Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Stable production rhythm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

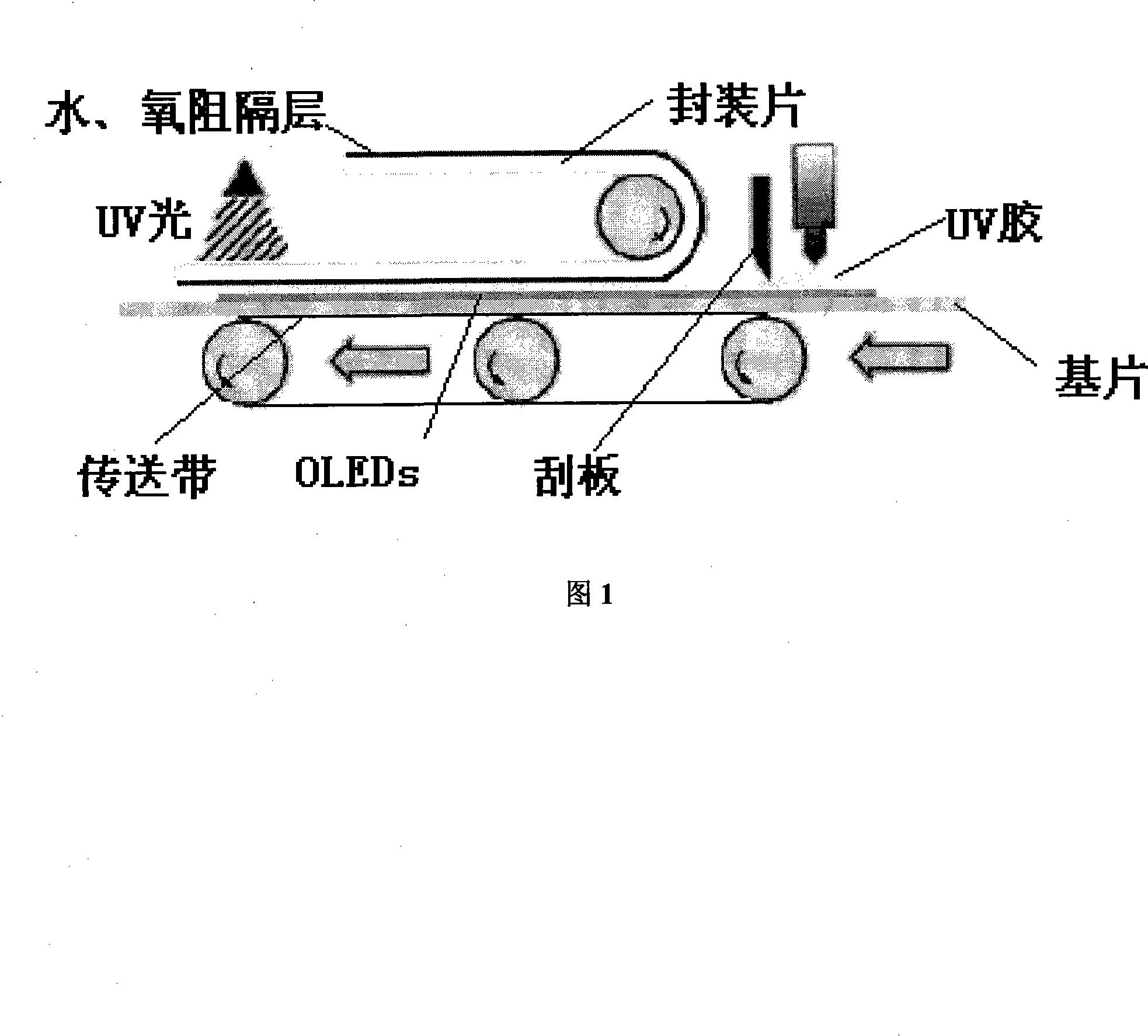

An organic EL part and its making method

InactiveCN101080121AContinuous production rhythmAvoid deformationElectrical apparatusElectroluminescent light sourcesDistortionOrganic electroluminescence

This invention relates to a package structure of an organic electroluminescent device and its manufacturing method, in which, the organic electroluminescent device includes a package structure with a flat packaged cover made of glass, polymer, metal or alloy material and its composite film material, and the flat package cover can be prepared by a roller extrusion method. The package structure is especially suitable for large size or soft OLED, since no gas space exists during the packaging process, the device can be made thinner and distortion of the cover can be avoided.

Owner:TSINGHUA UNIV +2

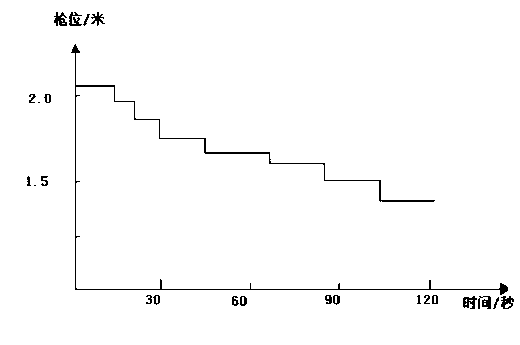

Operation method of lifting lance in the midway of converter steelmaking under dry dedusting condition

InactiveCN103074463APrevent explosion ventingAvoid explosive limitManufacturing convertersSteelmakingFerrosilicon

The invention relates to an operation method of lifting a lance in the midway of converter steelmaking under a dry dedusting condition, and belongs to the technical field of converter steelmaking operation process. The technical scheme is as follows: 1, lifting the lance to completely dump dregs; 2, standing for three minutes; 3, adding 500 jin of silicon iron; 4, swinging a converter forwards and backwards; 5, flushing nitrogen for 60 seconds; 6, descending the lance to observe components; and 7, enabling the oxygen lance to follow slowly. Therefore, the operation method provided by the invention is also called a seven-step operation method of lifting the lance in the midway of converter steelmaking under the dry dedusting condition. The operation method has the beneficial effects that the explosion limit of the mixed gas of CO and O2 is effectively kept away, so that the explosion venting is avoided. Practice shows that the implementation of the seven-step processing method of lifting the lance in the midway achieves zero explosion venting, so that the production rhythm of the converter is stabilized to the greatest extent, the capacity of the converter is increased, and the service life of an electrostatic precipitator is prolonged.

Owner:宣化钢铁集团有限责任公司 +1

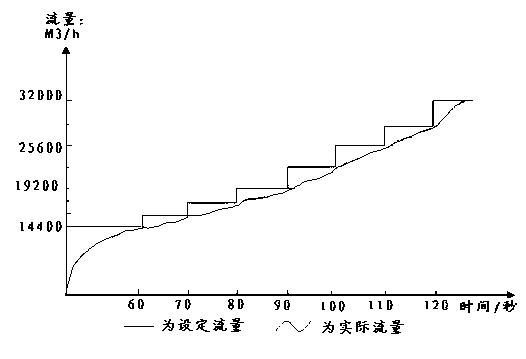

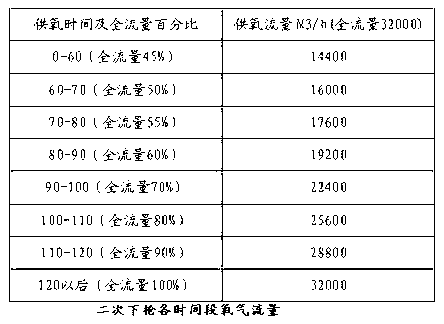

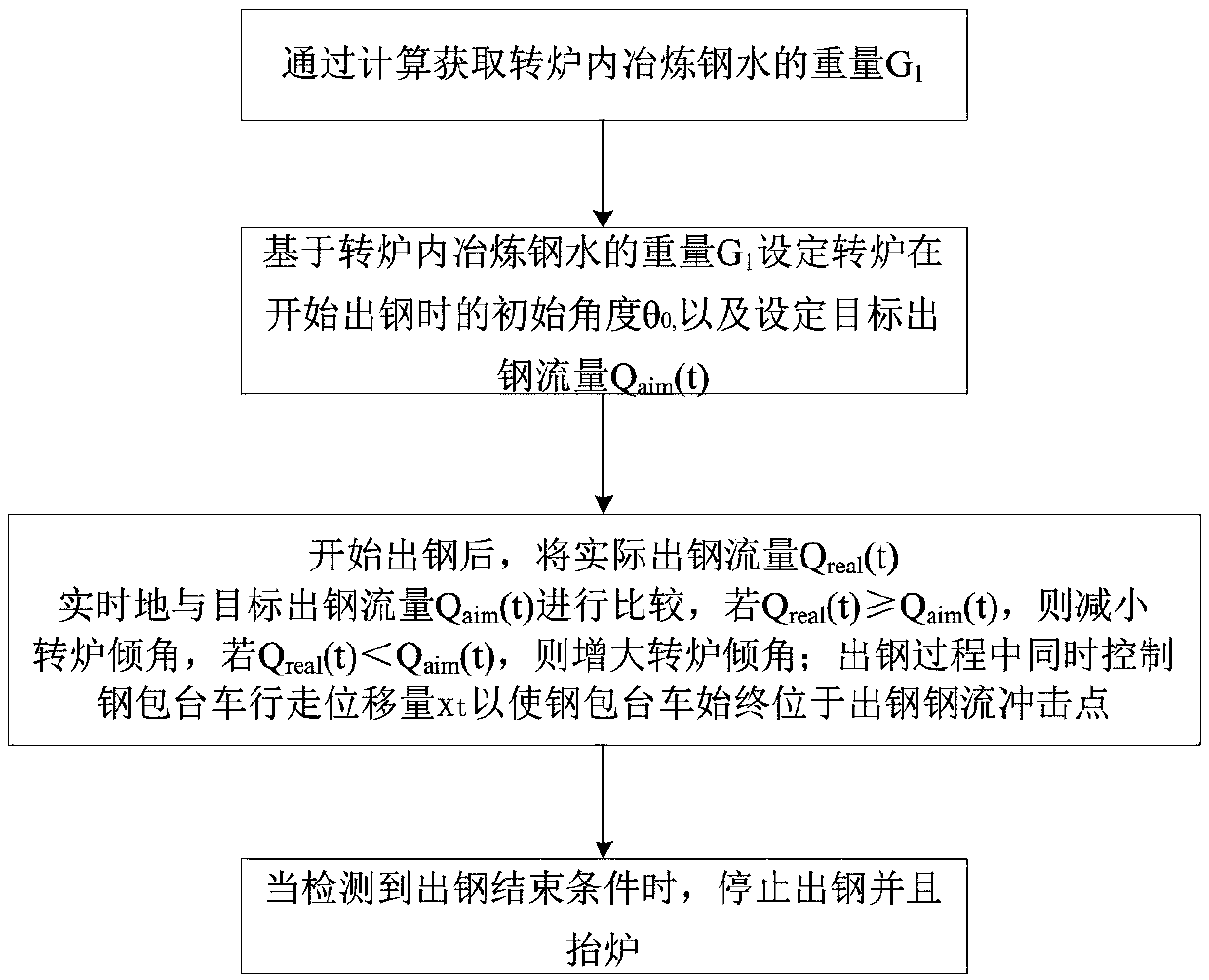

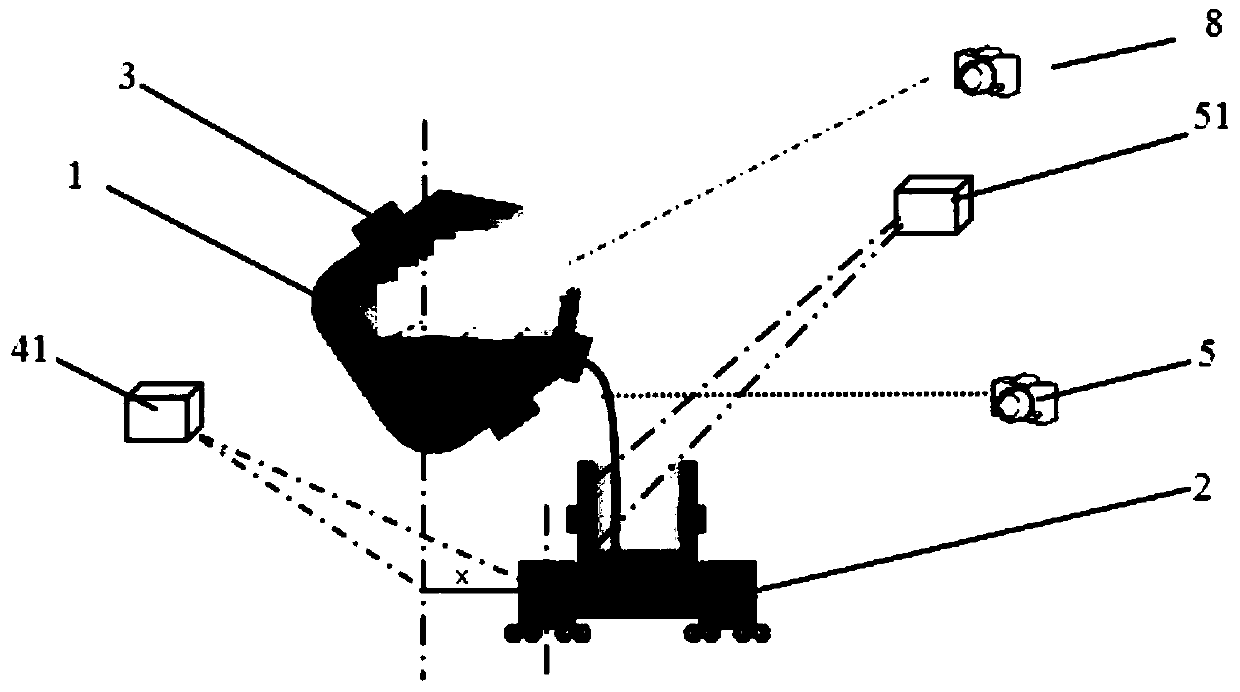

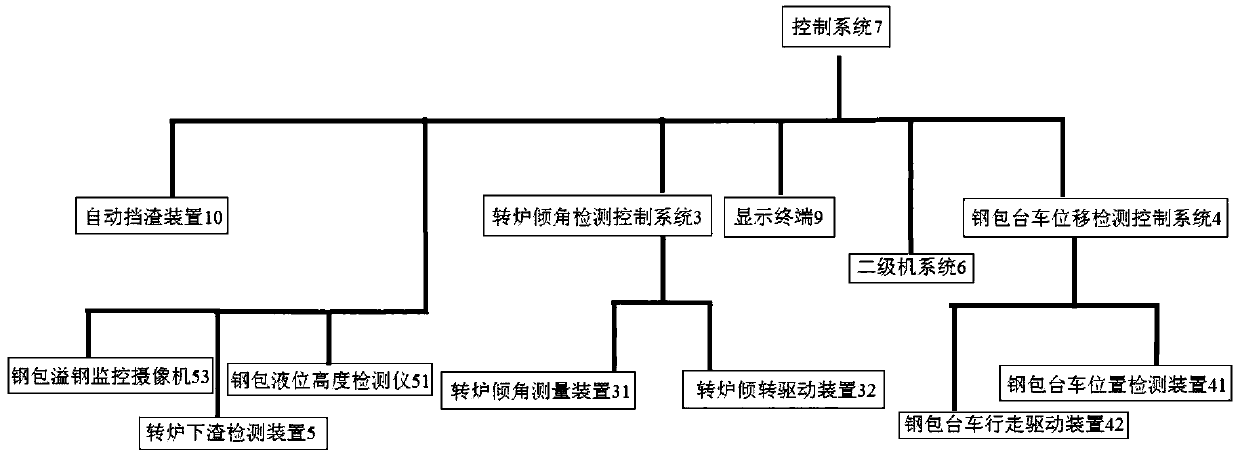

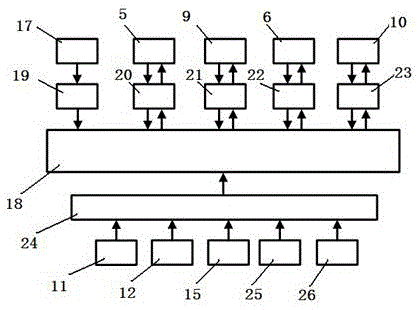

Tapping flow control method and system for full-automatic converter tapping

InactiveCN110616289ALess investmentReduce maintenance and repair costsManufacturing convertersSpecial data processing applicationsControl systemMolten steel

The invention discloses a tapping flow control method for full-automatic converter tapping. The method comprises the following steps that (1) the weight G 1 of molten steel in a converter is obtainedthrough calculation; (2) the initial angle Theta 0 of the converter when tapping starts is set based on the weight of the molten steel in the converter, and target tapping flow Q<aim> (t) is set; (3)when the tapping starts, actual tapping flow Q<real> (t) is compared with the target tapping flow the Q<aim> (t) in real time, if the Q<real> (t) is larger than or equal to the Q<aim> (t), the inclination of the converter is reduced, and if the Q<real> (t) is smaller than the Q<aim> (t), the inclination angle of the converter is increased; and in the tapping process, the walking displacement amount xt of a ladle trolley is controlled at the same time, so that the ladle trolley is always located at an impact point of tapping steel flow; and (4) when the condition that the tapping is finished isdetected, the is stopped and the converter is lifted. In addition, the invention further discloses a tapping flow control system for full-automatic converter tapping.

