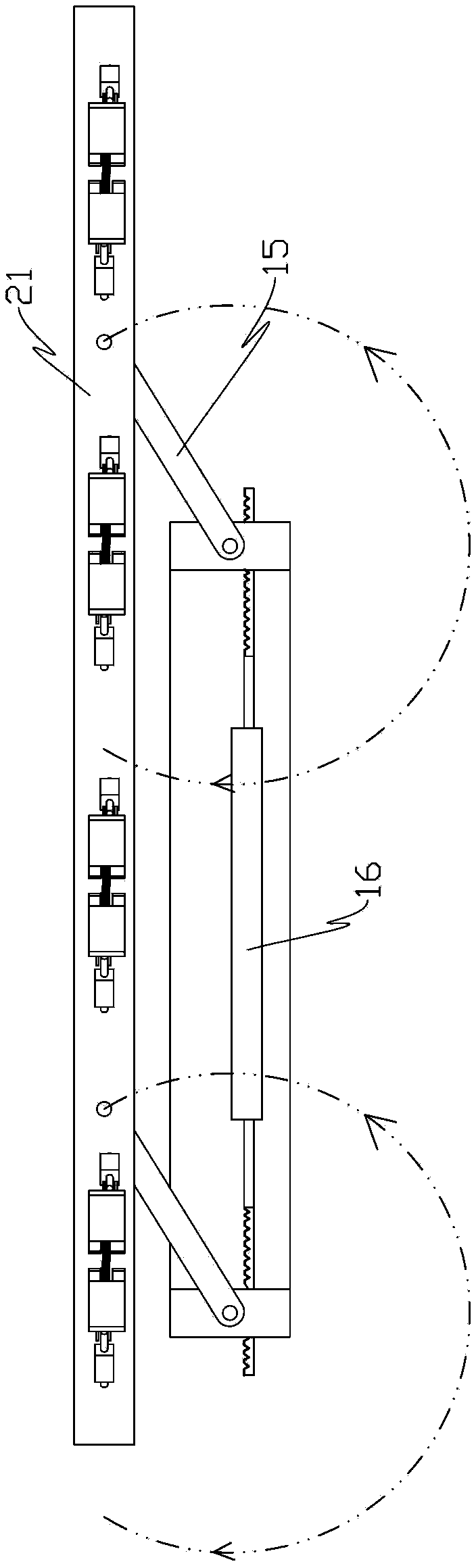

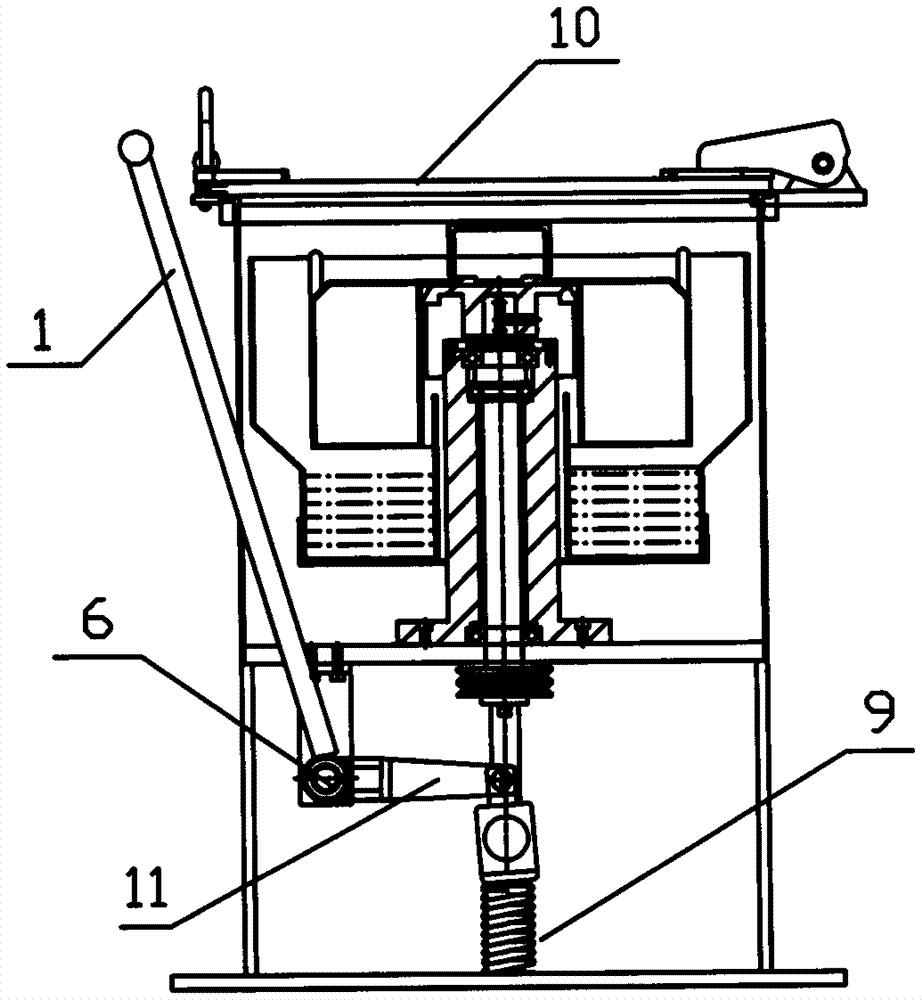

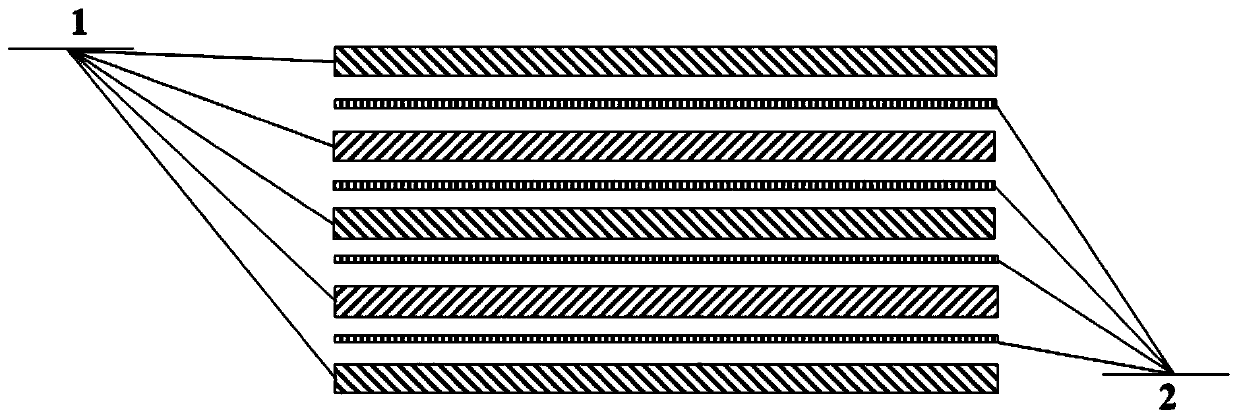

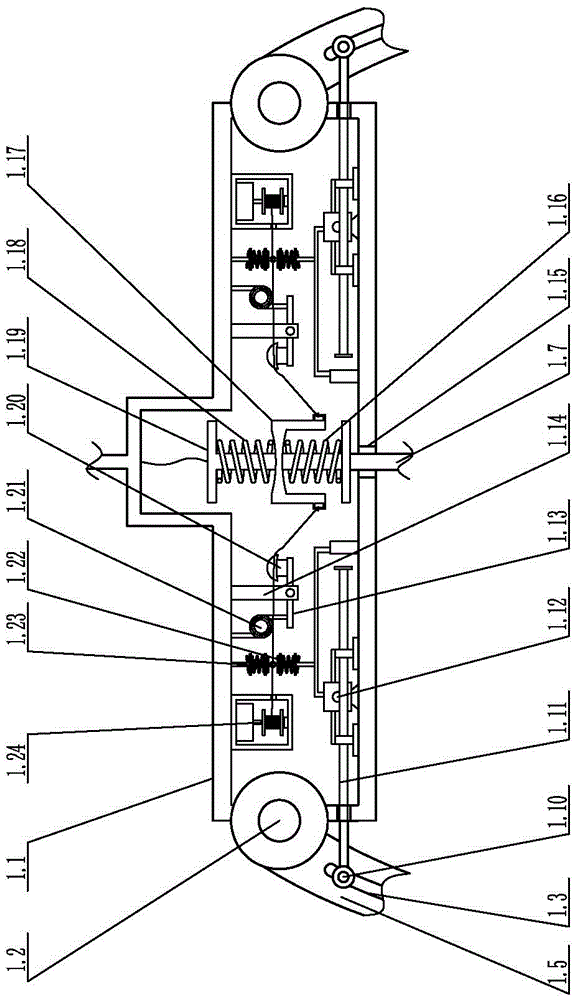

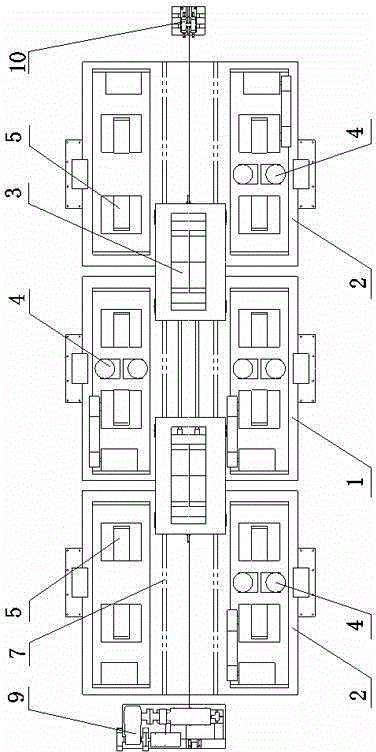

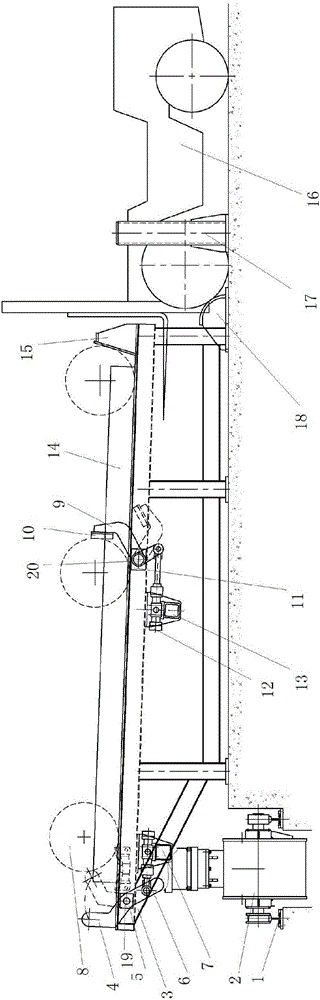

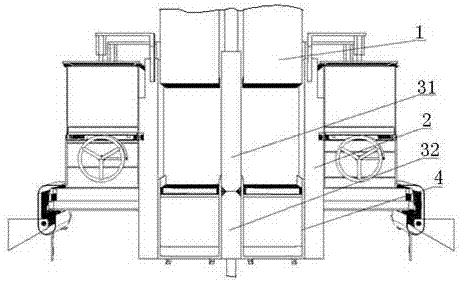

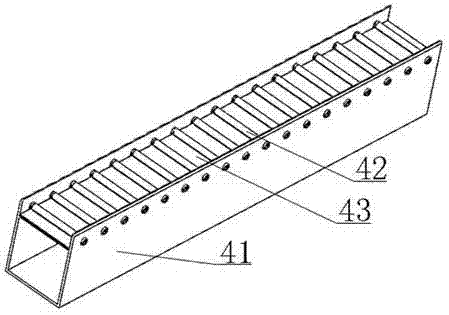

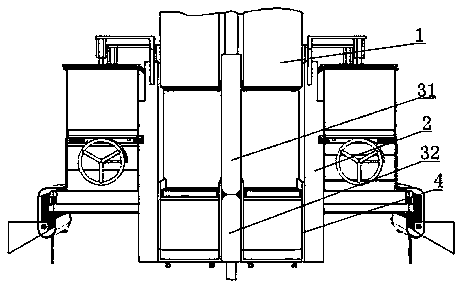

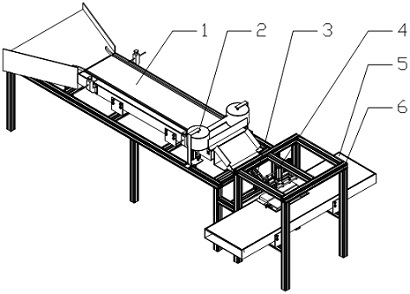

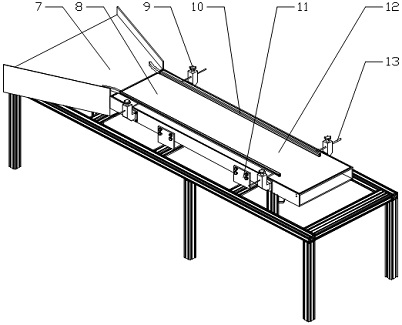

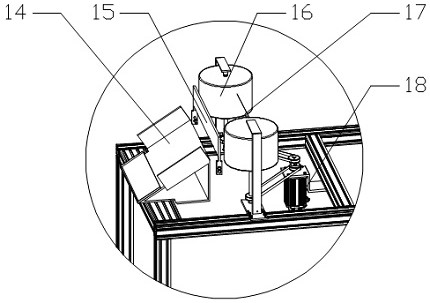

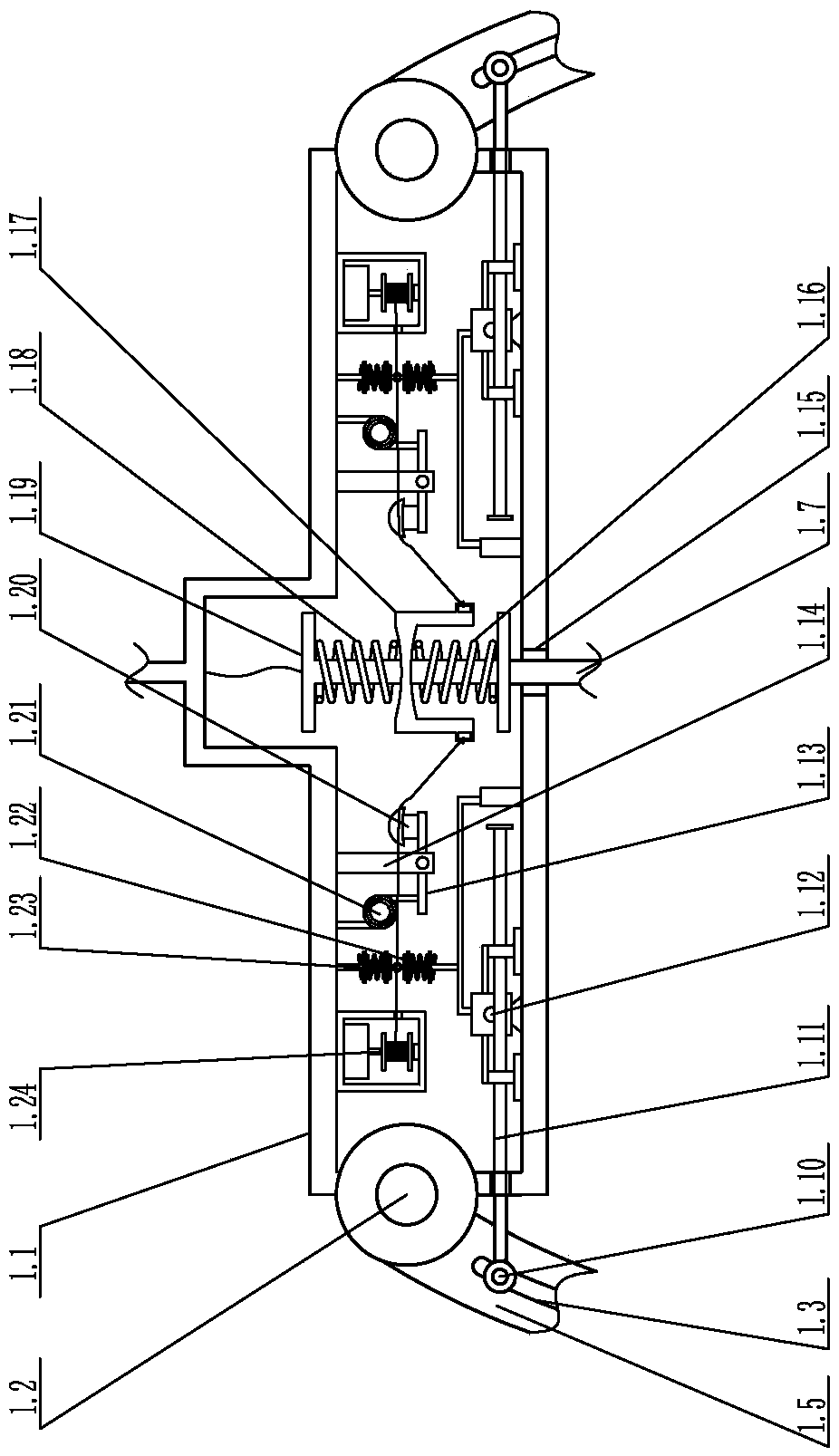

Automatic four-station three-process feeding mechanism

ActiveCN103350171AFast pace of productionIncrease productivityMetal-working feeding devicesRocker armEngineering

An automatic four-station three-process feeding mechanism comprises a base, a feeding frame beam, connecting rods and clamping devices. The front end and the rear end of the base are respectively provided with a vertical shaft hole, a rotating shaft is installed in each shaft hole, a rocker arm and one connecting rod are respectively fixed at the upper end and the lower end of each rotating shaft, the other ends of the connecting rods are connected to the feeding frame beam in a pivot mode, the pivot points among the feeding frame beam, the base and the two connecting rods form a parallelogram connecting mechanism, a power source is installed among the rocker arms and the base, and the four clamping devices are evenly arranged on the upper side of a feeding frame from front to rear at equal intervals. The parallelogram connecting mechanism is fast in transposition production rhythm and high in production efficiency and saves working auxiliary time effectively; the four-connecting-rod structure is adopted for the whole structure, in feeding and discharging processes, receding action exists between the feeding mechanism and a main shaft of a roll forming machine, and the feeding mechanism can automatically conveying rim blanks to the main shaft and is reasonable in structure, accurate, and high in stability.

