Heating furnace temperature control method capable of quickly and automatically adapting to speed of rolling mill

An automatic adaptation, furnace temperature technology, applied in temperature control and other directions, can solve the problems of reduced model accuracy, large calculation amount of multi-dimensional model, poor result accuracy, etc., to achieve accurate furnace temperature setting, high control accuracy, and output. The effect of steel temperature stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

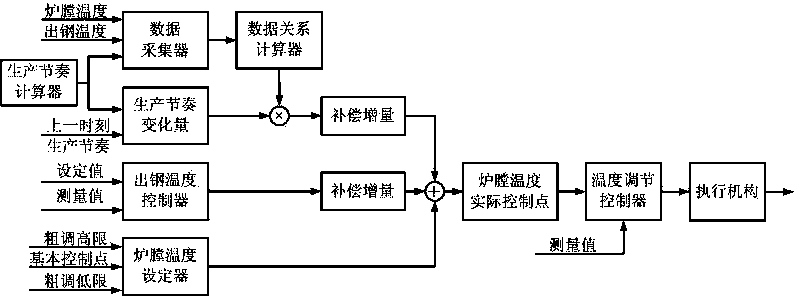

[0014] Taking the 130t / h walking heating furnace as an example, the number of billets in the furnace is 60 during normal production, and one billet is tapped in 2 minutes on average. The effective length of the heating furnace is 18m, which is divided into a preheating section, a heating section and a soaking section , the three segments are equal in length. The temperature control method in the furnace of the present invention is as figure 1 shown.

[0015] 1. Production rhythm calculator

[0016] The production rhythm v is the amount that characterizes the tapping interval, and the unit is "second / piece or second / piece". It is the time Ti (i=1,2,..., 60), when i60,

[0017] T(i)=T(i-1), i is 1, 2,...,60 starting from the number of furnace entering direction

[0018] v=Ti / 60, 60 is the number of billets in the furnace during normal production

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com