Owner:BAOSHAN IRON & STEEL CO LTD

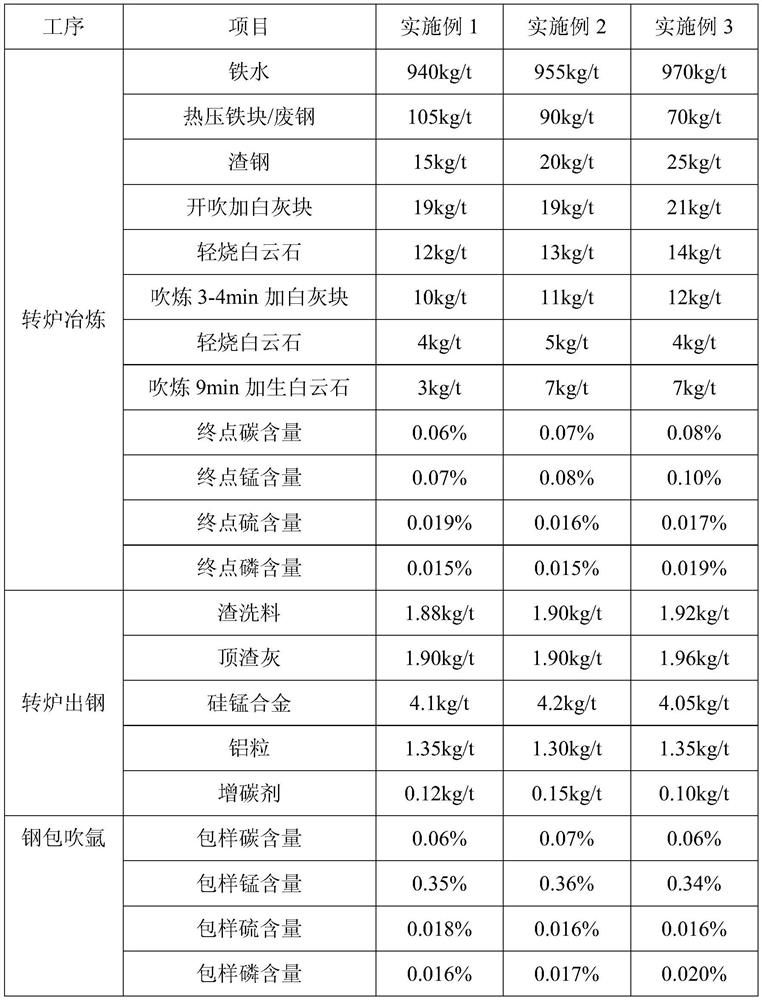

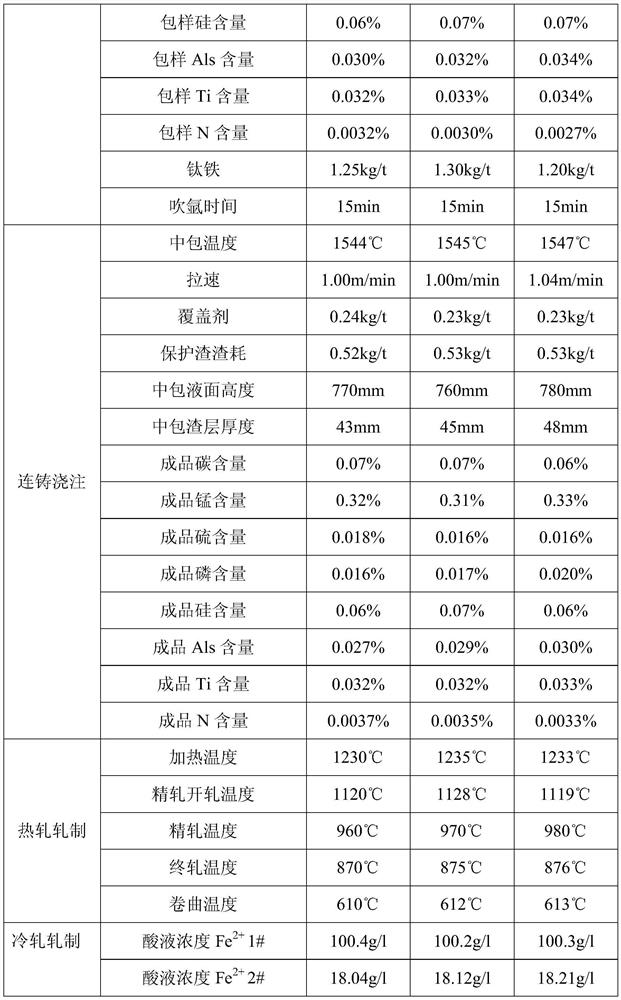

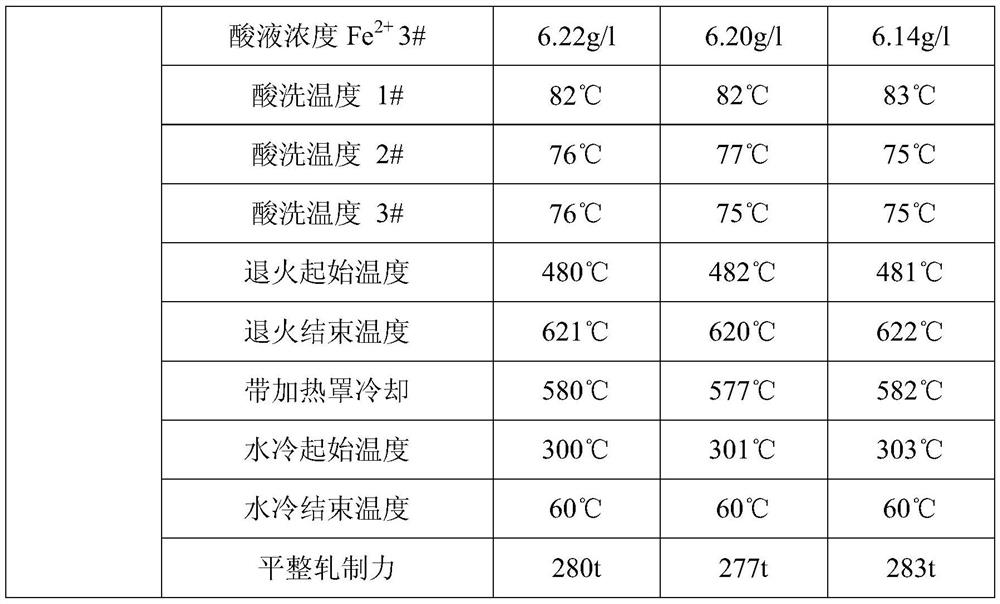

Production process of phosphorated high-strength gapless atomic steel

ActiveCN106148821AReduce temperature dropSteady control of carbon contentManufacturing convertersProcess MeasuresContinuous casting

The invention discloses a production process of phosphorated high-strength gapless atomic steel. The production process of the phosphorated high-strength gapless atomic steel comprises the working procedures of molten iron desulphurization, converter smelting, RH vacuum treatment and conventional slab continuous casting. According to a method, a continuously cast billet which meets a requirement and has no any defects is produced by adopting phosphorated high-strength gapless atomic steel which is produced by a converter of which the nominal capacity is below 110t and through process measures of the control of the non-turning-down direct steel tapping of the converter, the reduction of the temperature drop from the converter to a steel ladle, the quick, accurate and stable control of carbon content by adopting a vacuum mechanical pump, the stabilization of a production rhythm, a constant pulling rate and the like; a high-quality hot-rolled coiled plate is produced in a hot rolling manner; and a high-quality continuously annealed product is finally produced through cold rolling. According to the method, the continuously cast billet which meets the requirement and has no the any defects is produced through controlling the process parameters of each working produce; the high-quality hot-rolled coiled plate is produced in the hot rolling manner; and the high-quality continuously annealed product is finally produced through the cold rolling.

Owner:TANGSHAN IRON & STEEL GROUP

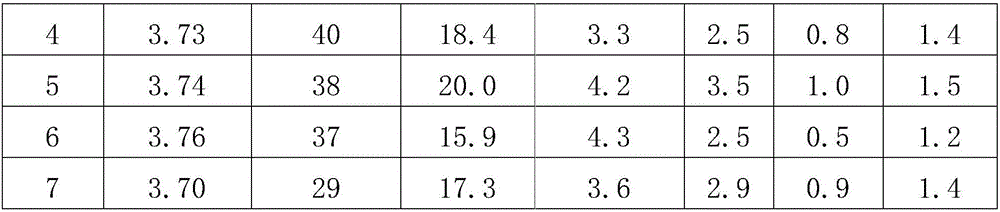

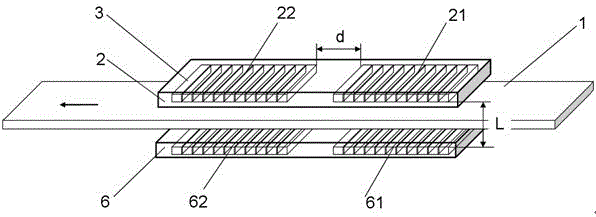

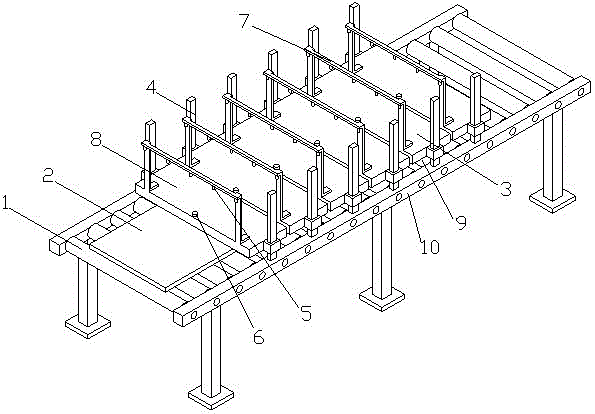

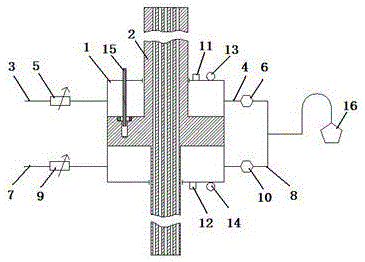

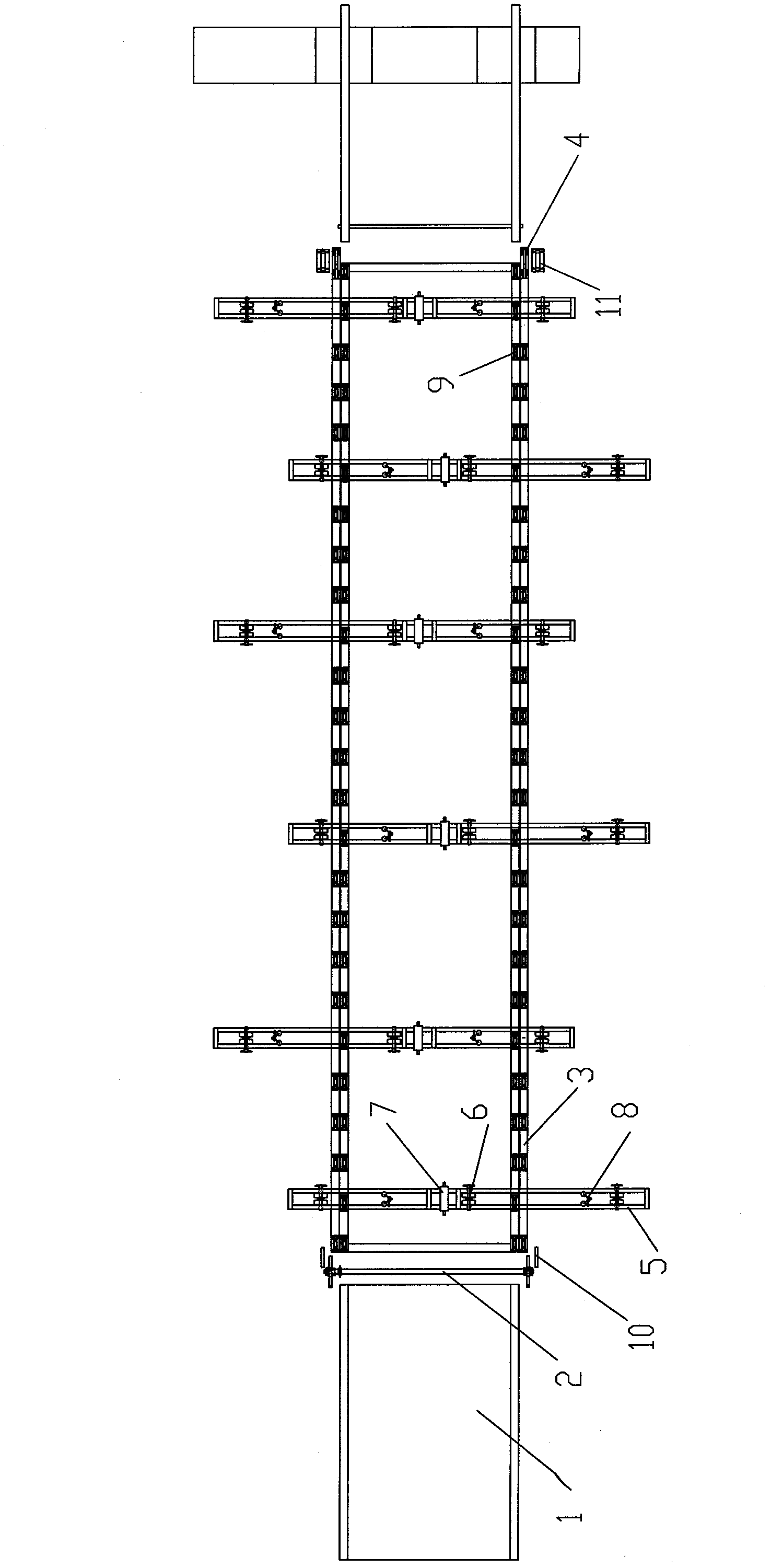

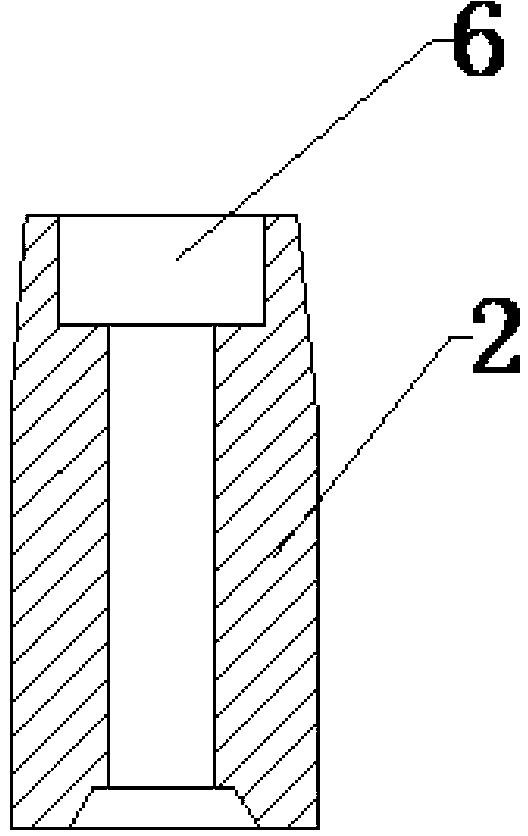

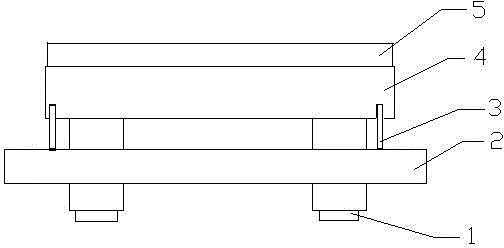

Induction heating furnace provided with half-split panel induction coils

ActiveCN105698525ADoes not affect normal productionMeet temperature distribution requirementsCoil arrangementsFurnace typesHeating furnaceCopper

The invention relates to an online induction heating technology for steel plates. An induction heating furnace with split flat induction coils, comprising an upper set of flat induction coils (2) and a lower set of flat induction coils (6), the lower set of flat induction coils is fixedly installed on the induction furnace support, and the upper set of flat induction coils The coil is installed on the frame that can move up and down. The upper group of flat induction coils and the lower group of flat induction coils form a pair of flat induction coils. The heated plate (1) passes between the upper and lower two groups of flat induction coils; the flat induction coil includes copper tubes (3) and yoke (4), the yoke is E-shaped, and the two working sections of the multi-turn copper tube coil are respectively placed in two inner grooves of the E-shaped yoke and placed in parallel, and placed in front of the E-shaped groove of the yoke The copper tube inside is the front copper tube, and the copper tube placed at the back of the E-shaped groove of the yoke is the rear copper tube. The current direction flowing through the front copper tube and the rear copper tube is opposite. When encountering a severely warped steel plate during production, the upper set of plate induction coils can be lifted quickly.