Owner:SHANDONG XIAOYA PRECISE MACHINERY

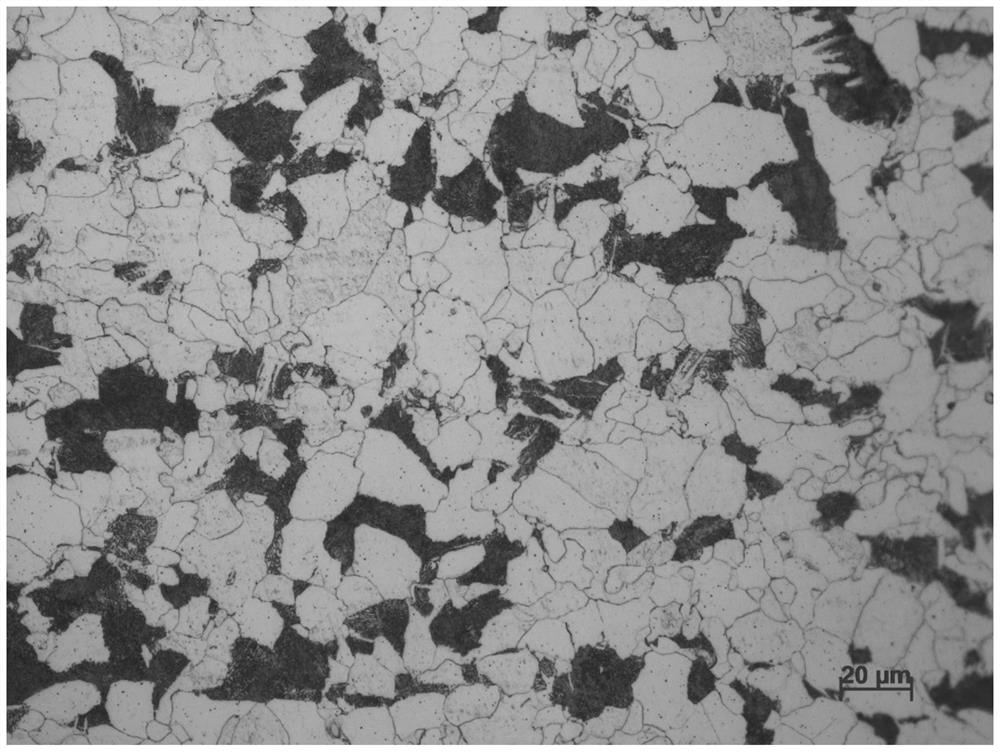

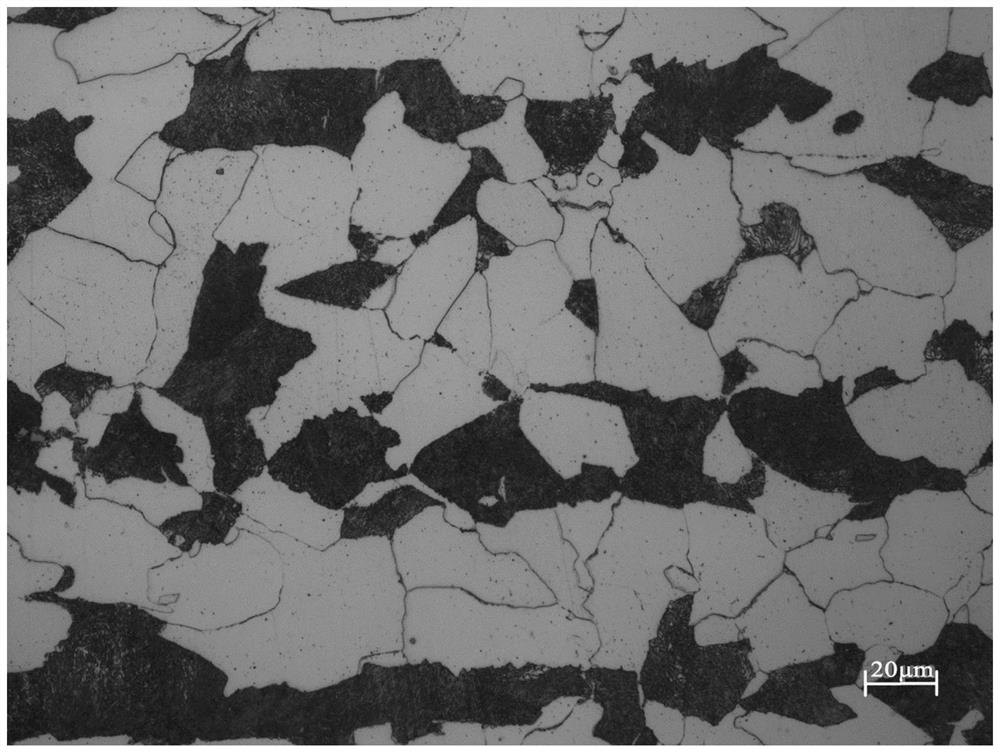

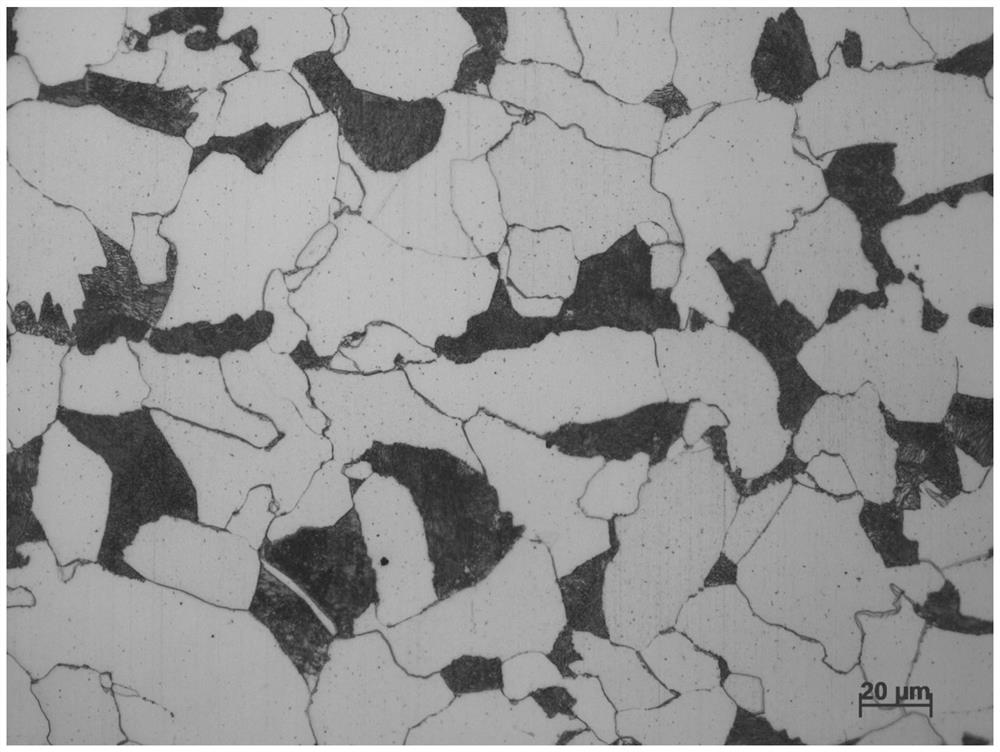

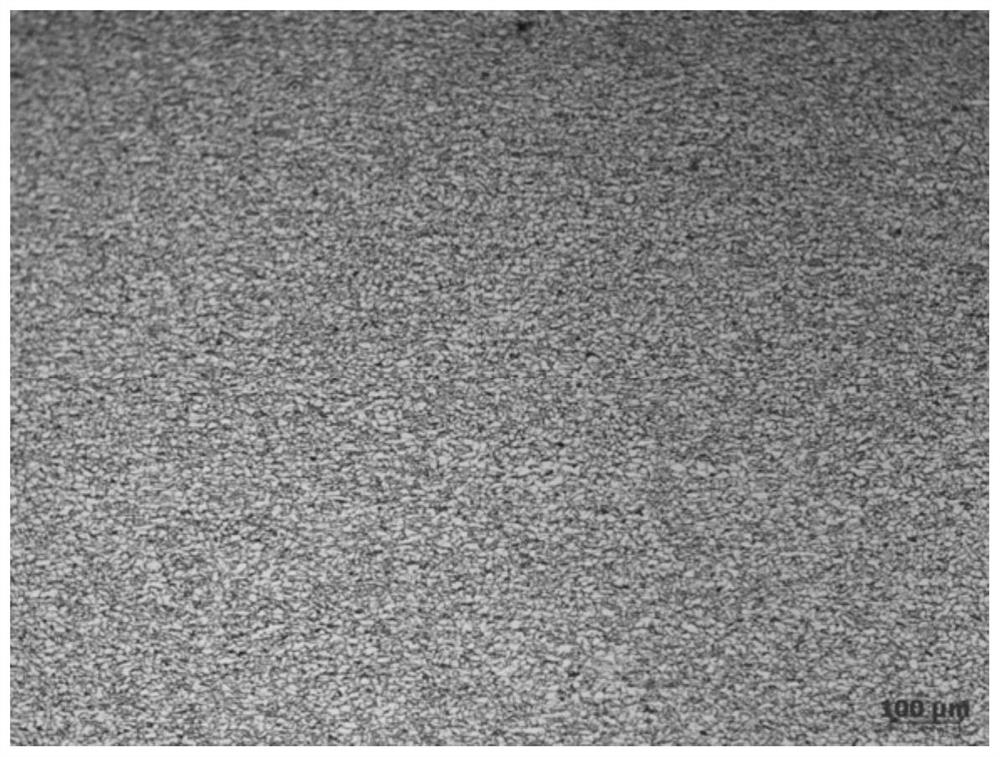

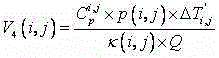

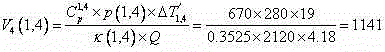

Micro-titanium alloying Q355B medium-thickness steel plate and low-cost production method therefor

ActiveCN112322982AImprove rolling efficiency and control performance uniformityRefined organizationProcess efficiency improvementSteel platesFerrous metallurgy

The invention discloses a micro-titanium alloying Q355B medium-thickness steel plate and a low-cost production method therefor, and belongs to the technical field of ferrous metallurgy. The steel plate comprises the following chemical components in percentage by mass: 0.15-0.18% of C, less than or equal to 0.24% of Si, less than or equal to 1.60% of Mn, 0.020-0.045% of Al, 0.020-0.040% of Ti, lessthan or equal to 0.10% of Cr, less than or equal to 0.025% of P, less than or equal to 0.008% of S, less than or equal to 0.080% of N, and the balance of iron and inevitable impurity elements. In order to solve the technical problem that in the prior art, the continuous production rhythm can be affected due to the fact that a blank needs to be kept warm in the rolling process of a 30-40 mm medium-thickness Q355B steel plate, the micro-titanium alloying Q355B medium-thickness steel plate has the advantages that precious elements such as V, Nb and Cu are not added, controlled rolling is not needed, and the production rhythm can be greatly improved.

