Production method of cold-rolled strip steel for titanium microalloying refrigerator side plate under non-refining process condition

A technology of micro-alloying and process conditions, which is applied in the field of cold-rolled strip steel for titanium micro-alloying refrigerator side plates, can solve the problems of low yield strength and tensile strength control, and achieve the reduction of inclusion level and reduction of The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

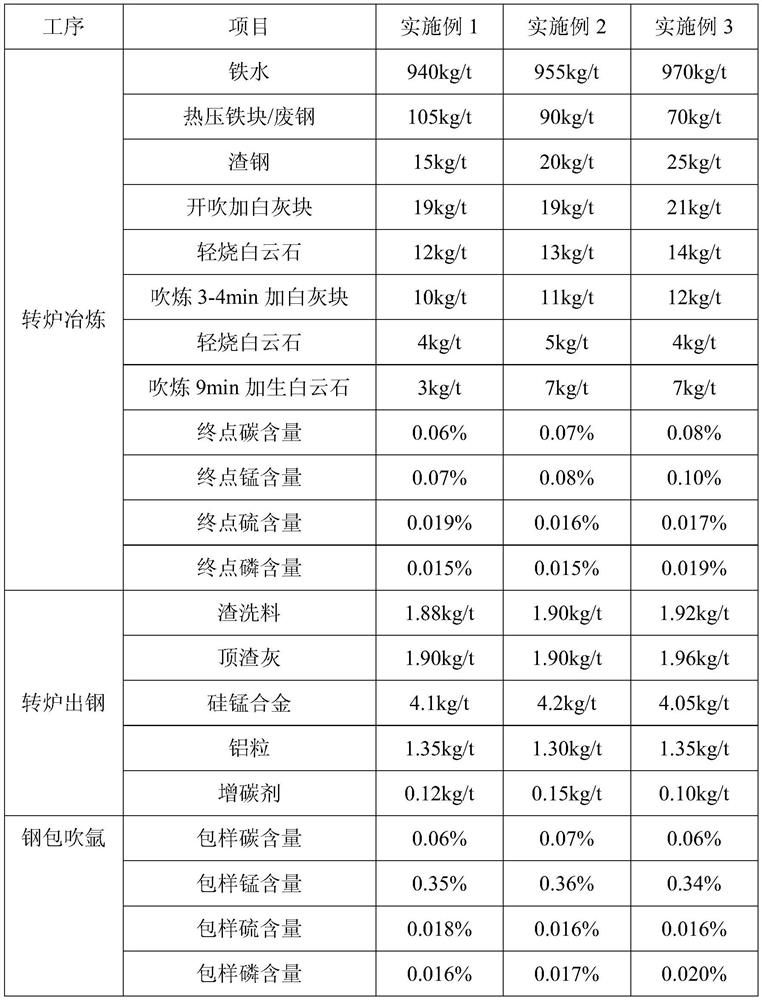

[0025] The present invention will be further described below in conjunction with the examples, and the purpose is only to better understand the content of the present invention. Therefore, the examples given do not limit the protection scope of the present invention.

[0026] In the following examples, the converter is a 120t top-bottom combined blowing converter, the steel type is Q235B-T series, the continuous casting is a four-machine four-strand slab continuous casting machine, the billet size is 180*870mm, the hot rolling is 950mm, the cold rolling is 950mm. Each embodiment sees the following table:

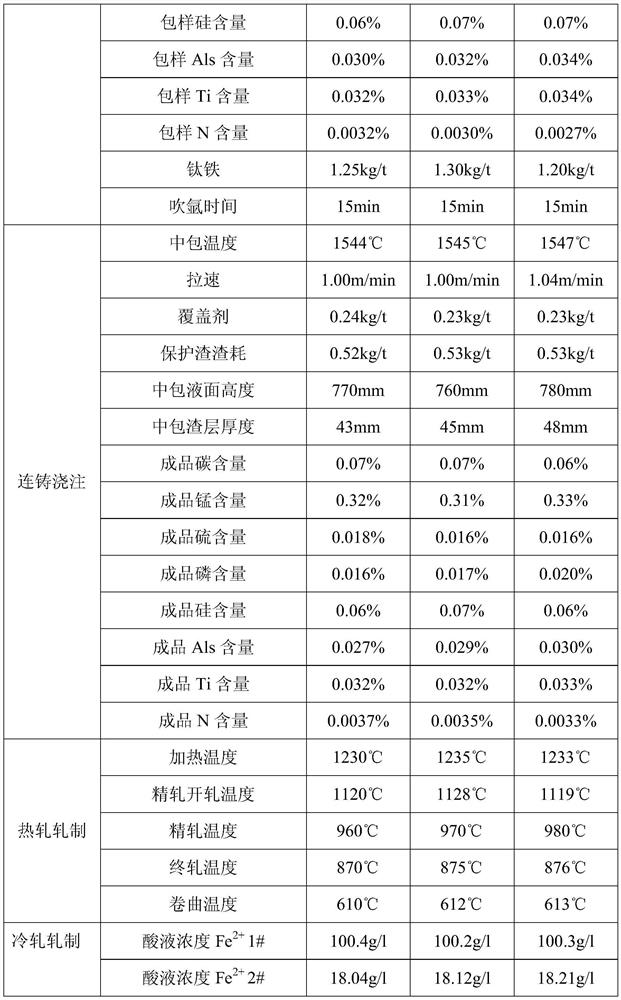

[0027]

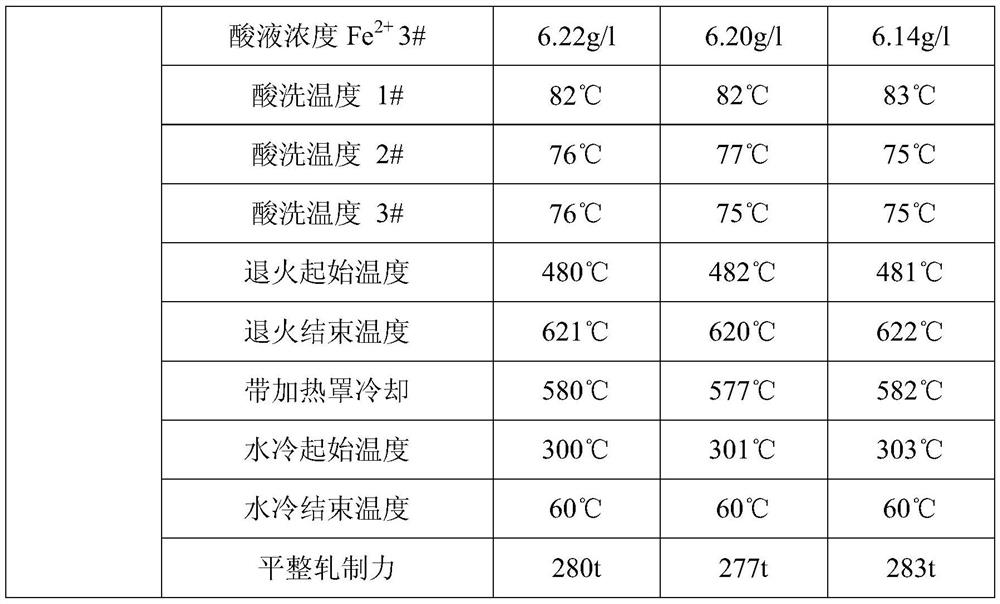

[0028]

[0029]

[0030] Conventional production process route: hot metal pretreatment→converter→LF→continuous casting→hot rolling→cold rolling, conventional Q235B refrigerator side panel steel component system C: 0.15-0.20%, Mn: 0.27-0.45%, Si: 0.05-0.16 %, S ≤ 0.030%, P ≤ 0.030%, the present invention fully considers the influence of the original C cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com