Owner:BAOSHAN IRON & STEEL CO LTD

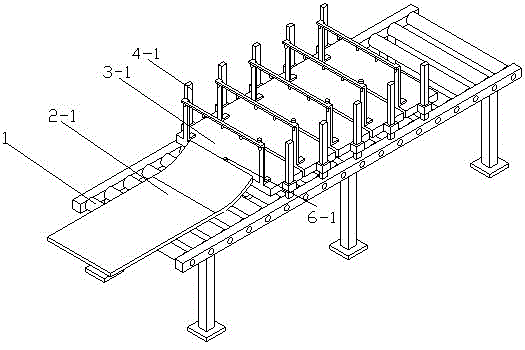

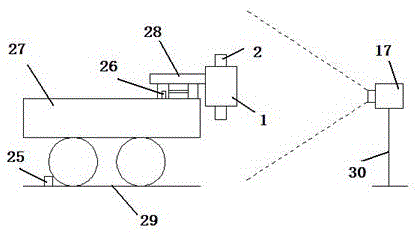

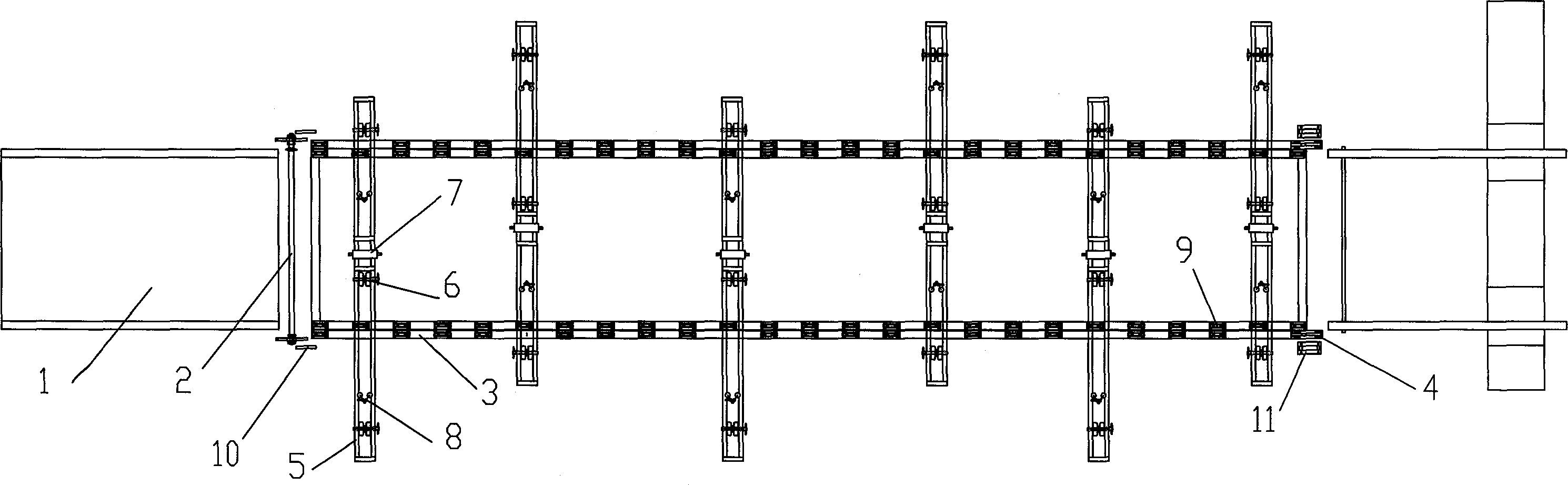

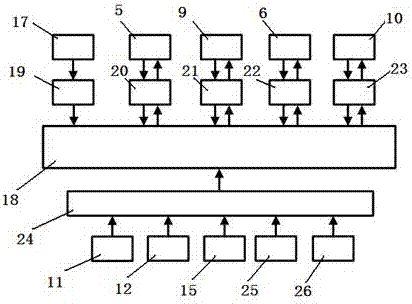

Induction heating method and device with self-adaptive distance adjusting function

ActiveCN105648164ABroaden and enhance processing capabilitiesIncrease productivityFurnace typesIncreasing energy efficiencyControl systemEngineering

The invention discloses an induction heating method suitable for steel plates with any warping degree. Firstly, a steel plate (2) is moved to an inlet of inductors (8) of an induction heating furnace through a roller bed system (1), displacement sensors (5) located on the upper portion of the front end of each upper inductor (3) are used for detecting the distance between the surface of the steel plate and the sensors and sending a measurement result to an intelligent processing unit; secondly, the intelligent processing unit works out the warping degree of the steel plate and an upper inductor position adjusting mode and sends the warping degree of the steel plate and the upper inductor position adjusting mode to a PLC control system; thirdly, the PLC control system sends adjustment commands to an upper inductor position adjusting system (4), so that the distance between the steel plate and the upper inductors is kept relatively constant; and fourthly, when the steel plate enters the inductors, infrared temperature measuring units (6) mounted at the inlet ends of the upper inductors are used for detecting the temperature of the steel plate, power needed for heating the steel plate to a target temperature is worked out, and an inductor heating system is started to heat the steel plate, so that when the steel plate leaves the induction heating furnace, the temperature of the steel plate reaches the target temperature.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for preventing electrostatic dust collection explosion venting in converter double-slag smelting process

InactiveCN107805683AAvoid explosive conditionsPrevent explosion ventingManufacturing convertersSmelting processNitrogen

The invention discloses a method for preventing electrostatic dust collection explosion venting in the converter double-slag smelting process. The method includes the steps that when lance carrying deslagging is carried out for the first time in the converter smelting process, an oxygen lance is carried to a fire hole for nitrogen flushing, and as for the volume contents of gases in a dust remover, nitrogen flushing is stopped after O2 is smaller than or equal to 6% and CO is smaller than or equal to 9%. According to the method, by optimizing the primary slagging gas supply system, the converter oxygen lance is used for nitrogen flushing, the volume content of O2 entering the electrostatic field dust remover after converting is stopped is controlled to be 6% or below, the explosion conditions of a gas mixture of CO and O2 are effectively evaded, and therefore explosion venting of the electrostatic field dust remover in converter double-slag operation can be avoided, and the effects ofstabilizing the converter production rhythm, reducing the damage to dust removing equipment and prolonging the service life are achieved. Meanwhile, the double-slag operation is adopted in a converter, P controllability of the converter is improved and the volume production needs of high-end branded steel are met.

Owner:HEBEI IRON AND STEEL

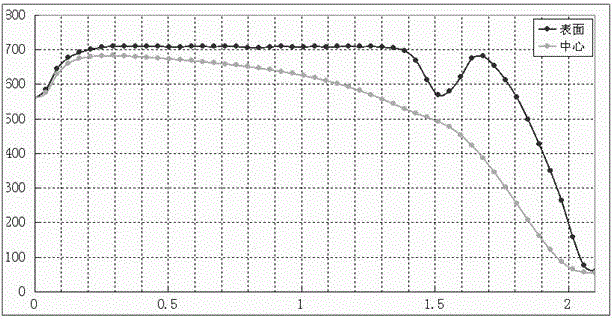

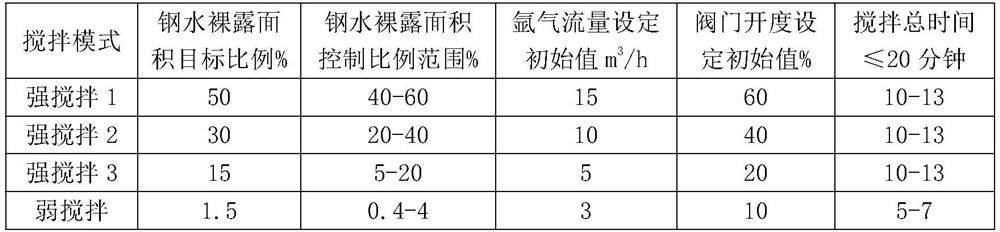

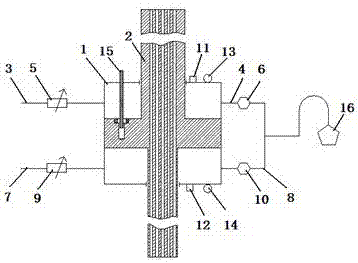

Device and method for regulating and controlling ladle bottom argon blowing flow

ActiveCN111679622AUniform compositionQuality improvementFlow control using electric meansProgramme control in sequence/logic controllersImage manipulationEngineering

The invention discloses a device and a method for regulating and controlling ladle bottom argon blowing flow, which mainly solve the technical problems of low control precision and low automation degree of the existing ladle bottom argon blowing flow. The scheme of the invention is as follows: the device for regulating and controlling ladle bottom argon blowing flow comprises a steel ladle bottomargon blowing valve opening degree control PLC and a steel ladle bottom argon blowing flow regulating valve, wherein the ladle bottom argon blowing flow regulating valve is fixedly arranged on a ladlebottom argon blowing pipeline, the ladle bottom argon blowing valve opening degree control PLC is connected with the ladle bottom argon blowing flow regulating valve through a communication cable, and the ladle bottom argon blowing flow regulating valve is an electric valve; the device further comprises a visual sensor, an image processing unit and a steel ladle bottom blowing valve opening degree control unit which are installed above the steel ladle, the visual sensor is connected with the image processing unit through a communication cable, and the steel ladle bottom blowing valve openingdegree control unit is a steel ladle bottom blowing valve opening degree control computer. The molten steel refining cost is reduced.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

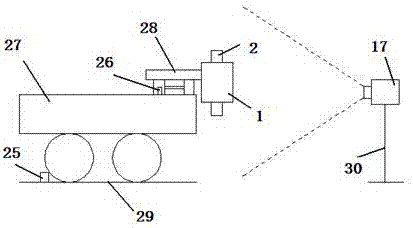

Plate slab flame spray gun cutting height control system and using method thereof

ActiveCN105537720AEnsure heating requirementsPrecise adjustment of vertical distanceGas flame welding apparatusEngineeringFlame cutting

The invention relates to a plate slab flame spray gun cutting height control system which comprises a cutting machine rail, a flame cutting machine, a flame cutting trolley, a spray gun, a pneumatic cylinder, a camera and a process control system, wherein the flame cutting trolley is arranged on the flame cutting machine; the pneumatic cylinder is mounted on the flame cutting trolley; and the camera is used for shooting the spray gun and spray gun flame. The system using method comprises the following steps: acquiring a distance from a nozzle of the flame spray gun to a point with the highest flame temperature in real time by utilizing the camera; comparing the acquired distance with a vertical distance from the nozzle of the flame spray gun to a midpoint position of a casting blank in a thickness direction; and according to a comparison result, by a computer, controlling the piston type flame spray gun to move up and down to carry out regulation so as to guarantee that the distance between the nozzle of the flame spray gun and the point with the highest flame temperature is equal to the vertical distance between the nozzle of the flame spray gun and the midpoint position of the casting blank in the thickness direction in real time and to guarantee that a high-temperature part of the outer flame of the flame spray gun is sufficiently utilized to heat a slab, thereby fulfilling the aims of promoting plate slab cutting quality and stabilizing the continuous casting production rhythm, and greatly reducing labor intensity of field personnel.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Smelting method of high-nitrogen sulfur-containing free-cutting steel

InactiveCN111876688AImprove purityQuality improvementManufacturing convertersProcess efficiency improvementSlagIngot

The invention discloses a smelting method of high-nitrogen sulfur-containing free-cutting steel. The smelting method mainly comprises the following steps of converter smelting tapping, LF refining furnace treatment, RH vacuum furnace treatment and continuous casting; an aluminum ingot is added in the tapping process for pre-deoxidation, low-alkalinity slag is made by an LF refining furnace, a small amount of aluminum particles are added in the slag surface, the diffusion deoxidation efficiency is improved, and molten steel is greatly purified; and an RH vacuum furnace adopts nitrogen drive, limit vacuum is kept for a certain time, a first-stage pump is retreated to a fourth-stage pump after vacuum breaking, a nitrogen-containing alloy is added, and circulation is conducted for 5 min, so that the S content and the N content in the steel can be accurately controlled, narrow-range accurate control over molten steel components is guaranteed, meanwhile, the refining period is stabilized, operation is easy, and the method is suitable for mass production. The method is simple, effective, easy to operate, capable of accurately controlling refining time and refining components, improving molten steel quality and guaranteeing the production rhythm and suitable for wide popularization.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