Owner:SHAGANG GROUP +1

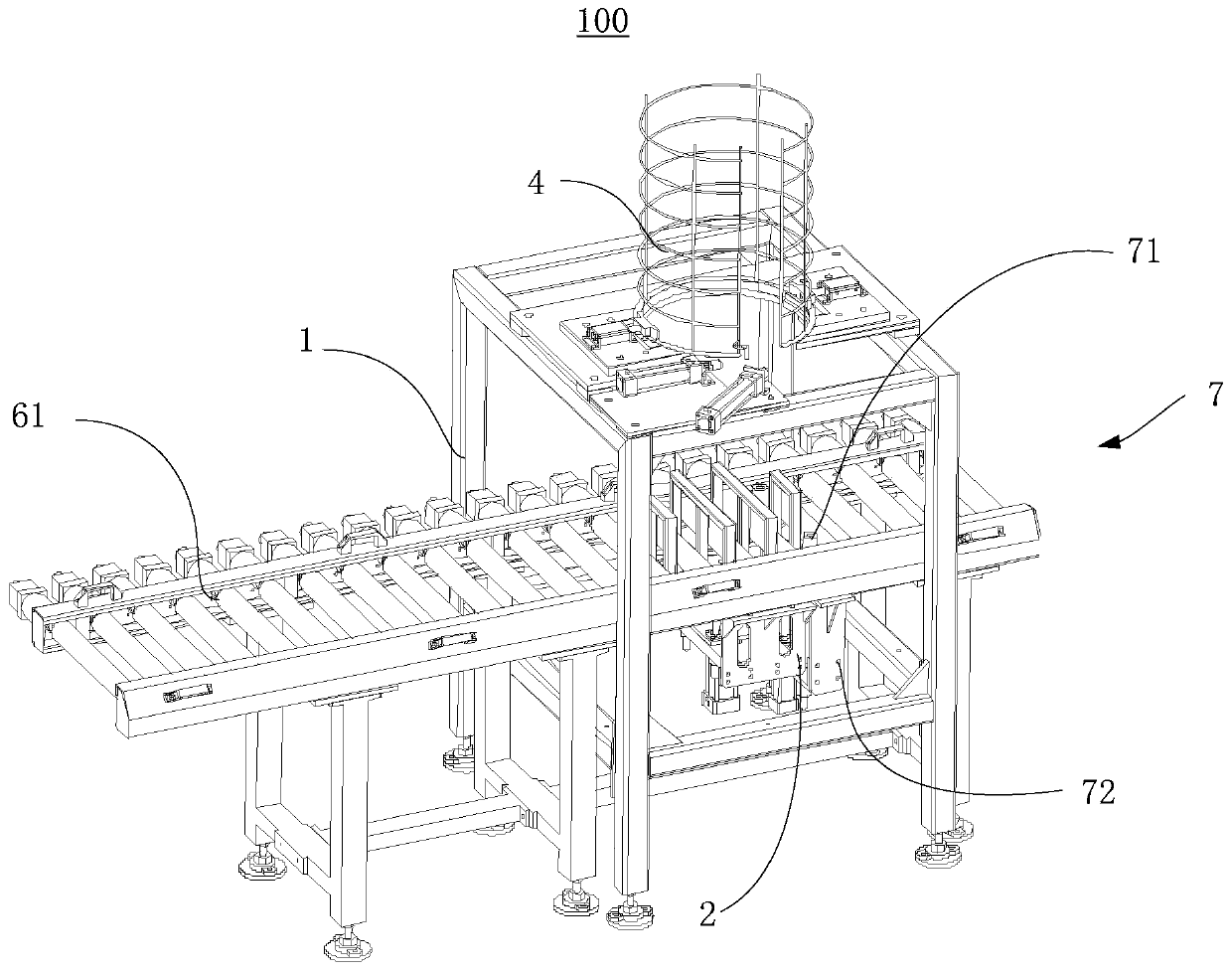

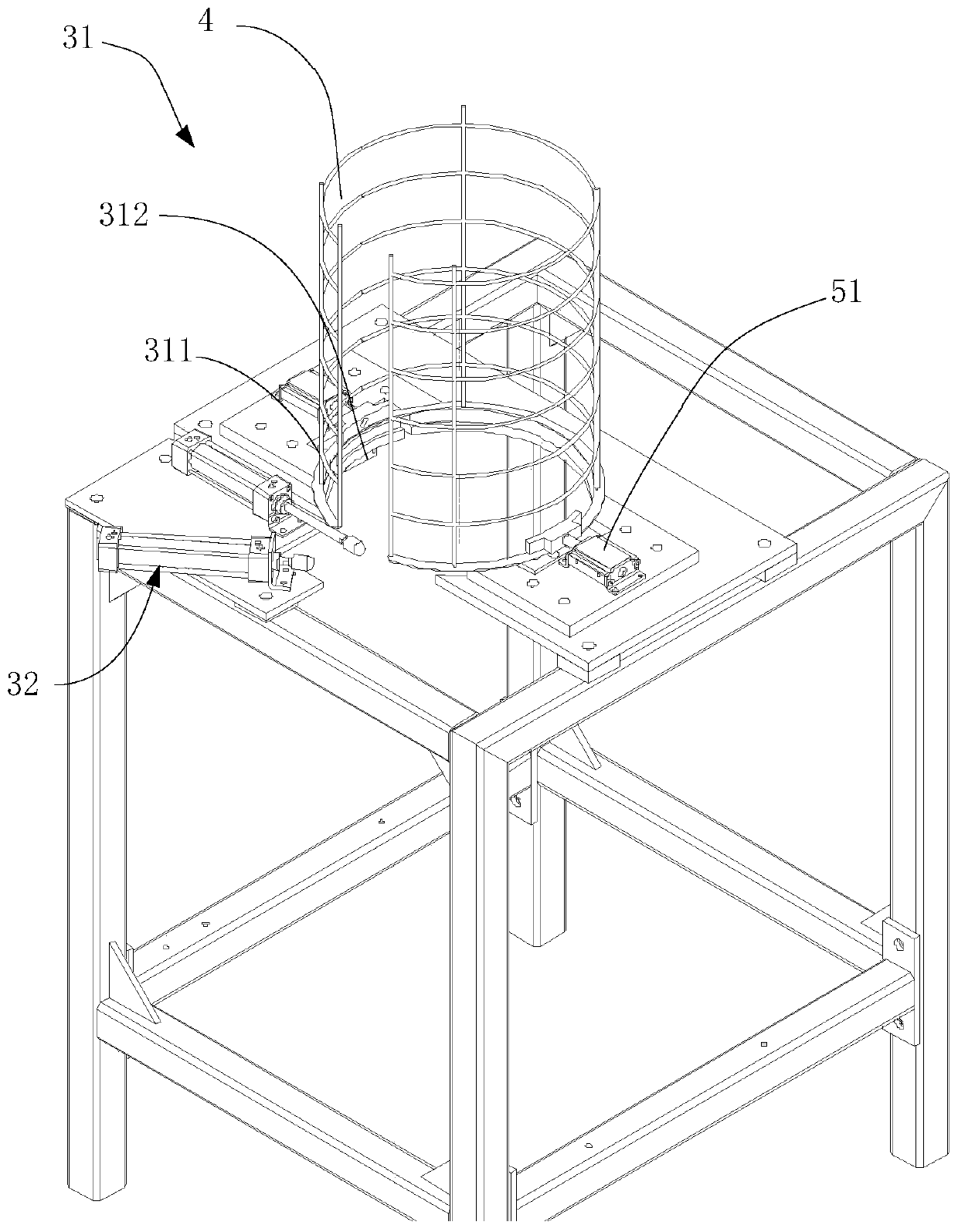

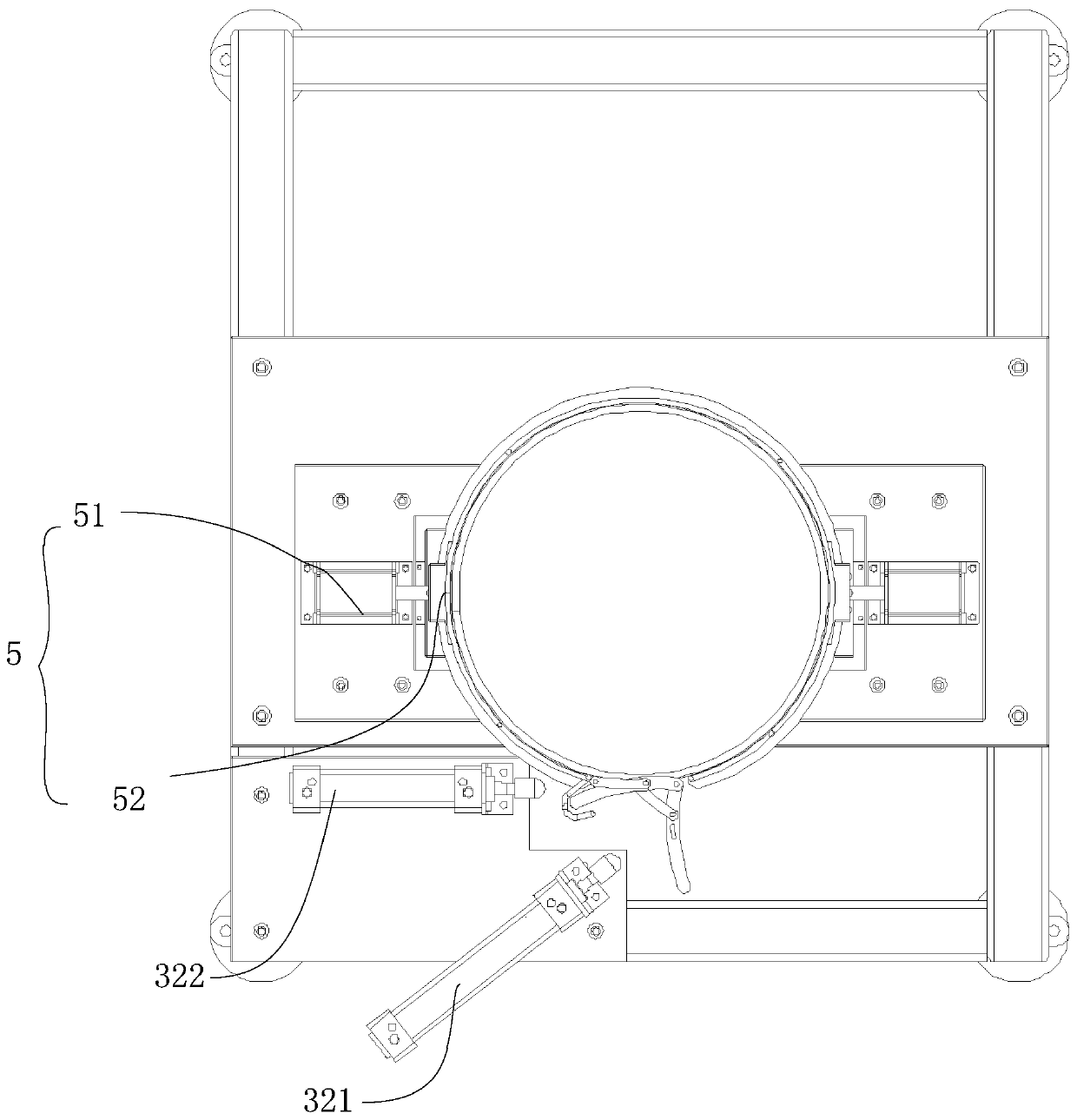

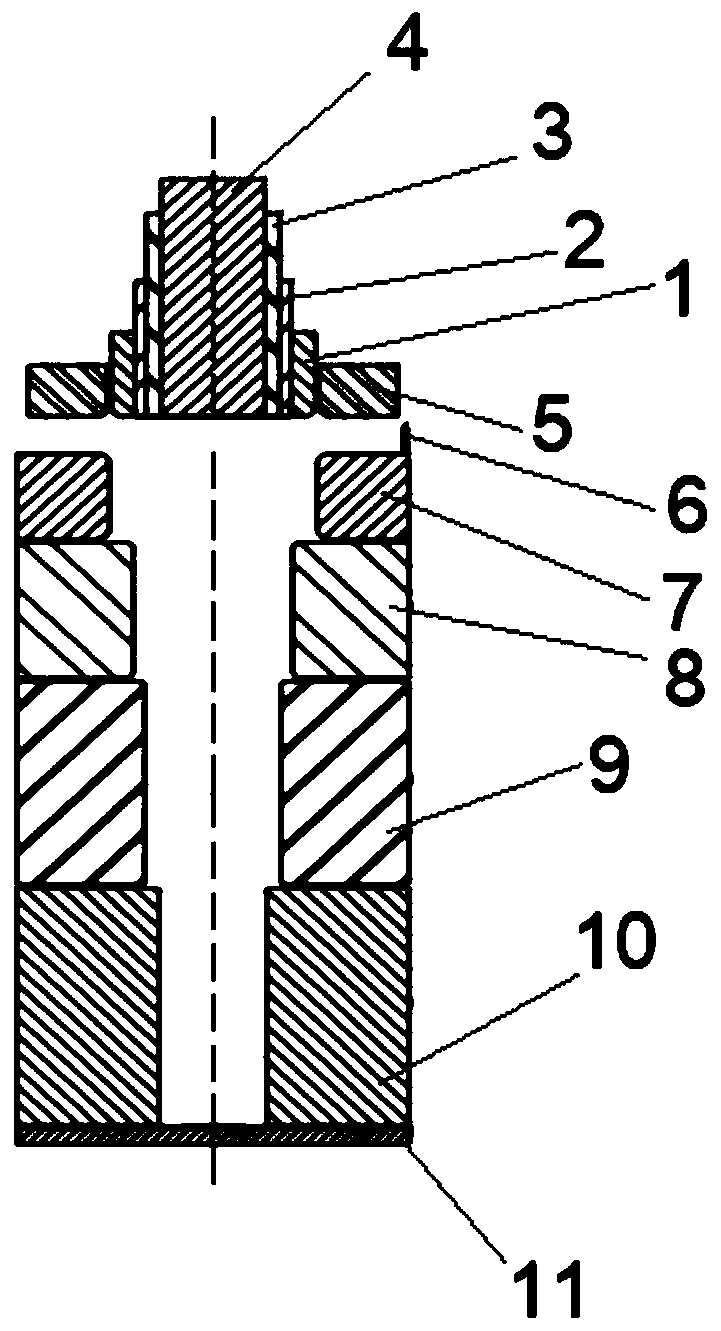

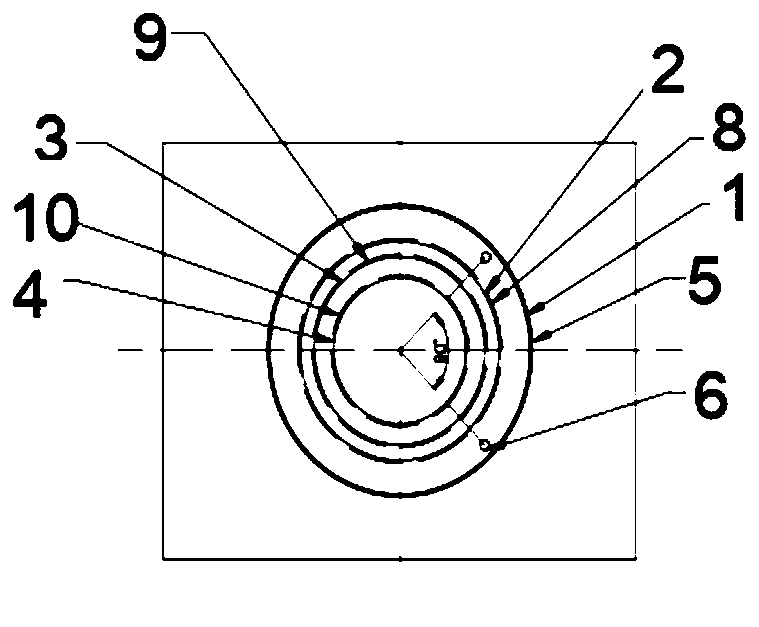

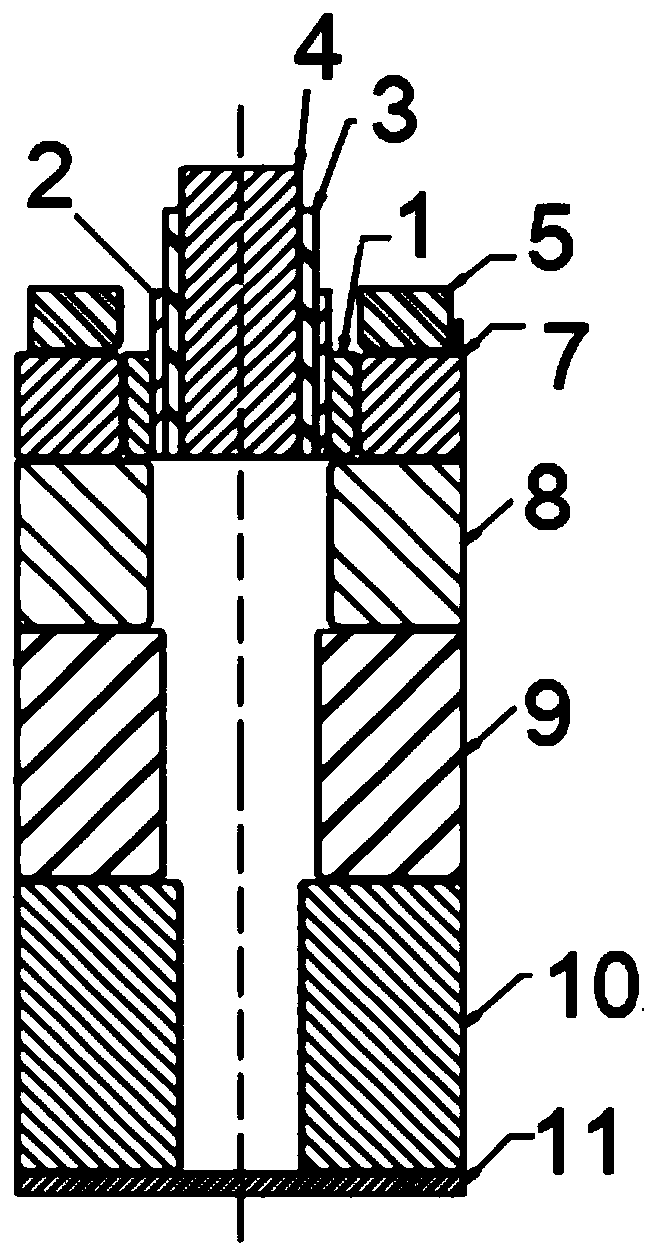

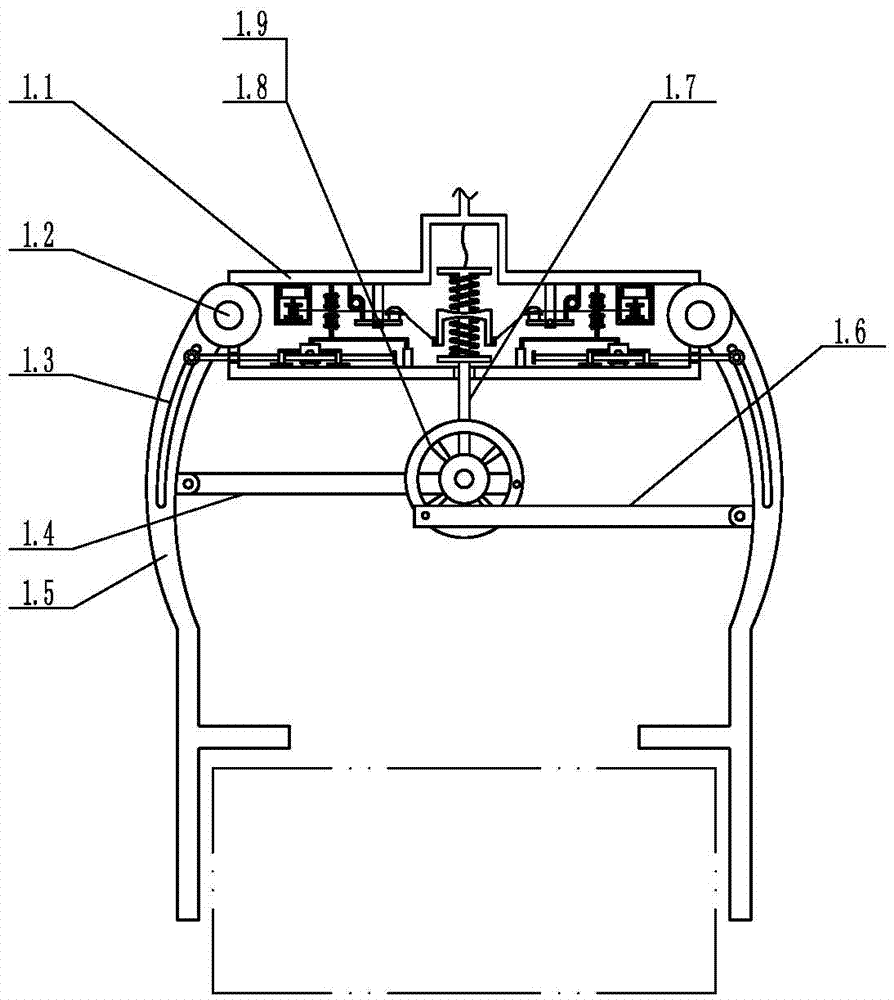

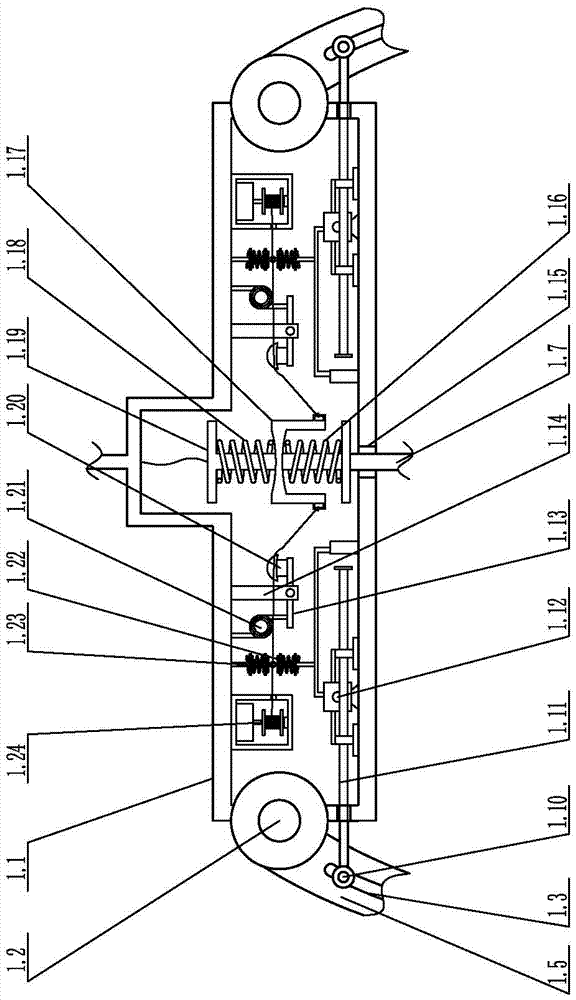

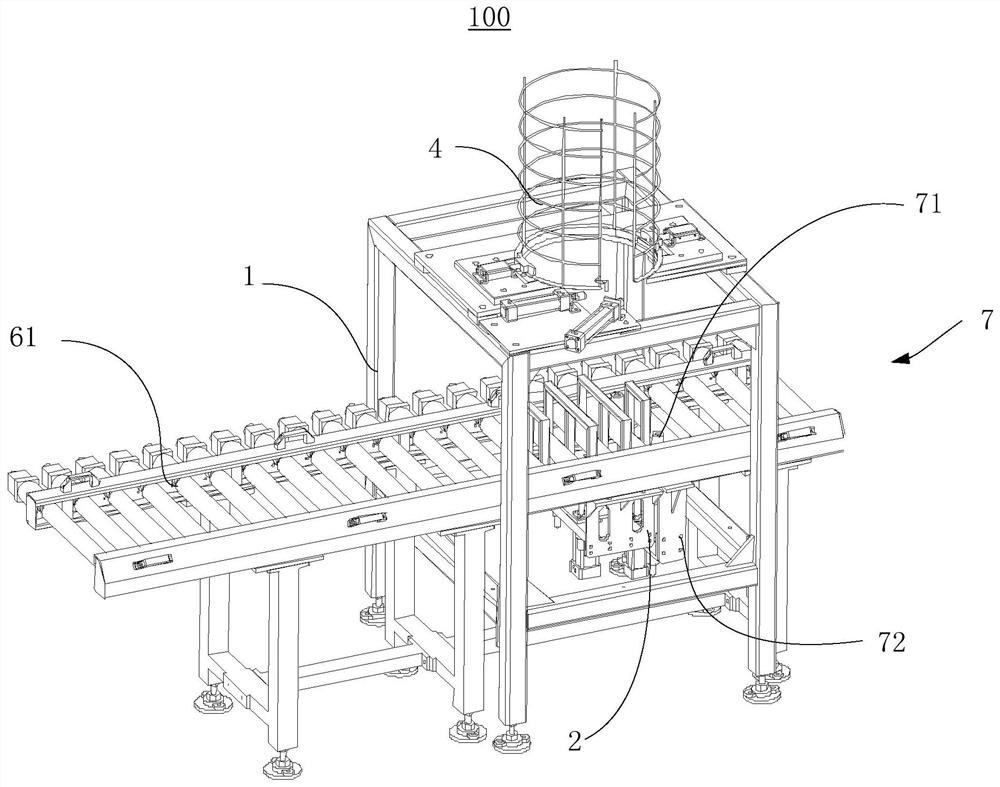

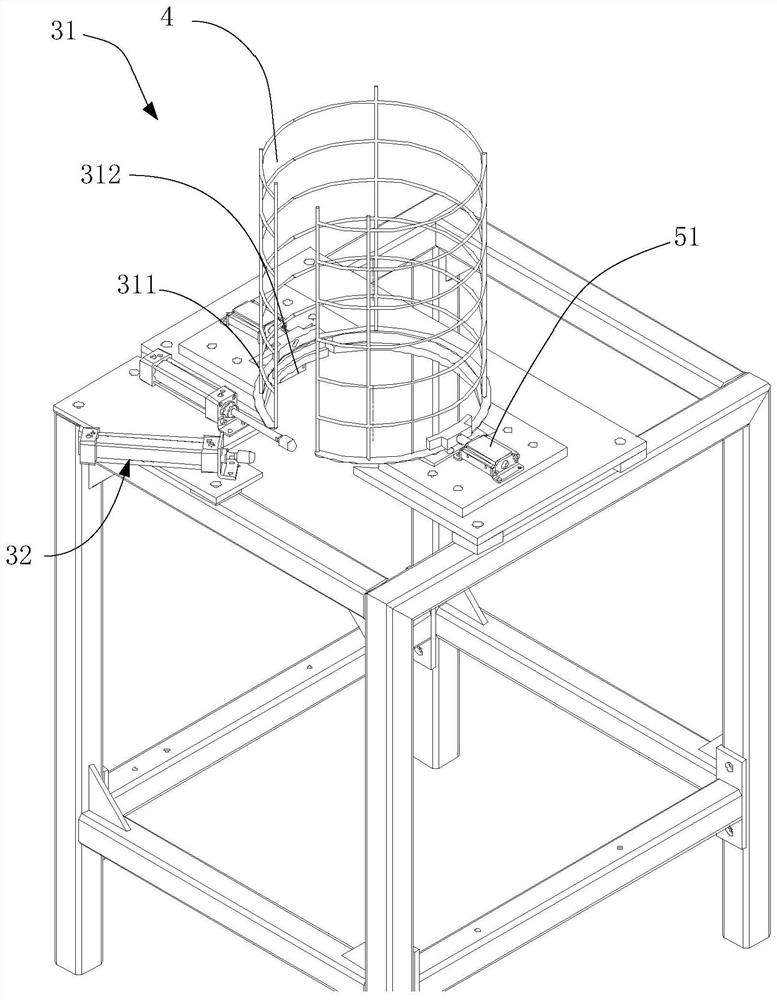

Device for tightening cylinder hoop after covering of cylinder

ActiveCN111284739AAchieving a lock sealFast pace of productionPackagingClassical mechanicsEngineering

The invention discloses a device for tightening a cylinder hoop after covering of a cylinder. The device is used for locking the cylinder hoop of the cylinder; the cylinder hoop comprises a cylinder hoop ring, a clamping seat and a buckle seat, wherein the clamping seat and the buckle seat are located at an opening of the cylinder hoop ring; the device for tightening the cylinder hoop after covering of the cylinder comprises a machine seat, a cylinder supporting assembly and a cylinder hoop clamping assembly; the machine seat forms a hoop tightening space used for containing the cylinder hoopwhich is horizontally placed and is in a loose state; the cylinder supporting assembly comprises a supporting frame which is arranged on the machine seat and correspondingly located below the hoop tightening space; the supporting frame has an active stroke in the up-down direction to upwards push a to-be-locked part of the cylinder covered with a cylinder cover into the hoop tightening space to belocated in the cylinder hoop ring of the cylinder hoop; and the cylinder hoop clamping assembly comprises a clamping driving assembly arranged on the machine seat to enable the cylinder hoop ring ina loose state to be tightened and enable the clamping seat and the buckle seat of the cylinder hoop to be in buckle locking. Manual work is replaced with mechanical equipment, and thus the productionefficiency is improved.

