Automatic four-station three-process feeding mechanism

An automatic feeding and process technology, applied in the direction of manufacturing tools, metal processing equipment, feeding devices, etc., can solve the problems of scattered arrangement of three rolling machines, extended production line layout, and insufficient compactness, so as to save work auxiliary time, The effect of fast production rhythm and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

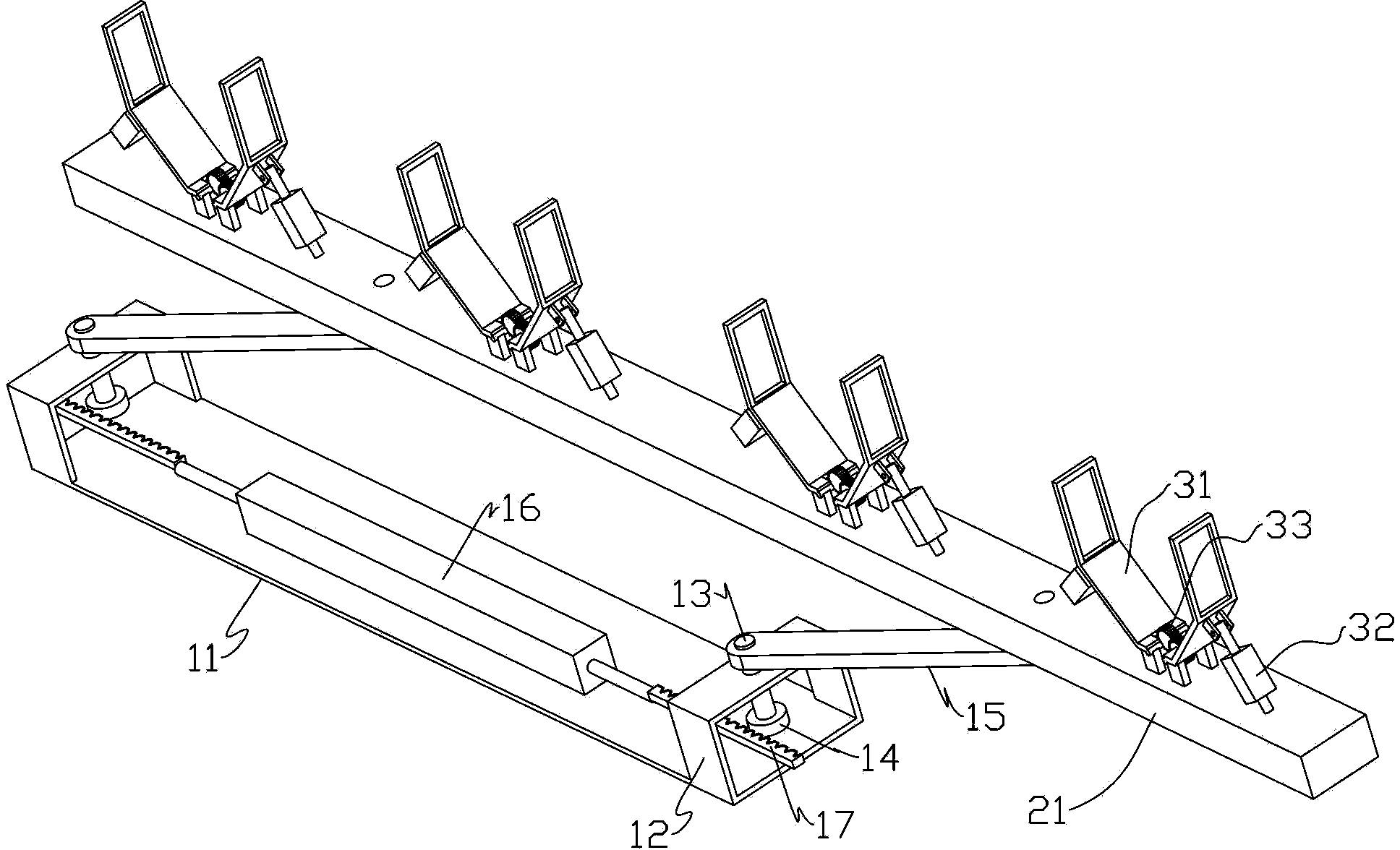

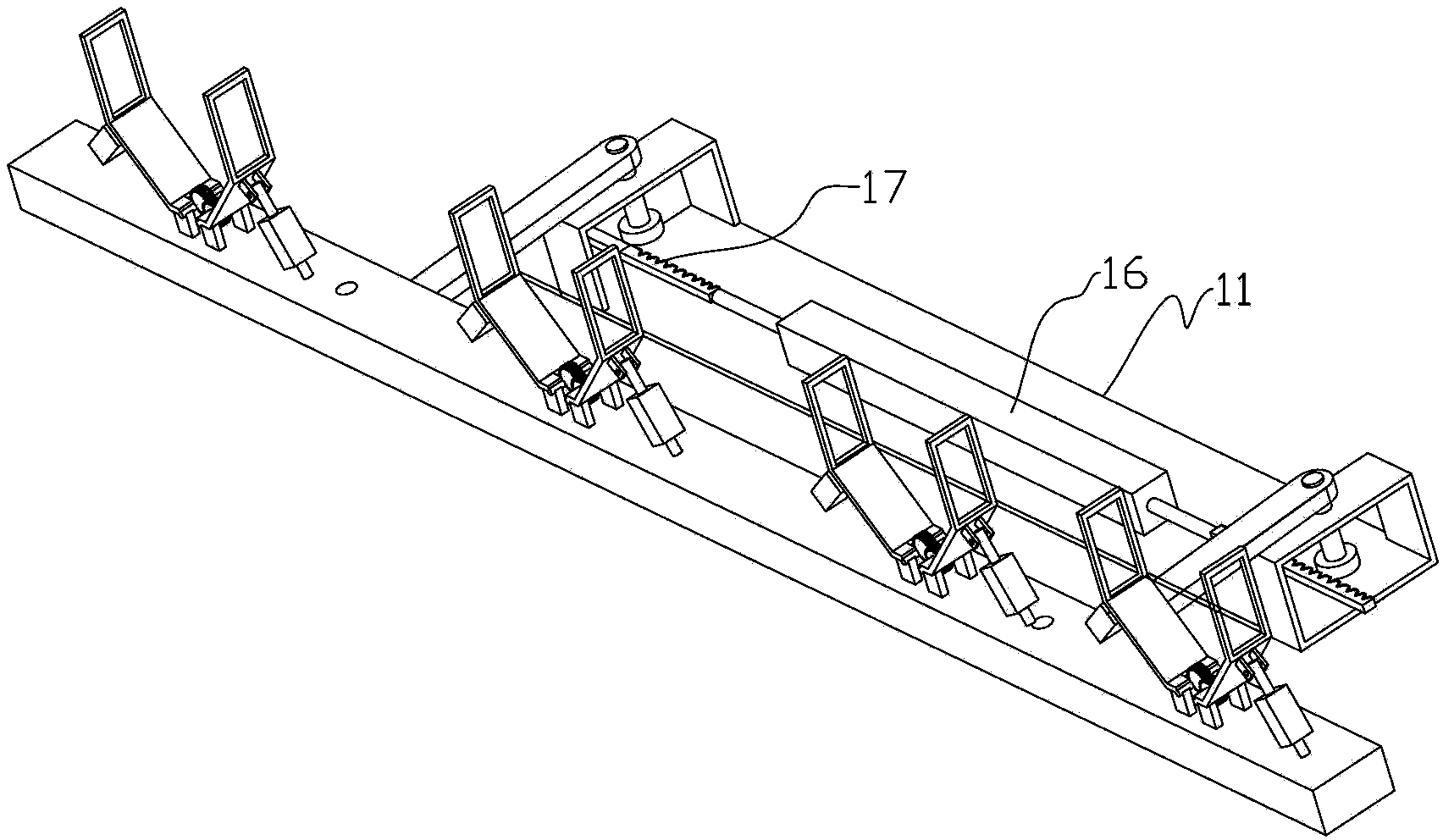

[0021] Embodiment one, such as Figure 1 to Figure 4 As shown, a four-position three-process automatic feeding mechanism includes a base, a feeding frame beam, a connecting rod and a clamping device. Wherein the base 11 is