Unmanned electric trackless three-way stacker forklift

An unmanned driving and electric technology, which is applied in the direction of electric vehicles, electric vehicle charging technology, control drive, etc., can solve the problems of inability to carry out pallet forklift operation, no unmanned forklift, etc., and achieve good object overload characteristics, stable operation, The effect of taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

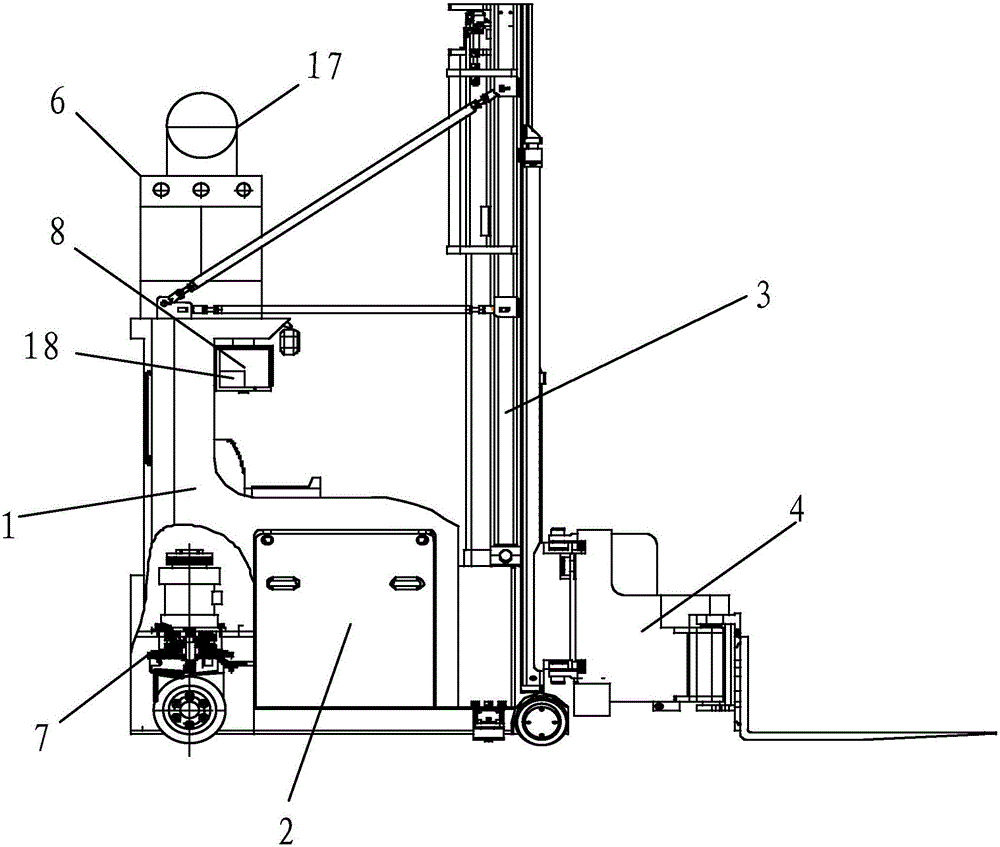

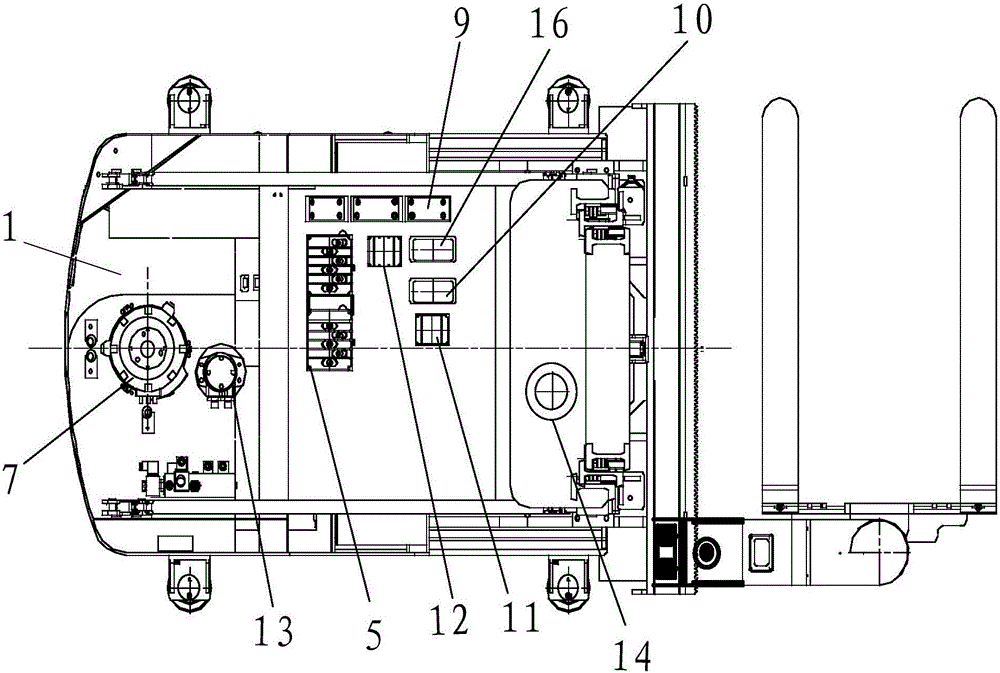

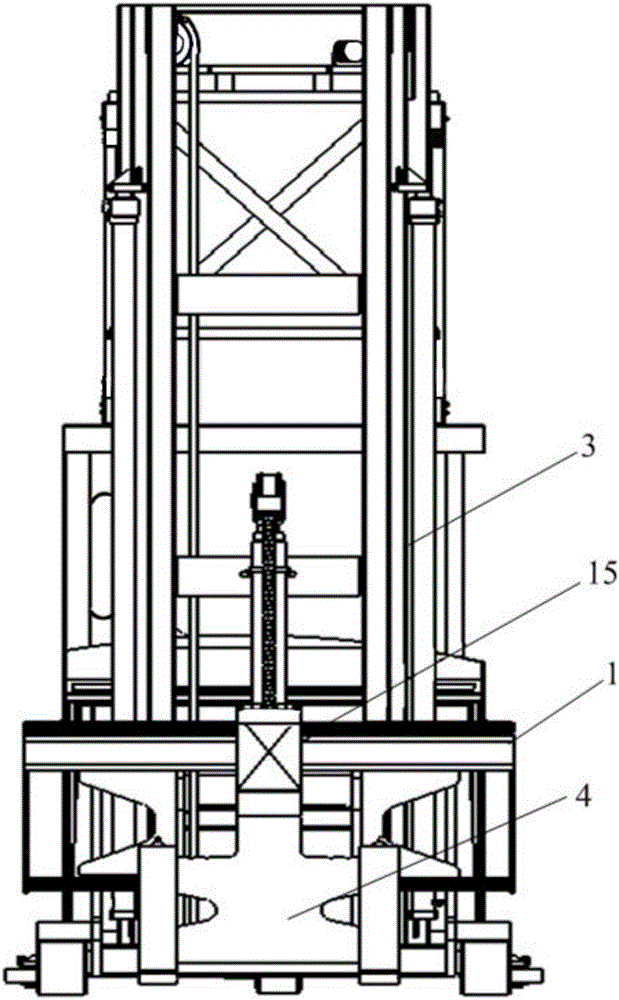

[0019] Attached below Figure 1-4 An embodiment of the present invention is described.

[0020] An unmanned electric trackless three-way stacking forklift has a car body 1 and a power source 2 arranged on the outside of the car body 1. The front end of the car body 1 is provided with a working device 3 and the working device 3 is provided with a three-way stacker head 4. The cab of the car body 1 is provided with a vehicle controller PLC5 for controlling the operation of a single unmanned vehicle, and the left end of the top plane of the car body 1 is provided with a vehicle Ethernet wireless signal receiver 6, and the vehicle controller PLC5 It is connected with the vehicle Ethernet wireless signal receiver 6 and performs data communication, and the vehicle controller PLC5 is connected with the mechanism assembly provided on the vehicle body 1 for monitoring, detecting, displaying, driving and controlling the running state of the vehicle body 1 to realize the vehicle Automat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com