Owner:WUHAN POLYTECHNIC UNIVERSITY

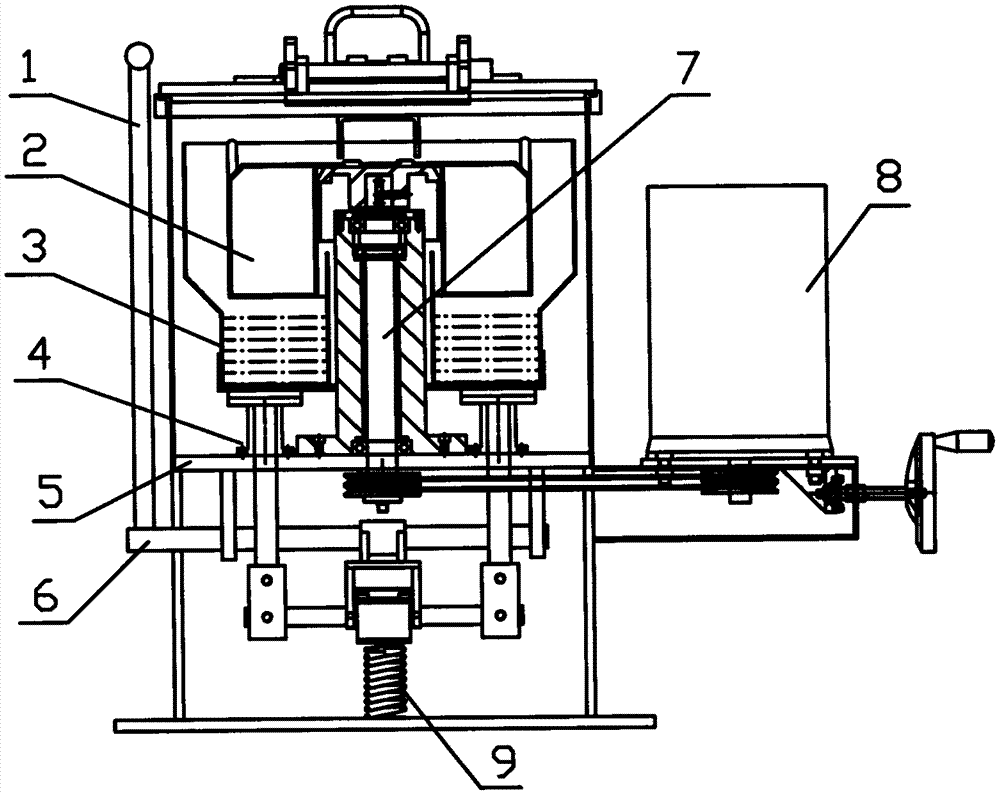

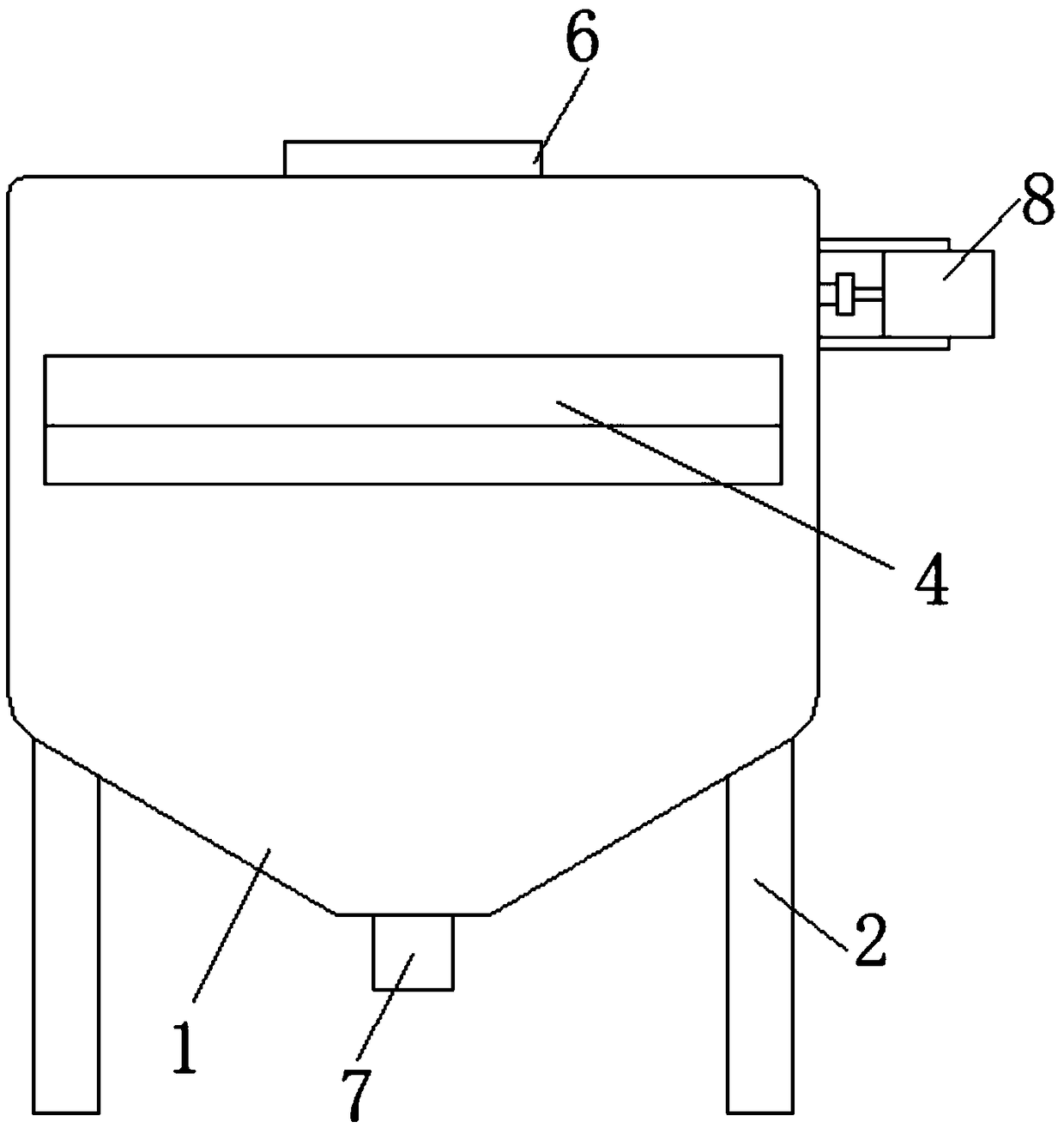

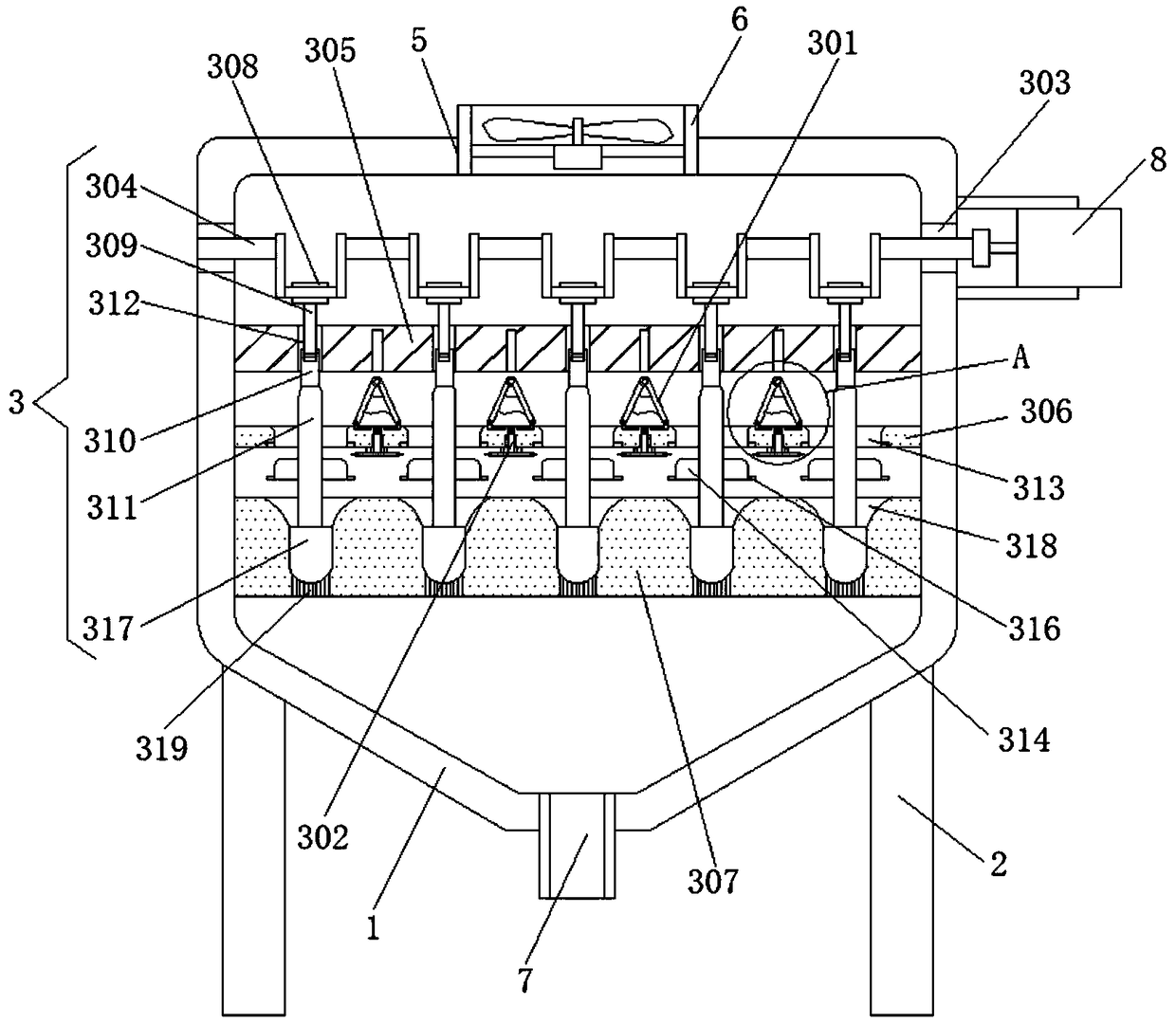

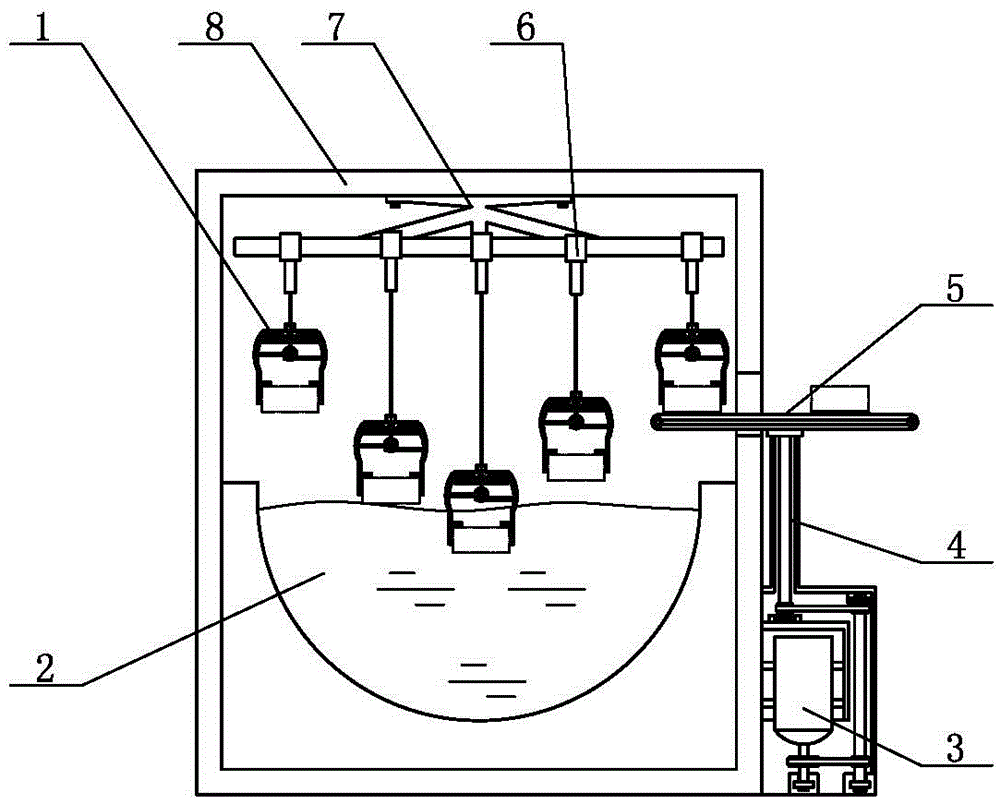

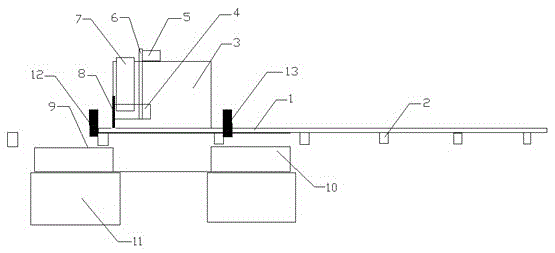

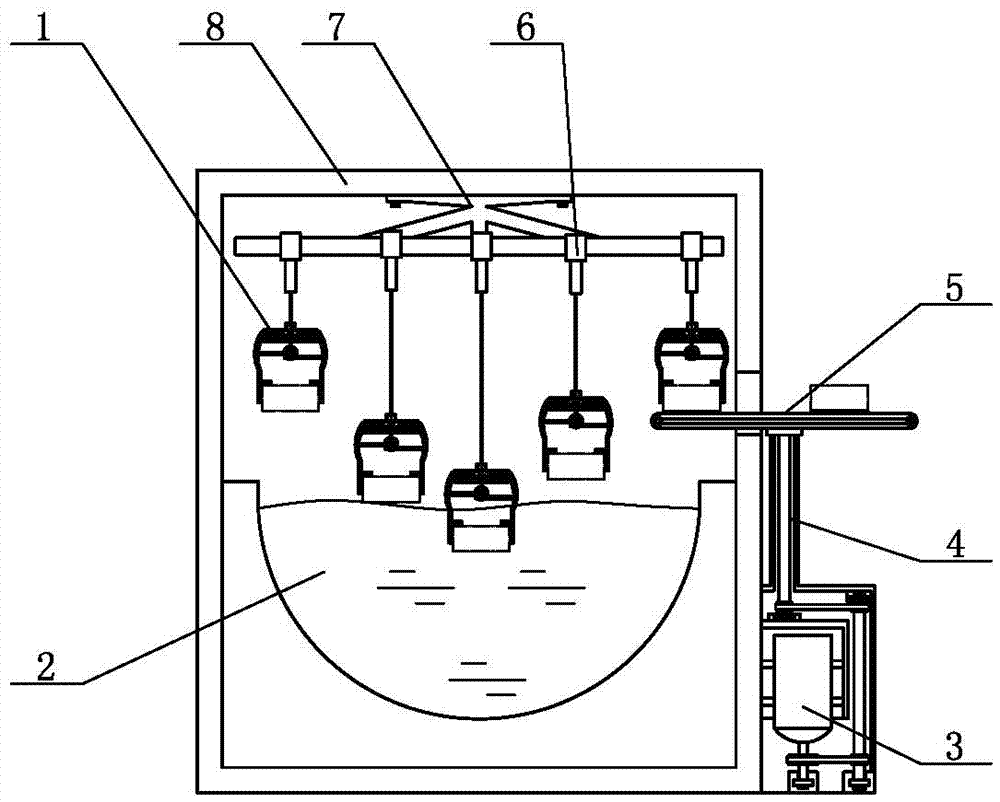

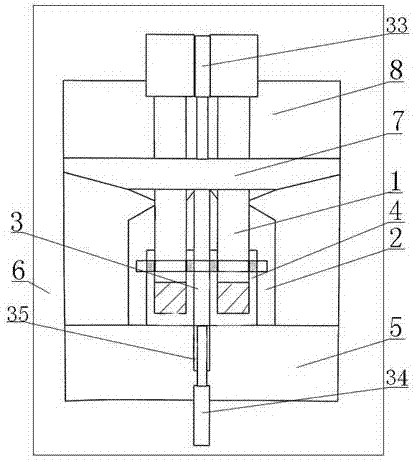

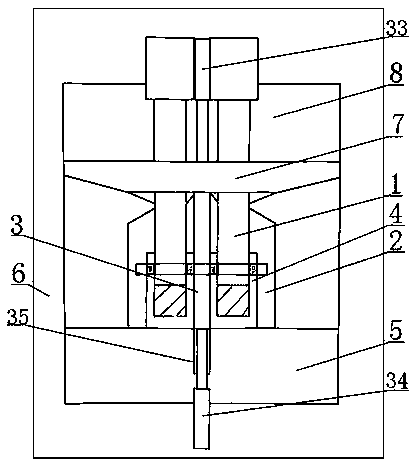

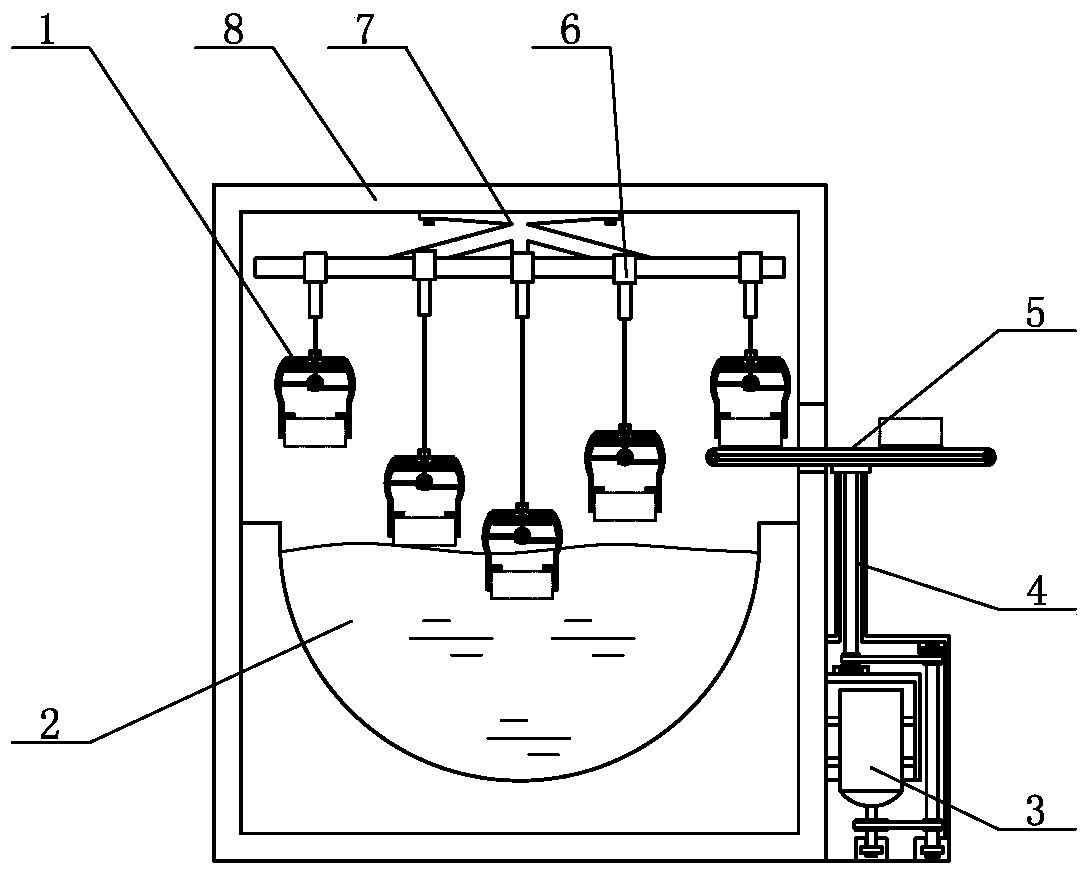

Single-barrel dipping-coating all-in-one machine

ActiveCN103934151ALabor savingFast pace of productionLiquid surface applicatorsCoatingsElectric machineryRhythm

The invention discloses a single-barrel dipping-coating all-in-one machine. The single-barrel dipping-coating all-in-one machine comprises a machine body, a dipping-coating device arranged inside the machine body and a motor (8) arranged outside the machine body, wherein a machine cover (10) is arranged at the top end of the machine body; the dipping-coating device comprises a coating liquid barrel (3), a material frame (2) of which the diameter is less than the inner diameter of the coating liquid barrel (3), and a hand-operated liquid barrel lifting device connected with the coating liquid barrel (3), wherein a main shaft (7) is arranged at the center of the coating liquid barrel (3), the lower end of the main shaft (7) is connected with the motor (8) by a belt, and the material frame (2) is movably connected with the top end of the main shaft (7) penetrating through the coating liquid barrel (3). The single-barrel dipping-coating all-in-one machine has the beneficial effects of quick production rhythm, good economic practicability and high coating utilization rate, can coat blind hole type parts and is labor-saving in operation.

