Operation method of lifting lance in the midway of converter steelmaking under dry dedusting condition

A technology for dry dust removal and converter steelmaking, which is applied in the manufacture of converters and other directions, can solve problems such as blasting and waste electrostatic precipitators, high explosion hazards, and production interruptions, and achieves improved converter productivity, extended service life, and stabilized production rhythm. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below through the examples (the present example is a 150 ton converter).

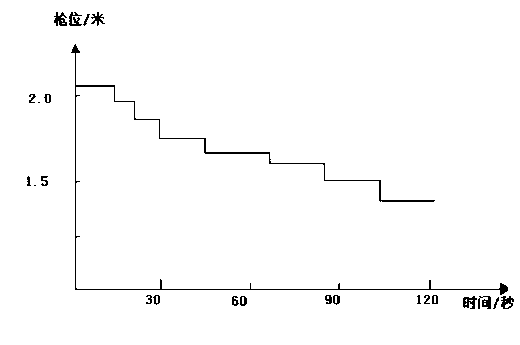

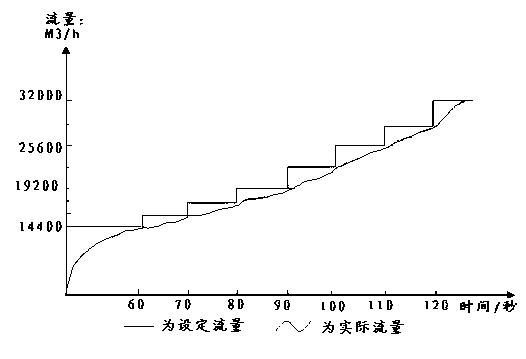

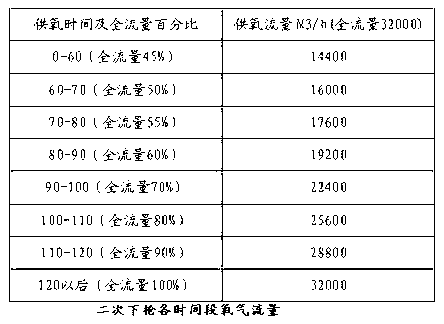

[0019] An operation method for lifting a gun in the middle of converter steelmaking under the condition of dry dust removal, comprising the following steps:

[0020] ① Dump the slag immediately after the gun is lifted, and find out the reason for the gun lifting; when the converter smelting enters the decarburization period, a considerable part of FeO has been accumulated in the slag, shake the furnace immediately after lifting the gun halfway, and pour out most of the oxidized slag as much as possible, In this way, the FeO in the slag will not react rapidly with the C in the molten pool to produce a large amount of CO gas when the gun is fired again, effectively avoiding the occurrence of explosion venting;

[0021] ② The time of firing the gun again should be at least 3 minutes apart from the time of firing the gun, which is conducive to the remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com