A ladle nozzle capable of increasing self-opening rate

A technology of self-opening rate and ladle, which is applied in the direction of casting molten material container, metal processing equipment, casting equipment, etc., can solve the problems of affecting the quality of molten steel, not being able to start pouring by itself, and affecting the production rhythm, so as to improve the self-opening rate of molten steel , Stabilize the production rhythm and reduce the effect of molten steel quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

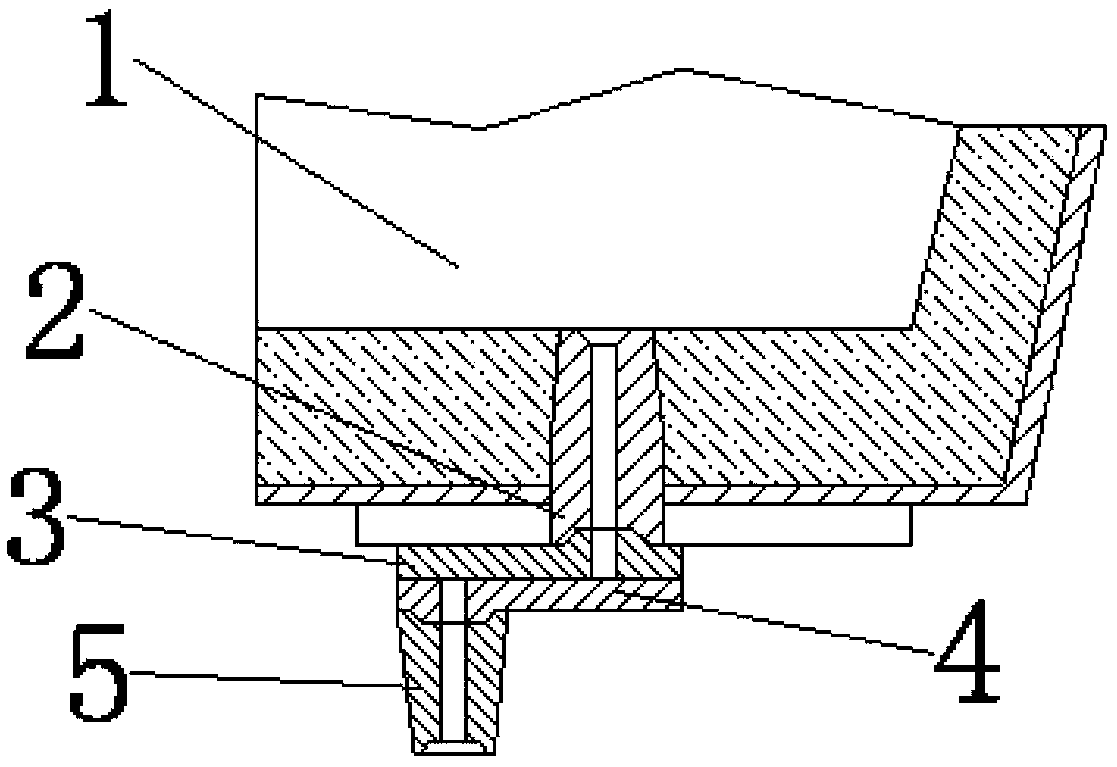

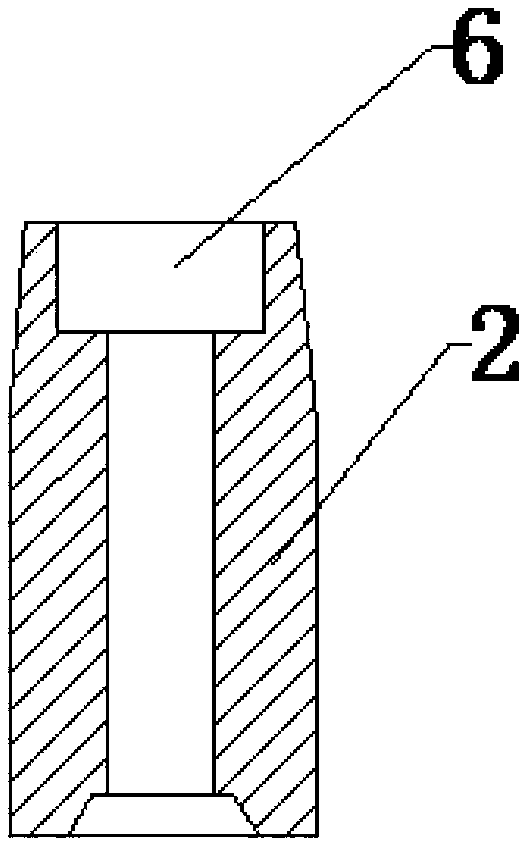

[0020] Such as figure 2 As shown, the technical solution provided by the present invention is a ladle nozzle used in the steel casting process, and the nozzle 2 is provided with a drainage sand circulation channel with a variable diameter. The upper nozzle 2 is composed of an upper part and a lower part, and the inner diameter of the upper part of the upper nozzle is larger than the inner diameter of the lower part of the upper nozzle. The upper nozzle 2 is provided with a drainage sand transition section 6, the transition section 6 is arranged on the upper part of the upper nozzle 2, and the diameter of the transition section 6 is larger than the inner diameter of the lower part of the upper nozzle. The upper nozzle 2 is a variable diameter structure with a thick top and a thin bottom, and the cross-sectional shape of the transition section 6 is circular. The upper nozzle 2 is a variable diameter structure with a thicker top and a thinner bottom, and the cross-sectional sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com