Induction heating furnace provided with half-split panel induction coils

An induction heating furnace and induction coil technology, applied in induction heating, coil devices, lighting and heating equipment, etc., can solve problems such as over-burning at the end, non-operability, over-burning of temperature, etc., and achieve stable heating and improved The effect of product adaptability and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The induction heating furnace with split flat plate induction coils of the present invention is mainly aimed at performing induction heating heat treatment on steel plates after they are rolled, so as to improve the structure and mechanical properties. Heating, made of pipeline steel. It is required to heat the steel plate from room temperature to 700 degrees. After the heating is completed, the temperature distribution of the steel plate on the section at the exit of the induction coil is controlled within + / -10 degrees, and the temperature during the heating process does not exceed 710 degrees.

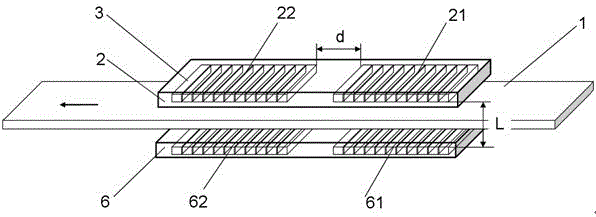

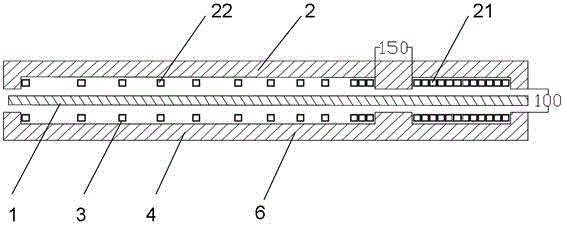

[0042] In order to achieve the above object, the present invention provides a kind of induction heating furnace with split plate induction coil, such as figure 2 As shown, the upper and lower two sets of plate induction coils 2, 6 cover the range of the heated steel plate 1, and the copper pipe 3 is located on a horizontal plane. The two groups of plate induction coils 2 an...

Embodiment 2

[0047] In this embodiment, it is required to heat multiple steel plates with specifications of 2200mm*20mm*25000mm, and the material is mold steel. It is required to heat the steel plate from 200 degrees to 600 degrees. After the heating is completed, the temperature distribution of the steel plate on the section at the exit of the induction coil is controlled within + / -10 degrees, and the temperature during the heating process does not exceed 610 degrees.

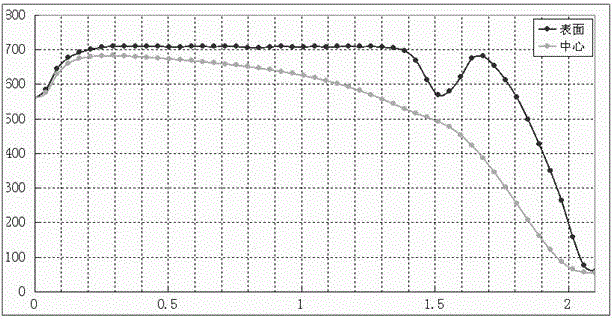

[0048] In order to achieve the above object, the present invention provides a kind of induction heating furnace with split flat plate induction coil, the copper tube surface distance of its upper and lower plate induction coils 2, 6: L=80mm; The distance between the front copper tube and the rear copper tube: d=200mm. Since the heat transfer in the thickness direction of the steel plate takes a certain amount of time, when the surface temperature reaches the target temperature, the center temperature does not reach the tar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com