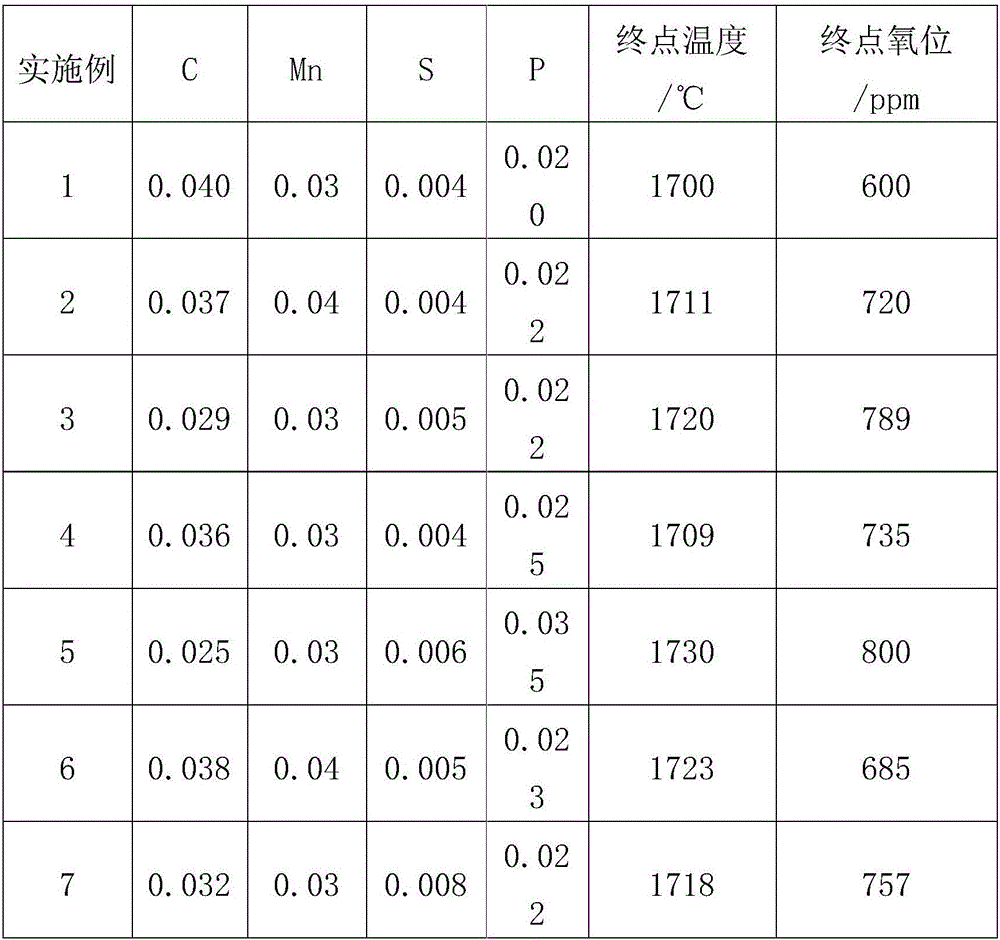

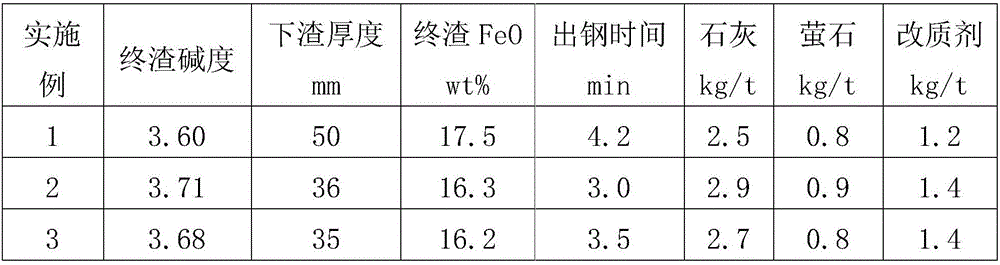

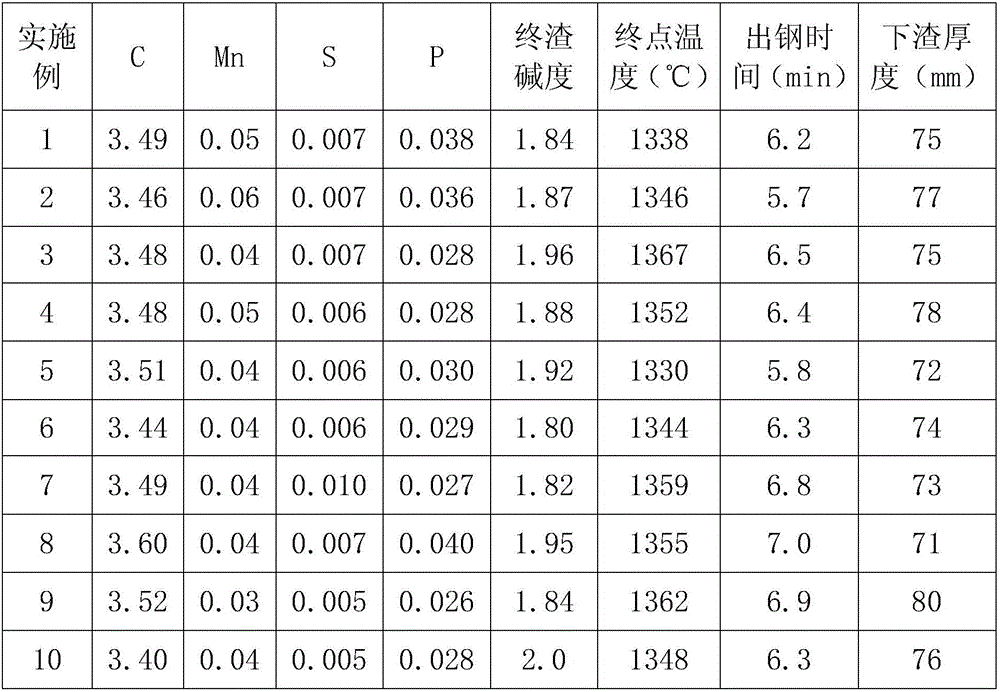

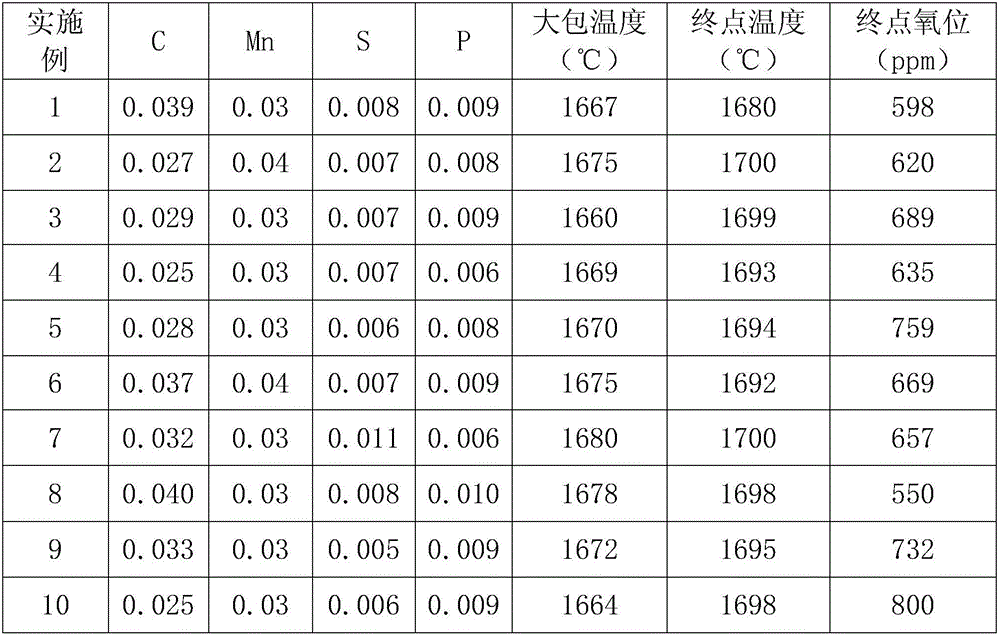

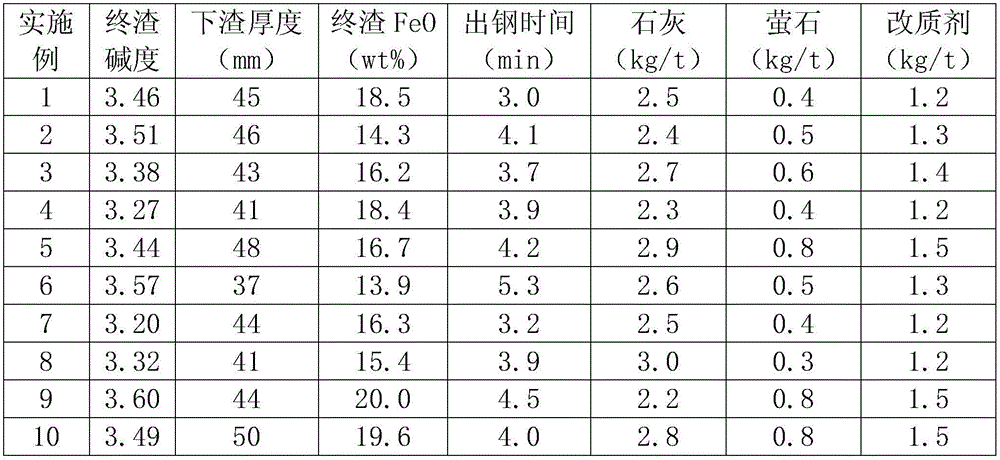

Production process of high-quality ultra-low-carbon IF steel

The invention discloses a production process of high-quality ultra-low-carbon IF steel. The production process includes the procedures of blast furnace molten iron, DeS pretreatment desulfurization, DeP dephosphorization, DeC decarbonization, RH vacuum treatment and CC conventional slab continuous casting. In the DeP dephosphorization procedure, the final temperature is not lower than 1330 DEG C, and the mass percent of final semi-steel components are controlled so that the mass percent of C can range from 3.40% to 3.60%, the mass percent of S cannot be higher than 0.010% and the mass percent of P cannot be higher than 0.040%. In the DeC decarbonization procedure, non-turning-down direct discharge is adopted, and the mass percent of final molten steel components are controlled so that the mass percent of C can range from 0.025% to 0.040%, the mass percent of S cannot be larger than 0.011% and the mass percent of P cannot be larger than 0.010%, and the final temperature ranges from 1680 DEG C to 1700 DEG C. In the RH vacuum treatment procedure, a vacuum mechanical pump is used for adjusting the vacuum degree. In the CC conventional slab continuous casting procedure, a tundish is made of non-carbon and non-magnesium refractory, and the draw speed is controlled to range from 1.1 m / min to 1.4 m / min. By means of the method, a continuous casting billet without any defect is produced, high-quality hot-rolled coiled plates are produced through hot rolling, and high-quality continuously-annealed and zinc-plated products are finally produced through cold rolling.

Owner:TANGSHAN IRON & STEEL GROUP

Automatic logistic conveying device for machining end face of lift guide rail

InactiveCN102689223AReduce labor intensityHigh degree of automationMetal working apparatusProduction lineEngineering

The invention relates to an automatic logistic conveying device for machining an end face of a lift guide rail. The automatic logistic conveying device comprises a feeding rack, and is characterized in that a feeding turnover mechanism is arranged at the output end of the feeding rack; and a step fixing rack is arranged at the output end of the feeding turnover mechanism. Meanwhile, a discharging turnover assembly is arranged at the output end of the step fixing rack; and lathe feeding and discharging racks are distributed on the step fixing rack. Thus, the labor intensity of workers can be reduced, and the production enthusiasm can be improved. Meanwhile, the transporting and turning-over frequency of products in a process can be reduced, so that the product collision defect is reduced, and the product quality is improved. Furthermore, the labor participation in a product manufacturing process is further reduced, and the influence on the product quality due to factors, such as human mood, can be reduced. More importantly, the automation of an assembly line is improved, and the risk and the hidden danger of influencing the production by staff variation can be reduced. Moreover, the layout is more compact, the production beat is stable and consistent, and the entire production image is improved.

Owner:长江润发(张家港)机械有限公司

Secondary cast-on process for continuous-casting tundishes

The invention relates to a secondary cast-on process for continuous-casting tundishes and belongs to the technical field of continuous casting of the metallurgical industry. According to the technical scheme, the process comprises the steps that (1), before casting of the tundishes is stopped, slagging treatment is conducted on the tundishes; (2), when the liquid steel level of the tundishes remains at 200 mm, the remaining one to two middle streams of water gaps are cast continuously; (3), when the tundish liquid steel level is at 10-20 mm, casting of the tundishes is stopped; (4), the tundishes are baked, the baking temperature ranges from 1,100 DEG C to 1,300 DEG C, and the baking time ranges from 45 minutes to 180 minutes; (5), after baking of the tundishes is completed, liquid steel in steel ladles is injected into the tundishes; and (6), the liquid steel level of the tundishes is greater than 300 mm, and secondary casting is conducted on the tundishes. The secondary cast-on process has the beneficial effects that the temperature loss of the tundishes is reduced, the service life of the tundishes is guaranteed, the consumption of continuous-casting refractory is lowered, and the smooth production of iron and steel enterprises is guaranteed.

Owner:乌海市包钢万腾钢铁有限责任公司

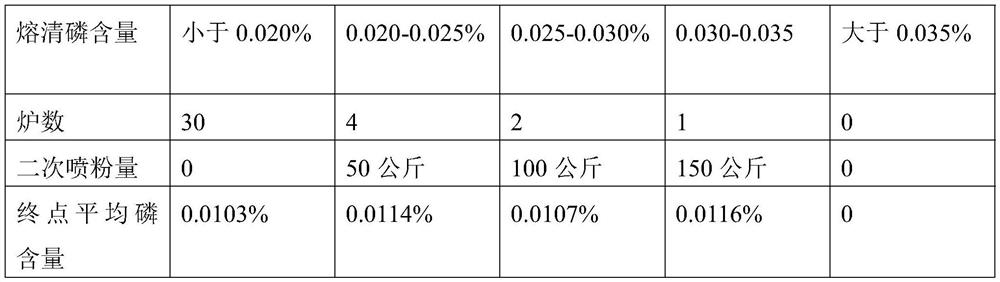

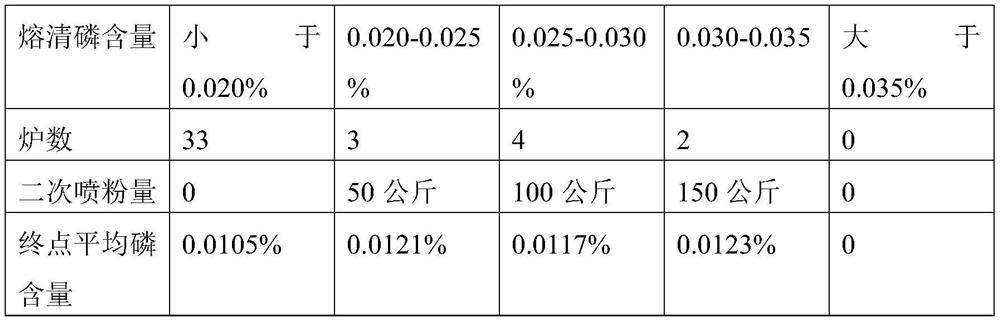

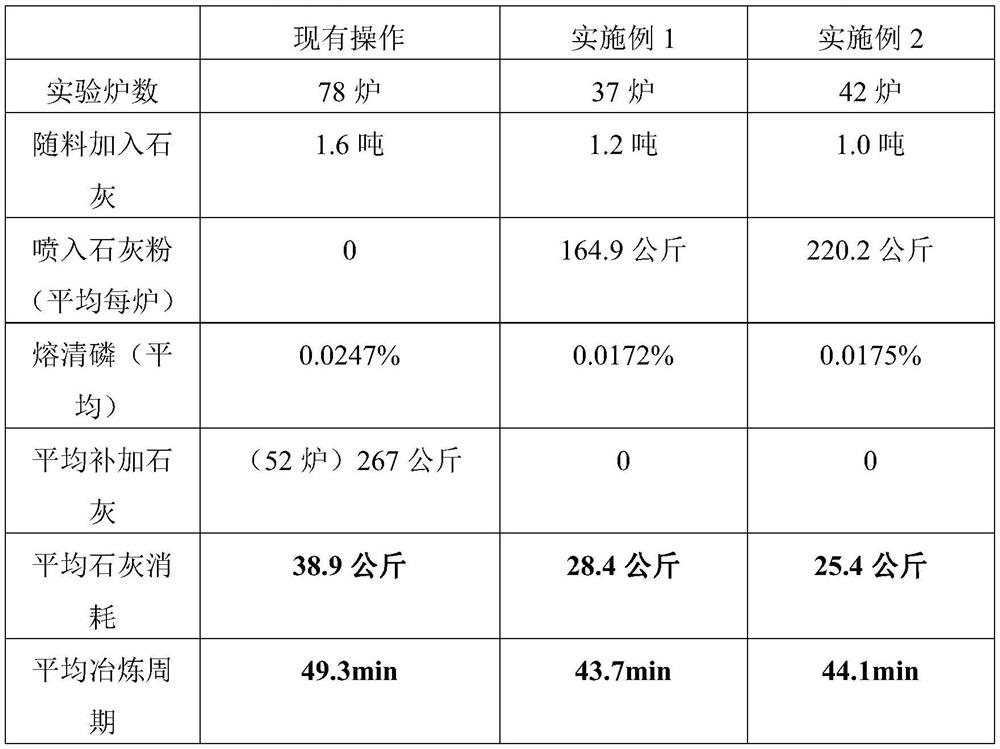

Method for dephosphorizing by blowing lime powder in electric furnace

InactiveCN112301184AWork around constraintsSolve the requestElectric furnaceProcess efficiency improvementSteelmakingMaterial consumption

The invention relates to the field of electric furnace steelmaking, in particular to a method for dephosphorizing by blowing lime powder. The method comprises the following steps: in the early stage of smelting, when the smelting temperature in an electric furnace is 1470-1500 DEG C, starting a low-oxygen mode, and blowing the lime powder with the particle size of 0-10mm into the electric furnace;and after powder blowing is finished, adjusting the oxygen supply amount to 5000-5500 Nm < 3 > / h, and conducting stirring for dephosphorization. According to the method, lime consumption is effectively reduced, so that the increase of steel and iron material consumption and smelting power consumption caused by high lime consumption is reduced.