Owner:CHANGZHOU GAOKEXIU MACHINERY

Vertical-linkage and reciprocating rolling-type mashed potato preparing device

The invention belongs to the technical field of food processing, and discloses a vertical-linkage and reciprocating rolling-type mashed potato preparing device. The vertical-linkage and reciprocatingrolling-type mashed potato preparing device comprises a box, wherein the section of the bottom wall of the box is funnel-shaped; supporting legs are fixedly connected to four corners of the bottom wall of the box; the discharge end of a feed hopper is fixedly communicated with the front surface of the box; a mounting hole is formed in the middle part of the top wall of the box; an exhaust fan is fixedly mounted inside the mounting hole; the feed end of a discharge pipe is fixedly communicated with the middle part of the bottom wall of the box; a driving motor is fixedly mounted at the top endof the right side surface of the box through a mounting rod; a rolling mechanism is arranged inside the box. Through arrangement of the rolling mechanism, the vertical-linkage and reciprocating rolling-type mashed potato preparing device can quickly roll potatoes after feeding to quickly destroy the structures of the potatoes, so that rapid mashing of the potatoes is achieved and improvement on the preparation efficiency of mashed potato is facilitated.

Owner:曾早生

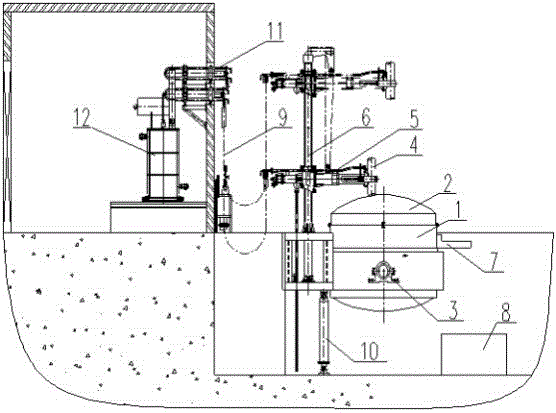

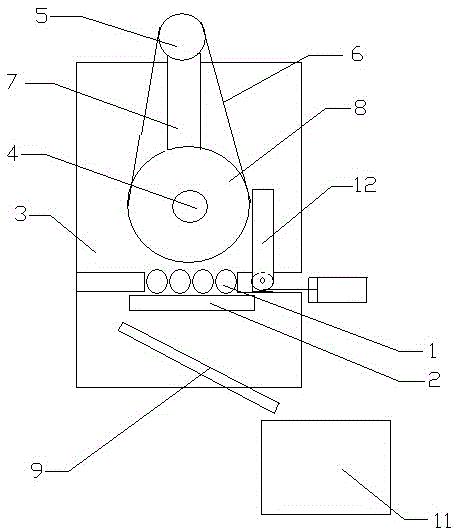

Novel corundum smelting furnace

InactiveCN104422278AContinuous productionFast pace of productionCrucible furnacesProduction rateContinuous production

The invention relates to the field of corundum smelting, in particular to a novel corundum smelting furnace. The novel corundum smelting furnace is structurally characterized in that a conductive cross arm (5) is arranged above a furnace body (1); an electrode (4) is arranged at the end part of the conductive cross arm (5); a furnace cover (2) is arranged at the top of the furnace body (1); the furnace body (1) is arranged on a tilting frame (3), and a turndown oil cylinder (10) is arranged at the bottom of the tilting frame (3); a discharging groove (7) is formed in one side of the furnace body (1); a receiving bag (8) is placed below the discharging groove (7); the conductive cross arm (5) is arranged on an upright lifting column (6); the tail end of the conductive cross arm (5) is connected with a water-cooled cable (9); the water-cooled cable (9) is connected with an electric furnace transformer (12) through a short net (11). Compared with the prior art, the novel corundum smelting furnace has the advantages that continuous production can be realized, the production rhythm is quick, and the lower consumption is low; moreover, the furnace cover is simple in structure, safe and reliable, water feeding is not needed, and the productivity is greatly improved.

Owner:XI AN BANGHE ELECTRICAL EQUIP

Titanium microalloyed Q355B structural steel plate and recrystallization controlled rolling process method thereof

The invention belongs to the technical field of medium plate production, and particularly relates to a titanium microalloyed Q355B structural steel plate and a recrystallization controlled rolling process method thereof. The steel plate comprises the following chemical components in percentage by mass: 0.16 to 0.20 percent of C, 0.15 to 0.30 percent of Si, 0.70 to 0.90 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.015 percent of S, 0.015 to 0.045 percent of Als, 0.055 to 0.070 percent of Ti and the balance of Fe and inevitable impurities. The process method comprises the steps of blast furnace molten iron smelting, molten iron pre-desulfurization, converter smelting, deoxidation alloying, LF refining furnace refining, slab continuous casting, slab reheating, rolling mill rolling, laminar cooling, steel plate straightening, finished product sampling inspection and warehousing. The recrystallization controlled rolling process is adopted in the rolling stage, conventional two-stage controlled rolling is not adopted, temperature holding after first-stage rolling is avoided, and the production rhythm is high.

Owner:天津市新天钢钢铁集团有限公司

Deep drawing forming method for metal housing of deep cylindrical part and multi-pass one-time forming die

InactiveCN110743955ASimple processReduce scrap rateShaping toolsStructural engineeringStamping process

The invention discloses a deep drawing forming method for a metal housing of a deep cylindrical part and a multi-pass one-time forming die. The deep drawing forming method comprises the following specific steps of (1) performing blanking, (2) locating a plate, (3) pressing the plate with a blank holder 5, and (4) performing multi-pass one-time molding. The multi-pass one-time forming die comprisesa male die and a female die corresponding to the male die; the male die comprises a last-pass male die as well as an intermediate-pass male die and a first-pass male die which sequentially sleeve thelast-pass male die; the female die comprises a last-pass female die as well as an intermediate-pass female die and a first-pass female die which are sequentially arranged on the last-pass female die;the first-pass female die is provided with locating pins for locating the plate; and the edge pressing ring sleeves the first-pass male die. The trouble of positioning the plate in multiple times dueto transverse movement of a blank in a multi-pass multi-step continuous stamping process can be saved, the problems of waste materials, die clamping and the like generated during multi-pass multi-step deep drawing can be solved, and the production rhythm and rate can be increased.

Owner:MAANSHAN IRON & STEEL CO LTD

Ultrahigh-phosphorus molten iron low-cost smelting method for polar region steel

ActiveCN113322364AReduce consumptionFast pace of productionManufacturing convertersProcess efficiency improvementSteelmakingMolten steel

The invention discloses an ultrahigh-phosphorus molten iron low-cost smelting method for polar region steel. The method sequentially comprises the following steps of a converter smelting step of smelting raw materials including molten iron, deoxidizing and tapping and alloying; an LF refining step of performing slag adjusting and refining on molten steel obtained in the converter smelting step, to obtain refined molten steel; an RH degassing step of performing vacuum degassing on the refined molten steel; and a continuous casting step of performing continuous casting on the molten steel obtained after the RH degassing step, to obtain a casting blank. According to the method, single and double slag area smelting is performed according to the content of Si in the molten iron, and thus consumption of the smelting raw materials is greatly reduced, the smelting period is shortened, and the production process is accelerated.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

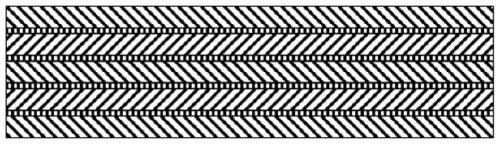

Thermoplastic composite, composite part and composite part manufacturing method

InactiveCN111086234AImprove interlayer shear strengthReduce weightCoatingsPolymer scienceInterlaminar shear

The invention relates to a thermoplastic composite, a composite part and a composite part manufacturing method. The composite comprises a plurality of stacked fiber dry cloth layers, and reinforcing sheet layers are laid between the adjacent fiber dry cloth layers, wherein the reinforcing sheet layers contain thermoplastic resin and discontinuous fibers, at least part of the discontinuous fibers extend in the thickness direction of the reinforcing sheet layers, and the end parts of at least part of the discontinuous fibers extend into one or more adjacent fiber dry cloth layers. According to the technical scheme, the composite is high in interlayer shear strength and goof in mechanical strength, and has the advantage of being light in weight.

Owner:BEIJING AUTOMOTIVE IND CORP +1

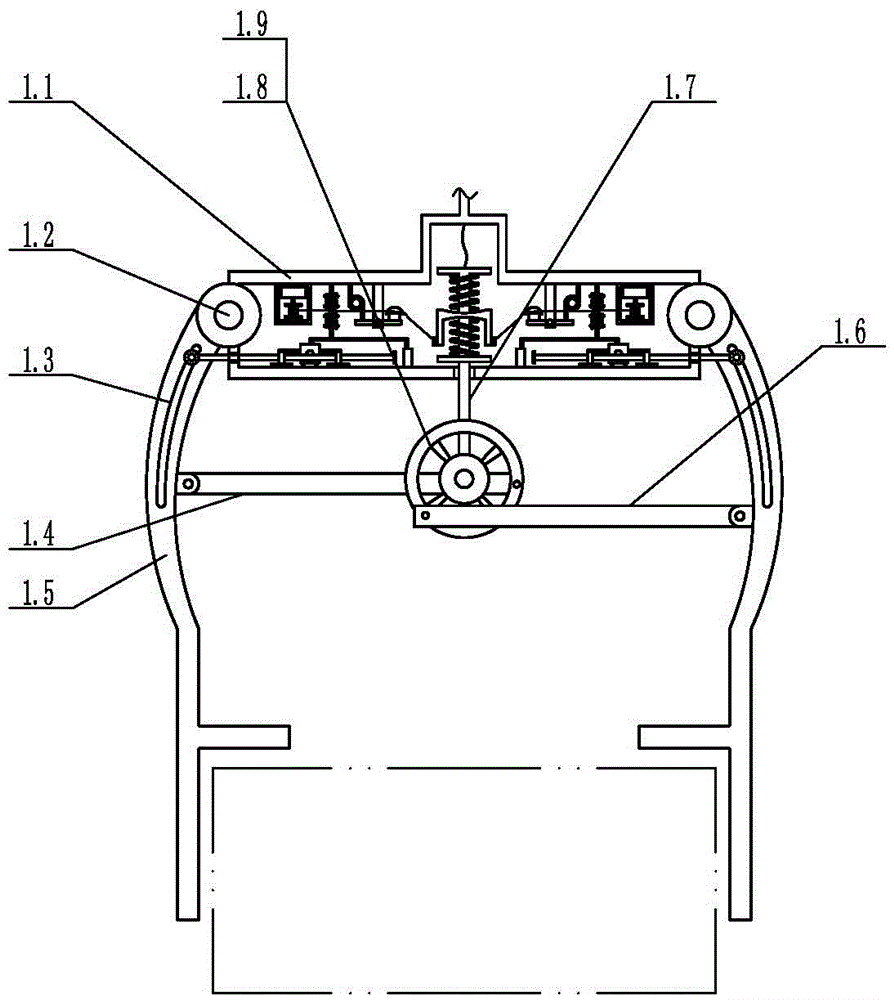

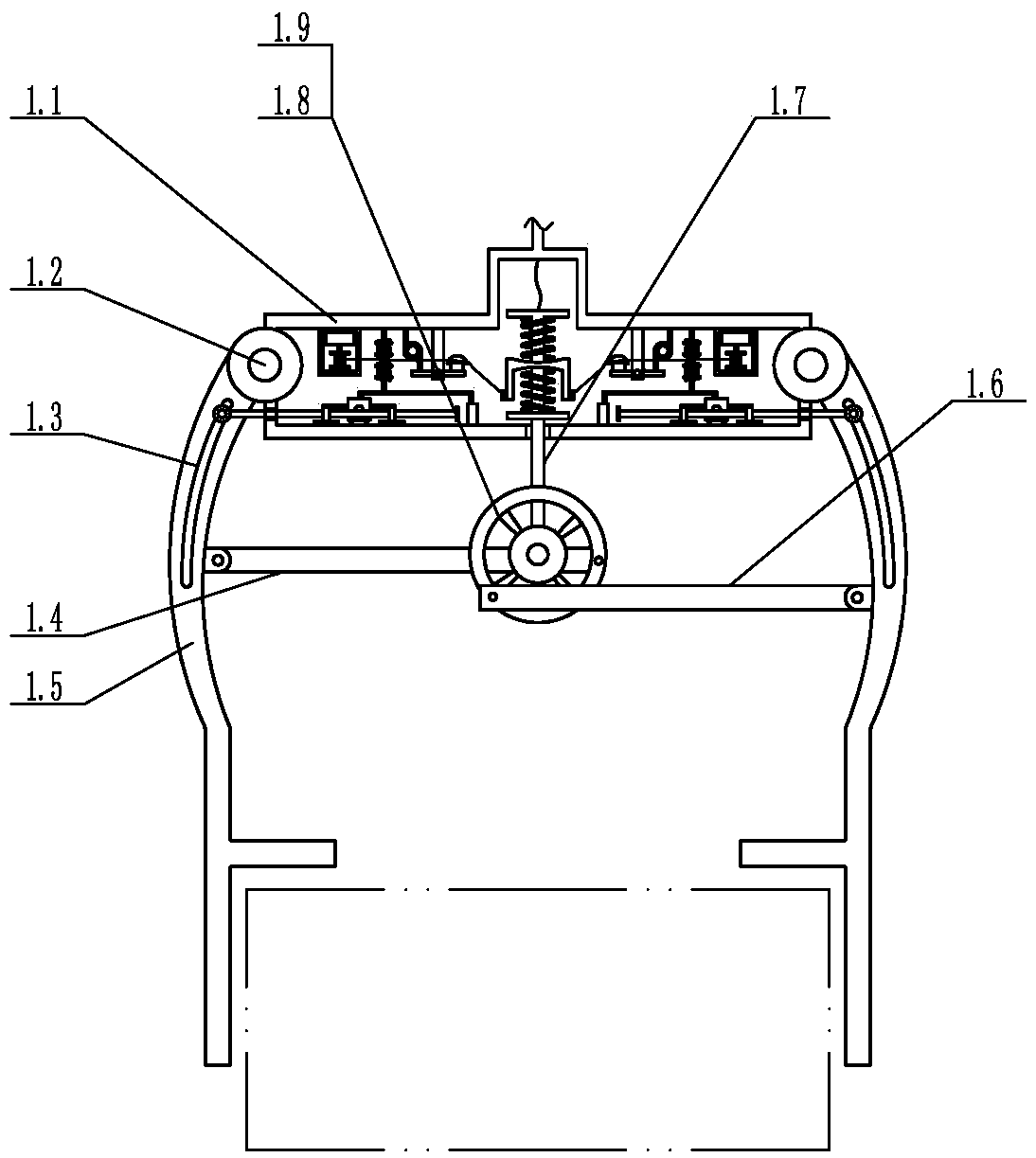

Dedicated quenching device of steel plate spring

ActiveCN106119482AIdeal organizationIdeal performanceFurnace typesHeat treatment process controlCooling curveQuenching

The invention discloses a dedicated quenching device of a steel plate spring, and belongs to the field of heat treatment quenching cooling equipment of steel plate springs. According to a whole quenching and cooling dedicated device designed by an inventor, quenching cooling temperature is controlled through a numeric terminal, the cooling curve approaching to the design technology is achieved, the ideal material structure and the ideal performance can be obtained, and the finished product quality of the steel plate spring is greatly improved. The dedicated quenching device can be suitable for small-batch multispecies steel plate spring heat treatment, the production rhythm is rapid, the device is compact in rhythm, and energy consumption losses are small.

