Method for improving self-opening rate of drainage sand

A technology of drainage sand and self-opening rate, which is applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve problems such as potential safety hazards, increased oxygen content of molten steel, and slag entrainment of molten steel, so as to ensure product quality and production efficiency. The effect of stabilizing rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

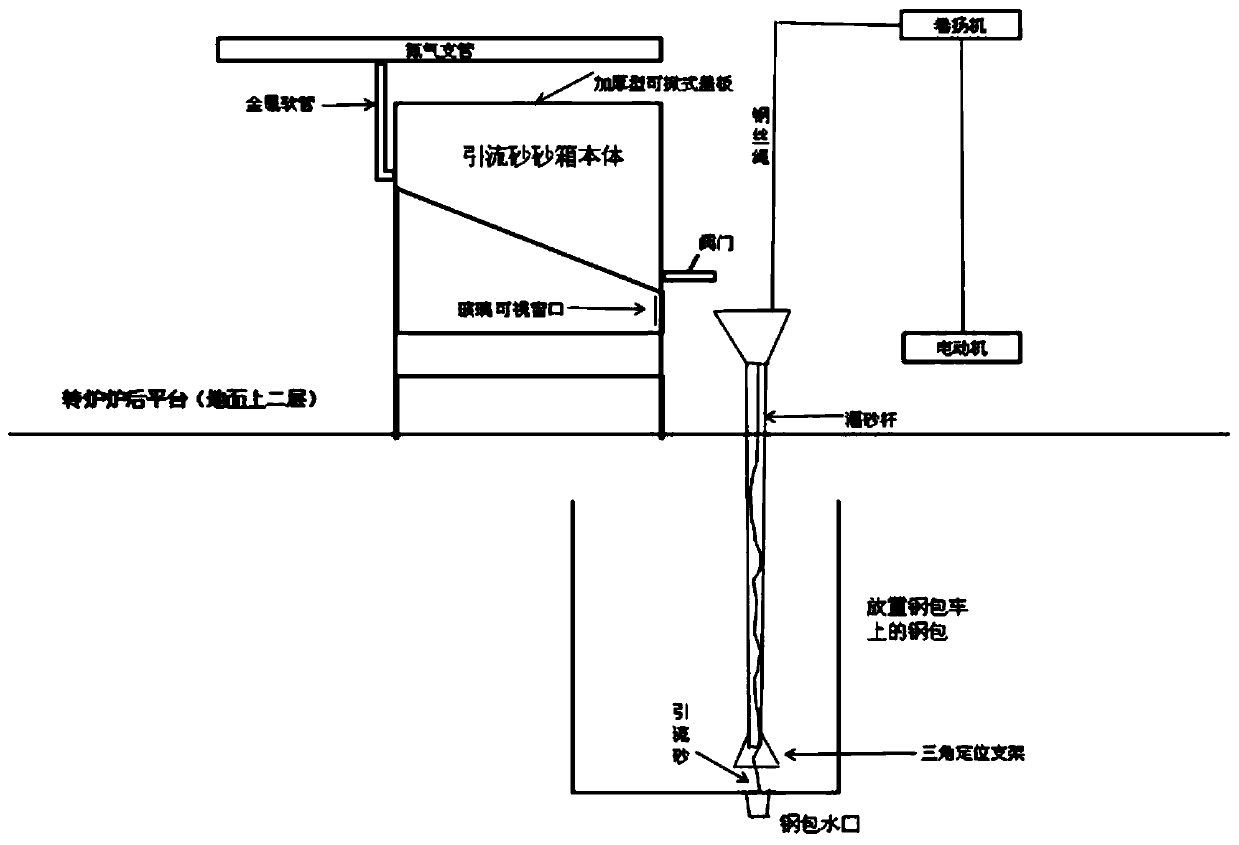

[0012] Such as figure 1 As shown, the present invention improves on the basis of the existing drainage sand adding device, opens a hole on the drainage sand box body to connect the nitrogen purge pipe, and then adds a liftable cover plate on the drainage sand box body, Moreover, there is a sealing ring on the cover plate, which can make the drainage sand box body a closed space, and impurities and water vapor in the outside air are difficult to enter the box to contaminate the drainage sand, ensuring that the drainage sand is dry and pure. In addition, the drainage sand adding device controls the addition of drainage sand at the upper nozzle of the steel ladle through the valve, and the amount of sand added is controllable. At the same time, a tripod is added to the upper nozzle of the steel ladle for positioning, so that the injection point of the drainage sand is accurate, which can effectively ensure the cleanness of the drainage sand. The degree and addition amount are sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com