Owner:SHANDONG IRON & STEEL CO LTD

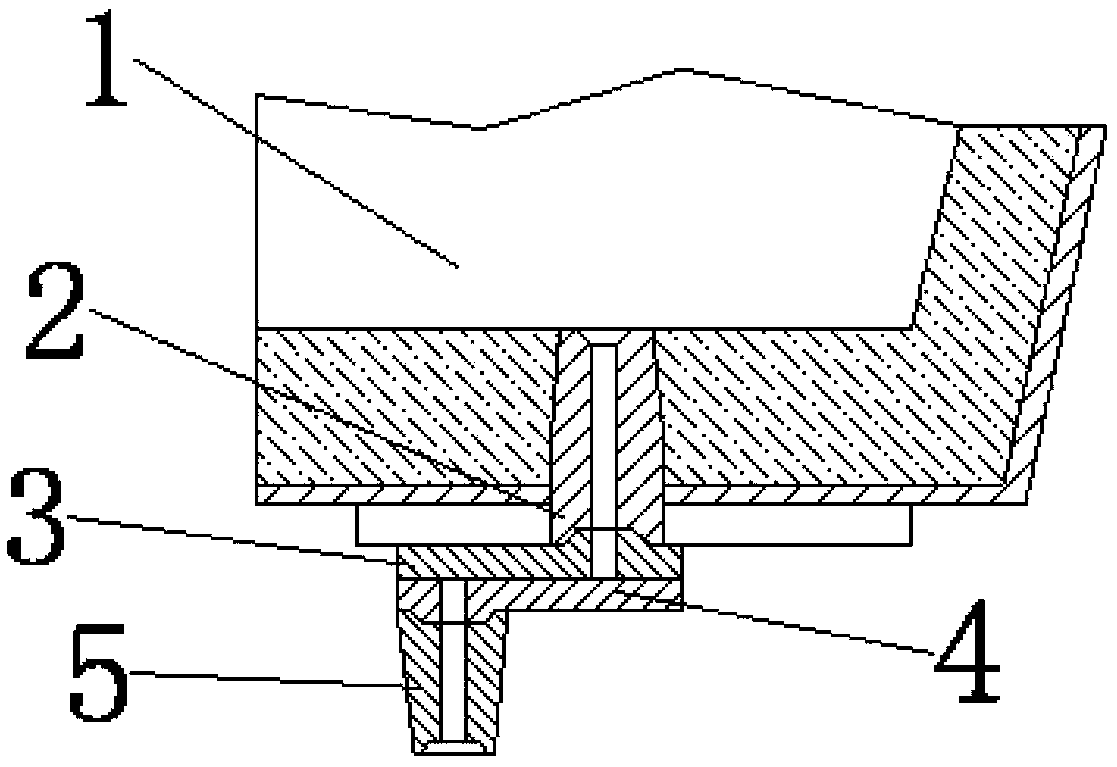

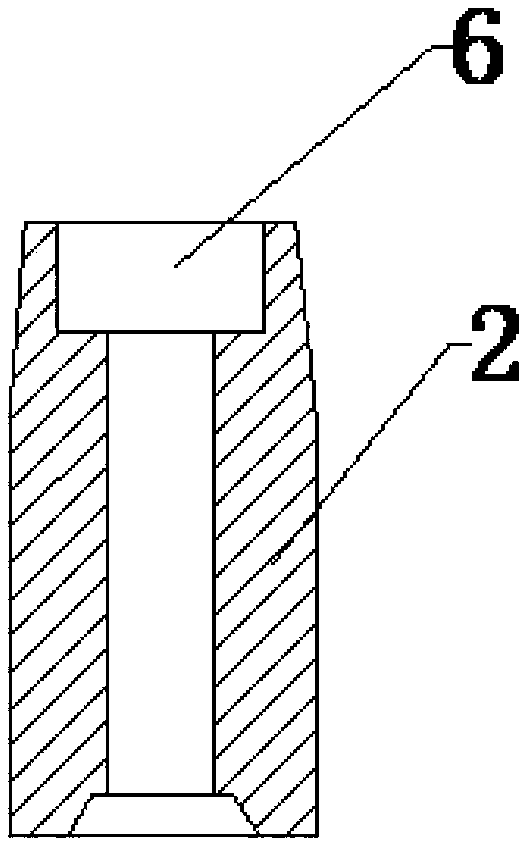

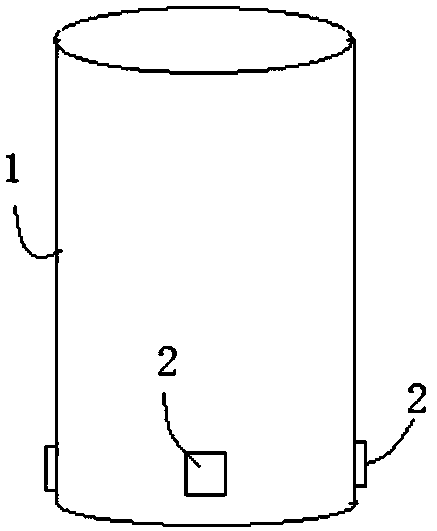

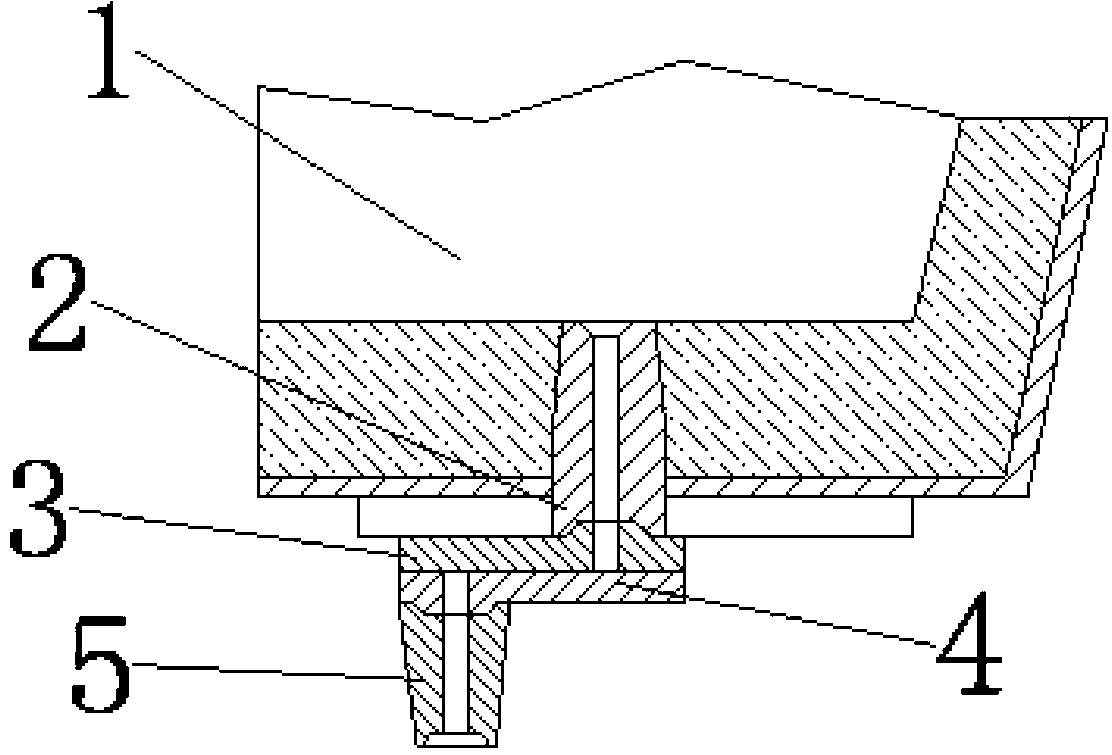

A ladle nozzle capable of increasing self-opening rate

The invention discloses a ladle nozzle applied to the steel casting technology and particularly relates to a ladle nozzle capable of improving the automatic casting rate. A variable-diameter stuffing sand flowing channel is arranged at an upper water inlet. The upper water inlet is composed of an upper portion and a lower portion, and the inner diameter of the upper portion of the upper water inlet is larger than that of the lower portion of the upper water inlet. By means of the ladle nozzle, upper arch drainage sand piles are not produced, flowing of stuffing sand is facilitated, and the automatic casting rate is improved, the defect of manual oxygen burning casting in the prior art is overcome, the molten steel automatic casting rate is improved, the production rhythm is stabilized, effects of oxygen burning on the quality of molten steel are reduced, residual slag of steel ladles is reduced, and the like.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

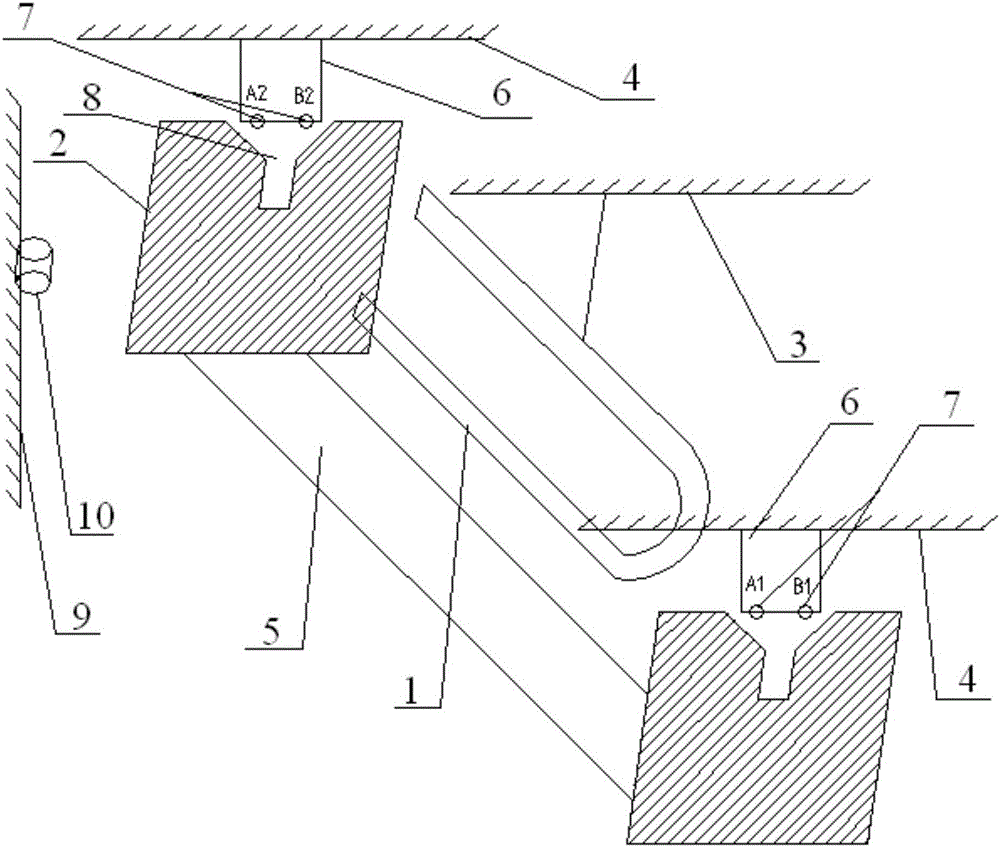

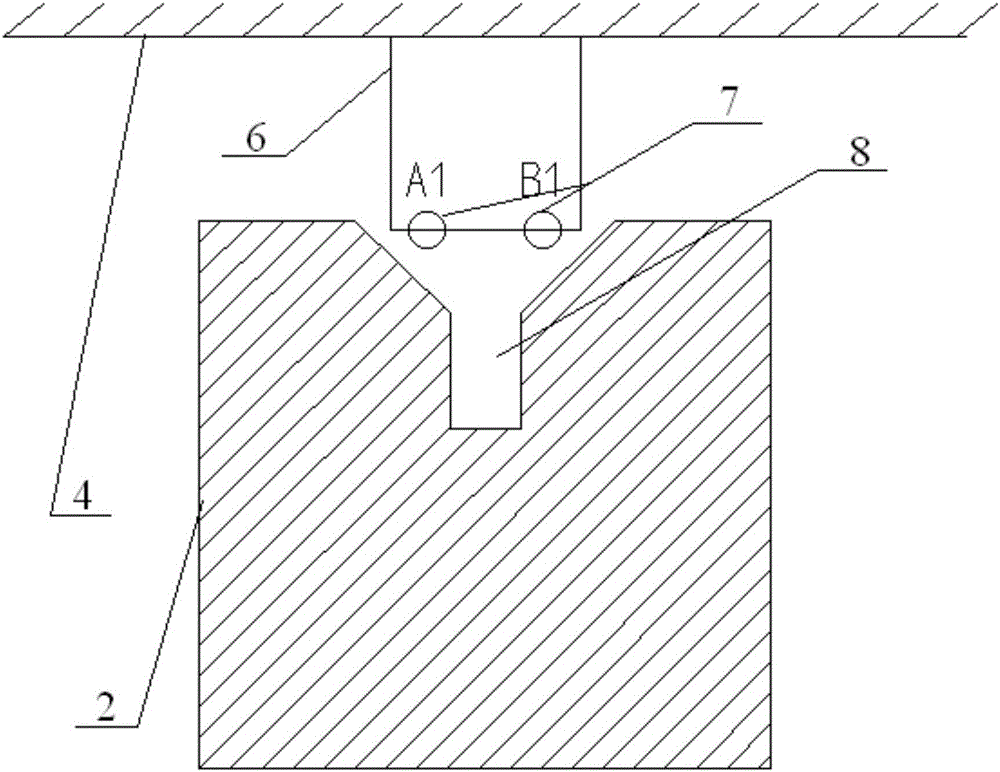

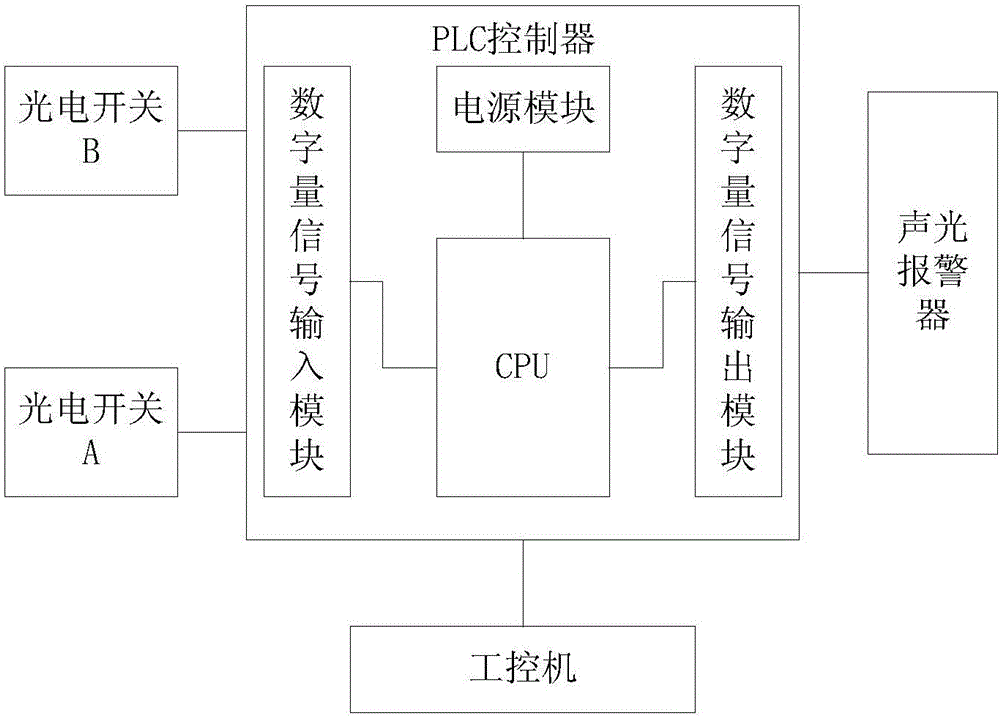

Automatic anti-collision device for packaging machine platens

The invention relates to an automatic anti-collision device for packaging machine platens. The automatic anti-collision device comprises a PF wire transmission chain, a C-shaped hook, a clamping claw, a PF wire fixing support, a PLC, the packaging machine platens, a photoelectric detection device and an external alarming device. The C-shaped hook is fixed to the PF wire transmission chain in a hung manner. The packaging machine platens are arranged on the packaging machine base below the C-shaped hook. The clamping claw and the photoelectric detection device are fixedly mounted on the PF wire fixing support. The external alarming device is arranged on one sides of the packaging machine platens. A reserved platen opening is formed in the center axis of the top of each packaging machine platen and allows the C-shaped hook in the normal shape at the normal position to pass. The photoelectric detection device is arranged over the reserved platen openings. The photoelectric detection device and the external alarming device are both electrically connected with the PLC. According to the automatic anti-collision device, the position and the shape of the C-shaped hook can be detected automatically, and it is guaranteed that the coil extrusion operation by the platens is prohibited under the risky condition.

