Plate slab flame spray gun cutting height control system and using method thereof

A flame spray gun and flame cutting technology, applied in the field of large slab flame spray gun cutting height control system, can solve the problems of affecting the slab cutting effect, high labor intensity, unable to adjust the flame spray gun cutting height, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

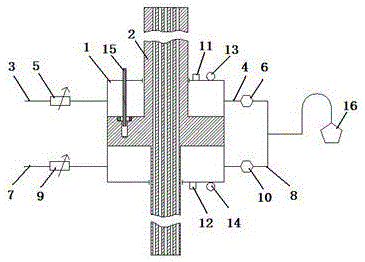

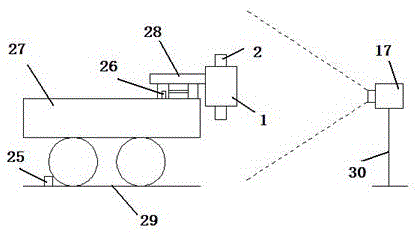

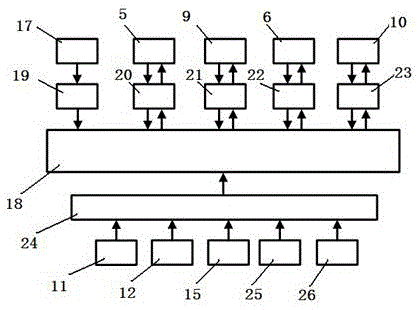

[0055] Figure 1 ~ Figure 3 It shows that the large slab flame spray gun cutting height control system of the present invention includes a cutting machine track 29, a flame cutting machine 27, a flame cutting trolley 28 arranged on the flame cutting machine 27, a pneumatic cylinder 1 installed on the flame cutting trolley 28, Piston type flame spray gun 2, camera 17 and process control system for photographing spray gun 2 and spray gun flame; Chamber air intake pipe 3 communicates with upper chamber air outlet pipe 4, and upper chamber air intake pipe 3 and upper chamber air outlet pipe 4 are respectively equipped with upper chamber electromagnetic regulating valve 5 and upper chamber electromagnetic switch valve 6; lower chamber is connected with lower chamber air inlet pipe 7 and The lower chamber outlet pipe 8 is connected, the lower chamber air intake pipe 7 and the lower chamber outlet pipe 8 are respectively installed with a lower chamber electromagnetic regulating valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com