Method for stabilizing tapping temperature based on ladle automatic positioning

A technology of tapping temperature and automatic positioning, applied in the field of metallurgy, can solve the problems of insufficient tapping temperature, shorten refining time, etc., and achieve the effects of reducing heat radiation, improving service life and ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

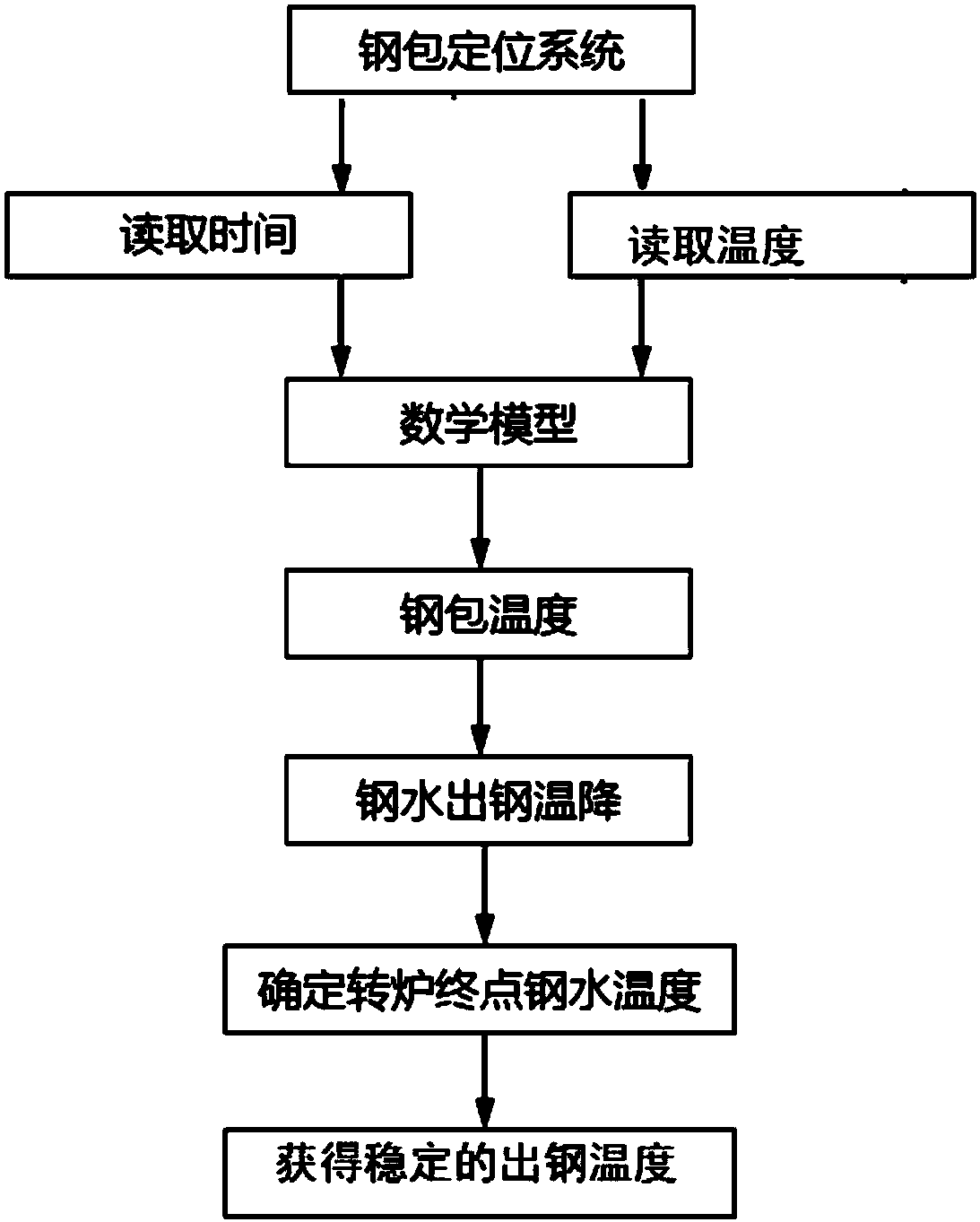

[0053] Such as Figure 1 ~ Figure 3 As shown, a method for stabilizing the tapping temperature based on the automatic positioning of the ladle in this embodiment uses radio frequency identification tags for positioning, and proceeds according to the following steps:

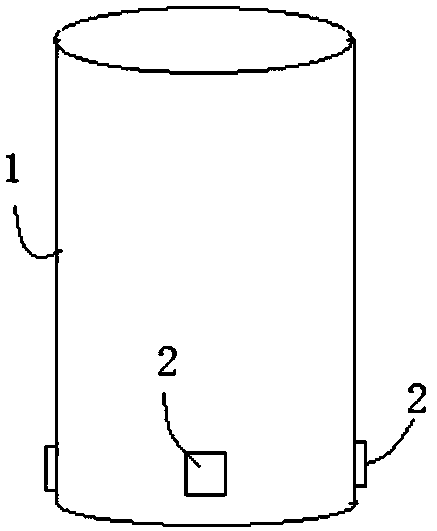

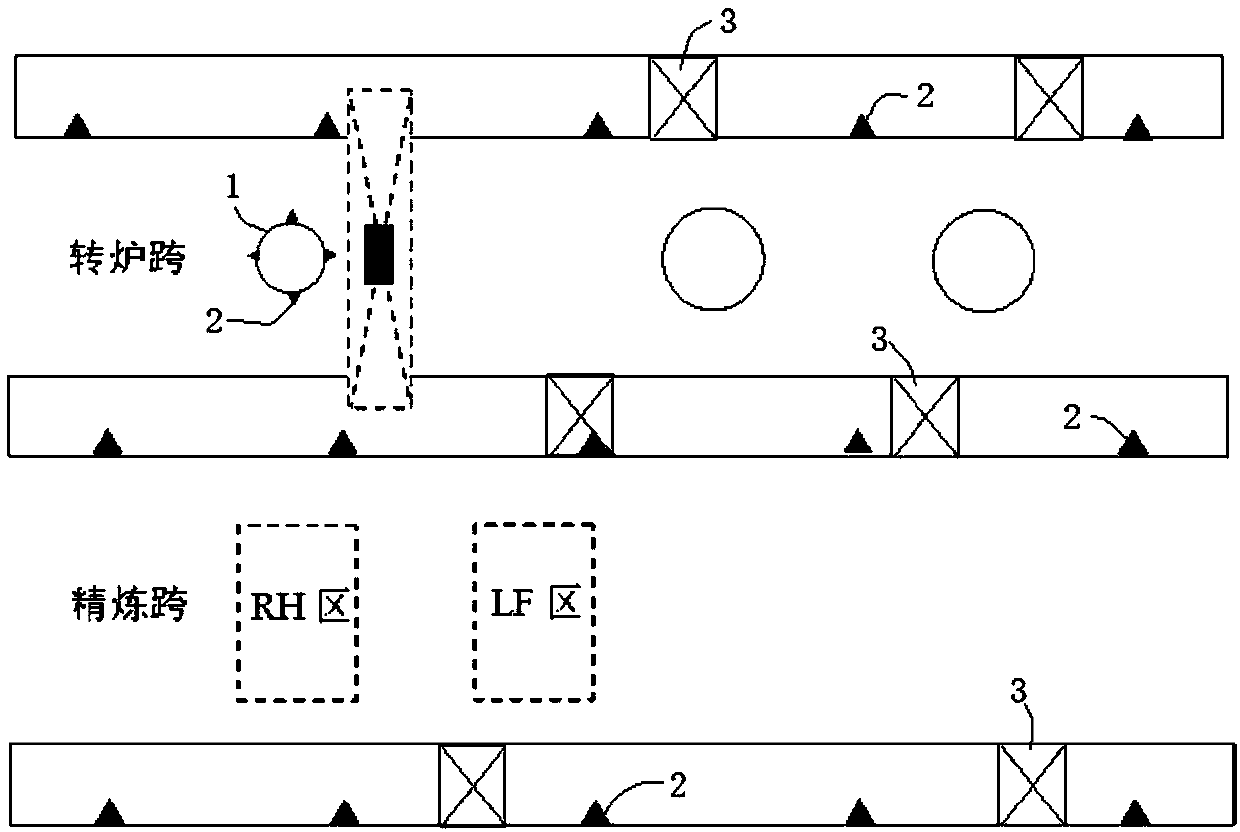

[0054] Step 1. Install the electronic tag 2 on the ladle 1 and the driving track, and run continuously on the various stations of the ladle 1 (such as tapping position, argon blowing position, RH and LF refining position, casting position, etc.) Each segment is equipped with a card reader; wherein the steel ladle 1 is provided with at least 4 electronic tags 2, and a plurality of electronic tags 2 are evenly spaced and symmetrically arranged on the surface of the steel ladle 1, specifically, as figure 1 with figure 2 As shown, four electronic tags 2 are arranged on the upper and outer surface of the steel ladle 1, and the four electronic tags 2 are symmetrically arranged on the outer wall of the steel ladle 1 i...

Embodiment 2

[0086] A method of stabilizing the tapping temperature based on the automatic positioning of the ladle in this embodiment is basically the same as in Embodiment 1, except that the height of the electronic tag 2 in this embodiment is located at 1 / 3 of the height of the ladle 1; Card readers are installed at evenly spaced intervals of 12m on the continuous running span of steel ladle 1.

[0087] In this embodiment, the electronic tag 2 is a high-temperature-resistant passive electronic tag, which is packaged with a high-temperature-resistant material. The high-temperature-resistant material includes the following components in mass percentage: 4.0% ZrO, 5% SiO 2 , 85% CaO, 5% MnO, and the rest are unavoidable impurities.

Embodiment 3

[0089] A method of stabilizing the tapping temperature based on the automatic positioning of the ladle in this embodiment is basically the same as that in Embodiment 1, except that the span section of the continuous operation of the ladle 1 on the crane 3 is equipped with a card reader every 11m evenly spaced .

[0090] In this embodiment, the electronic tag 2 is a high-temperature-resistant passive electronic tag, which is packaged with a high-temperature-resistant material. The high-temperature-resistant material includes the following components in mass percentage: 2.0% ZrO, 15% SiO 2 , 80% CaO, 2% MnO, and the rest are unavoidable impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com