Owner:江苏联峰实业有限公司

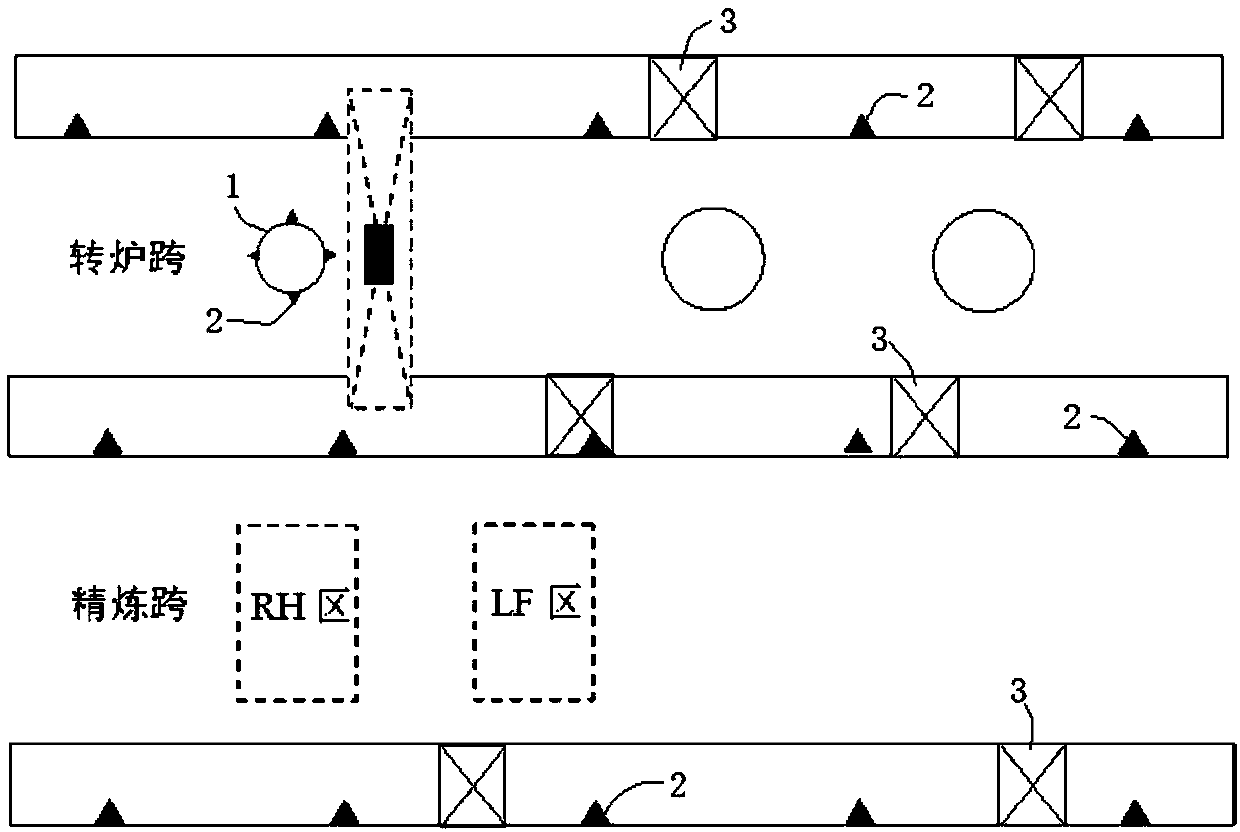

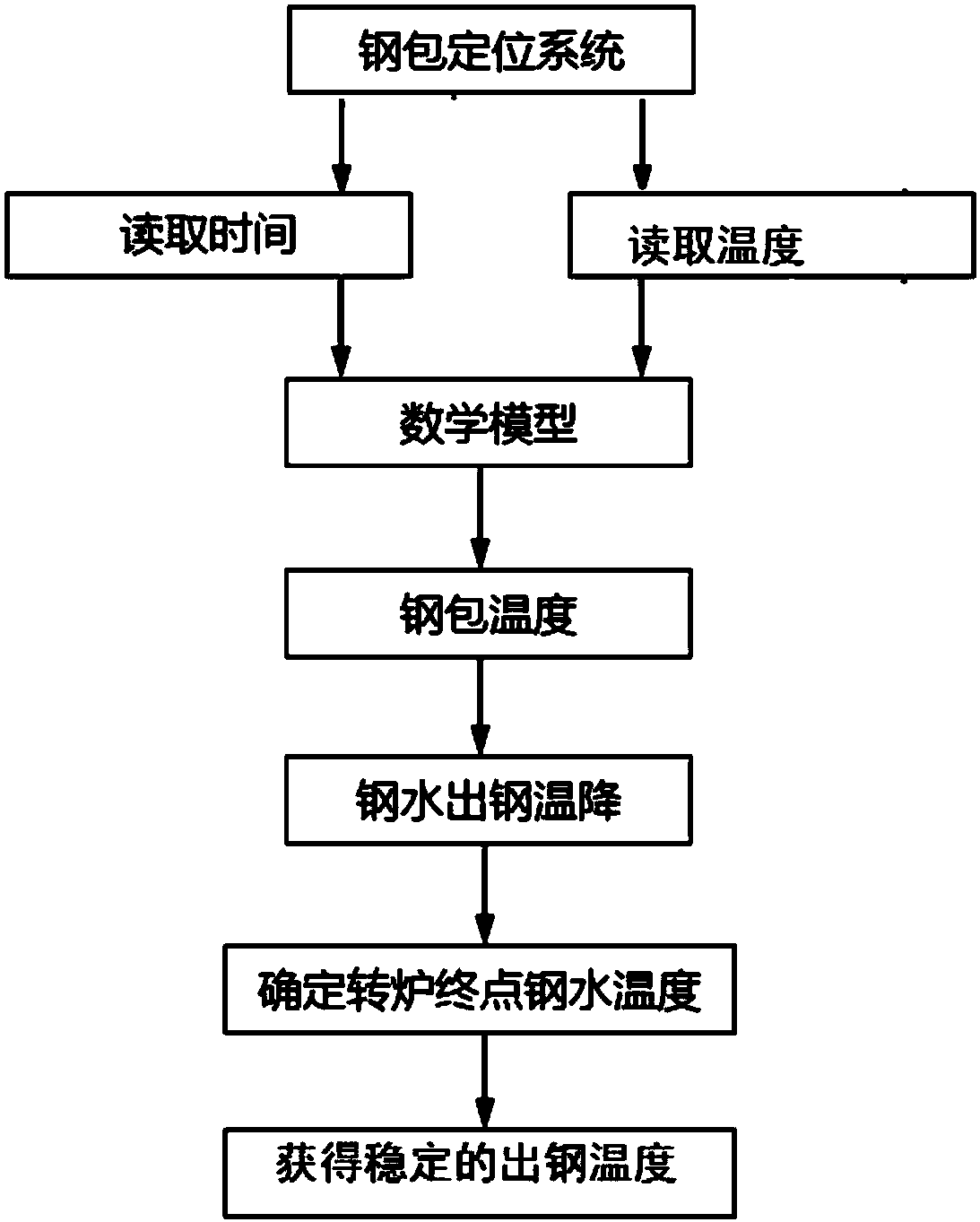

Method for stabilizing tapping temperature based on ladle automatic positioning

ActiveCN107765550AStable tapping temperatureGuaranteed stabilityAuxillary controllers with auxillary heating devicesAdaptive controlEngineeringCard reader

The present invention discloses a method for stabilizing a tapping temperature based on ladle automatic positioning, belonging to the metallurgy field. The method comprises the steps that: based on the radio frequency identification technology, card readers are installed at positions where a ladle is operated, and a plurality of electronic tags are installed at front, back, left and right outer surfaces of the ladle; the card readers perform identification of the ladle when the position of the ladle is changed; a homemade algorithm is employed to calculate the temperature of the ladle based oninformation such as the position of the ladle and the initial temperature of the ladle; temperature loss of liquid steel is obtained when tapping according to different ladle temperatures; the liquidsteel temperature of a converter smelting terminal point is dynamically regulated to balance the temperature loss; and finally, a stable tapping temperature of the liquid steel in the ladle is obtained. The method for stabilizing a tapping temperature based on ladle automatic positioning overcomes defects that it is difficult to stabilize the tapping temperature of the liquid steel and productionstability is influenced, stabilizes the tapping temperature of the liquid steel, ensures the stability of the production rhythm, obtains a stable casting temperature for follow-up continuous castingand ensures stability of the casting blank quality.

Owner:上海宝衢自动化系统工程有限公司

Ladle nozzle capable of improving automatic casting rate

The invention discloses a ladle nozzle applied to the steel casting technology and particularly relates to a ladle nozzle capable of improving the automatic casting rate. A variable-diameter stuffing sand flowing channel is arranged at an upper water inlet. The upper water inlet is composed of an upper portion and a lower portion, and the inner diameter of the upper portion of the upper water inlet is larger than that of the lower portion of the upper water inlet. By means of the ladle nozzle, upper arch drainage sand piles are not produced, flowing of stuffing sand is facilitated, and the automatic casting rate is improved, the defect of manual oxygen burning casting in the prior art is overcome, the molten steel automatic casting rate is improved, the production rhythm is stabilized, effects of oxygen burning on the quality of molten steel are reduced, residual slag of steel ladles is reduced, and the like.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

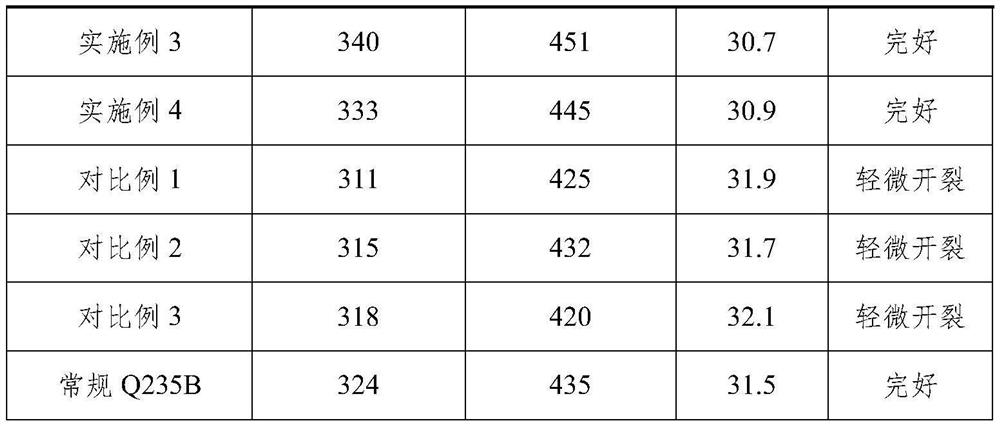

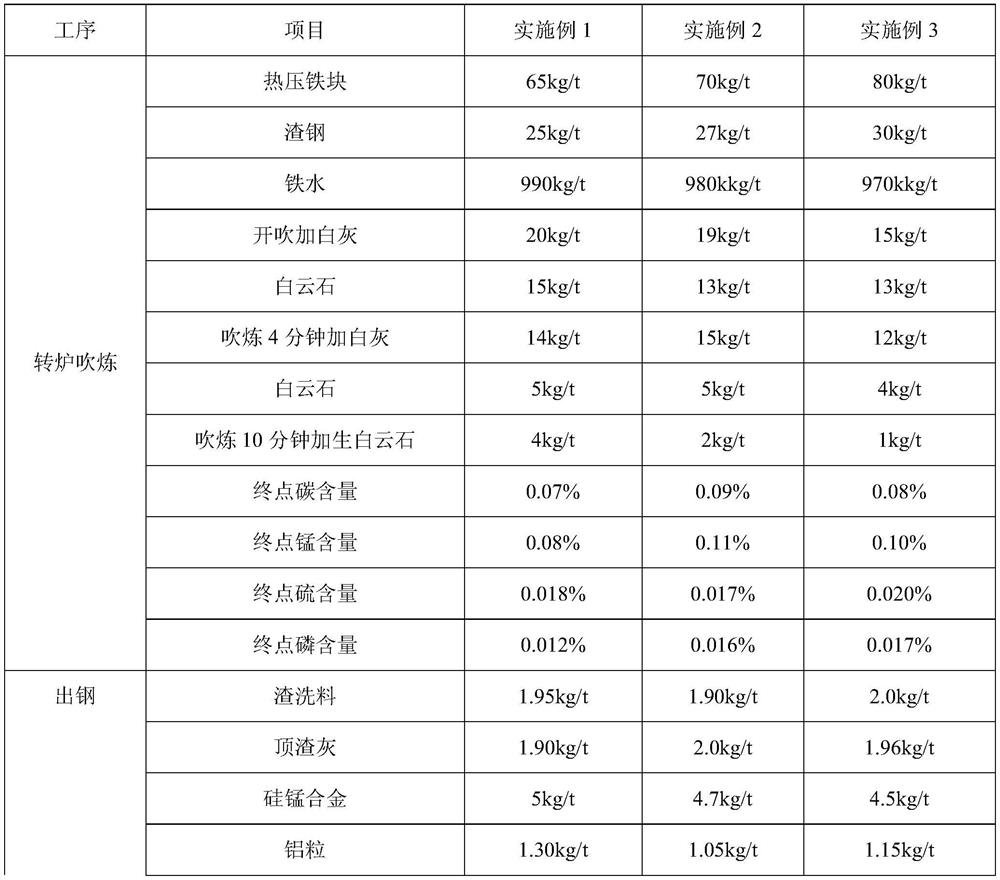

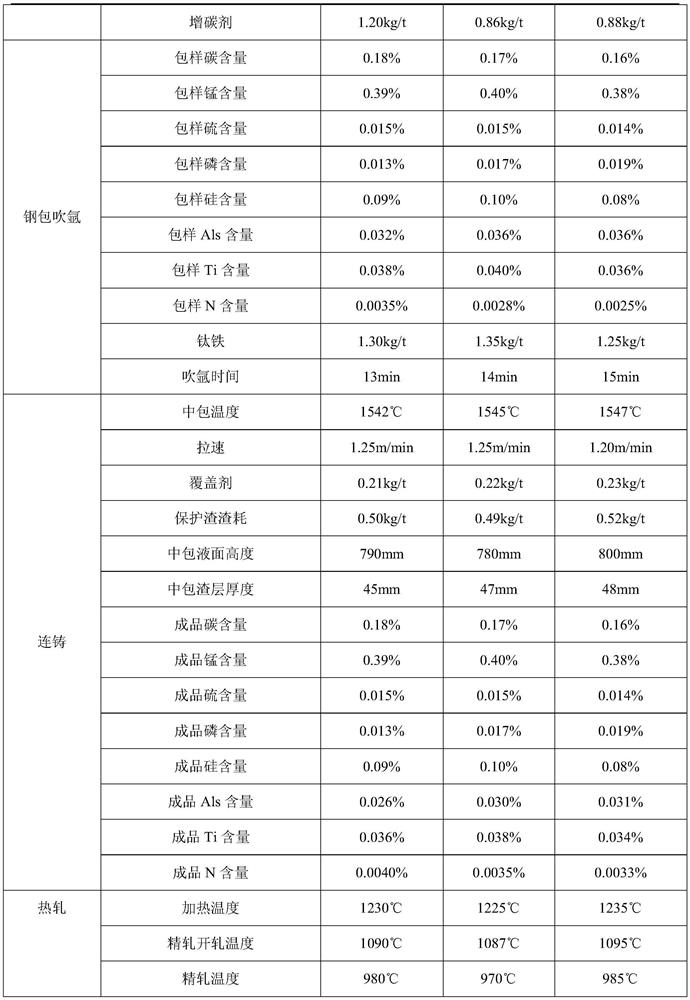

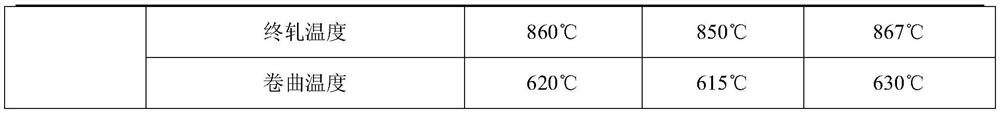

Production process of high-efficiency Q235B micro-titanized steel grade

ActiveCN114015930AReduced crack susceptibilityImprove internal qualityProcess efficiency improvementTitaniumCalcium handling

The invention relates to the technical field of steelmaking processes, and in particular relates to a high-efficiency Q235B micro-titanized steel grade. The steel grade is composed of, by weight, 0.04% to 0.07% of C, smaller than or equal to 0.10% of Si, 0.35% to 0.55% of Mn, smaller than or equal to 0.040% of P, smaller than or equal to 0.035% of S, 0.010% to 0.050% of Als, 0.030% to 0.050% of Ti and the balance Fe. The invention provides a production process of the high-efficiency Q235B micro-titanized steel grade. Desulfurization and calcium treatment process are carried out by adding titanium to reduce carbon and "slag washing" after converter furnace, low-superheat-degree casting is adopted in the continuous casting process, the influence of sulfide in steel and a finished product banded structure on the product and performance is reduced, and the cold bending process requirements of customers are met.

