Device for prolonging service life of inclined grate liner plate

An oblique grate and grate technology are applied in the field of devices for improving the service life of oblique grate linings, and can solve the problems of inability to feed materials, high consumption cost, affecting production continuity, etc., and achieve cost saving, stable production rhythm, The effect of reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

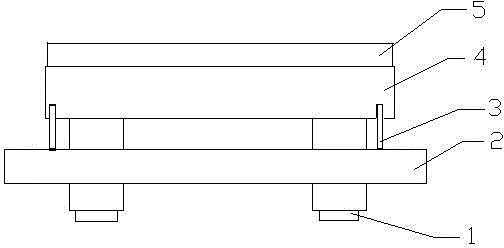

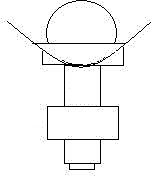

[0014] The present invention comprises an oblique grating bar and a connecting plate 2, the connecting plate 2 is fixedly installed on one side of the oblique grating bar, the connecting plate 2 is symmetrically provided with a screw hole, the screw hole is provided with a screw rod 1, and the upper part of the screw rod 1 is provided with a There is a tank body 4, baffle plates are provided at both ends of the tank body 4, and short steel pipes 5 are arranged inside the tank body 4. In order to increase the stability of the tank body 4, a support frame 3 is provided between the tank body 4 and the connecting plate 2 .

[0015] By adjusting the screw mandrel 1 on the connecting plate 2, the upper surface of the short steel pipe 5 in the tank body 4 and the upper surface of the inclined grate liner are on the same level.

[0016] During production, multiple steel pipes will be arranged on the oblique grating bar that acts as a transition between processes. When a single feeder ...

Embodiment 2

[0018] The present invention includes an oblique grating bar, a tank body 4 fixedly connected to one side of the oblique grating bar, shelves are provided on both sides of the tank body 4 , and short steel pipes 5 are arranged inside the tank body 4 .

[0019] When the tank body 4 is fixedly connected with the oblique grate bar, it is necessary to ensure that the short steel pipe 5 upper surface of the tank body 4 inside is equipped with the oblique grate bar liner upper surface on the same horizontal plane.

[0020] During production, multiple steel pipes will be arranged on the oblique grating bar that acts as a transition between processes. When a single feeder takes a single steel pipe, it will block the subsequent steel pipes at the same time, and the single feeder will return after taking the material. In this way, a steel pipe at the back will be squeezed during the return process of the single feeder, causing the steel pipe to rub and rotate on the inclined grating bar....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com