a mounting platform for other parts, and the bottom is provided with wheels. The wheels preferably have universal wheels with a locking function, so that they can be moved easily, and can be locked to fix them in one position. These are prior art means, no more details.

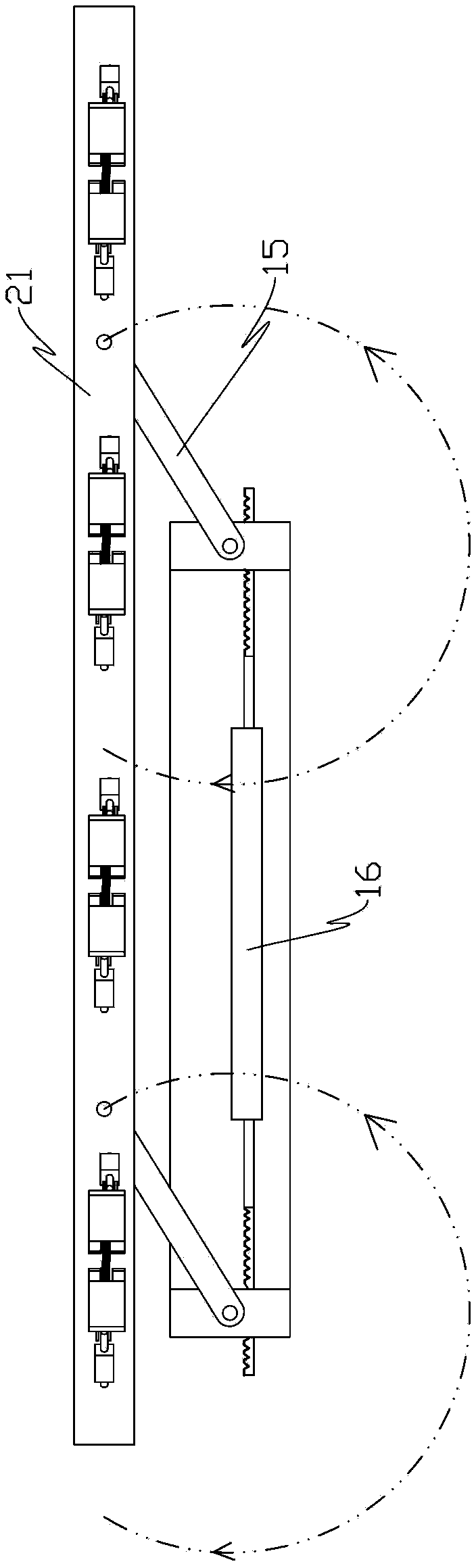

[0022] First, there are two horizontal plates and two mounting blocks 12 in the base 11, and the two mounting blocks are located at the front and rear ends of the base, and each mounting block 12 is respectively provided with a vertical shaft hole, and each shaft hole A rotating shaft 13 is installed in the middle, and in order to improve the lubricating performance, a bearing bush is installed between the two. The upper and lower ends of the rotating shaft are respectively fixed with a g...

Embodiment 2

[0029] like Figure 5 As shown, the difference from Embodiment 1 is that a rocker arm 41 and a connecting rod are respectively fixed at the upper and lower ends of the rotating shaft, and the other end of the connecting rod is pivotally connected to the beam of the loading rack, the beam of the loading rack, the base and two The pivot joints between the connecting rods form a parallelogram linkage mechanism, and a power source is installed between the rocker arm and the base, and the power source driving the deformation of the parallelogram linkage mechanism is a two-way oil cylinder or an air cylinder; the force is realized through the rocker arm. transmission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com