Owner:武安市裕华钢铁有限公司

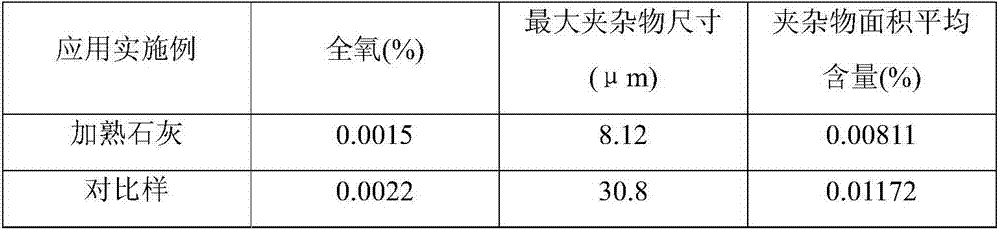

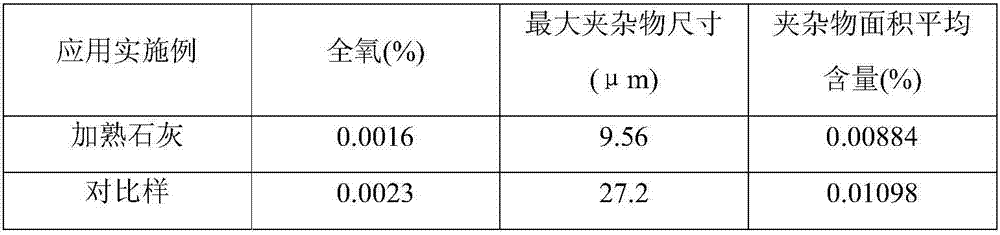

Method for producing clean steel through RH

The invention discloses a method for producing clean steel through RH. The method for producing clean steel through RH comprises the following steps that (1) tapping from a converter in a boiling or semi-boiling mode is conducted, and then steel enters an RH station; decarburization is conducted after temperature measurement and oxygen determination are conducted, after carbon is decarburized to a target value, the temperature measurement and oxygen determination are conducted; (2) aluminum is one-time added according to oxygen activity, the objective adding amount is 0.003%-0.007% more than the upper limit of the weight percentage of the aluminum; while adding the aluminum, slaked lime is added to a vacuum chamber through an overhead bunk, wherein the adding amount of the slaked lime is 0.4-0.6 kg per ton of steel, circulation is conducted for 3-5 min, and the temperature measurement and oxygen determination are conducted; and (3) when the oxygen activity is less than 0.0010%, the aluminum is not added any more, or the aluminum is replenished; the rest alloy materials are added and circulated for 3-5 min; then the temperature measurement and oxygen determination are conducted for ensuring that hydrogen content is less than 0.00015%, vacuum is eliminated, and then steel is moved out; still standing for 15-30 min and pouring on a machine are conducted. Total oxygen of the IF steel billet treated in this way decreases averagely 0.0005%-0.0008%, the size of the maximum inclusion is significantly reduced, and cleanliness is improved obviously.

Owner:ANGANG STEEL CO LTD

A secondary pouring process for continuous casting tundish

The invention relates to a secondary cast-on process for continuous-casting tundishes and belongs to the technical field of continuous casting of the metallurgical industry. According to the technical scheme, the process comprises the steps that (1), before casting of the tundishes is stopped, slagging treatment is conducted on the tundishes; (2), when the liquid steel level of the tundishes remains at 200 mm, the remaining one to two middle streams of water gaps are cast continuously; (3), when the tundish liquid steel level is at 10-20 mm, casting of the tundishes is stopped; (4), the tundishes are baked, the baking temperature ranges from 1,100 DEG C to 1,300 DEG C, and the baking time ranges from 45 minutes to 180 minutes; (5), after baking of the tundishes is completed, liquid steel in steel ladles is injected into the tundishes; and (6), the liquid steel level of the tundishes is greater than 300 mm, and secondary casting is conducted on the tundishes. The secondary cast-on process has the beneficial effects that the temperature loss of the tundishes is reduced, the service life of the tundishes is guaranteed, the consumption of continuous-casting refractory is lowered, and the smooth production of iron and steel enterprises is guaranteed.

Owner:乌海市包钢万腾钢铁有限责任公司

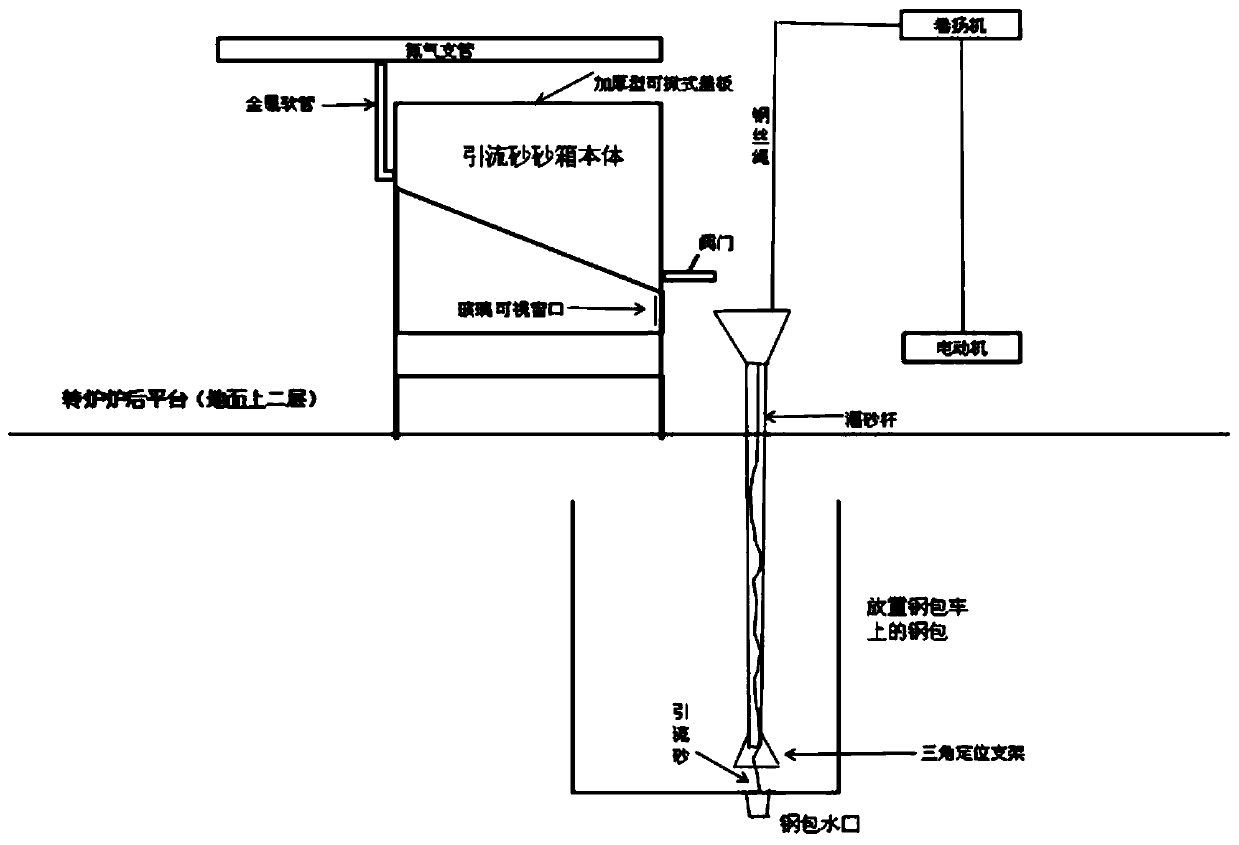

Method for improving self-opening rate of drainage sand

The invention discloses a method for improving the self-opening rate of drainage sand. A nitrogen purging part is provided on the basis of forming a drainage sand adding device into a closed space, soas to ensure that the drainage sand is dry and pure. A positioning support is disposed on a steel ladle nozzle to control the uniform addition of drainage sand. The method can solve problems such asdamping and agglomeration of the drainage sand, dust fall, unstable addition amount, and poor molding, achieves a stable self-opening rate more than 99%, and ensures a stable production rhythm and product quality.

Owner:ZHANGJIAGANG HONGCHANG STEEL PLATE CO LTD +1

Control method for reducing common steel refining power consumption

PendingCN112813225AIncrease the amount of slag produced at the stationIncrease the amount of slaggingProcess efficiency improvementElectric furnaceSlagProcess engineering

The invention discloses a control method for reducing common steel refining power consumption. The control method is applied to a 125t steel ladle. The control method comprises the following steps of adding a slag former during refining entering. According to the control method, a foaming agent is added during refining entering. By means of the technical scheme, the molten steel station entering slagging amount is increased, and submerged arc stability is promoted; the foaming agent is added to promote foaming and improve the submerged arc efficiency; the heating rate is increased, the power transmission time is reduced from 8-9 min / furnace to 6 min / furnace, and the heating rate is increased from 3-4 DEG C / min to 6-7 DEG C / min; the power transmission time is shortened, the production rhythm is stabilized, and the power consumption is reduced from the original about 19 kwh / t to about 10 kwh / t; and the submerged arc efficiency is improved and the cost is reduced.

Owner:WUHU XINXING DUCTILE IRON PIPES

Method for producing titanium microalloyed Q355B hot-rolled strip steel under non-refining condition

ActiveCN113564450ALower levelReduce manufacturing costTemperature control deviceManufacturing convertersSteelmakingThermal dilatation

The invention relates to a method for producing titanium microalloyed Q355B hot-rolled strip steel under a non-refining condition. The method is characterized in that through converter blowing and steel ladle argon blowing, components of a ladle sample are controlled to meet the requirements that C is in the range of 0.15%-0.20%, Si is in the range of 0.06%-0.15%, Mn is in the range of 0.35%-0.55%, S is less than or equal to 0.030%, P is less than or equal to 0.030%, Als is in the range of 0.020%-0.030%, and Ti is in the range of 0.030%-0.050%. Through continuous casting of a thermal expansion type asbestos gasket and control of the heating temperature being 1220-1240 DEG C, the finish rolling starting temperature being 1065-1115 DEG C, the finish rolling temperature being 930-1030 DEG C, the finish rolling temperature being 840-880 DEG C and the curling temperature being 605-635 DEG C, ferrotitanium is added under the condition of no refining furnace, so that the alloying cost is reduced, the constant-speed yield of the titanium alloy is guaranteed, then the inclusion content is reduced, and the product quality is guaranteed.

Owner:唐山瑞丰钢铁(集团)有限公司

Large slab flame spray gun cutting height control system and its application method

ActiveCN105537720BEnsure heating requirementsPrecise adjustment of vertical distanceGas flame welding apparatusControl systemEngineering

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

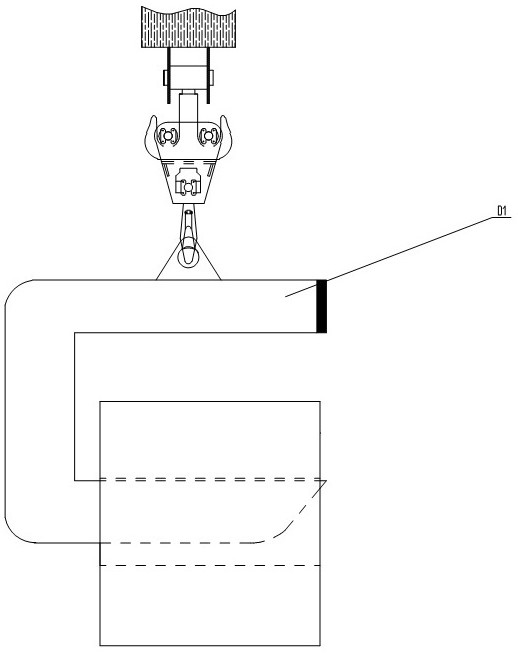

Single-hook and double-hook conversion type hook head of hoisting equipment

PendingCN113860148AQuick conversionIncrease profitLoad-engaging elementsIndustrial engineeringLifting equipment

The invention discloses a single-hook and double-hook conversion type hook head of hoisting equipment. The single-hook and double-hook conversion type hook head comprises a double-hook hook head connected to the hoisting equipment, wherein the lower end of the double-hook hook head is detachably connected with a single-hook hook head; two connecting pieces are arranged on the upper portion of the single-hook hook head, and when the single-hook hook head is connected to the double-hook hook head, the two connecting pieces are clamped in grooves of the double-hook hook head correspondingly; and each connecting piece is a convex hanging rod, a hook or a hanging ring. According to the single-hook and double-hook conversion type hook head of the hoisting equipment, the utilization rate of the 80T crown block in the production process can be improved; and particularly, after finished steel coil transportation equipment breaks down, an anchor-head-hook hook head can be quickly converted into the single-hook hook head, and the single-hook hook head can be matched with a C-shaped lifting appliance to participate in the operation activity of lifting finished steel coils from a coiling machine, so that the production rhythm is stabilized, the production guarantee is improved, the accident potential of production interruption is completely eradicated, and stable and smooth production is ensured.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

