Induction heating method and device with self-adaptive distance adjusting function

An induction heating device and induction heating technology, applied in heat treatment furnaces, manufacturing tools, heat treatment equipment, etc., can solve the problems of difficult temperature control, low heating efficiency, unfavorable matching of production line rhythms, etc., to reduce abnormal steel plate processing links , The effect of reducing processing procedures and costs, and improving product adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

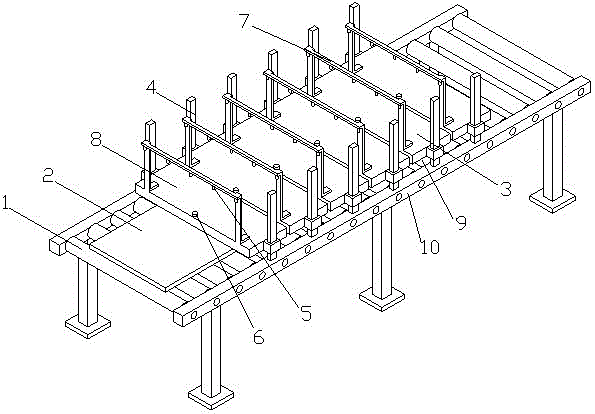

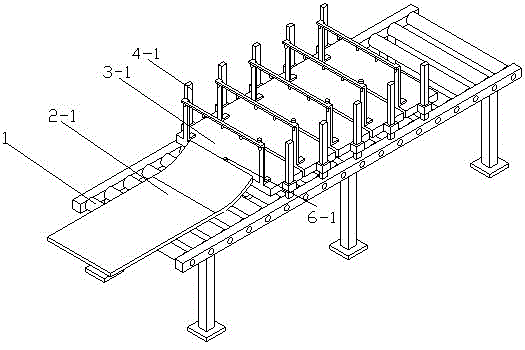

[0030] see figure 1 and figure 2 , an induction heating device suitable for steel plates with any degree of warpage, including an induction heating furnace, the induction heating furnace includes an inductor 8, an intelligent processing unit, and a PLC control system, and the inductor 8 includes an upper inductor 3 and a lower inductor 9, The lower sensor 9 is fixedly installed on the sensor bracket 10, the sensor bracket 10 is located between the roller tables in the furnace, the upper sensor 3 is installed on the upper sensor position adjustment system 4, and the sensor bracket 7 is installed above the front end of the upper sensor 3 , several displacement sensors 5 are installed on the bracket 7, an infrared temperature measuring device 6 is installed at the entrance of the upper sensor 3, the infrared temperature measuring device 6 is loc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com