Scrimber double-station forming device

A double-station technology for heavy wood, applied in double-station forming devices for heavy wood and forming devices for manufacturing heavy wood, can solve the problem of insufficient mass production capacity of heavy wood, raise the investment threshold of the heavy wood industry, and fail to take advantage of scale and other issues, to achieve obvious energy-saving effects, simplified host structure, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

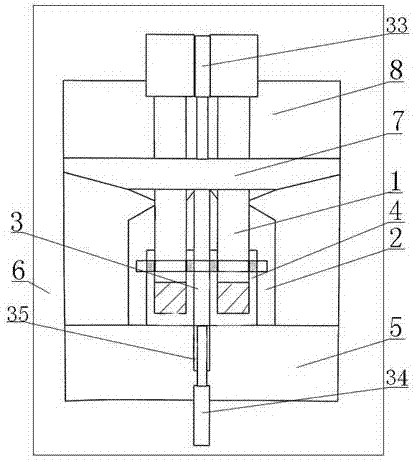

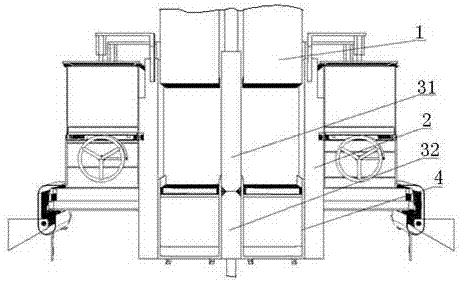

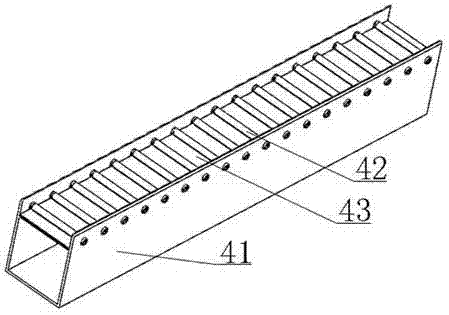

[0019] Refer to attached Figure 1-6 , a double-station forming device for recombined wood, which includes a pressure head 1, a clamping module 2, a partition module 3, a mold 4, and a workbench 5. Two clamping modules 2 are installed on the workbench 5, and a The partition module 3, the mold 4 is installed between the clamp module 2 and the partition module 3 and the mold 4 is located on the workbench 5, the upper end between the clamp module 2 and the partition module 3 is designed with a pressure head 1, and the pressure head 1 is between the clamp module 2 and the partition module 3. The partition modules 3 move up and down; the double-station forming device for heavy wood is installed on the hydraulic press 6, and the pressure head 1 is fixed at the lower end of the slider 7 of the hydraulic press.

[0020] The width of the pressure head 1 is the same as the inner cavity width of the mould.

[0021] A plurality of pin holes 21 are formed at the lower middle of the clamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com