Owner:陕西雷帕得悬架系统有限公司

Pipe layer sawing machine and method for pipe layer sawing machine to cut heads and tails

ActiveCN105478892AFast pace of productionLow costMetal sawing devicesPipe layerMechanical engineering

The invention relates to a pipe layer sawing machine, in particular relates to a pipe layer sawing machine and a method for the pipe layer sawing machine to cut heads and tails, and belongs to the field of steel pipe production. Slope boards are fixedly mounted on a front end and a rear end of the pipe layer sawing machine of the present invention, respectively; a header is placed below each slope board. The pipe layer sawing machine avoids equipment faults and saves cost as traditional head-cutting shifting device and tail-cutting shifting device are replaced with the immobilized slope boards; after head cutting and tail cutting of steel pipes in a row, the actions of the head-cutting shifting device and the tail-cutting shifting device all are outward translation, downward turning-over, upward turning-over and backward translation, and the multiple actions may affect the rhythm of sawing; however, the immobilized slope boards are utilized to take the place of the head-cutting shifting device and the tail-cutting shifting device; the cut-off steel heads directly drop down on the slope boards when the steel pipes move forwards; and the production rhythm is accelerated.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

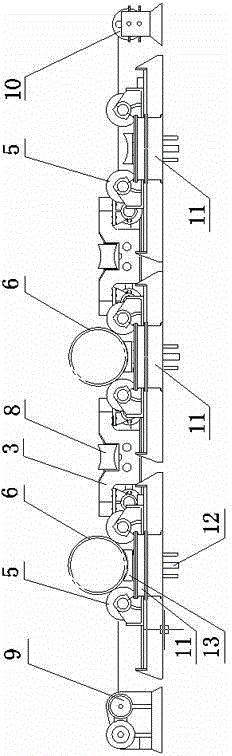

Multi-station hot mold centrifuge production system

The invention discloses a multi-station hot mold method centrifugal production system and relates to the technical field of centrifugal casting machines. Two spaying and cleaning devices are arranged on the two sides of a horizontal centrifugal casting pipe drawing device side by side, and the two ends of each spraying and cleaning device and the two ends of the horizontal centrifugal casting pipe drawing device are respectively provided with a pipe mold lifting device. Supporting wheel mechanisms are arranged in the spraying and cleaning devices. Pipe mold position changing transport carts are arranged on the central axis of the horizontal centrifugal casting pipe drawing device and the central axis of the spaying and cleaning devices. After one procedure is completed for two pipe molds on two adjacent stations, the pipe molds are placed on the pipe mold position changing transport carts through the pipe mold lifting devices, the pipe mold position changing transport carts walk to the next two adjacent stations, the pipe molds are placed on the horizontal centrifugal casting pipe drawing device and the spaying and cleaning devices through the pipe mold lifting devices, and then work of the next procedure starts. Due to the production arrangement of the three stations and the two pipe molds, the production transition smoothness is good. The multi-station hot mold method centrifugal production system has the advantages of being small in occupied land, compact in structure, reasonable in arrangement, convenient to operate and particularly suitable for producing large-aperture cast pipes.

Owner:XINXING DUCTILE IRON PIPES CO LTD

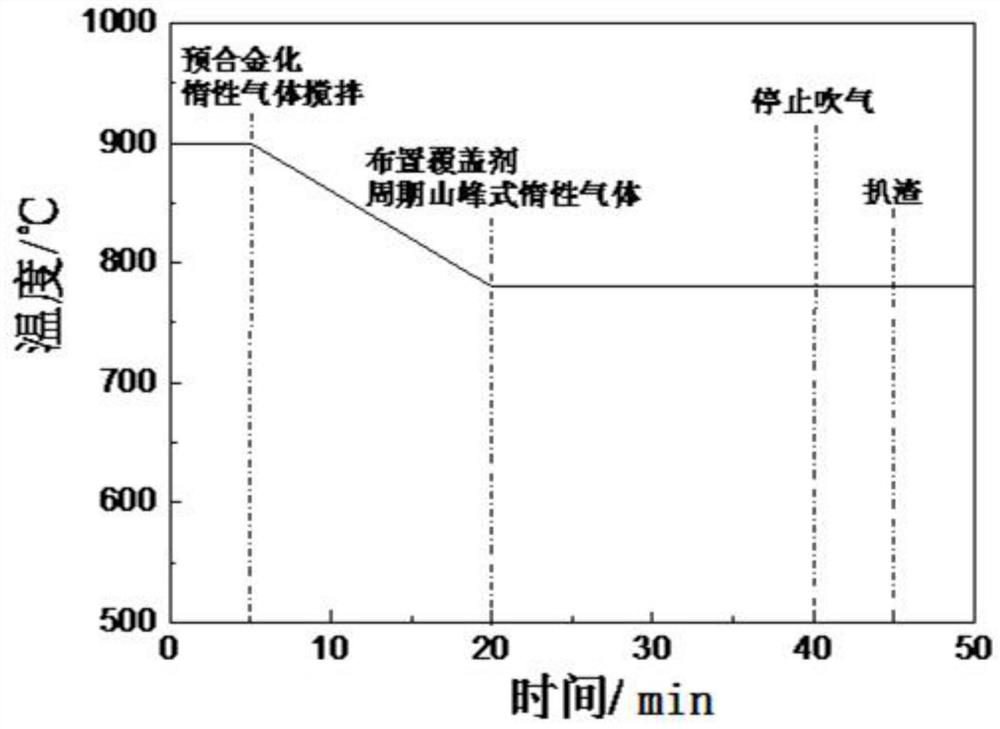

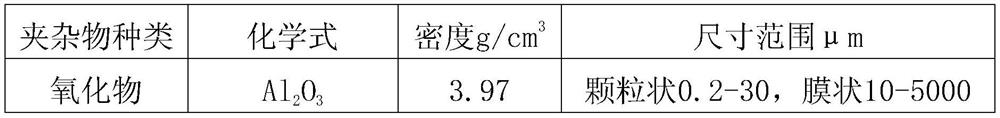

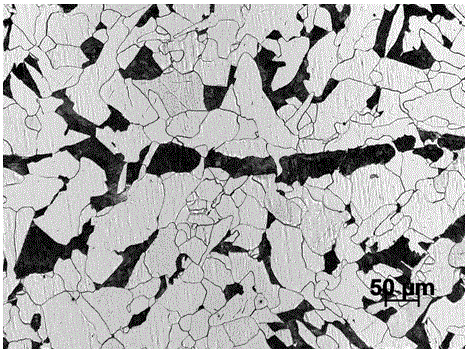

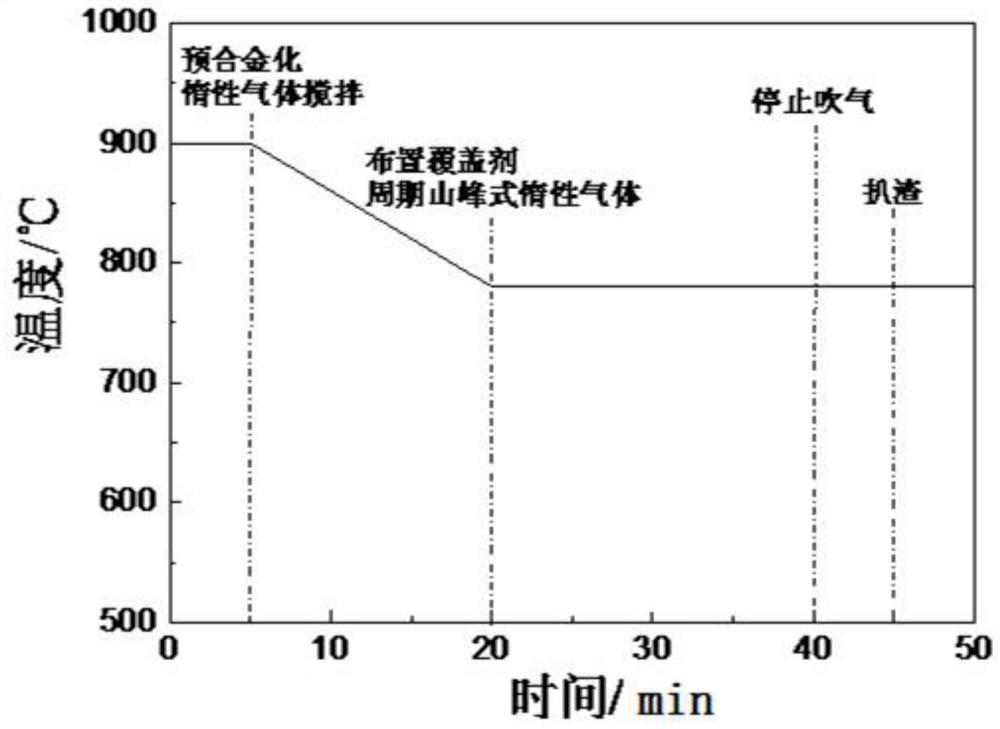

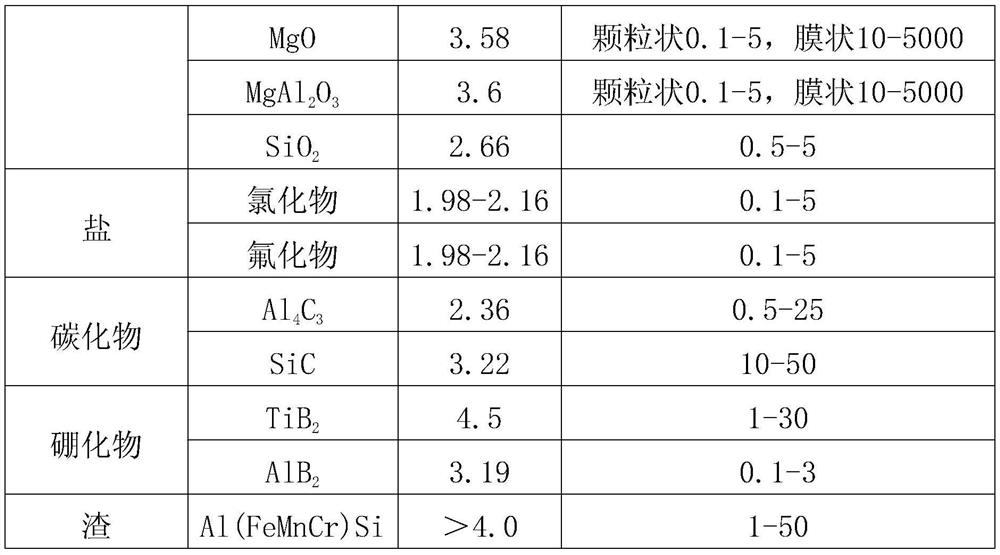

Pre-smelting process of electrolytic aluminum liquid

The invention relates to a pre-smelting process of electrolytic aluminum liquid. The pre-melting process of the electrolytic aluminum liquid comprises the following steps that (1) pre-alloying treatment is carried out, specifically, after the electrolytic aluminum liquid enters a transfer vacuum ladle, pre-alloying treatment is carried out, and after intermediate alloy is put into the transfer vacuum ladle, inert gas is blown into the transfer vacuum ladle from a micropore gas permeable brick at the bottom of the transfer vacuum ladle till the intermediate alloy is completely molten; (2) blowing purification treatment is carried out, specifically, after the intermediate alloy is completely molten, a covering agent is arranged on the surface of melt firstly, then the flow and pressure of the inert gas are adjusted, and the flow and pressure of the inert gas are controlled to be in a periodic hill peak mode of gradually increasing and then gradually decreasing; and (3) after blowing purification is finished, standing is carried out for 2 - 5 min, and then the covering agent is removed. According to the pre-smelting process of the electrolytic aluminum liquid, the electrolytic aluminum liquid is pre-smelted in the transfer vacuum ladle, components are pre-adjusted, the gas content and the slag content are reduced, and the melt cleanliness is improved so that the electrolytic aluminum liquid can be directly used for high-quality aluminum alloy production, production efficiency is high, pollution is less, and cost is low.

Owner:XINJIANG JOINWORLD CO LTD

Removing device of tail coil of cold-rolling unit and tail coil removing method thereof

The invention discloses a removing device of a tail coil of a cold-rolling unit. The removing device of the tail coil of the cold-rolling unit comprises a support. The top of the support is an inclined face. A coil pushing plate, a coil partition plate and a baffle are arranged on the top of the support. The coil pushing plate and the coil partition plate are connected with the support through a rotating shaft a and a rotating shaft b correspondingly. The rotating shaft a and the rotating shaft b are connected with a coil pushing hydraulic cylinder and a coil partition hydraulic cylinder correspondingly through hinged joints. The coil pushing hydraulic cylinder and the coil partition hydraulic cylinder are both connected with the support. According to the removing device of the tail coil of the cold-rolling unit, the tail coil can be rapidly and effectively removed without the need for a crane. A tail coil removing method comprises the following steps that firstly, the tail coil is made to be identical with the top of the support in height; secondly, the coil pushing hydraulic cylinder drives the coil pushing plate to push the tail coil to reach the coil partition plate; and thirdly, the coil partition hydraulic cylinder is started, the coil partition plate is made to be unfolded, the tail coil rolls to the baffle along the support, and a forklift lifts the tail coil and conveys the tail coil to a workshop tail coil storage area. By the adoption of the tail coil removing method, the work efficiency is improved.

Owner:MCC SFRE HEAVY IND EQUIP

Digital quenching equipment for leaf springs

ActiveCN106244778BImprove finished product qualityReduce energy lossFurnace typesHeat treatment process controlCooling curveTemperature control

The invention discloses a digital quenching device for a steel plate spring, and belongs to the field of heat treatment quenching and cooling devices for steel plate springs. The quenching and cooling temperature of the complete dedicated quenching and cooling device, designed by an applicant, is controlled by a digital terminal to obtain a cooling curve approaching to the cooling curve in the design technology, an ideal material structure is obtained, high performance is achieved, and the finished product quality of the steel plate spring is improved greatly. The digital quenching device is suitable for heat treatment of small-batch and multiple-variety steel plate springs, the production speed is high, the device structure is compact, and energy loss is low. An intelligent temperature control system is adopted to strictly control the heating quality, and the temperature uniformity of a quenching bath and the surface decarburization control index of the product are remarkably improved.