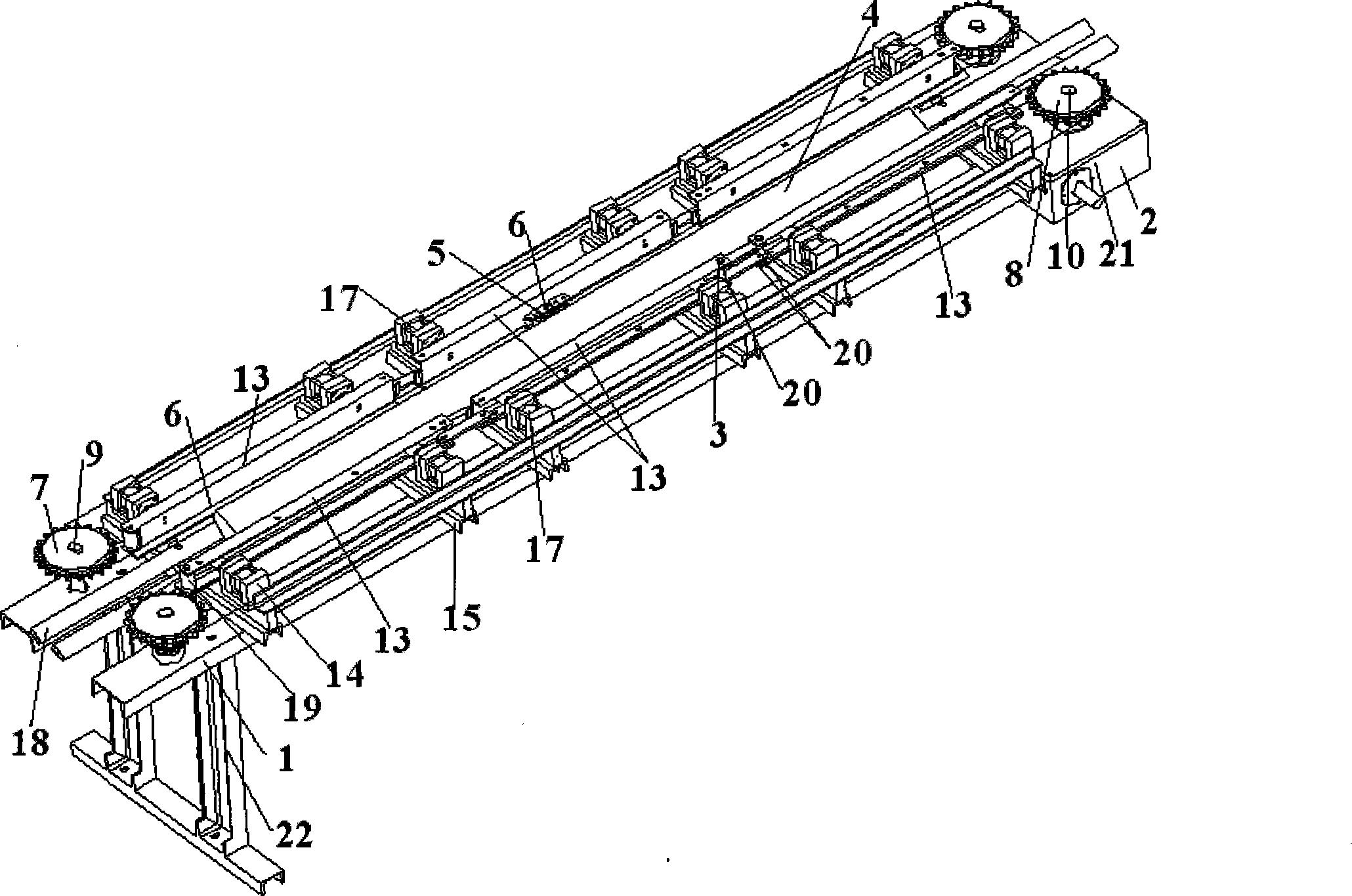

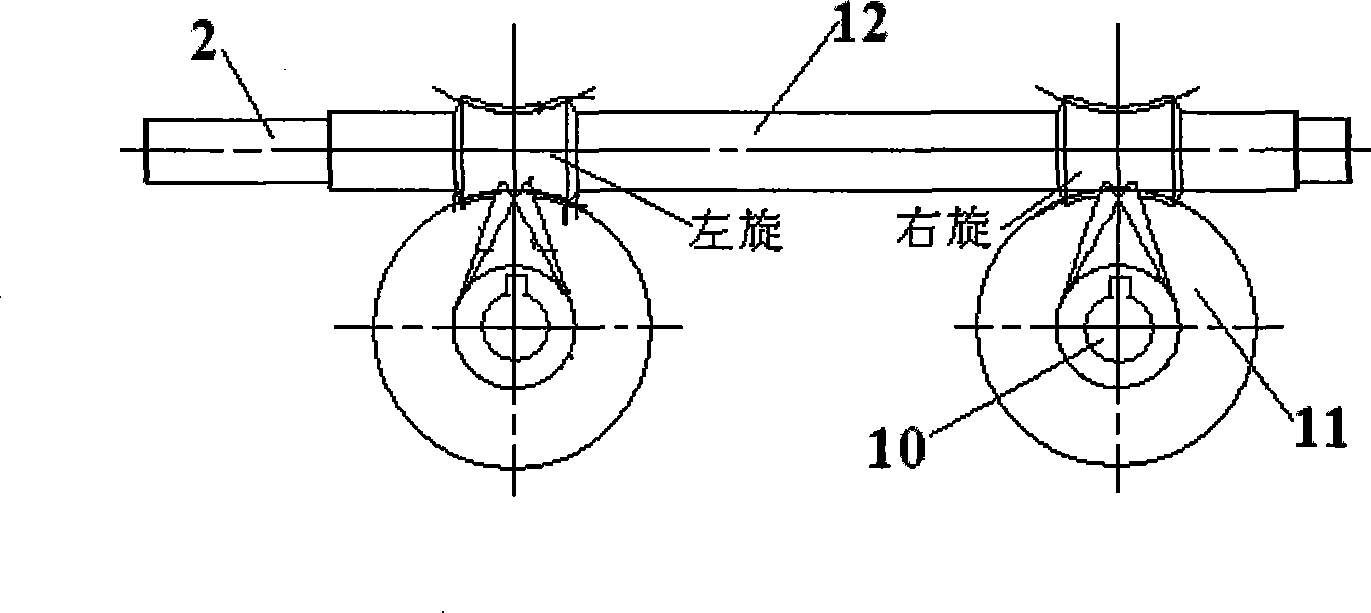

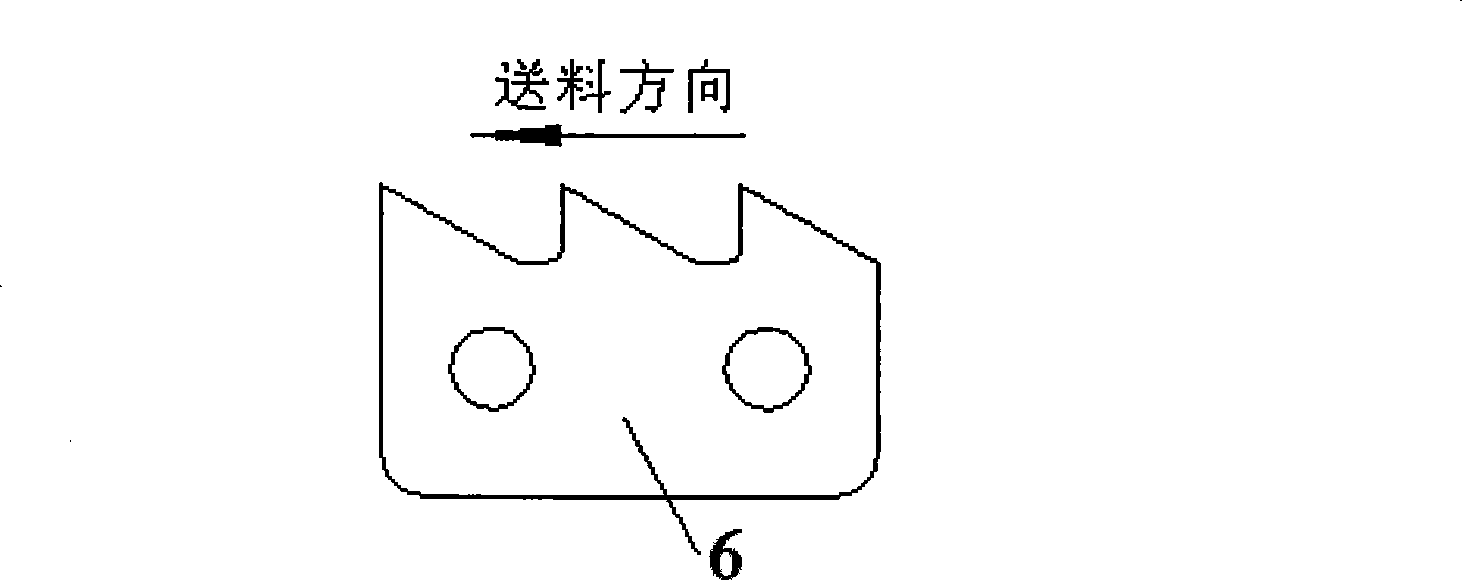

Sawmill automatic feeding system

InactiveCN101254601BClamping is stable and reliableStable and reliable feedingFeeding devicesWood machiningSprocket

The invention discloses an automatic material feeding system of sawmill, which belongs to the field of wood processing. A wood clamping and feeding device (3) has chain wheel transmission mechanisms (5) on both sides of a wood material (4) to be processed, and the wood material (4) to be processed is clamped and fed through chains (6) of the two chain wheel transmission mechanism. By adopting theabove technical scheme, the automatic material feeding system can achieve automatic and continuous feeding of the wood material to be processed, thus improving the production efficiency, remarkably stabilizing the production rhythm, lowering labor intensity, achieving convenient operation and improving the work condition. The equipment has reasonable structure and stable and reliable clamping andfeeding of the wood material to be processed.

Owner:冯士祥

Device for prolonging service life of inclined grate liner plate

The invention relates to a device for prolonging the service life of an inclined grate liner plate, in particular to the device for prolonging service life of inclined grate liner plate, which is used in a steel pipe production process, and belongs to the field of steel pipe production. One side of the inclined grate is fixedly provided with a tank body, a short steel pipe is arranged in the tank body, and the upper surface of the short steel pipe and the surface of the inclined grate liner plate are arranged at the same horizontal line. The tank body for arranging the short steel pipe is arranged on the side end of the inclined grate, the trouble of exchanging the whole liner plate due to the fact that a pit is worn in the liner plate on the front end inclined grate of a single feeder in the feeding process is avoided, the problem of incapability of feeding due to the fact that the steel pipe stops on the liner plate groove of the inclined grate and cannot enter the material taking surface of the single feeder is solved by only rotating the short steel pipe in periphery direction to deflect the short steel pipe from the groove position. The cost is saved, the rhythm of production is stable, and the labour load of maintaining workers is reduced.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

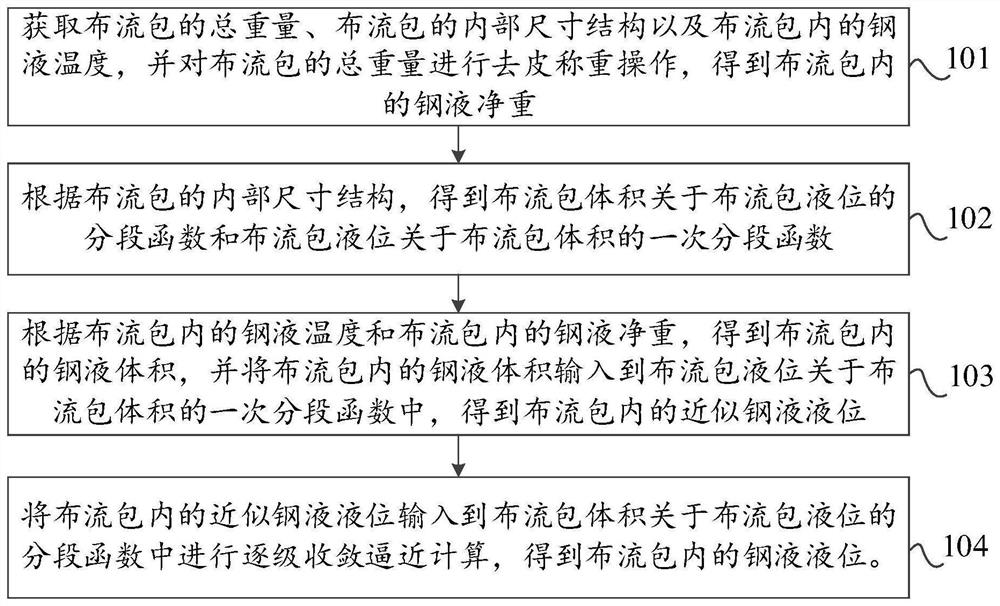

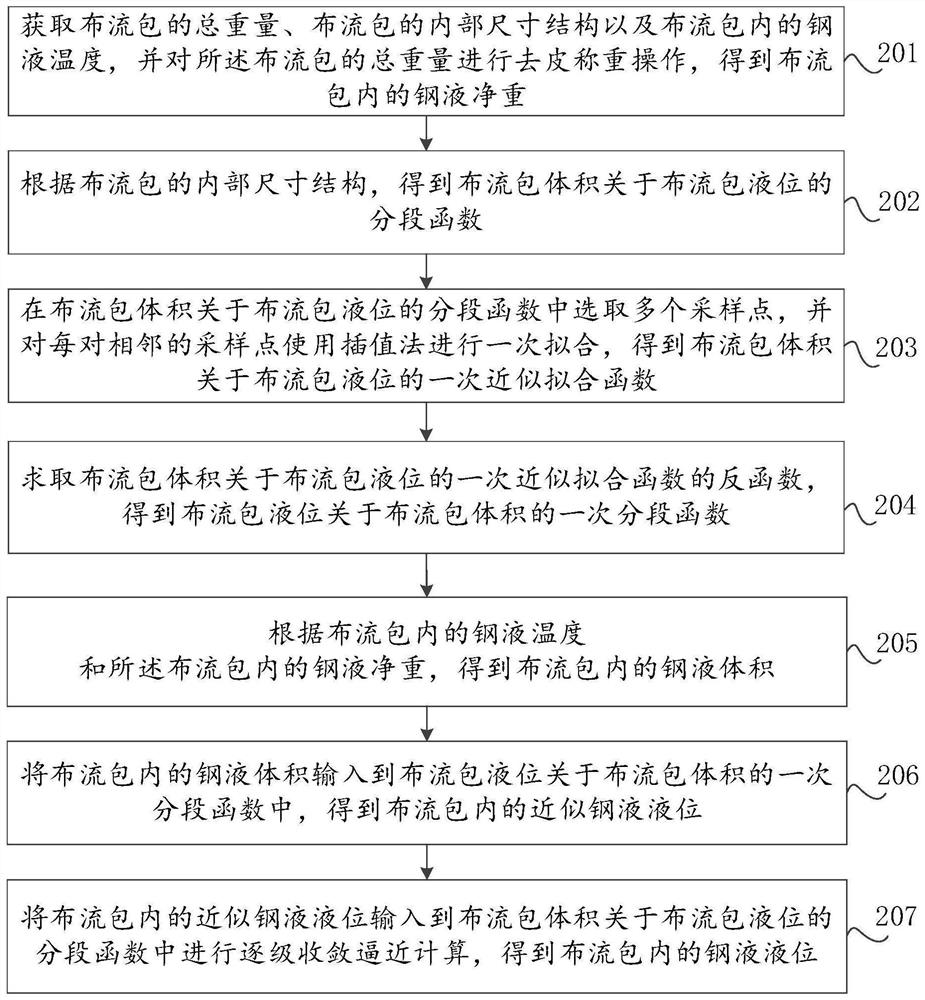

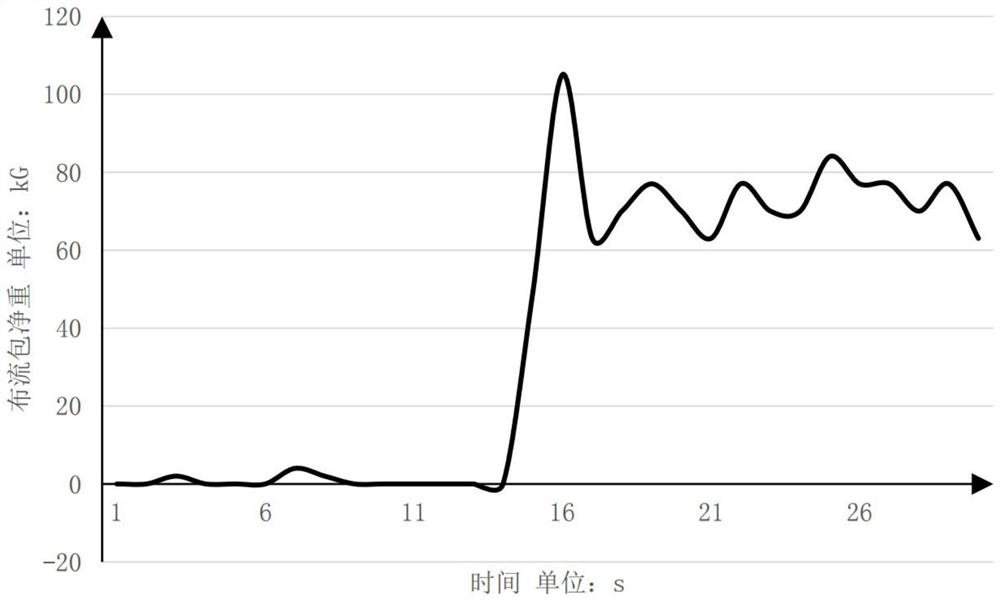

Thin strip continuous casting cloth ladle liquid level detection method and device

ActiveCN112139468BReduce difficultyLow costComplex mathematical operationsProcess engineeringMolten steel

The invention discloses a method, a device, a storage medium and a computer device for detecting the liquid level of a thin strip continuous casting cloth ladle. The method includes: obtaining the total weight of the flow bag, the internal size and structure of the flow bag, and the temperature of the molten steel in the flow bag, and performing a peeling and weighing operation on the total weight of the flow bag to obtain the weight of the flow bag. The net weight of molten steel; according to the internal size structure of the flow distribution bag, the segmental function of the volume of the flow distribution bag with respect to the liquid level of the flow distribution bag and the first-order segmental function of the liquid level of the flow distribution bag with respect to the volume of the flow distribution bag; The temperature of the molten steel and the net weight of the molten steel in the flow distribution bag are used to obtain the volume of molten steel in the flow distribution bag, and the volume of molten steel in the flow distribution bag is input into the first-order piecewise function of the liquid level of the flow distribution bag with respect to the volume of the flow distribution bag , to obtain the approximate liquid steel liquid level in the flow distribution bag; input the approximate liquid steel liquid level in the flow distribution bag into the piecewise function of the volume of the flow distribution bag with respect to the liquid level of the flow distribution bag to perform a step-by-step convergent approximation calculation, and obtain the distribution Liquid steel level in ladle.

Owner:NORTHEASTERN UNIV LIAONING

Production method of cold-rolled strip steel for titanium microalloying refrigerator side plate under non-refining process condition

ActiveCN113846261ALower levelReduce carbon contentTemperature control deviceProcess efficiency improvementSlagIcebox

The invention relates to a production method of cold-rolled strip steel for a titanium microalloying refrigerator side plate under a non-refining process condition. The cold-rolled strip steel comprises the following chemical components: 0.06%-0.10% of C, 0.05%-0.12% of Si, 0.30%-0.45% of Mn, less than or equal to 0.025% of S, less than or equal to 0.025% of P, greater than or equal to 0.015% of Als and 0.025%-0.040% of Ti. Under the non-refining condition, deoxidation alloying, steel ladle slag washing and molten steel component optimization are carried out, the pouring protection effect is improved, hot rolling, controlled rolling and controlled cooling and cold rolling cover annealing processes are optimized, and operation steps of converter operation, argon blowing, continuous casting, hot rolling and cold rolling are carried out. According to the production method, the alloy cost is reduced while the product performance is ensured, and the inclusion content of molten steel is reduced. The yield strength of the cold-rolled steel strip is 330-380 MPa, the tensile strength of the cold-rolled steel strip is 440-480 MPa, and the percentage elongation after fracture of the cold-rolled steel strip is 22-26%.

Owner:唐山瑞丰钢铁(集团)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com