Owner:SHANDONG LEOPARD AUTOMOTIVE HLDG

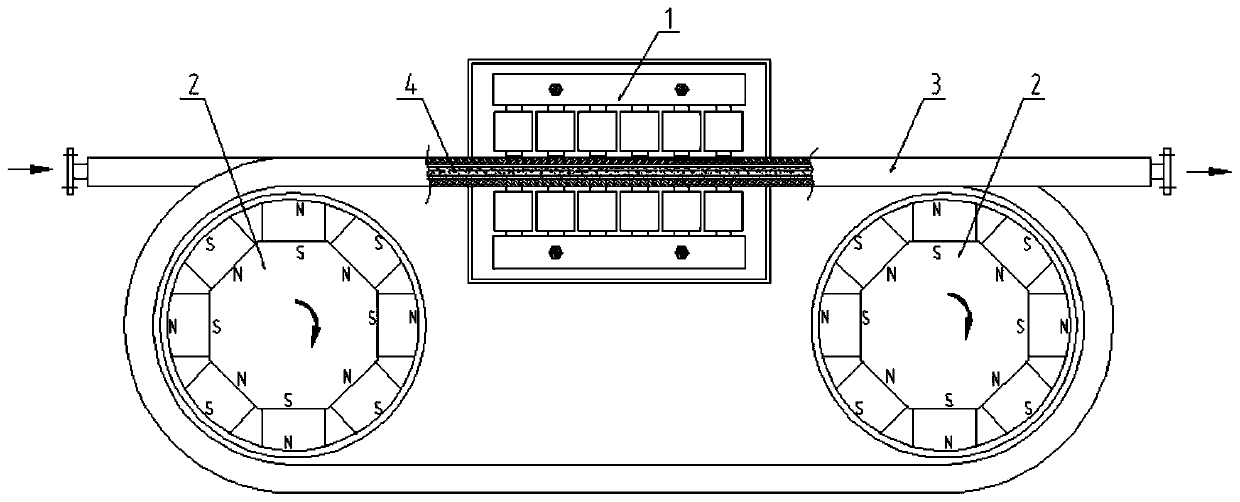

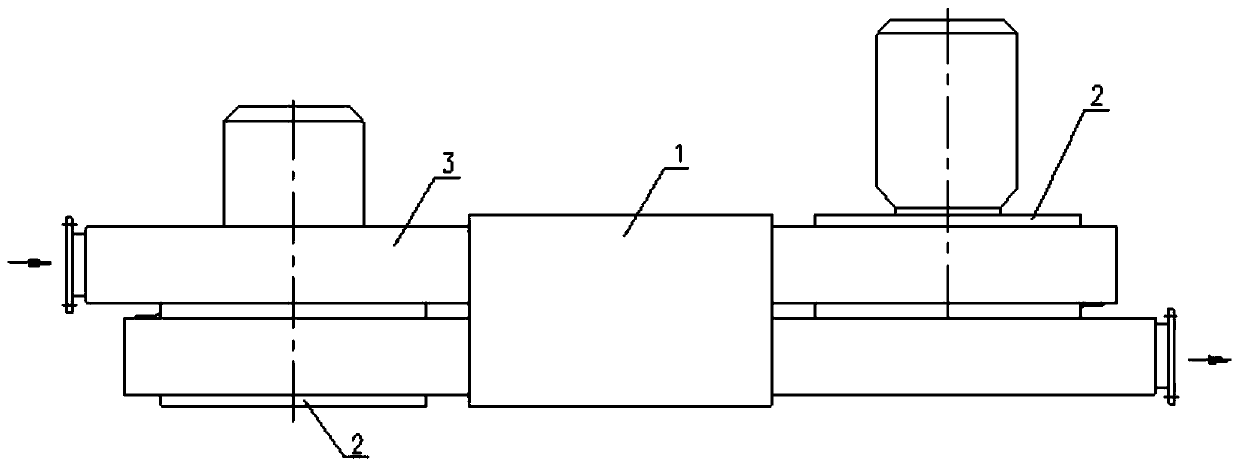

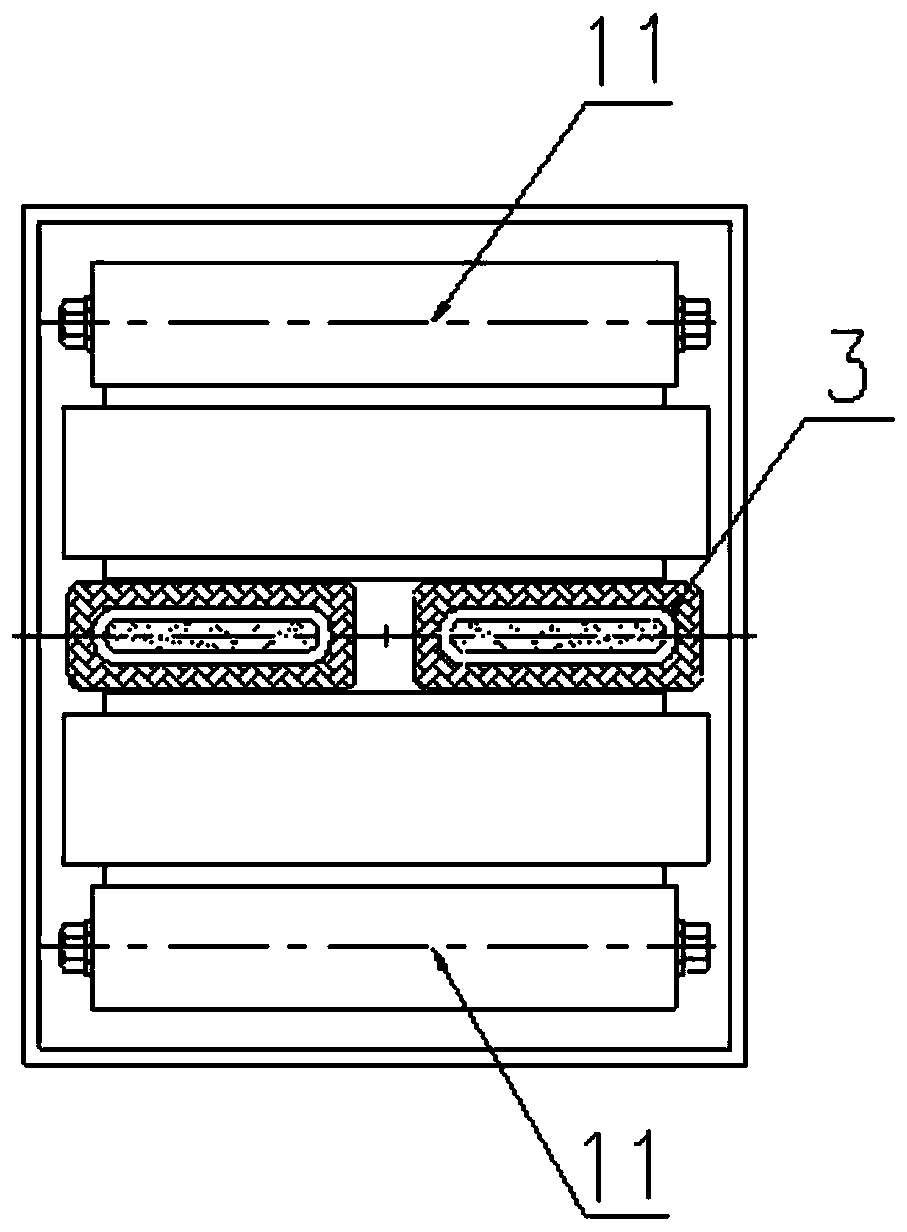

A liquid metal magnetic conveying device

ActiveCN106961205BIncrease delivery speedImprove delivery capacityDynamo-electric machinesMagnetic tension forceThermal insulation

The invention discloses liquid metal magnetic force transmission equipment. The liquid metal magnetic force transmission equipment comprises a magnetic force transmission pump unit and a transmission pump groove. The magnetic force transmission pump unit comprises at least one electromagnetic pump and at least one permanent magnet pump. The electromagnetic pump is disposed on the transmission pump groove, and the permanent magnet pump is disposed on the transmission pump groove. The liquid metal magnetic force transmission equipment is advantageous in that by adopting multi-stage push, the transmission speed of the liquid metal is accelerated, and a transmission capability is improved, and the liquid metal magnetic force transmission equipment is adapted to a fast production rhythm; the electromagnetic transmission of the liquid metal having a large proportion and low conductivity is realized; the whole transmission equipment is more energy-saving by adopting the permanent magnet pump; strong thermal insulation is realized by small space via nano-meter thermal insulation materials, and therefore the operating air gap of the electromagnetic pump and the operating air gap of the permanent magnet pump are reduced, and the working efficiency of the electromagnetic pump and the working efficiency of the permanent magnet pump are improved.

Owner:HUNAN KEMEIDA ELECTRIC +1

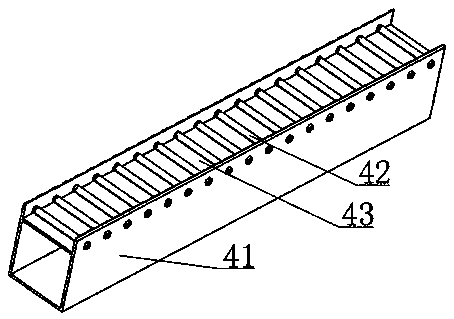

Scrimber double-station forming device

ActiveCN107443498ASimple structureImprove reliabilityPlywood pressesVeneer pressesEngineeringMechanical engineering

The invention relates to a scrimber double-station forming device. The scrimber double-station forming device comprises pressure heads, two die clamping blocks, die separating blocks, dies and a workbench. The two die clamping blocks are installed on the workbench, the die separating blocks are installed between the two die clamping blocks, the dies are installed between the die clamping blocks and the die separating blocks and located on the workbench, and the pressure heads are arranged at the upper ends of the positions between the die clamping blocks and the die separating blocks and move up and down between the die clamping blocks and the die separating blocks. The scrimber double-station forming device is installed on a hydraulic machine, and the pressure heads are fixed to the lower end of a slide block of the hydraulic machine. The scrimber double-station forming device has the advantages that the potency of a super-tonnage main machine of the frame-type hydraulic machine is sufficiently realized, one device is provided with the two dies, and thus, the forming efficiency is multiplied; a one-station movable die clamping block, a one-station clamping wedge and a driving cylinder are omitted; and the main machine structure is greatly simplified, the reliability is higher, and the manufacturing cost is lower.

Owner:NANTONG METALFORMING EQUIP +2

Reconstituted material double station forming device

ActiveCN107443498BSimple structureImprove reliabilityPlywood pressesVeneer pressesEngineeringMachine

The invention relates to a scrimber double-station forming device. The scrimber double-station forming device comprises pressure heads, two die clamping blocks, die separating blocks, dies and a workbench. The two die clamping blocks are installed on the workbench, the die separating blocks are installed between the two die clamping blocks, the dies are installed between the die clamping blocks and the die separating blocks and located on the workbench, and the pressure heads are arranged at the upper ends of the positions between the die clamping blocks and the die separating blocks and move up and down between the die clamping blocks and the die separating blocks. The scrimber double-station forming device is installed on a hydraulic machine, and the pressure heads are fixed to the lower end of a slide block of the hydraulic machine. The scrimber double-station forming device has the advantages that the potency of a super-tonnage main machine of the frame-type hydraulic machine is sufficiently realized, one device is provided with the two dies, and thus, the forming efficiency is multiplied; a one-station movable die clamping block, a one-station clamping wedge and a driving cylinder are omitted; and the main machine structure is greatly simplified, the reliability is higher, and the manufacturing cost is lower.

Owner:NANTONG METALFORMING EQUIP +2

Tighten the hoop device after the drum is covered

ActiveCN111284739BAchieving a lock sealFast pace of productionPackagingStructural engineeringMechanical equipment

The invention discloses a device for tightening the barrel hoop after the drum is covered, which is used for locking the barrel hoop of the drum. The device for tightening the barrel hoop after the drum is covered includes: a machine base, a barrel support assembly and a barrel hoop clamping assembly. hoop, the bucket support assembly includes a bracket arranged on the base and correspondingly located below the hoop space, the bracket has a movable stroke up and down, and is used to cover the drum with the lid The part to be locked is pushed upwards to be placed in the hoop space, and is located in the hoop ring of the hoop, and the hoop clamping assembly includes a clamping drive assembly arranged on the machine base , which is used to tighten the bucket hoop in a loose state, and make the buckle and buckle of the bucket hoop buckle and lock. Improve production efficiency by replacing labor with mechanical equipment.

Owner:WUHAN POLYTECHNIC UNIVERSITY

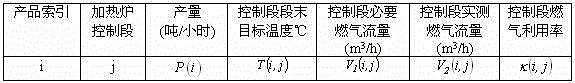

Model Control Method of Heating Furnace Temperature

ActiveCN104049649BFast pace of productionTemperatue controlAdaptive controlFurnace temperatureTemperature control

The invention relates to the field of metallurgical production, in particular to a method for controlling the temperature of a heating furnace. A model control method for heating furnace temperature. Firstly, based on the actual production data, a statistical sample of gas under the stable production rhythm of each single product in the heating furnace is established; then a linear distribution curve of furnace temperature and a product temperature tracking model are established and combined parameters and product types in the furnace to obtain the initial set value of the furnace temperature in a certain control section; then calculate the gas flow standard value and gas flow calculation value of the control section, and compare it with the gas flow measured value of the control section to obtain the control The temperature correction adjustment factor of the section, and finally the final set value of the furnace temperature of the control section is calculated by using the temperature correction adjustment factor. The invention can effectively alleviate problems such as abnormal furnace temperature measurement accuracy, abnormal product heating quality, and energy waste caused by changes in the heat load of the heating furnace, and is a concrete embodiment of refined control of industrial production and environmental management.

Owner:BAOSHAN IRON & STEEL CO LTD

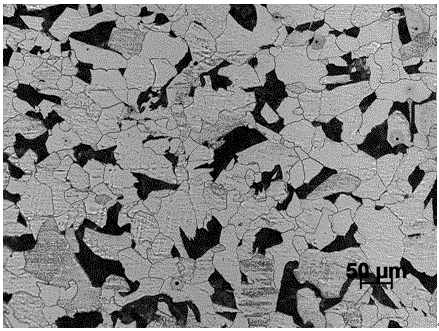

A kind of 160mm thick q235c low compression bit thick steel plate and its preparation method

ActiveCN104451375BImprove performanceIncreasing the thicknessProcess efficiency improvementHeating timeHeating temperature

The invention discloses a Q235C super-thick steel plate having a thickness of 160mm and low compression ratio and a preparation method of the steel plate. The Q235C super-thick steel plate comprises the following components in percentage by weight: 0.10-0.17% of C, 0.10-0.35% of Si, 0.80-1.40% of Mn, less than or equal to 0.018% of P, less than or equal to 0.0050% of S, 0.020-0.050% of Alt, 0.28-0.34% of Ceq and the balance of Fe and unavoidable impurities. During rolling, the heating temperature of a continuous casting billet having a thickness of 320mm is 1140-1240 DEG C, the heating time of the billet is 300-400 minutes, the temperature of a soaking zone is 1130-1230 DEG C, the soaking time is at least 70 minutes, and the tapping temperature is 1130-1230 DEG C; a one-stage controlled rolling is adopted, greatest reduction is adopted in each pass, the finishing rolling temperature is 800-900 DEG C, and a swing-type reciprocating water-cooled process is used after the rolling. By the preparation method, on the premise that the compression ratio is only 2: 1, a carbon structural steel having a thickness of 160mm and the yield strength being greater than 195MPa can be obtained through rolling, the production pace is quick, the strong applicability is achieved and the Q235C super-thick steel plate has the advantages of excellent lamellar tearing resistance, no need of heat treatment and low production cost.

Owner:NANJING IRON & STEEL CO LTD

A pre-smelting process for electrolytic aluminum liquid

The invention relates to a pre-smelting process for electrolytic aluminum liquid. A pre-smelting process for electrolytic aluminum liquid, comprising the following steps: (1) pre-alloying treatment: after the electrolytic aluminum liquid enters the transfer vacuum bag, it is pre-alloyed Blow in inert gas until the master alloy is completely melted; (2) Gas blowing purification treatment: After the master alloy is completely melted, first place a covering agent on the surface of the melt, and then adjust the flow and pressure of the inert gas. Periodic mountain peak style that gradually increases and then gradually decreases; (3) After blowing and purifying, let it stand for 2-5 minutes, and remove the covering agent. The present invention pre-smelts the electrolytic aluminum liquid in the transfer vacuum bag, pre-adjusts the composition, reduces the amount of gas and slag, and improves the cleanliness of the melt, so that it can be directly used in the production of high-quality aluminum alloys, with high production efficiency and low pollution Small and low cost.

Owner:石河子众和新材料有限公司

Displayer back plate mounting mechanism

PendingCN113878321AIncrease profitHigh degree of automationConveyorsMetal working apparatusDisplay deviceMechanical engineering

The invention discloses a displayer back plate mounting mechanism. The mechanism comprises a back plate feeding mechanism, a displayer feeding mechanism, a material distributing mechanism, an overturning mechanism, a pressing mechanism and an aluminum profile support, and belongs to the technical field of machining engineering. The back plate feeding mechanism is installed above the aluminum profile support through T-shaped bolts, the material distributing mechanism is located at the tail of the back plate feeding mechanism, the overturning mechanism is located at the right side of the material distributing mechanism, and the pressing mechanism is located at the right side of the material distributing mechanism and above the displayer feeding mechanism. The displayer feeding mechanism is fixed on the aluminum profile support through a T-shaped bolt. The displayer back plate mounting mechanism is suitable for displayers of various sizes and specifications, and has the advantages of low equipment cost, high production efficiency, a wide application range, a high automation level and the like.

Owner:四川极速智能科技有限公司

Special Quenching Equipment for Leaf Springs

ActiveCN106119482BImprove finished product qualityReduce energy lossFurnace typesHeat treatment process controlCooling curveQuenching

The invention discloses a dedicated quenching device of a steel plate spring, and belongs to the field of heat treatment quenching cooling equipment of steel plate springs. According to a whole quenching and cooling dedicated device designed by an inventor, quenching cooling temperature is controlled through a numeric terminal, the cooling curve approaching to the design technology is achieved, the ideal material structure and the ideal performance can be obtained, and the finished product quality of the steel plate spring is greatly improved. The dedicated quenching device can be suitable for small-batch multispecies steel plate spring heat treatment, the production rhythm is rapid, the device is compact in rhythm, and energy consumption losses are small.

Owner:陕西雷帕得悬架系统有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com